Discover Top Strategies to Choose a Transistor Manufacturer (2025)

Introduction: Navigating the Global Market for transistor manufacturer

In today’s fast-paced technological landscape, sourcing reliable transistor manufacturers poses a significant challenge for international B2B buyers. The need for high-quality transistors is paramount, as they are integral components in a wide array of applications, from consumer electronics to industrial machinery. As buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Poland and Germany) navigate this complex global market, understanding the nuances of supplier selection and cost management becomes critical for maintaining competitive advantage.

This comprehensive guide delves into the multifaceted world of transistor manufacturing, offering insights into various types of transistors, their applications across different sectors, and best practices for supplier vetting. We will explore critical factors that influence cost, quality assurance measures, and logistical considerations that can affect the purchasing process. By equipping B2B buyers with actionable insights and strategic approaches, this guide empowers them to make informed decisions that align with their operational needs and market demands.

Whether you are looking to enhance your supply chain, streamline procurement processes, or ensure compliance with regional standards, understanding the global landscape of transistor manufacturing is essential. This guide serves as your roadmap to navigate challenges, seize opportunities, and foster successful partnerships in the ever-evolving electronics market.

Understanding transistor manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bipolar Junction Transistor (BJT) | High current and voltage handling, analog signal amplification | Audio amplifiers, power supplies | Pros: High gain, robust performance; Cons: Slower switching speeds, less efficient. |

| Field Effect Transistor (FET) | Voltage-controlled device, low power consumption | RF amplifiers, switching applications | Pros: High input impedance, faster switching; Cons: Sensitive to static, can be more complex. |

| Insulated Gate Bipolar Transistor (IGBT) | Combines BJT and FET features, high efficiency at high voltages | Electric vehicles, industrial motors | Pros: Excellent efficiency, thermal stability; Cons: More expensive, requires careful handling. |

| Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) | High-speed switching, low on-resistance | Power management, digital circuits | Pros: Fast operation, suitable for high-density applications; Cons: Limited to lower voltage applications. |

| Darlington Pair | Two BJTs connected for high current gain | Motor drivers, amplifiers | Pros: Very high gain, simple to use; Cons: Slower response time, higher saturation voltage. |

What Are Bipolar Junction Transistors (BJTs) and Their B2B Benefits?

Bipolar Junction Transistors (BJTs) are known for their ability to handle high currents and voltages, making them ideal for applications like audio amplifiers and power supplies. They operate using both electron and hole charge carriers, which contributes to their high gain characteristics. For B2B buyers, BJTs are suitable for projects requiring robust performance, but it’s important to consider their slower switching speeds and lower efficiency compared to other types.

How Do Field Effect Transistors (FETs) Stand Out in the Market?

Field Effect Transistors (FETs) are characterized by their voltage-controlled operation and low power consumption. They are widely used in RF amplifiers and various switching applications. Their high input impedance allows for minimal loading on preceding circuits, making them ideal for sensitive applications. However, B2B buyers must be cautious of their sensitivity to static electricity and the potential complexity in their integration.

What Makes Insulated Gate Bipolar Transistors (IGBTs) Suitable for Heavy-Duty Applications?

Insulated Gate Bipolar Transistors (IGBTs) combine the best features of BJTs and FETs, offering high efficiency and thermal stability at high voltages. This makes them particularly well-suited for applications in electric vehicles and industrial motors. While they provide excellent performance, B2B buyers should be prepared for a higher upfront cost and the need for careful handling during installation.

Why Choose Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs)?

Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) are favored for their high-speed switching capabilities and low on-resistance, making them ideal for power management and digital circuits. Their ability to operate at high densities is particularly beneficial in compact designs. However, B2B buyers need to consider that MOSFETs are typically limited to lower voltage applications, which may restrict their use in certain industrial settings.

What Advantages Do Darlington Pairs Offer for B2B Buyers?

Darlington pairs consist of two BJTs connected to achieve very high current gain, making them useful in applications like motor drivers and amplifiers. They are easy to use and integrate into circuits, providing significant amplification. However, B2B buyers should be aware of their slower response times and higher saturation voltage, which could impact performance in fast-switching applications.

Related Video: JUNCTION FIELD EFFECT TRANSISTOR || JFET | TYPES, CONSTRUCTION, WORKING OF JFET | WITH EXAM NOTES |

Key Industrial Applications of transistor manufacturer

| Industry/Sector | Specific Application of Transistor Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power Management Systems in Electric Vehicles | Improved energy efficiency and performance | Reliability and compliance with automotive standards |

| Telecommunications | Signal Amplification in Mobile Networks | Enhanced signal quality and coverage | Scalability and compatibility with existing infrastructure |

| Industrial Automation | Control Systems for Robotics | Increased precision and reduced operational costs | Durability in harsh environments and support for integration |

| Consumer Electronics | Audio Amplifiers in Home Theater Systems | Superior sound quality and user experience | Size, weight, and thermal management considerations |

| Renewable Energy | Inverters for Solar Power Systems | Efficient energy conversion and sustainability | Performance in varying environmental conditions |

How Are Transistors Used in the Automotive Industry?

