Discover Top Throttle Body Manufacturers: A Comprehensive Guide (2025)

Introduction: Navigating the Global Market for throttle body manufacturer

In the ever-evolving automotive industry, sourcing a reliable throttle body manufacturer can be a daunting challenge for international B2B buyers. With the increasing demand for high-performance vehicles and stringent emission regulations, it is crucial to find a supplier that not only meets quality standards but also aligns with your specific application needs. This comprehensive guide delves into the various aspects of selecting a throttle body manufacturer, including types of throttle bodies available, their applications across different vehicle models, and essential criteria for supplier vetting.

Understanding the nuances of throttle body technology can empower B2B buyers from regions like Africa, South America, the Middle East, and Europe—such as Turkey and South Africa—to make informed purchasing decisions. Throughout this guide, you will gain insights into cost considerations, the significance of certifications, and the importance of establishing robust communication channels with potential suppliers.

By equipping yourself with the right knowledge, you can navigate the global market with confidence, ensuring that your procurement process not only fulfills technical requirements but also fosters long-term partnerships with reputable manufacturers. This resource is designed to streamline your sourcing journey, ultimately enhancing your operational efficiency and competitiveness in the automotive sector.

Understanding throttle body manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Designed to meet specific vehicle requirements and standards | Automotive manufacturing, aftermarket parts | Pros: High reliability, perfect fit. Cons: Often more expensive than alternatives. |

| Aftermarket Manufacturers | Offers a wide range of products for various vehicle models | Replacement parts, performance upgrades | Pros: Competitive pricing, diverse options. Cons: Varies in quality, potential compatibility issues. |

| Electronic Throttle Control | Integrates electronic sensors for precise airflow control | Advanced automotive systems, electric vehicles | Pros: Improved performance, fuel efficiency. Cons: More complex, higher repair costs. |

| Custom Throttle Bodies | Tailored designs for specific performance needs | Racing, specialty vehicles | Pros: Optimized for performance, unique designs. Cons: Longer lead times, potentially higher costs. |

| Integrated Systems | Combines throttle body with other engine management components | High-performance vehicles, custom builds | Pros: Streamlined installation, enhanced functionality. Cons: Complexity may require specialized knowledge for installation. |

What Are OEM Throttle Body Manufacturers and Their Benefits?

OEM throttle body manufacturers produce components that are designed specifically for original vehicle models. These products comply with strict industry standards, ensuring that they fit perfectly and function reliably. B2B buyers in the automotive manufacturing sector often prefer OEM parts for their durability and compatibility with existing systems. However, the higher price point can be a drawback, especially for businesses focused on cost-efficiency.

How Do Aftermarket Throttle Body Manufacturers Differ from OEM?

Aftermarket manufacturers provide a broad selection of throttle bodies that can fit multiple vehicle models. This flexibility allows businesses to cater to various customer needs, whether for replacements or performance upgrades. While aftermarket options can be more affordable, buyers must be cautious about quality variations and compatibility with specific vehicles. Conducting thorough research and choosing reputable brands is essential for ensuring reliable performance.

What Are the Advantages of Electronic Throttle Control Systems?

Electronic throttle control (ETC) systems utilize sensors and actuators to manage airflow with precision. These systems are increasingly common in modern vehicles, particularly in electric and hybrid models. B2B buyers in sectors focused on innovation may find ETC beneficial for enhancing vehicle performance and fuel efficiency. However, the complexity of these systems can lead to higher repair costs and necessitate specialized training for technicians.

Why Consider Custom Throttle Bodies for Specialized Applications?

Custom throttle bodies are designed to meet specific performance requirements, making them ideal for racing or specialty vehicles. These tailored components allow manufacturers to optimize airflow for increased power and efficiency. While the benefits are significant, B2B buyers should be prepared for longer lead times and potentially higher costs associated with custom manufacturing processes.

What Are Integrated Systems and Their Role in High-Performance Vehicles?

Integrated throttle body systems combine the throttle body with other engine management components, providing a comprehensive solution for high-performance vehicles. This integration streamlines installation and enhances overall functionality. Businesses looking to offer advanced solutions may find integrated systems appealing, but they also come with increased complexity, requiring skilled technicians for installation and maintenance.

Related Video: Should you clean your Throttle Body and How to clean it on Toyotas

Key Industrial Applications of throttle body manufacturer

| Industry/Sector | Specific Application of Throttle Body Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of Fuel Injection Systems | Enhances vehicle performance and fuel efficiency | Quality certifications, compliance with local regulations |

| Industrial Equipment | Integration in Heavy Machinery | Improves operational efficiency and reduces emissions | Customization options, durability under harsh conditions |

| Aerospace | Application in Aircraft Engine Systems | Increases reliability and safety in flight operations | Advanced materials, precision engineering capabilities |

| Marine | Use in Marine Engine Systems | Boosts fuel efficiency and engine performance | Resistance to corrosion, compliance with maritime standards |

| Agricultural Machinery | Implementation in Tractors and Harvesters | Enhances power output and operational efficiency | Adaptability to different fuel types, reliability in diverse climates |

How is Throttle Body Manufacturer Used in Automotive Manufacturing?

In the automotive sector, throttle bodies are critical components of fuel injection systems. They regulate the air intake into the engine, thereby influencing fuel efficiency and overall vehicle performance. For international B2B buyers, especially from regions like Africa and South America, sourcing throttle bodies requires ensuring compatibility with local vehicle specifications and compliance with environmental regulations. Manufacturers must provide robust quality certifications to assure buyers of their product’s reliability and performance under varied driving conditions.

