Discover Top Tips to Choose a Universal Joint Manufacturer (2025)

Introduction: Navigating the Global Market for universal joint manufacturer

In the ever-evolving landscape of global manufacturing, sourcing high-quality universal joints can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With various applications ranging from automotive to industrial machinery, the demand for reliable and durable universal joints is on the rise. However, navigating the complexities of supplier selection, cost management, and compliance with international standards can be daunting. This guide aims to demystify the process of sourcing universal joint manufacturers by providing actionable insights and practical strategies tailored for international buyers.

Throughout this comprehensive resource, we will explore the various types of universal joints available in the market, their specific applications, and the key factors to consider when vetting suppliers. We will also delve into pricing structures, enabling you to make informed decisions that align with your budget while ensuring product quality. By understanding the nuances of the global market and equipping yourself with the right knowledge, you can confidently engage with suppliers across different regions, ensuring that your procurement process is efficient and effective.

This guide is designed to empower B2B buyers from emerging markets and established economies alike, helping you to overcome the challenges of sourcing universal joints. Whether you are based in Brazil, Germany, or elsewhere, our insights will facilitate your purchasing decisions, ultimately enhancing your business operations and competitiveness in the global marketplace.

Understanding universal joint manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cross Joint | Traditional design with two yokes and a cross | Automotive, machinery, agricultural | Pros: Cost-effective, widely available. Cons: Limited angular flexibility. |

| Double Cardan Joint | Two universal joints connected by a shaft | Off-road vehicles, heavy machinery | Pros: High torque capacity, better balance. Cons: More complex installation. |

| Hooke Joint | Simple design allowing for limited angle movement | Marine applications, conveyors | Pros: Durable, easy to maintain. Cons: Reduced efficiency at high angles. |

| Constant Velocity Joint (CV) | Maintains constant speed across varying angles | High-performance vehicles, robotics | Pros: Smooth operation, high efficiency. Cons: Higher cost, requires precise alignment. |

| Rzeppa Joint | Spherical design allowing for greater angular range | Automobiles, industrial machinery | Pros: Excellent load distribution, compact design. Cons: Sensitive to contamination. |

What Are the Key Characteristics of Cross Joints?

Cross joints are the most common type of universal joint, characterized by their simple design featuring two yokes and a cross. This traditional construction is particularly suited for applications in automotive and agricultural machinery. Buyers should consider the cost-effectiveness and wide availability of cross joints, but be aware that they may not provide the best angular flexibility, which can limit performance in certain dynamic applications.

How Do Double Cardan Joints Enhance Performance?

Double Cardan joints consist of two universal joints connected by an intermediate shaft, offering superior torque handling and balance. These joints are ideal for off-road vehicles and heavy machinery where high torque and stability are crucial. While they provide better performance compared to single joints, buyers should note that their installation can be more complex and may require specialized knowledge or tools.

Why Choose Hooke Joints for Durability?

Hooke joints are recognized for their robust design, allowing for limited angle movement. This makes them suitable for marine applications and conveyor systems where durability is essential. Buyers appreciate the ease of maintenance associated with Hooke joints, but they should also consider that efficiency may decrease significantly when operating at high angles, which could impact performance in certain scenarios.

What Are the Benefits of Constant Velocity Joints (CV)?

Constant velocity joints are engineered to maintain a consistent speed regardless of the angle, making them a popular choice for high-performance vehicles and robotics. Their ability to provide smooth operation and high efficiency is a significant advantage for buyers looking for reliability in dynamic applications. However, the higher cost and need for precise alignment may deter some buyers, especially those with budget constraints.

How Do Rzeppa Joints Provide Unique Advantages?

Rzeppa joints feature a spherical design that allows for a greater angular range while maintaining load distribution. This makes them particularly effective in automotive and industrial machinery applications where space is at a premium. While Rzeppa joints offer excellent performance, buyers must be cautious of their sensitivity to contamination, which can affect longevity and reliability.

