Discover Top USB Cable Manufacturers: Your Guide for 2025

Introduction: Navigating the Global Market for usb cable manufacturer

In today’s rapidly evolving digital landscape, sourcing high-quality USB cables is a critical challenge for international B2B buyers. As businesses expand across borders—from Africa to South America, the Middle East to Europe—the need for reliable USB cable manufacturers becomes paramount. This guide is designed to navigate the complexities of the global market for USB cables, addressing key considerations such as types of cables, their various applications, and the nuances of supplier vetting.

International buyers will find actionable insights into the costs associated with sourcing USB cables, as well as strategies to identify reputable manufacturers who can meet specific business needs. Whether you’re operating in tech, consumer electronics, or industrial applications, understanding the landscape of USB cable manufacturing is essential for making informed purchasing decisions.

By leveraging this comprehensive guide, buyers will be empowered to forge effective partnerships with suppliers, ensuring they acquire the right products at competitive prices. With a focus on the unique challenges and opportunities faced by businesses in diverse regions such as Colombia and Thailand, this resource serves as a vital tool for optimizing your supply chain and enhancing your product offerings. Let’s delve deeper into how to successfully navigate the global market for USB cable manufacturing and position your business for success.

Understanding usb cable manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| USB Type-A | Standard rectangular connector, widely used | Computers, chargers, peripherals | Pros: Universal compatibility; Cons: Limited data transfer speed compared to newer types. |

| USB Type-C | Reversible design, supports high-speed data | Mobile devices, laptops, and power delivery | Pros: Versatile, fast charging; Cons: Higher cost for cables and devices. |

| Micro USB | Smaller connector, common in older devices | Smartphones, cameras, and portable devices | Pros: Cost-effective; Cons: Becoming obsolete with newer devices. |

| USB 3.0/3.1 | Enhanced data transfer rates, often blue color | Data-heavy applications, external drives | Pros: High speed, backward compatible; Cons: Requires compatible ports for full speed. |

| USB OTG (On-The-Go) | Allows direct connection between devices | Mobile data transfer, peripherals | Pros: Increases functionality; Cons: Limited device support. |

What are the characteristics of USB Type-A cables?

USB Type-A cables are the most recognizable and commonly used type of USB cable. They feature a rectangular connector that plugs into host devices like computers and chargers. This type is primarily used for connecting peripherals such as keyboards, mice, and printers. When purchasing Type-A cables, buyers should consider compatibility with existing devices and data transfer speeds, as they are limited compared to newer USB types.

How does USB Type-C differ from other USB types?

USB Type-C is distinguished by its reversible connector, allowing for easy insertion in either orientation. This modern cable type supports higher data transfer rates and power delivery, making it suitable for a wide range of applications, including laptops and smartphones. B2B buyers should evaluate the compatibility of Type-C with their devices and consider the investment in newer technology, as it may come at a higher price point.

Why is Micro USB still relevant in some markets?

Micro USB cables are smaller and have been widely used in older smartphones and portable devices. Despite the rise of USB Type-C, Micro USB remains relevant in many regions due to the large number of existing devices still in use. Buyers looking for cost-effective solutions for charging and data transfer may find Micro USB cables appealing, but they should be aware of the diminishing support for this type as newer models emerge.

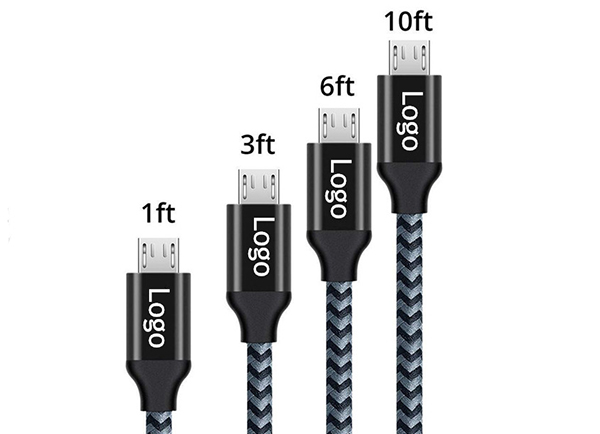

A stock image related to usb cable manufacturer.

What advantages do USB 3.0/3.1 cables offer?

USB 3.0 and 3.1 cables are designed for high-speed data transfer, making them ideal for applications that involve large files, such as video editing or data backup. The blue connectors often signify USB 3.0, while USB 3.1 offers even faster speeds. B2B purchasers should consider the need for speed and compatibility with existing ports, as these cables provide significant performance improvements over older USB types.

How does USB OTG enhance device connectivity?

USB On-The-Go (OTG) technology allows devices like smartphones to connect directly to peripherals such as flash drives and keyboards without needing a computer. This functionality increases the versatility of devices and is particularly useful in mobile data transfer. Buyers should assess the specific OTG capabilities of their devices and consider the limited support for this technology across all devices, which may affect usability.