What Role Does Throttle Body Manufacturer Play in Industrial Equipment?

In industrial equipment, throttle bodies are integrated into heavy machinery to control air intake and optimize engine performance. This application is crucial for enhancing operational efficiency and minimizing emissions, aligning with global sustainability goals. Buyers in the Middle East and Europe should consider sourcing manufacturers that offer customization options to meet specific machinery requirements. Additionally, evaluating the durability of these components under harsh working conditions is vital to ensure long-term performance and reliability.

How is Throttle Body Manufacturer Applied in Aerospace?

In the aerospace industry, throttle bodies are used in aircraft engine systems to manage airflow, ensuring optimal engine performance and safety during flight operations. The precision and reliability of these components are non-negotiable due to the stringent safety standards in aviation. International buyers must prioritize manufacturers that utilize advanced materials and precision engineering capabilities to meet aerospace specifications. This focus not only enhances safety but also contributes to overall operational efficiency in aviation.

Why is Throttle Body Manufacturer Important for Marine Applications?

For marine applications, throttle bodies are essential in engine systems to improve fuel efficiency and performance. The marine environment poses unique challenges, such as exposure to saltwater and varying temperatures, necessitating components that resist corrosion and comply with maritime standards. Buyers from regions with significant marine industries, like South Africa and Turkey, should seek manufacturers that specialize in marine-grade throttle bodies, ensuring durability and compliance with international maritime regulations.

How Does Throttle Body Manufacturer Benefit Agricultural Machinery?

In agricultural machinery, throttle bodies play a pivotal role in tractors and harvesters by regulating air intake to enhance power output and operational efficiency. This is particularly important in regions with diverse agricultural practices, where equipment must perform reliably under varying conditions. Buyers should look for manufacturers that provide adaptable throttle bodies capable of accommodating different fuel types and environmental conditions. Ensuring reliability in these components can significantly impact productivity and efficiency in the agricultural sector.

Related Video: Valve Parts Explained (Industrial Engineering)

3 Common User Pain Points for ‘throttle body manufacturer’ & Their Solutions

Scenario 1: Quality Concerns with Throttle Body Components

The Problem:

B2B buyers often face the challenge of ensuring the quality and reliability of throttle bodies when sourcing from manufacturers. Poor quality components can lead to engine performance issues, increased emissions, and ultimately, customer dissatisfaction. This concern is especially pronounced for international buyers from regions like Africa and South America, where inconsistent manufacturing standards may exist. The potential for defective parts can create costly delays and damage a buyer’s reputation in their local market.

The Solution:

To mitigate these quality concerns, buyers should prioritize manufacturers that offer transparent quality assurance processes and adhere to international standards such as ISO 9001. Conduct thorough due diligence by requesting certifications, quality control reports, and third-party testing results. Additionally, establishing a solid communication channel with the manufacturer can help clarify specifications and expectations. Consider implementing a trial order or a pilot run to assess product quality before committing to larger orders. Engaging in regular audits and inspections can further ensure that the manufacturing processes meet your quality standards, thus safeguarding your supply chain and customer satisfaction.

Scenario 2: Long Lead Times and Delays in Supply Chain

The Problem:

In the fast-paced automotive industry, lengthy lead times can severely hinder production schedules and affect a company’s ability to meet market demands. B2B buyers often experience this pain point when dealing with throttle body manufacturers, especially when sourcing from overseas. Delays in shipping, customs clearance, or production can result in inventory shortages and lost sales opportunities, particularly in competitive markets like Europe and the Middle East.

The Solution:

To address the issue of long lead times, B2B buyers should consider partnering with manufacturers that have established logistics networks and a reliable supply chain management system. It’s crucial to develop a strong relationship with your supplier to enhance communication regarding production timelines and potential bottlenecks. Additionally, buyers can implement a just-in-time inventory strategy to reduce stockouts while maintaining flexibility. Exploring local manufacturers or those with regional distribution centers can also significantly cut down lead times, allowing for quicker response to market changes. Lastly, investing in technology such as inventory management software can provide real-time visibility into stock levels and streamline the ordering process.

Scenario 3: Difficulty in Customization and Compatibility Issues

The Problem:

Many B2B buyers encounter challenges when seeking customized throttle bodies that fit specific engine models or performance requirements. Compatibility issues often arise when manufacturers do not fully understand the technical specifications or application needs of their clients. This can lead to misaligned parts, resulting in inefficiencies and increased costs for modifications or replacements.

The Solution:

To overcome customization challenges, buyers should provide detailed specifications, including dimensions, materials, and performance expectations, when initiating discussions with throttle body manufacturers. Engaging in collaborative design processes can significantly enhance the likelihood of achieving the desired outcome. Look for manufacturers that offer engineering support or design consultation services, as they can provide valuable insights into optimizing throttle body designs for specific applications. Moreover, utilizing rapid prototyping or 3D printing can facilitate quicker testing and adjustments, ensuring that the final product meets the exact requirements before full-scale production begins. Establishing clear communication and feedback loops throughout the development process will also help address any compatibility issues early on, ensuring a smooth transition from design to production.

Strategic Material Selection Guide for throttle body manufacturer

What Are the Key Materials Used in Throttle Body Manufacturing?

