Discover Top Wiring Harness Suppliers: Your Complete Guide (2025)

Introduction: Navigating the Global Market for wiring harness supplier

In the rapidly evolving landscape of global manufacturing, sourcing a reliable wiring harness supplier can pose significant challenges for international B2B buyers. The complexity of supply chains, coupled with the growing demand for high-quality, customized solutions, necessitates a strategic approach to procurement. This guide is designed to illuminate the multifaceted world of wiring harness suppliers, providing essential insights into various types of wiring harnesses, their applications across industries, and effective supplier vetting processes.

Understanding the intricacies of pricing, quality assurance, and logistical considerations is paramount for buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Thailand and Germany. The aim is to empower these international buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Throughout this guide, readers will discover actionable strategies for identifying reputable suppliers, evaluating product specifications, and negotiating favorable terms. By navigating the complexities of the wiring harness supply chain, B2B buyers can enhance their procurement processes, mitigate risks, and ultimately drive greater value for their businesses. Whether you are looking to upgrade existing systems or develop new applications, this comprehensive resource serves as your roadmap to successful sourcing in the global market.

Understanding wiring harness supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Wiring Harnesses | Tailored designs for specific applications; unique specifications | Automotive, Aerospace, Industrial Equipment | Pros: Perfect fit for unique needs; optimized performance. Cons: Higher costs; longer lead times. |

| Standard Wiring Harnesses | Pre-designed and manufactured to meet common specifications | Consumer Electronics, Appliances | Pros: Cost-effective; quicker delivery. Cons: Limited customization; may not fit specific needs. |

| Automotive Wiring Harnesses | Designed for vehicles; includes connectors, terminals, and insulation | Automotive Manufacturing, Repair Shops | Pros: Meets industry standards; reliable performance. Cons: May require specific knowledge for installation. |

| Industrial Wiring Harnesses | Built to withstand harsh environments; often includes heavy-duty materials | Manufacturing, Heavy Equipment | Pros: Durable and reliable; designed for high performance. Cons: Can be more expensive; bulkier design. |

| Multimedia Wiring Harnesses | Specialized for audio, video, and communication systems | Home Theater Systems, Broadcasting | Pros: High-quality signal transmission; tailored for multimedia applications. Cons: May require specialized installation; higher costs. |

What Are Custom Wiring Harnesses and When Should B2B Buyers Consider Them?

Custom wiring harnesses are specifically designed to meet the unique requirements of a business’s applications. They are ideal for companies in sectors like aerospace or automotive that require a precise fit for their equipment. Buyers should consider these when off-the-shelf solutions do not meet their specifications, as they can provide optimized performance tailored to specific operational needs. However, it’s essential to account for longer lead times and potentially higher costs associated with customization.

How Do Standard Wiring Harnesses Serve B2B Buyers?

Standard wiring harnesses are mass-produced to meet common industry specifications, making them a cost-effective choice for businesses that do not require specialized solutions. These harnesses are widely used in consumer electronics and household appliances. While they offer quicker delivery and lower costs, buyers should be aware that they may not meet specific needs or performance standards, which can lead to issues in unique applications.

What Should B2B Buyers Know About Automotive Wiring Harnesses?

Automotive wiring harnesses are essential components in vehicle manufacturing and repair. They are designed to meet strict industry standards for safety and reliability. B2B buyers in the automotive sector should prioritize these harnesses for their proven performance and compatibility with various vehicle systems. However, installation may require specialized knowledge, so buyers should ensure they have the necessary expertise or resources to install them correctly.

Why Choose Industrial Wiring Harnesses for Tough Environments?

Industrial wiring harnesses are constructed from durable materials to endure harsh conditions typically found in manufacturing and heavy equipment applications. These harnesses are designed for high performance, making them suitable for environments with extreme temperatures, moisture, or physical stress. While they provide reliability and longevity, buyers should be prepared for potentially higher costs and bulkier designs that may require more space in their applications.

How Do Multimedia Wiring Harnesses Enhance Communication Systems?

Multimedia wiring harnesses are tailored for audio, video, and communication systems, ensuring high-quality signal transmission. They are vital for businesses involved in home theater installations, broadcasting, and other multimedia applications. Buyers should consider these harnesses for their specialized performance, but they may face higher costs and the need for specialized installation techniques. Understanding the specific requirements of multimedia systems is crucial for selecting the right harness.

Related Video: LS Wiring Harness Part 1 | Project Rowdy Ep013

Key Industrial Applications of wiring harness supplier

| Industry/Sector | Specific Application of Wiring Harness Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electrical Systems in Vehicles | Enhances reliability and safety in vehicle operations | Compliance with automotive standards and certifications |

| Industrial Equipment | Control Systems in Manufacturing Machinery | Increases operational efficiency and reduces downtime | Customization options and material durability |

| Aerospace | Wiring for Avionics Systems | Ensures safety and performance in critical flight systems | Lightweight materials and resistance to environmental factors |

| Renewable Energy | Solar Panel Wiring Systems | Improves energy efficiency and maximizes output | Compatibility with various solar technologies |

| Consumer Electronics | Internal Wiring in Smart Devices | Supports advanced functionalities and user experiences | Scalability and adherence to global safety standards |

How Are Wiring Harness Suppliers Used in the Automotive Industry?