Related Video: Complete process of USB cable manufacturing

Key Industrial Applications of usb cable manufacturer

| Industry/Sector | Specific Application of USB Cable Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Charging and data transfer for smartphones and tablets | Ensures compatibility and reliability for end-users | Quality certifications, length, and durability of cables |

| Automotive | Connectivity in infotainment systems | Enhances user experience and vehicle integration | Temperature resistance, shielding against interference |

| Industrial Automation | Communication in machinery and robotics | Improves operational efficiency and reliability | Robustness, customization options, and compliance with industry standards |

| Healthcare | Data transfer in medical devices | Supports accurate diagnostics and patient monitoring | Biocompatibility, sterilization capabilities, and data integrity |

| Telecommunications | Network connectivity solutions | Facilitates high-speed data transfer and communication | Bandwidth capacity, length, and durability for outdoor conditions |

How Are USB Cables Used in Consumer Electronics?

In the consumer electronics sector, USB cables are pivotal for charging and data transfer in devices like smartphones and tablets. Manufacturers must ensure that their cables are compatible with various devices and provide reliable performance. International buyers, particularly from regions like Africa and South America, should prioritize sourcing cables that meet quality certifications to avoid issues with device functionality. Additionally, considerations such as cable length and durability are essential to cater to diverse consumer needs.

What Role Do USB Cables Play in the Automotive Industry?

USB cables are increasingly utilized in automotive infotainment systems, enabling connectivity for smartphones and other devices. This integration enhances user experience by allowing seamless access to apps and music. For automotive manufacturers, sourcing USB cables that can withstand temperature variations and electromagnetic interference is crucial. Buyers from the Middle East and Europe should focus on suppliers that offer cables with high durability and reliability to ensure long-term performance in vehicles.

How Are USB Cables Applied in Industrial Automation?

In industrial automation, USB cables facilitate communication between machinery and robotics, playing a critical role in operational efficiency. Manufacturers require robust cables that can endure harsh environments and provide stable connections. For international B2B buyers, particularly in emerging markets, it is essential to source cables that comply with industry standards and offer customization options to meet specific operational needs. This ensures that the automation processes run smoothly without interruptions.

Why Are USB Cables Important in Healthcare?

Healthcare devices rely heavily on USB cables for data transfer, which is vital for accurate diagnostics and patient monitoring. The cables must meet stringent biocompatibility standards and be capable of being sterilized to ensure patient safety. Buyers from regions like Africa and South America should focus on sourcing cables that maintain data integrity and are designed for medical environments, as this can significantly impact patient care and operational efficiency in healthcare facilities.

How Do USB Cables Enhance Telecommunications?

In telecommunications, USB cables are essential for network connectivity solutions, enabling high-speed data transfer and communication. The demand for reliable and high-capacity cables is growing, especially in regions undergoing digital transformation. Buyers from Europe and the Middle East should consider sourcing cables that offer durability, especially for outdoor applications, as well as those that meet bandwidth requirements. This ensures that the telecommunications infrastructure can support increasing data demands effectively.

3 Common User Pain Points for ‘usb cable manufacturer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compatibility with Diverse Devices

The Problem: B2B buyers often face challenges in ensuring that USB cables will be compatible with the wide range of devices they use. This is particularly relevant for companies in sectors like electronics, automotive, or telecommunications, where a variety of devices with different USB standards (USB-A, USB-C, USB 3.0, etc.) are in play. Mismatched cables can lead to device malfunctions, wasted resources, and delays in project timelines, causing frustration among teams and impacting productivity.

The Solution: To overcome compatibility issues, B2B buyers should prioritize sourcing USB cables from manufacturers that offer comprehensive specifications and certifications. When engaging with a manufacturer, ask for detailed product documentation that outlines compatibility with various devices. Additionally, consider establishing a testing phase before full-scale procurement. Order a sample batch of cables to conduct compatibility tests across your devices. This proactive approach will help ensure that the cables meet your specific needs and reduce the likelihood of future issues.

Scenario 2: Inconsistent Quality Across Different Suppliers

The Problem: Quality inconsistency is a common concern among B2B buyers who source USB cables from multiple suppliers. One shipment may feature high-quality cables, while the next may present significant defects or performance issues. This inconsistency can lead to increased warranty claims, customer dissatisfaction, and higher operational costs, particularly for companies that rely on large volumes of cables.

The Solution: Establishing strong relationships with reliable USB cable manufacturers is crucial. Begin by conducting thorough research to identify manufacturers with a proven track record of quality control. Request information about their manufacturing processes, quality assurance measures, and any relevant certifications (such as ISO). Implement regular audits or quality checks for products received, and consider creating a feedback loop where your quality concerns can lead to corrective actions from the manufacturer. This partnership approach will help ensure consistent quality and build trust over time.