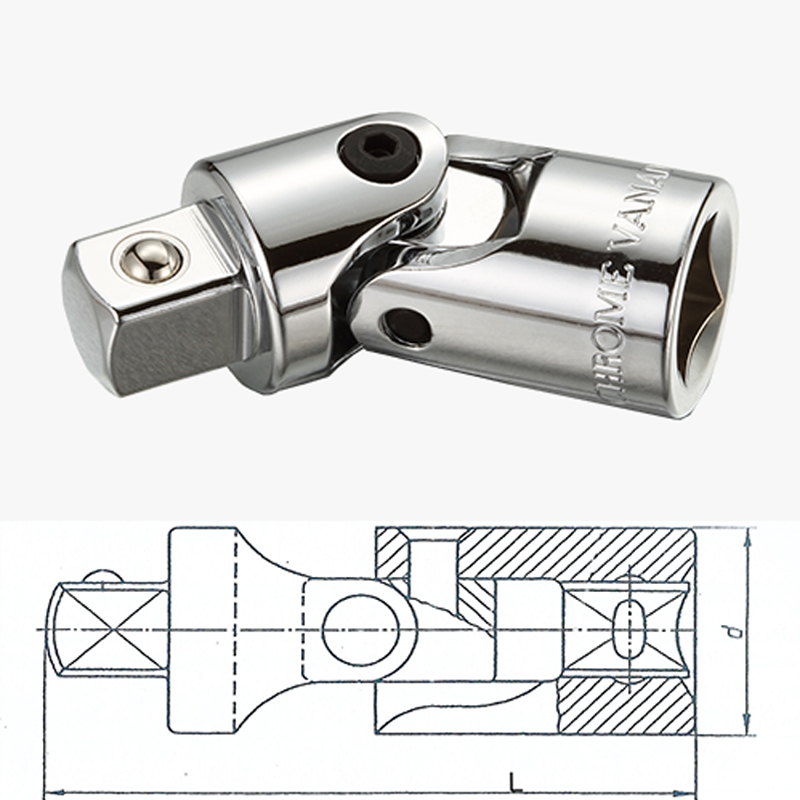

Related Video: Universal joint mechanism

Key Industrial Applications of universal joint manufacturer

| Industry/Sector | Specific Application of Universal Joint Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Drive Shafts in Electric Vehicles | Enhances torque transmission and vehicle efficiency | Material quality, precision engineering, and weight considerations |

| Agriculture | Machinery for Crop Harvesting | Improves operational efficiency and reduces downtime | Durability in harsh conditions and compatibility with existing systems |

| Aerospace | Control Surfaces in Aircraft | Ensures reliability and safety in flight operations | Compliance with industry standards and certifications |

| Oil & Gas | Rotary Equipment in Drilling Operations | Increases productivity and minimizes maintenance costs | Resistance to extreme conditions and custom solutions |

| Manufacturing | CNC Machines for Precision Parts | Enhances accuracy and reduces production costs | Customization options and lead times for delivery |

How Are Universal Joints Used in the Automotive Sector?

In the automotive industry, universal joints are critical components in drive shafts, particularly in electric vehicles. They facilitate the transfer of torque from the motor to the wheels, allowing for smooth operation and improved vehicle efficiency. International buyers, especially from Europe and South America, must consider factors such as material quality and precision engineering. These elements ensure that the joints can withstand high torque while minimizing weight, which is essential for electric vehicle performance.

What Role Do Universal Joints Play in Agriculture?

Universal joints are extensively used in agricultural machinery, particularly in crop harvesting equipment. They allow for the efficient transfer of power between different components, enhancing operational efficiency and reducing the likelihood of downtime. Buyers from Africa and South America should focus on the durability of these joints, as they often operate in harsh conditions. Compatibility with existing machinery is also crucial, as it ensures seamless integration and performance.

Why Are Universal Joints Important in Aerospace Applications?

In the aerospace sector, universal joints are employed in control surfaces of aircraft, where reliability and safety are paramount. They enable precise movement and control, which is essential for flight operations. International buyers from the Middle East and Europe need to ensure that the universal joints comply with stringent industry standards and certifications. This compliance guarantees that the components can withstand extreme conditions and perform reliably throughout their lifecycle.

How Do Universal Joints Enhance Oil & Gas Operations?

In the oil and gas industry, universal joints are used in rotary equipment during drilling operations. They facilitate the transfer of rotational force, which is vital for maintaining productivity and minimizing maintenance costs. Buyers from regions like Africa and the Middle East should prioritize sourcing joints that are resistant to extreme conditions, including temperature and pressure variations. Custom solutions may also be necessary to meet specific operational needs.

What Are the Applications of Universal Joints in Manufacturing?

In manufacturing, universal joints are integral to CNC machines used for producing precision parts. They enhance accuracy and reduce production costs by ensuring that the machinery operates smoothly and efficiently. B2B buyers, particularly in Europe, should consider customization options when sourcing universal joints, as different manufacturing processes may require specific configurations. Additionally, lead times for delivery can impact production schedules, making timely sourcing a critical factor.

Related Video: Understanding Universal Joint

3 Common User Pain Points for ‘universal joint manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality in Universal Joint Products

The Problem:

B2B buyers often face the challenge of inconsistent product quality when sourcing universal joints. This inconsistency can lead to unexpected downtimes, increased maintenance costs, and even product failures in machinery. For buyers in regions like Africa and South America, where supply chains may be less stable, the risk of receiving subpar products is heightened. This not only affects operational efficiency but also damages the buyer’s reputation with their own clients.

The Solution:

To mitigate the risk of inconsistent quality, buyers should prioritize sourcing universal joints from manufacturers with established quality assurance protocols. Look for suppliers who are certified by international standards such as ISO 9001. It’s also beneficial to request detailed product specifications, including material grades and testing methods. Conducting a thorough supplier audit, or requesting samples for testing before placing bulk orders, can ensure that the products meet the necessary quality criteria. Building strong relationships with manufacturers that offer transparency about their production processes will lead to more reliable sourcing in the long run.