In the automotive sector, wiring harness suppliers play a crucial role in integrating electrical systems within vehicles. These harnesses connect various components, such as sensors, lights, and control units, ensuring reliable operation. By sourcing high-quality wiring harnesses, automotive manufacturers can enhance vehicle safety and performance while minimizing the risk of electrical failures. International buyers must ensure that suppliers comply with regional automotive standards and certifications, which can vary significantly between markets like Europe and Africa.

What Role Do Wiring Harness Suppliers Play in Industrial Equipment?

Wiring harnesses are integral to the control systems of manufacturing machinery. They facilitate the communication between different machine components, enabling efficient operation and automation. By investing in robust wiring harnesses, businesses can significantly reduce operational downtime and improve overall productivity. Buyers from South America and the Middle East should prioritize suppliers that offer customization options to meet specific machinery requirements and ensure material durability for harsh industrial environments.

How Do Aerospace Applications Benefit from Wiring Harness Suppliers?

In the aerospace industry, wiring harnesses are vital for avionics systems, which include navigation, communication, and flight control systems. These harnesses must meet stringent safety and performance standards due to the critical nature of their applications. Sourcing lightweight and durable materials is essential to enhance fuel efficiency and ensure reliability during flight. International buyers need to consider suppliers that specialize in aerospace-grade wiring harnesses, which adhere to specific regulations and testing protocols.

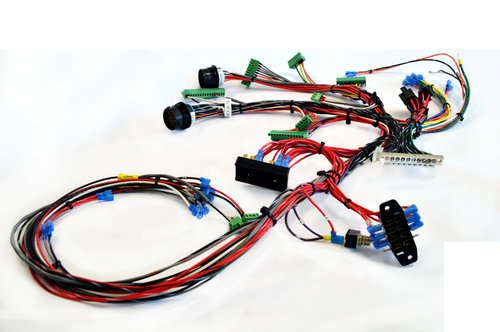

A stock image related to wiring harness supplier.

What Are the Advantages of Wiring Harness Suppliers in Renewable Energy?

Wiring harness suppliers are essential for solar panel systems, connecting photovoltaic cells to inverters and batteries. A well-designed wiring harness can significantly improve energy efficiency and maximize power output. As the renewable energy market grows, buyers must seek suppliers who offer compatibility with various solar technologies and ensure their products can withstand environmental factors such as UV exposure and moisture. This consideration is particularly important for buyers in regions with high solar potential.

How Do Wiring Harness Suppliers Enhance Consumer Electronics?

In the consumer electronics industry, wiring harnesses are crucial for the internal wiring of smart devices, facilitating communication between components. High-quality wiring harnesses support advanced functionalities, enhancing user experience and device reliability. For B2B buyers, especially in Europe, sourcing scalable wiring solutions that comply with global safety standards is paramount to ensure product quality and consumer safety. Choosing suppliers with a strong reputation in the electronics market can also provide an edge in competitive markets.

Related Video: Fully automated cable harness production in the automotive industry (EN)

3 Common User Pain Points for ‘wiring harness supplier’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Wiring Harness Supply

The Problem:

B2B buyers often face significant quality control issues when sourcing wiring harnesses. Many suppliers may promise high-quality products but fail to meet industry standards, leading to unreliable components that can result in operational failures, increased costs, and damage to reputation. This is particularly critical for buyers in sectors such as automotive, aerospace, and industrial machinery, where the performance of wiring harnesses is vital for safety and efficiency.

The Solution:

To mitigate quality control challenges, buyers should adopt a rigorous supplier evaluation process. Start by requesting detailed certifications and quality assurance processes from potential wiring harness suppliers. Look for ISO 9001 certification as a baseline, which indicates a commitment to quality management. Additionally, it’s beneficial to conduct on-site audits or request third-party inspection reports to ensure that the supplier adheres to specified standards.

A stock image related to wiring harness supplier.

Moreover, establish clear specifications for materials, tolerances, and testing procedures upfront. This can include requirements for insulation resistance, temperature ratings, and environmental resilience, which are crucial for ensuring durability. Regular communication with the supplier during the production phase can help address any quality concerns early on, preventing costly rectifications later in the supply chain.

Scenario 2: Overcoming Communication Barriers with International Suppliers

The Problem:

International B2B buyers often encounter communication barriers when dealing with wiring harness suppliers in different regions. Language differences, cultural misunderstandings, and varying business practices can lead to misinterpretations of product specifications, timelines, and quality expectations. This is particularly problematic when sourcing from suppliers in Africa, South America, or the Middle East, where local practices may differ significantly from European or North American standards.

