Discover Top Tips to Choose a Challenge Coin Manufacturer (2025)

Introduction: Navigating the Global Market for challenge coin manufacturer

In the ever-evolving landscape of global commerce, sourcing a reliable challenge coin manufacturer can pose significant challenges for international B2B buyers. Companies across Africa, South America, the Middle East, and Europe, including countries like Poland and Australia, often struggle to find suppliers who not only meet their quality expectations but also understand the cultural significance and diverse applications of challenge coins. This guide is designed to address these challenges by providing a comprehensive overview of the challenge coin market, including various types of coins, their applications, and the critical factors involved in supplier vetting.

By exploring essential topics such as production processes, customization options, and cost considerations, this guide empowers B2B buyers to make informed purchasing decisions. It delves into the nuances of working with manufacturers from different regions, offering insights into how to negotiate terms effectively and build lasting partnerships. Additionally, we will examine the importance of quality assurance and how to ensure that the coins produced align with your brand’s values and objectives.

Whether you are looking to commemorate a significant event, recognize employee achievements, or enhance your branding strategy, understanding the intricacies of sourcing challenge coins is paramount. This guide will serve as a valuable resource, equipping you with the knowledge needed to navigate the global market confidently and effectively.

Understanding challenge coin manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Design Manufacturers | Tailored designs based on client specifications | Corporate branding, military units | Pros: Unique products, strong branding. Cons: Longer lead times, potentially higher costs. |

| Stock Design Manufacturers | Pre-designed templates for quick customization | Events, promotional giveaways | Pros: Faster turnaround, cost-effective. Cons: Limited originality, less personal touch. |

| Specialty Materials Makers | Use of unique materials like wood, acrylic, or metal | Collectibles, high-end promotions | Pros: Distinctive products, premium feel. Cons: Higher prices, niche market appeal. |

| Eco-Friendly Manufacturers | Focus on sustainable materials and production methods | Corporate social responsibility (CSR) initiatives | Pros: Positive brand image, compliance with regulations. Cons: May have limited design options, higher costs. |

| Digital Printing Specialists | Employ advanced printing techniques for detailed designs | Marketing, event promotions | Pros: High detail, cost-effective for small runs. Cons: Less durable than traditional methods, may not suit all designs. |

What are the characteristics of Custom Design Manufacturers for Challenge Coins?

Custom design manufacturers specialize in creating unique challenge coins tailored to specific client requirements. They work closely with businesses to develop designs that reflect their branding, values, and messages. This type of manufacturer is particularly suitable for organizations looking to commemorate special events or achievements with a personalized touch. When considering a custom manufacturer, B2B buyers should evaluate the manufacturer’s design capabilities, lead times, and pricing structures, as bespoke options often come with longer production timelines and higher costs.

How do Stock Design Manufacturers differ from Custom Options?

Stock design manufacturers provide pre-existing templates that clients can customize with minimal alterations. This approach allows for quicker production times and is often more cost-effective, making it ideal for businesses needing challenge coins for events or promotions without extensive design requirements. Buyers should consider the trade-offs between speed and originality, as stock designs might not fully capture a company’s unique identity. This option is best for organizations focused on budget and time constraints.

What makes Specialty Materials Makers a unique choice for Challenge Coins?

Specialty materials makers focus on producing challenge coins using unique materials such as wood, acrylic, or various metals. These manufacturers cater to niche markets looking for distinctive products that stand out, such as collectibles or high-end promotional items. B2B buyers interested in specialty coins should assess the durability and aesthetic appeal of the materials used, as well as the target audience’s preferences. While these coins can command higher prices, their exclusivity can enhance brand prestige.

Why should businesses consider Eco-Friendly Manufacturers for Challenge Coins?

Eco-friendly manufacturers prioritize sustainable materials and production methods, aligning with corporate social responsibility (CSR) initiatives. By choosing eco-friendly options, B2B buyers can enhance their brand image and demonstrate commitment to environmental stewardship. However, these manufacturers may offer limited design options and potentially higher costs, which buyers need to weigh against their sustainability goals. This choice is particularly appealing for organizations focused on eco-conscious branding.

How do Digital Printing Specialists cater to the Challenge Coin Market?

Digital printing specialists utilize advanced printing techniques to create detailed designs on challenge coins. This method is particularly effective for small production runs or when intricate designs are required. B2B buyers should consider the trade-offs in durability, as digitally printed coins may not hold up as well as those produced through traditional methods. However, for marketing campaigns or events where high detail is paramount, this option provides a cost-effective solution.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of challenge coin manufacturer

| Industry/Sector | Specific Application of Challenge Coin Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military and Defense | Commemorative and Recognition Coins | Enhances morale and fosters a sense of belonging | Quality assurance, customization options, delivery timelines |

| Corporate and Business Awards | Employee Recognition and Incentive Programs | Boosts employee engagement and retention | Bulk order capabilities, design flexibility, pricing structure |

| Sports and Recreation | Team Spirit and Fundraising Initiatives | Strengthens team unity and supports local causes | Minimum order quantities, design intricacies, lead times |

| Education and Academia | Graduation and Achievement Tokens | Celebrates milestones and enhances institutional pride | Material specifications, customization levels, sourcing reliability |

| Non-Profit Organizations | Donor Recognition and Fundraising Tools | Acknowledges contributions and encourages donations | Cost-effectiveness, ethical sourcing, branding opportunities |

How Are Challenge Coins Used in the Military and Defense Sector?

