Discover Top Suspension Parts Suppliers: A Complete Guide (2025)

Introduction: Navigating the Global Market for suspension parts supplier

In an increasingly interconnected world, sourcing reliable suspension parts suppliers can pose significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, navigating the complexities of global supply chains requires a strategic approach. This guide is designed to help you effectively identify and evaluate suspension parts suppliers, ensuring that you secure quality components that meet your operational needs while adhering to budget constraints.

The scope of this guide encompasses a variety of critical elements, including the different types of suspension parts available, their applications across various industries, and the essential criteria for vetting suppliers. You’ll also gain insights into cost considerations and best practices for negotiating favorable terms. By addressing these key areas, this guide empowers you to make informed purchasing decisions that not only enhance your product offerings but also foster long-term partnerships with suppliers.

As you delve into the content, expect to find actionable strategies tailored to your specific market context. From understanding regional supply dynamics to leveraging digital tools for supplier discovery, you will be equipped with the knowledge needed to thrive in the competitive landscape of suspension parts procurement. Prepare to transform your sourcing strategy and optimize your supply chain efficiency as you navigate the global market for suspension parts.

Understanding suspension parts supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Suspension Parts Supplier | Supplies original equipment manufacturer (OEM) parts, ensuring compatibility and quality. | Automotive manufacturing, fleet management | Pros: High reliability, guaranteed fit. Cons: Often higher prices. |

| Aftermarket Suspension Parts Supplier | Offers replacement parts that may vary in quality and price, providing alternatives to OEM parts. | Vehicle repair shops, individual consumers | Pros: Cost-effective options, variety. Cons: Quality can be inconsistent. |

| Specialty Suspension Parts Supplier | Focuses on niche markets, such as performance or heavy-duty applications, often providing customized solutions. | Motorsports, off-road vehicles, heavy machinery | Pros: Tailored solutions, enhanced performance. Cons: Limited availability and higher costs. |

| Wholesale Suspension Parts Supplier | Distributes parts in bulk, catering to retailers and repair shops, often at discounted rates. | Retailers, auto repair businesses | Pros: Cost savings on bulk purchases, extensive inventory. Cons: Minimum order quantities may be required. |

| International Suspension Parts Supplier | Caters to global markets, often specializing in compliance with international standards and regulations. | Exporters, global automotive companies | Pros: Access to a wide range of products, adherence to regulations. Cons: Potential for longer lead times due to shipping. |

What Are the Characteristics of OEM Suspension Parts Suppliers?

OEM suspension parts suppliers are integral to the automotive industry, providing original components designed specifically for vehicle manufacturers. These suppliers ensure that every part meets the stringent quality and performance standards set by the OEMs. B2B buyers seeking reliability and compatibility will find OEM parts ideal, especially when maintaining fleet vehicles or manufacturing new cars. However, the premium pricing associated with OEM parts can be a consideration for budget-conscious buyers.

How Do Aftermarket Suspension Parts Suppliers Differ?

Aftermarket suspension parts suppliers present an alternative to OEM components, often at more competitive prices. They provide a wide range of options, from budget-friendly to high-performance parts, catering to diverse market needs. While these suppliers can offer significant cost savings, buyers should be cautious of quality variations. Thorough research and supplier vetting are essential to ensure that the aftermarket parts meet the necessary performance and safety standards.

What Makes Specialty Suspension Parts Suppliers Unique?

Specialty suspension parts suppliers focus on specific segments of the market, such as performance enhancements for racing or heavy-duty components for commercial vehicles. These suppliers often provide customized solutions that can significantly enhance vehicle performance. B2B buyers in niche markets will benefit from the expertise and tailored offerings of specialty suppliers. However, the trade-off may include higher costs and limited availability, which should be factored into purchasing decisions.

Why Choose Wholesale Suspension Parts Suppliers?

Wholesale suspension parts suppliers are ideal for businesses looking to purchase in bulk, such as repair shops or automotive retailers. They typically offer substantial discounts on larger orders, making it a cost-effective option for those needing high volumes of parts. However, buyers should be aware of minimum order requirements, which can affect cash flow and inventory management. Ensuring that the wholesaler has a reliable supply chain is also crucial for maintaining business continuity.

What Are the Benefits of International Suspension Parts Suppliers?

International suspension parts suppliers cater to the global market, offering a diverse range of products that comply with various international standards. This can be particularly advantageous for B2B buyers involved in exporting or dealing with multinational automotive companies. While these suppliers provide access to a broad inventory, buyers must consider potential challenges such as longer lead times and shipping costs. Ensuring that the supplier has a solid logistics plan can help mitigate these issues.

Related Video: What’s the Best Suspension System Setup for Your Vehicle?