The Solution:

To enhance communication with international suppliers, buyers should invest in building strong relationships by employing local representatives or intermediaries who understand both the buyer’s and supplier’s languages and cultures. This can facilitate smoother negotiations and ensure that critical details are not lost in translation.

Additionally, leveraging technology such as video conferencing tools can bridge the gap and enable real-time discussions, fostering a collaborative environment. Providing comprehensive documentation, including visual aids, diagrams, and specifications in both languages, can further reduce misunderstandings. Establishing a clear communication protocol, including regular updates and feedback loops, will ensure that both parties are aligned throughout the project lifecycle.

Scenario 3: Managing Lead Times and Delivery Issues in Wiring Harness Procurement

The Problem:

B2B buyers frequently struggle with lead times and delivery reliability when sourcing wiring harnesses, especially from suppliers located in different continents. Unpredictable shipping times, customs delays, and production bottlenecks can lead to project delays, impacting production schedules and operational efficiency. This is particularly crucial for industries that rely on just-in-time manufacturing processes.

The Solution:

To effectively manage lead times, buyers should first conduct a thorough analysis of the supply chain to identify potential bottlenecks. Establishing strategic partnerships with suppliers that have a proven track record of reliability and fast turnaround times is essential. Buyers should also consider diversifying their supplier base to include multiple sources for wiring harnesses, reducing reliance on a single supplier.

Implementing a vendor-managed inventory (VMI) system can further enhance delivery reliability. This allows suppliers to monitor inventory levels and manage stock replenishment proactively, ensuring that necessary components are available when needed. Additionally, buyers should set clear expectations regarding delivery timelines and incorporate penalties for late deliveries in contracts to incentivize suppliers to meet deadlines consistently. Regular performance reviews and open lines of communication will also help in addressing any delivery issues promptly, ensuring a smoother procurement process.

Strategic Material Selection Guide for wiring harness supplier

When selecting materials for wiring harnesses, international B2B buyers must consider various factors that impact performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in wiring harness applications, emphasizing their properties, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of PVC in Wiring Harnesses?

Polyvinyl Chloride (PVC) is a widely used material in wiring harnesses due to its favorable electrical insulation properties and flexibility. It can withstand temperatures ranging from -10°C to 70°C and offers good chemical resistance, making it suitable for various environments. However, PVC can become brittle over time, especially when exposed to UV light.

Pros & Cons:

– Pros: Cost-effective, excellent insulation properties, and good flexibility.

– Cons: Limited temperature range and potential degradation under UV exposure.

Impact on Application:

PVC is compatible with many automotive and industrial applications, but its limitations in extreme temperatures may affect its suitability for high-performance environments.

Considerations for International Buyers:

Buyers should ensure that the PVC used complies with local regulations, such as RoHS in Europe, which restricts hazardous substances. Understanding ASTM standards for PVC can also guide quality assurance.

How Does Polypropylene Perform in Wiring Harness Applications?

Polypropylene (PP) is another common material, known for its excellent chemical resistance and durability. It can handle temperatures up to 100°C and is resistant to many solvents, making it ideal for harsh environments.

Pros & Cons:

– Pros: High chemical resistance, lightweight, and good thermal stability.

– Cons: Higher cost compared to PVC and can be less flexible.

Impact on Application:

Polypropylene is particularly effective in automotive applications where exposure to chemicals is likely, such as in engine compartments.

Considerations for International Buyers:

Buyers should check for compliance with international standards like ISO 9001 for quality management systems, ensuring consistent quality in production.

What Are the Benefits of Using Teflon in Wiring Harnesses?

Teflon (PTFE) is renowned for its exceptional thermal stability and low friction properties. It can withstand temperatures up to 260°C and is highly resistant to chemicals and corrosion.

Pros & Cons:

– Pros: Outstanding temperature and chemical resistance, suitable for extreme conditions.

– Cons: Expensive and can be challenging to process.

Impact on Application:

Teflon is ideal for applications in aerospace and high-performance automotive sectors, where reliability in extreme conditions is paramount.

Considerations for International Buyers:

Due to its cost, buyers must evaluate the necessity of Teflon based on specific application requirements. Compliance with aerospace standards, such as AS9100, may also be relevant.

Why Is Thermoplastic Elastomer (TPE) a Good Choice for Wiring Harnesses?

Thermoplastic Elastomer (TPE) combines the properties of rubber and plastic, offering excellent flexibility and durability. It can operate within a temperature range of -40°C to 120°C and has good resistance to UV light and ozone.

Pros & Cons:

– Pros: Excellent flexibility, good weather resistance, and recyclability.

– Cons: Generally higher cost than PVC and may have lower chemical resistance.

