Discover Top Strategies to Choose a Beam Manufacturer (2025)

Introduction: Navigating the Global Market for beam manufacturer

The global market for beam manufacturers presents a unique set of challenges for international B2B buyers seeking to source high-quality structural components. Navigating this complex landscape requires not only a clear understanding of different beam types but also an awareness of regional specifications, compliance standards, and supplier capabilities. This guide aims to equip buyers—especially those from Africa, South America, the Middle East, and Europe—with actionable insights to streamline their sourcing processes.

Throughout this comprehensive resource, we will explore various beam types, including I-beams, H-beams, and T-beams, along with their specific applications in construction, manufacturing, and infrastructure projects. Additionally, we will provide valuable information on supplier vetting techniques, cost considerations, and logistics management to ensure that buyers can make informed decisions that align with their project requirements and budget constraints.

By addressing critical questions such as “How can I evaluate the reliability of a beam manufacturer?” and “What factors should I consider when comparing costs across regions?”, this guide empowers B2B buyers to overcome common hurdles in the procurement process. With a focus on best practices and strategic insights, we aim to enhance your purchasing experience and foster successful partnerships in the global market for beam manufacturers.

Understanding beam manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Structural Steel Beams | Made from high-strength steel; versatile shapes (I, H) | Commercial buildings, bridges, industrial sheds | Pros: High load-bearing capacity; Cons: Corrosion risk without treatment. |

| Wooden Beams | Natural material; available in various species | Residential construction, timber-framed buildings | Pros: Aesthetic appeal; Cons: Susceptible to pests and moisture. |

| Reinforced Concrete Beams | Composite material; designed for high tensile strength | High-rise buildings, parking garages | Pros: Durable and fire-resistant; Cons: Heavier and more complex to install. |

| Composite Beams | Combination of materials (steel and concrete) | Bridges, large-span structures | Pros: Optimized strength-to-weight ratio; Cons: Higher initial cost. |

| Precast Concrete Beams | Factory-manufactured; consistent quality and design | Infrastructure projects, highways | Pros: Quick installation; Cons: Transportation costs can be high. |

What are Structural Steel Beams and Their Applications?

Structural steel beams are characterized by their high strength and versatility, typically available in various shapes such as I-beams and H-beams. These beams are primarily used in commercial buildings, bridges, and industrial sheds due to their ability to support heavy loads. When considering a purchase, B2B buyers should assess the beam’s corrosion resistance, as untreated steel can be prone to rust, especially in humid environments. Additionally, understanding local regulations and standards for structural steel can facilitate smoother procurement processes.

How Do Wooden Beams Compare in Construction?

Wooden beams are a popular choice in residential construction and timber-framed buildings. They are available in various species, offering different aesthetics and structural properties. While they provide a warm, natural look that appeals to many buyers, it is crucial to consider their susceptibility to pests and moisture, which can compromise structural integrity over time. Buyers should evaluate the source of the wood and its treatment processes to ensure longevity and compliance with building codes.

What Makes Reinforced Concrete Beams a Preferred Choice?

Reinforced concrete beams combine concrete’s compressive strength with steel’s tensile strength, making them ideal for high-rise buildings and parking garages. Their durability and fire resistance are significant advantages, particularly in regions prone to high temperatures. However, the increased weight and installation complexity can pose challenges. B2B buyers should factor in the logistical aspects of transportation and installation, as well as the expertise required for proper reinforcement.

Why Consider Composite Beams for Large-Span Structures?

Composite beams utilize a combination of materials, typically steel and concrete, to optimize strength while minimizing weight. This makes them especially suitable for bridges and large-span structures where load distribution is critical. While they offer a superior strength-to-weight ratio, the initial investment can be higher than traditional materials. Buyers should conduct a thorough cost-benefit analysis to determine the long-term advantages of composite beams against their upfront costs.

What are the Advantages of Using Precast Concrete Beams?

Precast concrete beams are manufactured in controlled factory settings, ensuring consistent quality and design. They are particularly advantageous for infrastructure projects and highways, where rapid installation is essential. However, transportation costs can be a significant factor, especially for long distances. Buyers should evaluate the logistics of transporting precast elements to their project sites, considering both the cost implications and the time saved during installation.

Related Video: T and I-Beam manufacturing line

Key Industrial Applications of beam manufacturer

| Industry/Sector | Specific Application of Beam Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural beams for commercial buildings | Enhanced load-bearing capacity and durability | Compliance with local building codes and standards |

| Automotive | Frame components for vehicles | Improved safety and performance | Material quality certifications and weight specifications |

| Renewable Energy | Support structures for solar panels | Increased energy efficiency and longevity | Resistance to environmental factors and corrosion |

| Aerospace | Wing structures and fuselage components | Weight reduction while maintaining strength | Precision engineering and adherence to safety standards |

| Oil and Gas | Pipelines and support structures | Enhanced operational efficiency and safety | Material compatibility with harsh environments |

How is Beam Manufacturing Used in Construction Projects?

