Discover Top USB Cables Supplier: Cut Costs & Boost Quality (2025)

Introduction: Navigating the Global Market for usb cables supplier

In the ever-evolving landscape of technology, sourcing quality USB cables has become a critical challenge for international B2B buyers. With the rapid proliferation of devices requiring reliable connectivity, understanding the nuances of selecting the right USB cables supplier is paramount. This guide delves into the comprehensive landscape of USB cables, covering various types, their applications, and the essential criteria for vetting suppliers. From understanding the differences between USB 2.0, 3.0, and the latest Type-C connectors to exploring the implications of regional standards, this resource is designed to enhance your purchasing strategy.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Colombia and the UAE—will find actionable insights tailored to their unique market conditions. This guide empowers decision-makers with critical information on cost structures, compliance regulations, and quality assurance practices. By equipping buyers with the necessary tools to navigate the global market, we aim to facilitate informed decisions that not only meet their technical requirements but also align with their budgetary constraints.

As you journey through this guide, you will uncover the strategies needed to establish fruitful partnerships with reputable suppliers, ultimately ensuring that your organization remains competitive in a technology-driven world.

Understanding usb cables supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| USB Type-A | Standard rectangular connector, widely used | Computer peripherals, chargers | Pros: Universally compatible; Cons: Limited data transfer speed compared to newer types. |

| USB Type-B | Square-shaped connector, often used in printers | Printers, external hard drives | Pros: Reliable for power and data; Cons: Less common in modern devices. |

| USB Type-C | Reversible connector, supports higher data rates | Smartphones, laptops, and modern devices | Pros: Fast data transfer; supports power delivery; Cons: Requires adapters for older devices. |

| Micro USB | Smaller connector, commonly used in mobile devices | Smartphones, tablets, and accessories | Pros: Compact size; Cons: Fragile; being phased out in favor of USB-C. |

| Mini USB | Slightly larger than Micro USB, used in older devices | Cameras, some gaming controllers | Pros: Good for specific older devices; Cons: Limited availability and support. |

What Are the Characteristics of USB Type-A Cables for B2B Buyers?

USB Type-A cables are the most common form of USB connectors, characterized by their rectangular shape. They are typically used to connect devices like computers to peripherals such as keyboards, mice, and printers. For B2B buyers, the key consideration is compatibility, as Type-A is universally accepted across various devices. However, buyers should be aware that while they provide reliable connections, their data transfer speeds are slower compared to newer USB types, which may impact performance in high-speed applications.

How Does USB Type-B Differ in B2B Applications?

USB Type-B cables feature a square shape and are primarily used in connecting devices such as printers and external hard drives to computers. Their design helps prevent incorrect connections, making them reliable for B2B environments where stability is crucial. Buyers should consider the longevity and reliability of Type-B cables for equipment that requires consistent performance. However, as technology evolves, Type-B connectors are becoming less common, which may lead to future compatibility issues.

What Makes USB Type-C Ideal for Modern Business Needs?

USB Type-C cables are distinguished by their reversible connector and ability to support faster data transfer rates and higher power delivery. This makes them suitable for a wide range of applications, including smartphones, laptops, and other modern devices. B2B buyers should prioritize USB Type-C for future-proofing their technology investments, as it is rapidly becoming the industry standard. The only drawback is that older devices may require adapters, which can increase costs.

Why Are Micro USB Cables Still Relevant in the B2B Market?

Micro USB cables are widely used in mobile devices, particularly smartphones and tablets. Their compact size makes them ideal for portable applications. However, B2B buyers should consider that while Micro USB is still prevalent, it is gradually being replaced by USB Type-C. The fragility of Micro USB connectors may also be a concern for businesses looking for durable solutions. Buyers should assess their existing inventory and future needs when considering Micro USB.

What Are the Limitations of Mini USB Cables for Business Use?

Mini USB cables, larger than Micro USB, were commonly used in devices like cameras and some gaming controllers. While they serve specific older devices, their usage is declining, making them less relevant for modern B2B applications. Buyers should be cautious when investing in Mini USB cables, as their limited availability and support can lead to challenges in maintaining compatibility with newer devices. It’s essential to evaluate whether existing equipment necessitates Mini USB connections before purchasing.

Related Video: USB Types: Various Types of USB Cables (A, B and C) and Their Differences

Key Industrial Applications of usb cables supplier

| Industry/Sector | Specific Application of usb cables supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Connecting smartphones to computers | Facilitates seamless data transfer for backups and updates | Quality assurance and compatibility with devices |

| Automotive | Charging and data transfer for infotainment systems | Enhances user experience through reliable connections | Durability and resistance to environmental factors |

| Healthcare | Data transfer between medical devices and computers | Ensures accurate patient data management and reporting | Compliance with medical standards and certifications |

| Industrial Automation | Linking machinery and control systems | Improves operational efficiency and monitoring | Cable length, shielding, and connector types |

| Telecommunications | Connecting networking equipment | Supports high-speed data transmission and reliability | Compatibility with existing infrastructure and standards |

How Are USB Cables Used in Consumer Electronics?

