Discover Top Thread Manufacturers: Save Costs & Improve Quality (2025)

Introduction: Navigating the Global Market for thread manufacturer

In an increasingly interconnected world, sourcing high-quality thread manufacturers can be a daunting challenge for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the complexities of navigating diverse markets, regulatory environments, and varying supplier capabilities can complicate the procurement process. This guide aims to simplify your journey by providing a comprehensive overview of the thread manufacturing landscape.

You will explore various types of threads, their applications across industries, and essential criteria for vetting suppliers effectively. Additionally, we will delve into cost considerations and negotiation tactics that empower you to make informed purchasing decisions. By understanding the nuances of the global thread market, you will be better equipped to identify reliable suppliers that meet your specific needs, ensuring quality and compliance.

This guide is tailored to meet the unique challenges faced by B2B buyers from regions such as Germany and South Africa, offering actionable insights that enhance your sourcing strategies. Whether you are looking to streamline your supply chain or enhance product quality, the information provided will serve as a vital resource in your procurement toolkit. Embrace the opportunity to transform your sourcing approach and foster long-term partnerships with reputable thread manufacturers globally.

Understanding thread manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotton Thread Manufacturers | Utilizes natural fibers, eco-friendly options | Textile, fashion, upholstery | Pros: Sustainable, breathable. Cons: Less durable than synthetic. |

| Polyester Thread Manufacturers | Made from synthetic fibers, high tensile strength | Industrial sewing, automotive, outdoor gear | Pros: Strong, resistant to shrinking. Cons: Can be less breathable. |

| Nylon Thread Manufacturers | Known for elasticity and strength | Outdoor products, heavy-duty applications | Pros: Durable, resistant to abrasion. Cons: Can be more expensive. |

| Metallic Thread Manufacturers | Incorporates metallic fibers for aesthetics | Embroidery, decorative sewing | Pros: Eye-catching, unique finish. Cons: Can be difficult to work with. |

| Specialty Thread Manufacturers | Customized threads for specific applications | Medical, automotive, technical textiles | Pros: Tailored solutions, innovative. Cons: Higher costs, longer lead times. |

What Are the Characteristics of Cotton Thread Manufacturers?

Cotton thread manufacturers produce threads primarily from natural cotton fibers, which offer an eco-friendly alternative for various applications. They are particularly popular in textiles, fashion, and upholstery due to their breathable nature and comfort. However, while cotton threads are sustainable, they are less durable compared to synthetic options, making them less suitable for high-stress applications. B2B buyers should consider the balance between sustainability and durability when selecting cotton threads for their products.

How Do Polyester Thread Manufacturers Stand Out?

Polyester thread manufacturers focus on creating strong, synthetic threads that are widely used in industrial sewing, automotive applications, and outdoor gear. Polyester threads are known for their resistance to shrinking and fading, making them ideal for products exposed to harsh conditions. While they provide excellent strength and durability, buyers should note that polyester threads can be less breathable, which may be a consideration for specific applications where comfort is paramount.

What Makes Nylon Thread Manufacturers a Good Choice?

Nylon thread manufacturers offer threads that are highly elastic and exceptionally strong, making them suitable for outdoor products and heavy-duty applications. The durability and resistance to abrasion of nylon threads make them a preferred choice for items that experience significant wear and tear. However, B2B buyers should be aware that nylon threads can be more expensive than other options, so it’s essential to evaluate whether the added cost aligns with the product’s intended use.

Why Consider Metallic Thread Manufacturers?

Metallic thread manufacturers produce threads that incorporate metallic fibers, providing a unique aesthetic for embroidery and decorative sewing projects. These threads are ideal for applications where visual appeal is crucial, such as in fashion and decorative textiles. While they can create stunning finishes, buyers should be cautious as metallic threads can be more challenging to work with and may require specific sewing techniques to avoid breakage.

What Are the Benefits of Specialty Thread Manufacturers?

Specialty thread manufacturers focus on creating customized threads tailored for specific applications, such as medical textiles or automotive uses. These threads often incorporate innovative materials and designs to meet unique performance requirements. While specialty threads can provide tailored solutions that enhance product functionality, they may come at a higher cost and longer lead times. B2B buyers should assess the trade-off between customization and budget constraints when considering specialty threads for their projects.

Related Video: 90 Second Threading – Thread Forming – Screw Threads – Bolt Threads – Screw Manufacturing

Key Industrial Applications of thread manufacturer

| Industry/Sector | Specific Application of Thread Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile and Apparel | Production of high-performance fabrics | Enhanced durability and quality of end products | Certifications, raw material quality, and production capacity |

| Automotive | Manufacturing of seatbelts and upholstery | Improved safety features and customer satisfaction | Compliance with safety standards, material specifications |

| Medical Devices | Creation of sutures and medical textiles | Critical for patient safety and effective healing | Biocompatibility, regulatory compliance, and traceability |

| Furniture and Upholstery | Upholstery for sofas and chairs | Aesthetic appeal and durability in furniture products | Fabric compatibility, color matching, and design flexibility |

| Industrial Textiles | Heavy-duty stitching for tarps and tents | Increased strength and weather resistance | UV resistance, tensile strength, and environmental factors |

How is Thread Manufacturer Used in Textile and Apparel Industries?

