Discover Top Strategies to Choose a Waste Management Supplier (2025)

Introduction: Navigating the Global Market for waste management supplier

In today’s rapidly evolving global market, sourcing a reliable waste management supplier can pose significant challenges for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The increasing emphasis on sustainability and regulatory compliance has made the selection process more complex, requiring businesses to navigate a landscape filled with diverse suppliers and varying standards. This comprehensive guide is designed to demystify the process of finding the right waste management supplier, covering essential aspects such as types of waste management solutions, applications across different industries, and strategies for effective supplier vetting.

As you delve into this guide, you will gain insights into cost structures, best practices for negotiation, and how to assess supplier capabilities in terms of technology and service delivery. Whether you are based in South Africa, Colombia, or any other part of the globe, understanding the intricacies of the waste management supply chain is crucial for making informed purchasing decisions. This resource empowers you with the knowledge needed to identify and engage with suppliers that align with your organizational goals and compliance requirements. By leveraging the insights provided, you can streamline your procurement process, ultimately leading to enhanced operational efficiency and sustainability in your waste management practices.

Understanding waste management supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waste Collection Services | Focus on the collection of various waste types (solid, liquid, hazardous) | Municipal contracts, commercial sectors | Pros: Reliable service, established networks. Cons: May have limited customization options. |

| Recycling Facilities | Specialized in processing recyclable materials into new products | Manufacturing, retail, and construction | Pros: Reduces landfill waste, potential cost savings. Cons: Limited by material types accepted. |

| Waste Treatment Plants | Facilities that treat hazardous and non-hazardous waste to minimize environmental impact | Industrial waste management, healthcare | Pros: Advanced technology for safety, regulatory compliance. Cons: Higher operational costs. |

| Consultancy Services | Provide expertise on waste management strategies and regulations | Policy development, sustainability initiatives | Pros: Tailored solutions, expert insights. Cons: Can be costly, results may vary based on expertise. |

| Waste-to-Energy Providers | Convert waste materials into energy, reducing landfill use | Energy production, municipal waste management | Pros: Renewable energy source, reduces waste volume. Cons: Initial investment can be high, technology-dependent. |

What are the characteristics of Waste Collection Services?

Waste collection services are integral to waste management, focusing on the systematic removal of various types of waste. These suppliers typically operate under municipal contracts or serve commercial sectors, ensuring regular pickups and adherence to local regulations. When considering a waste collection service, B2B buyers should evaluate the supplier’s reliability, service frequency, and capacity to handle specific waste types, including hazardous materials. Additionally, understanding the service provider’s compliance with environmental standards is crucial for long-term sustainability.

How do Recycling Facilities contribute to waste management?

Recycling facilities play a pivotal role in transforming recyclable materials into new products, thereby conserving resources and reducing landfill waste. These suppliers often cater to industries such as manufacturing, retail, and construction, where recyclable materials are abundant. B2B buyers must assess the types of materials accepted, the facility’s processing capabilities, and its track record in maintaining quality standards. Engaging with a recycling facility can also lead to cost savings and improved corporate sustainability profiles, making it a valuable partnership.

What are the advantages of Waste Treatment Plants?

Waste treatment plants specialize in the safe treatment of both hazardous and non-hazardous waste, utilizing advanced technologies to minimize environmental impact. These facilities are essential for industries such as healthcare and manufacturing, where waste management compliance is critical. When selecting a waste treatment plant, B2B buyers should consider the facility’s technological capabilities, regulatory compliance history, and the range of services offered. While these plants can incur higher operational costs, their ability to ensure safety and sustainability can justify the investment.

Why are Consultancy Services important in waste management?

Consultancy services in waste management provide expert guidance on developing effective waste management strategies and navigating complex regulations. These suppliers are particularly beneficial for organizations aiming to enhance their sustainability initiatives or comply with local laws. B2B buyers should evaluate the consultancy’s experience, industry knowledge, and the ability to deliver tailored solutions. While consultancy services can be more costly, the insights gained can lead to significant long-term savings and operational efficiencies.

How do Waste-to-Energy Providers fit into the waste management landscape?

Waste-to-energy providers convert waste materials into energy, offering a dual benefit of reducing landfill use and generating renewable energy. This approach is particularly relevant for municipalities and industries seeking sustainable waste management solutions. B2B buyers should carefully assess the initial investment required, the technology employed, and the potential energy output from the waste processed. While the financial commitment can be substantial, the long-term environmental benefits and energy savings can make this an attractive option for forward-thinking businesses.