In the construction industry, beam manufacturers provide essential structural beams that support the framework of commercial buildings. These beams are designed to bear significant loads while ensuring structural integrity. For international B2B buyers, particularly in Africa and the Middle East, it is crucial to source beams that comply with local building codes and standards. Buyers should also consider the material’s durability and resistance to environmental factors, which can significantly impact construction timelines and costs.

What Role Do Beams Play in Automotive Manufacturing?

Beam manufacturers supply frame components for vehicles, which are critical for ensuring safety and performance. The automotive industry requires beams that not only meet stringent safety regulations but also optimize weight for fuel efficiency. B2B buyers from South America and Europe must prioritize suppliers that provide material quality certifications and can meet specific weight specifications. This focus on quality can lead to enhanced vehicle performance and reduced operational costs.

How Are Beams Utilized in Renewable Energy Projects?

In the renewable energy sector, beam manufacturers create support structures for solar panels and wind turbines. These beams are essential for maximizing energy efficiency and ensuring the longevity of renewable installations. Buyers, especially those in developing regions like Africa, should seek beams that resist environmental degradation, such as corrosion from saltwater or extreme weather. Understanding the environmental conditions where these structures will be installed is vital for making informed sourcing decisions.

What is the Importance of Beams in Aerospace Applications?

In aerospace manufacturing, beams are used in critical components such as wing structures and fuselage assemblies. The aerospace industry demands beams that provide a significant strength-to-weight ratio, essential for performance and safety. B2B buyers from Europe and the Middle East should focus on suppliers who adhere to precision engineering standards and safety regulations. This attention to detail can lead to enhanced aircraft performance and compliance with international safety standards.

How Do Beams Impact Oil and Gas Infrastructure?

Beam manufacturers play a vital role in the oil and gas sector by providing pipelines and support structures that enhance operational efficiency and safety. These beams must withstand harsh environmental conditions and corrosive materials, making material compatibility a crucial consideration for buyers. International B2B buyers from South America and Africa should ensure that their suppliers can deliver beams that meet industry-specific requirements, thereby reducing the risk of operational disruptions and increasing overall project viability.

Related Video: ZEMAN’s “SBA2 Conti+” – The largest and most efficient Steel Beam Assembler

3 Common User Pain Points for ‘beam manufacturer’ & Their Solutions

Scenario 1: Navigating Compliance in Diverse Markets

The Problem: International buyers often face the challenge of ensuring that the beams they purchase comply with various local regulations and standards. For instance, a construction firm in South America might struggle with beams that meet European Union standards while also adhering to local building codes. This can lead to delays, additional costs, and potential legal issues if the materials do not meet necessary compliance requirements.

The Solution: To overcome compliance challenges, B2B buyers should engage with beam manufacturers who are well-versed in the regulatory landscapes of both the buyer’s and seller’s countries. It’s crucial to request detailed product specifications and compliance certifications for each market. Buyers can also leverage third-party inspection services to ensure that the beams meet required standards before shipment. By establishing a clear line of communication with the manufacturer regarding compliance issues and conducting thorough due diligence, buyers can significantly reduce the risk of non-compliance.

Scenario 2: Dealing with Supply Chain Disruptions

The Problem: Global supply chain disruptions, exacerbated by recent events such as the pandemic or geopolitical tensions, can lead to significant delays in beam delivery. A construction project in Africa may depend on timely beam supplies, and unexpected delays can halt progress, resulting in financial losses and reputational damage.

The Solution: To mitigate supply chain risks, buyers should adopt a proactive approach by diversifying their supplier base. Instead of relying solely on one manufacturer, they should identify multiple beam suppliers in different regions. This strategy not only ensures a backup in case of delays but also allows buyers to negotiate better terms. Additionally, implementing a robust inventory management system can help track supplies and forecast needs accurately, enabling buyers to make informed decisions about ordering and stock levels.

Scenario 3: Quality Assurance and Product Reliability

The Problem: Many B2B buyers encounter issues with the quality and reliability of beams. A contractor in Europe might find that the beams received do not meet the expected strength or durability, causing project delays and increasing costs due to rework or replacement. Such discrepancies can arise from variations in manufacturing processes or substandard materials used by the manufacturer.

The Solution: To ensure quality assurance, buyers should prioritize sourcing from manufacturers that offer transparent production processes and quality control measures. Requesting samples before placing bulk orders is a prudent approach to assess the quality of the beams firsthand. Furthermore, buyers should consider manufacturers who provide warranties and guarantees on their products, ensuring accountability. Engaging in regular communication and feedback loops with the manufacturer can also help in addressing any quality issues promptly, fostering a partnership built on reliability and trust.

Strategic Material Selection Guide for beam manufacturer

When selecting materials for beam manufacturing, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials—steel, aluminum, fiberglass, and concrete—focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Beam Manufacturing?

