Discover Top Thermistor Manufacturers: A Complete Buyer’s Guide (2025)

Introduction: Navigating the Global Market for thermistor manufacturer

In an increasingly interconnected world, sourcing high-quality thermistors can be a daunting task for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe (including key markets like Italy and Germany) expand, the demand for reliable temperature sensors grows. However, navigating the complexities of the global market poses significant challenges, from identifying reputable manufacturers to understanding pricing structures and application suitability. This guide aims to demystify the process of sourcing thermistors, providing insights that empower informed purchasing decisions.

Throughout this comprehensive resource, we will explore various types of thermistors, their diverse applications across different sectors, and the critical factors to consider when vetting suppliers. Additionally, we will delve into cost considerations, quality standards, and logistics, ensuring that you are well-equipped to make sound investments. By addressing common questions and concerns, this guide serves as a valuable tool for B2B buyers seeking to optimize their sourcing strategies and establish long-term partnerships with thermistor manufacturers.

Our goal is to facilitate a smoother purchasing journey, enabling you to confidently navigate the global landscape of thermistor manufacturing. With the right knowledge and insights at your disposal, you can enhance your operational efficiency, reduce risks, and ultimately drive success in your business endeavors.

Understanding thermistor manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NTC Thermistors | Decrease in resistance with increasing temperature | Automotive, HVAC, Consumer Electronics | Pros: High sensitivity, cost-effective. Cons: Limited temperature range. |

| PTC Thermistors | Increase in resistance with increasing temperature | Overcurrent protection, Temperature control | Pros: Self-resetting, reliable. Cons: Slower response time. |

| Glass-Encapsulated | Encased in glass for protection and stability | Industrial, Medical Devices | Pros: High durability, wide temperature range. Cons: Higher cost. |

| Surface Mount Thermistors | Compact design for automated assembly | Telecommunications, Consumer Goods | Pros: Space-efficient, easy integration. Cons: Limited power handling. |

| Thermistor Arrays | Multiple thermistors in a single package | Data Centers, Climate Control Systems | Pros: Space-saving, integrated solutions. Cons: Complexity in design. |

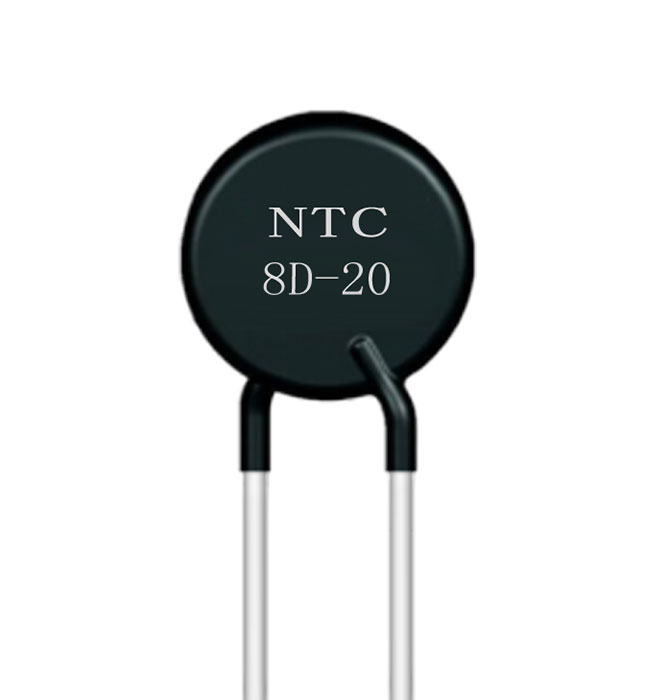

What are NTC Thermistors and Their Key B2B Considerations?

NTC (Negative Temperature Coefficient) thermistors are widely used in various applications due to their ability to provide high sensitivity to temperature changes. As the temperature increases, the resistance of NTC thermistors decreases, making them ideal for applications in automotive systems, HVAC units, and consumer electronics. When purchasing NTC thermistors, buyers should consider factors such as temperature range, response time, and accuracy, ensuring that the selected thermistor aligns with the specific operational requirements of their applications.

How Do PTC Thermistors Differ and What Should Buyers Know?

PTC (Positive Temperature Coefficient) thermistors exhibit an increase in resistance as the temperature rises, making them suitable for overcurrent protection and temperature control applications. They are self-resetting, which enhances reliability and minimizes maintenance costs. Buyers should evaluate the thermal characteristics, maximum current ratings, and response times of PTC thermistors to ensure they meet the protective needs of their systems. It’s also important to consider the potential trade-off of slower response times compared to NTC thermistors.

What Are the Advantages of Glass-Encapsulated Thermistors?

Glass-encapsulated thermistors are designed for demanding environments, providing excellent durability and stability. Encased in glass, these thermistors can withstand harsh conditions and are suitable for industrial and medical applications. Buyers should focus on the temperature range, sensitivity, and physical dimensions when selecting glass-encapsulated thermistors. While they offer superior performance and reliability, the higher cost may be a consideration for budget-conscious buyers.

Why Choose Surface Mount Thermistors for Your Applications?