In the consumer electronics sector, USB cables are essential for connecting smartphones, tablets, and laptops to computers for data transfer. These cables allow users to back up important data, update device software, and transfer files quickly. For international B2B buyers, sourcing high-quality USB cables that are compatible with various devices is crucial. Quality assurance is vital to prevent data loss or connection failures, especially in regions like Africa and South America, where device compatibility can vary widely.

What Is the Role of USB Cables in the Automotive Industry?

In the automotive industry, USB cables are pivotal for charging and data transfer within infotainment systems. They enable drivers to connect their smartphones for navigation, music, and communication, enhancing the overall driving experience. B2B buyers in this sector must prioritize sourcing durable and high-quality cables that can withstand automotive environments, including temperature fluctuations and vibrations. Ensuring the cables meet automotive standards is essential for safety and functionality.

How Are USB Cables Beneficial in Healthcare?

USB cables play a crucial role in the healthcare sector by facilitating data transfer between medical devices and computers. This capability is essential for accurate patient data management, ensuring that health records are up to date and accessible for healthcare professionals. International buyers must consider sourcing cables that comply with medical standards, ensuring they are safe for use in clinical settings. The reliability of these cables is paramount, as they directly impact patient care and data integrity.

How Are USB Cables Used in Industrial Automation?

In industrial automation, USB cables are used to link machinery to control systems, enabling efficient monitoring and data collection. This connection allows for real-time data analysis, enhancing operational efficiency and productivity. Buyers in this sector should focus on cables that offer optimal shielding and are resistant to electromagnetic interference, as these factors can significantly affect performance. Additionally, the length and connector types must be suitable for specific machinery setups.

What Is the Importance of USB Cables in Telecommunications?

In telecommunications, USB cables are vital for connecting networking equipment, such as routers and modems. They support high-speed data transmission, which is essential for maintaining reliable internet connectivity. For B2B buyers in this field, it is important to source cables that are compatible with existing infrastructure and meet industry standards. Ensuring the quality of these cables can prevent costly downtime and maintain service reliability, particularly in fast-growing markets in the Middle East and Europe.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘usb cables supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of USB Cables

The Problem:

International B2B buyers often face the challenge of inconsistent quality when sourcing USB cables. This can lead to frequent failures in devices, resulting in costly downtime and repairs. For instance, a company in Colombia might order bulk USB cables from a supplier in Asia, only to find that a significant percentage of the cables do not meet their performance standards. Such discrepancies can disrupt operations, affect productivity, and lead to dissatisfaction among clients relying on these products.

The Solution:

To mitigate the risk of inconsistent quality, B2B buyers should implement a rigorous quality assurance process when selecting USB cable suppliers. This includes requesting samples before placing large orders and performing quality checks on those samples. Additionally, buyers should inquire about the supplier’s manufacturing standards, certifications (like ISO 9001), and testing protocols. Establishing a clear quality agreement that outlines specific performance criteria can also help ensure that the products delivered meet expectations. Engaging with suppliers who have a proven track record in the industry can significantly reduce the likelihood of quality issues.

Scenario 2: Difficulty in Finding Compatible USB Cable Types

The Problem:

Another common pain point for B2B buyers is the challenge of finding USB cables that are compatible with various devices and technologies. For instance, a business in the UAE may require USB-C cables for the latest devices but also needs to maintain compatibility with older USB-A devices. This can lead to a fragmented purchasing process, requiring multiple suppliers and complicating inventory management.

The Solution:

To address compatibility issues, B2B buyers should conduct thorough research on the types of USB cables they need based on their current and future technology landscape. Creating a compatibility matrix that outlines the devices in use and the corresponding cable types can provide clarity. When approaching suppliers, buyers should clearly communicate their needs and ask for a comprehensive catalog that includes various types of USB cables (USB-A, USB-B, USB-C, Micro-USB, etc.). Working with a supplier that offers a wide range of cable types can streamline the purchasing process and help maintain a consistent supply chain.

Scenario 3: Long Lead Times Affecting Project Timelines

The Problem:

Long lead times for USB cable deliveries can severely impact project timelines for B2B buyers. For example, a company in South America may be launching a new product that requires a specific type of USB cable. If the supplier cannot deliver on time, it can delay the entire project, leading to missed market opportunities and potential revenue loss.

The Solution:

To combat long lead times, B2B buyers should prioritize suppliers with established logistics capabilities and a history of timely deliveries. It’s essential to discuss lead times upfront and request a clear timeline for order fulfillment. Buyers can also consider building relationships with multiple suppliers to create a fallback option in case of delays. Additionally, implementing a just-in-time inventory system can help ensure that the necessary components, including USB cables, are on hand when needed without excessive overstocking. Regular communication with suppliers regarding order status can also help identify potential delays early and allow for contingency planning.

Strategic Material Selection Guide for usb cables supplier

What Are the Key Materials Used in USB Cables and Their Properties?

When selecting materials for USB cables, suppliers must consider a variety of factors that influence performance, durability, and cost. Here, we analyze four common materials used in USB cable manufacturing: copper, PVC, TPE, and aluminum. Each material has unique properties and implications for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Copper Affect USB Cable Performance?