Key Industrial Applications of suspension parts supplier

| Industry/Sector | Specific Application of Suspension Parts Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of vehicle suspension systems | Enhanced vehicle performance and safety | Quality certifications, lead times, and regional compliance |

| Construction Equipment | Supply of suspension components for heavy machinery | Improved stability and load management | Durability, resistance to harsh environments, and supplier reliability |

| Agricultural Machinery | Suspension systems for tractors and harvesters | Increased efficiency and reduced maintenance costs | Material specifications, compatibility with existing equipment, and availability of parts |

| Rail Transport | Suspension parts for rail cars and freight systems | Enhanced ride quality and reduced wear on tracks | Compliance with safety standards, weight considerations, and long-term availability |

| Aerospace | Components for aircraft landing gear systems | Safety assurance and regulatory compliance | Precision engineering, weight reduction, and certification for aerospace applications |

How Are Suspension Parts Used in the Automotive Industry?

In the automotive sector, suspension parts suppliers play a crucial role in manufacturing and supplying components like shock absorbers, struts, and control arms. These components are vital for ensuring vehicle stability, safety, and comfort. International buyers from regions such as Africa and Europe must focus on suppliers that comply with local and international safety standards, as well as those that can provide timely delivery and quality assurance. By sourcing high-quality suspension parts, businesses can enhance vehicle performance and customer satisfaction, ultimately driving sales and brand loyalty.

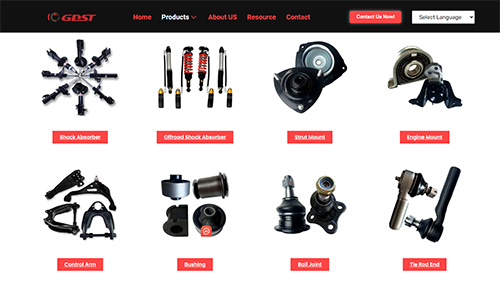

A stock image related to suspension parts supplier.

What Is the Role of Suspension Parts in Construction Equipment?

In the construction equipment industry, suspension parts are essential for heavy machinery, such as excavators and bulldozers. These parts help improve stability and load management, allowing machinery to operate efficiently on uneven terrain. Buyers should prioritize suppliers that offer durable components designed to withstand harsh conditions typical in construction sites. Additionally, understanding the specific requirements for machinery compatibility and the ability to provide rapid replacement parts can significantly reduce downtime and maintenance costs, directly impacting productivity.

How Do Suspension Parts Benefit Agricultural Machinery?

Suspension systems in agricultural machinery, like tractors and harvesters, are designed to enhance operational efficiency. Suppliers provide components that absorb shocks and maintain stability while traversing fields. For international buyers, especially in South America, it is crucial to consider the durability of materials used in suspension parts due to the challenging environments these machines operate in. Ensuring compatibility with existing equipment and obtaining parts with a long service life can lead to reduced maintenance costs and improved productivity in agricultural operations.

Why Are Suspension Parts Important for Rail Transport?

In the rail transport sector, suspension parts are critical for ensuring passenger comfort and freight stability. Components like air springs and dampers are necessary for reducing vibrations and maintaining track integrity. Buyers from the Middle East and Europe should look for suppliers that can meet stringent safety regulations and offer parts that are lightweight yet durable. Long-term availability and support for maintenance are essential factors to consider, as they can affect overall operational efficiency and safety in rail transport systems.

What Are the Requirements for Suspension Parts in Aerospace Applications?

In the aerospace industry, suspension parts are integral to aircraft landing gear systems. These components must meet high standards of precision and regulatory compliance to ensure safety during takeoff and landing. International B2B buyers need to focus on suppliers who specialize in aerospace applications, providing lightweight and high-strength materials. Certification from recognized aviation authorities is crucial, as is the ability to offer innovative solutions that enhance safety and operational efficiency. By sourcing reliable suspension parts, businesses can ensure compliance and safety in their aerospace operations.

Related Video: QA1 Handling Suspension Kits

3 Common User Pain Points for ‘suspension parts supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges with Suspension Parts

The Problem:

International B2B buyers often face significant challenges when it comes to ensuring the quality of suspension parts sourced from suppliers. In regions like Africa and South America, where local regulations might differ vastly from international standards, buyers may receive components that do not meet their expected quality benchmarks. This can lead to costly failures in vehicle performance, increased warranty claims, and a damaged reputation among end-users.

The Solution:

To mitigate quality assurance issues, B2B buyers should prioritize working with suspension parts suppliers who demonstrate a robust quality management system (QMS). Before committing to a supplier, conduct thorough research into their quality certifications, such as ISO 9001. Request samples to perform independent testing or engage third-party quality assurance services. Establishing clear quality expectations and regular audits can also help maintain standards. Collaborating with suppliers to develop a quality assurance plan tailored to your specific needs can create a solid foundation for long-term partnerships.

Scenario 2: Overcoming Lead Time Delays in Suspension Parts Delivery

The Problem:

Lead time delays can significantly disrupt supply chains, especially in industries where timely delivery of suspension parts is critical for vehicle assembly and maintenance. Buyers from Europe and the Middle East frequently encounter issues with suppliers who promise quick turnaround times but fail to deliver, resulting in production halts and financial losses.