When selecting materials for throttle body manufacturing, it is crucial to consider the properties that affect performance, durability, and compatibility with various media. Below, we analyze four common materials: aluminum, plastic, stainless steel, and magnesium. Each material has unique characteristics that cater to different operational requirements and market preferences.

How Does Aluminum Perform as a Material for Throttle Bodies?

Aluminum is a widely used material in throttle body manufacturing due to its favorable properties. It has excellent thermal conductivity, which helps in dissipating heat effectively. Aluminum typically has a temperature rating up to 250°C and can withstand moderate pressure levels, making it suitable for automotive applications.

Pros:

– Lightweight, which contributes to overall vehicle efficiency.

– Corrosion-resistant when treated with anodizing or coatings.

– Cost-effective compared to some other metals.

Cons:

– May not be as durable under extreme conditions as some heavier metals.

– Requires careful handling during manufacturing to avoid deformation.

Impact on Application: Aluminum is compatible with various fuel types and can handle the thermal expansion associated with engine operations.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure that the aluminum used meets local regulations regarding emissions and recyclability.

What Are the Benefits of Using Plastic in Throttle Body Manufacturing?

Plastic, particularly reinforced polymers, has gained traction in throttle body applications due to its lightweight nature and resistance to corrosion. The typical temperature rating for plastic throttle bodies is around 120°C, which is suitable for many automotive applications.

Pros:

– Low manufacturing costs and complexity, allowing for mass production.

– Excellent resistance to corrosion and chemical exposure.

– Flexibility in design, enabling intricate shapes.

Cons:

– Lower temperature and pressure ratings compared to metals.

– Potential for degradation over time when exposed to high temperatures or certain chemicals.

Impact on Application: Plastic throttle bodies are suitable for lower-performance applications and can handle various media, but may not be ideal for high-performance or racing environments.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with relevant standards, such as JIS in Japan or ISO certifications, especially in Europe where regulations on materials are stringent.

How Does Stainless Steel Compare in Throttle Body Manufacturing?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a prime choice for throttle bodies exposed to harsh conditions. It can withstand temperatures exceeding 500°C and high-pressure environments.

Pros:

– High durability and longevity, reducing the need for replacements.

– Excellent resistance to corrosion, even in extreme environments.

– Can be polished for aesthetic appeal.

Cons:

– Higher manufacturing costs compared to aluminum and plastic.

– Heavier, which can impact vehicle performance.

Impact on Application: Stainless steel is ideal for performance vehicles and applications where durability is crucial, such as in off-road or heavy-duty vehicles.

Considerations for International Buyers: Compliance with ASTM standards is critical, especially in markets like Europe where material quality is closely monitored. Buyers should also consider the environmental impact of stainless steel production.

What Advantages Does Magnesium Offer for Throttle Body Manufacturing?

Magnesium is an emerging material in throttle body manufacturing, prized for its lightweight properties and strength. It has a temperature rating similar to aluminum, around 200°C, making it suitable for various automotive applications.

Pros:

– Extremely lightweight, enhancing vehicle performance.

– Good strength-to-weight ratio, allowing for thinner walls and reduced material usage.

Cons:

– More expensive than aluminum and plastic.

– Prone to corrosion if not properly treated.

Impact on Application: Magnesium is suitable for performance applications where weight savings are critical, but it requires careful consideration of environmental exposure.

Considerations for International Buyers: Buyers should ensure that magnesium components meet local and international safety and environmental standards, as magnesium can be more reactive than other metals.

Summary of Material Selection for Throttle Body Manufacturing

| Material | Typical Use Case for throttle body manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Standard automotive applications | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

| Plastic | Low to mid-performance vehicles | Low manufacturing cost | Limited temperature tolerance | Low |

| Stainless Steel | High-performance and heavy-duty applications | Exceptional durability | Higher cost and weight | High |

| Magnesium | Performance and racing vehicles | Very lightweight | Corrosion potential | Medium to High |

This guide provides a comprehensive overview of material selection for throttle body manufacturers, equipping international B2B buyers with the insights needed to make informed decisions based on performance, cost, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for throttle body manufacturer

What are the Main Stages of Manufacturing a Throttle Body?

Manufacturing a throttle body involves several critical stages that ensure the product meets performance and quality standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing throttle bodies.

1. Material Preparation

The first step in the manufacturing process is selecting and preparing the raw materials. Throttle bodies are typically made from aluminum alloys or plastic composites due to their lightweight properties and resistance to corrosion. Buyers should verify that the supplier sources materials compliant with international standards, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization) specifications.

During this stage, the materials undergo quality checks to ensure they meet the required mechanical and thermal properties. This is crucial for the performance and durability of the throttle body in automotive applications.

2. Forming Techniques

Once the materials are prepared, the next step is forming the throttle body. This can involve various techniques, including:

- Die Casting: A common method for aluminum throttle bodies, where molten metal is injected into a mold to create precise shapes.

- Injection Molding: Used for plastic throttle bodies, this process involves injecting heated plastic into a mold.

- CNC Machining: For both aluminum and plastic components, CNC (Computer Numerical Control) machining is used to achieve high precision in dimensions and tolerances.

Buyers should inquire about the forming techniques used by suppliers, as these can significantly impact the product’s quality and performance.

3. Assembly

After forming, the components of the throttle body are assembled. This stage may involve the integration of electronic sensors, actuators, and mechanical parts. It is essential that assembly is performed under strict conditions to avoid contamination and ensure proper fit and function.