Steel is renowned for its high strength-to-weight ratio, making it a popular choice for beam manufacturing. It typically offers excellent temperature and pressure ratings, along with good corrosion resistance when treated properly. Steel beams can withstand significant loads, making them suitable for various structural applications, including commercial and industrial buildings.

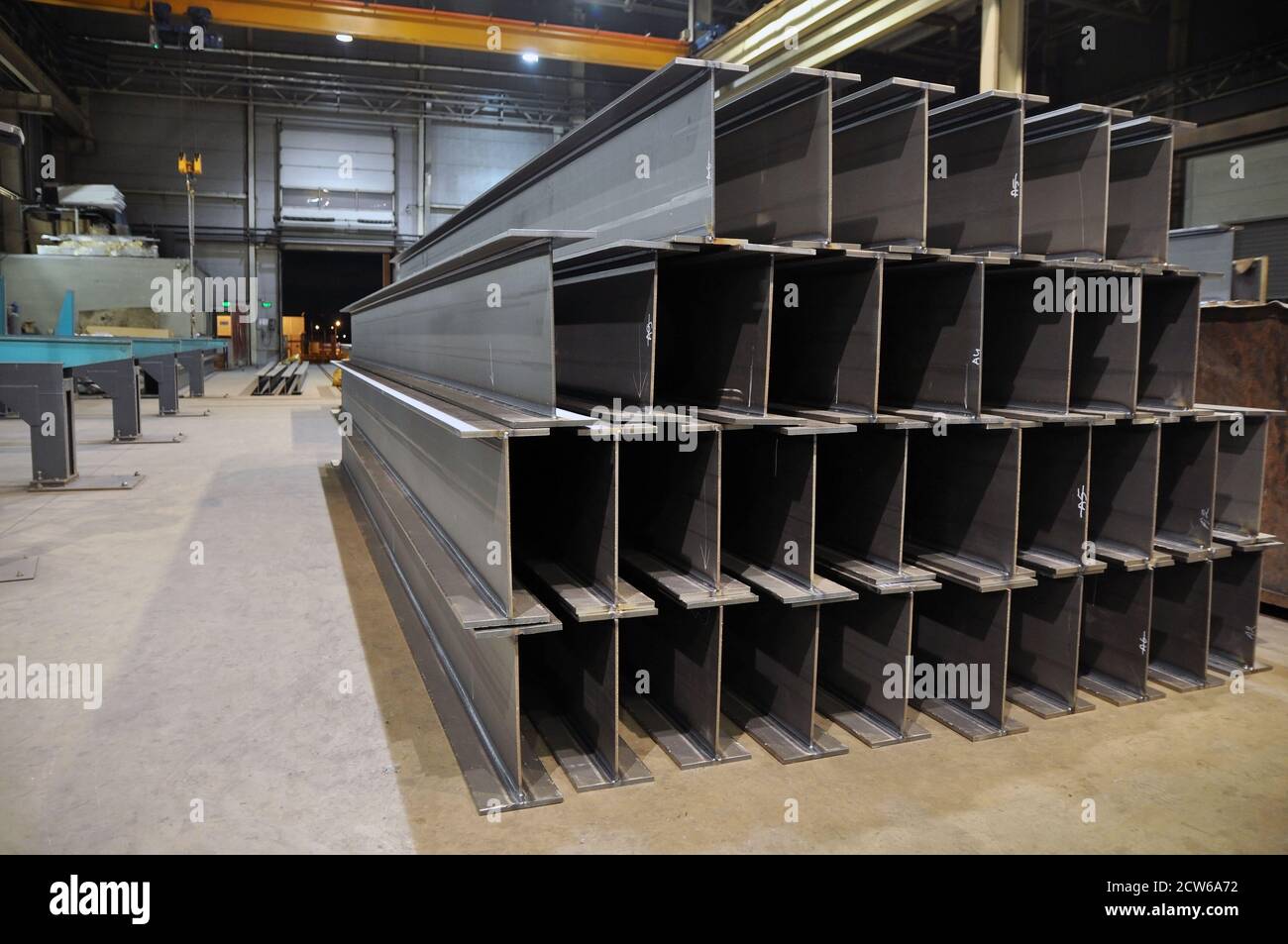

A stock image related to beam manufacturer.

Pros & Cons: The primary advantage of steel is its durability and strength, which allows for long spans without support. However, the cost of steel can fluctuate based on market conditions, and manufacturing complexity can increase with the need for specialized treatments to enhance corrosion resistance.

Impact on Application: Steel beams are compatible with a wide range of media, including water and chemicals, depending on the protective coatings applied.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM (American Society for Testing and Materials) or EN (European Norms). In regions like Africa and South America, sourcing local steel can mitigate costs, while European buyers might prioritize certifications for sustainability.

How Does Aluminum Compare as a Material for Beam Manufacturing?