The Solution:

To combat lead time issues, B2B buyers should implement a proactive sourcing strategy. This involves creating a detailed timeline for orders that factors in potential delays and setting up contingency plans with multiple suppliers. Establishing a close relationship with suppliers through regular communication can help in understanding their production capabilities and potential bottlenecks. Additionally, consider sourcing from suppliers who maintain a well-stocked inventory of commonly required suspension parts, which can significantly reduce lead times. Utilizing digital platforms for real-time tracking of shipments can also enhance transparency and improve delivery reliability.

Scenario 3: Managing Cost Fluctuations and Budget Constraints

The Problem:

Cost fluctuations in raw materials and transportation can create challenges for B2B buyers trying to maintain budget constraints. Buyers in regions like South America and Africa may find themselves facing unexpected price hikes from suppliers, which can impact their overall project budgets and profitability.

The Solution:

To effectively manage cost fluctuations, B2B buyers should adopt a strategic sourcing approach that includes long-term contracts with fixed pricing agreements. This allows for predictable budgeting and can shield against sudden market price changes. Regular market analysis is also essential; staying informed about global trends in raw material costs can aid in making timely purchasing decisions. Additionally, building relationships with multiple suppliers can provide leverage in negotiations, allowing buyers to seek competitive pricing options. Utilizing technology for supply chain management can also enhance visibility into costs, enabling smarter purchasing strategies that align with budget constraints.

By addressing these common pain points with actionable strategies, international B2B buyers can enhance their procurement processes, foster better supplier relationships, and ultimately drive operational success in their businesses.

Strategic Material Selection Guide for suspension parts supplier

What Are the Key Properties of Common Materials Used in Suspension Parts?

When selecting materials for suspension parts, it is essential to understand the key properties that influence performance. Common materials include steel, aluminum, composite materials, and rubber. Each material has distinct characteristics that can affect durability, weight, and overall functionality in various environments.

How Does Steel Perform as a Material for Suspension Parts?

Steel is one of the most widely used materials in suspension parts due to its excellent strength and durability. It offers high tensile strength, making it suitable for high-stress applications. Steel also has good temperature resistance, typically rated up to 300°C, and exhibits decent corrosion resistance when properly treated.

Pros: The primary advantage of steel is its durability and cost-effectiveness. It can withstand significant loads and impacts, making it ideal for heavy-duty applications.

Cons: However, steel is heavier than other materials, which can affect the overall weight of the vehicle. Additionally, if not treated for corrosion, it can rust, especially in humid or saline environments.

Impact on Application: Steel suspension parts are compatible with various media, including oils and lubricants, but may require protective coatings in corrosive environments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN for steel grades. In Europe, specific requirements may vary by country, and buyers should consider the availability of treated steel to mitigate corrosion issues.

What Are the Advantages of Aluminum in Suspension Parts?

Aluminum is increasingly popular in the automotive industry due to its lightweight nature and good strength-to-weight ratio. It typically performs well under temperature variations, with a melting point around 660°C, and offers excellent corrosion resistance, especially when anodized.

Pros: The primary advantage of aluminum is its lightweight, which can improve fuel efficiency and handling.

Cons: However, aluminum can be more expensive than steel and may not provide the same level of strength in high-load applications without additional reinforcement.

Impact on Application: Aluminum suspension parts are particularly effective in applications requiring weight reduction, such as performance vehicles. They are compatible with a wide range of media but may require careful selection of fasteners to avoid galvanic corrosion.

Considerations for International Buyers: Buyers from Europe, particularly in countries like Poland, should be aware of specific aluminum grades and standards (e.g., EN 573) to ensure compatibility and performance.

How Do Composite Materials Benefit Suspension Parts?

Composite materials, including carbon fiber and fiberglass, are known for their high strength-to-weight ratio and resistance to corrosion. They can withstand high temperatures and pressures, making them suitable for specialized applications.

Pros: The key advantage of composites is their lightweight nature and ability to absorb vibrations, enhancing ride quality.

Cons: The main limitation is their higher manufacturing complexity and cost. Additionally, composites may not be suitable for all load-bearing applications.

Impact on Application: Composites are ideal for high-performance vehicles where weight savings are critical. They are compatible with various media but require careful handling to prevent damage.

Considerations for International Buyers: Buyers from South America should consider the availability of composite materials and their compliance with international standards, as well as the need for specialized manufacturing processes.

What Role Does Rubber Play in Suspension Parts?

Rubber is primarily used in suspension systems for its excellent flexibility and vibration-damping properties. It can withstand a range of temperatures, typically from -40°C to 100°C, and is resistant to many chemicals.

Pros: The main advantage of rubber is its ability to absorb shocks and vibrations, improving ride comfort.

Cons: However, rubber can degrade over time due to environmental factors such as UV exposure and ozone, leading to potential failures.