Scenario 2: Difficulty in Finding Custom Solutions for Unique Applications

The Problem:

Many international B2B buyers struggle with the challenge of finding universal joints that fit specific machinery or unique operational needs. For instance, a construction company in Germany may require universal joints that can withstand extreme angles and heavy loads due to the nature of their equipment. The lack of customization options can lead to delays in project timelines and increased costs as companies resort to modifying existing parts, which can compromise performance.

The Solution:

To address this challenge, B2B buyers should engage with manufacturers that specialize in custom solutions for universal joints. When reaching out to potential suppliers, clearly communicate the specifications and operational conditions of the intended application. This may include details like torque requirements, environmental conditions, and angle ranges. Consider manufacturers who have a proven track record in engineering custom products, as they are more likely to provide tailored solutions that align with your needs. Additionally, collaborating with the manufacturer during the design phase can ensure that the final product meets all operational requirements.

Scenario 3: Uncertainty About Maintenance and Support Services

The Problem:

After acquiring universal joints, B2B buyers often encounter uncertainty regarding maintenance and support services. This is particularly true for companies in the Middle East and Europe, where machinery is expected to operate under high-stress conditions. Without proper support, businesses may struggle with maintenance schedules and fail to address issues before they escalate into costly repairs or replacements.

The Solution:

To alleviate this pain point, buyers should seek out universal joint manufacturers who provide comprehensive after-sales support and maintenance services. When evaluating potential suppliers, inquire about their support offerings, such as training on installation and maintenance, access to spare parts, and technical assistance. Manufacturers that offer regular maintenance programs can also help ensure optimal performance over time. Establishing a clear communication channel for ongoing support can foster a collaborative relationship, enabling buyers to address any operational concerns promptly. Creating a maintenance schedule in partnership with the manufacturer can further streamline operations and enhance equipment longevity.

Strategic Material Selection Guide for universal joint manufacturer

When selecting materials for universal joints, it is essential to consider various factors that can influence performance, durability, and cost. Below, we analyze four common materials used in universal joint manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Steel in Universal Joint Manufacturing?

Steel is the most widely used material for universal joints due to its excellent mechanical properties. It offers high tensile strength, good fatigue resistance, and can withstand high temperatures and pressures. Additionally, steel can be treated for enhanced corrosion resistance, making it suitable for various environments.

Pros & Cons:

Steel’s durability is a significant advantage, allowing for long service life in demanding applications. However, the manufacturing complexity can be higher due to the need for heat treatment and machining processes. The cost of high-grade steel can also be relatively high, which may impact budget considerations.

Impact on Application:

Steel universal joints are commonly used in automotive, aerospace, and industrial machinery applications, where high strength and reliability are crucial. They are compatible with various media, including oils and fuels, but may require additional coatings for corrosive environments.

Considerations for International Buyers:

Buyers from regions like Germany and Brazil should ensure compliance with standards such as DIN and ASTM. Additionally, understanding local sourcing options for high-quality steel can help reduce costs and lead times.

How Does Aluminum Compare as a Material for Universal Joints?

Aluminum is increasingly being used in universal joint manufacturing, particularly in applications where weight reduction is critical. It has a lower density than steel, which can enhance fuel efficiency in automotive applications.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, making it suitable for applications requiring reduced weight. However, aluminum has lower tensile strength compared to steel, which may limit its use in high-load scenarios. Additionally, the cost of aluminum can be moderate to high, depending on the alloy.

Impact on Application:

Aluminum universal joints are ideal for lightweight vehicles and machinery where performance is not compromised. They are generally resistant to corrosion, making them suitable for marine applications, but may not perform well under extreme loads.

Considerations for International Buyers:

B2B buyers in Africa and the Middle East should be aware of the specific aluminum grades that meet their application requirements and local regulations. Understanding the trade-offs between weight and strength is crucial for making informed purchasing decisions.

What are the Benefits and Limitations of Composite Materials in Universal Joints?

Composite materials, such as carbon fiber reinforced polymers, are gaining traction in the universal joint market due to their unique properties. They offer excellent strength-to-weight ratios and can be engineered for specific performance characteristics.

Pros & Cons:

The key advantage of composites is their lightweight nature combined with high strength and stiffness. However, they can be more expensive to manufacture and may require specialized processes that increase complexity. Their performance can also be sensitive to environmental factors like temperature and humidity.

Impact on Application:

Composites are suitable for high-performance applications in the aerospace and motorsport industries, where weight savings are critical. They can be designed to resist specific chemicals, making them versatile for various media.

Considerations for International Buyers:

Buyers from Europe should consider compliance with aerospace standards (e.g., EN 9100) when sourcing composite materials. Understanding the manufacturing capabilities of suppliers is essential to ensure quality and performance.

How Does Brass Measure Up for Universal Joint Applications?

Brass is sometimes used in universal joints, particularly in applications where corrosion resistance is paramount. It offers good machinability and is often utilized in marine and plumbing applications.

