Discover Top Suppliers: Your Guide to Compressor China (2025)

Introduction: Navigating the Global Market for compressor china

Navigating the global market for compressors from China presents a unique set of challenges and opportunities for international B2B buyers. As demand for efficient and reliable compressor solutions grows across industries, sourcing high-quality equipment can feel overwhelming. This guide aims to simplify that process by providing a comprehensive overview of the various types of compressors available, their applications, supplier vetting processes, and cost considerations.

By delving into the specifics of compressor technology and market dynamics, this resource empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like the UAE and Kenya—to make informed purchasing decisions. Understanding the landscape of compressor suppliers in China, including how to assess quality and negotiate terms, will not only enhance operational efficiency but also contribute to long-term business success.

Throughout this guide, we will address critical questions such as: What types of compressors are best suited for specific applications? How can buyers effectively vet suppliers to ensure reliability? and What are the hidden costs associated with importing compressors? By providing actionable insights, this guide is designed to arm international buyers with the knowledge they need to navigate the complexities of the global compressor market confidently.

Understanding compressor china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Screw Compressors | Continuous operation, high efficiency | Manufacturing, HVAC systems | Pros: Reliable, low maintenance. Cons: Higher initial cost. |

| Reciprocating Compressors | Piston-driven, versatile in pressure ranges | Automotive, refrigeration | Pros: Cost-effective, adaptable. Cons: Noisy, less efficient at large scales. |

| Scroll Compressors | Compact design, low vibration | Air conditioning, medical devices | Pros: Quiet operation, energy-efficient. Cons: Limited pressure capacity. |

| Centrifugal Compressors | High flow rates, suitable for large applications | Petrochemical, power generation | Pros: Efficient at large scales. Cons: Requires precise installation. |

| Diaphragm Compressors | Leak-free operation, ideal for sensitive gases | Pharmaceutical, food processing | Pros: High purity, reliable. Cons: Limited to low flow rates. |

What Are the Characteristics of Screw Compressors?

Screw compressors are known for their continuous operation and high efficiency, making them ideal for industries that require a constant air supply. They operate using two rotors that compress air as it moves through the unit. This type is particularly suitable for manufacturing and HVAC systems where reliability and low maintenance are crucial. Buyers should consider the initial investment, as screw compressors tend to be more expensive upfront, but their longevity and efficiency can lead to lower operational costs over time.

How Do Reciprocating Compressors Differ?

Reciprocating compressors are piston-driven machines that can adapt to various pressure requirements. They are versatile and commonly used in automotive applications and refrigeration systems. The main advantages of reciprocating compressors are their cost-effectiveness and adaptability to different scales of operation. However, they can be noisy and less efficient when scaled up for larger applications, which may be a consideration for buyers in noise-sensitive environments.

What Are the Benefits of Scroll Compressors?

Scroll compressors feature a compact design and operate with minimal vibration, making them suitable for applications such as air conditioning and medical devices. Their quiet operation and energy efficiency make them appealing for environments where noise reduction is important. However, they have limitations in terms of pressure capacity compared to other types. Buyers should evaluate their specific needs, particularly the required pressure and flow rates, to determine if a scroll compressor is the right fit.

Why Choose Centrifugal Compressors for Large Applications?

Centrifugal compressors are designed for high flow rates and are particularly effective in large industrial applications such as petrochemical processing and power generation. Their efficiency at larger scales makes them a popular choice for businesses with substantial air demand. However, they require precise installation and may involve higher maintenance costs. Buyers should assess their operational scale and ensure they have the necessary infrastructure for installation and maintenance.

What Makes Diaphragm Compressors Unique?

Diaphragm compressors are known for their leak-free operation, which is essential in industries that require high purity, such as pharmaceuticals and food processing. They utilize a diaphragm to compress gases, making them ideal for sensitive applications. While they provide high reliability and purity, diaphragm compressors are typically limited to low flow rates. Buyers should consider the specific requirements of their application, especially regarding flow rate and gas purity, before opting for this type.

Related Video: How does an Air Compressor work? (Compressor Types) – Tutorial Pneumatics

Key Industrial Applications of compressor china

| Industry/Sector | Specific Application of compressor china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pneumatic tools and machinery | Enhanced productivity and reduced operational costs | Reliability, energy efficiency, and after-sales support |

| Food and Beverage | Refrigeration and cooling systems | Improved product quality and extended shelf life | Compliance with health standards and energy consumption |

| Oil and Gas | Gas compression for transport and storage | Increased efficiency in resource extraction and distribution | Certification for hazardous environments and durability |

| Construction | Air compression for concrete mixing and tools | Accelerated project timelines and improved work quality | Portability, noise levels, and maintenance requirements |

| Automotive | Air conditioning systems in vehicles | Enhanced passenger comfort and energy efficiency | Compatibility with vehicle specifications and service availability |

How is ‘Compressor China’ Used in Manufacturing?