In the military and defense sector, challenge coins serve as commemorative and recognition items that honor service members’ achievements and foster camaraderie. These coins are often awarded during ceremonies or events, enhancing morale and a sense of belonging among troops. For international buyers, especially from regions with active military engagement, sourcing high-quality, customizable coins with a quick turnaround time is crucial to meet specific commemorative needs.

What Role Do Challenge Coins Play in Corporate and Business Awards?

Challenge coins are increasingly utilized in corporate environments as part of employee recognition and incentive programs. By awarding these coins, companies can effectively boost employee engagement and retention, recognizing achievements in a tangible form. Buyers from Africa, South America, and Europe should consider manufacturers that offer bulk order capabilities and flexible design options to align with their branding strategies while ensuring a competitive pricing structure.

How Are Challenge Coins Used in Sports and Recreation?

In the sports and recreation industry, challenge coins are used to promote team spirit and support fundraising initiatives. Teams can sell these coins to raise funds or as awards for achievements, fostering unity and community engagement. Buyers should focus on manufacturers that can accommodate minimum order quantities and provide intricate designs to reflect team branding, ensuring timely delivery for events or seasons.

What Are the Applications of Challenge Coins in Education and Academia?

Educational institutions utilize challenge coins as graduation and achievement tokens, celebrating milestones for students and enhancing institutional pride. These coins serve as memorable keepsakes that reinforce the values and accomplishments of graduates. When sourcing challenge coins, buyers from educational sectors should prioritize material specifications and customization levels to ensure that the coins reflect the institution’s identity and values effectively.

How Do Non-Profit Organizations Benefit from Challenge Coins?

Non-profit organizations often employ challenge coins as tools for donor recognition and fundraising efforts. By acknowledging contributions with these tokens, organizations can encourage further donations and build lasting relationships with supporters. Buyers in this sector should look for cost-effective solutions and ethical sourcing options, ensuring that the coins align with the organization’s mission while providing branding opportunities that resonate with donors.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘challenge coin manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Challenge Coin Manufacturing

The Problem:

B2B buyers often face the challenge of ensuring that the challenge coins they order meet their quality expectations. This is particularly critical for organizations in sectors such as military, corporate, and non-profit, where the coins serve as symbols of achievement or recognition. Buyers may receive products that do not match the specifications provided, leading to dissatisfaction among stakeholders and potential damage to the brand’s reputation.

The Solution:

To mitigate quality assurance challenges, buyers should prioritize establishing clear communication with the challenge coin manufacturer right from the outset. This includes providing detailed design specifications, material preferences, and quantity requirements. It’s also crucial to request samples before placing a large order. This not only ensures that the manufacturer understands the quality standards expected but also allows the buyer to evaluate the craftsmanship firsthand. When sourcing manufacturers, look for those with certifications or industry standards, such as ISO certifications, which indicate a commitment to quality. Regular updates and check-ins during the production process can further help in maintaining quality assurance.

Scenario 2: Dealing with Long Lead Times in Production

The Problem:

A common pain point for international B2B buyers is the extended lead times associated with the manufacturing of challenge coins. This can be particularly problematic for organizations that require coins for specific events, such as award ceremonies or promotional launches, which have fixed timelines. Delays in production can lead to missed opportunities and increased costs, as urgent shipping may be necessary.

The Solution:

To address issues related to lead times, buyers should engage in proactive project management and set realistic timelines. When negotiating with manufacturers, inquire about their production capacity and typical turnaround times. It’s advisable to place orders well in advance of any key dates. Additionally, consider establishing a long-term partnership with a reliable manufacturer, which can often lead to prioritized service and shorter lead times. Communication is also vital; regular check-ins can help identify any potential delays early, allowing buyers to adjust their plans accordingly.

Scenario 3: Understanding Customization Options and Costs

The Problem:

Many international B2B buyers struggle with understanding the full scope of customization options available for challenge coins and how these options impact pricing. This can lead to frustration when trying to balance aesthetic appeal with budget constraints. Additionally, hidden costs may arise from intricate designs or special finishes, complicating the purchasing decision.

The Solution:

To navigate the complexities of customization and associated costs, buyers should conduct thorough market research and seek detailed quotes from multiple manufacturers. It’s essential to ask for a breakdown of costs associated with different customization options, such as enamel colors, engraving, and additional features like packaging. Engage in open discussions with manufacturers about your budget and design goals; experienced manufacturers can often provide insights into cost-effective alternatives that do not compromise quality. Furthermore, consider running focus groups or surveys within your organization to gauge preferences on design elements, ensuring that the final product resonates well with the intended audience while staying within budget constraints.