In the textile and apparel industry, thread manufacturers supply high-performance threads that are crucial for producing durable fabrics. These threads enhance the overall quality of clothing, ensuring longevity and resistance to wear and tear. For B2B buyers, particularly in Africa and South America, sourcing threads that meet specific certifications and quality standards is essential to maintain competitive pricing and market acceptance. Additionally, understanding local production capabilities can help in negotiating better terms and ensuring timely delivery.

What Role Does Thread Manufacturer Play in the Automotive Sector?

In the automotive sector, thread manufacturers provide specialized threads used in the production of seatbelts and upholstery. These threads must meet stringent safety standards to enhance the safety features of vehicles. Buyers from Europe, especially Germany, need to consider compliance with European safety regulations when sourcing these materials. Additionally, factors such as material specifications and the manufacturer’s ability to deliver consistent quality over time are critical for maintaining brand reputation.

How Are Thread Manufacturers Integral to Medical Device Production?

Thread manufacturers are vital in the medical device sector, supplying threads for sutures and other medical textiles. The quality and biocompatibility of these threads are paramount, as they directly impact patient safety and healing effectiveness. For international buyers in the Middle East, understanding regulatory compliance and traceability of materials is crucial for sourcing decisions. Ensuring that suppliers can provide documentation of biocompatibility and adhere to medical standards is essential for successful procurement.

In What Ways Are Thread Manufacturers Important for Furniture and Upholstery?

In the furniture and upholstery industry, thread manufacturers provide threads that enhance the aesthetic appeal and durability of sofas, chairs, and other furniture items. Buyers need to consider fabric compatibility and color matching when sourcing threads to ensure a cohesive design. For international buyers, especially from Europe, the ability to customize thread specifications and receive samples for evaluation can significantly influence purchasing decisions.

How Do Thread Manufacturers Support Industrial Textiles Applications?

For industrial textiles, thread manufacturers supply heavy-duty threads that are essential for stitching tarps, tents, and other outdoor equipment. These threads must exhibit high tensile strength and UV resistance to withstand harsh environmental conditions. B2B buyers from Africa and South America should prioritize sourcing threads that meet these durability requirements while also considering local climate factors to ensure product longevity. Understanding the environmental implications of thread materials can also be a significant factor in sourcing decisions.

3 Common User Pain Points for ‘thread manufacturer’ & Their Solutions

Scenario 1: Quality Inconsistencies in Thread Supply

The Problem: International B2B buyers often face challenges with quality inconsistencies when sourcing threads from manufacturers. This is particularly problematic when businesses rely on threads for critical applications in textiles, automotive, or industrial products. Buyers may receive batches with variations in strength, color, or texture, leading to production delays, increased costs, and potential damage to their brand reputation.

The Solution: To mitigate these quality concerns, buyers should establish a comprehensive quality assurance process with their thread manufacturers. This includes requesting detailed specifications and samples before placing large orders. Implementing a strict vendor selection criterion that focuses on ISO certifications and industry standards can also significantly enhance quality assurance. Furthermore, buyers should negotiate agreements that include quality control measures, such as third-party inspections or periodic audits, ensuring that each batch meets the required standards before shipment. Regular communication with manufacturers about quality expectations and feedback can foster a collaborative relationship that prioritizes consistent quality.

Scenario 2: Complex Supply Chain Logistics

The Problem: Many B2B buyers encounter difficulties with the logistics of sourcing threads internationally, particularly when dealing with suppliers from Africa, South America, or the Middle East. Issues such as delayed shipments, customs complications, and fluctuating shipping costs can disrupt production schedules and lead to financial losses.

The Solution: To navigate these logistical challenges effectively, buyers should consider working with local sourcing agents who have expertise in the region. These agents can provide valuable insights into the local supply chain, assist with customs processes, and ensure that shipments adhere to local regulations. Additionally, establishing a buffer stock of threads can help mitigate the impact of delays, allowing businesses to maintain production levels while waiting for new supplies. Buyers should also explore the option of multi-sourcing from different manufacturers to diversify their supply base and reduce dependence on a single supplier. This strategy can enhance resilience against disruptions in the supply chain.

Scenario 3: Limited Customization Options

The Problem: B2B buyers often struggle with manufacturers that offer limited customization options for thread specifications, which can hinder their ability to meet unique product requirements. This is particularly critical for industries like fashion or automotive, where specific thread attributes—such as color, thickness, or material composition—are essential for product differentiation and performance.

The Solution: To overcome this limitation, buyers should engage with manufacturers who specialize in custom thread solutions. This involves clearly communicating their specific needs, including technical requirements and desired outcomes. Requesting prototypes or small test runs can help buyers assess the manufacturer’s ability to deliver customized solutions before committing to larger orders. Furthermore, buyers should prioritize manufacturers that have a track record of flexibility and innovation in their product offerings. Establishing long-term partnerships with these manufacturers can also lead to better terms for customization, allowing buyers to influence product development that aligns with their business needs.

Strategic Material Selection Guide for thread manufacturer

What Are the Key Materials Used in Thread Manufacturing?