Related Video: Biodegradable and Non-Biodegradable Waste | Waste Management | How to Recycle Waste

Key Industrial Applications of waste management supplier

| Industry/Sector | Specific Application of Waste Management Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial Waste Recycling and Management | Reduces disposal costs and improves sustainability | Compliance with local regulations and recycling standards |

| Food and Beverage | Organic Waste Treatment and Composting | Enhances brand reputation and reduces landfill use | Certification of processes and quality of end products |

| Construction and Demolition | Construction Waste Management Solutions | Minimizes project delays and reduces environmental impact | Availability of specialized equipment and local partnerships |

| Healthcare | Medical Waste Disposal and Management | Ensures safety and compliance with health regulations | Certifications and experience in handling hazardous waste |

| Retail and Distribution | Packaging Waste Reduction and Recycling Programs | Cost savings and improved corporate social responsibility | Scalability of services and flexibility in waste types |

How Does Waste Management Benefit the Manufacturing Sector?

In the manufacturing industry, waste management suppliers play a critical role in industrial waste recycling and management. By implementing effective recycling processes, manufacturers can significantly reduce disposal costs while enhancing their sustainability initiatives. International buyers from regions such as Africa and South America should prioritize suppliers who can demonstrate compliance with local regulations and possess a thorough understanding of recycling standards. This ensures that the waste management practices align with both corporate goals and environmental policies.

What Are the Advantages of Organic Waste Treatment in the Food and Beverage Industry?

For the food and beverage sector, waste management suppliers provide organic waste treatment and composting solutions. These applications not only reduce landfill contributions but also enhance brand reputation as consumers increasingly prefer environmentally responsible companies. B2B buyers in Europe and the Middle East should seek suppliers who are certified in composting processes, ensuring that the end products meet quality standards. This focus on sustainability can lead to improved customer loyalty and market competitiveness.

How Can Construction Waste Management Solutions Optimize Projects?

In construction and demolition, waste management suppliers offer specialized solutions for managing construction waste. By effectively sorting and recycling materials, these suppliers help minimize project delays and reduce the environmental impact of construction activities. For international buyers, particularly in developing regions, it is crucial to source suppliers who have the necessary equipment and can establish local partnerships. This ensures timely service delivery and adherence to local environmental regulations.

What Are the Key Considerations for Medical Waste Disposal in Healthcare?

In the healthcare sector, managing medical waste is critical for safety and compliance with health regulations. Waste management suppliers provide tailored solutions for the safe disposal and treatment of hazardous materials. B2B buyers must prioritize suppliers with the appropriate certifications and extensive experience in handling medical waste. This is particularly important in regions with stringent health regulations, where non-compliance can lead to severe penalties and reputational damage.

How Can Retail and Distribution Benefit from Waste Reduction Programs?

For the retail and distribution industry, waste management suppliers facilitate packaging waste reduction and recycling programs. These initiatives not only lead to significant cost savings but also enhance corporate social responsibility efforts. International buyers should focus on suppliers that offer scalable services and flexibility in handling various waste types. This adaptability allows businesses to respond effectively to changing regulations and consumer expectations regarding sustainability.

Related Video: Waste sorting plant MBT plant+Composting, the best waste recycling system (Peaks-eco)

3 Common User Pain Points for ‘waste management supplier’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance Challenges in Waste Management

The Problem:

B2B buyers in regions such as Africa and South America often struggle with the complex web of local, national, and international regulations governing waste management. For instance, a South African manufacturing company might find it difficult to comply with the National Environmental Management: Waste Act, which dictates specific procedures for waste disposal and recycling. Failing to adhere to these regulations can lead to hefty fines, legal repercussions, and damage to the company’s reputation. The confusion surrounding the appropriate waste classifications and disposal methods can create significant anxiety for procurement managers, who are tasked with ensuring compliance while managing costs effectively.

The Solution:

To effectively navigate these regulatory landscapes, B2B buyers should engage with waste management suppliers who offer expertise in local regulations and compliance strategies. Prioritize suppliers who provide comprehensive documentation and resources that outline relevant laws and best practices. This could involve requesting detailed compliance guides or engaging in workshops and training sessions offered by the supplier. Additionally, establishing a collaborative relationship with the supplier can facilitate ongoing communication about regulatory changes. This proactive approach not only ensures compliance but also positions the buyer as a responsible corporate citizen, enhancing their brand reputation.

Scenario 2: Overcoming Inconsistent Waste Collection Services

The Problem:

In regions such as the Middle East, international B2B buyers frequently face issues with unreliable waste collection services. A construction firm in Dubai may experience delays or irregular pickups, leading to operational disruptions and potential safety hazards on job sites. Inconsistent waste management can result in increased costs due to additional disposal fees, penalties for littering, or even project delays. This inconsistency can frustrate project managers who rely on timely waste removal to maintain workflow and adhere to project timelines.

The Solution:

To mitigate this challenge, buyers should conduct thorough due diligence when selecting waste management suppliers. Look for suppliers with a proven track record of reliability and service consistency, which can often be verified through customer testimonials and case studies. Establishing clear service level agreements (SLAs) can also help set expectations regarding collection frequency and response times. Consider leveraging technology, such as GPS tracking systems, to monitor collection schedules and ensure accountability. By holding suppliers to these standards, buyers can enhance the efficiency of their operations and minimize the risks associated with waste management disruptions.