Surface mount thermistors are compact components that facilitate automated assembly and are ideal for space-constrained applications such as telecommunications and consumer goods. Their design allows for efficient integration into circuit boards, making them an attractive option for manufacturers. Buyers should assess the power handling capabilities, thermal response, and mounting options to ensure compatibility with their designs. However, the limited power handling of these thermistors should be noted when considering their application.

What Are Thermistor Arrays and Their Benefits for B2B Buyers?

Thermistor arrays consist of multiple thermistors integrated into a single package, providing a space-saving solution for applications like data centers and climate control systems. These arrays can simplify design processes and reduce assembly time, making them appealing for manufacturers seeking efficiency. Buyers should consider the array’s configuration, individual thermistor characteristics, and thermal coupling effects. While they offer integrated solutions, the complexity of design and potential calibration challenges should be taken into account.

Related Video: Thermistor | Thermistor Types | NTC & PTC thermistor | Check thermistor | thermistor uses | working

Key Industrial Applications of thermistor manufacturer

| Industry/Sector | Specific Application of thermistor manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Temperature monitoring in electric vehicles | Enhanced safety and performance of vehicles | Compliance with automotive standards and reliability |

| HVAC Systems | HVAC temperature control systems | Improved energy efficiency and comfort | Durability in varying environmental conditions |

| Medical Devices | Patient temperature monitoring | Critical for patient safety and effective treatment | High precision and biocompatibility requirements |

| Industrial Automation | Process temperature management | Optimized production efficiency and reduced downtime | Scalability and integration with existing systems |

| Renewable Energy | Solar panel temperature regulation | Maximized energy output and system longevity | Resistance to environmental stressors and reliability |

How Are Thermistors Used in the Automotive Sector?

In the automotive industry, thermistors play a crucial role in temperature monitoring systems, particularly in electric vehicles. They ensure that battery packs operate within optimal temperature ranges, thereby enhancing both safety and performance. For international B2B buyers, especially from regions like Europe and the Middle East, sourcing thermistors that meet stringent automotive standards is essential. Buyers should prioritize manufacturers who offer high reliability and compliance certifications, as these factors directly impact vehicle safety and longevity.

What Role Do Thermistors Play in HVAC Systems?

In HVAC systems, thermistors are integral for precise temperature control, which is vital for both energy efficiency and user comfort. By providing real-time temperature data, thermistors enable systems to adjust heating and cooling outputs accordingly. For buyers in Africa and South America, where climate conditions can vary significantly, sourcing thermistors that can withstand extreme temperatures and humidity levels is crucial. Ensuring that suppliers can provide durable and reliable products tailored to local conditions can lead to significant operational savings.

How Are Thermistors Essential in Medical Devices?

Thermistors are pivotal in medical devices for patient temperature monitoring, where accuracy is critical. They help maintain patient safety during procedures and treatments by providing real-time temperature readings. B2B buyers from Europe, particularly in Italy and Germany, should focus on sourcing thermistors that meet high precision and biocompatibility standards. This ensures compliance with medical regulations and enhances the reliability of medical devices, ultimately leading to better patient outcomes.

How Do Thermistors Enhance Industrial Automation?

In industrial automation, thermistors are utilized for process temperature management, which is essential for optimizing production efficiency. By accurately monitoring temperature, businesses can reduce downtime caused by overheating equipment and ensure consistent product quality. For international buyers, particularly in South America and Africa, selecting thermistors that can easily integrate with existing systems and scale with production needs is vital. Buyers should seek suppliers who offer customization options to meet specific operational requirements.

Why Are Thermistors Important in Renewable Energy Applications?

Thermistors are used to regulate the temperature of solar panels, ensuring optimal energy output and extending system longevity. They help prevent overheating, which can lead to decreased efficiency and potential damage. For B2B buyers in the renewable energy sector, especially in Africa where solar energy is rapidly growing, sourcing thermistors that can withstand harsh environmental conditions is paramount. Reliability and resistance to temperature fluctuations are key factors to consider when selecting thermistors for solar applications.

Related Video: Thermistor Basics – NTC PTC

3 Common User Pain Points for ‘thermistor manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality of Thermistors in Supply Chain

The Problem:

For B2B buyers, particularly those in sectors like automotive or medical devices, the inconsistency in thermistor quality can lead to severe operational disruptions. For example, a manufacturer in Europe may source thermistors from multiple suppliers in Asia, only to find that the thermal response of these components varies significantly. Such discrepancies can result in faulty product performance, increased return rates, and ultimately damage to the brand’s reputation. The challenge is exacerbated when buyers are unaware of the quality standards and testing protocols used by different manufacturers.

The Solution:

To mitigate the risk of quality inconsistency, buyers should prioritize suppliers that provide detailed documentation on their quality assurance processes. This includes certifications such as ISO 9001 or IATF 16949, which indicate adherence to internationally recognized quality management systems. Additionally, buyers should request samples for rigorous testing in their own applications before committing to larger orders. Establishing a robust supplier relationship where ongoing quality assessments are part of the contract can also ensure that thermistors meet the required specifications consistently. Buyers should also consider working with local suppliers in their regions who are better aligned with their quality expectations and can provide more immediate support.