Scenario 3: Challenges with Customization and Specifications

The Problem: B2B buyers often require customized USB cables tailored to specific applications, such as unique lengths, colors, or functionalities (like waterproofing or reinforced connectors). However, many manufacturers may not offer the level of customization needed, leading to frustrations and the potential for selecting suboptimal products that do not meet the company’s needs.

The Solution: To address customization challenges, buyers should engage with manufacturers who specialize in custom cable solutions. Clearly outline your requirements and be specific about the intended application of the cables. Request prototypes before committing to larger orders to evaluate the design and functionality. Additionally, consider manufacturers that provide flexible design options or have experience in your industry to ensure they understand your specific needs. Building a collaborative relationship with your manufacturer can streamline the customization process and result in high-quality, tailored products that meet your operational demands.

Strategic Material Selection Guide for usb cable manufacturer

What Are the Common Materials Used in USB Cable Manufacturing?

When selecting materials for USB cable manufacturing, it is crucial to consider properties that will enhance product performance, durability, and compliance with international standards. Below are some of the most common materials used in the industry, along with their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of PVC in USB Cables?

Polyvinyl Chloride (PVC) is one of the most widely used materials for USB cables due to its excellent flexibility and durability. It can withstand a temperature range of -15°C to 70°C, making it suitable for various environments. PVC is also resistant to abrasion and moisture, which enhances its longevity.

Pros:

– Cost-effective and readily available.

– Good flexibility allows for easy handling and installation.

– Resistant to environmental factors like moisture and UV light.

Cons:

– Limited temperature resistance compared to other materials.

– Can become brittle over time, especially when exposed to extreme temperatures.

Impact on Application: PVC is compatible with most electronic devices, making it a versatile choice for USB cables. However, it may not be suitable for high-temperature applications.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure that PVC cables meet local regulations regarding environmental safety and compliance with standards such as RoHS (Restriction of Hazardous Substances).

How Does TPE Compare as a Material for USB Cables?

Thermoplastic Elastomer (TPE) offers a unique combination of rubber-like flexibility and plastic-like durability. It can operate effectively in a temperature range of -40°C to 100°C, making it suitable for extreme conditions.

Pros:

– Excellent flexibility and resilience.

– Good chemical resistance, making it suitable for various environments.

– Eco-friendly options are available, appealing to environmentally conscious buyers.

Cons:

– Generally more expensive than PVC.

– Manufacturing processes can be more complex, leading to higher production costs.

Impact on Application: TPE is ideal for applications requiring high flexibility and durability, such as in mobile devices or wearables.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential. Buyers should also consider the environmental certifications of TPE materials, especially in regions with stringent regulations.

What Are the Advantages of Using Nylon in USB Cable Manufacturing?

Nylon is increasingly used for USB cable sheathing due to its high tensile strength and resistance to abrasion. It can withstand temperatures from -40°C to 120°C, making it suitable for demanding applications.

Pros:

– High durability and resistance to wear and tear.

– Excellent thermal stability, making it suitable for high-temperature environments.

– Lightweight, which can reduce shipping costs.

Cons:

– Higher manufacturing costs compared to PVC and TPE.

– Can absorb moisture, which may affect electrical properties over time.

Impact on Application: Nylon’s durability makes it suitable for industrial applications, but moisture absorption can limit its use in humid environments.

Considerations for International Buyers: Buyers should verify that nylon cables comply with relevant international standards and consider the implications of moisture absorption in their specific regions.

Why Is Copper Wire Essential for USB Cable Performance?

Copper is the standard material used for the conductors in USB cables due to its excellent electrical conductivity. It can operate effectively in a wide temperature range, typically from -40°C to 90°C.

Pros:

– High electrical conductivity ensures efficient data transfer.

– Good ductility allows for easy manufacturing and flexibility.

– Resistant to corrosion when properly insulated.

Cons:

– More expensive than aluminum alternatives.

– Susceptible to oxidation if not properly coated.

Impact on Application: Copper is essential for high-speed data transfer in USB cables, making it suitable for applications that require fast charging and data transmission.

Considerations for International Buyers: Buyers should ensure that copper cables meet international standards for conductivity and insulation, particularly in regions where electrical safety regulations are stringent.

Summary Table of Material Selection for USB Cable Manufacturing

| Material | Typical Use Case for USB Cable Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose USB cables | Cost-effective and flexible | Limited temperature resistance | Low |

| TPE | High-performance USB cables | Excellent flexibility and eco-friendly options | Higher manufacturing costs | Med |

| Nylon | Industrial-grade USB cables | High durability and thermal stability | Moisture absorption can affect performance | High |

| Copper | Conductors in USB cables | High electrical conductivity | Susceptible to oxidation | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing USB cables that meet their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for usb cable manufacturer

What Are the Main Stages of the Manufacturing Process for USB Cables?

