Enhance Connectivity: Your Complete Cat6 Cable Supplier Guide (2025)

Introduction: Navigating the Global Market for cat6 cable supplier

Navigating the global market for a CAT6 cable supplier can be a daunting task for international B2B buyers, especially when seeking high-quality products that meet specific performance standards. With the increasing demand for high-speed internet and reliable networking solutions across diverse industries, understanding the nuances of CAT6 cables is essential. This guide serves as a comprehensive resource, addressing critical aspects such as the different types of CAT6 cables, their applications in various sectors, and strategies for vetting suppliers effectively.

By delving into the specifications and performance characteristics of CAT6 cables, buyers can make informed decisions that align with their operational needs. Whether you are in Africa, South America, the Middle East, or Europe, the insights provided will help you navigate supplier options and understand pricing structures, allowing you to optimize your procurement processes.

This guide empowers international B2B buyers by equipping them with actionable knowledge, enabling them to select suppliers that not only offer competitive pricing but also ensure quality and compliance with international standards. With the right information at your fingertips, you can confidently source CAT6 cables that enhance your network infrastructure and support your business growth.

Understanding cat6 cable supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Cat6 | Supports speeds up to 1 Gbps with a frequency of 250 MHz | Office networks, small businesses | Pros: Cost-effective, widely available. Cons: Limited future-proofing for higher speeds. |

| Shielded Cat6 (STP) | Additional shielding to reduce electromagnetic interference (EMI) | Data centers, industrial environments | Pros: Enhanced performance in high-EMI areas. Cons: Higher cost compared to unshielded variants. |

| Unshielded Cat6 (UTP) | Lacks shielding, making it lighter and more flexible | Residential setups, basic office networks | Pros: Easy installation, lower cost. Cons: More susceptible to interference. |

| Cat6a | Supports speeds up to 10 Gbps with a frequency of 500 MHz | High-performance applications, data centers | Pros: Future-proof, excellent performance. Cons: Bulkier and more expensive than standard Cat6. |

| Plenum-rated Cat6 | Designed for use in air circulation spaces, fire-resistant | Commercial buildings, HVAC systems | Pros: Safety compliant, ideal for sensitive environments. Cons: Higher cost and specific installation requirements. |

What are the characteristics of Standard Cat6 cables?

Standard Cat6 cables are designed for high-speed data transmission, supporting speeds of up to 1 Gbps over a distance of 100 meters. They operate at a frequency of 250 MHz, making them suitable for typical office environments and small businesses that require reliable network connections. When purchasing Standard Cat6 cables, buyers should consider the balance between performance and cost, as these cables are generally more affordable but may not be suitable for future upgrades to higher speeds.

How do Shielded Cat6 cables enhance performance?

Shielded Cat6 cables (STP) feature additional shielding that protects against electromagnetic interference (EMI), making them ideal for data centers and industrial environments where electronic noise is prevalent. This shielding improves the quality of the signal and reduces the chances of data loss. B2B buyers should evaluate their operating environment when considering these cables, as the investment may be justified in high-EMI areas, despite the higher cost compared to unshielded options.

In what scenarios are Unshielded Cat6 cables appropriate?

Unshielded Cat6 cables (UTP) are lightweight and flexible, making them easy to install in residential setups and basic office networks. They are cost-effective and widely available, but they are more susceptible to interference from external sources. B2B buyers should assess their network’s environment and potential interference issues before opting for UTP cables, as these may not deliver optimal performance in high-interference settings.

Why should businesses consider Cat6a cables?

Cat6a cables are an advanced version that supports speeds of up to 10 Gbps and operates at a frequency of 500 MHz. They are ideal for high-performance applications and data centers that require robust network infrastructure. While Cat6a cables are bulkier and more expensive than standard Cat6, they offer significant future-proofing. B2B buyers should consider their long-term network needs when investing in Cat6a cables, as the enhanced performance can justify the higher upfront cost.

What advantages do Plenum-rated Cat6 cables offer?

Plenum-rated Cat6 cables are specifically designed for installation in air circulation spaces, such as ceilings and walls, where fire safety is a concern. They are made from fire-resistant materials, making them compliant with building codes. These cables are ideal for commercial buildings and HVAC systems where safety is paramount. However, they come at a higher cost, and B2B buyers should weigh the safety benefits against the budgetary constraints of their projects.