Pros & Cons:

Brass provides excellent corrosion resistance and is relatively easy to machine, which can reduce manufacturing costs. However, its mechanical properties are generally inferior to steel, limiting its use in high-stress applications.

Impact on Application:

Brass universal joints are commonly found in low-pressure applications, such as plumbing and HVAC systems. They are compatible with water and various gases but may not be suitable for high-temperature environments.

Considerations for International Buyers:

Buyers from South America should ensure that the brass grades comply with local standards and regulations, particularly for plumbing applications. Understanding the specific requirements for corrosion resistance is vital for ensuring longevity in service.

Summary Table of Material Selection for Universal Joints

| Material | Typical Use Case for universal joint manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive and industrial machinery | High tensile strength and durability | Higher manufacturing complexity | High |

| Aluminum | Lightweight vehicles and machinery | Lightweight, enhances fuel efficiency | Lower tensile strength than steel | Medium |

| Composite | Aerospace and high-performance motorsport | Excellent strength-to-weight ratio | Expensive and complex to manufacture | High |

| Brass | Plumbing and HVAC systems | Excellent corrosion resistance | Inferior mechanical properties | Medium |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in universal joint manufacturing. By considering the properties, advantages, and regional compliance requirements, international B2B buyers can make informed decisions that align with their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for universal joint manufacturer

What Are the Main Stages in the Manufacturing Process of Universal Joints?

The manufacturing process of universal joints involves several critical stages, each contributing to the final product’s durability and performance. Understanding these stages is essential for B2B buyers, as it allows for better supplier evaluation and quality control.

-

Material Preparation

The first step involves selecting high-quality raw materials such as steel or alloys, known for their strength and fatigue resistance. The materials undergo processes like cutting, shaping, and heat treatment to enhance their mechanical properties. Buyers should verify that suppliers source materials compliant with industry standards, as this directly impacts the longevity of the universal joints. -

Forming

During this stage, the prepared materials are shaped into the desired forms through techniques like forging or machining. Forging is particularly favored due to its ability to produce parts with superior mechanical properties. Precision machining follows to create the necessary tolerances and surface finishes. Buyers should inquire about the forming methods used, as these can significantly influence the product’s quality and performance. -

Assembly

The assembly process integrates the various components of the universal joint, including the yokes, cross, and bearings. Automated assembly lines often enhance precision and reduce human error. B2B buyers should assess whether the manufacturer employs skilled labor or advanced robotics for assembly, as this can affect consistency and reliability. -

Finishing

The final stage involves surface treatments such as coating or polishing to prevent corrosion and enhance aesthetics. Techniques like shot blasting or electroplating may be utilized. Buyers should consider the types of finishes offered by suppliers, as these can provide additional protection in harsh operating environments.

How Is Quality Assurance Implemented in Universal Joint Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that each universal joint meets specific performance standards. Buyers must be familiar with both international and industry-specific quality standards to make informed purchasing decisions.

-

What Are the Relevant International Standards for Quality Assurance?

International standards such as ISO 9001 provide a framework for establishing an effective quality management system (QMS). Compliance with ISO 9001 indicates that the manufacturer has implemented processes that consistently meet customer and regulatory requirements. Additionally, industry-specific certifications like API (American Petroleum Institute) and CE (Conformité Européenne) are critical for ensuring products meet safety and performance benchmarks. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify defects early. Key checkpoints include:

– Incoming Quality Control (IQC): Assessing raw materials before production begins.

– In-Process Quality Control (IPQC): Monitoring production processes to ensure they adhere to specified standards.

– Final Quality Control (FQC): Conducting thorough inspections of finished products before shipment. -

What Common Testing Methods Are Used for Universal Joints?

Testing methods such as tensile strength tests, fatigue tests, and dimensional inspections are commonly employed. Non-destructive testing (NDT) techniques, including ultrasonic and magnetic particle testing, may also be utilized to identify internal flaws without damaging the product. Buyers should confirm that suppliers conduct these tests regularly and provide certificates of compliance.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that suppliers maintain robust quality control measures is crucial for B2B buyers, especially when sourcing universal joints from international manufacturers.

-

What Role Do Audits and Reports Play in Supplier Evaluation?

Regular audits of the manufacturing facilities can provide valuable insights into the supplier’s adherence to quality standards. Buyers should request audit reports and certifications to evaluate the supplier’s QMS. Engaging third-party inspection services can also provide an unbiased assessment of the supplier’s processes and product quality. -

How Important Is Third-Party Inspection?

Third-party inspections offer an additional layer of assurance for B2B buyers. Independent inspectors can verify compliance with international standards and provide detailed reports on the manufacturing process and product quality. Buyers should consider incorporating third-party inspections into their procurement strategy, particularly for high-value contracts. -

What Are the Quality Control and Certification Nuances for International Buyers?

For buyers from Africa, South America, the Middle East, and Europe, understanding local regulations and standards is essential. Different regions may have varying requirements for certifications and quality assurance practices. Buyers should ensure that suppliers are familiar with the compliance requirements of their target markets, such as the CE marking in Europe or API standards in the oil and gas sector.