In the manufacturing sector, compressors from China are integral for powering pneumatic tools and machinery. These compressors enhance productivity by providing consistent air pressure, which is essential for various applications, including assembly lines and packaging. International buyers, especially from regions like Africa and South America, should prioritize sourcing compressors that offer reliability and energy efficiency, as these factors directly impact operational costs and workflow efficiency.

What Are the Applications in the Food and Beverage Industry?

In the food and beverage sector, compressors are crucial for refrigeration and cooling systems. They help maintain the quality and safety of perishable goods by ensuring optimal storage temperatures. This application is particularly relevant for international buyers in the Middle East, where hot climates can affect product integrity. Buyers should consider compressors that comply with health regulations and have low energy consumption to maximize efficiency and sustainability.

How Do Compressors Benefit the Oil and Gas Industry?

For the oil and gas industry, compressors are essential for gas compression during transport and storage. They significantly increase efficiency in resource extraction and distribution, which is vital for maintaining profitability in this competitive sector. Buyers from Europe and the Middle East need to ensure that compressors are certified for hazardous environments and possess high durability to withstand challenging operational conditions.

What Role Do Compressors Play in Construction?

In the construction sector, compressors are used for air compression in concrete mixing and powering various tools. This application not only accelerates project timelines but also enhances the quality of work by providing reliable air pressure. International buyers, particularly from regions like Africa and South America, should focus on compressors that are portable, have manageable noise levels, and require minimal maintenance to ensure smooth operations on job sites.

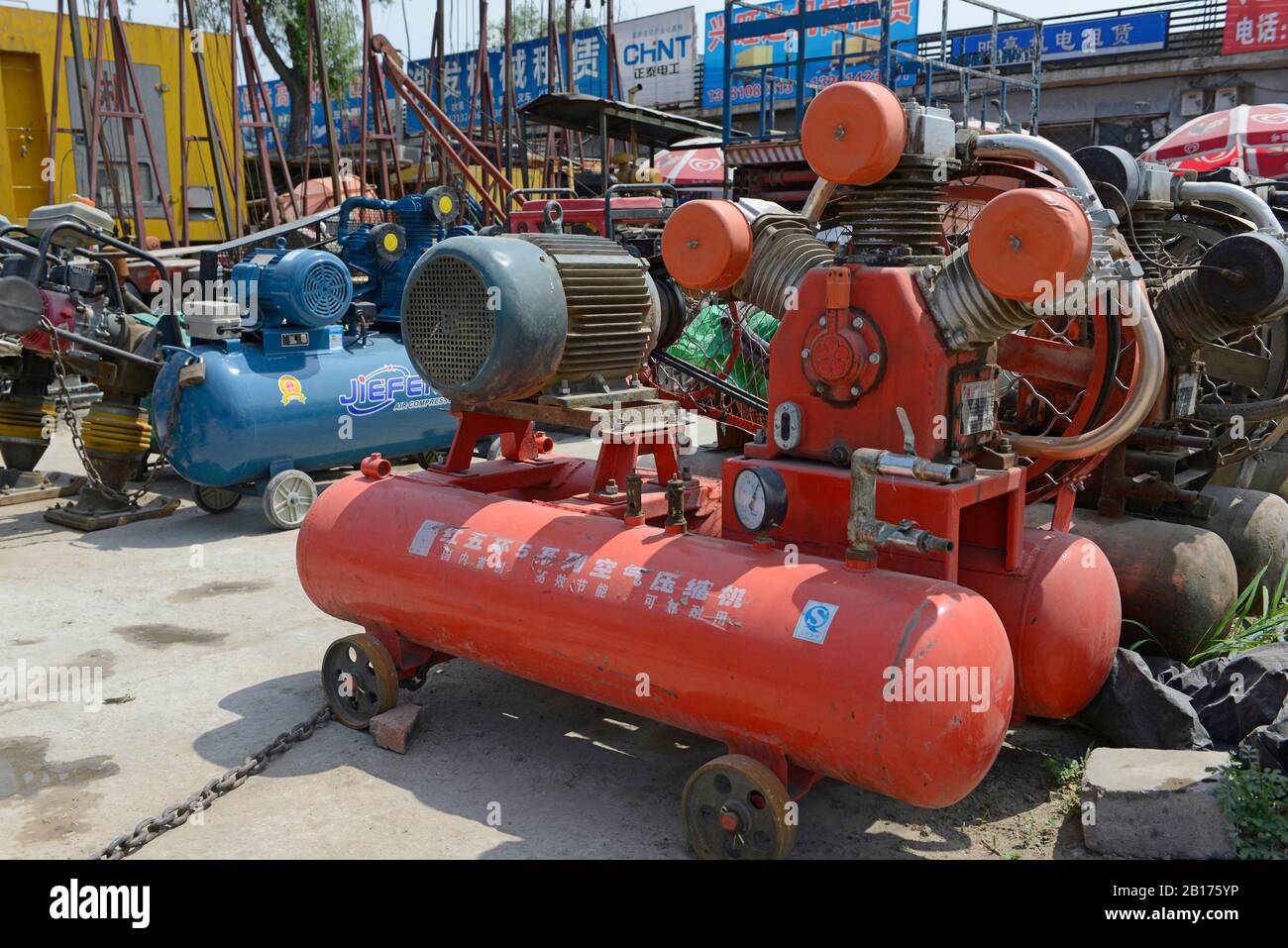

A stock image related to compressor china.