Key Properties: Copper is renowned for its excellent electrical conductivity, which is crucial for efficient data transmission and power delivery in USB cables. It can handle high temperatures and has a melting point of approximately 1,085°C, making it suitable for various operating environments.

Pros & Cons: The primary advantage of copper is its conductivity, which ensures minimal signal loss and high-speed data transfer. However, copper cables can be more expensive than alternatives and are susceptible to corrosion if not properly insulated, which can impact long-term reliability.

Impact on Application: Copper is compatible with all types of USB applications, including high-speed data transfer and charging. However, international buyers must ensure that copper cables meet local standards for electrical safety and performance.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM and IEC for electrical components. In regions like the UAE and Europe, certifications for copper quality and environmental impact may also be necessary.

What Role Does PVC Play in USB Cable Manufacturing?

Key Properties: Polyvinyl Chloride (PVC) is a widely used plastic known for its durability and flexibility. It can withstand temperatures ranging from -10°C to 70°C, making it suitable for various environments.

Pros & Cons: PVC is cost-effective and offers good insulation properties, which helps protect the internal wiring from external factors. However, it is less environmentally friendly compared to other materials and can become brittle over time, especially when exposed to UV light.

Impact on Application: PVC is commonly used in the outer sheathing of USB cables, providing protection against abrasion and moisture. However, its limitations in extreme temperatures may restrict its use in more demanding applications.

Considerations for International Buyers: Buyers should consider local regulations regarding the use of PVC, especially in regions with strict environmental laws. Compliance with standards like RoHS (Restriction of Hazardous Substances) is crucial for markets in Europe.

How Does TPE Compare as a Material for USB Cables?

Key Properties: Thermoplastic Elastomer (TPE) combines the properties of rubber and plastic, offering excellent flexibility and resilience. It performs well in temperature ranges from -40°C to 90°C, making it versatile for various applications.

Pros & Cons: TPE is highly durable and resistant to wear and tear, making it ideal for frequent handling. However, it can be more expensive than PVC and may not provide the same level of electrical insulation as other materials.

Impact on Application: TPE is suitable for applications requiring flexibility and durability, such as portable USB cables. Its resistance to extreme temperatures allows it to be used in diverse environments.

Considerations for International Buyers: Buyers should verify that TPE materials comply with local safety and environmental standards. In regions like South America, ensuring that TPE is free from harmful substances is increasingly important.

What Are the Benefits of Using Aluminum in USB Cables?

Key Properties: Aluminum is lightweight and has good conductivity, although not as high as copper. It is also resistant to corrosion, which can enhance the longevity of cables in humid environments.

Pros & Cons: The main advantage of aluminum is its lower cost compared to copper, making it an attractive option for budget-sensitive projects. However, its lower conductivity can lead to higher resistance and potential signal loss.

Impact on Application: Aluminum can be used in applications where weight is a critical factor, such as in mobile devices. However, it may not be suitable for high-speed data transfer applications where performance is paramount.

Considerations for International Buyers: Buyers should ensure that aluminum cables meet relevant standards for conductivity and safety. In markets like Africa, where infrastructure varies, the choice of aluminum may depend on local conditions and requirements.

Summary Table of Material Selection for USB Cables

| Material | Typical Use Case for usb cables supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-speed data transfer cables | Excellent conductivity | Expensive and prone to corrosion | High |

| PVC | General-purpose USB cables | Cost-effective and durable | Less environmentally friendly | Low |

| TPE | Flexible and portable USB cables | High durability and temperature resistance | More expensive than PVC | Medium |

| Aluminum | Lightweight USB cables | Lower cost compared to copper | Lower conductivity and potential signal loss | Medium |

This comprehensive analysis of materials provides international B2B buyers with actionable insights into selecting the right USB cable materials for their specific needs, ensuring compliance with regional standards and optimizing product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for usb cables supplier

What Are the Key Stages in the Manufacturing Process of USB Cables?

The manufacturing process of USB cables involves several critical stages, each designed to ensure that the final product meets the required standards for performance and durability. Understanding these stages is essential for international B2B buyers looking to source high-quality USB cables.

1. Material Preparation: What Materials Are Used in USB Cable Manufacturing?

The first step in USB cable production is the preparation of raw materials. This typically includes:

- Conductors: Copper is the most common material used for conductors due to its excellent conductivity. Some suppliers may also use aluminum, but this is less common due to its inferior conductivity.

- Insulation: PVC (Polyvinyl Chloride) and TPE (Thermoplastic Elastomer) are widely used for insulation, providing flexibility and protection against environmental factors.

- Shielding: To prevent electromagnetic interference (EMI), cables often include a shielding layer made from materials such as aluminum foil or braided copper.

Quality control begins here, as the choice of materials directly impacts the performance and safety of the cables.

2. Forming: How Are USB Cables Shaped and Structured?

Once materials are prepared, the next stage involves the shaping of the cables:

- Stranding: Conductors are twisted together to form strands, which enhances flexibility and reduces the risk of breakage.

- Insulation Application: The insulated conductors are then extruded with the chosen insulation material. This process must ensure a consistent thickness to prevent electrical shorts and enhance durability.