In the automotive sector, transistors are crucial for power management systems, particularly in electric vehicles (EVs). These systems regulate the flow of electricity, optimizing battery performance and extending vehicle range. For international B2B buyers, especially from Africa and Europe, sourcing transistors that meet stringent automotive standards is vital. Reliability and compliance with international certifications ensure that components can withstand the rigors of automotive applications, ultimately enhancing product safety and longevity.

What Role Do Transistors Play in Telecommunications?

Transistors are instrumental in signal amplification for mobile networks, enabling better communication quality and coverage. In regions like South America and the Middle East, where mobile connectivity is rapidly expanding, high-quality transistors can significantly improve network performance. B2B buyers must consider the scalability of these components, ensuring they can integrate seamlessly with existing telecommunications infrastructure while also meeting local regulatory requirements.

How Are Transistors Essential for Industrial Automation?

In industrial automation, transistors are used in control systems for robotics, enhancing precision and reducing operational costs. These systems rely on transistors to process signals that dictate robotic movements and functions. Buyers from Europe and Africa should prioritize sourcing transistors that exhibit durability and can operate effectively in harsh environments, ensuring long-term reliability and minimal downtime in production processes.

Why Are Transistors Important in Consumer Electronics?

Transistors play a pivotal role in audio amplifiers within home theater systems, where they enhance sound quality and user experience. With the growing demand for high-fidelity audio in consumer electronics, B2B buyers must focus on sourcing transistors that offer compact size and efficient thermal management. This is particularly important for manufacturers in Europe, where consumer preferences lean towards sleek, high-performance devices.

What Benefits Do Transistors Offer in Renewable Energy Applications?

In renewable energy, transistors are essential for inverters in solar power systems, facilitating efficient energy conversion from DC to AC. This efficiency is crucial for maximizing the output of solar installations, especially in regions with abundant sunlight, such as parts of Africa and the Middle East. Buyers should consider the performance of transistors under varying environmental conditions to ensure optimal operation and longevity of solar energy systems.

Related Video: What is Field Effect Transistor – FET – JFET – MOSFET – Applications of MOSFET

3 Common User Pain Points for ‘transistor manufacturer’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Transistors

The Problem: B2B buyers often face challenges in sourcing high-quality transistors that meet their specific requirements. This can be particularly frustrating for companies in Africa and South America where local suppliers may lack the necessary quality standards or certifications. Buyers may encounter issues such as inconsistent product quality, lack of reliable supply chains, and insufficient technical support from manufacturers. This can lead to production delays and increased costs, undermining the overall project timeline and budget.

The Solution: To overcome these sourcing challenges, buyers should adopt a multi-faceted approach to finding a reliable transistor manufacturer. Start by conducting thorough market research to identify manufacturers that have established a strong reputation for quality and reliability. Utilize online platforms and industry-specific forums to read reviews and gather feedback from other buyers. Additionally, consider requesting samples or pilot batches to evaluate the quality before committing to larger orders. Establishing direct communication with manufacturers can also facilitate better understanding of their quality assurance processes and certifications. Engage in discussions about product specifications and ensure that the supplier can meet your exact requirements. This proactive approach not only mitigates risks but also fosters long-term relationships with trustworthy suppliers.

Scenario 2: Navigating Complex Technical Specifications

The Problem: Many B2B buyers struggle with the technical specifications of transistors, which can be highly complex and vary significantly between manufacturers. This can lead to selecting the wrong type of transistor for a specific application, resulting in performance issues or even product failure. Buyers from the Middle East and Europe, particularly in sectors like automotive or telecommunications, may find that a lack of technical knowledge hinders their ability to make informed purchasing decisions.

The Solution: To navigate this challenge, buyers should invest time in understanding the fundamental parameters of transistors, such as voltage rating, current rating, and switching speed. Manufacturers often provide detailed datasheets that outline these specifications; reviewing these documents is crucial. Additionally, consider collaborating with engineering teams to align on the required specifications based on the intended application. Many reputable manufacturers offer technical support and consultation services—take advantage of these resources. Engaging in workshops or training sessions provided by manufacturers can also enhance your team’s knowledge base, enabling better decision-making when selecting transistors.

Scenario 3: Managing Supply Chain Disruptions

The Problem: Supply chain disruptions are a significant pain point for B2B buyers, particularly in regions like Africa and South America where logistical challenges are more pronounced. Delays in shipment, fluctuating costs, and geopolitical factors can affect the timely delivery of transistors, jeopardizing project timelines and increasing operational costs. This unpredictability can be particularly detrimental for businesses that rely on just-in-time manufacturing practices.

The Solution: To mitigate supply chain risks, buyers should diversify their supplier base rather than relying on a single manufacturer. By engaging multiple suppliers across different regions, companies can create a more resilient supply chain that is less susceptible to disruptions. Furthermore, establishing clear communication channels with suppliers can provide real-time updates on potential delays or issues. Implementing inventory management practices, such as maintaining safety stock or using forecasting tools, can also help ensure that you have a buffer against supply chain shocks. Lastly, consider building strategic partnerships with logistics providers to optimize shipping routes and reduce lead times, enhancing overall supply chain efficiency.