Scenario 3: Managing Rising Costs in Waste Disposal

The Problem:

Many B2B buyers, particularly in Europe, are grappling with escalating waste disposal costs due to increased landfill taxes and stricter recycling mandates. A food processing company in Germany may face significant financial strain as they are forced to adapt to these changes while trying to maintain profitability. The challenge lies not only in managing these rising costs but also in finding sustainable waste disposal solutions that align with corporate social responsibility goals.

The Solution:

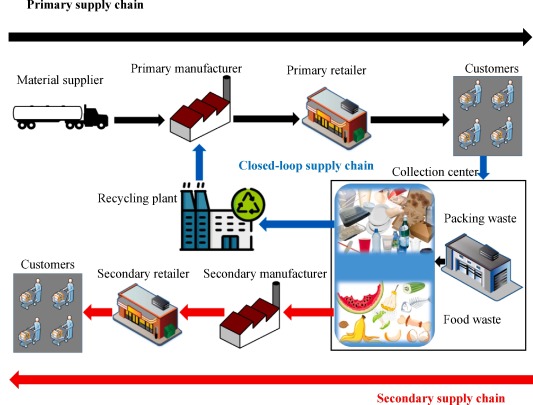

To address cost concerns, B2B buyers should explore innovative waste management strategies that emphasize recycling and waste reduction. Partnering with suppliers who offer comprehensive waste audits can identify opportunities for reducing waste at the source. Implementing a circular economy approach, where materials are reused and recycled, can significantly lower disposal costs over time. Additionally, consider negotiating flexible contracts that allow for adjustments based on fluctuating disposal needs or costs. By adopting these sustainable practices, buyers can not only manage expenses more effectively but also contribute to environmental sustainability, enhancing their corporate image and aligning with consumer expectations.

Strategic Material Selection Guide for waste management supplier

When selecting materials for waste management applications, it is crucial for international B2B buyers to consider the unique properties, advantages, and limitations of various materials. This analysis focuses on four common materials used in waste management: polyethylene, steel, fiberglass, and rubber. Each material presents distinct characteristics that can significantly impact performance, cost, and compliance with regional standards.

A stock image related to waste management supplier.

What Are the Key Properties of Polyethylene in Waste Management?

Polyethylene (PE) is a widely used thermoplastic known for its excellent chemical resistance and durability. It can withstand a temperature range of -50°C to 80°C and is resistant to corrosion, making it suitable for various waste types, including hazardous materials.

Pros and Cons: The primary advantage of polyethylene is its lightweight nature, which reduces transportation costs. Additionally, PE is relatively inexpensive and easy to manufacture. However, it may not perform well under high-pressure conditions and can degrade under prolonged exposure to UV light.

Impact on Application: Polyethylene is compatible with a wide range of waste media, including liquids and solids. Its flexibility allows for various applications, such as liners in landfills or containers for chemical waste.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local regulations regarding waste containment. Standards such as ASTM D3350 for PE materials may be relevant, depending on the specific application.

How Does Steel Perform in Waste Management Applications?

Steel, particularly stainless steel, is renowned for its strength and durability. It can withstand high temperatures and pressures, making it ideal for heavy-duty applications. Stainless steel also offers excellent corrosion resistance, especially in environments with aggressive chemicals.

Pros and Cons: The key advantage of steel is its longevity and structural integrity, which can justify a higher upfront cost. However, the manufacturing process can be complex, and the material is heavier, leading to increased shipping costs.

Impact on Application: Steel is often used in constructing waste bins, containers, and processing equipment, where strength and durability are paramount. Its compatibility with a wide range of waste types, including solid and liquid hazardous waste, makes it a versatile choice.

Considerations for International Buyers: Buyers should be aware of regional standards, such as DIN EN 10088 for stainless steel, and ensure that suppliers can meet these requirements. Additionally, the cost of steel can fluctuate based on market conditions, impacting overall project budgets.

What Are the Advantages of Fiberglass in Waste Management?

Fiberglass is a composite material known for its lightweight and high strength-to-weight ratio. It is highly resistant to corrosion and can endure harsh environmental conditions, making it suitable for various waste management applications.

Pros and Cons: The primary advantage of fiberglass is its resistance to chemical attack, which is essential for handling hazardous waste. However, the manufacturing process can be costly, and fiberglass may not be suitable for high-pressure applications.

Impact on Application: Fiberglass is often used for tanks, pipes, and containers in waste treatment facilities. Its compatibility with a variety of media, including corrosive chemicals, enhances its utility in the waste management sector.

Considerations for International Buyers: Buyers should check for compliance with standards such as ASTM D3299 for fiberglass reinforced plastic (FRP) and consider the availability of local suppliers to mitigate shipping costs.