Conclusion: Ensuring Quality in Universal Joint Procurement

International B2B buyers must be diligent in understanding the manufacturing processes and quality assurance measures employed by universal joint manufacturers. By focusing on material selection, manufacturing techniques, and rigorous quality control practices, buyers can ensure they procure reliable products that meet their operational needs. Engaging with suppliers who prioritize quality management and compliance with international standards will ultimately lead to better performance and longevity of universal joints in various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘universal joint manufacturer’

Introduction

Navigating the procurement process for universal joints can be complex, particularly for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This step-by-step checklist aims to streamline your sourcing efforts, ensuring you identify reliable manufacturers that meet your specific requirements. By following these actionable insights, you can mitigate risks and enhance the quality of your sourcing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical in the sourcing process. This includes determining the size, material, load capacity, and specific applications of the universal joints you require. By having detailed specifications, you can communicate effectively with potential suppliers and avoid misunderstandings that could lead to costly errors.

- Key Considerations:

- What are the load requirements for your application?

- Are there specific environmental conditions that the joints need to withstand?

Step 2: Conduct Market Research on Manufacturers

Before reaching out to suppliers, it’s essential to conduct thorough market research. This involves identifying potential manufacturers that specialize in universal joints and have a good reputation in the industry. Understanding the landscape helps you compare different suppliers based on their strengths and weaknesses.

- Action Items:

- Utilize online platforms and trade directories to find manufacturers.

- Read industry reports or customer reviews to gauge reputation and reliability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thorough evaluation of potential suppliers is essential. Request comprehensive company profiles, product catalogs, and case studies that highlight their experience in producing universal joints. This will allow you to assess whether they can meet your specific needs and quality standards.

- Documentation to Request:

- Certificates of compliance with international standards (e.g., ISO).

- References from other clients in your industry or region.

Step 4: Verify Supplier Certifications

Certifications ensure that manufacturers adhere to industry standards and regulations, which is crucial for quality assurance. Verify that the suppliers hold relevant certifications such as ISO 9001 for quality management or specific automotive standards if applicable.

- Why This Matters:

- Certifications provide assurance of quality and safety.

- They can also enhance the credibility of your supply chain.

Step 5: Request Samples for Testing

Once you have narrowed down your options, request samples of the universal joints for testing. This step allows you to evaluate the product’s quality, durability, and compatibility with your application before placing a bulk order.

- Testing Criteria:

- Assess performance under real-world conditions.

- Check for any signs of manufacturing defects or inconsistencies.

Step 6: Negotiate Terms and Pricing

After confirming that a supplier meets your technical and quality requirements, enter into negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms that benefit your business.

- Negotiation Tips:

- Be clear about your budget and requirements.

- Discuss long-term relationships for potential volume discounts.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan to ensure ongoing collaboration. Regular check-ins and updates can help address any potential issues early and maintain transparency throughout the supply chain.

- Communication Strategies:

- Set up regular meetings or updates to discuss progress.

- Use project management tools to track milestones and deliverables.

By following this checklist, international B2B buyers can effectively source universal joints, ensuring a reliable supply chain that meets their operational needs.

Comprehensive Cost and Pricing Analysis for universal joint manufacturer Sourcing

What Are the Key Cost Components in Universal Joint Manufacturing?

When considering the sourcing of universal joints, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-grade steel or specialized alloys may offer better durability but at a higher price. Buyers should weigh the cost against the performance benefits these materials provide in their specific applications.

-

Labor: Labor costs can vary widely based on the region and the skill level required for manufacturing universal joints. Countries with lower labor costs, such as those in parts of Africa and South America, can offer competitive pricing, but this may also affect quality and precision.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Understanding the overhead structure of your suppliers can provide insights into their pricing strategies.

-

Tooling: The initial investment in tooling can be significant, especially for custom or high-precision universal joints. Buyers should inquire about tooling costs and whether they are included in the quoted price or billed separately.

-

Quality Control (QC): Robust QC processes ensure that products meet specified standards. While these processes may add to the cost, they are crucial for avoiding costly reworks or returns later in the supply chain.

-

Logistics: Shipping costs can vary based on distance, weight, and Incoterms. International buyers should factor in customs duties and freight charges when calculating total expenses.

-

Margin: Finally, the supplier’s profit margin influences the final price. Understanding a supplier’s cost structure can aid in negotiations, especially if you can provide them with consistent orders.

How Do Pricing Influencers Affect Universal Joint Costs?

Several factors can influence the pricing of universal joints:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower unit prices due to economies of scale. Buyers should negotiate MOQs that balance their needs with the supplier’s capabilities.

-

Specifications and Customization: Custom specifications can raise costs. Buyers must clearly communicate their requirements and understand how these will impact pricing.

-

Material Quality and Certifications: Higher-quality materials and compliance with international standards can increase costs. Ensure that the benefits justify the investment, particularly for critical applications.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can significantly influence the total landed cost. Buyers should understand the implications of terms like FOB, CIF, and DDP to manage logistics costs effectively.