Strategic Material Selection Guide for transistor manufacturer

When selecting materials for transistor manufacturing, it’s essential to consider various factors that influence performance, durability, and cost. Below, we analyze four common materials used in this industry, providing actionable insights for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Silicon in Transistor Manufacturing?

Silicon is the most widely used material in transistor manufacturing due to its excellent semiconductor properties. It operates effectively at temperatures up to 150°C and has a moderate thermal conductivity. Silicon exhibits good corrosion resistance, making it suitable for various environmental conditions.

Pros & Cons: The primary advantage of silicon is its abundance and low cost, which makes it an economical choice for large-scale production. However, its manufacturing complexity can lead to higher initial setup costs. Additionally, while silicon transistors are highly reliable, they may not perform optimally in high-frequency applications.

Impact on Application: Silicon is compatible with a wide range of electronic applications, including consumer electronics and industrial equipment. Its ability to handle moderate power levels makes it a versatile choice for many sectors.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and IEC. In regions like Europe, adherence to RoHS directives is crucial. Additionally, understanding local market preferences can help in selecting the right silicon grades.

How Does Gallium Arsenide Compare for High-Frequency Applications?

Gallium arsenide (GaAs) is another critical material, particularly for high-frequency and optoelectronic applications. It can operate at temperatures around 200°C and offers superior electron mobility compared to silicon, making it ideal for high-speed applications.

Pros & Cons: The main advantage of GaAs is its high efficiency in high-frequency applications, which is essential for telecommunications. However, it is significantly more expensive than silicon, and its manufacturing process is more complex, which can limit its use in cost-sensitive markets.

Impact on Application: GaAs transistors are particularly well-suited for RF and microwave applications, making them ideal for mobile phones and satellite communications. Its ability to handle high-frequency signals enhances performance in these areas.

Considerations for International Buyers: Buyers should be aware of the limited availability of GaAs in some regions, which can affect supply chains. Compliance with environmental regulations is also critical, as GaAs can pose disposal challenges.

What Role Does Silicon Carbide Play in High-Power Applications?

Silicon carbide (SiC) is gaining traction in high-power and high-temperature applications due to its wide bandgap and thermal conductivity. It can operate effectively at temperatures exceeding 200°C, making it suitable for harsh environments.

