Discover Top Suppliers: CNC Router China Buying Guide (2025)

Introduction: Navigating the Global Market for cnc router china

In today’s interconnected global economy, sourcing a CNC router from China presents a unique set of challenges and opportunities for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The rapid advancement of technology and manufacturing capabilities in China has positioned it as a leading supplier for various industries. However, navigating the complexities of supplier selection, quality assurance, and cost management can be daunting. This guide aims to simplify the process of acquiring CNC routers by providing actionable insights on critical factors such as types of CNC routers available, their diverse applications across industries, and effective strategies for vetting suppliers.

Understanding the intricacies of the global market for CNC routers is essential for making informed purchasing decisions. This comprehensive guide will delve into essential topics, including the different types of CNC routers tailored for specific applications, the cost implications of sourcing from China, and best practices for ensuring product quality and compliance with international standards. By equipping international buyers with the knowledge to effectively navigate these complexities, this guide empowers businesses to capitalize on the advantages of sourcing CNC routers from China while minimizing risks. Whether you’re a manufacturer in France seeking precision tools or a startup in South America looking to enhance production capabilities, this resource will serve as your roadmap to successful procurement in the dynamic landscape of CNC machinery.

Understanding cnc router china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wood CNC Router | Optimized for wood cutting, high-speed spindles | Furniture manufacturing, cabinetry | Pros: Excellent for wood; high precision. Cons: Limited to wood materials. |

| Metal CNC Router | Heavy-duty construction, capable of cutting metals | Automotive parts, industrial machinery | Pros: Durable and versatile; handles tough materials. Cons: Higher cost; requires skilled operators. |

| Laser CNC Router | Utilizes laser technology for precise cutting | Sign making, intricate designs | Pros: High accuracy; minimal material wastage. Cons: Limited material thickness; maintenance can be costly. |

| Stone CNC Router | Specialized for stone and hard materials | Monument engraving, architectural elements | Pros: Ideal for hard materials; great detail. Cons: Slower operation; more expensive. |

| Multi-Function CNC Router | Combines various functionalities (cutting, engraving, milling) | Prototyping, custom manufacturing | Pros: Versatile; saves space and cost. Cons: Complexity may lead to higher maintenance. |

What are the Characteristics of Wood CNC Routers?

Wood CNC routers are specifically designed for woodworking applications, featuring high-speed spindles and precision cutting tools. They are ideal for businesses involved in furniture manufacturing and cabinetry, where intricate designs and high-quality finishes are crucial. When considering a wood CNC router, buyers should evaluate the machine’s speed, cutting depth, and compatibility with various wood types to ensure it meets production needs.

How Do Metal CNC Routers Differ from Other Types?

Metal CNC routers are built with robust frames and powerful motors, enabling them to cut through various metals, including aluminum and steel. These machines are essential in industries like automotive and aerospace, where precision is paramount. Buyers should consider factors such as the machine’s load capacity, tooling options, and the type of metals it can handle when making a purchasing decision.

What Advantages Does a Laser CNC Router Offer?

Laser CNC routers employ advanced laser technology to achieve high levels of precision in cutting and engraving. They are well-suited for applications in sign making and intricate design work, where detail is key. Buyers should assess the laser power, cutting speed, and maintenance requirements, as these factors significantly affect operational efficiency and overall costs.

Why Choose a Stone CNC Router for Hard Materials?

Stone CNC routers are designed to handle dense materials like granite and marble, making them ideal for applications in monument engraving and architectural design. These machines offer high detail and durability, but buyers should be aware of their slower operation speed and higher cost. Key purchasing considerations include the router’s power, tooling options, and the types of stone it can effectively process.

What Makes Multi-Function CNC Routers a Smart Investment?

Multi-function CNC routers combine various cutting, engraving, and milling capabilities in one machine, catering to businesses that require flexibility in their production lines. They are particularly beneficial for prototyping and custom manufacturing. When investing in a multi-function router, buyers should consider its versatility, space-saving design, and potential for higher maintenance due to its complexity.

Key Industrial Applications of cnc router china

| Industry/Sector | Specific Application of CNC Router China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom Furniture Parts Production | Increased design flexibility and reduced lead times | Evaluate the machine’s precision and the ability to handle various materials. |

| Signage and Advertising | Sign Making and Custom Displays | Enhanced branding opportunities and scalability | Ensure compatibility with different substrates and software. |

| Aerospace and Automotive | Prototype Development and Component Machining | Accelerated R&D cycles and improved product quality | Focus on the machine’s ability to work with advanced materials and maintain high tolerances. |

| Electronics Assembly | PCB and Enclosure Fabrication | Cost-effective production and high precision outputs | Look for machines that support intricate designs and small-scale production. |

| Architectural Modeling | Scale Models and Detailed Architectural Features | Improved presentation quality and client engagement | Consider the ability to create complex geometries and finish quality. |

How is CNC Router China Used in Furniture Manufacturing?