Scenario 2: Challenges in Thermistor Specification and Application

The Problem:

B2B buyers often face difficulties when it comes to specifying the right type of thermistor for their applications. For instance, a company in South America developing a new line of smart home devices may struggle to understand the differences between NTC and PTC thermistors and their respective applications. This lack of clarity can lead to selecting the wrong component, resulting in operational inefficiencies and costly redesigns.

The Solution:

To overcome this challenge, buyers should engage with thermistor manufacturers that offer comprehensive technical support and resources. Before making a purchase, buyers should take advantage of technical consultations or webinars provided by manufacturers to gain a better understanding of thermistor types and their specific applications. Additionally, developing a clear requirements document that outlines the application parameters—such as temperature range, response time, and environmental conditions—will help manufacturers recommend the best solutions. Buyers can also benefit from utilizing software tools or simulation models that allow them to visualize how different thermistors will perform in their specific applications.

Scenario 3: Navigating Compliance and Regulatory Standards

The Problem:

International B2B buyers, especially in sectors like healthcare and automotive, must navigate complex compliance and regulatory standards when sourcing thermistors. A manufacturer in the Middle East, for instance, may find it challenging to ensure that the thermistors they procure meet the stringent regulations set by European Union directives. Failure to comply can result in costly penalties and hinder market access.

The Solution:

To effectively navigate compliance challenges, buyers should partner with thermistor manufacturers who have experience in their specific industry regulations. It is crucial to ask potential suppliers about their compliance certifications and to review their product specifications against relevant regulatory frameworks, such as RoHS, REACH, or IEC standards. Additionally, buyers should consider engaging third-party testing services that can validate compliance and provide necessary documentation. Establishing a clear communication line with suppliers regarding compliance updates and regulatory changes can also ensure ongoing adherence to standards, thus safeguarding the buyer’s market position.

Strategic Material Selection Guide for thermistor manufacturer

What Are the Key Materials Used in Thermistor Manufacturing?

When selecting materials for thermistor manufacturing, it’s crucial to understand the properties, advantages, and limitations of each option. This knowledge enables international B2B buyers to make informed decisions that align with their specific application requirements. Below, we analyze four common materials used in thermistor production: ceramic, polymer, metal oxide, and glass.

How Do Ceramics Perform in Thermistor Applications?

Ceramics are widely used in thermistor manufacturing due to their excellent thermal stability and electrical insulation properties. They can typically withstand high temperatures, making them suitable for applications in harsh environments. Ceramics also exhibit low thermal conductivity, which is beneficial for precise temperature measurements.

Pros & Cons:

The durability of ceramic materials is a significant advantage, as they can resist mechanical stress and corrosion. However, they can be brittle, which may lead to breakage during handling or installation. Manufacturing complexity is moderate, often requiring specialized equipment for shaping and sintering.

Impact on Application:

Ceramics are compatible with various media, including gases and liquids, making them versatile for industrial applications. However, their brittleness may limit their use in environments with high vibration or shock.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as DIN and ASTM. The cost of ceramics can vary significantly based on the specific formulation and manufacturing processes used.

What Advantages Do Polymers Offer in Thermistor Manufacturing?

Polymers are increasingly popular in thermistor applications due to their flexibility and ease of processing. They can be tailored to meet specific thermal and electrical requirements, making them suitable for a wide range of applications, including consumer electronics and automotive systems.

Pros & Cons:

The primary advantage of polymers is their lightweight nature and resistance to chemical corrosion. However, they generally have lower temperature ratings compared to ceramics and can degrade over time when exposed to extreme conditions. Manufacturing complexity is low, which often translates to reduced costs.

Impact on Application:

Polymers are ideal for applications where weight and flexibility are critical. However, their lower temperature resistance may limit their use in high-temperature environments.

Considerations for International Buyers:

Buyers in South America and Africa should consider local climate conditions when selecting polymer materials, as extreme temperatures can affect performance. Compliance with international standards is also essential to ensure product reliability.

How Do Metal Oxides Contribute to Thermistor Performance?

Metal oxides, particularly those used in NTC (Negative Temperature Coefficient) thermistors, are known for their sensitivity to temperature changes. They provide excellent accuracy and stability, making them suitable for precise temperature measurements in various applications.

Pros & Cons:

Metal oxides offer high durability and can operate in a wide range of temperatures. However, they can be more expensive than other materials, and their manufacturing process can be complex due to the need for precise doping and sintering.

Impact on Application:

These materials are particularly effective in applications requiring high sensitivity, such as medical devices and industrial temperature monitoring systems. Their compatibility with various environments makes them a versatile choice.

Considerations for International Buyers:

Buyers from Europe, especially Germany, should be aware of the stringent regulations surrounding electronic components. Ensuring compliance with IEC and JIS standards is crucial for market acceptance.

What Role Does Glass Play in Thermistor Manufacturing?

Glass is another material used for thermistors, particularly in applications requiring high thermal stability and resistance to environmental factors. Glass thermistors can operate effectively in extreme conditions, making them suitable for industrial and scientific applications.

A stock image related to thermistor manufacturer.