How Are Compressors Used in the Automotive Sector?

In the automotive industry, compressors are vital for air conditioning systems in vehicles, contributing to passenger comfort and energy efficiency. This application is increasingly important as consumers demand better climate control in their vehicles. Buyers in Europe and the Middle East should seek compressors that are compatible with vehicle specifications and have readily available service options to ensure long-term reliability and customer satisfaction.

3 Common User Pain Points for ‘compressor china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges with Chinese Compressors

The Problem:

Many international B2B buyers, particularly from Africa and South America, often face significant challenges when sourcing compressors from China. A prevalent issue is the inconsistency in quality, which can stem from varying manufacturing standards and practices. Buyers might receive products that do not meet their specifications or industry standards, resulting in operational inefficiencies and financial losses. This situation is particularly concerning for businesses that rely heavily on compressed air systems for production processes, where any downtime can lead to substantial delays and costs.

The Solution:

To mitigate these quality assurance challenges, buyers should establish a robust vetting process for manufacturers. Start by conducting thorough research on potential suppliers, looking for those with international certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, consider engaging a third-party inspection service to verify product quality before shipment. This can include checking the manufacturing process, materials used, and final product testing. Building a relationship with reputable suppliers who have a proven track record in delivering consistent quality will also help reduce risks. Finally, clear communication regarding specifications and expectations at the outset can prevent misunderstandings and ensure that the delivered product meets your requirements.

Scenario 2: Overcoming Language Barriers in Supplier Communication

The Problem:

Language barriers can pose significant challenges for B2B buyers when negotiating with Chinese suppliers. Miscommunication can lead to misunderstandings regarding product specifications, pricing, delivery timelines, and after-sales support. This issue is particularly pronounced for businesses in the Middle East and Africa, where direct communication with suppliers may be limited by language differences, potentially resulting in costly errors and delays.

The Solution:

To effectively navigate this challenge, buyers should consider employing bilingual staff or hiring a professional translator who understands both the technical language of compressors and the nuances of business negotiations. Additionally, utilizing communication platforms that offer translation features can facilitate smoother interactions. When drafting contracts or product specifications, it is crucial to have documents translated accurately to prevent misinterpretations. Furthermore, establishing a clear line of communication through regular updates and feedback can help bridge any gaps caused by language differences, ensuring that both parties are aligned throughout the procurement process.

Scenario 3: Managing Logistics and Shipping Complexities from China

The Problem:

International shipping and logistics present a significant hurdle for B2B buyers sourcing compressors from China. Buyers may encounter unexpected delays, customs issues, or higher-than-anticipated shipping costs, particularly when importing to regions like Europe or South America. These logistical complexities can disrupt supply chains and affect the timely availability of critical equipment, leading to operational challenges and lost revenue.

The Solution:

To manage logistics effectively, buyers should work closely with experienced freight forwarders who specialize in international shipping of industrial equipment. These professionals can provide valuable insights into the best shipping routes, customs regulations, and potential pitfalls. It’s essential to factor in all logistics costs, including tariffs and duties, when budgeting for a purchase. Additionally, establishing a clear timeline for shipping and delivery, along with contingency plans for potential delays, can help mitigate the impact of unforeseen issues. Buyers should also explore options for local warehousing in strategic locations to streamline the supply chain and reduce lead times. By taking a proactive approach to logistics, businesses can ensure a smoother procurement process and maintain operational continuity.

Strategic Material Selection Guide for compressor china

When selecting materials for compressors manufactured in China, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in compressor manufacturing, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum in Compressors?

Aluminum is frequently used in compressor components due to its lightweight and excellent thermal conductivity. It typically has a temperature rating up to 150°C and can withstand moderate pressures. Aluminum’s natural corrosion resistance makes it suitable for various environments, although it is not ideal for high-stress applications.

Pros:

– Lightweight and easy to manufacture, reducing shipping costs.

– Excellent thermal conductivity enhances efficiency.

– Corrosion-resistant properties extend lifespan.

Cons:

– Lower strength compared to steel, which may limit its use in high-pressure applications.

– Higher cost compared to some alternatives like cast iron.

Impact on Application:

Aluminum is compatible with many refrigerants and air media, making it suitable for a wide range of compressor applications.

Considerations for Buyers:

Buyers should ensure that aluminum components meet international standards such as ASTM and JIS, especially when exporting to regions with strict compliance requirements.

How Does Steel Compare as a Material for Compressors?

Steel, particularly carbon steel, is another prevalent material in compressor manufacturing. It offers high strength and durability, making it suitable for high-pressure applications. Steel can withstand temperatures exceeding 200°C, depending on the alloy used.

Pros:

– Exceptional strength and durability make it ideal for heavy-duty applications.

– Cost-effective for large-scale production due to established manufacturing processes.