Impact on Application: Rubber components are crucial in applications where flexibility and shock absorption are required, such as bushings and mounts. They are compatible with various fluids but may require specific formulations for different environments.

Considerations for International Buyers: Buyers from the Middle East should ensure that rubber components meet local standards for temperature and chemical resistance, as extreme conditions can accelerate degradation.

Summary Table of Material Selection for Suspension Parts

| Material | Typical Use Case for suspension parts supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty suspension components | High strength and durability | Heavier, prone to corrosion | Medium |

| Aluminum | Performance and lightweight applications | Lightweight, improves fuel efficiency | Higher cost, lower strength in some cases | High |

| Composite | High-performance vehicles | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

| Rubber | Vibration dampening components | Shock absorption and flexibility | Degrades over time | Medium |

This guide serves as a strategic resource for international B2B buyers seeking to make informed decisions regarding material selection for suspension parts, ensuring compatibility with local standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for suspension parts supplier

What Are the Main Stages of Manufacturing Suspension Parts?

The manufacturing process for suspension parts is intricate, involving several key stages that ensure the quality and performance of the final product. Understanding these stages is crucial for international B2B buyers looking to source reliable suspension parts suppliers.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. Suspension parts are typically made from high-strength steel, aluminum alloys, or composite materials, chosen for their durability and weight properties. The selection of raw materials is critical, as it directly influences the performance and longevity of the suspension system.

Once the materials are selected, they undergo a series of treatments, such as heat treatment or surface hardening, to enhance their physical properties. Buyers should inquire about the source of raw materials and their certification, as this ensures compliance with international quality standards.

Forming: What Techniques Are Employed?

The next stage is forming, where raw materials are shaped into the desired components. This can be achieved through various techniques, including:

- Forging: This process involves shaping the material using compressive forces, resulting in a strong and dense part.

- Casting: Liquid metal is poured into a mold to create complex shapes, ideal for intricate suspension components.

- Machining: Precision cutting and shaping of parts using CNC machines ensures high accuracy and surface finish.

Each method has its advantages, and B2B buyers should evaluate the supplier’s capabilities in these techniques to ensure they meet specific design requirements.

Assembly: How Are Parts Joined?

Once formed, the components move to the assembly stage. This step may involve welding, bolting, or riveting, depending on the design and intended use of the suspension parts. A thorough understanding of assembly techniques can help buyers assess the strength and reliability of the final product.

For international buyers, particularly from regions such as Africa and South America, it is essential to discuss the assembly processes with suppliers. Ensuring that they utilize modern techniques and technologies can significantly impact the quality of the suspension parts.

Finishing: What Processes Ensure Quality?

The finishing stage is where the suspension parts receive surface treatments to enhance corrosion resistance and aesthetic appeal. Common finishing processes include:

- Painting or Powder Coating: Provides a protective layer against environmental factors.

- Anodizing: Particularly for aluminum parts, this process increases corrosion resistance and surface hardness.

- Plating: A thin layer of metal is deposited on the surface for protection and improved appearance.

Buyers should ask suppliers about their finishing processes and the quality of materials used, as these can affect both performance and durability.

How Do Quality Assurance Practices Impact Suspension Parts?

Quality assurance (QA) is integral to the manufacturing process, ensuring that all suspension parts meet stringent standards before they reach the market. For international B2B buyers, understanding these QA practices can help in selecting reliable suppliers.

What International Standards Should Buyers Look For?

Several international standards govern the quality of suspension parts. Key among them are:

- ISO 9001: This standard focuses on quality management systems, ensuring suppliers maintain consistent quality in their processes.

- CE Marking: Indicates compliance with European safety and environmental requirements, crucial for buyers in Europe.

- API Standards: Relevant for suspension parts used in the oil and gas industry, ensuring safety and performance.

Buyers should verify that their suppliers are compliant with these standards, as it reflects their commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves systematic checks throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early.

- Final Quality Control (FQC): The final product undergoes rigorous testing before shipment, ensuring it meets all quality criteria.

Understanding these checkpoints can help buyers ascertain the reliability of the supplier’s QC processes.

What Common Testing Methods Are Used?

Various testing methods are employed to ensure the quality and performance of suspension parts, including:

- Tensile Testing: Measures the strength of materials under tension.

- Fatigue Testing: Assesses how materials withstand repeated stress over time.

- Impact Testing: Evaluates the toughness of materials when subjected to sudden forces.

B2B buyers should request documentation of these tests to ensure that the products meet industry standards and performance expectations.

How Can Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for building a successful partnership. Here are actionable steps that B2B buyers can take:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality management system (QMS) documentation from potential suppliers. This includes:

- Audit Reports: These provide insights into the supplier’s compliance with quality standards.

- Quality Control Reports: Documentation of QC activities and testing results should be readily available.