When selecting materials for thread manufacturing, it’s essential to consider the specific properties, advantages, and limitations of each option. The choice of material can significantly impact the performance, durability, and suitability of the final product for various applications. Below, we analyze four common materials used in thread manufacturing: polyester, nylon, cotton, and Kevlar.

How Does Polyester Perform in Thread Manufacturing?

Key Properties: Polyester threads are known for their excellent strength and durability. They exhibit good resistance to UV light, moisture, and chemicals, making them suitable for both indoor and outdoor applications. Polyester threads can withstand temperatures ranging from -40°C to 150°C.

Pros & Cons: The primary advantage of polyester is its high tensile strength and resistance to abrasion, which enhances the longevity of the final product. However, polyester can be more expensive than cotton and may not provide the same level of comfort for applications like clothing.

Impact on Application: Polyester threads are ideal for use in outdoor gear, upholstery, and industrial applications due to their weather resistance. They are compatible with a wide range of media, including heavy-duty fabrics and synthetic materials.

Considerations for International Buyers: Buyers in regions like Europe and South Africa should ensure compliance with local standards such as ASTM and DIN. Additionally, the preference for sustainable materials is growing, prompting manufacturers to consider recycled polyester options.

What Are the Benefits of Nylon in Thread Manufacturing?

Key Properties: Nylon is renowned for its exceptional elasticity and strength. It can endure high temperatures (up to 180°C) and has good resistance to abrasion and chemicals.

Pros & Cons: The elasticity of nylon makes it suitable for applications requiring stretch, such as activewear and swimwear. However, nylon threads can absorb moisture, which may lead to mildew and degradation over time, especially in humid environments.

Impact on Application: Nylon threads are widely used in the production of garments, outdoor gear, and industrial applications where flexibility and strength are paramount. Their compatibility with various fabrics makes them a versatile choice.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for nylon in different regions. In Europe, for instance, compliance with REACH regulations is crucial, while buyers in the Middle East may prioritize cost-effectiveness.

Why Choose Cotton for Thread Manufacturing?

Key Properties: Cotton threads are soft, breathable, and biodegradable. They perform well in temperatures up to 100°C and are generally less durable than synthetic options.

Pros & Cons: The primary advantage of cotton is its comfort and natural feel, making it ideal for clothing and textiles. However, cotton is less resistant to moisture and UV light, which can lead to fading and wear over time.

Impact on Application: Cotton threads are particularly suitable for sewing garments, home textiles, and crafts. They are compatible with a wide range of fabrics, especially natural fibers.

Considerations for International Buyers: Buyers in South America and Africa often prefer cotton due to its availability and cost-effectiveness. However, they should ensure that the cotton meets international organic standards if sustainability is a concern.

What Makes Kevlar a Unique Choice in Thread Manufacturing?

Key Properties: Kevlar threads are known for their high tensile strength and heat resistance, withstanding temperatures up to 400°C. They are also resistant to chemicals and abrasion.

Pros & Cons: The key advantage of Kevlar is its exceptional strength-to-weight ratio, making it ideal for applications requiring high durability. However, Kevlar is significantly more expensive than other materials and can be challenging to work with during manufacturing.

Impact on Application: Kevlar threads are often used in high-performance applications such as protective clothing, military gear, and industrial safety equipment. They are compatible with specialized fabrics designed for extreme conditions.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for Kevlar products, particularly in Europe where safety standards are stringent. Additionally, the higher cost may limit its use in price-sensitive markets.

Summary Table of Materials for Thread Manufacturing

| Material | Typical Use Case for Thread Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor gear, upholstery | High tensile strength, UV resistant | More expensive than cotton | Medium |

| Nylon | Activewear, swimwear | Exceptional elasticity and strength | Absorbs moisture, prone to mildew | Medium |

| Cotton | Garments, home textiles | Soft, breathable, biodegradable | Less durable, moisture-sensitive | Low |

| Kevlar | Protective clothing, military gear | High strength-to-weight ratio | Expensive, difficult to manufacture | High |

This strategic material selection guide provides international B2B buyers with valuable insights into the properties, advantages, and limitations of common thread materials. Understanding these factors can help in making informed purchasing decisions that align with specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for thread manufacturer

What Are the Key Stages in Thread Manufacturing?

The manufacturing process for thread involves several critical stages, each designed to ensure that the final product meets quality standards and customer expectations. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

1. Material Preparation: How Is Raw Material Sourced and Processed?

The first step in thread manufacturing is sourcing and preparing the raw materials, which typically include cotton, polyester, nylon, or other synthetic fibers. Quality assurance begins here, as the type and quality of the material directly influence the thread’s durability and performance.

- Sourcing: Manufacturers often establish relationships with trusted suppliers who provide high-quality fibers. It’s essential for B2B buyers to inquire about the sourcing policies and sustainability practices of suppliers.

- Processing: The raw materials undergo cleaning, carding, and spinning processes to prepare them for thread formation. During this phase, manufacturers may apply treatments to enhance properties like color fastness or strength.

2. Forming: What Techniques Are Used to Create Thread?

The forming stage is where the prepared fibers are twisted and spun into thread. This process can vary depending on the desired characteristics of the final product.