In the furniture manufacturing sector, CNC routers from China are utilized to produce custom furniture parts with high precision. They enable businesses to create intricate designs and patterns that are difficult to achieve manually. This technology significantly reduces lead times, allowing manufacturers to respond quickly to market demands. International buyers should focus on sourcing CNC routers that can handle various wood types and thicknesses while ensuring the machine’s precision meets their design specifications.

What are the Applications of CNC Routers in Signage and Advertising?

CNC routers play a crucial role in the signage and advertising industry by enabling the production of custom signs and displays. These machines can cut and engrave a variety of materials, including acrylic, wood, and metal, which enhances branding opportunities. For B2B buyers, it’s essential to consider machines that offer compatibility with different substrates and are equipped with software that integrates seamlessly into existing workflows. This ensures a smooth production process and the ability to scale operations as needed.

How Does CNC Routing Benefit Aerospace and Automotive Industries?

In the aerospace and automotive sectors, CNC routers are employed for prototype development and component machining. The technology allows for rapid prototyping, which accelerates research and development cycles and enhances overall product quality. Buyers in these industries should prioritize sourcing CNC routers that can work with advanced materials like composites and metals, and that maintain high tolerances necessary for safety-critical applications. This ensures that the final products meet stringent industry standards.

In What Ways are CNC Routers Used in Electronics Assembly?

CNC routers are essential in the electronics assembly sector for fabricating printed circuit boards (PCBs) and enclosures. These machines provide cost-effective production methods while maintaining high precision, which is critical for electronic components. For international buyers, it is vital to choose CNC routers that can support intricate designs and small-scale production runs, as this flexibility can lead to significant cost savings and efficiency improvements in their manufacturing processes.

How Can CNC Routers Enhance Architectural Modeling?

In architectural modeling, CNC routers are used to create scale models and detailed architectural features that enhance presentation quality. These machines can produce complex geometries and fine details that are crucial for impressing clients and stakeholders. B2B buyers should look for CNC routers that offer excellent finish quality and can handle a variety of materials, such as foam and wood, which are commonly used in model-making. This capability can significantly improve client engagement and project outcomes.

Related Video: China Linear ATC CNC Wood Router with Saw Cutting Operational video

3 Common User Pain Points for ‘cnc router china’ & Their Solutions

Scenario 1: Navigating Quality Assurance in CNC Routers from China

The Problem:

One of the most significant challenges faced by international B2B buyers, particularly from Africa and South America, is the inconsistency in quality when sourcing CNC routers from China. Many buyers have reported receiving machines that do not meet their specifications or that are subpar in performance. This can lead to production delays, increased operational costs, and ultimately, a loss of client trust. Buyers often find it difficult to assess the quality of the machinery without seeing it firsthand, leading to uncertainty and risk in their investments.

The Solution:

To mitigate these risks, B2B buyers should prioritize conducting thorough supplier audits before making any purchasing decisions. This involves verifying the supplier’s certifications, manufacturing processes, and past client feedback. Engaging a third-party quality assurance firm in China can also be beneficial. They can conduct on-site inspections to ensure that the CNC routers meet the specified standards. Additionally, requesting samples or demos can provide insight into the machine’s performance and capabilities. Leveraging platforms such as Alibaba, which feature supplier ratings and reviews, can also help in identifying reputable manufacturers.

Scenario 2: Overcoming Language Barriers and Miscommunication

The Problem:

Language barriers can create significant challenges when sourcing CNC routers from Chinese manufacturers. Miscommunication regarding specifications, order details, and after-sales support can lead to costly errors. For B2B buyers in the Middle East and Europe, where English may not be the primary language, this issue can be particularly pronounced. Misunderstandings can result in receiving incorrect products, delayed shipments, or inadequate support, which can severely impact business operations.

The Solution:

To effectively overcome language barriers, B2B buyers should consider working with bilingual intermediaries or hiring local agents who are familiar with the Chinese market and language. These professionals can facilitate communication, ensuring that all specifications are accurately conveyed and understood. Additionally, utilizing technology such as translation software or services can help clarify any points of confusion. Establishing clear, written agreements that outline every detail of the order can also minimize misunderstandings. Including visual aids, such as diagrams or videos, can further bridge the communication gap, leading to a smoother transaction.

Scenario 3: Ensuring Reliable After-Sales Support and Spare Parts Availability

The Problem:

Another common pain point for B2B buyers is the lack of reliable after-sales support and availability of spare parts for CNC routers sourced from China. Many buyers have experienced difficulties in obtaining timely assistance or essential components needed for maintenance and repairs. This lack of support can lead to prolonged downtimes, impacting production schedules and profitability. Buyers from Europe and Africa often find themselves stranded without local resources to address technical issues promptly.