Aluminum is lightweight yet strong, making it an attractive alternative to steel for specific applications. It has excellent corrosion resistance and is non-magnetic, which can be beneficial in certain environments.

Pros & Cons: The primary advantage of aluminum beams is their lightweight nature, which simplifies handling and installation. However, they are generally more expensive than steel and may not support as heavy loads, limiting their use in high-stress applications.

Impact on Application: Aluminum beams are ideal for environments where weight reduction is crucial, such as in aerospace or automotive applications. They are also suitable for marine environments due to their corrosion resistance.

Considerations for International Buyers: Buyers should ensure that aluminum beams meet standards like JIS (Japanese Industrial Standards) or DIN (Deutsches Institut für Normung) for quality assurance. In the Middle East, where high temperatures can affect material performance, selecting the right alloy is essential.

What Role Does Fiberglass Play in Beam Manufacturing?

Fiberglass, or glass-reinforced plastic (GRP), is increasingly used in beam manufacturing due to its lightweight and high strength. It offers excellent corrosion resistance and is non-conductive, making it suitable for electrical applications.

Pros & Cons: The main advantage of fiberglass beams is their resistance to environmental factors, including chemicals and moisture. However, they can be more expensive to produce and may require specialized manufacturing processes.

Impact on Application: Fiberglass beams are particularly useful in corrosive environments, such as chemical plants or coastal areas. Their lightweight nature also allows for easy installation.

Considerations for International Buyers: Buyers should look for compliance with international standards like ASTM or ISO (International Organization for Standardization). In regions like Europe, sustainability certifications may also be a consideration.

Why is Concrete a Viable Option for Beam Manufacturing?

Concrete is a traditional material used in beam manufacturing, known for its compressive strength and durability. It is often reinforced with steel to enhance its tensile strength.

Pros & Cons: Concrete beams can support heavy loads and are fire-resistant, making them suitable for various structural applications. However, they are heavy, which can complicate transportation and installation. The curing process can also extend manufacturing timelines.

Impact on Application: Concrete is compatible with various media, but its porous nature can lead to issues if not properly sealed, especially in wet environments.

Considerations for International Buyers: Buyers should ensure compliance with local building codes and standards, such as EN or ASTM. In regions like South America, where seismic activity is a concern, selecting the right reinforcement is critical.

Summary Table of Material Selection for Beam Manufacturing

| Material | Typical Use Case for beam manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural beams in buildings | High strength and durability | Cost fluctuations | Medium |

| Aluminum | Lightweight structures in aerospace | Lightweight and corrosion-resistant | Higher cost and load limitations | High |

| Fiberglass | Marine and chemical plant applications | Excellent corrosion resistance | Higher production costs | High |

| Concrete | Foundations and heavy load structures | Fire-resistant and durable | Heavy and longer curing times | Low |

This guide provides a foundational understanding of material selection for beam manufacturing, helping international B2B buyers make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for beam manufacturer

What Are the Key Stages in the Manufacturing Process of Beam Products?

The manufacturing process for beams involves several critical stages that ensure the final product meets the required specifications and standards. Understanding these stages is essential for B2B buyers to evaluate potential suppliers effectively.

1. Material Preparation

Material selection is the foundation of quality beam production. Common materials include steel, aluminum, and concrete, each chosen for specific applications based on strength, weight, and environmental resistance.

- Sourcing Quality Materials: B2B buyers should prioritize suppliers who source materials from reputable providers. This can often be verified through certifications and material test reports.

- Pre-Processing Techniques: Techniques like cutting, slitting, and shearing are employed to prepare raw materials into manageable sizes. This is crucial for maintaining the integrity of the materials used in beam production.

2. Forming Techniques: How Are Beams Shaped?

The forming stage is where the raw materials are transformed into the desired beam shapes. This is typically done using various techniques, including:

- Hot and Cold Rolling: These methods are used for steel beams, where the material is passed through rollers to achieve the desired shape and thickness. Hot rolling is generally used for larger sections, while cold rolling provides tighter tolerances for smaller beams.

- Extrusion: Commonly used for aluminum beams, this process involves forcing material through a die to create a specific cross-section. It allows for complex shapes and is often utilized for lightweight applications.

- Casting: Concrete beams are often produced using casting methods, where concrete is poured into molds and allowed to set. This is particularly important for precast concrete beams, widely used in construction.

What Quality Assurance Measures Are Essential for Beam Manufacturers?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures the beams produced meet industry standards and client specifications. For international buyers, understanding these QA measures is vital.

International Standards: Which Certifications Should You Look For?

B2B buyers should be aware of relevant international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to maintain consistent quality. Buyers should request ISO certifications from potential suppliers.

- CE Marking: Essential for products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For beams used in oil and gas applications, the American Petroleum Institute (API) provides specifications that must be adhered to for quality assurance.

What Are the Key Quality Control Checkpoints in Beam Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that any defects are identified and addressed promptly.