The manufacturing of USB cables involves several critical stages that ensure quality and functionality. Understanding these stages is essential for B2B buyers to make informed purchasing decisions.

Material Preparation: How Are Materials Selected and Processed?

The first stage in USB cable manufacturing is material preparation. The primary materials used include copper wire for conductivity, PVC or TPE for insulation, and connectors made from metals like aluminum or nickel.

- Selection Criteria: Manufacturers typically select materials based on conductivity, durability, and compliance with international standards. For example, copper is preferred for its excellent conductivity, while PVC is common for its cost-effectiveness and flexibility.

- Processing Techniques: Materials undergo processes such as extrusion and annealing. Extrusion shapes the PVC or TPE into the desired insulation profile, while annealing softens the copper wire, making it easier to work with.

Forming: What Techniques Are Used to Shape USB Cables?

After material preparation, the next step is forming, where the insulated wires are shaped into the final cable structure.

- Wire Twisting: Multiple strands of copper are twisted together to enhance flexibility and reduce electromagnetic interference. This is particularly important for maintaining data integrity in USB cables.

- Insulation Application: The insulated wires are then assembled in a specific configuration, often in pairs or quads, and additional outer insulation is applied to provide protection and durability.

Assembly: How Are USB Cables Assembled?

The assembly stage is where the various components come together to form the final product.

- Connector Attachment: Connectors are attached to both ends of the cable, which may include USB Type-A, Type-B, or Type-C connectors. This process often involves precision machinery to ensure a secure fit.

- Quality Checks: At this stage, manufacturers often implement initial quality checks to ensure that the connectors are properly attached and that there are no visible defects in the cable.

Finishing: What Final Touches Are Added to USB Cables?

The finishing stage involves finalizing the product for packaging and distribution.

- Marking and Branding: Cables may be marked with specifications, branding, and compliance information. This is important for B2B buyers as it provides immediate verification of the cable’s specifications and standards.

- Packaging: USB cables are then packaged in protective materials to prevent damage during transportation. Proper labeling is crucial for international shipping and compliance with various regulations.

What Are the Key Quality Assurance Practices for USB Cable Manufacturing?

Quality assurance (QA) is vital in ensuring that USB cables meet international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

Understanding the relevant international standards is crucial for B2B buyers to ensure product quality and compliance.

- ISO 9001: This is a widely recognized quality management standard that ensures consistent quality in manufacturing processes. A manufacturer certified to ISO 9001 demonstrates a commitment to quality management principles.

- CE Marking: For cables sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. This is especially relevant for buyers in European markets.

- RoHS Compliance: This standard restricts the use of specific hazardous materials in electrical and electronic equipment, ensuring environmental safety.

What Are the Key QC Checkpoints in USB Cable Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process, helping to identify defects early and ensure product reliability.

- Incoming Quality Control (IQC): This involves checking the raw materials upon arrival to ensure they meet specifications. For B2B buyers, verifying the quality of incoming materials is essential for maintaining the integrity of the final product.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed at various stages to monitor the process and identify any deviations from quality standards.

- Final Quality Control (FQC): Before packaging, a final inspection is conducted to ensure that the cables meet all specifications and quality criteria. This is the last line of defense against defects.

What Common Testing Methods Are Used for USB Cables?

Testing methods are crucial for verifying the performance and safety of USB cables.

- Electrical Testing: This includes measuring resistance and continuity to ensure the cable can transmit data and power effectively. Common tests include voltage drop tests and insulation resistance tests.

- Mechanical Testing: Cables undergo stress tests to assess durability under various conditions, such as bending and pulling. This helps ensure they can withstand everyday use.

- Environmental Testing: Cables are tested under extreme temperatures and humidity levels to ensure they perform reliably in different conditions.

How Can B2B Buyers Verify Supplier QC Practices?

Verifying a supplier’s quality control practices is essential for B2B buyers, particularly when sourcing from international manufacturers.

What Steps Can Buyers Take to Assess Supplier Quality?

-

Supplier Audits: Conducting audits of potential suppliers is a critical step. Buyers can evaluate manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Reports: Manufacturers should be able to provide detailed quality reports, including results from testing and inspections. Buyers should request these documents to assess compliance and reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. This is particularly important for buyers in regions like Africa and South America, where local regulations may differ significantly from international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification can help B2B buyers navigate the complexities of sourcing USB cables internationally.

- Regional Compliance: Different regions may have specific compliance requirements. For example, cables sold in the Middle East may require additional certifications compared to those sold in Europe.