Strategic Material Selection Guide for challenge coin manufacturer

When selecting materials for challenge coins, it’s essential to understand the properties, advantages, and limitations of each option. This guide analyzes four common materials used in challenge coin manufacturing, providing actionable insights for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Zinc Alloy in Challenge Coins?

Zinc alloy is one of the most popular materials for challenge coins due to its favorable properties. It offers excellent malleability, allowing for intricate designs and details. Zinc alloys typically have a good corrosion resistance, making them suitable for various environments. They can withstand moderate temperatures and pressures, which is beneficial for coins that may be exposed to different conditions.

Pros: The primary advantages of zinc alloy include its cost-effectiveness and ease of manufacturing. It is relatively inexpensive compared to other metals, making it a popular choice for bulk orders. The material also allows for high-quality finishes, which enhances the aesthetic appeal of the coins.

Cons: However, zinc alloy is not as durable as some other materials, such as brass or stainless steel. It can be prone to scratching and may tarnish over time if not properly coated.

Impact on Application: Given its properties, zinc alloy is suitable for commemorative and promotional coins that do not require extreme durability. Buyers should consider the environmental conditions where the coins will be used to ensure longevity.

How Does Brass Compare as a Material for Challenge Coins?

Brass is another widely used material for challenge coins, known for its attractive golden appearance and excellent durability. It has good corrosion resistance and can withstand higher temperatures than zinc alloys, making it a reliable choice for various applications.

Pros: The primary advantage of brass is its durability and aesthetic appeal. It can be polished to a high shine, making it visually striking. Additionally, brass coins can be plated with other metals, such as gold or silver, enhancing their value and appeal.

Cons: On the downside, brass can be more expensive than zinc alloy, which may affect budget considerations for large orders. It is also heavier, which could impact shipping costs.

Impact on Application: Brass is ideal for high-end commemorative coins or military challenge coins where durability and appearance are paramount. International buyers should be aware of any specific standards for brass quality in their regions, such as ASTM or DIN.

What are the Benefits of Using Stainless Steel for Challenge Coins?

Stainless steel is recognized for its outstanding durability and corrosion resistance, making it an excellent choice for challenge coins intended for long-term use. It can withstand extreme temperatures and pressures, ensuring that the coins maintain their integrity over time.

Pros: One of the key advantages of stainless steel is its strength and resistance to wear and tear. It is also hypoallergenic, making it suitable for a wider audience. The material can be finished in various ways, providing versatility in design.

Cons: The main disadvantage of stainless steel is its higher cost compared to zinc alloys and brass. The manufacturing process can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel is particularly suitable for coins that will be used in outdoor or rugged environments. Buyers should consider the specific grades of stainless steel that comply with international standards, ensuring quality and consistency.

What Role Does Copper Play in Challenge Coin Manufacturing?

Copper is less commonly used alone for challenge coins but is often alloyed with other metals to enhance properties. It offers excellent thermal and electrical conductivity and has a unique reddish appearance that can be appealing.

Pros: The advantages of copper include its malleability and the ability to create detailed designs. It can also be plated with other metals to improve its appearance and resistance to tarnishing.

Cons: However, copper is prone to corrosion and tarnishing if not properly treated. It is also heavier than other materials, which could affect shipping and handling.

Impact on Application: Copper is best used in limited edition or artistic coins where aesthetic appeal is prioritized over durability. Buyers should consider the environmental factors that may affect copper coins, particularly in humid or coastal regions.

Summary Table of Material Selection for Challenge Coins

| Material | Typical Use Case for challenge coin manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Zinc Alloy | Commemorative and promotional coins | Cost-effective and easy to manufacture | Less durable, prone to tarnishing | Low |

| Brass | High-end commemorative or military coins | Durable and aesthetically appealing | Higher cost, heavier | Med |

| Stainless Steel | Outdoor or rugged environment coins | Outstanding durability and corrosion resistance | Higher cost, complex manufacturing | High |

| Copper | Artistic or limited edition coins | Malleable and allows detailed designs | Prone to corrosion and tarnishing | Med |

This strategic material selection guide provides essential insights for international B2B buyers, ensuring informed decisions that align with both budgetary constraints and product requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for challenge coin manufacturer

What Are the Key Stages in the Manufacturing Process for Challenge Coins?

The manufacturing process for challenge coins involves several critical stages, each contributing to the final product’s quality and appeal. Understanding these stages is essential for B2B buyers looking to procure high-quality challenge coins.

Material Preparation: What Materials Are Used for Challenge Coins?

The first stage in the manufacturing process is material preparation. Common materials used for challenge coins include brass, zinc alloy, and stainless steel. Each material offers distinct properties, such as durability, weight, and aesthetic appeal. For instance, brass is favored for its classic look and malleability, while stainless steel is chosen for its strength and resistance to corrosion.