Quality assurance during assembly can be enhanced through the use of jigs and fixtures that ensure consistent alignment and positioning of components. Suppliers should provide information on their assembly processes and any automation used to enhance precision and reduce human error.

4. Finishing Processes

The final stage in manufacturing is finishing, which includes surface treatment, painting, or coating. These processes enhance the throttle body’s resistance to wear and corrosion, thus prolonging its lifespan. Common finishing techniques include:

- Anodizing: For aluminum parts, this process increases corrosion resistance and surface hardness.

- Powder Coating: Provides a durable finish and can be customized in various colors.

- Polishing: Improves aesthetic appeal and reduces surface roughness.

B2B buyers should confirm that the supplier uses appropriate finishing techniques that comply with industry standards and customer requirements.

How is Quality Assurance Implemented in Throttle Body Manufacturing?

Quality assurance (QA) is critical in ensuring that throttle bodies meet the necessary specifications and performance standards. Here are some key aspects of QA in the manufacturing process:

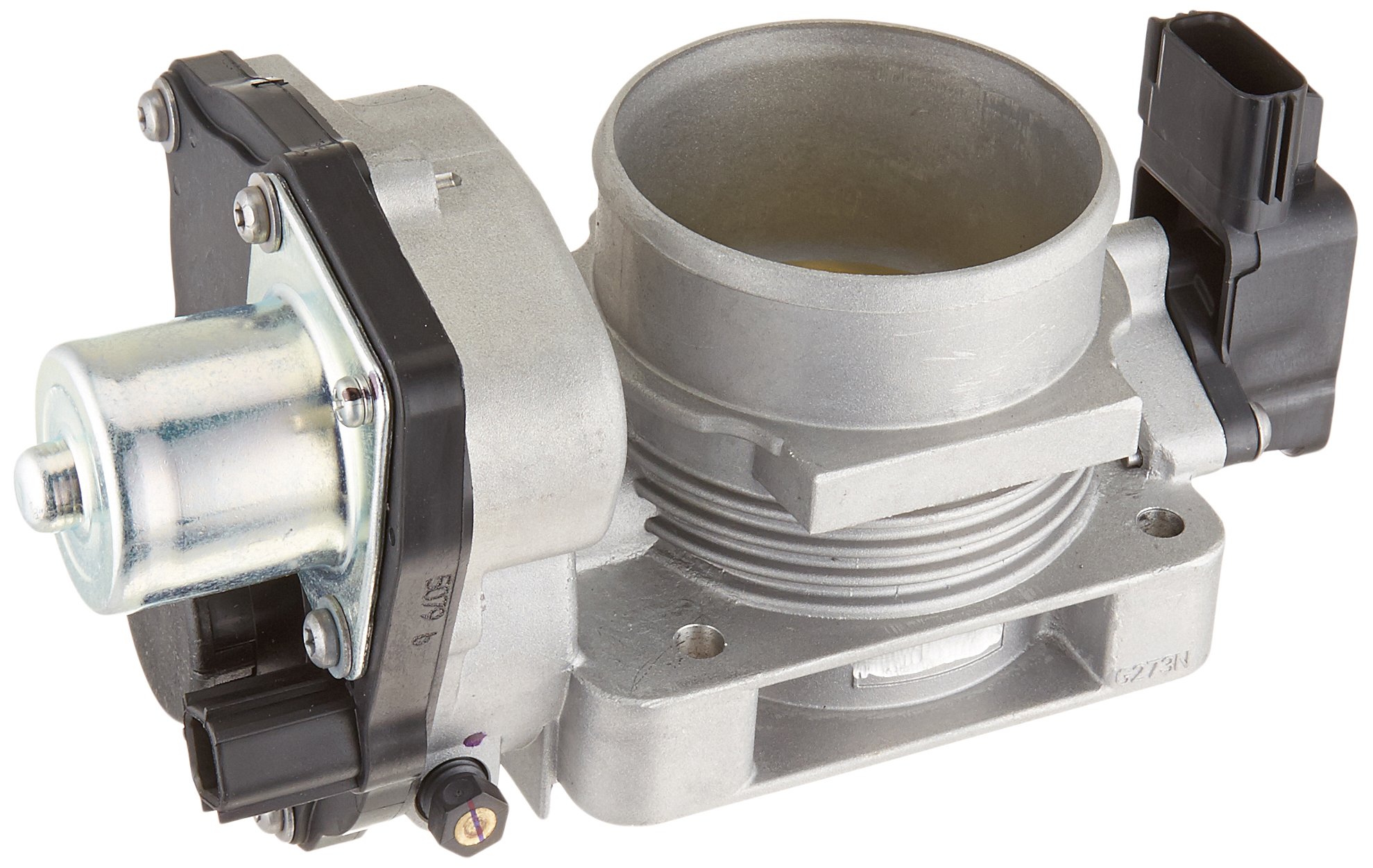

A stock image related to throttle body manufacturer.

Relevant International Standards for Throttle Body Quality

For throttle body manufacturers, compliance with international standards is crucial. Common standards include:

- ISO 9001: This standard specifies requirements for a quality management system and is applicable to any organization, regardless of size or industry. Compliance ensures that the manufacturer consistently provides products that meet customer and regulatory requirements.

- CE Marking: Essential for products sold in Europe, CE marking indicates that the product complies with EU safety, health, and environmental protection standards.