- Traceability: Buyers should ensure that manufacturers maintain traceability for materials and components used in their products. This is important for both quality assurance and regulatory compliance.

- Documentation: Comprehensive documentation, including certificates of conformity and testing results, is essential for smooth customs clearance and compliance with local laws.

By understanding the manufacturing processes and quality assurance practices involved in USB cable production, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘usb cable manufacturer’

Introduction

Sourcing USB cables from manufacturers can be a complex process, especially for international B2B buyers. This checklist aims to streamline your procurement journey by outlining essential steps that ensure you select the right supplier for your needs. By following these steps, you can mitigate risks, ensure quality, and foster a successful partnership.

Step 1: Define Your Technical Specifications

Before approaching suppliers, it’s vital to clearly define your technical requirements for the USB cables. This includes specifications like cable type (USB-A, USB-C, Micro USB), length, data transfer speed, and power delivery capabilities.

- Why It Matters: Clearly defined specifications help avoid miscommunication and ensure you receive products that meet your operational needs.

- What to Look For: Create a detailed document that outlines all necessary features, including compliance with relevant standards like USB-IF certification.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential USB cable manufacturers that align with your specifications. Utilize online directories, trade shows, and industry contacts to gather a list of suppliers.

- Why It Matters: A broad list of potential suppliers allows you to compare offerings and find the best match for your requirements.

- What to Look For: Prioritize manufacturers with a strong reputation, extensive experience, and positive reviews from previous clients.

Step 3: Verify Supplier Certifications

It’s crucial to verify that your chosen suppliers hold the necessary certifications and comply with international quality standards, such as ISO 9001 or RoHS.

- Why It Matters: Certifications are indicators of a manufacturer’s commitment to quality and safety, which can significantly impact your product’s performance and reliability.

- What to Look For: Request copies of certifications and assess their validity, especially if you are sourcing from regions with varying compliance standards.

Step 4: Request Samples

Before placing a bulk order, always request samples of the USB cables to assess their quality and functionality. This step allows you to evaluate the product firsthand.

- Why It Matters: Sampling helps you confirm that the product meets your specifications and expectations in real-world conditions.

- What to Look For: Check for build quality, material durability, and performance metrics such as charging speed and data transfer efficiency.

Step 5: Evaluate Pricing and Payment Terms

Once you have identified suitable suppliers, request detailed quotes that outline pricing, payment terms, and potential discounts for bulk orders.

- Why It Matters: Understanding pricing structures helps you budget effectively and compare costs across different suppliers.

- What to Look For: Pay attention to hidden costs, such as shipping and customs fees, and ensure the payment terms are favorable and secure.

Step 6: Assess Communication and Support

Effective communication is crucial for a successful supplier relationship. Assess how responsive and supportive the suppliers are during your inquiries.

- Why It Matters: Good communication ensures that any issues can be resolved quickly, minimizing disruptions to your supply chain.

- What to Look For: Evaluate their response time, willingness to provide additional information, and support throughout the ordering process.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure all terms are documented in a formal contract that includes pricing, delivery timelines, and quality expectations.

- Why It Matters: A well-drafted contract protects both parties and clarifies expectations, reducing the potential for disputes.

- What to Look For: Ensure the contract includes clauses for quality assurance, penalties for non-compliance, and terms for dispute resolution.

By following this comprehensive checklist, international B2B buyers can enhance their sourcing strategy for USB cables and establish productive relationships with reliable manufacturers.

Comprehensive Cost and Pricing Analysis for usb cable manufacturer Sourcing

What Are the Key Cost Components for USB Cable Manufacturing?

When sourcing USB cables, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials (copper, plastic, connectors) significantly affect the price. Higher-grade materials typically come with a higher cost but offer better performance and durability.

-

Labor: Labor costs vary by region and can influence overall pricing. Countries with lower labor costs can provide competitive pricing, but it is essential to assess the skill level and efficiency of the workforce.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, impacting the final price.

-

Tooling: Initial tooling costs for custom designs can be substantial. These costs are often amortized over larger production runs, making it more cost-effective to order higher volumes.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability, which can add to production costs. However, this investment can minimize returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly based on distance, mode of transport, and volume. International buyers should consider these costs when calculating the total price.

-

Margin: Manufacturers add a margin to cover their costs and generate profit. This can vary widely depending on the manufacturer’s positioning in the market.

How Do Price Influencers Affect USB Cable Sourcing?

Several factors can influence the pricing of USB cables, and understanding these can help buyers negotiate better deals:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually qualify for bulk discounts, making it essential to assess your needs against suppliers’ MOQ policies.

-

Specifications and Customization: Custom cables designed to specific standards or features can incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Cables that meet international quality certifications (like CE, UL) may cost more but are necessary for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers may charge a premium for their brand assurance and quality guarantees.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is crucial, as they determine who bears the cost and risk at different stages of transport, affecting total pricing.