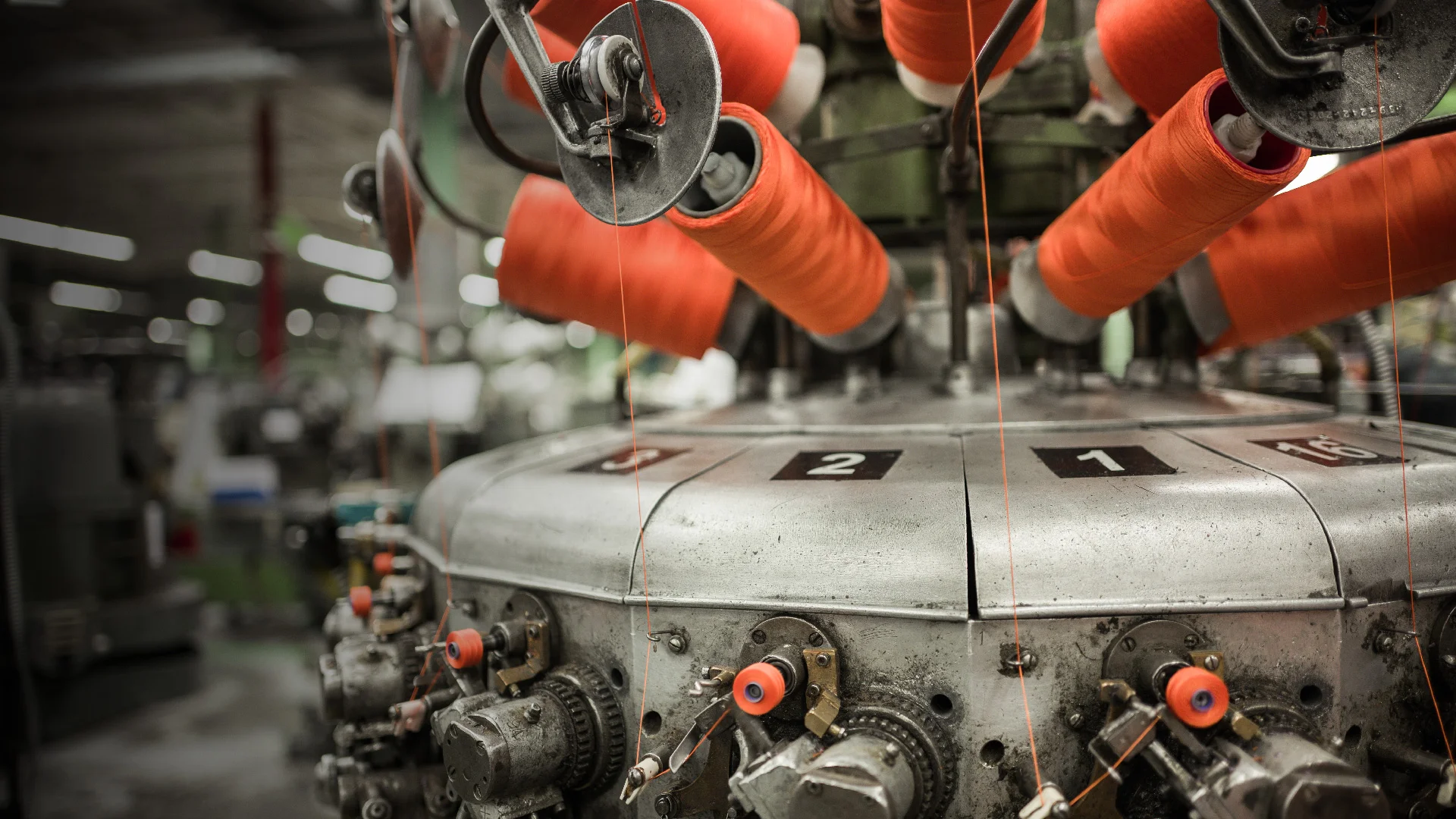

A stock image related to thread manufacturer.

- Spinning Techniques: Common spinning techniques include ring spinning, open-end spinning, and air-jet spinning. Each technique produces different thread textures and strengths. B2B buyers should specify their requirements clearly to ensure they receive the appropriate thread type.

- Twisting: After spinning, fibers are twisted together to create a cohesive thread. The degree of twist can affect the thread’s strength and elasticity, making it crucial for manufacturers to adhere to specific industry standards.

3. Assembly: How Are Threads Prepared for Final Use?

During the assembly stage, the spun thread is wound onto spools or cones, ready for distribution. This stage often includes quality checks to ensure consistency and quality across batches.

- Winding: Automated winding machines are used to ensure uniformity in spool size and thread tension. Quality control at this stage can help identify any defects early on.

- Labeling and Packaging: Proper labeling is essential for identification and compliance with international standards. B2B buyers should ensure that the packaging includes relevant certifications and product details.

4. Finishing: What Final Treatments Enhance Thread Quality?

The finishing stage involves several processes designed to enhance the thread’s properties and appearance. This can include dyeing, coating, and applying protective finishes.

- Dyeing: Color consistency is crucial, especially for fashion and textile applications. Manufacturers often use advanced dyeing techniques to ensure vibrant and lasting colors.

- Coating: Some threads are coated with substances to improve their performance characteristics, such as water resistance or friction reduction. B2B buyers should inquire about the types of coatings used and their suitability for specific applications.

What Quality Assurance Practices Should B2B Buyers Be Aware Of?