- Shielding Application: For cables requiring shielding, the next step involves wrapping the insulated conductors with a shielding layer before applying the outer jacket.

This stage is crucial for ensuring that the cable can withstand physical stress and environmental conditions.

3. Assembly: What Processes Are Involved in Assembling USB Cables?

The assembly stage includes several steps:

- Connector Attachment: Connectors are attached to both ends of the cable. This process may involve soldering or crimping, depending on the design of the connectors.

- Final Insulation: An outer jacket is applied, typically made from PVC or another durable material, to provide additional protection.

At this point, the cables are assembled and ready for quality assurance testing.

4. Finishing: How Is the Final Product Prepared for Distribution?

The finishing stage includes:

- Quality Control Inspections: Each batch of cables undergoes thorough inspections to ensure they meet specifications.

- Packaging: Cables are then packaged for distribution, ensuring they are protected during shipping and handling.

This final stage is critical for maintaining the integrity of the product throughout its lifecycle.

What Quality Assurance Practices Should B2B Buyers Expect from USB Cable Suppliers?

Quality assurance (QA) is paramount in the USB cable manufacturing process, ensuring products meet international standards and customer specifications. Here are some essential QA practices to look for:

1. What International Standards Should USB Cable Suppliers Comply With?

B2B buyers should ensure that their suppliers adhere to relevant international standards, including:

- ISO 9001: This standard focuses on quality management systems, ensuring that suppliers consistently meet customer requirements and enhance satisfaction.

- CE Marking: This indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- RoHS Compliance: Ensures that the cables are free from hazardous substances, which is crucial for safety and environmental considerations.

Which Quality Control Checkpoints Are Essential in the Manufacturing Process?

Quality control checkpoints are crucial in maintaining the integrity of USB cables throughout the manufacturing process:

- Incoming Quality Control (IQC): Checks the quality of raw materials before production begins. This includes testing the electrical properties of conductors and the quality of insulation materials.

- In-Process Quality Control (IPQC): Conducts inspections during the manufacturing process to catch defects early. This may include checking insulation thickness and connector integrity.

-

Final Quality Control (FQC): This step involves comprehensive testing of the finished cables, including:

-

Electrical Testing: Ensures that the cables meet the required electrical specifications, such as resistance and capacitance.

- Mechanical Testing: Assesses the durability of the cables under physical stress and bending.

- Environmental Testing: Evaluates performance under various temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers:

- Conduct Audits: Regular audits of the supplier’s facilities can provide insights into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and compliance certificates.

- Engage Third-Party Inspectors: Hiring third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices.

What Are the Common Testing Methods for USB Cables?

Testing methods play a critical role in ensuring the quality and safety of USB cables. Buyers should inquire about the specific testing methods used by suppliers:

- Continuity Testing: Ensures that electrical pathways are intact and that there are no breaks in the conductor.

- Insulation Resistance Testing: Verifies that the insulation is effective and that there are no electrical leaks.

- Environmental Testing: Assesses how the cables perform under extreme conditions, such as high temperatures, humidity, and exposure to chemicals.

What Quality Control Nuances Should International Buyers Be Aware Of?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, there are unique considerations regarding quality control:

- Understanding Local Regulations: Different regions may have specific regulations regarding product safety and environmental impact. Buyers should ensure that their suppliers comply with these regulations to avoid legal complications.

- Cultural and Language Barriers: Effective communication is essential for ensuring quality. Buyers should consider suppliers that have experience dealing with international clients and can provide clear documentation and support in multiple languages.

By understanding the manufacturing processes and quality assurance practices for USB cables, international B2B buyers can make informed decisions and ensure they partner with reliable suppliers that meet their quality standards.