Cons:

– Heavier than aluminum, potentially increasing transportation costs.

– Susceptible to corrosion unless treated or coated.

Impact on Application:

Steel is often used in high-pressure systems and can handle a variety of media, including corrosive gases, when properly treated.

Considerations for Buyers:

International buyers should verify that the steel used complies with relevant standards like DIN or ASTM to ensure quality and safety.

What Role Does Cast Iron Play in Compressor Manufacturing?

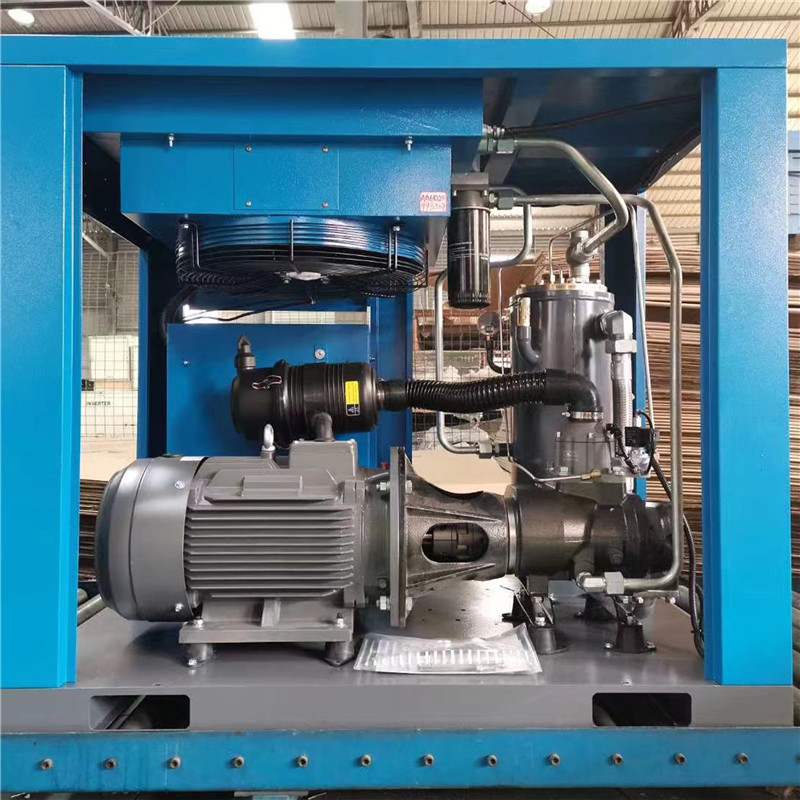

A stock image related to compressor china.

Cast iron is traditionally used in compressor manufacturing due to its excellent wear resistance and vibration-damping properties. It can handle high temperatures and pressures, making it suitable for heavy-duty applications.

Pros:

– High durability and longevity in demanding environments.

– Good machinability allows for complex shapes and designs.

Cons:

– Heavier than aluminum and steel, which can increase shipping costs.

– More brittle than other materials, which may lead to cracking under stress.

Impact on Application:

Cast iron is often used in industrial compressors where high durability is required, but it may not be suitable for all refrigerants due to potential corrosion.

Considerations for Buyers:

Buyers should confirm that cast iron components meet relevant international standards to ensure compatibility with local regulations.

Why is Stainless Steel a Preferred Material for Certain Compressors?

Stainless steel is favored in applications requiring high corrosion resistance and hygiene, such as food processing and pharmaceuticals. It can withstand a wide range of temperatures and pressures, making it versatile for various compressor applications.

Pros:

– Excellent corrosion resistance extends the lifespan of components.

– High strength-to-weight ratio makes it suitable for various applications.

Cons:

– Higher cost compared to carbon steel and aluminum.

– More complex manufacturing processes may lead to increased lead times.

Impact on Application:

Stainless steel is ideal for compressors dealing with corrosive media or where cleanliness is paramount.

Considerations for Buyers:

Buyers should ensure that the stainless steel used complies with international standards, particularly in industries with strict hygiene requirements.

Summary Table of Material Selection for Compressors

| Material | Typical Use Case for compressor china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight components in air compressors | Excellent thermal conductivity | Lower strength for high-pressure use | Medium |

| Steel | Heavy-duty industrial compressors | Exceptional strength and durability | Heavier, susceptible to corrosion | Low |

| Cast Iron | Industrial applications requiring durability | High wear resistance | Brittle, heavy | Medium |

| Stainless Steel | Food processing and pharmaceutical compressors | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers considering compressors from China. By understanding the properties and implications of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for compressor china

What Are the Main Stages of Compressor Manufacturing in China?

The manufacturing process for compressors in China is intricate and involves several key stages, each designed to ensure that the final product meets both quality and performance standards. Understanding these stages can provide B2B buyers with insights into the reliability of their potential suppliers.

Material Preparation

The manufacturing process begins with material preparation, where raw materials such as metals and alloys are sourced. Common materials include aluminum, steel, and cast iron, each selected based on the specific type of compressor being produced. Suppliers often use advanced sourcing techniques to ensure high-quality materials, which can significantly impact the durability and efficiency of the compressor.