Pros & Cons:

The key advantage of glass is its ability to withstand high temperatures and corrosive environments. However, glass can also be brittle, posing challenges during installation and transport. The manufacturing process can be complex and costly.

Impact on Application:

Glass thermistors are ideal for applications where high accuracy and stability are required, such as in laboratories and high-temperature industrial processes. Their resistance to various media enhances their versatility.

Considerations for International Buyers:

International buyers should consider the logistics of transporting fragile glass components, especially in regions with less developed infrastructure. Compliance with international standards is also necessary to ensure quality and reliability.

Summary Table of Material Selection for Thermistor Manufacturing

| Material | Typical Use Case for thermistor manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ceramics | High-temperature industrial applications | Excellent thermal stability | Brittle and prone to breakage | Medium |

| Polymers | Consumer electronics and automotive systems | Lightweight and flexible | Lower temperature resistance | Low |

| Metal Oxides | Medical devices and industrial monitoring | High sensitivity and accuracy | Higher cost and complex manufacturing | High |

| Glass | Laboratories and high-temperature processes | High thermal stability and resistance | Brittle and complex manufacturing process | Medium |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in thermistor manufacturing, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for thermistor manufacturer

What Are the Key Stages in the Manufacturing Process of Thermistors?

The manufacturing process for thermistors involves several critical stages that ensure the final product meets the necessary specifications for performance and reliability. Understanding these stages can help B2B buyers identify the capabilities and quality of potential suppliers.

-

Material Preparation

– The first step in manufacturing thermistors is the preparation of raw materials. This typically includes metal oxides like manganese, nickel, and cobalt, which are blended to create a ceramic material. The quality of these materials is crucial, as they directly affect the thermistor’s resistance-temperature characteristics. Suppliers should provide certifications for the materials used, including their chemical composition and sourcing. -

Forming

– After material preparation, the mixture is shaped into the desired form. Common techniques include pressing and extrusion, depending on the type of thermistor being produced. The forming stage must be conducted under controlled conditions to ensure uniformity and precision. B2B buyers should inquire about the methods used and the machinery involved, as advanced technology can lead to higher quality products. -

Assembly

– In this stage, the formed components are assembled into the final thermistor configuration. This can include attaching leads and encapsulating the thermistor in protective materials. Automation plays a significant role in modern assembly lines, contributing to consistency and efficiency. Buyers should assess the supplier’s assembly capabilities, including whether they employ automated systems or manual labor, as this can impact lead times and costs. -

Finishing

– The finishing stage involves applying any necessary coatings and conducting final inspections. This may include soldering connections and ensuring that the thermistors are properly packaged for shipment. Quality finishing not only protects the thermistors during transit but also enhances their performance. B2B buyers should ensure that suppliers follow best practices in finishing to avoid potential issues down the line.

How Is Quality Assurance Implemented in Thermistor Manufacturing?

Quality assurance (QA) is integral to thermistor manufacturing, ensuring that products meet international and industry-specific standards. Understanding QA processes can help B2B buyers make informed decisions when selecting suppliers.

-

What International Standards Are Relevant for Thermistor Manufacturing?

– Many thermistor manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to maintaining high-quality processes and continuous improvement. Additionally, industry-specific certifications like CE marking and API standards may apply, depending on the application of the thermistors. -

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

– Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that each thermistor meets the required specifications. Key checkpoints include:- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify any deviations in real-time.

- Final Quality Control (FQC): The final products undergo comprehensive testing to verify their performance and compliance before shipping.

-

What Common Testing Methods Are Used for Thermistors?

– Various testing methods are employed to assess the performance and reliability of thermistors. Common tests include:- Resistance-Temperature Characteristic Testing: This ensures that the thermistor’s resistance changes predictably with temperature.

- Stability Testing: Assessing how the thermistor performs over time under varying environmental conditions.

- Electrical Testing: Verifying the electrical integrity and performance under specific loads.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are several strategies to ensure that the supplier meets the required standards:

-

Conducting Supplier Audits

– One of the most effective ways to assess a supplier’s quality control processes is through on-site audits. Buyers should request to visit the manufacturing facility to observe the QC practices in place. This provides an opportunity to evaluate the supplier’s adherence to international standards and internal protocols. -

Requesting Quality Control Reports

– Suppliers should be able to provide documentation of their quality control processes, including reports from IQC, IPQC, and FQC. These reports can highlight any issues encountered during manufacturing and the corrective actions taken, offering insights into the supplier’s commitment to quality. -

Engaging Third-Party Inspectors

– For buyers who may not have the resources to conduct audits, engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. These agencies can conduct random inspections and testing to verify compliance with international standards.

What Are the Specific Quality Control Considerations for International Buyers?