What Are the Best Negotiation Strategies for B2B Buyers?

Effective negotiation can lead to significant savings. Here are some actionable tips for international buyers:

-

Research and Benchmarking: Understand market prices and benchmark against similar suppliers. This knowledge empowers you during negotiations.

-

Long-Term Relationships: Consider building long-term relationships with suppliers. Loyalty can lead to better pricing and priority service.

-

Highlighting Volume Potential: If you can commit to larger orders, use this as leverage to negotiate better terms and pricing.

-

Flexibility on Payment Terms: Offering favorable payment terms can be appealing to suppliers and may lead to discounts.

-

Explore Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, including maintenance, downtime, and replacement costs, to make informed decisions.

What Should International Buyers Consider Regarding Pricing Nuances?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several pricing nuances should be kept in mind:

-

Currency Fluctuations: Exchange rates can impact pricing significantly. It’s wise to negotiate prices in your local currency to mitigate risks.

-

Regional Market Conditions: Be aware of local economic conditions that could influence pricing, such as tariffs, trade agreements, and local sourcing incentives.

-

Cultural Considerations: Understanding cultural differences in negotiation styles can enhance communication and lead to better deals.

Disclaimer on Pricing

Prices in the universal joint manufacturing sector can vary widely based on the factors discussed above. The information provided serves as a guideline and should not be construed as definitive pricing. Always consult with multiple suppliers and conduct thorough market research to get accurate, up-to-date pricing for your specific needs.

Alternatives Analysis: Comparing universal joint manufacturer With Other Solutions

When evaluating solutions for power transmission and motion control, B2B buyers must consider various options beyond traditional universal joints. Understanding the strengths and weaknesses of alternative solutions helps organizations optimize performance, cost, and implementation efficiency. Below, we compare universal joint manufacturers with two viable alternatives: flexible couplings and constant velocity joints (CV joints).

Comparison Table of Universal Joint Manufacturer and Alternatives

| Comparison Aspect | Universal Joint Manufacturer | Flexible Couplings | Constant Velocity Joints (CV Joints) |

|---|---|---|---|

| Performance | High torque transmission; accommodates misalignment | Moderate torque capacity; less effective with high misalignment | Excellent torque transfer; minimizes vibration and noise |

| Cost | Mid-range pricing | Generally lower cost | Higher initial investment |

| Ease of Implementation | Requires precise alignment | Easier to install; less precision needed | More complex installation |

| Maintenance | Moderate maintenance needs; periodic checks recommended | Low maintenance; generally wear-resistant | Moderate maintenance; check for wear periodically |

| Best Use Case | Heavy machinery, automotive applications | General industrial applications, lower torque needs | High-performance automotive, high-speed applications |

What Are the Advantages and Disadvantages of Flexible Couplings?

Flexible couplings are designed to accommodate slight misalignments between connected shafts, making them suitable for various industrial applications. Their primary advantage is cost-effectiveness, as they are generally less expensive than universal joints. Additionally, they are easier to install and require minimal maintenance, which can lead to reduced downtime. However, their torque capacity may not match that of universal joints, especially in heavy-duty applications, limiting their use in high-load scenarios.

How Do Constant Velocity Joints (CV Joints) Compare?

Constant velocity joints are specifically engineered to transmit power efficiently at constant speed, regardless of the angle of the connected shafts. This makes them ideal for high-performance automotive applications where smooth operation is crucial. The advantages of CV joints include excellent torque transfer and minimized vibration, enhancing the overall performance of the system. However, they come with a higher upfront cost and a more complex installation process, which may deter some buyers. Maintenance requirements are moderate, necessitating periodic checks to ensure optimal function.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between a universal joint manufacturer and its alternatives, B2B buyers should consider their specific application requirements, including the operational environment, load conditions, and budget constraints. For high-torque and heavy-duty applications, universal joints may be the best fit. Conversely, if cost and ease of installation are paramount, flexible couplings may offer a suitable alternative. For industries requiring high performance and minimal vibration, CV joints could be the ideal choice despite their higher investment. By thoroughly assessing these factors, buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for universal joint manufacturer

What Are the Essential Technical Properties of Universal Joints?

Understanding the technical specifications of universal joints is crucial for B2B buyers to ensure they select the right components for their applications. Here are some critical specifications that every buyer should be familiar with:

1. Material Grade

The material grade of a universal joint refers to the type of materials used in its construction, such as steel or aluminum alloys. High-grade materials like 4140 steel are commonly used for their durability and resistance to wear. For buyers, selecting a universal joint made from the appropriate material grade is essential to ensure longevity and performance under specific operating conditions, particularly in heavy machinery or automotive applications.

2. Tolerance

Tolerance defines the allowable deviation from specified dimensions in the manufacturing process. High tolerance levels ensure better fit and function between components. For international buyers, especially those in precision-driven industries, understanding tolerance specifications is vital to avoid compatibility issues and ensure the efficiency of the final assembly.