Quality assurance is a fundamental aspect of thread manufacturing, ensuring that products meet international standards and customer specifications. Understanding the key quality control practices can help B2B buyers make informed choices.

International Standards: Which Certifications Should Be Considered?

Manufacturers often adhere to international quality standards, such as ISO 9001, which outlines criteria for quality management systems. Other relevant industry-specific certifications may include:

- CE Marking: Important for products sold in the European Economic Area, indicating compliance with safety and environmental regulations.

- API Standards: Relevant for threads used in oil and gas applications, ensuring they meet stringent quality and safety requirements.

B2B buyers should request documentation proving compliance with these standards, as it can be a significant factor in supplier selection.

Key Quality Control Checkpoints: What Are the Main QC Stages?

Quality control checkpoints are integral throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for defects before they enter the production process. Buyers should verify that suppliers conduct thorough IQC to prevent issues downstream.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. B2B buyers can ask about the IPQC methods used by suppliers, including sampling and testing protocols.

- Final Quality Control (FQC): Before shipment, finished products undergo rigorous testing to ensure they meet specifications. Buyers should ensure that suppliers provide FQC reports that detail the tests conducted and their results.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is essential for B2B buyers to ensure reliability and consistency in product quality.

1. Conducting Audits: What Should Be Included in a Supplier Audit?

Conducting a supplier audit can provide valuable insights into the quality assurance practices of a thread manufacturer. Key elements to include in an audit are:

- Facility Inspection: Examine the manufacturing environment and equipment to ensure compliance with safety and quality standards.

- Document Review: Assess the manufacturer’s quality management documentation, including SOPs (Standard Operating Procedures) and quality records.

2. Requesting Quality Reports: What Information Should Be Included?

Buyers should request detailed quality reports from suppliers, which should include:

- Testing Results: Information on the types of tests conducted, such as tensile strength, color fastness, and abrasion resistance.

- Certification Documentation: Proof of compliance with international standards and industry-specific certifications.

3. Engaging Third-Party Inspectors: How Can External Inspections Add Value?

Employing third-party inspectors can provide an unbiased assessment of a supplier’s quality control practices. These inspectors can:

- Verify Compliance: Ensure that the manufacturer adheres to both internal quality standards and external regulations.

- Identify Risks: Highlight potential areas of concern that may require attention before placing large orders.

Conclusion: Navigating Quality Assurance in Thread Manufacturing

For B2B buyers in Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices of thread manufacturers is crucial. By focusing on the key stages of production, international standards, and verification methods, buyers can make informed decisions that lead to successful partnerships with suppliers. Prioritizing quality assurance not only enhances product reliability but also strengthens the overall supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thread manufacturer’

The following practical sourcing guide provides a comprehensive checklist for international B2B buyers looking to procure thread manufacturing services. This step-by-step approach will help you ensure that you select a reliable supplier that meets your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications of the thread you require. Consider factors such as material type (cotton, polyester, nylon), thread count, and any specific finishes or treatments needed. A well-defined specification helps suppliers understand your needs and enables them to provide accurate quotes.

- Material Type: Different applications require different materials. Ensure you choose the right one for your intended use.

- Thread Count: This affects the durability and strength of the thread. Make sure your specifications reflect your quality standards.

Step 2: Conduct Market Research for Suppliers

Engage in thorough market research to identify potential thread manufacturers. Utilize online platforms, trade shows, and industry directories to compile a list of suppliers that operate within your target regions, such as Africa, South America, the Middle East, and Europe.

- Online Platforms: Websites like Alibaba or Global Sources can provide a wide range of options.

- Trade Shows: Attending industry-specific trade shows can facilitate direct interactions with manufacturers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Company Profile: Look for information about their experience, production capabilities, and client base.

- References: Contact previous clients to assess their satisfaction levels and any challenges faced during the procurement process.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers have the necessary certifications and adhere to quality standards relevant to your industry. Certifications such as ISO 9001 for quality management systems can be indicators of a supplier’s commitment to quality.

- Quality Management: Verify if they follow strict quality control measures throughout their production process.

- Sustainability Standards: If important to your brand, confirm if the supplier meets environmental regulations and standards.

Step 5: Request Samples and Test Quality

Always request samples of the thread to evaluate the quality before placing large orders. Testing the samples in your specific application can reveal potential performance issues early on.

- Application Testing: Use the samples in actual production to assess compatibility and performance.

- Quality Assessment: Look for consistency in color, strength, and finish.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear terms can prevent misunderstandings and ensure a smooth transaction.

- Pricing Structure: Discuss bulk discounts and payment methods that suit both parties.

- Delivery Timelines: Confirm lead times and delivery schedules to align with your production needs.

Step 7: Establish a Communication Plan

Set up a communication plan to maintain regular contact with your supplier throughout the production process. Effective communication helps address issues quickly and fosters a strong working relationship.

- Regular Updates: Schedule regular check-ins to monitor progress and address any concerns.

- Feedback Mechanism: Establish a process for providing feedback on product quality and service.

By following this checklist, you can enhance your sourcing strategy and ensure that you partner with a thread manufacturer that aligns with your business objectives.