When sourcing thermistors from suppliers in different regions, B2B buyers must consider various quality control nuances:

-

Understanding Regional Standards

– Different countries may have specific quality and safety standards for electronic components. Buyers should familiarize themselves with these regulations to ensure compliance. For example, European buyers need to be aware of CE marking requirements, while buyers from Africa or South America may encounter different compliance frameworks. -

Navigating Language and Cultural Barriers

– Effective communication is crucial in quality assurance. Buyers should ensure that there are no language barriers that could lead to misunderstandings regarding quality expectations. It may be beneficial to work with suppliers who have experience exporting to your region and understand the local market’s requirements. -

Evaluating Supply Chain Stability

– The stability of a supplier’s supply chain can significantly impact quality control. Buyers should assess the supplier’s ability to source high-quality materials consistently and whether they have contingency plans in place to mitigate risks.

A stock image related to thermistor manufacturer.

By understanding the manufacturing processes and quality assurance practices involved in thermistor production, B2B buyers can make informed decisions when selecting suppliers. This insight not only enhances product reliability but also fosters long-term partnerships that drive business success across international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermistor manufacturer’

Introduction

Sourcing thermistors effectively is crucial for international B2B buyers aiming to enhance their product offerings and meet market demands. This guide provides a structured checklist designed to streamline your procurement process, ensuring you select the right thermistor manufacturer that aligns with your specific needs and standards. By following these steps, you will mitigate risks and improve your sourcing outcomes.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s vital to have a clear understanding of your technical requirements. This includes defining the type of thermistor needed (NTC or PTC), temperature range, resistance values, and physical dimensions. Establishing these specifications early on helps you communicate effectively with potential suppliers and ensures compatibility with your applications.

- Consider Application Needs: Identify the specific applications your thermistors will be used in, such as automotive, consumer electronics, or industrial equipment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify a shortlist of thermistor manufacturers. Use online directories, trade shows, and industry publications to find reputable suppliers. Pay attention to their expertise, production capabilities, and market presence.

- Leverage Industry Networks: Reach out to industry peers or associations for recommendations on reliable manufacturers.

Step 3: ✅ Verify Supplier Certifications

It’s essential to ensure that potential suppliers have the necessary certifications and quality assurance processes in place. Check for ISO certifications, compliance with relevant industry standards, and any specific regulations pertinent to your region.

- Request Documentation: Ask suppliers for copies of their certifications and quality control processes to verify compliance.

Step 4: Evaluate Supplier Capabilities

Assess the manufacturing capabilities and technology used by potential suppliers. Understanding their production processes, capacity, and lead times is crucial for ensuring they can meet your demands without compromising quality.

- Inquire About Customization: If your project requires specific designs, check if the manufacturer can accommodate custom solutions.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the thermistors you intend to buy. Testing samples allows you to evaluate their performance in real-world conditions and ensure they meet your specifications.

- Conduct Comprehensive Testing: Perform reliability tests, temperature response evaluations, and compatibility checks with your systems.

Step 6: Assess Pricing and Payment Terms

Once you have evaluated the samples, discuss pricing structures and payment terms with your shortlisted suppliers. Ensure you understand the total cost of ownership, including shipping and customs duties, to avoid unexpected expenses.

- Negotiate Terms: Don’t hesitate to negotiate terms that can lead to better pricing or extended payment options, particularly if you’re making a large order.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Ensure that the supplier has a dedicated point of contact who can provide timely updates on production status, shipping timelines, and any issues that may arise.

- Set Expectations Early: Clearly outline your communication preferences and expectations regarding response times and updates to foster a smooth collaboration.

By following this checklist, international B2B buyers can navigate the complexities of sourcing thermistors, ensuring they partner with manufacturers that meet their technical, quality, and logistical needs.

Comprehensive Cost and Pricing Analysis for thermistor manufacturer Sourcing

What Are the Key Cost Components in Thermistor Manufacturing?

Understanding the cost structure of thermistor manufacturing is crucial for B2B buyers seeking to optimize their sourcing strategies. The primary cost components typically include:

-

Materials: The raw materials used in thermistor production, such as semiconductor materials and substrate components, significantly impact the overall cost. Fluctuations in the prices of these materials due to market demand can lead to cost variability.

-

Labor: Skilled labor is essential for the manufacturing process. Labor costs can vary greatly depending on the region, with countries in Europe generally having higher wage standards compared to those in Africa or South America.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, contributing to a more favorable pricing structure.

-

Tooling: The initial investment in tooling can be significant, especially for custom thermistor designs. Buyers should consider whether the tooling costs can be amortized over a larger production volume.

-

Quality Control (QC): Ensuring product quality often requires additional investment in testing and certification processes. Certifications such as ISO or RoHS compliance can elevate costs but are crucial for meeting international standards.

-

Logistics: Transportation and shipping costs are pivotal, particularly for international buyers. Incoterms can also affect the final pricing, as they define the responsibilities of buyers and sellers concerning shipping.

-

Margin: Manufacturers typically build in a profit margin that varies by supplier and market conditions. Understanding this margin can help buyers negotiate better prices.

How Do Price Influencers Impact Thermistor Sourcing?

Several factors can influence the pricing of thermistors, and international buyers should be aware of these nuances:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Custom thermistors with specific specifications generally incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: The choice of materials and the necessary certifications can significantly impact pricing. Premium materials may lead to higher costs, but they can also enhance product performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may offer higher-quality products at a premium, while new entrants may have lower prices but unproven quality.