Forming Techniques

Once the materials are prepared, the next stage involves forming. This can include processes like casting, machining, and forging. For instance, in casting, molten metal is poured into molds to create specific compressor components, while machining involves removing material from a solid block to achieve precise dimensions. Techniques such as CNC (Computer Numerical Control) machining are often employed for their accuracy and repeatability, ensuring that parts fit together perfectly during assembly.

Assembly of Components

After forming, the individual components are assembled. This stage is critical as it combines all the parts, including rotors, pistons, and housings, into a functioning unit. Skilled technicians often perform the assembly, following detailed specifications and using specialized tools to ensure that each component is correctly installed. The assembly process may also include initial testing to catch any issues early on.

Finishing Processes

The final stage in the manufacturing process is finishing, which may involve surface treatments, painting, or coating. These processes not only enhance the aesthetic appeal of the compressors but also improve their resistance to corrosion and wear. In high-quality compressors, finishing is a crucial step that directly influences longevity and performance.

How Is Quality Assurance Integrated into Compressor Manufacturing?

Quality assurance (QA) is vital in compressor manufacturing, as it ensures that the products meet international standards and industry-specific requirements. For B2B buyers, understanding these QA processes is essential for evaluating suppliers.

What International Standards Should B2B Buyers Look For?

Many manufacturers in China adhere to international quality standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard indicates that the manufacturer has a systematic approach to managing quality, which includes continuous improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant. These certifications demonstrate that the compressors meet regulatory requirements for safety and performance in specific markets, making them particularly important for buyers from Europe and the Middle East.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in compressor manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. Suppliers perform inspections to ensure materials meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed at various stages to monitor the quality of components and assembly. This helps identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly, compressors undergo FQC, where they are tested for functionality, performance, and safety. This stage often includes pressure testing, leak testing, and performance evaluations.

What Testing Methods Are Commonly Used?

Testing methods for compressors can vary, but some common approaches include:

-

Performance Testing: Compressors are tested under simulated operating conditions to evaluate efficiency, output pressure, and noise levels.

-

Durability Testing: This involves subjecting compressors to extended periods of operation to assess their reliability and longevity.

-

Leak Testing: Ensuring that there are no leaks in the compressor is critical. Common methods include pressure decay testing and helium leak testing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are some actionable steps:

Conduct Supplier Audits

One of the most effective ways to assess a supplier’s quality assurance processes is through on-site audits. These audits allow buyers to review the manufacturing facilities, quality control systems, and compliance with international standards firsthand. During an audit, buyers should look for documentation of quality procedures and evidence of compliance with relevant certifications.

Request Quality Reports

Buyers should ask suppliers for detailed quality reports, including results from IQC, IPQC, and FQC. These reports provide transparency about the quality control measures in place and the results of any testing conducted.

Engage Third-Party Inspection Services

Using third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct thorough inspections and testing of compressors before shipment, ensuring that they meet specified quality standards. This step is particularly crucial for buyers from regions such as Africa and South America, where local resources for quality verification may be limited.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control and certification that can affect their purchasing decisions. Different markets may have specific regulatory requirements, and understanding these can help buyers avoid compliance issues.

For example, in Europe, CE marking is not just a quality assurance symbol; it also indicates compliance with health, safety, and environmental protection standards. In contrast, buyers in the Middle East may prioritize suppliers with API certifications for compressors used in oil and gas applications.

By understanding these regional differences and actively engaging in the verification of quality control practices, international B2B buyers can make informed decisions that align with their operational standards and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘compressor china’

In the competitive landscape of international B2B procurement, sourcing compressors from China can be a strategic advantage. This guide provides a comprehensive checklist designed to help buyers effectively navigate the sourcing process, ensuring they secure high-quality products at the best prices.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to outline your specific requirements for the compressors. This includes understanding the type, capacity, and performance standards needed for your applications.

– Key considerations: Ensure clarity on power requirements, efficiency ratings, and any industry-specific standards that must be met.

Step 2: Research the Market Landscape

Conduct thorough market research to identify potential suppliers in China. Use industry forums, trade publications, and supplier directories to gather information.

– Helpful tools: Websites like Alibaba and Global Sources provide access to a wide range of suppliers and user reviews. Networking through trade shows can also yield valuable contacts.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet potential suppliers meticulously. Request detailed company profiles, case studies, and references from past clients, particularly those in your industry or region.

– What to look for: Assess their experience, production capabilities, and customer feedback. A supplier’s history of reliability can be a good indicator of future performance.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers adhere to international quality standards and possess necessary certifications such as ISO 9001 or relevant industry-specific certifications.

– Importance of compliance: Certifications not only indicate quality but also assure compliance with safety and environmental regulations, which can be crucial for certain markets.

Step 5: Request Samples and Conduct Quality Checks

Once you have shortlisted suppliers, request samples of the compressors. This step is essential to evaluate the quality and performance of the products firsthand.

– Quality control: Assess the materials used, build quality, and functionality. If possible, conduct tests in real operational conditions to ensure they meet your specifications.