What Tips Can Help International B2B Buyers in Negotiating Prices?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency when sourcing USB cables:

-

Negotiate Terms: Always negotiate not just on price but also on payment terms, delivery schedules, and after-sales support to maximize value.

-

Consider Total Cost of Ownership (TCO): Look beyond the unit price. Consider factors such as shipping, customs duties, and potential returns. A slightly higher initial cost might lead to lower overall expenses.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Regular communication and trust can result in preferential treatment.

-

Research Market Trends: Stay informed about market conditions and material costs. This knowledge can empower you during negotiations and help you identify the best timing for orders.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing offers from multiple manufacturers can give you leverage to negotiate better terms and prices.

Disclaimer on Pricing

Prices for USB cables can fluctuate based on market conditions, raw material availability, and geopolitical factors. It is advisable to obtain multiple quotes and conduct thorough due diligence before finalizing any sourcing agreement. Always request a detailed breakdown of costs to ensure transparency and clarity in pricing.

Alternatives Analysis: Comparing usb cable manufacturer With Other Solutions

Exploring Alternatives to USB Cable Manufacturing: What Are Your Options?

In today’s fast-paced technological environment, businesses often seek alternatives to traditional USB cable manufacturing to enhance their operational efficiency and reduce costs. Understanding these alternatives can provide B2B buyers with a clearer perspective on which solution aligns best with their specific needs.

| Comparison Aspect | Usb Cable Manufacturer | Alternative 1: Wireless Charging Solutions | Alternative 2: Fiber Optic Cables |

|---|---|---|---|

| Performance | High data transfer rates; reliable connection | Moderate performance; depends on proximity | Extremely high data transfer rates; long-distance capability |

| Cost | Moderate initial investment; ongoing material costs | Higher initial setup costs; potential savings on cables | Higher upfront costs; lower long-term maintenance |

| Ease of Implementation | Straightforward; requires standard equipment | Requires compatible devices; installation may vary | Requires specialized installation and maintenance |

| Maintenance | Low; minimal upkeep required | Low; minimal upkeep but requires updates | Moderate; regular checks needed for performance |

| Best Use Case | General data transfer; consumer electronics | Mobile devices, tablets, and modern appliances | High-speed internet and enterprise-level data transfer |

What Are the Pros and Cons of Wireless Charging Solutions?

A stock image related to usb cable manufacturer.

Wireless charging solutions present a modern alternative to USB cables, particularly in environments where convenience is paramount. The primary advantage is the elimination of physical connectors, which reduces wear and tear on devices. This technology is especially beneficial for mobile devices and tablets, allowing for quick charging without the hassle of connecting cables. However, these solutions may have moderate performance limitations, as the charging speed can vary based on the device’s proximity to the charger. Additionally, initial setup costs can be higher compared to traditional USB solutions, making it essential for buyers to weigh convenience against financial implications.

How Do Fiber Optic Cables Compare?

Fiber optic cables are another viable alternative, particularly for businesses that require high-speed data transfer over long distances. These cables offer superior performance, capable of handling vast amounts of data at lightning speeds. They are best suited for enterprise-level applications, such as high-speed internet and large data centers. However, the cost of fiber optic infrastructure can be significantly higher than USB manufacturing, with ongoing maintenance requirements that necessitate specialized knowledge and tools. For B2B buyers in industries with high data demands, the investment in fiber optics can yield substantial long-term benefits despite the initial costs.

Making the Right Choice: How Should B2B Buyers Decide?

Choosing the right solution hinges on several factors, including the specific operational needs, budget constraints, and future scalability requirements. For businesses focused on consumer electronics or general data transfer, USB cable manufacturing remains a practical choice due to its reliability and ease of implementation. Conversely, organizations aiming for cutting-edge technology and higher data demands may find wireless charging or fiber optic solutions more beneficial. Ultimately, it is crucial for B2B buyers to assess their unique circumstances and align their choice with their long-term strategic goals.

By thoroughly evaluating these alternatives, international B2B buyers can make informed decisions that enhance their operational efficiency and support future growth.

Essential Technical Properties and Trade Terminology for usb cable manufacturer

What Are the Essential Technical Properties of USB Cables for B2B Buyers?

When sourcing USB cables, international B2B buyers must understand key technical specifications that impact performance, durability, and compatibility. Here are some critical properties to consider:

1. Material Grade

The material used for the cable conductors and insulation significantly influences performance. Copper is the standard conductor material due to its excellent conductivity. The insulation material, often PVC or TPE, affects flexibility and durability. Selecting high-quality materials ensures reduced signal loss and enhances the cable’s lifespan, crucial for businesses that rely on reliable technology.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions, impacting the cable’s fit and function. For example, a USB cable with tight tolerances ensures consistent power delivery and data transfer rates. This is especially important for industries like electronics and telecommunications, where precision can affect device performance and user experience.