-

Incoterms: Understanding Incoterms is essential for managing shipping costs and responsibilities. Different terms can lead to variations in total costs, affecting the overall pricing strategy.

What Are the Best Negotiation Tips for International B2B Buyers?

When sourcing thermistors, particularly from regions like Africa, South America, the Middle East, and Europe, buyers can employ various strategies to enhance cost efficiency:

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just the initial purchase price. This includes considering logistics, quality control, and potential warranty costs. A lower upfront cost may not always result in long-term savings.

-

Leverage Volume Discounts: When possible, consolidate orders to achieve higher volumes. This can lead to better pricing and reduced shipping costs.

-

Build Relationships with Suppliers: Establishing long-term relationships with manufacturers can lead to more favorable terms and pricing. Trust and reliability are often rewarded with better deals.

-

Negotiate Terms and Conditions: Be prepared to negotiate not just price but also payment terms, delivery schedules, and return policies. Flexibility in these areas can lead to overall cost savings.

-

Stay Informed About Market Trends: Understanding fluctuations in material costs and market dynamics can provide leverage in negotiations. Being informed allows buyers to time their purchases strategically.

Final Thoughts on Sourcing Thermistors

While this analysis provides a framework for understanding the costs and pricing of thermistors, it’s essential to note that prices can vary widely based on numerous factors. Buyers should conduct thorough research and consider multiple suppliers to ensure they secure the best possible deal for their specific needs. By leveraging the insights provided here, B2B buyers can navigate the complexities of thermistor sourcing effectively.

Alternatives Analysis: Comparing thermistor manufacturer With Other Solutions

Understanding Alternatives to Thermistor Manufacturers

In the realm of temperature sensing and monitoring, thermistors are widely recognized for their precision and reliability. However, businesses often seek alternative solutions that may better suit their specific applications, budget constraints, or operational environments. This analysis provides a comparative overview of thermistor manufacturers against two viable alternatives: resistance temperature detectors (RTDs) and semiconductor temperature sensors. By understanding these options, B2B buyers can make informed decisions based on their unique requirements.

Comparison Table of Temperature Sensing Solutions

| Comparison Aspect | Thermistor Manufacturer | Resistance Temperature Detector (RTD) | Semiconductor Temperature Sensor |

|---|---|---|---|

| Performance | High sensitivity and accuracy at specific ranges | Excellent linearity and wide temperature range | Moderate accuracy, quick response time |

| Cost | Generally cost-effective for high-volume applications | Higher initial investment, but long-term reliability | Low-cost, mass-produced units |

| Ease of Implementation | Simple integration in circuits | Requires careful calibration and installation | Easy to integrate with digital systems |

| Maintenance | Low maintenance needs | Moderate, requires periodic calibration | Minimal maintenance required |

| Best Use Case | Medical devices, HVAC systems | Industrial applications, laboratory settings | Consumer electronics, automotive applications |

What Are the Advantages and Disadvantages of Resistance Temperature Detectors (RTDs)?

RTDs are known for their superior accuracy and stability over a broad temperature range, making them ideal for industrial and laboratory settings. They provide excellent linearity and can handle higher temperatures than thermistors, which makes them suitable for demanding applications. However, the initial cost of RTDs can be significantly higher, and they often require more complex calibration processes. This can lead to increased setup time and expenses, which may not be feasible for all businesses.

How Do Semiconductor Temperature Sensors Compare in Performance and Cost?

Semiconductor temperature sensors are typically less expensive and widely available, making them an attractive option for businesses looking to minimize costs. They offer quick response times and are ideal for applications in consumer electronics and automotive sectors. However, their accuracy is generally lower compared to thermistors and RTDs, which may be a crucial factor for applications requiring precise temperature control. Additionally, while they are easy to integrate into digital systems, the trade-off may be in sensitivity and reliability in extreme conditions.

How Can B2B Buyers Choose the Right Temperature Sensing Solution?

When selecting the appropriate temperature sensing technology, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and the operational environment. For example, if high accuracy and stability are paramount for industrial processes, RTDs may be the best choice despite their higher cost. Conversely, for applications where cost and rapid response are critical, semiconductor sensors may provide the best value. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make a choice that aligns with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for thermistor manufacturer

What Are the Critical Technical Properties of Thermistors?

When sourcing thermistors for industrial applications, understanding their technical properties is essential for making informed purchasing decisions. Below are some critical specifications that international B2B buyers should consider:

1. Material Grade: Why Is It Important?

Thermistors are primarily made from ceramic materials or polymer composites. The choice of material affects the thermistor’s thermal stability, resistance range, and sensitivity. For example, NTC (Negative Temperature Coefficient) thermistors are typically made from metal oxides, offering high sensitivity and accuracy for temperature measurement. Buyers should assess material grades to ensure compatibility with their specific applications, particularly in environments with extreme temperatures.

2. Tolerance: How Does It Affect Performance?

Tolerance refers to the allowable deviation from a specified resistance value at a given temperature. Common tolerances for thermistors range from ±1% to ±10%. A lower tolerance indicates higher accuracy, which is crucial in applications requiring precise temperature control, such as in medical devices or aerospace. Understanding tolerance levels helps buyers evaluate whether a thermistor meets their operational needs.