Conducting supplier audits can also provide firsthand knowledge of the supplier’s capabilities and adherence to quality standards.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can further ensure that suppliers adhere to quality standards. This independent verification adds an extra layer of confidence, particularly for buyers from regions with varying standards of manufacturing quality.

What Are the QC/CERT Nuances for International B2B Buyers?

International buyers must be aware of regional differences in quality certification and standards. For instance, while CE marking is crucial for European buyers, other regions may have different compliance requirements. Buyers should familiarize themselves with the specific standards relevant to their market to ensure that the products they source are compliant and safe for use.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices is essential for international B2B buyers looking to source suspension parts. By focusing on material preparation, forming, assembly, finishing, and stringent quality control, buyers can make informed decisions that lead to successful partnerships with suppliers around the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘suspension parts supplier’

Introduction

Sourcing suspension parts from reliable suppliers is a critical process for businesses looking to ensure the quality and performance of their vehicles. This checklist provides a structured approach to help international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, navigate the complexities of selecting the right suspension parts supplier. By following these actionable steps, you can streamline your procurement process and mitigate risks associated with sourcing.

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, clearly outline your technical requirements for suspension parts. This includes details such as material specifications, load capacities, and compliance with local regulations.

- Why It’s Important: Precise specifications prevent miscommunication and ensure that the parts meet your operational standards.

- What to Look For: Ensure your requirements reflect the intended application, whether for passenger vehicles, commercial trucks, or specialized machinery.

Step 2: Research Potential Suppliers

Conduct thorough market research to identify potential suppliers who specialize in suspension parts. Utilize online platforms, industry forums, and trade shows to gather information about their capabilities.

- Why It’s Important: Not all suppliers offer the same level of expertise or product range, so understanding the market landscape is vital.

- What to Look For: Focus on suppliers with a proven track record in your specific region and industry, and gather insights into their reputation and customer satisfaction.

Step 3: Verify Supplier Certifications

Confirm that potential suppliers possess the necessary certifications and compliance with international quality standards, such as ISO 9001 or specific automotive industry standards.

- Why It’s Important: Certifications are indicators of a supplier’s commitment to quality and reliability.

- What to Look For: Request copies of certifications and check for any relevant industry-specific accreditations that may apply.

Step 4: Request Samples and Product Documentation

Before making a bulk purchase, request samples of the suspension parts along with detailed product documentation, including technical sheets and warranty information.

- Why It’s Important: Testing samples ensures that the parts meet your quality standards and function correctly within your systems.

- What to Look For: Evaluate the materials used, finish quality, and compatibility with your existing systems.

Step 5: Assess Pricing and Payment Terms

Analyze the pricing structures offered by different suppliers and understand their payment terms. Look for transparency in pricing and any hidden costs that may arise.

- Why It’s Important: Competitive pricing can significantly affect your overall budget, but it should not compromise quality.

- What to Look For: Evaluate whether the payment terms align with your cash flow cycles, and consider any discounts for bulk purchases.

Step 6: Check Logistics and Delivery Capabilities

Investigate the logistics capabilities of your shortlisted suppliers, including shipping times, delivery methods, and their ability to handle customs clearance.

- Why It’s Important: Efficient logistics are crucial for maintaining your supply chain and minimizing downtime.

- What to Look For: Ensure that the supplier can meet your delivery schedules and has a reliable shipping process.

Step 7: Establish Communication Channels

Set up clear communication channels with your chosen supplier to facilitate ongoing dialogue throughout the procurement process.

- Why It’s Important: Effective communication helps address any issues promptly and fosters a stronger business relationship.

- What to Look For: Choose suppliers who are responsive and willing to engage in regular updates regarding production and delivery status.

By following this checklist, international B2B buyers can make informed decisions when sourcing suspension parts, ensuring a smooth procurement process and long-term supplier partnerships.

Comprehensive Cost and Pricing Analysis for suspension parts supplier Sourcing

What Are the Key Cost Components in Sourcing Suspension Parts?

When sourcing suspension parts, understanding the cost structure is essential for effective budgeting and negotiation. The primary components influencing the total cost include:

-

Materials: The choice of materials significantly affects pricing. High-quality materials, such as advanced composites or specific alloys, can increase costs but may offer better performance and durability. Buyers should analyze material specifications to ensure they meet their requirements without overspending.

-

Labor: Labor costs vary by region and supplier. Regions with higher labor costs may offer better-skilled workers and advanced manufacturing techniques, while lower-cost regions may compromise on quality. It’s crucial to assess the balance between labor cost and the skill level of workers.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, maintenance, and facility costs. Overhead can vary widely between suppliers, impacting the final price. Buyers should seek transparency in a supplier’s overhead costs to understand pricing better.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. Suppliers may require upfront investment for molds or dies. Buyers should inquire about these costs upfront to avoid surprises later in the procurement process.

-

Quality Control (QC): Effective QC processes can add to costs but are essential for ensuring product reliability. Buyers should assess the supplier’s QC measures and certifications, as robust QC can lead to lower long-term costs through reduced failure rates.