Impact on Application:

TPE is suitable for applications requiring flexibility and durability, such as in consumer electronics and automotive interiors.

Considerations for International Buyers:

Buyers should verify that TPE materials meet relevant standards like UL 94 for flammability, especially in regions with stringent safety regulations.

Summary Table of Material Selection for Wiring Harnesses

| Material | Typical Use Case for wiring harness supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Automotive wiring, general electrical applications | Cost-effective and flexible | Limited temperature range | Low |

| Polypropylene | Automotive engine compartments, chemical exposure | High chemical resistance | Higher cost than PVC | Medium |

| Teflon | Aerospace, high-performance automotive wiring | Exceptional thermal stability | Expensive and hard to process | High |

| Thermoplastic Elastomer | Consumer electronics, automotive interiors | Excellent flexibility and durability | Higher cost, lower chemical resistance | Medium |

This guide serves as a strategic resource for international B2B buyers, enabling informed decisions when selecting materials for wiring harnesses tailored to their specific applications and compliance needs.

In-depth Look: Manufacturing Processes and Quality Assurance for wiring harness supplier

What Are the Main Stages of Manufacturing Wiring Harnesses?

Manufacturing wiring harnesses involves several critical stages that ensure the final product meets both functional and quality standards. Understanding these stages is essential for B2B buyers looking to source wiring harnesses effectively.

1. Material Preparation

The first step in the wiring harness manufacturing process is material preparation. This involves selecting high-quality materials such as copper wires, insulation, connectors, and terminals. Suppliers typically source materials that comply with international standards to ensure durability and performance. For buyers, it is crucial to inquire about the origin of these materials, as this can affect the overall quality and reliability of the wiring harness.

2. Forming

Once materials are prepared, they undergo forming processes. This stage includes cutting the wires to the required lengths and shaping them to fit specific designs. Techniques such as crimping, stripping, and bending are commonly used. Buyers should pay attention to the machinery used in this stage; advanced machinery can enhance precision and reduce defects, which is vital for high-stakes applications like automotive and aerospace.

3. Assembly

The assembly stage is where the wiring harness comes to life. Wires are connected to terminals and connectors through methods like soldering and crimping. The assembly process often utilizes automated machinery to ensure consistency and efficiency. For international buyers, particularly those from Africa and South America, it’s beneficial to understand the automation level of the supplier’s processes, as higher automation can lead to lower costs and faster turnaround times.

4. Finishing

The finishing stage involves applying protective coatings, labeling, and testing the assembled wiring harnesses. This step is crucial for ensuring that the products are ready for shipping and installation. Buyers should ask for details about the finishing processes, including any protective measures taken to enhance the longevity and reliability of the wiring harnesses in harsh environments.

How Is Quality Assurance Integrated into Wiring Harness Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of wiring harnesses, ensuring that each product meets the necessary standards and specifications. For international B2B buyers, understanding the quality assurance processes can help in selecting reliable suppliers.

Relevant International Standards for Wiring Harness Quality

Quality assurance for wiring harnesses often adheres to several international standards, such as ISO 9001, which sets out criteria for a quality management system. Compliance with this standard demonstrates a supplier’s commitment to quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications are essential indicators of product reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are vital for maintaining high standards throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Buyers should confirm that suppliers conduct thorough IQC processes.

-

In-Process Quality Control (IPQC): During the assembly process, regular inspections are carried out to catch defects early. It’s advisable for buyers to inquire about the frequency and methods of these inspections.

-

Final Quality Control (FQC): Before shipment, the final products undergo rigorous testing to ensure they meet all specifications. B2B buyers should request FQC reports as part of the purchasing process.

What Testing Methods Are Commonly Used in Wiring Harness Quality Assurance?

Testing methods play a critical role in validating the quality of wiring harnesses. Some common testing methods include:

-

Electrical Testing: Ensures that the wiring harness can handle the required voltage and current without failure.

-

Environmental Testing: Simulates various environmental conditions to assess durability, such as temperature extremes and moisture exposure.

-

Mechanical Testing: Evaluates the physical strength of the wiring harness, including tensile strength and flexibility.

For international buyers, particularly those from regions with diverse climates like Africa and the Middle East, confirming that suppliers conduct comprehensive environmental testing is crucial.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Ensuring a supplier’s quality control measures are effective is essential for international buyers. Here are several strategies to verify QC processes:

Conducting Audits

Buyers should consider conducting supplier audits to evaluate their manufacturing processes and quality control systems firsthand. This can provide insights into the supplier’s capabilities and adherence to international standards.

Requesting Quality Reports

Requesting detailed quality reports, including IQC, IPQC, and FQC documentation, can help buyers assess the supplier’s commitment to quality. These reports should outline any defects found and corrective actions taken.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial for buyers operating in regions where direct oversight may be challenging.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of international quality control can be challenging for B2B buyers. Here are some nuances to consider:

-

Cultural Differences: Understanding cultural attitudes towards quality and manufacturing practices in different regions can impact supplier relationships. Buyers from Europe may have different expectations compared to those from Africa or South America.