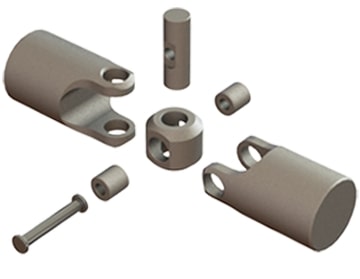

A stock image related to universal joint manufacturer.

3. Load Capacity

A stock image related to universal joint manufacturer.

Load capacity indicates the maximum load a universal joint can handle without failure. This specification is critical for buyers who need to ensure that the component can withstand the forces it will encounter in real-world applications. Understanding the load capacity helps in making informed decisions that can prevent equipment failures and costly downtimes.

4. Angular Range

The angular range specifies the maximum angle through which a universal joint can operate without losing efficiency. This property is particularly important for applications that require significant movement or flexibility. Buyers must evaluate the angular range to ensure that the joint can accommodate the specific requirements of their machinery or vehicles.

5. Lubrication Type

Lubrication is a key factor in the longevity and performance of universal joints. Buyers should know whether the joints are greaseable or sealed, as this affects maintenance requirements and operational efficiency. Understanding lubrication types can help in selecting joints that align with the operational practices of their industry.

What Are Common Trade Terms Used in Universal Joint Manufacturing?

Familiarity with industry jargon can streamline communication and negotiations. Here are several important terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers who need components that are compatible with existing systems, ensuring quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For international buyers, being aware of MOQ can help in budgeting and inventory management. It’s essential to negotiate MOQs that align with your purchasing needs without incurring excessive costs.

3. RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers to request pricing and terms for specific products. This term is vital for initiating procurement processes. Buyers should prepare detailed RFQs to ensure they receive accurate quotes that meet their specifications.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, risk, and insurance. Understanding these terms helps buyers mitigate risks and clarify shipping responsibilities, especially when sourcing from different continents.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For international B2B buyers, understanding lead times is crucial for effective supply chain management. It allows for better planning and reduces the risk of production delays.

By familiarizing themselves with these technical properties and trade terminology, international B2B buyers can make informed decisions when sourcing universal joints, ensuring they meet their specific operational requirements.

Navigating Market Dynamics and Sourcing Trends in the universal joint manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Universal Joint Manufacturing Sector?

The global universal joint manufacturing sector is experiencing a significant transformation driven by various factors, including technological advancements, shifting consumer preferences, and evolving geopolitical landscapes. One of the primary market drivers is the rise of automation and digitalization in manufacturing processes. This trend not only enhances efficiency but also facilitates the integration of IoT (Internet of Things) technologies, allowing manufacturers to monitor performance in real-time. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these technological trends is crucial for making informed sourcing decisions.

Emerging trends also highlight the importance of customization in universal joint products. As industries such as automotive, aerospace, and industrial machinery demand more tailored solutions, suppliers must adapt their offerings to meet specific requirements. This demand for customization is particularly pronounced in regions like Brazil and Germany, where manufacturers are focusing on high-performance applications. Additionally, sustainability is gaining traction as a key factor influencing procurement strategies. Buyers are increasingly looking for suppliers who prioritize eco-friendly materials and processes, aligning with global sustainability goals.

Furthermore, the geopolitical landscape significantly impacts sourcing dynamics. Tariffs, trade agreements, and supply chain disruptions can affect the availability and cost of universal joints. Buyers must stay informed about these changes to navigate potential risks and seize opportunities for cost-effective sourcing.

How Important Is Sustainability and Ethical Sourcing in the Universal Joint Manufacturing Sector?

Sustainability and ethical sourcing are becoming non-negotiable aspects of the universal joint manufacturing sector. The environmental impact of manufacturing processes, particularly in terms of waste generation and carbon emissions, is under increasing scrutiny. International B2B buyers are now more aware of the need to partner with manufacturers who demonstrate a commitment to sustainable practices. This shift is particularly relevant for buyers from environmentally conscious regions in Europe and the Middle East, where regulatory frameworks often mandate adherence to strict environmental standards.

Ethical supply chains are equally important. Buyers should prioritize suppliers who maintain transparency in their sourcing practices, ensuring that raw materials are acquired responsibly. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices. Additionally, the use of ‘green’ materials, such as recycled metals and sustainable composites, is gaining traction. This trend not only helps reduce the environmental footprint but also enhances brand reputation, which is vital in competitive markets.

Investing in sustainable and ethical sourcing not only aligns with corporate social responsibility initiatives but can also result in long-term cost savings. As the demand for sustainable products increases, companies that fail to adapt may face reputational risks and a decline in market share.

What Is the Historical Context of the Universal Joint Manufacturing Sector?

The evolution of the universal joint manufacturing sector dates back to the early 20th century, when these components were primarily used in automotive applications. Initially designed to allow for the transmission of torque while accommodating angular misalignment, universal joints have since found applications across various industries, including aerospace, agriculture, and robotics.