3. Data Transfer Rate

USB cables come with various specifications, such as USB 2.0, 3.0, and 3.1, each offering different data transfer speeds. For instance, USB 3.0 can support speeds up to 5 Gbps, while USB 3.1 can reach up to 10 Gbps. Understanding these rates is vital for businesses that need to transfer large amounts of data quickly, such as in media and software development.

4. Voltage Rating

The voltage rating indicates the maximum voltage the cable can safely carry without risk of failure. Most USB cables are rated for 5V, but some can handle higher voltages, especially those designed for fast charging. Buyers must ensure the cable’s voltage rating aligns with their devices’ requirements to prevent damage and ensure efficient charging.

5. Shielding

Shielding protects the cable from electromagnetic interference (EMI) that can degrade data signals. Cables with proper shielding (like foil or braided shields) are essential for maintaining performance in environments with high electronic noise, such as industrial settings or urban areas. This property is crucial for ensuring stable connections, particularly for businesses relying on data integrity.

What Are Common Trade Terms in the USB Cable Manufacturing Industry?

Navigating the B2B landscape also involves understanding industry jargon. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can streamline the procurement process, ensuring that the components meet specific standards and specifications required for their products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a manufacturer is willing to produce or sell. Understanding MOQ is vital for B2B buyers to manage inventory costs effectively. Ordering below the MOQ may result in higher prices or inability to fulfill orders, which can disrupt supply chains.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific quantities and types of products. Crafting a detailed RFQ can help buyers receive accurate quotes and compare suppliers effectively, ensuring they secure the best terms and pricing for USB cables.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and rights during the shipping process, reducing the risk of misunderstandings and ensuring smooth transactions.

5. Lead Time

Lead time is the amount of time from placing an order to receiving the goods. For B2B buyers, understanding lead times is crucial for planning and inventory management. Long lead times can affect production schedules, making it essential to communicate clearly with suppliers about expected timelines.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the usb cable manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the USB Cable Manufacturing Sector?

The USB cable manufacturing sector is experiencing significant growth, driven by the increasing demand for connectivity solutions across various industries, including electronics, automotive, and telecommunications. The proliferation of smart devices, the rise of the Internet of Things (IoT), and the ongoing transition to USB-C technology are propelling market expansion. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing strategies.

Emerging trends include the shift towards custom cable solutions tailored to specific applications. Manufacturers are increasingly offering bespoke designs that meet unique customer requirements. Moreover, the integration of advanced materials such as braided nylon and reinforced connectors is enhancing durability and performance, appealing to businesses seeking high-quality products. The growing emphasis on fast charging capabilities also influences product development, leading to innovations that cater to consumer preferences for efficiency and convenience.

B2B buyers should be aware of the competitive landscape, characterized by a mix of established players and new entrants. This competition fosters innovation but also poses challenges in terms of price negotiations and supplier selection. Buyers are advised to conduct thorough market research and evaluate multiple suppliers to identify those who can provide not only quality products but also competitive pricing and reliable delivery timelines.

How Does Sustainability and Ethical Sourcing Impact the USB Cable Manufacturing Industry?

Sustainability has become a cornerstone of modern manufacturing practices, and the USB cable sector is no exception. The environmental impact of production processes, particularly in terms of plastic waste and energy consumption, is prompting manufacturers to adopt more sustainable practices. For international B2B buyers, the importance of sourcing from companies that prioritize environmental responsibility cannot be overstated.

Ethical supply chains are increasingly vital as consumers and businesses alike demand transparency. Buyers should look for manufacturers that utilize eco-friendly materials, such as recyclable plastics and biodegradable components. Certifications like RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management) can serve as indicators of a supplier’s commitment to sustainability.

Additionally, the shift towards circular economy principles is gaining traction, with manufacturers exploring ways to recycle and repurpose materials. By partnering with suppliers that embrace these practices, buyers can not only contribute to environmental sustainability but also enhance their brand reputation in an increasingly eco-conscious marketplace.

How Has the USB Cable Manufacturing Sector Evolved Over Time?

The USB cable manufacturing sector has undergone significant evolution since its inception in the late 1990s. Initially designed for basic data transfer, USB cables have transformed into essential components for charging and data synchronization across a myriad of devices. The transition from USB-A to USB-C technology marks a pivotal moment in this evolution, offering faster data transfer rates and improved versatility.

As technology advances, so too has the manufacturing process. The introduction of automated production lines and enhanced quality control measures has led to increased efficiency and product reliability. Furthermore, the growing demand for customization and specialized applications has prompted manufacturers to innovate continuously, ensuring they remain competitive in a fast-paced market.