-

Regulatory Compliance: Each region may have specific regulations regarding wiring harnesses, such as electrical safety and environmental standards. Buyers must ensure that their suppliers are compliant with these regulations to avoid legal issues.

-

Communication: Clear communication regarding quality expectations is critical. Buyers should establish strong communication channels with suppliers to address any concerns promptly.

By comprehensively understanding the manufacturing processes and quality assurance practices of wiring harness suppliers, international B2B buyers can make informed decisions that align with their operational needs and quality standards. This knowledge will not only help in sourcing reliable products but also in fostering long-term partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wiring harness supplier’

In the competitive landscape of B2B procurement, sourcing a reliable wiring harness supplier is crucial for ensuring the quality and efficiency of your products. This checklist serves as a practical guide to help international buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the complexities of sourcing.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of successful sourcing. This step ensures that potential suppliers understand your requirements regarding materials, dimensions, and performance standards.

– Considerations:

– Voltage ratings and environmental conditions.

– Compatibility with existing systems.

Step 2: Conduct Market Research on Suppliers

Engaging in thorough market research will help you identify potential wiring harness suppliers that meet your specifications. Look for suppliers with a proven track record in your industry.

– Actions:

– Use industry databases and trade shows to find reputable suppliers.

– Gather insights from industry forums and peer recommendations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

– What to look for:

– Experience in producing wiring harnesses specific to your sector.

– Customer testimonials and case studies demonstrating reliability.

Step 4: Verify Supplier Certifications and Compliance

Ensuring that your supplier complies with industry standards and certifications is essential for quality assurance. This step reduces the risk of non-compliance in your supply chain.

– Key Certifications:

– ISO 9001 for quality management systems.

– UL certification for safety standards.

Step 5: Request Samples for Evaluation

Before making a bulk order, always request samples of the wiring harnesses. This allows you to assess the quality and craftsmanship firsthand.

– Evaluation Criteria:

– Durability and flexibility of the materials.

– Precision in manufacturing and adherence to specifications.

Step 6: Negotiate Terms and Conditions

Negotiating favorable terms is vital to establish a healthy supplier relationship. Ensure that you discuss pricing, payment terms, and delivery schedules comprehensively.

– Focus Areas:

– Volume discounts based on order size.

– Clear terms regarding lead times and penalties for delays.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership with your supplier. Establish a clear communication plan that outlines how you will interact throughout the procurement process.

– Best Practices:

– Set regular check-in meetings or updates.

– Utilize project management tools for transparency.

By following this checklist, international B2B buyers can ensure they make informed decisions when sourcing wiring harness suppliers, ultimately leading to better quality and more efficient production processes.

Comprehensive Cost and Pricing Analysis for wiring harness supplier Sourcing

What Are the Key Cost Components for Wiring Harness Suppliers?

When sourcing wiring harnesses, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials like copper for wires and various types of insulation can vary in cost depending on market fluctuations. Sustainable or specialized materials may incur additional expenses but can improve product longevity.

-

Labor: Labor costs are influenced by the region of manufacturing. Countries with lower labor costs, such as those in parts of Africa and South America, may offer competitive pricing. However, labor quality and expertise should not be overlooked as they directly affect the quality of the harnesses produced.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can help lower overhead costs, making suppliers more competitive.

-

Tooling: Custom tooling for specific harness designs can require significant upfront investment. Buyers should factor in these costs, especially when ordering custom harnesses, as they can lead to higher initial pricing.

-

Quality Control (QC): Quality assurance processes are vital in the wiring harness industry to ensure safety and reliability. Suppliers with rigorous QC standards may charge more, but this often results in fewer defects and lower long-term costs for buyers.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and chosen Incoterms. Buyers should consider both domestic and international logistics costs, including tariffs and duties, which can add to the total cost.

-

Margin: Supplier profit margins vary based on their market positioning and the level of customization required. Understanding the typical margins in the industry can aid buyers in negotiations.

How Do Price Influencers Affect Wiring Harness Costs?

Several factors can influence the final price of wiring harnesses:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specific requirements can lead to increased costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or UL) can increase the price but ensure compliance with safety standards, which is crucial for industries like automotive and aerospace.

-

Supplier Factors: The reputation, reliability, and capabilities of a supplier can also affect pricing. Established suppliers may charge a premium for their experience and quality assurance processes.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate who is responsible for shipping, insurance, and tariffs. Understanding these terms can help buyers avoid hidden costs.

What Are the Best Practices for Negotiating Wiring Harness Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential:

-

Conduct a Total Cost of Ownership (TCO) Analysis: Beyond just the purchase price, consider the long-term costs associated with maintenance, logistics, and potential downtime. A slightly higher initial price might lead to lower overall expenses.