1. Incoming Quality Control (IQC)

This initial stage involves inspecting raw materials upon arrival at the manufacturing facility. Key aspects include:

- Material Testing: Samples of incoming materials should be tested for compliance with specified standards. This includes tensile strength tests and chemical composition analysis.

- Supplier Verification: Buyers should verify suppliers’ quality management systems and request documentation that demonstrates compliance with relevant standards.

2. In-Process Quality Control (IPQC)

During manufacturing, ongoing inspections are essential to catch any deviations from quality standards. This includes:

- Real-Time Monitoring: Operators should monitor parameters such as temperature and pressure during processes like rolling and casting to ensure they remain within acceptable limits.

- Dimensional Checks: Regular measurements of beam dimensions at various stages help ensure consistency and adherence to specifications.

3. Final Quality Control (FQC)

Once the beams are completed, a final inspection is conducted to ensure they meet all quality requirements before shipment. This often includes:

- Visual Inspections: A thorough examination for surface defects, such as cracks or weld imperfections, is essential.

- Load Testing: For certain applications, beams may undergo load testing to verify their strength and durability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying the quality control practices of potential suppliers is crucial to ensure product reliability and compliance with standards.

1. Audits and Inspections

- Conducting Supplier Audits: B2B buyers should consider conducting on-site audits to assess the manufacturing processes, quality control measures, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality management practices.

2. Requesting Documentation and Reports

- Quality Assurance Reports: Buyers should request comprehensive QA reports that detail the results of IQC, IPQC, and FQC checks.

- Certification Validity: Ensure that the supplier’s certifications are current and cover all relevant products. This may involve direct communication with certifying bodies for verification.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control requirements can be complex for international buyers, especially those from Africa, South America, the Middle East, and Europe. Here are some nuances to consider:

- Regional Standards: Different regions may have specific standards that go beyond international requirements. For example, the Middle East may have unique specifications for construction materials that should be considered.

- Import Regulations: Buyers must be aware of import regulations in their respective countries, which may mandate additional testing or certification for beams, particularly when sourced from different continents.

- Cultural Considerations: Building relationships with suppliers can often impact the quality and reliability of products. Understanding cultural business practices can facilitate better communication and cooperation.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they select suppliers that meet their rigorous standards for beam manufacturing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘beam manufacturer’

Introduction

This practical sourcing guide aims to equip international B2B buyers with a comprehensive checklist for procuring beam manufacturing services. Whether you are based in Africa, South America, the Middle East, or Europe, following these steps will help ensure you select a reliable supplier that meets your technical and operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of a successful sourcing process. This includes details such as beam dimensions, material types, load-bearing capacities, and any specific industry standards that must be met. By being precise about your requirements, you will streamline the selection process and avoid miscommunication with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential beam manufacturers that align with your specifications. Utilize online platforms, industry directories, and trade shows to gather a list of candidates. Pay attention to their industry experience and geographical presence, as these factors can significantly influence their ability to meet your needs.

Step 3: Verify Supplier Certifications

Before moving forward, it is essential to verify that your potential suppliers hold the necessary certifications. Look for ISO certifications, compliance with local and international standards, and any industry-specific certifications that may apply. These credentials are indicators of a supplier’s commitment to quality and safety, which are crucial in the beam manufacturing sector.

Step 4: Request Samples and Conduct Quality Checks

Request samples of the beams to evaluate the quality of materials and workmanship. Conduct quality checks to ensure they meet your specifications and standards. This step is vital as it provides firsthand insight into the supplier’s production capabilities and allows you to assess the durability and performance of their products.

Step 5: Evaluate Supplier Lead Times and Capacity

Understanding a supplier’s lead times and production capacity is crucial for planning your project timelines effectively. Inquire about their current production schedules and their ability to scale up or down based on your needs. This information will help you avoid delays and ensure that your project stays on track.

Step 6: Assess Pricing Structures and Payment Terms

Analyze the pricing structures offered by different suppliers to determine the best value for your investment. Ensure you understand the breakdown of costs, including any additional fees for customization or expedited shipping. Also, discuss payment terms to find a mutually agreeable arrangement that supports your cash flow.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful partnership with your chosen supplier. Establish clear lines of communication and agree on preferred methods (email, phone, or project management tools). Regular updates and feedback loops will help mitigate misunderstandings and ensure that both parties are aligned throughout the manufacturing process.

By following this structured checklist, international B2B buyers can navigate the complexities of sourcing beam manufacturing services with confidence, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for beam manufacturer Sourcing

What Are the Key Cost Components in Beam Manufacturing?

Understanding the cost structure of beam manufacturing is crucial for international B2B buyers. The primary components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. Common materials used in beam manufacturing include steel, aluminum, and composite materials. Fluctuations in commodity prices can affect sourcing costs, so buyers should monitor market trends closely.

-

Labor: Labor costs vary by region and can be influenced by local wage laws and the availability of skilled workers. In developing regions, labor may be less expensive, but this can also correlate with varying levels of expertise and quality.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and administrative expenses. Efficient production processes can minimize overhead, thereby reducing costs.