- API Standards: For manufacturers focusing on the automotive sector, adherence to American Petroleum Institute (API) standards can ensure that the components are suitable for use in specific environments.

What are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC includes monitoring forming and assembly processes to identify and rectify any issues immediately.

- Final Quality Control (FQC): This final inspection checks the completed throttle bodies for defects, ensuring they meet all specifications before shipping.

B2B buyers should ask about the supplier’s QC processes and how they document and manage these checkpoints.

What Testing Methods are Commonly Used for Throttle Bodies?

To ensure the reliability and performance of throttle bodies, various testing methods are employed, including:

- Functional Testing: Ensures that the throttle body operates correctly under different conditions, simulating real-world usage.

- Pressure Testing: Checks for leaks and verifies that the throttle body can withstand the pressure conditions it will face in operation.

- Durability Testing: Assesses the throttle body’s ability to perform over extended periods and under varying temperatures and conditions.

Buyers should request details about the testing methods used by suppliers and any certifications that validate the results.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are several strategies:

- Conduct Audits: Regular audits of suppliers can help buyers assess compliance with quality standards and manufacturing practices. This can be done through on-site visits or third-party audits.

- Request Quality Reports: Suppliers should provide documentation of their quality management practices, including QC reports and certifications.

- Engage Third-Party Inspection Services: Utilizing independent inspection agencies can provide an objective assessment of product quality before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances can be complex for international buyers. Key considerations include:

- Regulatory Compliance: Different regions have varying regulations and standards. Buyers must ensure that their suppliers comply with local laws and international standards relevant to their markets.

- Cultural Differences: Understanding cultural attitudes towards quality and business practices in different regions can help buyers establish better relationships with suppliers.

- Supply Chain Transparency: Buyers should seek suppliers who are transparent about their supply chain practices, including sourcing materials and manufacturing processes.

By focusing on these aspects, international B2B buyers can enhance their sourcing strategy for throttle bodies, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘throttle body manufacturer’

In the ever-evolving landscape of automotive manufacturing, sourcing the right throttle body manufacturer is crucial for ensuring quality and performance in your products. This guide aims to provide a practical checklist for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to streamline their procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the specific requirements for the throttle bodies you need, including dimensions, materials, and performance metrics. This clarity will help potential suppliers understand your needs and deliver products that meet your expectations.

- Key Considerations:

- Engine compatibility (e.g., gasoline, diesel).

- Desired features (e.g., electronic vs. mechanical).

- Compliance with regional automotive standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential throttle body manufacturers. Utilize online directories, industry trade shows, and networking to compile a list of candidates. Focus on suppliers with a solid reputation and a history of reliable performance.

- Where to Look:

- Industry-specific platforms like ThomasNet or Alibaba.

- Trade associations and local chambers of commerce.

- Recommendations from industry peers.

Step 3: Verify Supplier Certifications

Before engaging with a supplier, verify their certifications and compliance with international quality standards. Look for ISO certifications, as these indicate a commitment to quality management systems and product consistency.

- Important Certifications:

- ISO 9001 (Quality Management).

- IATF 16949 (Automotive Quality Management).

- Relevant environmental certifications (e.g., ISO 14001).

Step 4: Request Samples for Evaluation

Always request product samples before finalizing a supplier. Evaluating samples allows you to assess the quality, fit, and functionality of the throttle bodies. This step is essential to ensure the supplier can meet your specifications in mass production.

- What to Assess:

- Material quality and durability.

- Design accuracy and compatibility.

- Performance under simulated operating conditions.

Step 5: Assess Production Capacity and Lead Times

Understanding a supplier’s production capacity and lead times is vital for your project planning. Ensure the manufacturer can meet your order volume and delivery timelines, particularly if you have tight deadlines or fluctuating demand.

- Questions to Ask:

- What is the maximum production capacity per month?

- What are the typical lead times for orders of various sizes?

- How do they handle peak demand periods?

Step 6: Review Payment Terms and Conditions

Clarify payment terms early in the negotiation process to avoid any misunderstandings later. Determine whether the supplier offers flexible payment options that align with your cash flow and financial strategy.

- Considerations:

- Payment methods (e.g., letter of credit, wire transfer).

- Deposit requirements and payment schedules.

- Discounts for bulk orders or early payments.

Step 7: Establish Communication Channels

Effective communication is key to a successful supplier relationship. Establish clear communication channels and protocols to address any issues that may arise during the manufacturing and delivery process.

- Best Practices:

- Schedule regular updates and check-ins.

- Utilize project management tools for tracking progress.

- Designate points of contact for quick resolution of queries.

By following this step-by-step checklist, you can enhance your sourcing strategy for throttle body manufacturers, ensuring you select a supplier that meets your technical requirements and supports your business objectives effectively.

Comprehensive Cost and Pricing Analysis for throttle body manufacturer Sourcing

Understanding the cost structure and pricing dynamics of throttle body manufacturing is crucial for international B2B buyers seeking to optimize their sourcing strategies. This section provides a comprehensive breakdown of the cost components, price influencers, and actionable tips for negotiations, particularly relevant for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Throttle Body Manufacturing?

-

Materials: The primary materials used in throttle body production include aluminum, plastics, and rubber gaskets. The choice of materials significantly affects the overall cost. Buyers should consider sourcing high-quality materials to ensure durability and performance, even if they come at a higher initial cost.