Buyers should inquire about the source of these materials, as high-quality raw materials are crucial for the durability and longevity of the coins. It’s also wise to consider suppliers that adhere to sustainable practices, especially in regions where environmental standards may vary.

How Are Challenge Coins Formed?

Once the materials are prepared, the next step is forming the coins. This process typically involves die casting or stamping. Die casting is advantageous for producing intricate designs and is often used for high-volume orders. Stamping, on the other hand, is suitable for simpler designs and can be more cost-effective for smaller runs.

During this stage, it’s essential to ensure that the manufacturer has the necessary equipment and expertise to handle various complexities in design. B2B buyers should request samples of previous work to assess the manufacturer’s capability in producing detailed and precise designs.

What Happens During Assembly and Finishing of Challenge Coins?

The assembly stage may involve adding features such as enamel coloring, plating, or edge finishes. These finishing touches are critical as they enhance the aesthetic value of the coins. Common techniques include soft enamel, hard enamel, and antique finishes. Each technique offers a different look and feel, allowing buyers to customize their coins according to branding needs.

Quality assurance in this stage is vital. Manufacturers should have stringent checks to ensure that the finishing processes do not compromise the coin’s design or structural integrity. Buyers should ask for detailed descriptions of the finishing techniques used and any customization options available.

How Is Quality Assurance Integrated into Challenge Coin Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets industry standards and client expectations. B2B buyers must understand the QA processes in place when selecting a challenge coin manufacturer.

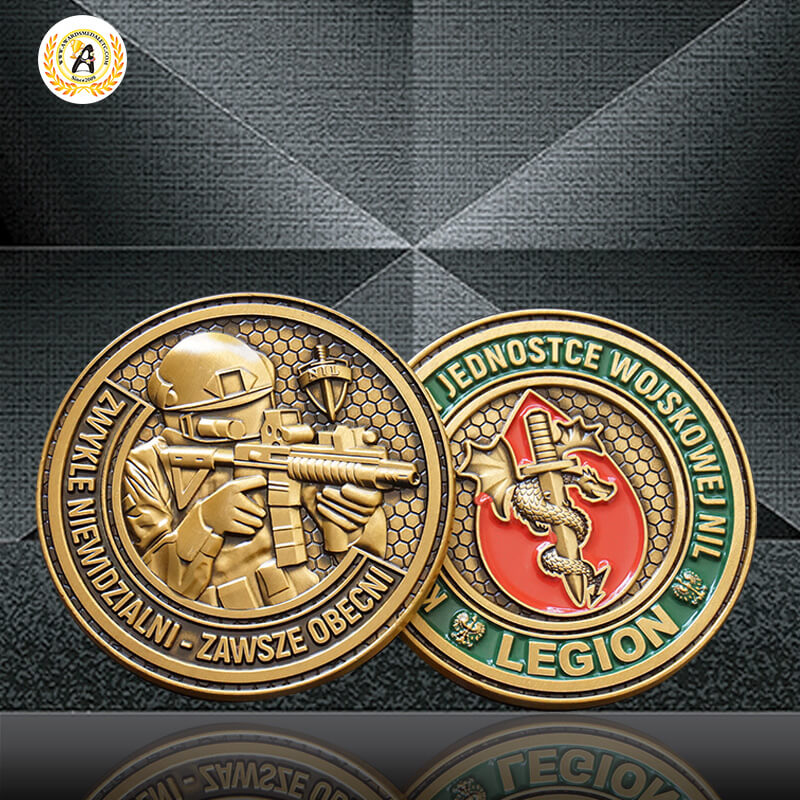

A stock image related to challenge coin manufacturer.

What International Standards Should Challenge Coin Manufacturers Adhere To?

International standards such as ISO 9001 are crucial for manufacturers to ensure consistent quality. ISO 9001 certification indicates that the manufacturer has implemented a quality management system that meets international benchmarks. Additionally, industry-specific standards like CE marking in Europe and API standards for certain applications may apply, depending on the intended use of the coins.

B2B buyers should verify that their chosen manufacturers hold the relevant certifications. This can often be done through official documentation or by visiting the manufacturer’s facility.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints should be established at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks should be conducted to monitor compliance with design specifications and quality standards.

- Final Quality Control (FQC): Once production is complete, a thorough inspection of the finished coins is necessary to ensure they meet all quality and design specifications.

B2B buyers should inquire about the specific QC procedures a manufacturer follows and request documentation demonstrating compliance with these processes.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a challenge coin manufacturer maintains high-quality standards, buyers can take several proactive steps:

What Audit Processes Should Be Considered?

A stock image related to challenge coin manufacturer.

Conducting regular audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Audits can be performed in person or through third-party inspection services that specialize in manufacturing oversight. Buyers should look for manufacturers who are open to audits and provide transparent access to their production facilities.