-

Leverage Volume Discounts: If possible, consolidate orders to take advantage of volume pricing. Building a long-term relationship with a supplier can also lead to better pricing and service.

-

Be Clear About Specifications: Clearly communicating requirements can prevent costly misunderstandings and ensure that the final product meets expectations without incurring extra costs.

-

Stay Informed on Market Trends: Understanding current market trends and material costs can empower buyers during negotiations, providing leverage to secure better pricing.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Gathering multiple quotes can provide a clearer picture of the market and help in negotiating better terms.

Conclusion: Why Understanding Wiring Harness Pricing is Crucial for Buyers

Navigating the complexities of wiring harness pricing requires a comprehensive understanding of cost components and influencing factors. By leveraging this knowledge, international B2B buyers can make informed decisions, negotiate effectively, and ultimately secure the best value for their sourcing needs. Keep in mind that prices can vary significantly based on numerous factors, and due diligence is essential for achieving cost efficiency in sourcing wiring harnesses.

Alternatives Analysis: Comparing wiring harness supplier With Other Solutions

Understanding Alternatives to Wiring Harness Suppliers

When evaluating a wiring harness supplier, it is essential to consider alternative solutions that may better align with your business needs, budget, and operational goals. Various methods and technologies can achieve similar outcomes in terms of electrical connectivity and signal transmission. This analysis will provide insight into how these alternatives compare to traditional wiring harness suppliers.

Comparison Table of Wiring Harness Supplier vs. Alternatives

| Comparison Aspect | Wiring Harness Supplier | Flexible Circuit Board | Connector Solutions |

|---|---|---|---|

| Performance | High reliability and customizability | Moderate reliability, limited to specific designs | Varies widely based on type; generally reliable |

| Cost | Higher initial investment, but long-term durability | Lower initial costs but may require more frequent replacements | Cost-effective for small projects, but can add up |

| Ease of Implementation | Requires skilled labor for installation | Can be complex to design and fabricate | Generally easy to implement with standard connectors |

| Maintenance | Low maintenance, designed for durability | Moderate maintenance required due to wear | Easy to replace, but can lead to connection issues over time |

| Best Use Case | Large-scale manufacturing, automotive, aerospace | Consumer electronics, compact devices | Prototyping, custom applications with modular needs |

What Are the Benefits and Drawbacks of Flexible Circuit Boards?

Flexible circuit boards (FPCs) offer a unique alternative to traditional wiring harnesses, particularly in applications where space and weight are concerns. Their main advantage lies in their ability to bend and fit into compact spaces, making them ideal for consumer electronics and portable devices. However, the trade-off is that FPCs may not offer the same level of reliability in high-stress environments, such as automotive or industrial applications. Additionally, the design and fabrication process can be complex, requiring specialized knowledge and equipment.

How Do Connector Solutions Compare to Wiring Harness Suppliers?

Connector solutions can be a more straightforward and cost-effective alternative for specific applications. They allow for easy assembly and disassembly, making them suitable for prototyping or projects requiring modular setups. While connector solutions can be less expensive initially, they may lead to connectivity issues if not maintained properly. The variety of connectors available also means that performance can vary significantly depending on the type used, making it essential to choose wisely based on the specific requirements of the project.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution between a wiring harness supplier and its alternatives hinges on understanding your specific operational needs. Consider factors such as performance requirements, budget constraints, and the complexity of implementation. For large-scale or high-reliability applications, a wiring harness supplier may be the best choice. Conversely, if your project demands flexibility and cost-effectiveness, exploring flexible circuit boards or connector solutions could yield significant benefits. Assessing these aspects will ensure you make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for wiring harness supplier

What Are the Essential Technical Properties of Wiring Harnesses?

When sourcing wiring harnesses, understanding key technical properties is crucial for ensuring compatibility and performance in your applications. Here are several critical specifications that international B2B buyers should consider:

-

Material Grade

The choice of materials (like copper or aluminum) significantly influences conductivity and durability. Copper is preferred for its superior conductivity, while aluminum is lighter and more cost-effective. Selecting the right material grade ensures optimal performance in specific environments, which is especially important for industries like automotive and aerospace. -

Wire Gauge (AWG)

The American Wire Gauge (AWG) system indicates the wire’s diameter, impacting current capacity and flexibility. Lower gauge numbers signify thicker wires, which can carry more current but may be less flexible. Buyers must assess the wire gauge according to the intended electrical load and space constraints within the application. -

Insulation Type

The insulation material (such as PVC, Teflon, or silicone) protects the wires from environmental factors and electrical interference. Different insulation types provide varying degrees of heat resistance, chemical resistance, and flexibility. Understanding the insulation type is vital for ensuring the wiring harness can withstand specific operational conditions, such as high temperatures or exposure to chemicals. -