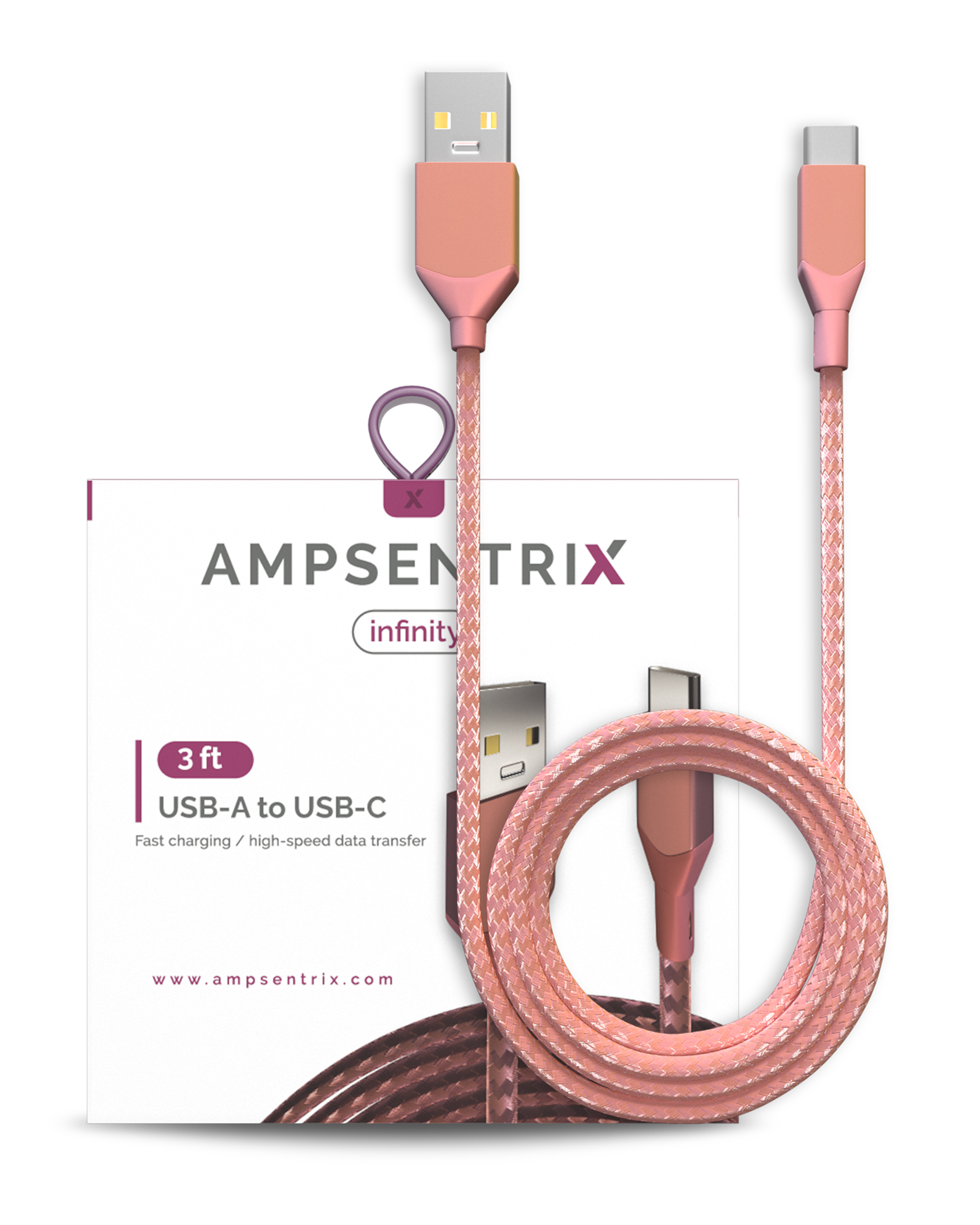

A stock image related to usb cables supplier.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘usb cables supplier’

In the fast-evolving landscape of technology and consumer electronics, sourcing USB cables from reliable suppliers is crucial for businesses looking to maintain efficiency and quality. This guide provides a clear, step-by-step checklist for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications you require for the USB cables. Consider factors such as cable type (USB 2.0, 3.0, or Type-C), length, compatibility with devices, and any special features like fast charging capabilities. Providing detailed specifications helps suppliers understand your needs and reduces the likelihood of mismatches later in the process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Use platforms like Alibaba, Global Sources, or local trade directories to find manufacturers that specialize in USB cables. Pay attention to their market reputation, years of operation, and customer reviews, as this can provide insights into their reliability and product quality.

Step 3: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications, such as ISO 9001 or CE marking. These certifications indicate adherence to quality management standards and compliance with safety regulations. Request documentation to verify these certifications, as they can be pivotal in ensuring the products meet international quality standards.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the USB cables you are interested in. Testing these samples allows you to evaluate the quality, durability, and performance of the products. Check for factors like transfer speed, build quality, and compatibility with your devices to ensure they meet your expectations.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget and explore options for bulk discounts. Additionally, discuss warranty and return policies to protect your investment and ensure you have recourse in case of defective products.

Step 6: Assess Logistics and Shipping Options

Consider the logistics involved in shipping the USB cables from the supplier’s location to your business. Discuss shipping methods, lead times, and costs with the supplier. Evaluate whether they offer support in customs clearance, especially if importing to regions with strict regulations, to avoid delays in receiving your order.

Step 7: Establish a Long-Term Relationship

After successfully sourcing USB cables, focus on building a long-term relationship with your supplier. Regular communication and feedback can help enhance product quality and service. Consider setting up periodic reviews of product performance and supplier reliability to ensure ongoing satisfaction with your procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing USB cables effectively, ensuring they partner with reliable suppliers who can meet their technical and business needs.

Comprehensive Cost and Pricing Analysis for usb cables supplier Sourcing

What Are the Key Cost Components in USB Cable Manufacturing?

When sourcing USB cables, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The raw materials for USB cables, including copper wire, plastic, and connectors, significantly impact the overall cost. Higher quality materials can lead to better durability and performance but will increase the initial price.

-

Labor: Labor costs vary by region, with some countries having lower wages. However, skilled labor may demand higher wages, especially for quality assurance and specialized manufacturing processes.

-

Manufacturing Overhead: This includes costs related to the factory operations such as utilities, equipment maintenance, and facility costs. Efficient production processes can help reduce overhead costs.