How to Request Quality Reports and Testing Methods?

Buyers should request detailed quality reports that outline the testing methods used to assess the coins. Common testing methods include:

- Visual Inspections: Checking for defects in design and finish.

- Dimensional Measurements: Ensuring that coins meet specified dimensions.

- Material Testing: Verifying the composition and durability of materials used.

By obtaining these reports, buyers can better assess the quality of the coins they plan to purchase.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Different regions may have unique standards, certifications, and expectations regarding product quality.

How to Navigate Regional Compliance and Standards?

Buyers should familiarize themselves with the specific regulations and standards applicable in their regions. For instance, European buyers may require CE marking, while buyers in the Middle East might prioritize compliance with local regulations. Understanding these nuances can help buyers select manufacturers who are not only compliant but also adaptable to different market requirements.

Why Is Communication Key in Quality Assurance?

Effective communication with suppliers is crucial. Buyers should clearly articulate their quality expectations and ensure that manufacturers can meet these demands. Regular communication can help address any potential issues early in the process and foster a collaborative relationship focused on quality.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting a challenge coin manufacturer, ensuring they receive a high-quality product that meets their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘challenge coin manufacturer’

This guide serves as a comprehensive checklist for international B2B buyers looking to procure challenge coins from manufacturers. By following these actionable steps, you can ensure that your sourcing process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to have a clear understanding of your technical requirements. Consider the size, material, design, and finish of the challenge coins you need.

– Material Choices: Common options include zinc alloy, brass, and copper; each offers different durability and aesthetic qualities.

– Design Elements: Think about custom engravings, logos, and any specific color requirements that reflect your brand or purpose.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify manufacturers that specialize in challenge coins. Look for companies with a proven track record in your region or industry.

– Online Directories: Utilize platforms like Alibaba, ThomasNet, or local trade directories to find potential suppliers.

– Trade Shows and Exhibitions: Attend industry-specific events to meet manufacturers face-to-face and assess their offerings.

Step 3: Evaluate Supplier Capabilities

Once you’ve shortlisted potential manufacturers, evaluate their production capabilities. This step is crucial to ensure they can meet your volume and quality requirements.

– Production Capacity: Inquire about their ability to handle both small and large orders.

– Technology and Equipment: Assess whether they use modern manufacturing techniques that can ensure precision and quality.

Step 4: Request Samples

Before finalizing any agreements, request samples of their previous work. This allows you to assess the quality and craftsmanship of the challenge coins they produce.

– Quality Check: Examine the finish, weight, and overall feel of the coins.

– Customization Accuracy: Ensure that the samples align with your design specifications, including any logos or text.

Step 5: Verify Supplier Certifications

It’s important to verify that the manufacturers comply with industry standards and certifications. This step helps mitigate risks associated with quality and safety.

– Quality Management System (QMS): Look for ISO certifications or similar standards that indicate a commitment to quality.

– Ethical Practices: Ensure they adhere to ethical sourcing practices, especially if you are importing to regions with strict regulations.

Step 6: Negotiate Terms and Pricing

Once you’ve settled on a manufacturer, negotiate the terms of your order, including pricing, lead times, and payment terms.

– Bulk Discounts: Inquire about pricing tiers based on order quantities.

– Payment Security: Consider using secure payment methods that offer buyer protection, especially for large orders.

Step 7: Establish Clear Communication Channels

Maintain open lines of communication with your chosen supplier throughout the production process. Clear communication can prevent misunderstandings and ensure that your specifications are met.

– Regular Updates: Set a schedule for progress updates to keep track of production milestones.

– Point of Contact: Designate a primary contact person on both sides to streamline communication.

By following these steps, international B2B buyers can navigate the sourcing process for challenge coins effectively, ensuring that their needs are met while maintaining high standards of quality and ethical practices.

Comprehensive Cost and Pricing Analysis for challenge coin manufacturer Sourcing

What Are the Key Cost Components in Challenge Coin Manufacturing?

Understanding the cost structure of challenge coin manufacturing is crucial for international B2B buyers looking to optimize their sourcing strategies. The primary components contributing to the overall cost include:

-

Materials: The choice of materials significantly impacts the cost of challenge coins. Common materials include zinc alloy, brass, and copper. Specialty finishes, like enamel or antique plating, can also add to material costs. It’s essential to evaluate the durability and aesthetic qualities of the materials to ensure they meet your requirements.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs, such as certain areas in Africa and South America, might offer competitive pricing. However, consider the skill level and experience of the workforce, as these factors can influence the quality of the final product.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Understanding the overhead in different regions can help you identify the most cost-effective manufacturing partners.

-

Tooling: Initial tooling costs for molds and dies are a significant upfront investment. If you plan to order large volumes, negotiating these costs can lead to substantial savings over time.