This historical context is essential for B2B buyers who are looking to understand not just the current landscape but also the trajectory of the industry, enabling them to make informed decisions regarding sourcing and partnerships.

Frequently Asked Questions (FAQs) for B2B Buyers of usb cable manufacturer

-

How do I select the right USB cable manufacturer for my business needs?

Choosing the right USB cable manufacturer involves assessing several factors such as product quality, manufacturing capabilities, and compliance with international standards. Start by reviewing their certifications, such as ISO or CE, which indicate adherence to quality and safety regulations. Also, consider their experience in your specific industry and their ability to customize products to meet your unique requirements. Request samples to evaluate the quality and performance of their cables before making a commitment. -

What are the minimum order quantities (MOQs) when sourcing USB cables?

Minimum order quantities can vary significantly between manufacturers, often ranging from 100 to 10,000 units. When sourcing USB cables, inquire about the MOQ for different types of cables and customization options. Some manufacturers may offer flexibility on MOQs based on product type or first-time orders. Understanding the MOQ is crucial for managing your inventory and cash flow, especially if you are a smaller business or a startup. -

What customization options should I consider when sourcing USB cables?

Customization options for USB cables typically include length, color, connector type, and branding features such as logo printing. When evaluating manufacturers, ask about their capabilities to provide tailored solutions that align with your brand identity. Additionally, consider how customization may affect lead times and costs. A manufacturer that offers a wide range of customization options can help differentiate your products in a competitive market. -

What payment terms should I expect when dealing with international USB cable manufacturers?

Payment terms can vary widely among manufacturers, especially in international trade. Common terms include 30% upfront payment with the balance due before shipment or upon delivery. Some manufacturers may offer letters of credit or escrow services to ensure security for both parties. It’s essential to clarify payment methods accepted (e.g., wire transfers, PayPal) and negotiate terms that align with your cash flow needs while minimizing risk. -

How can I ensure quality assurance when sourcing USB cables?

To ensure quality assurance, request detailed information on the manufacturer’s quality control processes, including testing methods and certifications. Many reputable manufacturers perform routine tests on their products to ensure compliance with international standards. Consider implementing a quality assurance agreement that outlines your expectations for product quality and performance, and inquire about the possibility of third-party inspections to verify compliance before shipment. -

What logistics considerations should I be aware of when importing USB cables?

Logistics play a critical role in the import process for USB cables. Understand the shipping methods available (e.g., air freight vs. sea freight) and their associated costs and transit times. Additionally, familiarize yourself with customs regulations in your country to avoid delays. Working with a freight forwarder can help navigate these complexities and ensure that your shipments are handled efficiently. Always factor in potential tariffs and duties when calculating total import costs. -

How do I vet a USB cable manufacturer for reliability and reputation?

To vet a USB cable manufacturer, start by researching their online presence, including customer reviews and case studies. Utilize platforms like LinkedIn or industry-specific forums to gather insights from other businesses that have worked with them. Additionally, consider requesting references and reaching out to their past clients to discuss their experiences. Assessing their financial stability and industry reputation can provide further confidence in their reliability. -

What are the common certifications I should look for in USB cable manufacturers?

When sourcing USB cables, look for certifications that indicate compliance with safety and quality standards. Common certifications include UL (Underwriters Laboratories), CE (Conformité Européenne), RoHS (Restriction of Hazardous Substances), and FCC (Federal Communications Commission). These certifications ensure that the cables meet specific performance and safety benchmarks, which is crucial for maintaining product quality and regulatory compliance in your target markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for usb cable manufacturer

What are the Key Takeaways for B2B Buyers in USB Cable Sourcing?

In conclusion, strategic sourcing of USB cables is not merely about price; it encompasses quality, reliability, and supplier relationships. International B2B buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who demonstrate robust quality assurance processes and compliance with international standards. This not only mitigates risks but also enhances the overall value of your supply chain.

How Can Strategic Sourcing Drive Competitive Advantage?

Investing in strategic sourcing can lead to significant cost savings and operational efficiencies. By leveraging data analytics and market insights, buyers can make informed decisions that align with their long-term business goals. Furthermore, as technology evolves, staying ahead of the curve with innovative USB solutions will be crucial for maintaining competitiveness in a rapidly changing marketplace.

What Does the Future Hold for USB Cable Manufacturers?

Looking ahead, the demand for high-quality USB cables will continue to rise, driven by advancements in technology and increasing connectivity needs. B2B buyers are encouraged to remain proactive in their sourcing strategies, exploring new partnerships and innovations in the market. Embrace the opportunity to enhance your supply chain by engaging with forward-thinking USB cable manufacturers who can support your growth in the years to come.