3. Resistance Value: What Should You Look For?

The resistance value at a specific temperature (often 25°C) is another key property. This value determines how the thermistor will behave in a circuit and influences its sensitivity to temperature changes. Buyers need to select resistance values that align with their system’s requirements. For example, a 10kΩ thermistor might be ideal for a specific application, but its performance will vary if used inappropriately.

4. Temperature Coefficient: What Is Its Role?

The temperature coefficient indicates how much the resistance changes with temperature. This property is typically expressed in parts per million (ppm) per degree Celsius. A high temperature coefficient means the thermistor will respond more significantly to temperature changes, making it suitable for applications like HVAC systems. Buyers should consider their operational temperature ranges when evaluating this property.

5. Thermal Time Constant: Why Is It Relevant?

The thermal time constant represents how quickly a thermistor can respond to temperature changes. A lower time constant indicates a quicker response, which is essential in dynamic environments where temperature fluctuates rapidly. For applications in automotive or industrial processes, understanding this characteristic can enhance system performance.

What Are Common Trade Terms in the Thermistor Industry?

Familiarizing yourself with industry-specific terminology can streamline communications and negotiations with manufacturers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For thermistor buyers, partnering with OEMs ensures that the components meet specific industry standards and are reliable for integration into larger systems.

2. MOQ (Minimum Order Quantity): How Does It Impact Purchases?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or supply shortages.

3. RFQ (Request for Quotation): What Is Its Purpose?

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. For B2B buyers, issuing RFQs can lead to competitive pricing and better service terms. It’s a vital step in the procurement process that helps in budget planning.

4. Incoterms: Why Are They Important for International Trade?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade, including shipping costs, risk transfer, and delivery obligations. Understanding Incoterms is essential for avoiding misunderstandings and ensuring smooth transactions, especially for buyers from regions like Africa and South America.

5. Lead Time: What Should You Expect?

Lead time refers to the time it takes from placing an order to receiving the goods. This term is critical for inventory management and project planning. Buyers should always clarify lead times with manufacturers to align with their production schedules.

Understanding these technical properties and trade terms can significantly enhance the purchasing process for thermistors, ensuring that B2B buyers make informed decisions that meet their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the thermistor manufacturer Sector

What Are the Current Market Dynamics and Key Trends Affecting Thermistor Manufacturers?

The thermistor manufacturing sector is witnessing significant changes driven by technological advancements, global supply chain shifts, and evolving consumer demands. One of the primary global drivers is the increasing demand for temperature-sensitive applications across various industries, such as automotive, healthcare, and industrial automation. As these sectors embrace the Internet of Things (IoT), the need for precise temperature measurement and control systems becomes crucial. This trend fosters innovation in thermistor design and functionality, pushing manufacturers to enhance their product offerings.

Emerging B2B tech trends, such as digital transformation and Industry 4.0, are reshaping the sourcing landscape. Manufacturers are leveraging advanced analytics and machine learning to optimize production processes and improve product quality. Furthermore, international B2B buyers are increasingly looking for suppliers that can offer customization and rapid prototyping services, enabling them to tailor thermistors to specific applications. This shift not only enhances product performance but also strengthens supplier relationships through collaborative innovation.

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional market dynamics is vital. Variations in regulatory requirements, local manufacturing capabilities, and economic conditions can significantly influence sourcing strategies. Buyers must stay informed about geopolitical developments and trade agreements that could affect supply chains, ensuring they select suppliers that can navigate these complexities effectively.

How Is Sustainability Influencing Sourcing Decisions in the Thermistor Manufacturing Sector?

Sustainability is becoming a cornerstone of sourcing decisions in the thermistor manufacturing sector. The environmental impact of manufacturing processes has come under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. For international B2B buyers, this means looking for manufacturers that utilize sustainable materials and implement energy-efficient production methods.

Ethical sourcing is equally important, as companies increasingly recognize the value of transparent supply chains. Buyers are encouraged to assess suppliers based on their adherence to ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a manufacturer’s commitment to sustainability.

In addition, the rise of ‘green’ materials, such as bioplastics and recycled components, is reshaping product offerings. Buyers should inquire about the availability of thermistors that incorporate these materials, as they can contribute to reduced carbon footprints and align with corporate sustainability goals. This shift not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

What Is the Evolution of the Thermistor Manufacturing Industry?

The thermistor manufacturing industry has evolved significantly since its inception in the mid-20th century. Initially developed as a simple temperature-sensing device, thermistors have transformed into sophisticated components integral to modern technology. The introduction of digital technology in the 1980s and 1990s marked a turning point, enabling the miniaturization and integration of thermistors into a wide range of electronic devices.

As industries have become more automated and reliant on precise temperature control, the demand for high-performance thermistors has surged. This evolution has prompted manufacturers to invest in research and development, leading to innovations that improve accuracy, response time, and thermal stability. Today, thermistors are not only used in traditional applications but are also critical in emerging fields such as smart home technology and renewable energy systems.