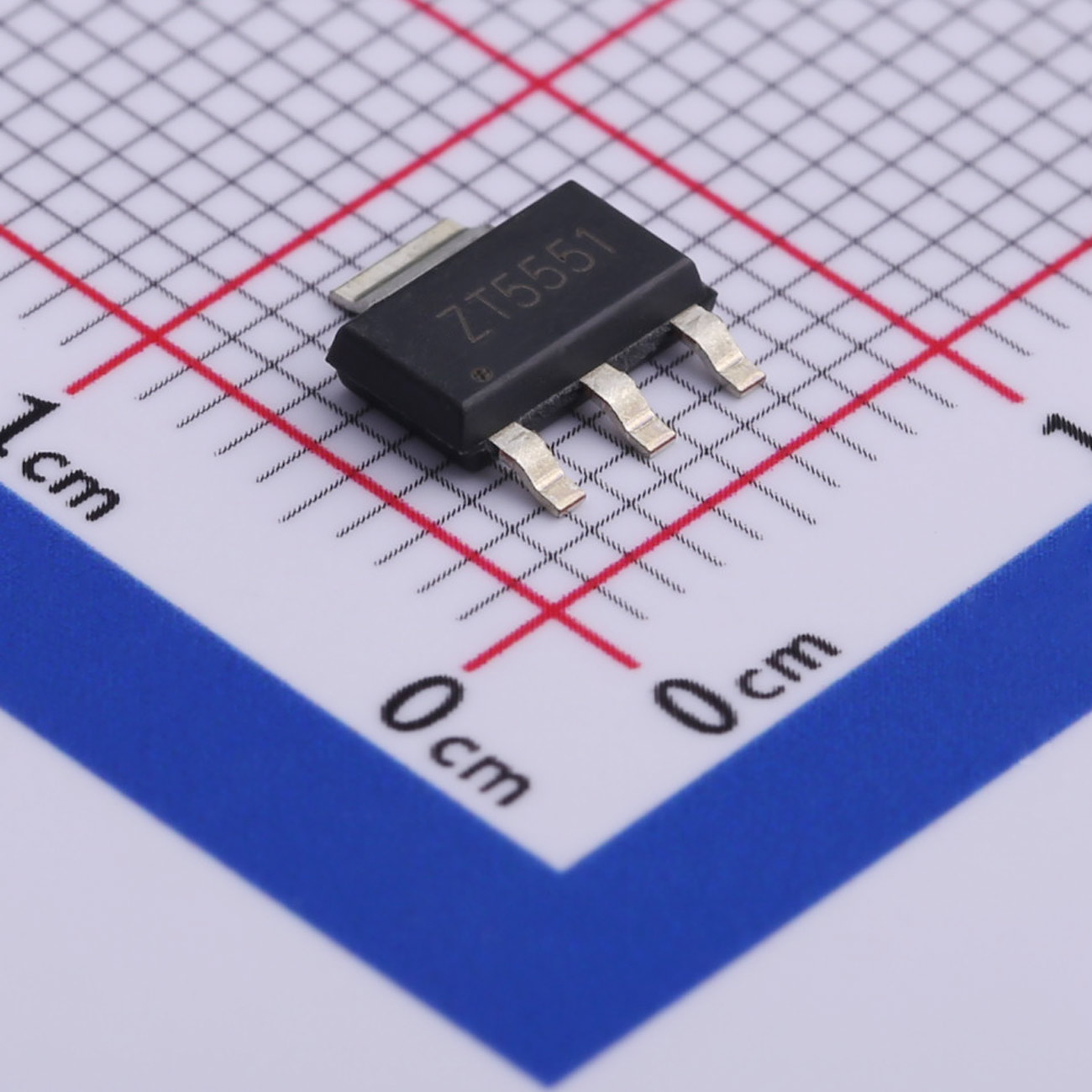

A stock image related to transistor manufacturer.

Pros & Cons: SiC offers excellent thermal stability and efficiency, leading to reduced energy losses in high-power applications. However, its manufacturing costs are higher, and it requires specialized equipment, which can complicate production.

Impact on Application: SiC is ideal for power transistors in electric vehicles and renewable energy systems. Its ability to handle high voltages and currents makes it a preferred choice for modern power electronics.

Considerations for International Buyers: Buyers should consider the availability of SiC components in their regions, as well as compliance with international standards. In Europe, for instance, the focus on energy efficiency may drive demand for SiC solutions.

Why is Indium Phosphide Important for Specialized Applications?

Indium phosphide (InP) is primarily used in specialized applications such as photonics and high-speed electronics. It operates effectively at temperatures up to 150°C and has excellent electron mobility.

Pros & Cons: The key advantage of InP is its superior performance in optoelectronic applications, such as laser diodes. However, it is one of the most expensive semiconductor materials, which can limit its use in mainstream applications.

Impact on Application: InP is essential for fiber optic communication systems and high-frequency transistors, where performance is critical. Its ability to efficiently convert electrical signals into optical signals makes it invaluable in telecommunications.

Considerations for International Buyers: Buyers should be mindful of the supply chain for InP, as it may not be as readily available as silicon or GaAs. Compliance with international standards is also necessary, particularly in regions with stringent regulations.

Summary Table of Material Selection for Transistor Manufacturing

| Material | Typical Use Case for transistor manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon | General-purpose transistors | Abundant and cost-effective | Limited performance in high-frequency | Low |

| Gallium Arsenide | RF and microwave applications | High efficiency in high-frequency | High cost and complex manufacturing | High |

| Silicon Carbide | High-power applications | Excellent thermal stability | Higher manufacturing costs | Med |

| Indium Phosphide | Optoelectronics and fiber optics | Superior performance in specialized areas | Very high cost | High |

This analysis provides a comprehensive overview of material options for transistor manufacturing, helping international B2B buyers make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for transistor manufacturer

What Are the Key Stages in the Manufacturing Process of Transistors?

The manufacturing process of transistors involves several critical stages, each crucial for ensuring the performance and reliability of the final product. Understanding these stages can help international B2B buyers make informed decisions when selecting a supplier.

-

Material Preparation: The first step involves sourcing high-purity materials, such as silicon, germanium, or gallium arsenide. Suppliers typically conduct a thorough evaluation of raw materials to ensure they meet specific purity standards, which is vital for the performance of the transistors. Buyers should look for manufacturers that provide certifications for material purity, as this can significantly impact the overall quality of the transistors.

-

Forming: In this stage, the prepared materials undergo processes like doping, oxidation, and photolithography to create the semiconductor structure. Doping introduces impurities to modify electrical properties, while photolithography allows for precise patterning of the semiconductor layers. Advanced techniques such as chemical vapor deposition (CVD) and molecular beam epitaxy (MBE) are often employed. Buyers should inquire about the technologies used and their impact on yield rates and performance.

-

Assembly: After forming, the components are assembled into functional units. This can involve wire bonding, die bonding, and encapsulation. The choice of assembly techniques can affect the thermal and electrical performance of the transistor. For B2B buyers, understanding the assembly methods used by potential suppliers can provide insights into the durability and application suitability of the transistors.

-

Finishing: The final stage involves testing, packaging, and labeling. Manufacturers conduct rigorous testing to ensure that the transistors meet the required specifications. This includes electrical testing, thermal cycling, and moisture sensitivity testing. Buyers should seek suppliers that provide comprehensive testing reports and adhere to relevant international standards to ensure product reliability.

How Is Quality Assurance Implemented in Transistor Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for transistors, ensuring that every product meets stringent standards before reaching the market. Here’s how quality assurance is typically structured:

-

Relevant International Standards: Manufacturers often comply with ISO 9001, which sets out the criteria for a quality management system. Additionally, industry-specific standards such as CE marking for European markets and API specifications may apply, depending on the application of the transistors. B2B buyers should confirm that suppliers have certifications for these standards to ensure compliance and quality.