Over the decades, advancements in materials science and engineering have led to the development of more durable and efficient universal joints. The introduction of advanced manufacturing techniques, such as CNC machining and additive manufacturing, has further refined the production process, enabling greater precision and customization. As global industries continue to evolve, the universal joint sector is poised for further growth, driven by innovations in technology and increasing demand for specialized applications. Understanding this historical context allows B2B buyers to appreciate the ongoing advancements and future potential of universal joint solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of universal joint manufacturer

-

How do I solve quality issues when sourcing universal joints from international manufacturers?

To address quality issues in sourcing universal joints, establish clear quality assurance (QA) protocols before engaging with suppliers. Request certifications such as ISO 9001 to ensure adherence to quality standards. Conduct pre-shipment inspections or utilize third-party quality control services to verify product specifications. Communicate your expectations clearly and consider starting with a smaller order to evaluate the supplier’s reliability and product quality before scaling up. -

What is the best universal joint for heavy-duty applications?

For heavy-duty applications, the best universal joints are those designed with high-strength materials like alloy steel and feature robust engineering to withstand extreme loads. Consider options that provide enhanced torque capacity and flexibility, such as cross and bearing designs specifically engineered for high-performance vehicles or machinery. Be sure to consult with manufacturers regarding their product specifications and performance ratings to ensure compatibility with your equipment. -

How can I ensure that my chosen universal joint manufacturer meets my customization needs?

To ensure your manufacturer can meet customization requirements, start by providing detailed specifications and requirements for your application. Ask about their design capabilities and experience with custom solutions. Request samples or prototypes to evaluate their manufacturing flexibility and ability to adhere to your specifications. Engaging in open communication throughout the design process will help align expectations and ensure the final product meets your needs. -

What are the typical minimum order quantities (MOQs) for universal joints?

MOQs for universal joints can vary significantly among manufacturers, generally ranging from 100 to 1,000 units. Factors influencing MOQs include production costs, material availability, and the complexity of the joint design. It is advisable to negotiate MOQs with your supplier, particularly if you are a small to mid-sized business. Some manufacturers may offer flexibility on MOQs for first-time orders or long-term contracts. -

What payment terms should I expect when sourcing from international manufacturers?

Payment terms can vary widely based on the manufacturer’s policies and your negotiation skills. Common arrangements include a deposit upfront (usually 30-50%) followed by the balance upon shipment or delivery. Some suppliers may offer credit terms, especially for established relationships. Be cautious of any payment methods that do not provide buyer protection. Utilizing letters of credit can mitigate risk, especially in international transactions. -

How do logistics and shipping impact the cost of sourcing universal joints?

Logistics and shipping can significantly affect the total cost of sourcing universal joints. Factors such as distance, shipping method (air vs. sea), and tariffs can influence final pricing. It’s crucial to work with suppliers who have experience in international shipping and can provide insight into the most cost-effective methods. Additionally, consider discussing freight forwarding options and customs duties to ensure a smooth delivery process. -

What certifications should I look for when vetting universal joint manufacturers?

When vetting universal joint manufacturers, look for certifications that indicate adherence to international quality and safety standards. Common certifications include ISO 9001 for quality management systems, TS16949 for automotive parts, and CE marking for compliance with European safety standards. These certifications not only reflect the manufacturer’s commitment to quality but also enhance your credibility when sourcing components for your business. -

How can I assess the reliability of a universal joint supplier?

To assess the reliability of a universal joint supplier, conduct thorough due diligence that includes reviewing their business history, client testimonials, and case studies. Request references from previous clients to gauge their experiences regarding delivery timelines, product quality, and customer service. Additionally, consider visiting the manufacturing facility if possible or utilizing third-party audits to validate their operational capabilities and quality assurance processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for universal joint manufacturer

In today’s global market, strategic sourcing has become a cornerstone for businesses seeking to enhance their supply chain efficiency, particularly for universal joint manufacturers. By adopting a proactive approach, international B2B buyers can tap into a diverse range of suppliers across Africa, South America, the Middle East, and Europe, ensuring not only cost-effectiveness but also the quality and reliability of their products.

How Can Strategic Sourcing Benefit International Buyers?

Engaging in strategic sourcing allows buyers to evaluate suppliers based on key performance indicators such as quality assurance, delivery timelines, and sustainability practices. This thorough vetting process is crucial for establishing long-term partnerships that can adapt to evolving market conditions and technological advancements. Furthermore, leveraging local suppliers can foster regional economic growth and reduce lead times, which is vital for maintaining competitive advantage.

What’s Next for Universal Joint Manufacturers?

As we move forward, the demand for innovative and high-performance universal joints will continue to rise, driven by advancements in automotive and industrial applications. B2B buyers should remain vigilant about market trends and emerging technologies that can impact product specifications and sourcing strategies. By prioritizing strategic sourcing initiatives today, businesses can position themselves for success in a rapidly changing landscape.

In conclusion, now is the time for international B2B buyers to embrace strategic sourcing as a catalyst for growth. By aligning with the right partners and investing in quality, your business can thrive in the global marketplace.