-

Tooling: The initial investment in tooling and machinery can be significant. Custom tooling for specialized beams may lead to higher upfront costs but can offer long-term savings through increased production efficiency.

-

Quality Control (QC): Ensuring product quality is paramount, especially for beams used in construction and heavy industries. Implementing robust QC measures can add to costs but is essential for avoiding costly defects and ensuring compliance with international standards.

-

Logistics: Shipping and transportation costs can vary widely depending on the distance from the manufacturing site to the buyer. Considerations such as packaging, freight costs, and potential tariffs also play a significant role in the total cost.

-

Margin: Manufacturers typically add a markup to cover their profit margin. This can vary based on competition, market demand, and supplier relationships.

How Do Price Influencers Affect Beam Manufacturing Costs?

Several factors influence the pricing of beams, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their purchasing capabilities.

-

Specifications and Customization: Customized beams tailored to specific project requirements can drive up costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, CE marking) can affect pricing. Buyers should assess whether premium materials are necessary for their application.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices due to perceived quality and reliability, while newer suppliers may offer competitive rates to penetrate the market.

-

Incoterms: The terms of shipment (Incoterms) can significantly affect the total landed cost. Buyers should clarify responsibilities for shipping, insurance, and duties to avoid unexpected costs.

What Buyer Tips Can Help Optimize Beam Sourcing Costs?

To navigate the complexities of beam sourcing effectively, consider the following tips:

-

Negotiate Effectively: Establishing a rapport with suppliers can lead to better pricing and terms. Be prepared to discuss volume commitments and long-term partnerships to leverage better rates.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on purchase price, consider the TCO, which includes maintenance, operational efficiency, and potential resale value. This holistic view can lead to better investment decisions.

-

Understand Pricing Nuances for Different Regions: Pricing structures can vary significantly between regions like Africa, South America, the Middle East, and Europe. Buyers should familiarize themselves with local market conditions, currency fluctuations, and import regulations.

-

Conduct a Market Analysis: Before making a commitment, perform a market analysis to compare prices and offerings from multiple suppliers. This can provide leverage during negotiations and help identify the best value.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing in beam manufacturing, prices can vary widely based on market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough research and consult multiple sources to obtain accurate and current pricing information tailored to their needs.

Alternatives Analysis: Comparing beam manufacturer With Other Solutions

Introduction: What Are the Key Alternatives to Beam Manufacturers?

In the B2B landscape, selecting the right beam manufacturing solution is critical for ensuring structural integrity and cost-effectiveness. However, various alternative technologies and methods can also fulfill similar needs. Understanding the strengths and weaknesses of these alternatives can empower international buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed decisions that align with their specific requirements.

Comparison Table: Beam Manufacturer vs. Alternatives

| Comparison Aspect | Beam Manufacturer | Steel Fabrication | Prefabricated Concrete |

|---|---|---|---|

| Performance | High durability and strength | Moderate durability; variable quality | High compressive strength; consistent quality |

| Cost | Higher initial investment; long-term savings | Moderate cost; dependent on design | Lower initial cost; potential transport costs |

| Ease of Implementation | Requires specialized equipment and expertise | Customizable but labor-intensive | Quick installation; less labor required |

| Maintenance | Low maintenance; long lifespan | Moderate maintenance; depends on environmental factors | Low maintenance; resistant to corrosion |

| Best Use Case | Large-scale industrial projects | Custom structures or complex designs | Residential buildings and bridges |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Steel Fabrication?

Steel fabrication is a traditional method of creating structural components. One of its main advantages is flexibility; it allows for custom designs to meet unique project specifications. However, this method can be labor-intensive and may lead to variability in quality if not managed properly. Additionally, while the upfront costs can be moderate, the need for skilled labor can increase overall expenses, especially in regions with limited expertise.

How Does Prefabricated Concrete Compare to Beam Manufacturers?

Prefabricated concrete is gaining traction due to its cost-effectiveness and ease of installation. This method involves manufacturing concrete elements in a controlled environment, ensuring consistent quality. One of its key benefits is the reduced labor required on-site, which can significantly lower project timelines. However, it may not be as strong as steel options for certain applications and could incur additional transportation costs for heavy components. Prefabricated concrete is ideal for residential projects and simpler structures but may fall short in complex industrial applications.

Conclusion: How Can B2B Buyers Select the Right Solution for Their Needs?

Choosing the right beam manufacturing solution requires careful consideration of various factors, including performance, cost, ease of implementation, and maintenance needs. International B2B buyers should evaluate their project requirements, budget constraints, and the availability of skilled labor in their region. By comparing beam manufacturers with alternatives like steel fabrication and prefabricated concrete, buyers can make strategic decisions that not only meet their structural needs but also optimize their overall project efficiency and cost-effectiveness.