Why Is Rubber Important in Waste Management?

Rubber, particularly synthetic rubber, is valued for its flexibility and resilience. It can withstand a range of temperatures and is resistant to many chemicals, making it suitable for various waste applications.

Pros and Cons: The main advantage of rubber is its excellent sealing properties, which are crucial for preventing leaks in waste containment. However, rubber can degrade over time, particularly when exposed to UV light and extreme temperatures.

Impact on Application: Rubber is commonly used in seals, gaskets, and liners for waste containers, providing effective barriers against leaks and spills.

Considerations for International Buyers: Buyers should be aware of the specific rubber grades suitable for their applications and ensure compliance with local regulations. Standards like ASTM D2000 may be relevant for rubber materials used in waste management.

Summary Table of Material Selection for Waste Management

| Material | Typical Use Case for waste management supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Liners for landfills, chemical waste containers | Lightweight, cost-effective | Poor UV resistance, limited pressure tolerance | Low |

| Steel | Waste bins, processing equipment | High strength, durability | Higher cost, heavier weight | High |

| Fiberglass | Tanks, pipes, containers | Corrosion-resistant, lightweight | Higher manufacturing cost, pressure limits | Medium |

| Rubber | Seals, gaskets, liners | Excellent sealing properties | Degrades under UV exposure | Medium |

This strategic material selection guide equips international B2B buyers with the necessary insights to make informed decisions when sourcing materials for waste management applications, ensuring compliance with standards and optimizing performance.

In-depth Look: Manufacturing Processes and Quality Assurance for waste management supplier

What Are the Main Stages of Manufacturing for Waste Management Suppliers?

The manufacturing process for waste management products typically involves several key stages that ensure the final product meets the necessary performance and safety standards. Understanding these stages is crucial for international B2B buyers looking to source reliable suppliers.

-

Material Preparation: This initial stage involves selecting and preparing the raw materials required for production. Suppliers often use materials like high-density polyethylene (HDPE), metals, and composites, which must be sourced responsibly to meet environmental standards. Buyers should inquire about the supplier’s sourcing practices and whether they comply with international sustainability guidelines.

-

Forming: In this stage, raw materials are transformed into specific shapes and forms using techniques such as injection molding, blow molding, or extrusion. Each technique has its advantages depending on the product type—e.g., injection molding is often used for creating complex shapes in waste bins and containers. B2B buyers should assess the supplier’s capabilities in these techniques to ensure they can meet specific product requirements.

-

Assembly: Once the components are formed, they undergo assembly, where various parts are joined together to create the final product. This stage may involve manual labor or automated processes, depending on the complexity of the product. Buyers should ask about the level of automation in the assembly process, as this can impact consistency and lead times.

-

Finishing: The final stage involves applying coatings, treatments, or additional features to enhance the product’s durability and aesthetics. This may include painting, surface treatment, or adding protective layers. International buyers should ensure that finishing processes comply with local regulations, particularly concerning environmental and safety standards.

What Quality Assurance Practices Should B2B Buyers Look For?

Quality assurance (QA) is vital in the waste management sector to ensure products perform reliably over their lifespan. Here are the key aspects of QA that B2B buyers should consider:

-

International Standards Compliance: Suppliers should adhere to internationally recognized standards such as ISO 9001, which outlines criteria for quality management systems. This certification indicates that the supplier has a robust framework for ensuring product quality. Other relevant certifications may include CE marking for products sold in Europe and API standards for equipment used in the oil and gas sector.

-

Quality Control Checkpoints: Effective quality control typically involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify and rectify issues in real-time.

– Final Quality Control (FQC): This final assessment ensures that the finished product meets all specifications and standards before shipment. -

Testing Methods: Common testing methods include mechanical testing (to assess strength and durability), chemical testing (to ensure material safety), and environmental testing (to evaluate performance under various conditions). B2B buyers should request detailed reports on these tests to verify compliance with safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

International buyers should take proactive steps to ensure that their suppliers maintain high-quality standards. Here are some strategies to verify supplier QC:

-

Conduct Audits: Regular audits of the supplier’s manufacturing facilities can provide valuable insights into their processes and quality management systems. Audits should focus on adherence to ISO standards, operational efficiency, and employee training.

-

Review Quality Reports: Requesting comprehensive quality control reports can give buyers a clearer picture of a supplier’s performance. These reports should detail the outcomes of various quality checks and any corrective actions taken.

-

Engage Third-Party Inspectors: Hiring independent third-party inspectors can add an additional layer of assurance. These inspectors can provide unbiased assessments of the supplier’s manufacturing processes and product quality, ensuring compliance with international standards.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing from suppliers in different regions, international buyers must navigate various quality control and certification nuances:

-

Regional Certification Requirements: Different regions have distinct certification requirements. For instance, while ISO 9001 is widely recognized, local certifications may also be necessary. Buyers should familiarize themselves with these requirements in their target markets, such as South Africa, Colombia, and European nations.