-

Logistics: Transportation and shipping costs play a vital role in the overall pricing. Factors such as distance, mode of transport, and shipping terms (Incoterms) can significantly impact logistics costs. Buyers should negotiate logistics as part of the pricing discussion.

-

Margin: Supplier profit margins can vary significantly. It’s essential to understand the market standards for margins in the suspension parts industry to gauge whether a supplier’s pricing is competitive.

How Do Price Influencers Affect Suspension Parts Sourcing?

Several factors influence the pricing of suspension parts, including:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk typically reduces per-unit costs. Suppliers often have MOQs that can affect overall pricing, so negotiating these terms can yield better pricing.

-

Specifications and Customization: Custom parts tailored to specific requirements can lead to increased costs. Buyers should weigh the necessity of customizations against potential cost savings from standard parts.

-

Quality and Certifications: Higher quality standards and specific certifications (like ISO or IATF) may result in higher prices but can also ensure reliability and compliance with industry regulations.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can all impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting overall costs.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing Suspension Parts?

To optimize sourcing strategies and achieve better pricing, international B2B buyers should consider the following tips:

-

Effective Negotiation: Leverage volume orders to negotiate better pricing or terms. Building long-term relationships with suppliers can also lead to more favorable conditions.

-

Focus on Total Cost of Ownership (TCO): Evaluate the overall costs associated with a part, including maintenance, potential failure rates, and logistics, rather than just the initial purchase price. A higher upfront cost may be justified by lower long-term expenses.

-

Pricing Nuances for Different Regions: Buyers in Africa, South America, the Middle East, and Europe should be aware of regional market dynamics. For instance, suppliers in Turkey or Poland may offer competitive pricing due to lower operational costs, but buyers should assess quality and delivery timelines.

-

Request for Quotations (RFQs): Always seek multiple quotations from different suppliers to ensure competitive pricing. Analyze these quotes critically, focusing on the breakdown of costs and services offered.

Disclaimer on Pricing Variability

It’s important to note that the prices for suspension parts can fluctuate based on market conditions, currency exchange rates, and supplier negotiations. Buyers should regularly review and update their pricing strategies to adapt to these changes.

Alternatives Analysis: Comparing suspension parts supplier With Other Solutions

When evaluating options for sourcing suspension parts, international B2B buyers must consider various alternatives to traditional suppliers. Each alternative presents unique advantages and disadvantages, making it crucial to analyze them effectively to make informed decisions.

| Comparison Aspect | Suspension Parts Supplier | Alternative 1: In-House Manufacturing | Alternative 2: 3D Printing Solutions |

|---|---|---|---|

| Performance | High quality and reliability; established supply chain | Variable quality; depends on expertise and equipment | High precision; rapid prototyping capabilities |

| Cost | Moderate to high; includes shipping and tariffs | Potentially lower; initial setup costs can be high | Generally low for small runs; high for larger volumes |

| Ease of Implementation | Straightforward; established processes | Complex; requires skilled workforce and equipment | Moderate; requires knowledge of 3D design and printing |

| Maintenance | Supplier-managed; usually lower maintenance burden | High; requires ongoing resources for upkeep | Low; minimal maintenance post-production |

| Best Use Case | Large-scale production with consistent demand | Custom parts for specialized applications | Rapid prototyping and low-volume production |

What Are the Advantages and Disadvantages of In-House Manufacturing for Suspension Parts?

In-house manufacturing offers the benefit of greater control over the production process. B2B buyers can customize parts to specific needs and maintain stringent quality checks. However, this option often requires substantial initial investment in machinery, skilled labor, and ongoing maintenance, making it less viable for companies lacking resources. Additionally, the learning curve can delay production and affect time-to-market.

How Does 3D Printing Solutions Compare for Suspension Parts?

3D printing solutions provide flexibility and innovation, allowing for rapid prototyping and the ability to create complex geometries that traditional manufacturing might not accommodate. This approach is especially beneficial for low-volume needs or specialized parts. However, while the cost for small runs is low, scaling production can become expensive, and the materials used may not always meet the durability standards required for suspension parts in heavy vehicles. Companies must also invest in design software and potentially retrain staff to utilize this technology effectively.

Conclusion: How Can B2B Buyers Select the Right Solution for Suspension Parts?

Choosing the right solution for suspension parts hinges on a thorough understanding of specific business needs, including budget constraints, production scale, and quality requirements. For large-scale operations with consistent demands, a traditional suspension parts supplier may be the most reliable choice. In contrast, companies needing customization or rapid prototyping may find in-house manufacturing or 3D printing to be more beneficial. Ultimately, B2B buyers must weigh these options carefully to align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for suspension parts supplier

What Are the Key Technical Properties of Suspension Parts?