Step 6: Negotiate Pricing and Terms

Initiate discussions on pricing, payment terms, and delivery schedules. Having clear communication can prevent misunderstandings and ensure a smooth transaction.

– Negotiation tips: Consider factors such as bulk order discounts and warranties. Don’t hesitate to compare offers from multiple suppliers to secure the best deal.

Step 7: Finalize Contracts and Monitor Deliveries

Once terms are agreed upon, draft a contract that includes all specifications, pricing, and delivery timelines. Ensure both parties understand their obligations.

– Ongoing monitoring: Stay in touch with the supplier throughout the production and shipping process to address any issues that may arise promptly.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing compressors from China more effectively, ensuring they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for compressor china Sourcing

When sourcing compressors from China, understanding the comprehensive cost structure is crucial for international B2B buyers. This analysis breaks down the cost components and price influencers that can significantly impact your purchasing decisions, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Compressor Sourcing?

-

Materials: The choice of materials directly affects the cost of compressors. Common materials include aluminum, steel, and specialized alloys. Buyers should assess the material quality based on the intended application to ensure durability and efficiency.

-

Labor: Labor costs in China are generally lower than in many Western countries, which can lead to competitive pricing. However, fluctuations in labor costs can occur due to regional differences and economic conditions. Understanding the local labor market can aid in negotiating better terms.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and administrative costs. Efficient manufacturing processes can reduce overhead, ultimately lowering the price for the buyer.

-

Tooling: Custom tooling for specific compressor designs can incur significant upfront costs. Buyers should weigh the long-term benefits of custom tooling against initial expenses, especially for large volume orders.

-

Quality Control (QC): Implementing rigorous QC measures is essential to ensure that compressors meet international standards. While this may increase costs, it can prevent expensive returns and rework later.

-

Logistics: Transportation costs from China to the buyer’s location can vary widely based on shipping methods, distances, and current freight rates. It’s essential to factor in logistics when calculating the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help buyers negotiate a fair margin while ensuring supplier sustainability.

What Influences Compressor Pricing in the B2B Market?

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to significant discounts. Buyers should determine their MOQ to optimize pricing while considering their inventory management.

-

Specifications and Customization: Customized compressors that meet specific operational requirements may incur additional costs. Buyers should define their specifications clearly to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or CE) may increase costs but ensure compliance with international standards, which is crucial for operational safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital as they define the responsibilities of buyers and sellers in shipping and logistics. Choosing the right Incoterms can affect overall costs and delivery times.

How Can Buyers Optimize Costs When Sourcing Compressors?

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms that align with your business goals. Building long-term relationships with suppliers can lead to better pricing and terms.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, energy efficiency, and operational costs over the compressor’s lifespan. A lower initial price might lead to higher long-term costs.

-

Stay Informed About Pricing Trends: Market fluctuations can impact the cost of materials and shipping. Keeping abreast of these trends allows buyers to time their purchases effectively.

-

Understand Pricing Nuances for Your Region: Each region may have unique considerations regarding tariffs, regulations, and market dynamics. Tailoring your approach based on these factors can lead to cost savings.

Conclusion

Sourcing compressors from China involves a multifaceted cost structure and various pricing influencers. By understanding these components and strategically negotiating, international B2B buyers can optimize their sourcing strategy, ensuring they get the best value for their investment. It’s essential to remember that prices can fluctuate, and obtaining quotes from multiple suppliers can provide a clearer picture of the market landscape.

Alternatives Analysis: Comparing compressor china With Other Solutions

The search for efficient and effective compressor solutions is critical for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. As companies evaluate their options, understanding alternatives to “Compressor China” can provide valuable insights to inform purchasing decisions. Below, we analyze “Compressor China” against other viable alternatives.

Comparison Table of Compressor Solutions

| Comparison Aspect | Compressor China | Scroll Compressor | Reciprocating Compressor |

|---|---|---|---|

| Performance | High efficiency; suitable for continuous operation | Very quiet and energy-efficient | High starting torque; versatile |

| Cost | Competitive pricing; lower upfront costs | Higher initial investment; potential for savings over time | Lower purchase cost; high maintenance costs |

| Ease of Implementation | Relatively easy to install | Requires professional installation | Simple setup; often requires skilled labor |

| Maintenance | Moderate maintenance; parts readily available | Low maintenance; long lifespan | High maintenance due to moving parts |

| Best Use Case | General industrial applications | Food processing, pharmaceuticals | Construction, automotive sectors |

Detailed Breakdown of Alternative Solutions

What are the Advantages and Disadvantages of Using Scroll Compressors?

Scroll compressors are known for their quiet operation and energy efficiency, making them ideal for applications in sensitive environments such as food processing and pharmaceuticals. The initial investment for scroll compressors is typically higher than that of traditional compressors, but their energy savings can lead to lower operating costs over time. However, their complexity may require professional installation, which could add to the overall expense.

How Do Reciprocating Compressors Compare in Terms of Versatility and Cost?