-

Labor: Labor costs vary by region and can significantly impact the final price. In countries with lower labor costs, such as some in Africa and South America, buyers may find more competitive pricing. However, it’s essential to assess the skill level and training of the workforce, as this can influence product quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Understanding the overhead costs of potential suppliers can help buyers identify cost-effective options.

-

Tooling: Initial tooling costs can be substantial, especially for custom throttle bodies. Buyers should inquire about the tooling charges upfront, particularly if they require specific designs or modifications.

-

Quality Control (QC): Effective quality control processes are vital for ensuring product reliability. Suppliers with robust QC measures may charge higher prices, but this investment can lead to long-term savings by reducing defects and returns.

-

Logistics: Transportation and handling costs can vary widely based on the supplier’s location and the chosen shipping method. Buyers should evaluate logistics costs in conjunction with the supplier’s pricing to understand the total cost of ownership.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the average margins in the throttle body industry can help buyers negotiate better deals.

How Do Price Influencers Affect Throttle Body Sourcing?

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly influence pricing. Higher order volumes often lead to discounts, making it advantageous for buyers with larger needs to negotiate bulk pricing.

-

Specifications and Customization: Custom designs or specifications can increase costs due to additional engineering and tooling requirements. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and specific certifications (e.g., ISO, TS) can lead to increased costs. Buyers should weigh the benefits of certified products against their budgets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium, but they often provide better support and quality assurance.

-

Incoterms: The terms of sale (Incoterms) can impact the final price due to variations in shipping responsibilities and costs. Understanding these terms is crucial for international transactions.

What Negotiation Tips Can Help International B2B Buyers?

-

Conduct Thorough Market Research: Understanding the market landscape and average pricing can empower buyers during negotiations. This knowledge helps in identifying reasonable offers and recognizing red flags.

-

Focus on Total Cost of Ownership (TCO): Rather than just the upfront price, consider long-term costs associated with the product, including maintenance and logistics. This perspective can justify higher initial investments in quality products.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Regular communication and mutual understanding can foster trust and collaboration.

-

Be Transparent About Needs: Clearly articulating your requirements and constraints can help suppliers provide more tailored solutions that meet your needs without unnecessary costs.

-

Negotiate Terms Beyond Price: Consider negotiating other factors such as payment terms, delivery schedules, and after-sales support, which can provide additional value beyond the initial price.

Final Thoughts

While the cost structure of throttle body manufacturing involves various components that can fluctuate based on multiple factors, understanding these intricacies allows international B2B buyers to make informed sourcing decisions. It is essential to approach negotiations with a comprehensive understanding of both costs and value to achieve the best outcomes for your business. Keep in mind that pricing can vary widely, and all figures should be treated as indicative, requiring further verification based on specific supplier discussions.

Alternatives Analysis: Comparing throttle body manufacturer With Other Solutions

In the competitive landscape of automotive components, particularly throttle bodies, it’s essential for B2B buyers to explore various solutions that can meet their specific requirements. While traditional throttle body manufacturers offer proven products, there are alternative technologies and methods that may provide similar or enhanced benefits. This analysis presents a comparative look at throttle body manufacturers alongside two viable alternatives: electronic throttle control (ETC) systems and variable geometry throttle bodies (VGTBs).

| Comparison Aspect | Throttle Body Manufacturer | Electronic Throttle Control (ETC) | Variable Geometry Throttle Body (VGTB) |

|---|---|---|---|

| Performance | Reliable and consistent airflow control | Enhanced responsiveness and efficiency | Optimized airflow across various RPMs |

| Cost | Varies widely based on brand and specifications | Generally higher initial costs | Moderate cost, but potential savings on fuel |

| Ease of Implementation | Standard installation procedures | Requires advanced integration with ECU | More complex installation and tuning |

| Maintenance | Regular maintenance needed | Low maintenance, fewer mechanical parts | Moderate maintenance, depending on design |

| Best Use Case | Conventional vehicles, racing applications | Modern vehicles with advanced engine management systems | High-performance engines needing precise control |

What Are the Advantages and Disadvantages of Electronic Throttle Control (ETC)?

Pros: Electronic throttle control systems replace traditional mechanical throttle bodies with electronically controlled ones. This transition results in improved responsiveness and efficiency, as the system can adapt to driving conditions in real-time. Additionally, ETC enhances vehicle safety by integrating with traction control and stability systems.

Cons: The primary drawback of ETC is its higher initial cost and the complexity of integration with the vehicle’s electronic control unit (ECU). This complexity may require specialized skills for installation and troubleshooting, which could be a concern for some buyers, especially in regions with limited technical expertise.

How Do Variable Geometry Throttle Bodies (VGTB) Enhance Engine Performance?

Pros: Variable geometry throttle bodies offer optimized airflow management, allowing for better performance across a range of engine speeds. This adaptability can lead to improved fuel efficiency and reduced emissions, making VGTBs an attractive choice for buyers focused on sustainability and performance.

Cons: Despite their advantages, VGTBs are often more complex and expensive to install compared to traditional throttle bodies. The tuning required for optimal performance can also pose a challenge, necessitating a higher level of expertise during installation and maintenance.

How Can B2B Buyers Choose the Right Throttle Body Solution?

When considering throttle body solutions, B2B buyers should evaluate their specific needs, including performance requirements, budget constraints, and the technical capabilities of their installation teams. For conventional applications, established throttle body manufacturers may be the best choice due to their reliability and ease of maintenance. However, for modern vehicles requiring advanced control and efficiency, electronic throttle control systems or variable geometry throttle bodies may provide significant long-term benefits. Ultimately, the decision should align with the buyer’s operational goals and the specific demands of their vehicle applications.