The Solution:

To secure dependable after-sales support, B2B buyers should carefully assess the manufacturer’s service offerings before making a purchase. It is crucial to inquire about the availability of technical support, warranty terms, and the logistics of spare parts delivery. Establishing a clear communication channel with the supplier for ongoing support can also enhance post-purchase satisfaction. Additionally, buyers should consider partnering with local service providers who can offer maintenance and repairs, ensuring that they have immediate access to expertise when issues arise. Creating a network of contacts within the supplier’s ecosystem can also facilitate quicker resolutions to potential problems, enhancing the overall operational efficiency of their business.

Strategic Material Selection Guide for cnc router china

When selecting materials for CNC routers sourced from China, international B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Below, we analyze four common materials used in CNC routing, focusing on their properties, advantages, disadvantages, and implications for buyers, particularly those in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum for CNC Routing?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressure. Its low density makes it ideal for applications where weight is a concern, such as in automotive and aerospace components.

Pros: Aluminum is durable, easy to work with, and offers a good strength-to-weight ratio. It is also relatively inexpensive compared to other metals, making it a cost-effective choice for various applications.

Cons: While aluminum is resistant to corrosion, it can be prone to scratching and denting. Additionally, its thermal conductivity can lead to challenges in maintaining consistent temperatures during machining.

Impact on Application: Aluminum is compatible with many media types, including plastics and wood, making it versatile for different industries. However, buyers should be aware of specific alloys that may be required for specialized applications.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is crucial. Buyers from Europe may prefer specific grades of aluminum that meet these standards, while those in Africa and South America should ensure that suppliers can provide the necessary certifications.

How Does Plywood Perform in CNC Routing Applications?

Plywood is a popular material for CNC routing due to its versatility and ease of use. It typically has a pressure rating that varies based on the grade and type of adhesive used in its construction, and it can withstand moderate temperatures.

Pros: Plywood is lightweight, cost-effective, and available in various thicknesses and finishes. It is also easy to machine, making it suitable for intricate designs and prototypes.

Cons: The quality of plywood can vary significantly, affecting its durability and suitability for certain applications. Additionally, exposure to moisture can lead to warping or delamination.

Impact on Application: Plywood is ideal for furniture, cabinetry, and decorative items. However, buyers should consider the type of plywood needed for specific environments, especially in humid regions.

Considerations for International Buyers: Buyers should ensure that the plywood meets local standards, such as JIS for Japan or EN for Europe. Sourcing from reputable suppliers who provide quality certifications is essential.

What Are the Advantages of Using MDF in CNC Routing?

Medium Density Fiberboard (MDF) is an engineered wood product made from wood fibers, wax, and resin. It is known for its smooth surface and uniform density, making it an excellent choice for detailed machining.

Pros: MDF is easy to cut and shape, providing a smooth finish that is ideal for painting and veneering. It is also less expensive than solid wood and offers good dimensional stability.

Cons: MDF is not as strong as solid wood or plywood and can be susceptible to moisture damage. It also emits formaldehyde, which may be a concern for some buyers.

Impact on Application: MDF is commonly used for cabinetry, moldings, and decorative items. Its compatibility with various finishing techniques makes it a favorite among manufacturers.

Considerations for International Buyers: Compliance with environmental regulations, such as CARB in California or E1 in Europe, is essential for MDF products. Buyers should verify that suppliers adhere to these standards.

Why Is Steel a Preferred Material for Heavy-Duty Applications?

Steel is a robust material that provides high strength and durability, making it suitable for heavy-duty applications. It has high temperature and pressure ratings, often exceeding 1000°F (538°C) and 10,000 psi, respectively.

Pros: Steel is incredibly durable and resistant to wear and tear, making it ideal for industrial applications. It is also recyclable, which can be an important consideration for environmentally conscious buyers.

Cons: Steel can be more expensive than other materials, and its machining can be complex due to its hardness. Additionally, it is prone to corrosion if not properly treated.

Impact on Application: Steel is commonly used in manufacturing machinery, automotive components, and structural applications. Its strength makes it suitable for high-stress environments.

Considerations for International Buyers: Buyers should ensure that the steel meets relevant standards, such as ASTM for the U.S. or EN for Europe. Understanding the specific grades and treatments available is crucial for ensuring compatibility with intended applications.