-

Quality Control Checkpoints: Quality control (QC) checkpoints play a vital role throughout the manufacturing process. Common checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

– Final Quality Control (FQC): At this stage, finished products undergo comprehensive testing to verify they meet specifications. -

Common Testing Methods: Various testing methods are employed, including:

– Electrical Testing: Verifying the electrical characteristics of transistors under different conditions.

– Environmental Testing: Assessing performance under extreme temperature and humidity.

– Reliability Testing: Long-term testing to ensure consistent performance over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure product quality:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing process and quality control measures firsthand. During audits, buyers should evaluate the supplier’s adherence to international standards, cleanliness of the manufacturing environment, and the qualifications of personnel.

-

Requesting Quality Reports: Buyers should request documentation detailing the quality control processes, including IQC, IPQC, and FQC results. These reports provide insights into the supplier’s commitment to quality and can highlight any recurring issues or improvements.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the manufacturer’s processes and products. These inspections can be particularly beneficial for international buyers who may not have the resources for on-site audits.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is essential for international B2B buyers, especially those operating in diverse regulatory environments. Here are key considerations:

-

Regional Certification Requirements: Different regions have specific certification requirements that may not be universally applicable. For instance, the CE marking is essential for products sold in Europe, while other regions may have their own standards. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Supplier Certifications: Beyond general quality certifications, buyers should look for specific certifications relevant to their industry, such as automotive (IATF 16949) or aerospace (AS9100). These certifications indicate a higher level of quality assurance and can be pivotal for sectors with stringent requirements.

-

Cultural and Regulatory Differences: Navigating cultural and regulatory differences can be challenging. Buyers should engage suppliers who are knowledgeable about the export regulations and quality standards specific to their regions. This can help avoid potential pitfalls and ensure smoother transactions.

Conclusion: Making Informed Decisions in Transistor Procurement

Understanding the manufacturing processes and quality assurance measures in transistor production is crucial for international B2B buyers. By focusing on the key stages of manufacturing, quality control checkpoints, and verification methods, buyers can make informed decisions that align with their operational needs and quality standards. Engaging suppliers who demonstrate robust quality control processes and compliance with relevant international standards will ultimately lead to better product reliability and business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘transistor manufacturer’

In today’s global market, sourcing transistors from reliable manufacturers is essential for companies seeking quality and efficiency. This practical sourcing guide provides a step-by-step checklist tailored for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By following this guide, you can streamline your procurement process and ensure that you select the best suppliers for your needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing transistors. This includes understanding the type of transistors you need (e.g., bipolar junction transistors, field-effect transistors) and their specifications such as voltage, current rating, and packaging. A well-defined specification will not only assist in finding the right supplier but also help avoid costly mistakes in the procurement process.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers and understand the landscape of transistor manufacturing. Look for companies with a solid reputation and a track record of reliability. Utilize resources such as industry reports, trade shows, and online directories to compile a list of manufacturers that meet your criteria.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their manufacturing capabilities, quality assurance processes, and production capacity to ensure they can meet your demands consistently.

- Tip: Look for suppliers with ISO certifications or other relevant quality management certifications to ensure they adhere to international standards.

Step 4: Request Samples and Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of the transistors. This step allows you to evaluate the quality of their products firsthand. Check for performance, reliability, and compliance with your specifications before making any purchasing decisions.

- Tip: Analyze the samples in the context of your specific application to ensure they meet all necessary requirements.

Step 5: Verify Supplier Certifications

It’s essential to verify that your chosen suppliers have the necessary certifications to ensure compliance with industry standards. This includes checking for certifications related to quality management (such as ISO 9001), environmental management (such as ISO 14001), and industry-specific standards.

- Tip: Ask for documentation and ensure that the certifications are up-to-date and relevant to the transistors you intend to purchase.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize the terms and conditions of the contract. Discuss pricing, payment terms, lead times, and warranty policies. Clear agreements on these aspects will prevent misunderstandings and facilitate a smoother procurement process.

Step 7: Establish a Relationship for Long-term Collaboration

Building a strong relationship with your chosen supplier can lead to better pricing, priority service, and improved collaboration in the future. Regular communication and feedback are key to maintaining a successful partnership. Consider scheduling regular reviews to assess performance and address any issues that may arise.

By following this comprehensive checklist, you can enhance your sourcing strategy for transistors and establish fruitful partnerships with manufacturers that meet your technical and business needs.

Comprehensive Cost and Pricing Analysis for transistor manufacturer Sourcing

What Are the Key Cost Components in Transistor Manufacturing?

Understanding the cost structure of transistor manufacturing is crucial for international B2B buyers looking to source effectively. The primary cost components include:

-

Materials: The raw materials used in transistor production, such as silicon wafers, metals, and polymers, significantly impact pricing. Prices can vary based on market fluctuations and regional availability.