-

Cultural and Regulatory Differences: Understanding cultural attitudes towards quality and regulatory compliance can aid in evaluating potential suppliers. For example, some regions may prioritize environmental sustainability, while others may focus on cost-effectiveness. Buyers should consider these factors when assessing supplier capabilities.

-

Communication and Transparency: Establishing open lines of communication with suppliers is essential. Buyers should seek suppliers who are transparent about their processes, certifications, and quality assurance practices. This transparency can build trust and facilitate smoother negotiations.

Conclusion

For international B2B buyers, understanding the manufacturing processes and quality assurance practices of waste management suppliers is critical to making informed sourcing decisions. By focusing on the key stages of manufacturing, verifying quality control measures, and recognizing the nuances of international certifications, buyers can ensure that they partner with reliable suppliers capable of meeting their specific needs. In an increasingly globalized market, this knowledge not only enhances procurement strategies but also contributes to sustainable waste management practices worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘waste management supplier’

Introduction to Sourcing Waste Management Suppliers

Navigating the procurement process for waste management suppliers can be complex, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to streamline your sourcing efforts, ensuring you select a reliable partner who meets your operational needs and sustainability goals.

Step 1: Define Your Technical Specifications

Before you begin reaching out to suppliers, it is essential to clearly define your technical specifications. Identify the types of waste you need to manage, the volume of waste, and any specific treatment or disposal methods required. This clarity will help you communicate effectively with potential suppliers and ensure they can meet your needs.

- Consider regulatory requirements in your region, as these may influence your specifications.

- Include sustainability goals in your criteria, such as recycling targets or waste reduction initiatives.

Step 2: Conduct Market Research

Understanding the market landscape is vital. Conduct thorough research to identify potential suppliers who specialize in waste management solutions relevant to your industry and region. This research will inform your choices and help you identify suppliers with a proven track record.

- Utilize online platforms and industry directories to gather information.

- Attend trade shows and conferences to network and gather insights into emerging trends.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it is crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation process will help you gauge their reliability and performance.

- Check for client testimonials and case studies that demonstrate their capabilities.

- Inquire about their experience with international clients, particularly in your specific region.

Step 4: Verify Supplier Certifications

Certifications play a significant role in ensuring that a supplier adheres to industry standards and regulatory requirements. Verify that potential suppliers hold relevant certifications, such as ISO 14001 for environmental management or other local certifications applicable in your country.

- Request copies of certifications and verify them with issuing bodies.

- Ensure compliance with local regulations to avoid future legal issues.

Step 5: Assess Financial Stability

The financial health of a supplier can significantly impact your partnership. Assess their financial stability to ensure they can meet your long-term needs without risk of disruption.

- Request financial statements for the past few years to analyze their revenue trends.

- Consider their credit rating or seek third-party assessments if available.

Step 6: Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline their services, pricing structures, and any additional costs. This step allows you to compare offerings comprehensively and negotiate better terms.

- Ensure quotes are itemized to understand all components of the pricing.

- Look for flexibility in contract terms, especially regarding service scalability.

Step 7: Establish Clear Communication Channels

Effective communication is essential for a successful partnership. Once you select a supplier, establish clear communication channels to facilitate ongoing dialogue and address any issues promptly.

- Set regular check-ins to discuss service performance and any operational changes.

- Utilize project management tools to streamline collaboration and maintain transparency.

By following this checklist, B2B buyers can enhance their sourcing process for waste management suppliers, ensuring they make informed decisions that align with their operational and environmental objectives.

Comprehensive Cost and Pricing Analysis for waste management supplier Sourcing

What Are the Key Cost Components in Waste Management Supplier Pricing?

When sourcing waste management suppliers, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The type of materials used in waste management equipment and services significantly impacts pricing. Suppliers often use varying grades of steel, plastics, and other materials, which can affect durability and cost.

-

Labor: Labor costs vary depending on the region and the skill level required for installation and maintenance. In regions like South Africa and Colombia, labor costs may be lower than in Europe, but the availability of skilled labor can affect overall service quality.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and indirect labor. Suppliers with advanced manufacturing processes may pass on these costs, impacting the final pricing.

-

Tooling and Equipment: Specialized tooling for manufacturing waste management solutions can add to upfront costs. Buyers should inquire about tooling costs, especially for custom solutions.

-

Quality Control (QC): Implementing rigorous QC processes ensures the reliability of waste management products. Suppliers who prioritize QC may charge higher prices, but this often results in lower long-term costs due to reduced failures and maintenance.

-

Logistics: Transportation and shipping costs can vary widely based on location and shipping terms. For international buyers, understanding Incoterms and their implications on shipping costs is essential.

-

Margin: Supplier profit margins can differ significantly based on market competition and perceived value. Buyers should research typical margins in their region to gauge whether pricing is reasonable.