-

Quality Control (QC): Ensuring that your coins meet the required specifications involves QC processes that can add to the overall cost. Investing in robust QC measures can prevent costly reworks or returns, particularly when sourcing from international suppliers.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and the chosen Incoterms. Understanding these logistics costs is vital for calculating the total cost of ownership.

-

Margin: Manufacturers typically add a profit margin on top of production costs. This margin can vary based on the supplier’s business model, market demand, and competition.

How Do Price Influencers Affect Challenge Coin Sourcing?

Several factors can influence the pricing of challenge coins, and being aware of these can help buyers make informed decisions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may have minimum order quantities, so negotiating MOQs can be beneficial if you anticipate repeat orders.

-

Specifications and Customization: Custom designs or unique specifications can significantly increase costs. Providing clear specifications upfront can help suppliers give accurate quotes, minimizing the risk of unexpected costs later.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO standards) can add to the cost but may be necessary for certain applications. Assess the importance of these factors in your purchasing decision.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers with a proven track record may charge more but can offer better quality assurance and service.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Understanding terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is critical for cost management in international transactions.

What Are Effective Buyer Tips for Negotiating Challenge Coin Prices?

To achieve cost-efficiency in sourcing challenge coins, consider the following tips:

-

Negotiate Terms and Pricing: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may be willing to offer discounts for bulk purchases or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with your purchase, including production, shipping, and potential tariffs. A lower upfront price may not always translate to lower TCO.

-

Understand Pricing Nuances for Different Regions: Regional factors can influence pricing. For example, sourcing from South America might be more cost-effective due to lower labor costs, while European suppliers may offer higher quality assurance.

-

Build Relationships with Suppliers: Developing strong relationships can lead to better pricing, more favorable terms, and improved service. Long-term partnerships often yield better negotiation outcomes.

-

Request Multiple Quotes: Obtaining quotes from several manufacturers can provide a clearer picture of the market and help you identify the best value for your investment.

By understanding the cost components, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions when sourcing challenge coins. Always keep in mind that prices can vary widely, and it’s essential to conduct thorough research and due diligence before finalizing any agreements.

Alternatives Analysis: Comparing challenge coin manufacturer With Other Solutions

Exploring Alternatives to Challenge Coin Manufacturing

In the realm of corporate branding and recognition, challenge coins have gained popularity as tangible tokens of appreciation and achievement. However, as international B2B buyers consider their options, it is essential to explore alternative solutions that can achieve similar objectives. This section delves into how challenge coin manufacturing compares to other methods of recognition and branding, providing a well-rounded view for decision-makers in regions such as Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Challenge Coin Manufacturer | Custom Medals | Digital Badges |

|---|---|---|---|

| Performance | High-quality craftsmanship | Durable but may vary | Instant delivery |

| Cost | Moderate to high | Moderate | Low to moderate |

| Ease of Implementation | Moderate complexity | Simple | Very simple |

| Maintenance | Low maintenance | Low maintenance | No maintenance |

| Best Use Case | Corporate recognition | Sports events | Online achievements |

What Are the Benefits and Drawbacks of Custom Medals?

Custom medals serve as a viable alternative to challenge coins, particularly in scenarios such as sporting events or academic achievements. They are generally more cost-effective and can be produced in bulk easily. However, while custom medals offer durability, their design may not achieve the same level of intricacy and craftsmanship as challenge coins. B2B buyers should consider the context in which these medals will be used, as they might not convey the same level of prestige associated with challenge coins.

How Do Digital Badges Compare to Traditional Challenge Coins?

Digital badges represent a modern alternative to physical tokens, focusing on online recognition. They can be issued instantly and are often integrated into digital platforms, making them ideal for virtual events or remote team recognition. The primary advantage of digital badges lies in their low cost and ease of implementation. However, they lack the tactile and sentimental value that physical challenge coins provide. Businesses targeting tech-savvy audiences may find digital badges to be an effective solution, while industries that value tradition might prefer physical tokens.

How Can International B2B Buyers Make the Right Choice?

When selecting between challenge coin manufacturers and alternative solutions, B2B buyers should evaluate their specific goals and audience. If the intention is to foster a sense of tradition and loyalty within teams, challenge coins may be the best fit. Conversely, for organizations looking to recognize achievements in a more cost-effective and modern way, custom medals or digital badges could be appropriate. Understanding the unique attributes of each option will empower buyers to make informed decisions that align with their branding and recognition strategies.

Essential Technical Properties and Trade Terminology for challenge coin manufacturer

What Are the Key Technical Properties of Challenge Coins?

When sourcing challenge coins, understanding their technical properties is crucial for making informed purchasing decisions. Here are the essential specifications that B2B buyers should consider:

1. Material Grade: Why Does It Matter?

Challenge coins are typically made from a variety of metals, including zinc alloy, brass, copper, and nickel. The material grade impacts not only the aesthetic appeal but also the durability and cost of the coins. High-quality materials are more resistant to wear and corrosion, ensuring that the coins maintain their appearance over time. For buyers, selecting the right material is vital to ensure the coins meet their branding and commemorative needs.