Summary Table of Material Selection for CNC Routers

| Material | Typical Use Case for cnc router china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Prone to scratching and denting | Medium |

| Plywood | Furniture, cabinetry | Cost-effective and versatile | Quality can vary, moisture-sensitive | Low |

| MDF | Cabinetry, decorative items | Smooth finish, easy to machine | Not moisture-resistant, emits formaldehyde | Low |

| Steel | Industrial machinery, automotive components | High strength and durability | More expensive, complex machining | High |

This strategic material selection guide provides essential insights for international B2B buyers looking to optimize their CNC routing processes. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc router china

What Are the Key Manufacturing Processes for CNC Routers in China?

Understanding the manufacturing processes for CNC routers in China is essential for international B2B buyers. The production of these machines involves several critical stages, each contributing to the overall quality and functionality of the final product.

1. Material Preparation

The first step in manufacturing CNC routers is material preparation. High-quality materials such as steel, aluminum, and composite materials are sourced, typically from local suppliers. Buyers should inquire about the origin of these materials, as this can impact both the durability and performance of the machines. Additionally, the use of advanced techniques like laser cutting or water jet cutting may be employed to ensure precision in the initial stages.

2. Forming and Machining

Once the materials are prepared, they undergo forming and machining processes. This includes CNC machining, where computer-controlled tools shape the material into specific components. Techniques such as milling, turning, and grinding are commonly used. It is vital for buyers to ensure that the manufacturer utilizes modern CNC technology and skilled operators, as this directly influences the precision of the components produced.

3. Assembly

After machining, the various components are assembled. This stage requires meticulous attention to detail, as the alignment and fitting of parts are crucial for the router’s performance. Some manufacturers employ automated assembly lines to enhance efficiency, while others may use manual assembly for more complex components. Buyers should verify whether the manufacturer uses skilled labor and strict protocols during assembly to minimize errors.

4. Finishing Touches

The final stage involves finishing processes, which may include painting, anodizing, or powder coating. These processes not only enhance the aesthetic appeal of the CNC routers but also contribute to their longevity and resistance to corrosion. Buyers should inquire about the types of finishing techniques used and their environmental compliance, especially if they are sourcing from regions with strict regulations.

How is Quality Assurance Implemented in CNC Router Manufacturing?

Quality assurance (QA) is a critical aspect of CNC router manufacturing, especially for international B2B buyers who need to ensure they receive reliable and compliant products.

1. Adherence to International Standards

Many Chinese manufacturers adhere to international quality standards, such as ISO 9001, which focuses on maintaining consistent quality in production processes. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) are crucial for buyers in sectors that require stringent compliance. Buyers should verify these certifications during the supplier selection process to ensure product safety and reliability.

2. Key Quality Control Checkpoints

Quality control is integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify and rectify issues early.

- Final Quality Control (FQC): A thorough examination of the finished product ensures it meets design specifications and quality standards before shipment.

Buyers should ask manufacturers for details on their QA processes and how these checkpoints are implemented.

3. Common Testing Methods for CNC Routers

Testing is essential to verify the performance and safety of CNC routers. Common methods include:

- Functional Testing: Checking if the CNC router operates according to specifications.

- Load Testing: Assessing the machine’s performance under maximum load conditions.

- Durability Testing: Evaluating the router’s longevity through repeated use simulations.

International buyers should request test reports to ensure that the products have passed these assessments.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that their suppliers maintain high-quality standards, B2B buyers should engage in several verification practices.

1. Conducting Supplier Audits

Performing supplier audits is an effective way to assess the manufacturing processes and quality control measures in place. Buyers should look for opportunities to visit production facilities or engage third-party inspection services that can provide an unbiased evaluation of the supplier’s operations.

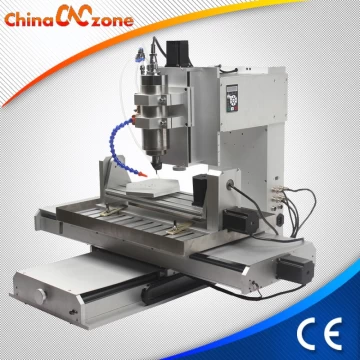

A stock image related to cnc router china.

2. Reviewing Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can provide insight into their QA processes. These reports should outline the results of IQC, IPQC, and FQC, as well as any corrective actions taken for non-conformities.

3. Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an additional layer of assurance. These firms can conduct independent checks on the manufacturing processes, materials used, and final products to ensure compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing CNC routers from China.

1. Understanding Regional Regulations

Each region has its own set of regulations and compliance standards that may affect the importation and use of CNC routers. For instance, European buyers must ensure that products meet CE marking requirements, while buyers in the Middle East may need to comply with local safety standards.

2. Cultural and Communication Barriers

Cultural differences can impact communication regarding quality expectations. Buyers should establish clear lines of communication with suppliers and consider using bilingual representatives if necessary. This can help mitigate misunderstandings related to quality standards and product specifications.