-

Tooling: The initial investment in molds and manufacturing tools can be substantial, particularly for custom designs. Tooling costs are typically amortized over the production run, impacting the unit price.

-

Quality Control (QC): Ensuring that USB cables meet safety and performance standards requires investment in quality control measures. This can include testing equipment and personnel, contributing to the overall cost.

-

Logistics: Shipping and handling costs vary depending on the distance and method of transportation. This is especially crucial for international buyers who must factor in customs duties and import fees.

-

Margin: Suppliers will include a profit margin in their pricing, which can be influenced by market demand, competition, and the perceived value of their products.

How Do Price Influencers Affect USB Cable Costs?

Several factors can influence the pricing of USB cables, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order size. Larger orders typically receive discounts, so understanding MOQ can lead to significant savings.

-

Specifications and Customization: Customized cables or those meeting specific technical standards may incur higher costs. Buyers should assess whether they need bespoke solutions or if standard products suffice.

-

Materials and Quality Certifications: The choice of materials affects both durability and cost. Additionally, cables that are certified for safety standards (like CE, UL, or RoHS) can have higher prices due to the compliance processes involved.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to brand trust and proven quality, while newer suppliers might offer lower prices to enter the market.

-

Incoterms: The shipping terms defined by Incoterms (e.g., FOB, CIF) can impact the total landed cost. Buyers should understand these terms to accurately calculate their total expenses.

What Are the Best Buyer Tips for Cost-Efficiency in USB Cable Sourcing?

When navigating the complexities of USB cable sourcing, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Smartly: Don’t hesitate to negotiate prices, especially for larger orders. Establishing a good relationship with suppliers can lead to better pricing and terms over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes shipping, potential returns, and replacement costs. A cheaper cable may cost more in the long run if it fails prematurely.

-

Research Pricing Nuances: Prices can vary significantly between suppliers and regions. Conduct thorough market research to understand average prices and identify competitive offers.

-

Leverage Local Resources: For buyers in Africa or South America, leveraging local suppliers can minimize logistics costs and lead to faster delivery times.

-

Stay Informed About Market Trends: Keeping abreast of technological advancements and market shifts can help buyers anticipate price changes and adjust their sourcing strategies accordingly.

Conclusion

Sourcing USB cables requires a comprehensive understanding of the cost structure, pricing influencers, and strategic negotiation techniques. By considering these elements, international B2B buyers can make informed decisions that align with their budget and operational needs. Always remember that prices can fluctuate, and it’s crucial to conduct due diligence and remain adaptable in your sourcing strategies.

Alternatives Analysis: Comparing usb cables supplier With Other Solutions

When considering a USB cables supplier, it is essential for international B2B buyers to understand the alternatives available in the market. Various technologies and methods can accomplish similar tasks, each with its unique advantages and limitations. This section provides a comparative analysis of USB cables suppliers against two viable alternatives: wireless file transfer technologies and cloud-based solutions.

Comparison Table of USB Cables Supplier and Alternatives

| Comparison Aspect | USB Cables Supplier | Wireless File Transfer Technologies | Cloud-Based Solutions |

|---|---|---|---|

| Performance | High speed; reliable for large file transfers | Moderate; speed can vary based on signal strength | Dependent on internet connection; can be slow for large files |

| Cost | Low initial investment; ongoing costs for replacements | Low to moderate; may require compatible devices | Subscription-based; costs can accumulate over time |

| Ease of Implementation | Simple plug-and-play setup; minimal technical knowledge required | Requires compatible devices and configuration | Requires internet access and user training |

| Maintenance | Low; cables may need replacement occasionally | Moderate; may require software updates and troubleshooting | High; ongoing subscription and potential data management |

| Best Use Case | Ideal for large files and secure transfers | Best for quick, temporary file transfers between devices | Suitable for collaborative work and remote access to files |

Detailed Breakdown of Alternatives

What are Wireless File Transfer Technologies?

Wireless file transfer technologies, such as Bluetooth and Wi-Fi Direct, allow devices to exchange files without physical connections. These methods are increasingly popular for their convenience and mobility.

Pros:

– Convenience: No need for physical cables, enabling easy access to files across devices.

– Mobility: Great for transferring files on the go, especially in mobile environments.

Cons:

– Variable Performance: Speed can fluctuate based on distance and interference, which may not be suitable for large file transfers.

– Compatibility Issues: Not all devices support the same wireless protocols, potentially complicating transfers.

How do Cloud-Based Solutions Work?

Cloud-based solutions enable users to store, share, and access files over the internet. Services like Google Drive, Dropbox, and OneDrive provide robust platforms for file management.

Pros:

– Accessibility: Files can be accessed from any device with internet connectivity, facilitating remote work.

– Collaboration: Multiple users can work on documents simultaneously, enhancing productivity.

Cons:

– Ongoing Costs: Subscription fees can add up, especially for businesses that require substantial storage.