When sourcing suspension parts, understanding the technical specifications is crucial for ensuring compatibility, performance, and longevity. Here are some essential technical properties to consider:

1. Material Grade

The material grade determines the strength, durability, and weight of suspension components. Common materials include high-strength steel, aluminum alloys, and composites. For B2B buyers, selecting the right material grade is vital as it directly impacts the part’s performance under load and environmental conditions. Higher-grade materials often lead to better reliability and reduced maintenance costs.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. In suspension parts, tight tolerances are necessary to ensure proper fit and function. For example, components like control arms and struts must meet specific tolerance levels to avoid premature wear or failure. Buyers should prioritize suppliers who can consistently meet tight tolerances to guarantee the quality and safety of their vehicles.

3. Load Capacity

Load capacity indicates the maximum weight a suspension part can support without failure. This property is crucial for determining the suitability of components for specific vehicle applications. B2B buyers should assess the load capacity of suspension parts to ensure they meet or exceed the demands of their intended use, especially in heavy-duty applications.

4. Corrosion Resistance

Corrosion resistance is the ability of materials to withstand deterioration due to environmental factors like moisture and salt. Suspension parts often face harsh conditions, making this property essential for longevity. Buyers should inquire about protective coatings or treatments that enhance corrosion resistance, particularly in regions with extreme weather conditions.

5. Fatigue Strength

Fatigue strength is the maximum stress a material can endure for a specified number of cycles without failing. This property is critical for suspension parts that undergo repetitive loading and unloading. Understanding fatigue strength helps buyers evaluate the long-term performance and reliability of components, which is particularly important for commercial vehicle applications.

What Common Trade Terms Should International B2B Buyers Know?

Navigating the terminology of the suspension parts industry is essential for effective communication and negotiation. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold under another company’s brand. For B2B buyers, sourcing OEM parts can ensure compatibility and quality, as these parts are designed to meet specific standards set by vehicle manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing strategies while ensuring they can maintain sufficient stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and negotiate better terms. Crafting a clear and detailed RFQ can lead to more accurate quotes and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding these terms helps buyers manage logistics and costs effectively. Key Incoterms to consider include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which define who is responsible for shipping costs and risks during transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for planning and inventory management. Clear communication with suppliers about lead times can help avoid delays and ensure timely project execution.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions and establish successful partnerships in the suspension parts supply chain.

Navigating Market Dynamics and Sourcing Trends in the suspension parts supplier Sector

What Are the Current Market Dynamics and Key Trends in the Suspension Parts Supplier Sector?

The suspension parts supplier sector is experiencing significant transformation driven by global demand for advanced automotive technologies and increasing emphasis on vehicle safety and performance. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (including Turkey and Poland), understanding these dynamics is crucial for effective sourcing strategies.

One of the primary drivers is the rise in electric vehicles (EVs) and hybrid technologies. This shift not only influences the type of suspension systems being developed but also the materials used, as manufacturers seek lighter and more efficient components. Furthermore, the increasing integration of smart technologies, such as adaptive suspension systems that utilize sensors and software, is reshaping the market landscape. B2B buyers should focus on suppliers that can provide innovative solutions and are adaptable to these technological changes.

Emerging sourcing trends highlight the importance of digital platforms for procurement processes. The adoption of e-procurement systems allows buyers to streamline their sourcing operations, enhance transparency, and reduce lead times. Additionally, data analytics is becoming vital in assessing supplier performance and market conditions, providing a competitive edge in decision-making.

Finally, geopolitical factors and supply chain disruptions, particularly those stemming from the COVID-19 pandemic, have pushed buyers to reconsider their sourcing strategies. Diversifying suppliers and investing in local partnerships can mitigate risks associated with global supply chains, ensuring a more resilient procurement process.

How Is Sustainability Shaping the Suspension Parts Supplier Sector?

Sustainability and ethical sourcing are becoming increasingly important in the suspension parts supplier sector. As global awareness of environmental issues rises, buyers are seeking suppliers who prioritize eco-friendly practices and materials. This shift is particularly relevant for B2B buyers from regions like Africa and South America, where sustainable development is a pressing concern.

The environmental impact of suspension parts manufacturing includes resource extraction, energy consumption, and waste generation. As a result, many suppliers are adopting sustainable practices, such as using recycled materials and reducing carbon footprints in their production processes. Buyers should prioritize suppliers who offer ‘green’ certifications, such as ISO 14001, which demonstrates a commitment to environmental management.

A stock image related to suspension parts supplier.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should ensure that their suppliers adhere to fair labor practices and contribute positively to the communities from which they source materials. This not only enhances brand reputation but also aligns with the growing consumer demand for responsible sourcing.

Investing in suppliers who emphasize sustainability can lead to long-term cost savings and improved market positioning, making it a strategic imperative for B2B buyers in the suspension parts sector.

What Is the Brief Evolution of the Suspension Parts Supplier Sector?

The suspension parts supplier sector has evolved significantly over the past few decades, influenced by advancements in automotive technology and shifting consumer preferences. Initially focused on traditional mechanical systems, the industry has rapidly adapted to the demands of modern vehicles, including enhanced safety features and performance metrics.