Essential Technical Properties and Trade Terminology for throttle body manufacturer

What Are the Essential Technical Properties for Throttle Body Manufacturing?

When sourcing throttle bodies, understanding the technical specifications is crucial for ensuring compatibility and performance. Here are key properties to consider:

-

Material Grade

The material used in throttle body manufacturing typically includes aluminum alloys or reinforced plastic. Aluminum provides durability and is lightweight, which is essential for performance vehicles. The material grade affects thermal resistance, weight, and corrosion resistance. For B2B buyers, selecting the right material grade ensures longevity and reliability, especially in harsh operating conditions. -

Tolerance Levels

Tolerances refer to the allowable deviation from specified dimensions. For throttle bodies, tight tolerances are critical to ensure proper airflow and engine performance. A typical tolerance might range from ±0.01 mm to ±0.05 mm. Understanding tolerance levels helps buyers assess the precision of the manufacturing process and its impact on the throttle body’s functionality. -

Flow Rate

The flow rate indicates the volume of air the throttle body can manage, typically measured in liters per minute (L/min). A higher flow rate can enhance engine performance, making this specification vital for performance-oriented applications. B2B buyers should evaluate flow rate against their specific engine requirements to achieve optimal performance. -

Pressure Rating

Throttle bodies must withstand varying pressure levels, especially in forced induction applications. Pressure ratings, often expressed in psi (pounds per square inch), denote the maximum pressure the throttle body can handle without failure. Understanding this property is essential for buyers to prevent system failures and ensure safety. -

Surface Finish

The surface finish impacts airflow characteristics and overall performance. A smoother finish can reduce turbulence and improve air delivery to the engine. B2B buyers should consider the surface finish in relation to the expected performance requirements, as it can significantly affect efficiency and power output.

What Are Common Trade Terms Used in Throttle Body Manufacturing?

Familiarity with industry jargon can facilitate better negotiations and agreements. Here are essential trade terms relevant to throttle body manufacturing:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of another company’s end products. In the throttle body industry, sourcing from OEMs ensures that components meet the original design specifications, which is critical for maintaining vehicle integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, especially those in smaller markets, as it affects inventory management and overall cost. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. By providing detailed specifications and quantities, buyers can receive tailored quotes, enabling them to compare costs effectively and choose the best supplier. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, detailing who pays for shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers navigate logistical complexities, ensuring that both parties understand their obligations. -

Lead Time

Lead time is the period between the initiation of an order and its delivery. For throttle body manufacturers, understanding lead times is crucial for project planning and inventory management, enabling buyers to align their production schedules with supply availability. -

Aftermarket Parts

Aftermarket parts are components made by manufacturers other than the OEM. For buyers, understanding the implications of using aftermarket throttle bodies can help in assessing quality, compatibility, and warranty considerations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and ensure the success of their projects.

Navigating Market Dynamics and Sourcing Trends in the throttle body manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Throttle Body Manufacturer Sector?

The throttle body manufacturing sector is experiencing significant transformation, driven by global economic shifts, technological advancements, and evolving consumer preferences. One of the primary drivers of this market is the increasing demand for fuel-efficient and high-performance vehicles, particularly in emerging markets like Africa and South America. This demand is prompting manufacturers to innovate and improve throttle body designs, focusing on electronic throttle control systems that enhance vehicle responsiveness and fuel economy.

A stock image related to throttle body manufacturer.

Additionally, the integration of Industry 4.0 technologies—such as IoT, AI, and automation—has revolutionized the manufacturing processes within this sector. These technologies are enabling manufacturers to optimize production efficiency, reduce waste, and improve product quality. For B2B buyers, sourcing suppliers that leverage these advancements can lead to significant cost savings and enhanced product reliability.

Moreover, the global push towards electrification and hybrid vehicles is shaping the throttle body market. As automotive manufacturers transition to electric and hybrid models, the demand for specialized throttle body components is expected to rise. International buyers from Europe, the Middle East, and Africa must stay informed about these trends to align their sourcing strategies with manufacturers capable of meeting these evolving requirements.

How Is Sustainability and Ethical Sourcing Impacting the Throttle Body Manufacturing Sector?

Sustainability is becoming a critical consideration in the throttle body manufacturing sector. The environmental impact of manufacturing processes and materials used in production is under scrutiny, prompting companies to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and minimizing waste. This trend is particularly strong in Europe, where stringent regulations and consumer preferences are driving manufacturers towards greener practices.

Ethical sourcing is also gaining traction, as companies seek to establish transparent supply chains that ensure fair labor practices and responsible sourcing of materials. Buyers should look for manufacturers that have obtained ‘green’ certifications or utilize eco-friendly materials in their throttle body production. Certifications like ISO 14001 (Environmental Management) and adherence to REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) standards are indicators of a company’s commitment to sustainability.

By prioritizing sustainable and ethical sourcing, B2B buyers not only contribute to environmental preservation but can also enhance their brand reputation and customer loyalty. This alignment with ethical practices is becoming increasingly important in competitive markets across Africa, South America, and the Middle East.

What Is the Historical Context Behind Throttle Body Manufacturing?