2. Tolerance: What Is the Importance of Precision?

Tolerance refers to the allowable deviation from a specified dimension in the manufacturing process. For challenge coins, this can include the thickness, diameter, and any engravings. Tight tolerances are essential for achieving a high-quality finish and ensuring that coins fit perfectly with any accompanying display cases or promotional materials. Buyers should ensure that their manufacturers can meet specific tolerance requirements to avoid issues in the final product.

3. Finish Type: How Does It Influence Presentation?

The finish type of a challenge coin can significantly affect its visual appeal. Common finishes include antique, polished, or matte. Each finish not only alters the look of the coin but can also impact its perceived value. B2B buyers should consider how the finish aligns with their branding strategy, as a well-finished coin can enhance brand image and recognition.

4. Weight: Why Is It a Key Consideration?

The weight of a challenge coin often conveys quality and significance. Heavier coins are frequently perceived as more valuable, which can enhance their desirability for collectors or recipients. When sourcing, buyers should evaluate the weight specifications to ensure they align with the intended purpose of the coins, whether for awards, promotions, or commemorations.

What Are Common Trade Terminology and Jargon in the Challenge Coin Industry?

Understanding trade terminology is essential for effective communication with manufacturers and suppliers. Here are some key terms that B2B buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of challenge coins, an OEM might produce the coins based on designs and specifications provided by the buyer. This relationship is crucial for ensuring that the coins meet exact requirements and branding standards.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ refers to the smallest quantity of product that a supplier is willing to sell. For challenge coins, MOQs can vary widely based on the manufacturer. Understanding MOQ is essential for budgeting and inventory planning, especially for businesses looking to launch a new campaign or commemorate an event.

3. RFQ (Request for Quotation): How Should It Be Used?

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. When dealing with challenge coin manufacturers, an RFQ should detail the desired specifications, including material, design, and quantity. This helps ensure that buyers receive accurate quotes and can compare offerings effectively.

4. Incoterms: What Do They Mean for Shipping?

Incoterms (International Commercial Terms) are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping costs, risk, and insurance responsibilities when importing challenge coins. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which dictate who is responsible for various aspects of the shipping process.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing challenge coins, ensuring that they select the right manufacturer and product to meet their needs.

Navigating Market Dynamics and Sourcing Trends in the challenge coin manufacturer Sector

What Are the Key Market Dynamics and Trends in the Challenge Coin Manufacturing Sector?

The challenge coin manufacturing sector is experiencing a transformative phase driven by globalization, technological advancements, and shifting consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate a landscape influenced by rising demand for customization and personalization. These trends are propelled by the growing significance of branding and employee recognition programs across various industries. Moreover, the increasing use of e-commerce platforms for sourcing challenge coins has streamlined procurement processes, making it easier for buyers to access a diverse range of suppliers and products.

Emerging technologies such as 3D printing and laser engraving are revolutionizing the production of challenge coins, allowing for rapid prototyping and intricate designs. This shift not only enhances creativity but also reduces lead times, which is crucial for B2B buyers seeking timely deliveries. Furthermore, the integration of digital tools in supply chain management is facilitating better transparency and communication between manufacturers and buyers, thus fostering stronger partnerships.

How Does Sustainability Influence Sourcing Decisions in the Challenge Coin Sector?

Sustainability has become a pivotal concern in the challenge coin manufacturing industry. B2B buyers are increasingly recognizing the environmental impact of their sourcing decisions, prompting a shift toward more sustainable practices. Ethical supply chains are now a priority, as businesses aim to align their procurement strategies with their corporate social responsibility goals. This is particularly relevant for international buyers from regions like Africa and Europe, where consumers are demanding greater accountability from brands.

The adoption of eco-friendly materials and production processes is gaining traction. Manufacturers are now exploring options such as recycled metals and sustainable packaging, which not only reduce environmental footprints but also appeal to a growing demographic of eco-conscious consumers. Certifications like ISO 14001 for environmental management and the use of green materials can enhance a manufacturer’s credibility in the eyes of international buyers. Engaging with suppliers who prioritize sustainability can provide a competitive edge in the market while contributing positively to global environmental efforts.

What Is the Historical Context of Challenge Coin Manufacturing?

The origins of challenge coins can be traced back to military traditions, where they served as symbols of camaraderie and achievement. Over the decades, the concept has evolved, transcending military use to become a popular tool for branding, recognition, and marketing across various sectors. In the early 2000s, as corporate culture began to embrace employee recognition programs, the demand for challenge coins surged, prompting manufacturers to innovate in design and production techniques.

Today, challenge coins are not only prevalent in military and corporate environments but have also found applications in nonprofit organizations, educational institutions, and sports teams. This evolution reflects a broader trend towards personalization in branding and employee engagement, making challenge coins a versatile product for international B2B buyers seeking unique ways to foster loyalty and recognition. Understanding this historical context can help buyers appreciate the significance of challenge coins and their potential impact on organizational culture and branding strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of challenge coin manufacturer

-

How do I solve supply chain challenges when sourcing challenge coins internationally?