-

Labor: Labor costs encompass wages for skilled workers involved in design, manufacturing, and quality control. Regions with higher labor costs, such as Western Europe, may influence the final pricing compared to regions with lower labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and facility management. Efficient overhead management can lead to competitive pricing.

-

Tooling: Initial tooling costs for creating molds and specialized equipment can be substantial. However, these costs are often amortized over large production runs, which can lower the per-unit cost.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability but adds to overall costs. Buyers should prioritize suppliers with certifications (e.g., ISO) that guarantee high-quality production.

-

Logistics: Shipping and handling costs can vary widely based on location, volume, and shipping method. Incoterms play a critical role in determining who bears these costs.

-

Margin: Supplier profit margins can differ based on the supplier’s positioning in the market, brand reputation, and the value-added services they provide.

How Do Pricing Influencers Affect Transistor Sourcing Decisions?

Several factors influence pricing for B2B buyers sourcing transistors:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes typically result in lower per-unit costs due to economies of scale. It’s essential to negotiate MOQs that align with your operational needs.

-

Specifications and Customization: Custom-designed transistors or specific performance criteria can lead to increased costs. Clearly defining your requirements can help suppliers provide accurate quotes.

-

Material Quality and Certifications: Higher-quality materials and certifications generally increase costs but can reduce long-term risks associated with product failure.

-

Supplier Factors: The supplier’s experience, reputation, and production capabilities can significantly affect pricing. Buyers should conduct thorough research and consider supplier history.

-

Incoterms: Understanding Incoterms is crucial as they dictate the distribution of costs and responsibilities between buyers and sellers. This can influence the overall total cost of ownership.

What Buyer Tips Can Optimize Cost-Efficiency in Transistor Sourcing?

International B2B buyers can adopt several strategies to optimize costs:

-

Effective Negotiation: Building strong relationships with suppliers can lead to better pricing. Engage in discussions that consider long-term partnerships rather than one-time transactions.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider all associated costs, including shipping, handling, customs duties, and potential warranty claims. A lower upfront cost may not always equate to better value.

-

Understand Pricing Nuances for Different Regions: Buyers in Africa, South America, the Middle East, and Europe should be aware of regional pricing dynamics influenced by local economic conditions, tariffs, and trade agreements.

-

Leverage Technology: Utilizing procurement software can aid in comparing quotes from different suppliers, ensuring competitive pricing.

-

Stay Informed on Market Trends: Keeping abreast of global semiconductor trends and supply chain disruptions can provide leverage in negotiations and help anticipate price changes.

Disclaimer on Indicative Prices

It is essential to note that pricing in the semiconductor industry can be highly volatile and influenced by various external factors, including geopolitical events and market demand. Therefore, the prices discussed in this analysis are indicative and should be verified with suppliers for accuracy.

Alternatives Analysis: Comparing transistor manufacturer With Other Solutions

Understanding Alternatives to Transistor Manufacturing

In the rapidly evolving electronics industry, understanding the alternatives to traditional transistor manufacturing is crucial for international B2B buyers. The choice of components can significantly affect performance, costs, and overall project success. This section explores viable alternatives to conventional transistor manufacturers, providing insights to help buyers make informed decisions.

Comparison Table of Transistor Manufacturer and Alternatives

| Comparison Aspect | Transistor Manufacturer | Alternative 1: Integrated Circuits (ICs) | Alternative 2: Field-Effect Transistors (FETs) |

|---|---|---|---|

| Performance | High efficiency and reliability | Optimized for specific functions | Excellent for switching and amplification |

| Cost | Moderate to high | Generally lower due to mass production | Varies widely, often lower for specific applications |

| Ease of Implementation | Requires specialized knowledge | User-friendly with existing frameworks | Moderate, requires understanding of FET technology |

| Maintenance | Low, once implemented | Low, minimal upkeep needed | Moderate, can require recalibration |

| Best Use Case | General-purpose applications | Specific applications (e.g., audio, computing) | High-frequency and power applications |

What are the Advantages and Disadvantages of Integrated Circuits (ICs)?

Integrated Circuits (ICs) represent a significant alternative to traditional transistors. They combine multiple functions into a single chip, making them incredibly efficient for specific applications, such as audio processing or computing. The primary advantages include lower costs due to mass production and compact design, which saves space in electronic devices. However, the trade-off is that ICs may not offer the same level of customization as discrete transistors, potentially limiting their use in specialized applications.

How do Field-Effect Transistors (FETs) Compare?

Field-Effect Transistors (FETs) are another viable alternative, particularly known for their high efficiency in switching applications. FETs excel in high-frequency and power applications, making them suitable for telecommunications and audio equipment. They generally offer lower costs for specific uses; however, their implementation requires a solid understanding of the underlying technology. Maintenance can be moderate due to the need for periodic recalibration, especially in sensitive applications.