The evolution of throttle body manufacturing can be traced back to the early development of automotive technology. Initially, throttle bodies were simple mechanical devices that regulated airflow into the engine, primarily using a cable connected to the accelerator pedal. Over the decades, advancements in automotive engineering led to the introduction of electronic throttle control (ETC) systems, which significantly improved vehicle performance and efficiency.

By the late 20th century, the shift towards fuel injection systems and electronic controls transformed throttle body designs, making them more complex and efficient. This evolution has allowed manufacturers to enhance vehicle emissions control and fuel efficiency, aligning with global regulatory requirements.

Today, the throttle body manufacturing sector is characterized by continuous innovation, with a focus on integrating smart technologies that improve vehicle responsiveness and performance. This historical context is crucial for B2B buyers to understand as they navigate their sourcing decisions, ensuring that they select suppliers who are not only experienced but also forward-thinking in their approach to manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of throttle body manufacturer

-

How can I assess the quality of throttle bodies from manufacturers?

When sourcing throttle bodies, it is crucial to evaluate the manufacturer’s quality assurance processes. Request certifications such as ISO 9001 or TS 16949, which indicate adherence to international quality management standards. Additionally, ask for samples to assess material quality and craftsmanship firsthand. Engaging with third-party testing labs for independent quality checks can also provide assurance. Consider visiting the manufacturing facility if possible, as this can help verify their production capabilities and quality control measures. -

What factors should I consider when selecting a throttle body manufacturer?

Key factors to consider include the manufacturer’s experience in the industry, their production capacity, and technological capabilities. Evaluate their reputation by checking reviews and testimonials from other B2B clients. It’s also vital to assess their ability to meet your specific needs, including customization options and minimum order quantities (MOQs). Finally, consider their logistics capabilities, including shipping times and costs, especially if sourcing from regions like Africa or South America. -

What is the minimum order quantity (MOQ) for throttle bodies?

MOQs can vary significantly among throttle body manufacturers, often depending on the complexity of the design and production capabilities. Generally, MOQs can range from 100 to 1,000 units. It’s advisable to discuss your specific needs with potential suppliers, as many are willing to accommodate smaller orders for new clients or pilot projects. Negotiating terms based on your long-term purchasing potential can also be beneficial. -

How can I customize throttle bodies for my specific applications?

Most manufacturers offer customization options, including size, material, and design modifications. To initiate this process, provide detailed specifications and performance requirements to the manufacturer. Discuss potential prototypes and request samples to ensure the modifications meet your expectations. Establishing a collaborative relationship with the manufacturer can facilitate smoother adjustments and lead to better final products tailored to your applications. -

What payment terms are typically available when sourcing throttle bodies?

Payment terms vary widely among manufacturers and can include options like net 30, net 60, or upfront payments. Many manufacturers may require a deposit before production begins, especially for custom orders. It’s essential to clarify these terms in the initial discussions and explore flexible options, such as letters of credit or escrow services, to mitigate risks in international transactions. -

How do I ensure timely delivery of throttle bodies from international suppliers?

Timely delivery can be secured by establishing clear communication channels with the manufacturer. Discuss lead times upfront and set realistic delivery expectations based on production schedules. Consider using logistics partners with experience in international shipping to navigate customs and other regulatory hurdles. Additionally, tracking shipments and maintaining regular updates can help manage any potential delays proactively. -

What are the best practices for vetting throttle body suppliers?

Vetting suppliers involves thorough research and due diligence. Start by checking their business credentials and certifications. Request references from previous clients and review case studies or success stories. Conduct audits or site visits to assess their manufacturing capabilities and quality control processes. Finally, utilize platforms like Alibaba or industry-specific directories that provide ratings and reviews to evaluate supplier reliability. -

How can I address potential language barriers with international manufacturers?

Language barriers can be mitigated by using clear, concise communication and confirming understanding through paraphrasing. Employing a professional translator for critical discussions or documents can also help avoid misunderstandings. Additionally, many manufacturers may have English-speaking representatives or use translation software to facilitate smoother interactions. Establishing a clear point of contact can streamline communication and ensure that all parties are aligned on expectations and requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for throttle body manufacturer

What Are the Key Takeaways for Strategic Sourcing in Throttle Body Manufacturing?

In the evolving landscape of throttle body manufacturing, international B2B buyers must prioritize strategic sourcing to enhance competitiveness and operational efficiency. The key takeaways include the importance of establishing robust supplier relationships, leveraging advanced technologies for quality assurance, and maintaining flexibility in sourcing strategies to adapt to market changes. Buyers should also consider local sourcing options to mitigate risks associated with global supply chains, particularly in regions like Africa and South America, where local partnerships can yield significant benefits.

How Can Buyers Prepare for Future Trends in Throttle Body Manufacturing?

Looking ahead, the throttle body manufacturing sector is poised for innovation driven by advancements in automotive technology, including the rise of electric vehicles and increased demand for eco-friendly solutions. Buyers are encouraged to stay informed about these trends and assess how they can align their sourcing strategies to incorporate sustainable practices and cutting-edge technologies.

What Is the Next Step for International B2B Buyers?

Now is the time for international B2B buyers from Africa, South America, the Middle East, and Europe to take proactive steps in their strategic sourcing efforts. By focusing on collaboration with reliable manufacturers and exploring new technologies, businesses can ensure they remain at the forefront of the industry. Engage with suppliers, attend industry expos, and participate in relevant forums to cultivate relationships that can drive growth and innovation.