To mitigate supply chain challenges when sourcing challenge coins, start by establishing clear communication with your manufacturer about timelines and expectations. Conduct thorough research to identify suppliers with a proven track record in international shipping and customs compliance. Utilize technology for real-time tracking of shipments and consider regional suppliers to reduce lead times. Building strong relationships with logistics partners can also streamline the process, ensuring your orders are delivered on time and within budget. -

What is the best way to vet a challenge coin manufacturer before placing an order?

The best way to vet a challenge coin manufacturer is to conduct a comprehensive background check. Look for reviews and testimonials from previous clients, and request samples of their work to assess quality. Verify their certifications and compliance with international standards, especially if you’re sourcing from regions like Africa or the Middle East. Engaging in direct communication, such as video calls, can also provide insights into their operational practices and responsiveness. -

What customization options are available for challenge coins?

Customization options for challenge coins typically include size, shape, metal finish, and design elements such as logos and text. Many manufacturers offer a range of finishes like antique, shiny, or matte, as well as the option to add color enamel or edge designs. Discuss your specific requirements with the manufacturer to explore innovative designs that align with your brand identity. Ensure you receive a digital proof before final production to confirm that the design meets your expectations. -

What are the typical minimum order quantities (MOQ) for challenge coins?

Minimum order quantities (MOQ) for challenge coins can vary significantly between manufacturers, typically ranging from 50 to 100 units. However, some manufacturers may accommodate smaller orders at a higher price per unit. When negotiating, consider your budget and future needs to determine the most cost-effective solution. It’s also beneficial to inquire if the manufacturer offers tiered pricing for larger orders, as this can lead to significant savings in the long run. -

What payment terms should I expect when ordering challenge coins from a manufacturer?

Payment terms for challenge coin orders can differ widely, but common practices include a deposit (usually 30-50%) upfront, with the balance due upon completion or before shipping. Some manufacturers may offer payment via bank transfer, credit card, or escrow services for added security. Always clarify the payment terms and conditions in your contract to avoid misunderstandings. Additionally, consider negotiating better terms if you plan on making repeat orders to foster a long-term relationship. -

How can I ensure quality assurance (QA) for my challenge coin orders?

To ensure quality assurance (QA) for your challenge coin orders, request detailed production samples before full-scale manufacturing. Establish clear quality standards and guidelines, including specifications for materials, dimensions, and finish. Implement regular communication with the manufacturer during the production process to address any potential issues promptly. Consider hiring a third-party inspection service to conduct quality checks before shipment, especially for larger orders, to ensure compliance with your standards. -

What logistics considerations should I keep in mind when importing challenge coins?

When importing challenge coins, consider logistics factors such as shipping methods, customs regulations, and import duties. Choose a reliable shipping partner that can navigate the complexities of international shipping, especially if you are sourcing from regions with stricter customs requirements. Familiarize yourself with the import laws in your country to avoid delays and unexpected costs. Planning for adequate insurance coverage during transit can also protect your investment from potential damages or losses. -

How do cultural differences impact the design and marketing of challenge coins in different regions?

Cultural differences can significantly influence the design and marketing of challenge coins. For instance, symbols and colors may hold different meanings across regions, so it’s crucial to research local customs and preferences. Engage with local stakeholders or hire regional marketing experts to ensure your designs resonate with the target audience. Tailoring your marketing approach to align with cultural values can enhance the appeal of your challenge coins, fostering stronger connections with buyers in Africa, South America, the Middle East, and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for challenge coin manufacturer

What Are the Key Takeaways for B2B Buyers in Sourcing Challenge Coins?

In conclusion, strategic sourcing for challenge coins is pivotal for international B2B buyers aiming to enhance brand visibility and foster strong relationships. Understanding the unique characteristics of different manufacturers across regions such as Africa, South America, the Middle East, and Europe is essential. Buyers should prioritize manufacturers that offer customization options, quality assurance, and competitive pricing, as these factors significantly influence the overall value and effectiveness of the coins.

How Can Strategic Sourcing Enhance Your Business Relationships?

The value of strategic sourcing extends beyond cost savings; it cultivates long-term partnerships that can lead to collaborative opportunities and innovation. By engaging with manufacturers who share your commitment to quality and service, you position your organization for sustainable growth. This approach not only ensures the production of high-quality challenge coins but also strengthens your brand’s reputation in diverse markets.

What Should International B2B Buyers Do Next?

As you navigate the global landscape of challenge coin manufacturing, consider leveraging digital platforms and trade shows to connect with potential suppliers. Embrace the opportunity to engage with manufacturers from different regions to explore unique offerings that can set your business apart. The future of challenge coin sourcing is bright, and by making informed decisions today, you can secure a competitive edge tomorrow.