Reciprocating compressors are characterized by their ability to handle a wide range of pressures and applications, particularly in the construction and automotive sectors. They tend to be less expensive upfront compared to scroll compressors, but their maintenance requirements are higher due to the wear and tear on moving parts. This makes them a less attractive option for businesses looking to minimize long-term costs.

Conclusion: How to Choose the Right Compressor Solution for Your Business Needs

When selecting a compressor solution, international B2B buyers must consider several factors, including performance, cost, ease of implementation, and maintenance requirements. “Compressor China” offers a competitive option, particularly for general industrial applications, while scroll and reciprocating compressors may be better suited for specific needs. Understanding these alternatives allows businesses to make informed decisions that align with their operational goals and budget constraints. Ultimately, the right choice will depend on the specific requirements of your industry, the environment in which the compressor will operate, and long-term maintenance considerations.

Essential Technical Properties and Trade Terminology for compressor china

What Are the Essential Technical Properties of Compressors from China?

When sourcing compressors from China, understanding the key technical properties is crucial for making informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

The material grade of a compressor directly influences its durability and performance. Common materials include cast iron, aluminum alloys, and stainless steel. Selecting the right material can enhance corrosion resistance and thermal conductivity, leading to longer operational life and reduced maintenance costs. -

Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension or measured value. In compressor manufacturing, tighter tolerances can lead to improved efficiency and reduced wear and tear. For B2B buyers, understanding tolerance levels ensures that the components will fit correctly and function optimally in their applications. -

Pressure Rating

The pressure rating indicates the maximum pressure the compressor can handle safely. It is essential for applications that require specific pressure levels, such as pneumatic systems in manufacturing. Knowing the pressure rating helps buyers select a compressor that meets their operational needs without risking equipment failure. -

Flow Rate

Flow rate measures the volume of air or gas a compressor can deliver in a given time, typically expressed in cubic feet per minute (CFM). This specification is vital for buyers to ensure that the compressor can meet the demands of their operations. An inadequate flow rate can lead to inefficiencies and downtime. -

Power Consumption

Power consumption is an important specification that reflects how much energy the compressor will use during operation. Lower power consumption translates to reduced operating costs, making energy-efficient models more attractive for long-term investments. Buyers should consider this aspect to optimize their operational budgets.

What Are the Common Trade Terms Used in the Compressor Industry?

Navigating the compressor trade involves familiarizing oneself with industry jargon. Here are some commonly used terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM products can help buyers identify high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQ requirements to avoid overcommitting resources or facing increased costs. It is essential to negotiate favorable terms that align with their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and other information from suppliers. Utilizing RFQs can help buyers gather competitive offers, ensuring they make informed decisions based on market pricing and supplier capabilities. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risk transfer, and delivery responsibilities. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. Understanding lead times is essential for effective supply chain management and can impact project timelines and operational efficiency. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and their commitment to repair or replace defective parts. Knowing the warranty terms can provide peace of mind and protect buyers’ investments in compressors.

By grasping these technical properties and trade terms, international B2B buyers can make better-informed decisions when sourcing compressors from China, ultimately enhancing their operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the compressor china Sector

What Are the Key Market Dynamics and Trends in the Compressor Sector in China?

The compressor sector in China is rapidly evolving, driven by both domestic demand and international market dynamics. Global economic recovery post-pandemic has increased the need for energy-efficient and reliable compressor systems across various industries, including manufacturing, automotive, and HVAC. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends such as the integration of IoT (Internet of Things) technology in compressor systems are revolutionizing maintenance and operational efficiency. IoT-enabled compressors can provide real-time data analytics, predictive maintenance alerts, and enhanced energy management, thereby reducing operational costs. Additionally, buyers are increasingly seeking suppliers who offer comprehensive after-sales support and warranty services, emphasizing the importance of a robust supply chain.

Sourcing strategies are also shifting toward greater flexibility and customization. International buyers are looking for manufacturers that can provide tailored solutions to meet specific operational needs, particularly in regions with unique climate conditions or regulatory frameworks. Furthermore, the rise of e-commerce platforms dedicated to industrial equipment is making it easier for buyers to compare products and suppliers from China, streamlining the procurement process.

How Can Sustainability and Ethical Sourcing Impact Your Supply Chain in the Compressor Sector?

Sustainability has emerged as a key concern for international B2B buyers in the compressor sector. The environmental impact of compressor production, particularly in terms of energy consumption and emissions, is prompting companies to seek greener alternatives. Buyers are increasingly inclined to partner with manufacturers who prioritize sustainability in their operations, including the use of eco-friendly materials and energy-efficient technologies.

Ethical sourcing is also gaining traction, as buyers become more aware of the social implications of their supply chains. Companies are looking for suppliers who adhere to fair labor practices and have transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to attract international clients.

Moreover, many manufacturers are investing in research and development to create “green” compressors that utilize environmentally friendly refrigerants and minimize energy usage. This shift not only helps companies meet regulatory requirements but also enhances their brand reputation and appeal to environmentally conscious consumers.

How Has the Compressor Sector in China Evolved Over Time?