Tolerance Levels

Tolerance levels refer to the acceptable variations in wire length, gauge, and other dimensions during manufacturing. Tight tolerances are essential for applications requiring precise connections, while looser tolerances may suffice for less critical applications. Ensuring the supplier meets your tolerance requirements can prevent issues in assembly and functionality. -

Temperature Rating

Every wiring harness has a specified temperature range within which it operates safely. Buyers should consider the thermal environment of their applications, as exceeding this range can lead to insulation breakdown and electrical failures. -

Connector Type

The connectors used in wiring harnesses can vary widely (e.g., Molex, Delphi, or custom connectors). Selecting the right connector type is essential for ensuring compatibility with the device or system it connects to. Buyers should confirm that the connectors meet their specific application requirements, including ease of assembly and reliability.

Which Trade Terminology Is Commonly Used in Wiring Harness Supply?

Understanding industry jargon can facilitate smoother negotiations and communications with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing wiring harnesses, knowing if a supplier is an OEM can indicate the quality and compatibility of the parts with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, especially when assessing budget constraints and inventory requirements. Understanding MOQ can help buyers negotiate better terms based on their needs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Crafting a clear RFQ can streamline the procurement process, ensuring that you receive accurate quotes that meet your specifications. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial for clarifying shipping, risk, and cost responsibilities, which can vary greatly depending on the agreed terms (like FOB, CIF, etc.). -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead time is essential for planning production schedules and managing inventory effectively, especially in industries where timing is critical. -

Certification Standards

This refers to compliance with specific industry standards, such as ISO, UL, or RoHS. Certification ensures that the wiring harness meets safety, quality, and environmental standards, which is vital for international buyers to ensure compliance in their respective markets.

By familiarizing yourself with these technical properties and trade terminologies, you can make more informed decisions when selecting a wiring harness supplier, ultimately leading to better product performance and reliability in your applications.

Navigating Market Dynamics and Sourcing Trends in the wiring harness supplier Sector

What Are the Key Market Dynamics and Sourcing Trends in the Wiring Harness Supplier Sector?

The wiring harness supplier sector is experiencing significant transformation driven by technological advancements and changing market demands. Key global drivers include the rapid growth of electric vehicles (EVs), increasing automation in manufacturing, and the rise of smart technologies across various industries. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends in sourcing include digitalization and the adoption of Industry 4.0 practices, which enhance supply chain transparency and efficiency. Technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are being integrated into the production and management of wiring harnesses, enabling real-time monitoring and predictive maintenance. Furthermore, as companies seek to optimize their supply chains, many are shifting towards local sourcing to mitigate risks associated with global disruptions, such as those experienced during the COVID-19 pandemic.

In addition to technological advancements, buyers should also consider the competitive landscape. The wiring harness market is increasingly characterized by consolidation, with larger suppliers acquiring smaller firms to expand their capabilities and market share. This trend can impact pricing and availability, making it essential for buyers to establish robust relationships with suppliers who can adapt to their evolving needs.

How Important Is Sustainability and Ethical Sourcing in the Wiring Harness Supplier Sector?

Sustainability and ethical sourcing are becoming paramount in the wiring harness supplier sector. As environmental concerns gain traction globally, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. The environmental impact of wiring harness production—such as energy consumption and waste generation—requires suppliers to adopt greener manufacturing processes.

Buyers should look for suppliers that utilize eco-friendly materials and possess certifications such as ISO 14001, which indicates a commitment to effective environmental management systems. Additionally, the use of recyclable and biodegradable materials in wiring harness production can significantly reduce the environmental footprint. By opting for suppliers who prioritize sustainability, buyers not only contribute to environmental preservation but also enhance their brand reputation among consumers who value corporate social responsibility.

Moreover, ethical supply chains are critical in ensuring fair labor practices and compliance with international labor standards. B2B buyers should conduct due diligence on their suppliers to ensure they uphold ethical sourcing principles, which can ultimately lead to stronger partnerships and reduced risk of supply chain disruptions.

What Is the Evolution of the Wiring Harness Supplier Sector?

The wiring harness supplier sector has evolved significantly over the decades, driven by technological advancements and shifting market demands. Initially focused on the automotive industry, the sector has diversified into various applications, including aerospace, telecommunications, and consumer electronics. The introduction of automation and sophisticated manufacturing techniques has transformed production processes, leading to higher efficiency and lower costs.

As the demand for electric and hybrid vehicles rises, the wiring harness sector is adapting to meet the unique requirements of these technologies. Innovations such as lightweight materials and compact designs are becoming increasingly important, allowing manufacturers to create more efficient and effective wiring solutions. This evolution highlights the importance of staying abreast of industry trends and technological advancements for international B2B buyers looking to source high-quality wiring harnesses.