3. Building Long-Term Relationships

Establishing a long-term relationship with a reliable supplier can lead to better quality control over time. Regular communication and feedback can help suppliers understand the buyer’s needs and enhance their quality assurance processes accordingly.

A stock image related to cnc router china.

By paying close attention to manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing CNC routers from China, ensuring they receive products that meet their standards and requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc router china’

In the competitive landscape of international B2B procurement, sourcing a CNC router from China requires careful planning and execution. This practical sourcing guide outlines essential steps to ensure you make informed decisions and secure a quality product that meets your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define your technical requirements. Consider the materials you will be working with, the size of the projects, and the specific functionalities needed, such as cutting speed and precision. Establishing these specifications upfront will help you narrow down potential suppliers and ensure that the CNC router you choose aligns with your operational goals.

Step 2: Conduct Market Research

Understanding the market landscape is crucial. Research various manufacturers in China that specialize in CNC routers, taking note of their product offerings, pricing, and customer feedback. Utilize platforms like Alibaba, Made-in-China, and Global Sources to gather information. This step will help you identify potential suppliers who not only meet your technical needs but also provide competitive pricing.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a solid reputation for quality and reliability, and consider visiting their facilities if possible. This diligence will minimize risks associated with international transactions and ensure you’re partnering with a credible manufacturer.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold necessary certifications, such as ISO 9001 for quality management and CE marking for compliance with European standards. These certifications indicate a commitment to quality and safety, which is crucial when sourcing machinery. Ask for documentation and check the validity of these certifications through official channels.

Step 5: Request Samples and Perform Quality Checks

Before placing a large order, request samples of the CNC router or components. Conduct quality checks to assess the material, craftsmanship, and functionality. This step is vital to ensure that the product meets your specifications and quality standards. It can also reveal any potential issues that may not be apparent from product descriptions alone.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget and any constraints you may have. Consider the total cost of ownership, including shipping, tariffs, and potential maintenance costs, to ensure that you are making a financially sound decision.

Step 7: Establish a Clear Communication Plan

Effective communication is key to a successful sourcing process. Set up regular check-ins with your supplier to monitor production progress and address any concerns promptly. Use tools like email, video calls, and project management software to maintain transparency. Clear communication will help avoid misunderstandings and ensure that your project stays on track.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing CNC routers from China with confidence, leading to successful procurement outcomes that support their business objectives.

Comprehensive Cost and Pricing Analysis for cnc router china Sourcing

What Are the Key Cost Components in CNC Router Sourcing from China?

When sourcing CNC routers from China, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel or aluminum components can increase durability but may also raise the price. Buyers should request detailed material specifications from suppliers to assess the best options for their needs.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and supplier. Understanding the labor rates and the skill levels of the workforce is crucial, as this can affect production quality and timelines.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, maintenance, and administrative expenses. Efficient manufacturers often have streamlined processes that can help minimize these overhead costs.

-

Tooling: Custom tooling can be a significant upfront cost, especially for specialized CNC router configurations. Buyers should evaluate the necessity of custom tooling versus standard options to balance cost with functionality.

-

Quality Control (QC): Investing in robust quality control processes can prevent costly errors and defects. Buyers should inquire about the QC measures employed by suppliers to ensure product reliability.

-

Logistics: Shipping costs can fluctuate based on the chosen Incoterms and the volume of the order. Understanding these logistics costs is vital, especially for international buyers, as they can significantly affect the total expenditure.

-

Supplier Margin: Each supplier will have a different markup based on their business model and market positioning. It’s essential to compare quotes from multiple suppliers to gauge fair pricing.

How Do Pricing Influencers Affect CNC Router Costs?

Several factors can influence the pricing of CNC routers sourced from China, including:

-

Volume/MOQ: The minimum order quantity (MOQ) often affects pricing. Larger orders typically lead to lower per-unit costs, making it beneficial for buyers with significant production needs.

-

Specifications/Customization: Customized machines with unique specifications will generally incur higher costs due to additional engineering and tooling requirements. Buyers should weigh the benefits of customization against the cost implications.

-

Materials and Quality Certifications: The type of materials used and the presence of quality certifications (like ISO or CE) can impact the pricing. Higher quality and certified products usually command a premium but provide greater assurance of performance.

-

Supplier Factors: Established suppliers with a good reputation may charge higher prices due to their reliability and service quality. Newer or less-known suppliers might offer lower prices but could pose risks in terms of quality and support.

-

Incoterms: Understanding the Incoterms (e.g., FOB, CIF) will determine which party is responsible for costs at various points in the shipping process. This knowledge can help buyers negotiate better terms and manage logistics expenses effectively.

What Are the Best Negotiation Strategies for International B2B Buyers?