Making the Right Choice: How to Select the Best Solution for Your Needs

When choosing between a transistor manufacturer and its alternatives, B2B buyers should carefully assess their specific requirements. Consider the performance needs of your application, the total cost of ownership, and the ease of implementation. For projects requiring high reliability and general-purpose use, traditional transistors may still be the best choice. Conversely, for specialized applications with budget constraints, ICs or FETs might provide a more efficient solution. Ultimately, aligning the technology with your business objectives will lead to the best outcomes.

Essential Technical Properties and Trade Terminology for transistor manufacturer

What Are the Key Technical Properties of Transistors That B2B Buyers Should Understand?

When sourcing transistors, it is crucial to understand specific technical properties that can significantly impact performance and compatibility with your applications. Here are some essential specifications:

1. Material Grade

Transistors are typically made from materials like silicon, germanium, or gallium nitride. The choice of material affects the transistor’s efficiency, heat resistance, and overall performance. For B2B buyers, understanding material grades can help in selecting the right transistor for high-frequency or high-power applications.

2. Tolerance

Tolerance refers to the permissible limits of variation in the transistor’s specifications. A lower tolerance indicates a higher precision, which is vital for applications where performance consistency is critical. B2B buyers should assess the tolerance levels to ensure that the transistors can meet the exact requirements of their projects, minimizing the risk of failure.

3. Current Rating (IC)

The current rating specifies the maximum continuous current that a transistor can handle without overheating. This property is crucial for ensuring the longevity and reliability of electronic devices. Buyers must match the current rating with the expected load in their applications to avoid potential damage and ensure optimal performance.

4. Voltage Rating (VCE)

The voltage rating is the maximum voltage that can be applied across the collector-emitter junction without causing breakdown. Understanding voltage ratings helps B2B buyers select transistors that can withstand the electrical demands of their applications, thus preventing circuit failures.

5. Gain (hFE)

Gain, or hFE, measures how much a transistor amplifies the input signal. This property is particularly important for applications in audio and radio frequency. Buyers need to consider the gain specifications to ensure the transistor will perform effectively in its intended role.

Which Trade Terms Should International B2B Buyers Be Familiar With When Dealing with Transistor Manufacturers?

Understanding trade terminology is essential for effective communication with suppliers and ensuring smooth transactions. Here are some common terms relevant to B2B transactions in the transistor manufacturing sector:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with OEMs can provide access to high-quality components tailored to specific applications, often at a lower cost.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. B2B buyers should negotiate MOQs to align with their production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing information for specified products. For international buyers, sending detailed RFQs can lead to more accurate quotes and better negotiations, ensuring they receive competitive pricing and terms.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps B2B buyers understand their obligations regarding shipping costs, insurance, and risks, which can aid in effective supply chain management.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. For international buyers, understanding lead times can assist in project planning and inventory management, ensuring that components arrive in time for production schedules.

By familiarizing themselves with these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing transistors, ultimately leading to more efficient operations and reduced risks in their projects.

Navigating Market Dynamics and Sourcing Trends in the transistor manufacturer Sector

What Are the Key Market Trends Influencing the Transistor Manufacturing Sector?

The global transistor manufacturing market is currently experiencing significant transformation driven by technological advancements, changing consumer demands, and geopolitical factors. A notable trend is the increasing demand for higher performance and energy-efficient devices, which is being propelled by the growth of the Internet of Things (IoT), electric vehicles (EVs), and renewable energy systems. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must keep an eye on how these sectors evolve, as they are likely to dictate future transistor specifications and requirements.

Additionally, the rise of Industry 4.0 is reshaping sourcing strategies, making automation and smart manufacturing key components of supply chain management. This shift encourages manufacturers to adopt advanced production techniques, resulting in shorter lead times and lower costs. Buyers in regions like Poland and Germany should prioritize suppliers who can demonstrate agility and technological capability to keep pace with these changes.

Another emerging trend is the increasing importance of localized sourcing due to supply chain disruptions caused by geopolitical tensions and the COVID-19 pandemic. Buyers are encouraged to evaluate suppliers not only on product quality but also on their ability to provide stability and reliability in supply chains. This consideration is particularly crucial for African and South American buyers who may face unique logistical challenges.

How Can Sustainability and Ethical Sourcing Shape the Future of Transistor Manufacturing?

As environmental concerns continue to gain traction globally, sustainability has become a critical focus for the transistor manufacturing sector. International B2B buyers are increasingly seeking suppliers that adhere to sustainable practices, as these align with both regulatory requirements and consumer expectations. The environmental impact of manufacturing processes, particularly in terms of waste and emissions, is under scrutiny, making it essential for buyers to assess their suppliers’ environmental policies and practices.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should ensure that their suppliers are compliant with labor laws and ethical sourcing standards, as this mitigates risks associated with reputational damage and legal ramifications. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are indicators of a supplier’s commitment to sustainability and ethical practices. By prioritizing suppliers with these credentials, buyers not only enhance their own brand reputation but also contribute to a more sustainable future for the industry.

Green materials, such as those that reduce energy consumption during production and use, are also gaining traction. Buyers should consider suppliers who incorporate eco-friendly materials into their transistor designs, as this can lead to more sustainable product offerings.

How Has the Transistor Manufacturing Sector Evolved Over Time?