How Do Price Influencers Impact Waste Management Supplier Costs?

Several factors influence the pricing of waste management solutions beyond the core cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should negotiate MOQs to take advantage of economies of scale.

-

Specifications and Customization: Custom solutions tailored to specific needs can lead to increased costs. When possible, standardize requirements to minimize expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO standards) can drive up costs but may provide better long-term value through enhanced performance and compliance.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can affect pricing. Established suppliers might charge a premium for their proven track record.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage logistics costs effectively. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can influence overall pricing.

What Are Some Effective Buyer Tips for Sourcing Waste Management Suppliers?

When sourcing waste management suppliers, particularly for international transactions, consider the following strategies:

-

Negotiate Wisely: Leverage your purchasing power by negotiating pricing and terms. Always compare multiple suppliers to ensure competitive pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational costs, and disposal fees associated with the waste management solutions.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Africa may offer more competitive rates compared to those in Europe due to lower labor costs.

-

Conduct Thorough Research: Investigate supplier backgrounds, reviews, and case studies to ensure they meet your quality and reliability standards.

-

Plan for Currency Fluctuations: For international buyers, currency exchange rates can impact costs. Consider locking in prices or using hedging strategies to mitigate risks.

Disclaimer on Indicative Prices

Pricing for waste management solutions can vary significantly based on numerous factors, including geographic location, market conditions, and specific project requirements. It is advisable for buyers to obtain detailed quotes and conduct thorough market research to arrive at accurate pricing expectations.

Alternatives Analysis: Comparing waste management supplier With Other Solutions

Understanding the Importance of Exploring Alternatives in Waste Management

In today’s dynamic business environment, selecting the right waste management solution is crucial for operational efficiency and environmental sustainability. While traditional waste management suppliers offer a range of services, it’s essential for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, to consider alternative solutions. This exploration can lead to better performance, cost savings, and improved compliance with local regulations.

Comparison of Waste Management Solutions

| Comparison Aspect | Waste Management Supplier | Recycling Technology | Composting Solutions |

|---|---|---|---|

| Performance | High reliability and efficiency in waste collection and disposal | Effective in reducing landfill waste and recovering materials | Converts organic waste into valuable compost, enhancing soil health |

| Cost | Varies by service level; generally higher upfront costs | Moderate initial investment; cost-saving potential over time | Low operational costs, especially if organic waste is abundant |

| Ease of Implementation | Requires contracts and service agreements; may involve operational changes | Installation of equipment needed; requires training | Simple setup; can be implemented at various scales |

| Maintenance | Regular service checks; typically low maintenance | Requires regular maintenance of machinery | Minimal maintenance; occasional monitoring of compost quality |

| Best Use Case | Ideal for urban areas with diverse waste streams | Best for areas with strong recycling programs and regulations | Suitable for agricultural sectors or communities with significant organic waste |

What Are the Pros and Cons of Recycling Technology?

Recycling technology focuses on the collection and processing of recyclable materials to reduce waste sent to landfills. One of its significant advantages is the ability to recover valuable materials, which can lead to cost savings and environmental benefits. However, this solution often requires a higher initial investment in machinery and infrastructure. Additionally, successful implementation depends heavily on local regulations and public participation, which can be a challenge in regions with less awareness of recycling practices.

How Do Composting Solutions Benefit Businesses?

Composting solutions transform organic waste into nutrient-rich compost, offering both environmental and economic advantages. The low operational costs and ability to utilize organic waste effectively make composting an attractive option for many businesses, particularly in the agricultural sector. However, composting may not be suitable for all waste types and requires a consistent supply of organic materials to maintain efficiency. Moreover, it may necessitate some training for staff to manage the composting process effectively.

Conclusion: How Can B2B Buyers Choose the Right Waste Management Solution?

When evaluating waste management solutions, B2B buyers should consider their specific operational needs, available budget, and long-term sustainability goals. While waste management suppliers provide comprehensive services, alternatives like recycling technology and composting solutions may offer more tailored benefits depending on the nature of the waste generated. Conducting a thorough analysis of the pros and cons of each option, alongside the unique characteristics of the business, will empower buyers to make informed decisions that align with both economic and environmental objectives.

Essential Technical Properties and Trade Terminology for waste management supplier

What Are the Key Technical Properties of Waste Management Supplies?

Understanding the essential technical properties of waste management supplies is critical for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here are some of the most important specifications to consider:

1. Material Grade

Material grade refers to the quality and type of materials used in manufacturing waste management equipment, such as bins, compactors, and shredders. Higher-grade materials typically offer better durability, resistance to corrosion, and longevity. For B2B buyers, selecting the right material grade is vital to ensure that the equipment can withstand harsh environmental conditions, which is particularly relevant in tropical climates or industrial settings.