Comprehensive Cost and Pricing Analysis for thread manufacturer Sourcing

What Are the Key Cost Components in Thread Manufacturing?

When sourcing threads from manufacturers, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of raw materials significantly influences the cost. High-quality fibers (e.g., cotton, polyester, or nylon) may come at a premium but offer better durability and performance.

-

Labor: Labor costs vary widely depending on the region of production. Countries in Africa or South America may have lower labor costs compared to Europe, but this can also affect the skill level and productivity of the workforce.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Understanding the overhead can help buyers assess the overall pricing strategy of the manufacturer.

-

Tooling: Custom tooling for specialized thread types can be a significant upfront cost. For unique specifications, buyers should inquire about tooling fees and amortization over production runs.

-

Quality Control (QC): Ensuring the threads meet required specifications necessitates a robust QC process. This may involve additional costs that can be pivotal in maintaining product integrity.

A stock image related to thread manufacturer.

-

Logistics: Shipping and handling costs can vary greatly based on the manufacturer’s location and the chosen Incoterms. Understanding these costs is vital, especially for international transactions.

-

Margin: Manufacturers typically add a margin to cover risks and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Thread Pricing?

Several factors can influence the pricing of threads, making it essential for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Unique thread specifications, such as color, thickness, and finish, can lead to higher costs. Customization often involves additional tooling and processing.

-

Materials and Quality Certifications: Sourcing high-quality materials may increase upfront costs but can reduce long-term expenses due to durability. Additionally, certifications (e.g., OEKO-TEX) may add to the cost but assure compliance with safety standards.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers with a track record may charge a premium for their reliability and service.

-

Incoterms: The chosen Incoterms dictate responsibility for shipping costs and risks. Buyers should clarify these terms to avoid unexpected expenses.

What Are Effective Buyer Tips for Thread Sourcing?

To ensure a successful sourcing experience, international B2B buyers should consider the following strategies:

-

Negotiation Techniques: Effective negotiation can lead to better pricing. Buyers should be prepared with data on market rates and alternative suppliers to leverage their position.

-

Cost-Efficiency Analysis: Perform a thorough analysis of the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, quality assurance, and potential returns or failures.

-

Understanding Pricing Nuances: Buyers from diverse regions such as Africa, South America, the Middle East, and Europe should be aware of regional pricing trends. For instance, European manufacturers may offer higher quality but at a premium, while African suppliers may provide competitive pricing with varying quality levels.

-

Seeking Transparency: Request detailed breakdowns of costs from suppliers. Transparency can help identify areas for negotiation and assess the fairness of pricing.

Disclaimer on Indicative Prices

Please note that prices for thread manufacturing can vary widely based on the factors discussed above. The information provided here is for indicative purposes only and should be verified with specific suppliers during the sourcing process.

Alternatives Analysis: Comparing thread manufacturer With Other Solutions

When considering thread manufacturers, it’s essential to explore various alternatives that may fulfill similar requirements in textile production and other applications. Each alternative brings unique benefits and limitations that can significantly impact business operations and product quality. Below, we analyze thread manufacturers against two viable alternatives: synthetic fiber production and adhesive bonding methods.

| Comparison Aspect | Thread Manufacturer | Synthetic Fiber Production | Adhesive Bonding Methods |

|---|---|---|---|

| Performance | High tensile strength, durability, and flexibility | Good tensile strength, lightweight, and resistant to moisture | Strong bond, quick application, and flexibility |

| Cost | Moderate to high | Generally lower | Variable costs depending on the adhesive used |

| Ease of Implementation | Requires specialized equipment and skilled labor | Easier setup with bulk production capabilities | Simple to apply, minimal training required |

| Maintenance | Regular equipment maintenance required | Low maintenance for machinery | Minimal maintenance, but adhesive storage conditions must be monitored |

| Best Use Case | Apparel, upholstery, industrial applications | Sportswear, outdoor gear, and household textiles | Quick repairs, temporary fixes, or non-sewing applications |

What Are the Advantages and Disadvantages of Synthetic Fiber Production?

Synthetic fiber production is a modern alternative that involves creating fibers from chemical substances. The primary advantage is cost-effectiveness, as synthetic fibers can often be produced in bulk at a lower price than natural threads. Additionally, they offer excellent moisture resistance and durability, making them suitable for sportswear and outdoor gear.

However, synthetic fibers can lack the aesthetic qualities and tactile feel of natural threads, which might be a disadvantage for high-end fashion applications. Furthermore, environmental concerns regarding the production and disposal of synthetic materials can impact brand reputation and consumer preference.

How Do Adhesive Bonding Methods Compare to Thread Manufacturers?

Adhesive bonding methods involve using adhesives to join materials together, providing a quick and effective alternative to traditional sewing. The main advantage of this method is its speed and ease of use, as it does not require specialized sewing machines or skilled labor. This can be particularly beneficial for small-scale operations or quick repairs.

On the downside, adhesive bonds may not provide the same level of durability and flexibility as thread-based stitching. Depending on the type of adhesive used, the bond may degrade under certain environmental conditions, such as heat or moisture. This could limit its application in high-stress environments.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right solution between thread manufacturers and alternative methods hinges on several factors, including the specific application, budget, and performance requirements. For high-quality textile products where durability and aesthetics are paramount, a traditional thread manufacturer is often the best choice. Conversely, for cost-sensitive projects or applications requiring quick assembly, synthetic fibers or adhesive bonding methods may provide a viable alternative.