Essential Technical Properties and Trade Terminology for beam manufacturer

What Are the Key Technical Properties Important for Beam Manufacturers?

Understanding the technical specifications of beams is crucial for B2B buyers, particularly when selecting materials that meet specific project requirements. Here are some essential properties to consider:

1. Material Grade

Material grade determines the quality and suitability of the beams for various applications. Common grades include structural steel grades like S235, S275, and S355, which denote different yield strengths. Choosing the right material grade is vital as it affects durability, load-bearing capacity, and resistance to environmental factors. Buyers should prioritize grades that align with project demands to ensure safety and longevity.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions. In beam manufacturing, tolerances are critical for ensuring that components fit together correctly during assembly. Tight tolerances may be necessary for precision applications, while looser tolerances can suffice for less critical structures. Understanding tolerance requirements helps buyers avoid costly rework and ensures the integrity of the final construction.

3. Yield Strength

Yield strength is the maximum stress a material can withstand before deforming. For beams, this property is essential for determining load capacity and safety margins. Higher yield strengths indicate that a beam can support more weight without failing. B2B buyers must assess the load requirements of their projects to select beams with appropriate yield strengths, ensuring structural reliability.

4. Dimensions and Cross-Sectional Shape

The dimensions and cross-sectional shape of beams, such as I-beams, H-beams, and T-beams, directly influence their performance characteristics. Each shape has unique benefits, such as improved stability or reduced weight. Buyers should consider the specific application and spatial constraints when selecting dimensions and shapes, as this will impact overall design and efficiency.

5. Corrosion Resistance

Corrosion resistance refers to a material’s ability to withstand environmental degradation. This property is especially crucial in regions with harsh weather conditions or high humidity. Buyers should inquire about protective coatings or treatments that enhance corrosion resistance, ensuring the longevity of the beams in their intended environments.

What Are Common Trade Terms Used in Beam Manufacturing?

Familiarity with industry terminology can streamline communication and negotiations between B2B buyers and manufacturers. Here are some common terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of beams, understanding OEM relationships can help buyers identify reliable sources for high-quality materials that meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it impacts budgeting and inventory management. Understanding MOQ can help buyers negotiate better terms or find alternative suppliers that align with their project scales.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications, quantities, and delivery requirements. By issuing an RFQ, buyers can compare pricing and terms across multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined trade terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and to ensure smooth logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. It encompasses manufacturing and shipping times. Understanding lead times is crucial for B2B buyers to plan project timelines effectively, ensuring materials arrive when needed to avoid delays.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, leading to more successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the beam manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Beam Manufacturing Sector?

The beam manufacturing sector is witnessing transformative shifts driven by various global factors. A surge in infrastructure development, particularly in emerging markets such as Africa and South America, is propelling demand for high-quality beams. Additionally, urbanization trends and the need for sustainable construction practices are influencing purchasing decisions among international B2B buyers. Companies are increasingly investing in advanced manufacturing technologies, such as automation and robotics, to enhance production efficiency and reduce lead times.

Emerging sourcing trends also play a crucial role. Digital platforms are revolutionizing how buyers interact with suppliers, allowing for real-time comparison of prices, quality, and delivery timelines. This shift towards e-commerce in B2B transactions is particularly beneficial for buyers in remote regions, as it broadens their supplier base and improves access to international markets. Furthermore, the integration of artificial intelligence and data analytics is enabling manufacturers to optimize inventory management and predict market demands more accurately.

As market dynamics evolve, international buyers must stay informed about fluctuations in raw material prices and geopolitical factors that may impact supply chains. For instance, the ongoing disruptions from global events can lead to increased transportation costs, prompting buyers to seek local suppliers or diversified sourcing strategies to mitigate risks.

How Can Sustainability and Ethical Sourcing Impact Your Beam Manufacturing Procurement?

Sustainability is becoming a cornerstone of procurement strategies in the beam manufacturing sector. The environmental impact of construction materials is under scrutiny, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and the minimization of waste throughout the supply chain.

Ethical sourcing is equally important, as buyers increasingly demand transparency regarding the origins of materials and the labor practices employed in production. Certifications such as FSC (Forest Stewardship Council) and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for selecting suppliers. These certifications not only assure buyers of the environmental integrity of the materials but also enhance their brand reputation in a market that increasingly values corporate social responsibility.

By aligning procurement strategies with sustainability goals, B2B buyers can not only reduce their environmental footprint but also tap into a growing market segment that prioritizes eco-friendly products. Engaging with suppliers who share similar values can lead to long-term partnerships and improved supply chain resilience.

What Is the Evolution of Beam Manufacturing and Its Significance for B2B Buyers?

The beam manufacturing sector has evolved significantly over the decades, transitioning from traditional methods to advanced technologies. Initially dominated by manual labor and basic tools, the industry has embraced innovations such as computer numerical control (CNC) machining and automated welding processes. This evolution has resulted in enhanced precision, reduced waste, and greater production capacity.