– Internet Dependency: Transfers and access speed are heavily reliant on internet quality, which can hinder operations in areas with poor connectivity.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right solution for file transfer needs largely depends on the specific requirements of your business. If your operations frequently involve transferring large files securely and reliably, a USB cables supplier may be your best option. However, if mobility and remote access are priorities, considering wireless file transfer technologies or cloud-based solutions might be more beneficial. Evaluate the performance, cost implications, ease of implementation, and maintenance requirements of each alternative to make an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for usb cables supplier

What Are the Essential Technical Properties of USB Cables?

When sourcing USB cables, international B2B buyers need to understand key technical properties that determine the quality and performance of the products. Here are some critical specifications to consider:

1. Material Grade

The quality of materials used in USB cables significantly affects durability and performance. Common materials include copper for conductors and PVC or TPE for insulation. High-grade materials ensure better conductivity and resistance to wear and tear, which is crucial for long-term usage in various environments, particularly in regions like Africa and South America where conditions may be harsher.

2. Current Rating (Amperage)

USB cables are designed to handle specific current levels, typically ranging from 0.5A for USB 2.0 to 3A or more for USB 3.0 and above. Understanding the current rating is vital for B2B buyers to ensure that the cables can support the devices they intend to connect, preventing overheating and potential damage to both the cable and the device.

3. Data Transfer Speed

The data transfer speed of USB cables varies by type, with USB 2.0 offering speeds up to 480 Mbps, while USB 3.0 can reach up to 5 Gbps, and USB 3.1 even higher. For businesses in the tech sector, this specification is crucial as it affects how quickly data can be transferred, impacting operational efficiency.

4. Length and Flexibility

Cable length can affect performance, especially in applications requiring long-distance connections. Additionally, flexibility is essential for ease of use in dynamic environments. Cables that are too stiff may not be practical for mobile applications or environments with limited space, making it important for buyers to assess the intended use before purchasing.

5. Tolerance and Compliance Standards

Tolerance refers to the acceptable range of variation in cable manufacturing. Compliance with international standards (such as CE, FCC, or RoHS) ensures that the cables are safe for use in target markets. Buyers should look for suppliers that provide detailed compliance documentation to avoid legal issues and ensure product safety.

What Are Common Trade Terms Used in the USB Cable Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms related to USB cables:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that can be marketed by another company. For buyers, partnering with an OEM can provide high-quality products tailored to specific requirements, ensuring that the cables meet the desired specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is critical for buyers to understand as it can impact budgeting and inventory management. Buyers should negotiate MOQs that align with their purchasing capacity while ensuring they receive competitive pricing.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to potential suppliers requesting price quotes for specified products. For international buyers, submitting an RFQ can streamline the procurement process and help compare offers from multiple suppliers effectively.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to navigate logistics, shipping costs, and risks associated with the delivery of USB cables.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, knowing the lead time is essential for planning and ensuring that products arrive when needed to avoid disruptions in business operations.

By being well-versed in these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing USB cables, ultimately ensuring that they select products that meet their specific needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the usb cables supplier Sector

What Are the Key Trends Shaping the Global USB Cables Supplier Market?

The USB cables supplier market is experiencing significant transformations driven by technological advancements and changing consumer demands. One of the primary global drivers is the increased adoption of USB Type-C connectors, which facilitate faster data transfer and charging capabilities. This trend is especially relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where there is a growing demand for devices that support high-speed connectivity.

Emerging B2B tech trends include the integration of smart technologies into USB cables, such as built-in chipsets that optimize charging speeds and compatibility with various devices. This innovation is crucial for businesses looking to streamline their operations and improve efficiency. Additionally, the rise of e-commerce platforms has made it easier for international buyers to source USB cables directly from manufacturers, enhancing market accessibility.

Market dynamics are also influenced by regional variations in demand. For instance, in Africa and South America, the growing mobile device penetration necessitates affordable yet reliable USB cables. In contrast, European and Middle Eastern markets may prioritize high-end features and sustainability in their sourcing decisions. Understanding these nuances can empower B2B buyers to make informed procurement choices that align with their specific market needs.

How Can Sustainability and Ethical Sourcing Impact Your USB Cables Procurement Strategy?

A stock image related to usb cables supplier.

Sustainability has become a pivotal concern in the USB cables supplier sector, with an increasing focus on minimizing environmental impact. The production of USB cables often involves materials that can harm the environment, such as plastics and metals. Therefore, B2B buyers should prioritize suppliers that utilize eco-friendly materials and practices in their manufacturing processes. This shift not only helps in reducing the carbon footprint but also aligns with the global movement towards sustainable business practices.

Ethical sourcing is equally important, as it ensures that suppliers adhere to fair labor practices and responsible sourcing of raw materials. Buyers should look for certifications such as ISO 14001, which indicates that a supplier has established an effective environmental management system. Additionally, materials like bioplastics and recyclable materials are gaining traction in the industry, providing sustainable alternatives for USB cables.

By adopting a sustainability-focused procurement strategy, businesses can enhance their brand reputation, meet regulatory requirements, and cater to the growing consumer preference for environmentally friendly products. This approach not only benefits the planet but can also lead to cost savings in the long run, as efficient resource management often translates into reduced operational costs.

What is the Brief Evolution of the USB Cables Supplier Sector?