B2B buyers should carefully assess their operational capabilities, market demands, and long-term goals when selecting a solution. Engaging with suppliers for samples and conducting performance tests can also provide valuable insights, enabling informed decision-making tailored to specific business needs.

Essential Technical Properties and Trade Terminology for thread manufacturer

What Are the Key Technical Properties for Thread Manufacturers?

When selecting threads for various applications, understanding the essential technical properties is crucial for international B2B buyers, particularly in sectors like textiles, automotive, and manufacturing. Here are some critical specifications to consider:

1. Material Grade

The material grade of thread determines its strength, durability, and suitability for specific applications. Common materials include polyester, nylon, cotton, and blends. For instance, polyester threads are known for their resistance to fading and shrinking, making them ideal for outdoor applications. Buyers should evaluate material grades based on their end-use requirements, ensuring the selected thread meets industry standards.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions of the thread, impacting its performance in manufacturing processes. Tight tolerances ensure consistency in stitching and can prevent issues like thread breakage or fabric distortion. Buyers must specify tolerance levels in their orders to align with manufacturing capabilities and ensure product quality.

3. Thread Count

Thread count indicates the number of threads per inch and significantly affects the fabric’s strength and texture. Higher thread counts usually result in stronger, more durable fabrics, essential for applications requiring high wear resistance. Understanding the thread count helps buyers select the appropriate thread for their production needs, particularly in sectors like fashion and upholstery.

4. Tensile Strength

Tensile strength measures the force required to break the thread and is a vital property for assessing thread performance under stress. Higher tensile strength is crucial for applications that involve heavy loads or frequent use. Buyers should request tensile strength specifications to ensure the thread can withstand operational demands.

5. Colorfastness

Colorfastness indicates how well a thread retains its color when exposed to various elements like washing, sunlight, and friction. Threads with high colorfastness are essential for products subjected to rigorous cleaning or outdoor exposure. Buyers should inquire about colorfastness ratings to ensure long-lasting aesthetics in their finished products.

What Are Common Trade Terms in the Thread Manufacturing Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common terms that international buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the thread manufacturing context, buyers may collaborate with OEMs to create custom thread solutions tailored to their specific production requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers to assess inventory needs and avoid overcommitting resources. Negotiating MOQs can lead to better cost efficiencies, especially for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. By providing detailed specifications, buyers can receive competitive pricing, which is essential for budgeting and cost management in production.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is critical for buyers to manage logistics, including shipping costs, insurance, and delivery timelines, particularly when sourcing from international manufacturers.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead time is crucial for production planning, allowing buyers to synchronize their supply chain and avoid delays in manufacturing processes.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, ensuring that they select the right threads for their applications while navigating the complexities of global trade effectively.

Navigating Market Dynamics and Sourcing Trends in the thread manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Thread Manufacturing Sector?

The thread manufacturing sector is experiencing a transformative period driven by globalization and technological advancements. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are increasingly influenced by several key trends. The demand for high-quality, specialized threads is rising, propelled by industries such as fashion, automotive, and home textiles. This shift is further accelerated by the growing trend of customization, where brands seek unique threads to differentiate their products in competitive markets.

Emerging technologies, such as digital printing and automation in manufacturing processes, are reshaping sourcing strategies. Digital tools facilitate easier communication and collaboration between manufacturers and buyers, streamlining the procurement process. Additionally, the adoption of data analytics is becoming essential for understanding market trends and consumer preferences, enabling B2B buyers to make informed sourcing decisions.

Another important dynamic is the shift towards nearshoring and local sourcing, particularly in Europe. This trend aims to mitigate risks related to supply chain disruptions and ensure faster delivery times. For buyers in Africa and South America, this offers opportunities to engage with local manufacturers and enhance regional trade relationships.

How Are Sustainability and Ethical Sourcing Shaping the Thread Manufacturing Industry?

Sustainability and ethical sourcing are increasingly crucial in the thread manufacturing sector, reflecting a broader industry shift towards environmentally responsible practices. The environmental impact of thread production, including water usage and chemical waste, is under scrutiny. B2B buyers are now prioritizing suppliers who implement sustainable practices, such as using organic or recycled materials.

Ethical supply chains are also gaining prominence, with companies seeking transparency in their sourcing processes. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® are becoming important benchmarks for buyers looking to ensure that their suppliers adhere to environmental and social responsibility standards.

Moreover, the demand for ‘green’ threads—those made from biodegradable or sustainably sourced materials—is on the rise. This shift not only meets consumer expectations but also aligns with regulatory pressures in various regions, particularly in Europe, where sustainability legislation is becoming increasingly stringent. By prioritizing ethical sourcing, B2B buyers can enhance their brand image and meet the growing consumer demand for responsible products.

What Is the Historical Context of the Thread Manufacturing Sector for B2B Buyers?

The thread manufacturing sector has evolved significantly over the last century, transitioning from manual production methods to highly automated processes. Early manufacturing was dominated by small workshops that relied on manual labor, leading to inconsistent quality and supply challenges. The industrial revolution brought about mechanization, increasing production capacity and efficiency.