For buyers from Africa, South America, the Middle East, and Europe, effective negotiation and understanding of total cost ownership are crucial for maximizing value:

-

Negotiate Wisely: Leverage multiple quotes to create competitive tension among suppliers. Be clear about your requirements and don’t hesitate to ask for discounts, especially for large orders.

-

Focus on Total Cost of Ownership (TCO): While the initial purchase price is important, consider long-term costs such as maintenance, operational efficiency, and potential downtime. A slightly more expensive CNC router may offer better reliability and lower operational costs over time.

-

Understand Pricing Nuances: International buyers should be aware that cultural differences may influence negotiation styles. Building relationships and trust can be as important as price in many cultures, especially in the Middle East and Africa.

Why Is It Important to Consider Indicative Prices?

While this analysis provides a framework for understanding costs and pricing in CNC router sourcing from China, it’s important to note that indicative prices can vary widely based on market conditions, supplier capabilities, and buyer specifications. Always conduct thorough research and obtain updated quotes to ensure accurate budgeting for your projects.

Alternatives Analysis: Comparing cnc router china With Other Solutions

Understanding the Importance of Alternatives in CNC Solutions

When considering investments in CNC technology, it’s crucial for international B2B buyers to explore various alternatives to the widely recognized “CNC Router China.” While these routers are popular for their affordability and efficiency, other solutions may offer unique advantages depending on specific business needs. This analysis will focus on comparing CNC Router China with laser cutting machines and traditional woodworking methods, providing insights into their respective strengths and weaknesses.

Comparison Table of CNC Router China and Alternatives

| Comparison Aspect | CNC Router China | Laser Cutting Machines | Traditional Woodworking Methods |

|---|---|---|---|

| Performance | High precision and speed | Excellent precision, versatile materials | Variable precision, manual labor required |

| Cost | Generally low initial cost | Higher initial investment | Low to moderate, depending on tools |

| Ease of Implementation | Moderate (requires setup) | Moderate (requires training) | High (skills-based, no tech needed) |

| Maintenance | Low (minimal upkeep) | Moderate (occasional part replacements) | High (tools need regular care) |

| Best Use Case | Mass production, intricate designs | Industrial applications, metals, and plastics | Custom projects, artisanal work |

What Are the Benefits and Drawbacks of Laser Cutting Machines?

Laser cutting machines provide a high level of precision and are capable of handling a variety of materials, including metals and plastics. This versatility makes them suitable for industrial applications where intricate designs are necessary. However, the initial investment can be significant, often requiring a budget that exceeds that of a CNC router. Additionally, while laser cutting machines offer high-speed cutting, they may require specialized training to operate effectively, which can pose a challenge for smaller businesses or those new to advanced manufacturing technologies.

How Do Traditional Woodworking Methods Compare?

Traditional woodworking methods rely on manual tools and skilled artisans, allowing for a level of craftsmanship that CNC routers or laser cutting machines may not replicate. This method is ideal for custom projects that require a personal touch, making it popular among artisans and small businesses. However, the drawbacks include variable precision and longer production times, which may not meet the demands of mass production. Moreover, maintaining and sharpening tools can be labor-intensive, requiring ongoing investment in time and resources.

How to Choose the Right CNC Solution for Your Business Needs?

Selecting the appropriate CNC solution involves assessing your specific operational requirements, budget constraints, and production goals. For B2B buyers from Africa, South America, the Middle East, and Europe, the choice may boil down to the scale of production, the types of materials being processed, and the level of craftsmanship desired. If high-volume production with intricate designs is the goal, CNC Router China may be the most cost-effective option. Conversely, if the focus is on versatility and precision across various materials, investing in laser cutting technology may yield better long-term results. For custom or artisanal work, traditional woodworking methods can preserve craftsmanship while meeting niche market demands.

In conclusion, evaluating these alternatives allows businesses to make informed decisions that align with their operational strategies and market expectations, ultimately leading to enhanced productivity and profitability.

Essential Technical Properties and Trade Terminology for cnc router china

When considering the acquisition of CNC routers from China, it’s essential for international B2B buyers to understand the technical properties and trade terminology associated with these machines. This knowledge not only enhances decision-making but also facilitates smoother negotiations and transactions.

What Are the Key Technical Properties of CNC Routers from China?

-

Material Grade

– Definition: The grade of materials used in the construction of CNC routers significantly affects their durability and performance. Common materials include high-grade steel for frames and aluminum for components.

– Importance: Understanding material grades helps buyers gauge the longevity and reliability of the machines. Higher-grade materials typically equate to better performance and lower maintenance costs, crucial for businesses in Africa and South America where equipment durability is vital. -

Tolerance

– Definition: Tolerance refers to the permissible limit of variation in a physical dimension. In CNC routers, tighter tolerances lead to more precise machining.