The compressor industry in China has undergone significant transformation over the past few decades. Initially dominated by basic mechanical designs, the sector has evolved to embrace advanced technologies such as variable speed drives and smart controls. This evolution was largely driven by the demand for energy efficiency and higher performance standards from both domestic and international markets.

In the early 2000s, China began to emerge as a global manufacturing hub for compressors, benefiting from its vast labor pool and lower production costs. However, as the market matured, the focus shifted from quantity to quality, with manufacturers investing in R&D to innovate and enhance product offerings.

Today, the Chinese compressor market is characterized by a diverse range of products, catering to various industries and applications. International buyers can find a plethora of options, from high-performance industrial compressors to specialized units designed for niche applications, making China a pivotal player in the global compressor landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of compressor china

-

How do I choose the right compressor from Chinese suppliers?

Selecting the right compressor involves assessing your specific needs, such as the application type, required pressure, and capacity. Research various suppliers in China, focusing on their product specifications, certifications, and customer reviews. Request product samples or technical data sheets to evaluate performance. Additionally, consider the supplier’s experience in your industry and their ability to provide after-sales support, which is crucial for maintenance and troubleshooting. -

What are the common types of compressors available in China?

China offers a wide range of compressors, including reciprocating, rotary screw, centrifugal, and scroll compressors. Each type has its advantages: reciprocating compressors are ideal for high-pressure applications, while rotary screw compressors are efficient for continuous operations. Centrifugal compressors suit large volume requirements, and scroll compressors are quieter and compact. Assess your operational needs to determine which type aligns best with your requirements. -

What should I know about minimum order quantities (MOQ) when sourcing compressors in China?

Minimum Order Quantities (MOQ) can vary significantly among Chinese suppliers. Typically, MOQs range from 1 to 100 units, depending on the manufacturer and the specific compressor model. It’s essential to communicate your needs clearly and negotiate with suppliers to find a suitable arrangement. Some manufacturers may offer lower MOQs for certain products or initial trial orders, which can help you assess product quality before committing to larger quantities. -

What payment terms are commonly accepted by Chinese compressor suppliers?

Chinese suppliers often accept various payment methods, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. Standard payment terms typically involve a 30% deposit upfront, with the remaining balance due before shipment. Ensure you clarify payment terms before finalizing your order to avoid any misunderstandings. It’s also advisable to use secure payment methods that provide buyer protection, especially for large transactions.

-

How can I ensure quality assurance when sourcing compressors from China?

To ensure quality assurance, request certifications such as ISO 9001 and CE marking from suppliers, indicating adherence to international quality standards. Conduct a factory audit if possible, or hire a third-party inspection service to verify product quality before shipment. Request detailed product specifications and samples for evaluation. Additionally, establish clear quality control criteria in your purchase agreement to hold suppliers accountable. -

What are the logistics considerations when importing compressors from China?

When importing compressors, consider shipping methods (air freight vs. sea freight), delivery times, and costs. Evaluate the total landed cost, including customs duties and taxes. Partner with a reliable freight forwarder who understands international shipping regulations and can handle documentation. Ensure that your suppliers are aware of your preferred shipping arrangements and that they package the compressors securely to prevent damage during transit. -

How do I navigate customs clearance for importing compressors from China?

Navigating customs clearance requires understanding the regulations in your country regarding imported goods. Ensure all documentation, including the bill of lading, commercial invoice, and packing list, is accurate and complete. Familiarize yourself with tariff codes and duties associated with compressors. It may be beneficial to work with a customs broker who can assist with the clearance process, ensuring compliance and timely delivery of your shipment. -

What are the options for customization when sourcing compressors from China?

Many Chinese manufacturers offer customization options, allowing you to tailor compressors to your specific needs. This can include modifications in size, capacity, or additional features such as variable speed drives or energy-efficient components. When discussing customization, provide detailed specifications and requirements to the supplier. Be prepared for potential lead times and costs associated with custom orders, and ensure that any changes are documented in your contract.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for compressor china

In conclusion, strategic sourcing in the compressor industry, particularly from China, presents a wealth of opportunities for international B2B buyers. By leveraging China’s advanced manufacturing capabilities and competitive pricing, businesses from regions such as Africa, South America, the Middle East, and Europe can significantly enhance their operational efficiency. The key takeaways include understanding the importance of supplier relationships, the necessity for rigorous quality assessments, and the benefits of engaging in long-term partnerships with reputable manufacturers.

Moreover, navigating the complexities of international trade, including compliance with local regulations and cultural nuances, is critical for successful sourcing. As the demand for high-quality compressors continues to rise globally, the outlook remains positive. Buyers are encouraged to proactively seek out innovative solutions and collaborate with Chinese suppliers who demonstrate a commitment to quality and sustainability.

Moving forward, it is imperative for international buyers to stay informed about emerging trends and technological advancements within the compressor sector. By doing so, they can position themselves to capitalize on future opportunities and drive their businesses forward. Embrace the potential of strategic sourcing today to unlock new avenues for growth and competitive advantage.