The introduction of electronic and adaptive suspension systems marked a pivotal shift, allowing for improved ride quality and vehicle handling. As the automotive industry continues to embrace electrification and automation, suppliers are increasingly focusing on innovative materials and designs that meet the needs of next-generation vehicles.

This evolution has created a dynamic market landscape where B2B buyers must stay informed about technological advancements and emerging trends to make strategic sourcing decisions that align with their operational goals. Understanding this historical context can provide valuable insights for navigating today’s complex supply chain challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of suspension parts supplier

-

How do I solve supply chain disruptions when sourcing suspension parts?

To mitigate supply chain disruptions, establish strong relationships with multiple suppliers across different regions. Diversifying your supplier base can help reduce dependency on a single source and enhance flexibility. Additionally, consider using local suppliers for urgent needs, and implement a robust inventory management system that allows for real-time tracking of stock levels. Regular communication with suppliers can also provide insights into potential delays and help in proactive planning. -

What is the best way to vet a suspension parts supplier?

Vetting a suspension parts supplier involves several key steps. Start by checking their certifications and compliance with international standards, such as ISO or TS certifications. Request references from existing clients, especially those within your industry, to gain insights into their reliability and product quality. Conduct site visits if possible, and utilize third-party services to assess their manufacturing capabilities. Lastly, evaluate their financial stability to ensure they can meet your long-term needs. -

How can I ensure the quality of suspension parts from an international supplier?

To ensure quality, request detailed product specifications and certifications before placing orders. Implement a quality assurance process that includes pre-shipment inspections and testing of samples. Additionally, consider establishing a long-term partnership with suppliers who have proven track records in quality management. Regular audits and performance reviews can further help maintain quality standards and address any issues promptly. -

What are the typical minimum order quantities (MOQs) for suspension parts?

Minimum order quantities for suspension parts can vary significantly based on the supplier and the specific components required. Generally, MOQs can range from a few dozen to several hundred units. It’s advisable to discuss your needs directly with potential suppliers, as some may offer flexibility depending on your business relationship or the potential for future orders. Keep in mind that lower MOQs might result in higher per-unit costs. -

What payment terms should I expect when dealing with international suspension parts suppliers?

Payment terms can differ widely among suppliers, but common practices include upfront deposits (typically 30-50%) followed by balance payment upon shipment or delivery. Letters of credit (LC) are also popular for international transactions, providing security for both parties. Always clarify payment terms during negotiations and ensure they align with your cash flow capabilities. Be cautious of suppliers requiring full payment in advance, as this may indicate higher risk. -

How do I handle customs and logistics when importing suspension parts?

Handling customs and logistics requires careful planning and understanding of import regulations in your country. Collaborate with a freight forwarder who specializes in automotive parts to ensure compliance with customs documentation and tariffs. Familiarize yourself with the import duties applicable to suspension parts and consider using bonded warehouses if necessary. Timely communication with your supplier about shipping schedules can also help streamline the process. -

What should I consider regarding product customization with suspension parts suppliers?

When seeking product customization, clearly communicate your specifications and requirements to the supplier. Discuss their capacity for customization and the associated costs and lead times. It’s essential to review prototypes or samples before full production to ensure they meet your expectations. Additionally, consider the impact of customization on MOQs and delivery timelines, as bespoke products may require longer lead times and larger orders. -

How can I ensure timely delivery of suspension parts from international suppliers?

To ensure timely delivery, establish clear timelines and expectations with your supplier at the outset. Utilize a reliable logistics partner to manage shipping and track progress. Regular follow-ups with your supplier can help identify potential delays early on. Additionally, factor in extra time for customs clearance and unexpected disruptions, especially when dealing with international shipments. Maintaining a buffer stock can also help mitigate the impact of delivery delays on your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for suspension parts supplier

In today’s competitive landscape, effective strategic sourcing of suspension parts is crucial for international B2B buyers. By prioritizing quality, reliability, and cost-efficiency, businesses can significantly enhance their supply chain resilience. Sourcing from reputable suppliers not only ensures compliance with regional standards but also fosters long-term partnerships that can lead to innovation and improved product offerings.

International buyers from regions such as Africa, South America, the Middle East, and Europe must focus on diversifying their supplier base to mitigate risks associated with geopolitical uncertainties and supply chain disruptions. Leveraging technology, such as digital platforms for supplier evaluation and procurement, can streamline the sourcing process and enhance decision-making.

As we look to the future, the demand for high-quality suspension parts will continue to rise, driven by advancements in automotive technology and increasing consumer expectations. Buyers are encouraged to stay proactive by continuously monitoring market trends and emerging suppliers. This strategic approach not only secures a competitive edge but also contributes to sustainable growth in an evolving marketplace.

Engage with trusted suppliers today and explore the opportunities that strategic sourcing can unlock for your business. The right partnerships can elevate your operations and drive success in the global market.