For B2B buyers, understanding this evolution is vital, as it highlights the importance of selecting manufacturers who leverage modern technologies to ensure quality and efficiency. Buyers should consider the technological capabilities of potential suppliers, as these factors can directly influence lead times and overall project success.

In conclusion, navigating the market dynamics and sourcing trends within the beam manufacturing sector requires a keen understanding of global drivers, sustainability imperatives, and the historical context of manufacturing practices. By leveraging this knowledge, international B2B buyers can make informed procurement decisions that align with their strategic objectives and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of beam manufacturer

-

How do I ensure quality when sourcing from a beam manufacturer?

To ensure quality when sourcing beams, start by conducting thorough research on potential manufacturers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples to evaluate the material quality and strength. Additionally, check for customer reviews and case studies to gauge their reliability. It’s also beneficial to visit the factory if possible or hire a third-party inspection service to verify production processes and output. -

What are the key factors to consider when choosing a beam manufacturer?

When choosing a beam manufacturer, consider their production capacity, technology, and specialization in the type of beams you need (e.g., steel, timber, composite). Assess their experience in international trade, especially in your region, to ensure they understand local regulations and logistics. Evaluate their responsiveness and customer service, as effective communication is crucial in addressing any concerns that may arise during the procurement process. -

What is the typical minimum order quantity (MOQ) for beams?

Minimum order quantities for beams can vary significantly based on the manufacturer and the type of beam. Generally, MOQs can range from a few tons to several hundred tons. Discuss your project needs upfront with the manufacturer to understand their MOQ and explore the possibility of negotiating a lower quantity for trial orders. This approach allows you to assess the quality and service before committing to larger orders. -

What payment terms should I negotiate with beam manufacturers?

When negotiating payment terms, aim for conditions that protect your cash flow while ensuring the manufacturer is secure. Common terms include a deposit (typically 30% upfront) with the balance due upon delivery or after inspection. Consider using letters of credit for larger orders, as this provides security for both parties. Always clarify the payment methods accepted and any additional fees for currency conversion or international transactions. -

How can I customize beams to fit my project specifications?

Most beam manufacturers offer customization options to meet specific project requirements. Discuss your needs regarding dimensions, material types, and load-bearing capacities with the manufacturer. Providing detailed specifications and drawings will help them understand your requirements better. Inquire about the additional costs and lead times associated with customization, as these can impact your project timeline and budget. -

What are the logistics considerations for importing beams?

Logistics play a crucial role in the procurement of beams. Consider factors like shipping methods (container vs. bulk), customs regulations, and potential tariffs in your destination country. Collaborate with a freight forwarder who specializes in heavy materials to optimize shipping routes and costs. Ensure that the manufacturer provides the necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. -

How do I vet a beam manufacturer for reliability?

To vet a beam manufacturer, start by reviewing their business history, including years in operation and market reputation. Request references from past clients, especially those in your industry or region, to gain insights into their reliability. Conduct online research to identify any complaints or legal issues. Additionally, consider visiting their facility or utilizing third-party verification services to assess their operational capabilities and compliance with industry standards. -

What quality assurance practices should I expect from a reputable beam manufacturer?

A reputable beam manufacturer should have established quality assurance practices in place. Expect them to conduct regular quality checks throughout the production process, including material testing and dimensional inspections. They should adhere to international standards and provide documentation of compliance. Inquire about their processes for handling defects or non-conformities, as well as any warranty or guarantee policies they offer on their products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for beam manufacturer

As we conclude our exploration of strategic sourcing for beam manufacturers, it is essential to recognize the pivotal role that effective sourcing strategies play in enhancing operational efficiency and profitability. International B2B buyers from Africa, South America, the Middle East, and Europe must prioritize building strong relationships with reliable suppliers who offer quality products at competitive prices. This approach not only minimizes risks associated with supply chain disruptions but also fosters long-term partnerships that can adapt to evolving market demands.

How Can Strategic Sourcing Enhance Your Competitive Edge?

By leveraging strategic sourcing, companies can optimize their procurement processes, ensuring that they are not only cost-effective but also aligned with sustainability goals. Engaging in thorough market analysis and supplier evaluations allows buyers to make informed decisions that enhance their supply chain resilience. Moreover, embracing technology in sourcing processes can streamline operations and improve transparency.

What Should International Buyers Consider for Future Sourcing?

A stock image related to beam manufacturer.

Looking ahead, B2B buyers should remain agile and receptive to emerging trends, such as the shift towards digitalization and sustainable practices within the manufacturing sector. By actively participating in industry networks and staying informed about market innovations, companies can position themselves to capitalize on new opportunities and mitigate potential challenges.

In summary, strategic sourcing is not just a procurement tactic; it is a vital component of a successful business strategy. We encourage international B2B buyers to take proactive steps in refining their sourcing approaches, ensuring they are well-equipped to navigate the complexities of the global market.