In the latter half of the 20th century, globalization reshaped the industry, allowing for the outsourcing of production to countries with lower labor costs. This trend enabled B2B buyers to access a wider range of products at competitive prices. However, recent years have seen a resurgence in local manufacturing due to rising shipping costs and supply chain vulnerabilities exposed by global crises. This historical context is essential for B2B buyers to understand the current market dynamics and make informed sourcing decisions that align with contemporary trends in sustainability and ethical practices.

By navigating these complex dynamics, B2B buyers can position themselves strategically within the thread manufacturing sector, ensuring they remain competitive and responsive to changing market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of thread manufacturer

-

How do I choose the right thread manufacturer for my business needs?

Choosing the right thread manufacturer involves assessing several factors including product quality, production capacity, and reliability. Start by defining your specific requirements, such as thread type, material, and intended application. Research potential suppliers through industry directories, trade shows, and online reviews. Request samples to evaluate quality, and inquire about their certifications and compliance with international standards. Establish communication to gauge their responsiveness and willingness to accommodate your needs, ensuring a good fit for a long-term partnership. -

What are the typical minimum order quantities (MOQs) for thread manufacturers?

Minimum order quantities can vary significantly among thread manufacturers, often ranging from 500 to 5,000 units, depending on the type of thread and the supplier’s production capabilities. It’s important to discuss MOQs upfront, as they can affect your cash flow and inventory management. Some manufacturers may offer lower MOQs for customized orders, while others may require higher quantities for standard products. Negotiating MOQs can also be beneficial, especially if you can demonstrate potential for larger future orders. -

What payment terms should I expect when sourcing from international thread manufacturers?

Payment terms vary among manufacturers but generally include options like upfront deposits (often 30-50%), payment upon shipment, or net terms (30-90 days). Discussing payment methods is crucial; common options include wire transfers, letters of credit, or PayPal. Ensure you understand the implications of each method, including fees and exchange rates. Establishing clear payment terms in your contract can help mitigate risks and ensure a smoother transaction process. -

How can I ensure quality assurance when sourcing thread from manufacturers?

To ensure quality assurance, ask potential manufacturers about their quality control processes. Request documentation of certifications such as ISO 9001 or other relevant standards. It’s beneficial to conduct factory audits or hire third-party inspection services to verify compliance with your specifications. Establish a clear set of quality standards in your contract and request samples before full production. Regular communication throughout the production process can also help address any quality issues promptly. -

What customization options are available when sourcing thread?

Many thread manufacturers offer customization options including color, thickness, and material type. Discuss your specific requirements with potential suppliers to understand their capabilities. Some manufacturers may also provide custom branding options, such as labels or unique packaging. Be prepared to provide detailed specifications and possibly a prototype to ensure the final product meets your expectations. Understanding the lead times for custom orders is also essential for planning your production schedule. -

What logistics considerations should I keep in mind when sourcing thread internationally?

When sourcing thread internationally, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure your supplier has experience with international shipping and can provide necessary documentation for customs clearance. Understanding import duties and taxes in your country can also help you budget effectively. It’s wise to work with a logistics partner who can navigate these complexities on your behalf. -

How can I vet potential thread suppliers before making a commitment?

Vetting suppliers is crucial for a successful partnership. Start by checking their business credentials, including registration and certifications. Look for reviews or testimonials from other clients, and consider their experience in your industry. Request references and follow up to gauge their reliability. Additionally, visiting their manufacturing facility or attending trade shows can provide insights into their operations and quality standards. Establishing a clear communication line can also help build trust. -

What are the common challenges faced when sourcing thread from manufacturers?

Common challenges include quality inconsistencies, communication barriers, and unexpected delays in production or shipping. To mitigate these issues, establish clear specifications and maintain open lines of communication with your supplier. Set realistic timelines and have contingency plans in place for delays. Additionally, consider starting with smaller orders to test the supplier’s reliability before committing to larger volumes. Regularly reviewing performance can help address any challenges proactively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for thread manufacturer

What Are the Key Takeaways for Strategic Sourcing in Thread Manufacturing?

In conclusion, strategic sourcing in the thread manufacturing sector is essential for international B2B buyers aiming to enhance supply chain resilience and optimize costs. Engaging with suppliers that prioritize quality, sustainability, and innovation can significantly impact your product offerings and market competitiveness. Buyers from Africa, South America, the Middle East, and Europe must leverage local market insights and global supply networks to identify the best partners.

How Can International Buyers Benefit from Strategic Sourcing?

The value of strategic sourcing extends beyond mere cost savings; it fosters long-term partnerships that can drive operational efficiencies and product quality. By investing time in supplier assessments and relationship management, buyers can ensure that they are not only securing favorable terms but also gaining access to cutting-edge technologies and sustainable practices.

What Does the Future Hold for Thread Manufacturers?

Looking ahead, the thread manufacturing industry is poised for transformation, driven by advancements in technology and shifting consumer preferences. International buyers should remain vigilant and adaptable, staying informed about emerging trends and innovations. By prioritizing strategic sourcing, you can position your business for success and lead in a rapidly evolving marketplace. Embrace the opportunities that lie ahead and take proactive steps towards building a robust and resilient supply chain.