The transistor manufacturing sector has undergone a remarkable evolution since its inception in the mid-20th century. Initially developed for basic electronic applications, transistors have become integral components in a multitude of devices, from smartphones to sophisticated industrial machinery. The shift from analog to digital technology in the late 20th century catalyzed advancements in transistor design and manufacturing processes, leading to smaller, more efficient devices.

In recent years, the advent of nanotechnology and advancements in semiconductor materials have further revolutionized the industry, allowing for greater miniaturization and enhanced performance. This evolution has created new opportunities for international B2B buyers to access cutting-edge technologies and innovative solutions, paving the way for enhanced productivity and efficiency across various sectors. As the industry continues to evolve, staying informed about technological advancements will be vital for buyers looking to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of transistor manufacturer

-

How do I assess the reliability of a transistor manufacturer?

To evaluate the reliability of a transistor manufacturer, start by checking their certifications, such as ISO 9001 or other relevant industry standards. Review customer testimonials and case studies to gauge their service quality and product performance. Additionally, consider their production capacity and technology used, as these factors can influence their ability to meet your demands. Engaging in direct communication can also provide insights into their customer service responsiveness and willingness to address concerns. -

What is the best way to negotiate pricing with a transistor manufacturer?

When negotiating pricing with a transistor manufacturer, research market rates and competitor pricing to establish a baseline. Clearly define your requirements, including specifications and expected order quantities, to help the manufacturer provide an accurate quote. Be open to discussing volume discounts or long-term contracts, which may result in better pricing. Finally, ensure that you understand all terms, including shipping and handling fees, to avoid unexpected costs. -

What are the minimum order quantities (MOQs) for transistors?

Minimum order quantities (MOQs) for transistors can vary significantly between manufacturers. Generally, MOQs range from a few hundred to several thousand units, depending on the type of transistor and customization options. When sourcing, inquire about the MOQ directly and discuss potential flexibility, especially if you are a smaller buyer. Some manufacturers may offer lower MOQs for sample orders or trial runs to foster long-term relationships. -

How can I ensure the quality of transistors from a supplier?

To ensure quality, request detailed specifications and quality assurance processes from the supplier. Look for manufacturers that provide test reports and compliance certifications for their transistors. Consider establishing a quality control agreement that outlines testing protocols and acceptable failure rates. Additionally, if possible, conduct site visits or audits to witness the manufacturing processes firsthand, which can further affirm their commitment to quality. -

What payment terms should I expect when working with international transistor manufacturers?

Payment terms can vary widely among international suppliers, but typical arrangements include upfront deposits (20-50%), followed by the balance upon delivery or through letters of credit. Be sure to discuss payment methods that suit both parties, such as wire transfers or PayPal. Understand any currency conversion fees and the implications of exchange rates, especially when sourcing from manufacturers in different regions, like Africa or South America. -

What are the logistics considerations when sourcing transistors internationally?

When sourcing transistors internationally, consider shipping times, customs regulations, and potential tariffs. Choose a reliable logistics partner familiar with international shipping to ensure timely delivery. Determine whether the manufacturer will handle logistics or if you need to arrange for freight forwarding. Additionally, factor in lead times for production and shipping to avoid delays in your supply chain. -

How do I customize transistors to meet specific project requirements?

To customize transistors, clearly articulate your project specifications, including electrical characteristics, packaging, and performance criteria. Engage with the manufacturer early in the design process to explore available customization options and any associated costs. Some manufacturers may have design engineers who can assist with modifications, so ensure you leverage their expertise. Always request prototypes to validate customizations before placing larger orders. -

What are the common challenges in sourcing transistors from different regions?

Common challenges in sourcing transistors from regions like Africa, South America, or the Middle East include navigating varying regulatory standards, language barriers, and cultural differences in business practices. Additionally, logistics can be complicated due to infrastructure limitations or political instability. To mitigate these challenges, conduct thorough research on the local market conditions, establish strong communication channels, and consider working with local intermediaries who understand the regional landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for transistor manufacturer

In today’s rapidly evolving market, strategic sourcing for transistors is not just a procurement function; it’s a critical component of a company’s overall competitive strategy. By leveraging strategic sourcing, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can optimize their supply chains, reduce costs, and enhance product quality. Emphasizing strong supplier relationships and thorough market research allows companies to adapt to fluctuating demand and technological advancements effectively.

A stock image related to transistor manufacturer.

What are the emerging trends in the global transistor market? As the demand for advanced electronics continues to rise, innovations in transistor technology, such as enhanced performance and energy efficiency, will shape future sourcing strategies. Buyers should remain vigilant about these trends to ensure they are partnering with manufacturers who can meet evolving specifications and regulatory standards.

Looking ahead, the opportunities for international buyers are substantial. Engaging in a proactive sourcing approach not only mitigates risk but also positions companies to capitalize on new market opportunities. We encourage B2B buyers to assess their current sourcing strategies and explore partnerships with leading transistor manufacturers that align with their growth objectives. Embrace this journey towards strategic sourcing to secure a competitive edge in the global marketplace.