Frequently Asked Questions (FAQs) for B2B Buyers of wiring harness supplier

-

How do I choose the right wiring harness supplier for my business needs?

Choosing the right wiring harness supplier involves several key factors. First, assess their industry experience and specialization to ensure they can meet your specific requirements. Look for suppliers with a solid reputation for quality and reliability by checking customer reviews and case studies. Additionally, consider their production capabilities, including customization options, minimum order quantities (MOQs), and lead times. Engaging in direct communication can help clarify their understanding of your needs and their willingness to collaborate on design modifications. -

What are the most important quality assurance (QA) measures to consider when sourcing wiring harnesses?

When sourcing wiring harnesses, prioritize suppliers who implement rigorous quality assurance measures. Look for certifications such as ISO 9001, which indicate adherence to international quality standards. Inquire about their testing processes, including electrical testing, environmental testing, and compliance with industry regulations. Regular audits and inspections can further ensure that the supplier maintains consistent quality. Establishing clear quality benchmarks in your contract can also help mitigate risks associated with product failures. -

What customization options should I look for in a wiring harness supplier?

A reliable wiring harness supplier should offer a variety of customization options to meet your unique specifications. These can include wire gauge, insulation types, connector types, and lengths. Additionally, inquire if they can accommodate specific design requests, such as color coding or labeling. The ability to provide prototypes and samples is also crucial to ensure the final product aligns with your expectations before committing to a larger order. -

What are the typical minimum order quantities (MOQs) for wiring harness suppliers?

Minimum order quantities (MOQs) for wiring harnesses can vary significantly among suppliers and depend on the complexity of the harness and the materials involved. Generally, MOQs range from a few hundred to several thousand units. It’s essential to communicate your project requirements clearly to negotiate favorable terms. Some suppliers may offer lower MOQs for customized products if you are open to longer lead times or bulk purchasing agreements. -

What payment terms should I negotiate with my wiring harness supplier?

When negotiating payment terms, aim for flexibility that suits your cash flow needs. Common terms include a deposit upfront (often 30-50%) with the balance due upon delivery. Consider requesting payment options such as letter of credit or escrow services for larger orders, which can provide additional security. Always clarify the consequences of late payments and explore any discounts for early payments to optimize your financial arrangements. -

How can I effectively vet a wiring harness supplier before placing a large order?

To vet a wiring harness supplier, start by conducting thorough research on their background, including years in business, customer testimonials, and industry certifications. Request samples or prototypes to evaluate product quality firsthand. Scheduling a factory visit can also provide insight into their manufacturing processes and capabilities. Engaging with other clients or industry references can further validate their reliability and commitment to service.

-

What logistics considerations should I keep in mind when sourcing wiring harnesses internationally?

When sourcing wiring harnesses internationally, logistics play a crucial role in ensuring timely delivery. Evaluate shipping options, including air freight and sea freight, to determine the most cost-effective and reliable method. Understand the customs regulations and import duties applicable in your country to avoid unexpected delays. Collaborating with a logistics provider experienced in international shipping can help streamline the process and minimize risks associated with cross-border trade. -

How do I handle potential communication barriers with international wiring harness suppliers?

Effective communication is key when dealing with international suppliers. To overcome potential language barriers, consider employing a translator or using professional communication tools that support multiple languages. Establish clear communication protocols, including regular updates and confirmations of orders. Utilizing visual aids, such as diagrams and specifications, can also help convey your requirements accurately. Building a strong relationship through consistent communication can enhance collaboration and reduce misunderstandings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wiring harness supplier

What Are the Key Takeaways for Strategic Sourcing in Wiring Harness Procurement?

In conclusion, strategic sourcing remains a vital component for international B2B buyers looking to optimize their supply chain for wiring harnesses. By prioritizing supplier relationships, buyers can ensure reliability, quality, and cost-effectiveness. It’s crucial to assess potential suppliers not just on price, but on their ability to meet specific technical standards and provide ongoing support.

How Can International Buyers Leverage Global Markets?

As buyers from Africa, South America, the Middle East, and Europe navigate the complexities of sourcing wiring harnesses, they must remain agile and informed about market trends. Utilizing regional suppliers can mitigate risks associated with shipping delays and geopolitical instability. Collaborating with suppliers who understand local regulations and market demands can enhance competitiveness and responsiveness.

What Does the Future Hold for Wiring Harness Suppliers?

Looking ahead, the demand for wiring harnesses is projected to grow, driven by advancements in automotive technology and the rise of electric vehicles. Buyers should embrace this trend by exploring partnerships with innovative suppliers that offer cutting-edge solutions. Engaging in continuous dialogue with suppliers will not only foster collaboration but also drive product improvement and sustainability initiatives.

Now is the time for B2B buyers to take decisive action—evaluate your sourcing strategies, invest in strong supplier relationships, and position your business for future success in the dynamic wiring harness market.