2. Load Capacity

Load capacity indicates the maximum weight a waste management product can safely handle. For example, a waste compactor’s load capacity will determine how much waste it can process at once. Understanding load capacity is essential for buyers to optimize their operations and avoid equipment failure due to overloading. This is especially important for businesses in sectors like construction or manufacturing that generate significant waste volumes.

3. Tolerance Levels

A stock image related to waste management supplier.

Tolerance levels refer to the permissible limits of variation in dimensions and performance of waste management equipment. High tolerance levels are crucial for ensuring that components fit together correctly and operate efficiently. For B2B buyers, knowing the tolerance levels helps in assessing the reliability and precision of the equipment, which is particularly important when integrating new machinery into existing waste management systems.

4. Energy Efficiency Rating

Energy efficiency rating measures how effectively a waste management machine utilizes energy. Equipment with high energy efficiency ratings can significantly reduce operational costs and minimize environmental impact. B2B buyers should prioritize energy-efficient options to align with sustainability goals and lower utility expenses, particularly in regions where energy costs are high.

5. Safety Standards Compliance

Safety standards compliance indicates whether a product meets local and international safety regulations. Equipment that adheres to safety standards not only protects workers but also reduces liability risks for businesses. B2B buyers must ensure that their suppliers provide documentation of compliance, especially in industries that handle hazardous waste or operate in regions with strict regulatory environments.

What Are Common Trade Terms in Waste Management Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in the waste management sector. Here are some key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure the quality of components used in waste management systems. It’s important for buyers to verify the reputation of OEMs when making purchasing decisions.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to gauge the financial commitment required for a purchase. This is particularly relevant for companies in emerging markets where budgets may be constrained, allowing buyers to plan their procurement strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing information for specific products or services. For international buyers, issuing an RFQ can streamline the procurement process and facilitate better negotiation terms. It’s advisable for buyers to provide detailed specifications in their RFQ to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is critical for B2B buyers to clarify shipping costs, risks, and delivery obligations. This knowledge can prevent misunderstandings and ensure smoother transactions across borders.

Conclusion

By grasping these essential technical properties and trade terms, B2B buyers in the waste management sector can make informed decisions that enhance operational efficiency and compliance. This knowledge not only aids in selecting the right suppliers but also fosters stronger business relationships in an increasingly competitive global marketplace.

Navigating Market Dynamics and Sourcing Trends in the waste management supplier Sector

What Are the Key Trends Driving the Waste Management Supplier Sector?

The waste management supplier sector is currently influenced by several global drivers, including urbanization, regulatory changes, and technological advancements. As cities expand in regions like Africa and South America, the demand for efficient waste management solutions is increasing. For B2B buyers, particularly in these regions, this presents an opportunity to engage with suppliers who can provide innovative solutions tailored to local challenges.

Emerging technologies such as IoT, AI, and blockchain are reshaping sourcing strategies in waste management. IoT devices enable real-time monitoring of waste levels, optimizing collection routes and reducing operational costs. In contrast, blockchain offers transparency in waste tracking, which is becoming increasingly important for compliance and ethical sourcing.

Additionally, the growing emphasis on circular economy principles is pushing suppliers to innovate towards waste reduction and resource recovery. Buyers in Europe and the Middle East are particularly focused on suppliers who can demonstrate sustainable practices. Thus, understanding these market dynamics allows international buyers to make informed decisions when sourcing waste management solutions that align with their operational goals and sustainability commitments.

How Important Is Sustainability and Ethical Sourcing in Waste Management?

Sustainability is no longer just a buzzword; it has become a critical consideration for B2B buyers in the waste management sector. The environmental impact of waste management practices is profound, influencing everything from regulatory compliance to corporate reputation. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as waste-to-energy technologies and material recovery facilities, which minimize landfill use and reduce carbon footprints.

Moreover, ethical sourcing is gaining traction as consumers and businesses alike demand greater accountability. Suppliers that adhere to ethical supply chains not only reduce risks associated with environmental violations but also enhance their marketability. Certifications like ISO 14001 and LEED can serve as benchmarks for buyers looking for reliable partners.

Investing in suppliers with ‘green’ certifications and sustainable materials can lead to long-term cost savings and improved brand loyalty. For international B2B buyers, particularly from regions like Africa and South America, aligning with suppliers committed to sustainability is crucial for meeting both local regulatory requirements and global market expectations.

What Is the Brief Evolution of the Waste Management Supplier Sector?

The waste management supplier sector has evolved significantly over the past few decades, transitioning from traditional waste disposal methods to more sophisticated and sustainable solutions. Initially dominated by landfill practices, the sector has shifted towards recycling and resource recovery in response to growing environmental concerns and regulatory pressures.

The introduction of advanced technologies has further propelled this evolution, enabling real-time data collection and analysis that improve operational efficiency. This shift has been particularly evident in developed markets in Europe, where stringent regulations have necessitated innovative waste management practices. Meanwhile, emerging markets in Africa and South America are increasingly adopting these technologies to address their unique waste challenges.