The USB cables supplier sector has evolved significantly since the introduction of USB technology in the mid-1990s. Initially, USB cables were primarily used for connecting peripheral devices like keyboards and mice to computers. Over the years, as technology advanced, the scope of USB cables expanded to accommodate a wider range of devices, including smartphones, tablets, and other consumer electronics.

The introduction of USB 2.0 in 2000 marked a significant milestone, increasing data transfer speeds and enhancing functionality. With the emergence of USB 3.0 and later USB Type-C, which supports higher speeds and reversible connectors, the market has seen a substantial shift towards more versatile and user-friendly products. This evolution has prompted suppliers to innovate continually, leading to a more competitive landscape that emphasizes quality, efficiency, and sustainability in sourcing practices.

Understanding this evolution helps B2B buyers appreciate the technological advancements that have shaped the current market and allows them to make informed decisions when sourcing USB cables that meet their specific requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of usb cables supplier

-

How do I solve compatibility issues with USB cables from suppliers?

To address compatibility issues, first, confirm the USB specifications required for your devices (e.g., USB 2.0, USB 3.0, or USB-C). When sourcing from suppliers, request samples to test compatibility with your equipment before placing large orders. It’s also advisable to check the supplier’s certifications and customer reviews regarding compatibility. If issues persist, communicate directly with the supplier for alternative options or custom solutions that meet your specific requirements. -

What is the best type of USB cable for commercial applications?

For commercial applications, USB 3.0 or higher cables are recommended due to their faster data transfer rates and improved power delivery capabilities. Depending on your specific needs, such as device compatibility and power requirements, you might consider USB Type-C cables, which offer versatility and support for various functionalities, including video output. Always discuss your needs with suppliers to ensure they can provide the right type and length of cables for your operations. -

What factors should I consider when vetting USB cable suppliers?

When vetting USB cable suppliers, consider their industry experience, certifications (such as ISO 9001), and product quality. Check their production capabilities, lead times, and the availability of customization options. Additionally, look for reviews or testimonials from previous clients to gauge reliability and customer service. Request samples to evaluate the quality firsthand before committing to larger orders. -

How can I negotiate better payment terms with USB cable suppliers?

To negotiate better payment terms, start by establishing a solid relationship with your supplier. Discuss your order volume and the potential for long-term partnership, which may encourage them to offer more favorable terms. Propose options like partial payment upfront and the balance upon delivery or after a specified period. Be transparent about your cash flow situation, as suppliers may be willing to accommodate your needs to secure a deal. -

What is the typical minimum order quantity (MOQ) for USB cables?

The MOQ for USB cables can vary significantly between suppliers, typically ranging from 100 to 1,000 units, depending on the type and customization options. When sourcing, inquire about flexibility in MOQs, especially if you are a smaller business or starting a new project. Some suppliers may offer lower MOQs for sample orders or initial trial runs, allowing you to test the market without significant upfront investment. -

How do I ensure quality assurance when sourcing USB cables internationally?

To ensure quality assurance, establish clear specifications and standards for the USB cables you require. Request samples for testing before placing bulk orders. Additionally, consider third-party inspections or audits during production to verify compliance with your quality standards. Establishing a written agreement outlining quality expectations can also help safeguard against potential issues. -

What logistics considerations should I be aware of when importing USB cables?

When importing USB cables, consider shipping methods, customs duties, and import regulations specific to your country. Choose reliable freight forwarders who are experienced in handling electronic goods. Be prepared for potential delays at customs by ensuring all paperwork, including invoices and certificates of origin, is accurate and complete. Understanding local regulations on electronic imports can also prevent costly complications. -

How can I customize USB cables to meet specific business needs?

Customizing USB cables involves selecting specific lengths, colors, connectors, and branding options. Discuss your requirements with potential suppliers to see what customization options they offer. Some suppliers may have minimum order quantities for customized products, so ensure that your order aligns with their capabilities. Providing a detailed specification sheet can help suppliers understand your needs clearly, leading to more accurate and satisfactory results.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for usb cables supplier

What Are the Key Takeaways for B2B Buyers of USB Cables?

In conclusion, the strategic sourcing of USB cables is essential for international B2B buyers to ensure reliability, quality, and cost-efficiency in their supply chains. By prioritizing suppliers who demonstrate strong compliance with international standards and possess a proven track record, companies can mitigate risks associated with product failures and delays. Additionally, fostering long-term relationships with suppliers in diverse regions such as Africa, South America, the Middle East, and Europe can enhance supply chain resilience and adaptability.

How Can Strategic Sourcing Impact Your Business Success?

Investing in strategic sourcing not only reduces procurement costs but also improves product availability and service quality. For buyers in emerging markets like Colombia and the UAE, leveraging local suppliers can lead to significant logistical advantages, including shorter lead times and reduced shipping costs.

What Should You Do Next as an International B2B Buyer?

As you navigate the complexities of sourcing USB cables, consider conducting thorough market research and engaging with suppliers who align with your business objectives. Explore opportunities for collaboration and innovation in your supply chain. By doing so, you position your business for sustainable growth and success in a competitive landscape. Embrace strategic sourcing today to unlock the full potential of your procurement strategies.