Understanding this historical context provides international B2B buyers with insights into the reliability and technological advancements of thermistor products, guiding them in making informed purchasing decisions that align with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of thermistor manufacturer

-

How do I choose the right thermistor manufacturer for my needs?

Selecting the ideal thermistor manufacturer requires assessing several factors. Start by evaluating their industry experience and expertise in producing thermistors that match your specific application. Check for certifications such as ISO 9001, which indicate quality management standards. Additionally, request samples to test product performance. It’s also beneficial to read client testimonials and case studies to gauge reliability and support. Lastly, consider their geographical location and logistical capabilities, especially if you are sourcing from regions like Africa or South America, which may face unique supply chain challenges. -

What are the key factors to consider when evaluating thermistor quality?

When assessing thermistor quality, focus on the manufacturer’s testing processes and quality assurance protocols. Look for detailed specifications regarding temperature range, resistance tolerance, and response time. Inquire about their compliance with international standards such as RoHS and REACH, which ensure safety and environmental responsibility. Additionally, request information about their production methods, including whether they utilize automated systems that enhance precision. Establishing a relationship with the manufacturer can also provide insights into their commitment to quality. -

What customization options are available when sourcing thermistors?

Many thermistor manufacturers offer customization options to meet specific application requirements. These may include variations in resistance values, temperature coefficients, and packaging types. When discussing customization, clearly communicate your application needs, including environmental factors and integration requirements. Some manufacturers may also provide tailored thermal profiles or packaging solutions for unique environments, such as high humidity or extreme temperatures. Always confirm lead times for customized orders, as these can differ significantly from standard products. -

What are the typical minimum order quantities (MOQs) for thermistors?

Minimum order quantities can vary widely among thermistor manufacturers, often depending on the type of thermistor and the level of customization required. Standard thermistors might have lower MOQs, while custom orders could demand higher quantities. It’s essential to clarify MOQs during the initial discussions to avoid unexpected costs. If your needs do not meet the MOQ, some manufacturers may offer the option to combine orders with other clients, especially in international markets like Europe and the Middle East. -

What payment terms should I expect when sourcing thermistors internationally?

Payment terms for international thermistor purchases can vary based on the manufacturer and the buyer’s location. Common terms include advance payment, net 30, or letter of credit. It’s important to negotiate terms that suit your cash flow and risk appetite. In regions such as Africa and South America, consider factors like currency exchange rates and transaction fees. Always ensure that payment terms are clearly outlined in your purchase agreement to prevent misunderstandings. -

How can I ensure reliable logistics and timely delivery of thermistors?

Ensuring reliable logistics begins with selecting a manufacturer experienced in international shipping. Discuss their shipping options, including express and standard delivery, and inquire about their partnerships with logistics providers. It’s also advisable to understand customs regulations in your region to avoid delays. Establishing clear communication channels with the manufacturer regarding tracking and delivery timelines is essential. If you’re operating in regions with complex logistics, consider working with a local freight forwarder to streamline the process. -

What quality assurance processes should I expect from a thermistor manufacturer?

Reputable thermistor manufacturers implement robust quality assurance processes to guarantee product reliability. Look for manufacturers that conduct thorough testing at various stages of production, including incoming material inspections, in-process quality checks, and final product testing. Certifications such as ISO 9001 or IATF 16949 indicate adherence to high-quality standards. Additionally, ask about their procedures for handling defective products and whether they offer warranties or guarantees, which can provide peace of mind for international buyers. -

How can I vet a thermistor manufacturer before making a purchase?

Vetting a thermistor manufacturer is crucial to ensure a successful partnership. Start by researching their reputation in the industry, looking for reviews and testimonials from other B2B buyers. Request references and case studies to understand their experience in your specific sector. Conduct site visits if possible, or arrange virtual tours to assess their manufacturing capabilities. Additionally, consider their financial stability and customer service responsiveness, as these factors can significantly impact your long-term relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for thermistor manufacturer

In conclusion, strategic sourcing for thermistors is paramount for international B2B buyers seeking reliable suppliers that can meet diverse market needs. By focusing on key factors such as quality assurance, supplier reliability, and cost-effectiveness, businesses in Africa, South America, the Middle East, and Europe can foster strong partnerships with thermistor manufacturers. The ability to source components that align with specific technical requirements not only enhances product performance but also drives innovation and competitiveness in various applications, from automotive to industrial electronics.

How Can B2B Buyers Leverage Market Trends in Thermistor Sourcing?

As we look to the future, it is essential for international buyers to stay informed about emerging market trends, technological advancements, and regional manufacturing capabilities. This knowledge enables companies to make informed decisions about their sourcing strategies, ensuring they remain ahead of the curve in an increasingly competitive landscape.

What Steps Should Buyers Take to Optimize Their Sourcing Strategy?

Engaging in proactive communication with suppliers, investing in quality assessments, and considering local sourcing options can significantly enhance procurement outcomes. By adopting a comprehensive approach to strategic sourcing, businesses can secure high-quality thermistors that meet their specifications while optimizing costs.

As we move forward, we encourage international B2B buyers to take actionable steps today to strengthen their sourcing strategies. By doing so, they can ensure access to the most innovative thermistor solutions, driving their business success in the global market.