– Importance: For B2B buyers, particularly those in industries requiring high precision (like aerospace or automotive), knowing the tolerance levels ensures that the machines can meet their production standards. -

Spindle Power

– Definition: This property indicates the power output of the spindle motor, often measured in kilowatts (kW). Higher spindle power allows for cutting through tougher materials.

– Importance: Buyers must consider their intended applications. For instance, a higher spindle power is crucial for companies in the Middle East that may be working with dense materials such as stone or metal. -

Working Area

– Definition: The working area is the maximum size of the material that the CNC router can accommodate. It is typically expressed in dimensions (length x width x height).

– Importance: Understanding the working area is essential for buyers to ensure that the CNC router can handle the size of projects they intend to undertake, especially in large-scale manufacturing setups in Europe. -

Control System

– Definition: The control system is the software and hardware that directs the CNC router’s operations. Common systems include Mach3, DSP, and Syntec.

– Importance: A user-friendly and reliable control system can significantly enhance productivity. Buyers should evaluate the compatibility of these systems with their existing technologies.

What Are Common Trade Terms Used in CNC Router Transactions?

-

OEM (Original Equipment Manufacturer)

– Definition: This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the CNC router context, it often indicates manufacturers who produce machines under different brand names.

– Importance: B2B buyers can leverage OEM relationships to procure machines that meet specific needs or standards, often at lower costs than branded alternatives. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant in bulk manufacturing.

– Importance: Understanding the MOQ is crucial for budget planning. Buyers from Africa or South America should assess whether they can meet these minimums to avoid excess inventory. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document that a buyer submits to suppliers to obtain pricing and other details about specific products or services.

– Importance: Submitting an RFQ is a critical step in the procurement process, allowing buyers to gather competitive quotes and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping and insurance.

– Importance: Familiarity with Incoterms is vital for mitigating risks in international shipping, ensuring that buyers understand their obligations and liabilities during the transport of CNC routers. -

Lead Time

– Definition: Lead time refers to the time taken from placing an order until it is received. This includes manufacturing, quality checks, and shipping.

– Importance: Understanding lead times helps buyers plan their production schedules effectively, particularly important for businesses that rely on timely delivery for competitive advantage.

By grasping these technical specifications and trade terminologies, B2B buyers can engage more effectively with suppliers, ensuring that they make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the cnc router china Sector

What Are the Current Market Dynamics in the CNC Router Sector from China?

The CNC router market in China is experiencing significant growth, driven by the increasing demand for automation and precision in manufacturing processes. As industries across Africa, South America, the Middle East, and Europe seek to enhance production efficiency, the adoption of CNC routers is becoming essential. Key trends influencing this sector include the integration of advanced technologies such as IoT and AI, which are enabling real-time monitoring and predictive maintenance. Additionally, there is a noticeable shift towards customizable solutions, allowing businesses to tailor CNC routers to specific operational needs.

International B2B buyers should also be aware of the competitive landscape shaped by China’s robust manufacturing capabilities. The country’s capacity to deliver high-quality products at competitive prices makes it an attractive sourcing destination. However, buyers must navigate challenges such as fluctuating tariffs and trade regulations, which can impact pricing and supply chain stability. Keeping abreast of these market dynamics will be crucial for international buyers looking to secure favorable contracts and maintain a consistent supply of CNC routers.

How Important Is Sustainability and Ethical Sourcing in the CNC Router Market?

In today’s B2B landscape, sustainability and ethical sourcing have emerged as critical considerations for international buyers of CNC routers. The environmental impact of manufacturing processes, including energy consumption and waste generation, has prompted a shift towards greener practices. Companies are increasingly seeking suppliers that prioritize sustainability, as this not only aligns with corporate social responsibility goals but also appeals to environmentally conscious consumers.

Buyers should look for suppliers in China that offer ‘green’ certifications, such as ISO 14001 for environmental management systems or Energy Star ratings for energy-efficient products. These certifications serve as indicators of a supplier’s commitment to reducing their ecological footprint. Furthermore, sourcing materials that are recyclable or produced through sustainable practices can enhance a company’s reputation and reduce long-term operational costs. By prioritizing ethical sourcing and sustainability, B2B buyers can not only contribute positively to the environment but also tap into a growing market segment that values responsible business practices.

What Is the Historical Context of CNC Router Development in China?

The evolution of CNC router technology in China can be traced back to the early 2000s when the country began to invest heavily in automation and manufacturing technology. Initially focused on basic functionality, CNC routers have advanced significantly, incorporating sophisticated features like multi-axis capabilities and enhanced software integration. As China’s manufacturing sector expanded, so did the demand for high-performance CNC routers, leading to rapid innovation and improvement in design.