As the global focus on sustainability intensifies, the evolution of the waste management supplier sector reflects a broader commitment to environmental stewardship and responsible sourcing, making it imperative for international buyers to stay informed about these changes.

Frequently Asked Questions (FAQs) for B2B Buyers of waste management supplier

-

How do I solve my waste management challenges as a B2B buyer?

To effectively address waste management challenges, start by conducting a thorough needs assessment of your current waste disposal processes. Identify the types of waste generated, the volume, and compliance requirements specific to your region, whether in Africa, South America, the Middle East, or Europe. Partner with suppliers who offer tailored solutions, including recycling programs or waste-to-energy services. Additionally, consider leveraging technology for tracking and reporting waste management metrics to improve efficiency and compliance. -

What is the best waste management supplier for my specific industry needs?

The best waste management supplier for your industry will depend on your unique operational requirements, regulatory environment, and waste types. For instance, manufacturers may need suppliers specializing in hazardous waste, while retailers might focus on general waste management. Research suppliers with experience in your sector, check client testimonials, and assess their certifications. It’s also beneficial to engage with suppliers who can offer scalable solutions that adapt to your growth and evolving needs. -

How can I evaluate the reliability of a waste management supplier?

Evaluating a supplier’s reliability involves several steps. Begin with a comprehensive background check, including their years in business, client portfolio, and industry reputation. Request references from other B2B clients, focusing on those in similar sectors or regions. Assess their compliance with local regulations and certifications, such as ISO standards. Finally, consider visiting their facility or operational sites to observe their processes and equipment firsthand. -

What are the minimum order quantities (MOQ) for waste management services?

Minimum order quantities for waste management services can vary significantly based on the supplier and the type of service offered. Some suppliers may have set MOQs for specific services like bulk waste collection or specialized recycling. It’s essential to discuss your needs directly with potential suppliers to understand their MOQ policies. Many suppliers are willing to negotiate terms, especially for long-term contracts or consistent service agreements. -

What payment terms should I expect from waste management suppliers?

Payment terms in the waste management industry typically range from upfront payments to net 30 or net 60 days after service delivery. Suppliers may also offer discounts for early payments or penalties for late payments. It’s crucial to clarify these terms before entering an agreement. Additionally, inquire about any additional fees for services such as emergency pickups or specialized waste handling, as these can affect overall costs. -

How do waste management suppliers ensure quality assurance (QA) in their services?

Quality assurance in waste management is maintained through regular audits, staff training, and adherence to industry standards. Reputable suppliers implement rigorous QA processes, including waste tracking systems, compliance checks, and customer feedback mechanisms. Ensure that your chosen supplier can demonstrate their QA protocols and provide documentation of their certifications and performance metrics. This will help ensure that you receive reliable and compliant waste management services. -

What logistics considerations should I keep in mind when sourcing a waste management supplier?

Logistics play a crucial role in waste management, impacting both efficiency and costs. When sourcing a supplier, consider their geographic coverage, fleet capabilities, and response times. Assess how they manage waste collection schedules and whether they have the infrastructure to handle your specific waste types. Additionally, discuss contingency plans for unexpected spikes in waste generation or changes in regulations that may affect logistics. -

How can I customize waste management solutions for my business?

Customizing waste management solutions involves a collaborative approach with your supplier. Start by outlining your specific waste types, volumes, and disposal requirements. Many suppliers offer tailored programs, including recycling initiatives or waste reduction strategies. Engage in open discussions about your goals, such as sustainability targets or cost reductions, and ask suppliers about their ability to adapt their services to meet these objectives. By fostering a partnership, you can create a waste management plan that aligns with your business’s operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for waste management supplier

In navigating the complexities of waste management sourcing, international B2B buyers must prioritize strategic partnerships that enhance sustainability and operational efficiency. Key takeaways include the importance of aligning with suppliers who not only meet regulatory standards but also innovate in waste reduction technologies. This alignment is crucial for companies in regions like Africa and South America, where resource optimization can significantly impact both environmental and economic outcomes.

How can strategic sourcing enhance waste management efficiency? By adopting a strategic sourcing framework, organizations can leverage data analytics to identify reliable suppliers, negotiate favorable terms, and ensure compliance with local regulations. This approach minimizes risks and maximizes value, ultimately leading to improved waste management practices.

Looking ahead, the demand for sustainable waste management solutions is set to rise globally, driven by increasing regulatory pressures and consumer expectations. B2B buyers in the Middle East and Europe should proactively engage with suppliers who are committed to innovation and sustainability. Embracing these strategic sourcing principles will not only enhance your operational capabilities but also position your organization as a leader in responsible waste management. Take the next step in your sourcing strategy today and build partnerships that pave the way for a cleaner, more sustainable future.