Today, China stands as a global leader in CNC router manufacturing, with a diverse range of products catering to various industries, including woodworking, metalworking, and plastics. This historical progression not only highlights China’s commitment to technological advancement but also reflects the country’s ability to adapt to the changing needs of international B2B buyers. Understanding this evolution can provide valuable insights for buyers looking to partner with reputable suppliers and leverage cutting-edge technology in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc router china

-

How do I ensure the quality of CNC routers sourced from China?

To ensure quality when sourcing CNC routers from China, it is crucial to conduct thorough supplier vetting. Look for manufacturers with ISO certifications and positive customer reviews. Request samples or visit the factory if possible to assess their production capabilities. Additionally, consider using third-party quality assurance services to inspect products before shipment. Establishing clear quality standards in your purchase agreement can also mitigate risks associated with product defects. -

What are the most important features to consider when selecting a CNC router?

When selecting a CNC router, key features to consider include the machine’s working area, precision, and speed. Evaluate the types of materials it can handle, such as wood, metal, or plastic. Look for advanced features like automatic tool changers, dust collection systems, and software compatibility. Additionally, consider the machine’s ease of use and the availability of technical support, especially if you are new to CNC technology. -

What are the typical minimum order quantities (MOQs) for CNC routers from Chinese suppliers?

Minimum order quantities (MOQs) for CNC routers can vary significantly among suppliers, typically ranging from one unit to several dozen. Many manufacturers may offer lower MOQs for standard models, while custom configurations may require higher quantities. It’s essential to communicate your needs directly with potential suppliers and negotiate MOQs that align with your business requirements, especially if you are testing the market. -

What payment terms should I expect when purchasing CNC routers from China?

Payment terms when sourcing CNC routers from China often include options such as T/T (telegraphic transfer), L/C (letter of credit), or PayPal for smaller transactions. Typically, suppliers may request a 30-50% deposit upfront, with the balance payable before shipment. Always ensure that payment terms are clearly outlined in your contract to avoid misunderstandings and consider using escrow services for added security. -

How can I navigate customs and import regulations for CNC routers in my country?

Navigating customs and import regulations for CNC routers requires understanding your country’s specific import laws. Research tariff classifications and ensure compliance with safety and quality standards. Engaging a customs broker can simplify the process, as they can handle documentation and facilitate communication with customs authorities. Additionally, check if your country has any trade agreements with China that could affect tariffs or duties. -

What are the logistics considerations for importing CNC routers from China?

Logistics for importing CNC routers from China involve several key considerations, including shipping methods, lead times, and costs. Choose between air freight for faster delivery or sea freight for cost-effectiveness, especially for larger machinery. Assess the total landed cost, including shipping, insurance, and customs duties. Collaborating with a reliable logistics provider can help streamline the process and ensure timely delivery to your location. -

How can I customize CNC routers to meet my specific needs?

Most Chinese CNC router manufacturers offer customization options to tailor machines to your specific requirements. This can include adjustments to size, power, spindle type, and software compatibility. When discussing customization, provide detailed specifications and desired features. Be aware that customizations may affect lead times and pricing, so ensure these factors are included in your negotiations with suppliers. -

What after-sales support should I expect from Chinese CNC router suppliers?

After-sales support from Chinese CNC router suppliers can vary widely. Reputable manufacturers typically offer technical support, warranty services, and spare parts availability. Clarify the terms of after-sales service before making a purchase, including response times for support requests and the duration of the warranty. Additionally, consider whether the supplier provides training resources, such as manuals or online tutorials, to assist with machine operation and maintenance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc router china

In the rapidly evolving landscape of CNC routers, strategic sourcing from China presents a compelling opportunity for international B2B buyers. By understanding the intricacies of the Chinese manufacturing ecosystem, businesses from Africa, South America, the Middle East, and Europe can leverage cost-effective solutions while ensuring high-quality production standards. Key takeaways include the importance of thorough supplier vetting, the need for transparent communication, and the value of establishing long-term partnerships to navigate potential challenges in logistics and compliance.

Why is strategic sourcing essential for your business growth? It not only optimizes your procurement process but also enhances your competitive advantage by providing access to advanced technology and innovative designs that can differentiate your offerings in the market. As you consider your sourcing strategies, prioritize suppliers that demonstrate a commitment to quality assurance and customer service, as these factors are crucial for sustaining your operations.

Looking ahead, the demand for CNC routers will continue to grow, driven by advancements in automation and customization. Now is the time to engage with reliable Chinese manufacturers who can meet your specific needs. Take proactive steps today to secure your position in this dynamic market, and transform your sourcing strategy into a powerful tool for success.