Related Video: CAT6 CABLE RUN AND CAT6 WALL FISHING – HOW TO – QUICK & EASY!

Key Industrial Applications of cat6 cable supplier

| Industry/Sector | Specific Application of cat6 cable supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed internet services in urban areas | Enhanced data transfer speeds improve customer experience and service reliability. | Look for suppliers offering certified and compliant cables to ensure performance. |

| Education | Network infrastructure for universities and schools | Supports online learning platforms and digital resources, fostering improved educational outcomes. | Ensure cables meet local standards and are suitable for large-scale installations. |

| Healthcare | Data transmission in hospitals and clinics | Facilitates real-time patient monitoring and data sharing, crucial for effective healthcare delivery. | Select cables with high shielding to minimize interference in sensitive environments. |

| Manufacturing | Automation systems and IoT connectivity | Increases operational efficiency through reliable data flow between machines and control systems. | Consider suppliers who provide customization options for industrial-grade cables. |

| Retail | Point of Sale (POS) systems and inventory management | Streamlines transactions and inventory tracking, enhancing customer service and operational efficiency. | Look for durable and flexible cables that can withstand high traffic and usage. |

How is ‘cat6 cable supplier’ used in Telecommunications?

In the telecommunications sector, cat6 cables are integral for establishing high-speed internet services in urban areas. These cables support data transfer speeds of up to 1 Gbps, significantly enhancing customer experience and service reliability. International B2B buyers should prioritize sourcing from suppliers who offer certified cables that comply with regional standards, ensuring optimal performance and longevity in various environmental conditions.

What are the applications of cat6 cable suppliers in Education?

For educational institutions, cat6 cables are essential in building robust network infrastructures that support online learning platforms and digital resources. The use of these cables enables seamless connectivity, which is critical for fostering improved educational outcomes. Buyers in this sector should ensure that the cables sourced meet local compliance standards and are designed for large-scale installations, as many educational facilities require extensive wiring to accommodate numerous devices.

How does ‘cat6 cable supplier’ benefit Healthcare?

In healthcare settings, cat6 cables facilitate the transmission of vital patient data in hospitals and clinics. These cables enable real-time monitoring and swift data sharing among healthcare professionals, which is crucial for effective patient care. Buyers must select cables with high shielding capabilities to minimize interference in sensitive environments, ensuring data integrity and compliance with health regulations.

What role does cat6 cable play in Manufacturing?

In the manufacturing industry, cat6 cables are used to connect automation systems and Internet of Things (IoT) devices, enhancing operational efficiency through reliable data flow. These cables support the communication between machines and control systems, leading to streamlined processes and reduced downtime. Buyers should consider suppliers who provide customization options for industrial-grade cables that can withstand the demanding conditions often found in manufacturing environments.

Why are cat6 cables important in Retail?

In the retail sector, cat6 cables are vital for connecting Point of Sale (POS) systems and inventory management solutions. They enable quick and efficient transactions, which enhances customer service and improves operational efficiency. Retail buyers should look for durable and flexible cables that can endure high traffic and usage, ensuring that the network remains reliable and efficient throughout peak business hours.

Related Video: Comparison of Ethernet Cable CAT5, CAT6, CAT7 and CAT8 |Types of LAN Cable

3 Common User Pain Points for ‘cat6 cable supplier’ & Their Solutions

Scenario 1: Inconsistent Quality and Standards in Cat6 Cables

The Problem: Many B2B buyers encounter challenges related to inconsistent quality when sourcing Cat6 cables. Suppliers often claim compliance with standards, but variations in manufacturing processes can lead to significant differences in performance. For example, a buyer in South America might find that the cables sourced from one supplier do not meet the expected data transmission speeds, resulting in network outages and reduced productivity. This inconsistency can be particularly frustrating for IT managers who require reliable, high-speed connections for their operations.

The Solution: To mitigate these quality concerns, buyers should prioritize suppliers that provide detailed product specifications and certifications. Request samples before committing to large orders and conduct thorough testing in your specific environment. Look for suppliers who offer a warranty and have a strong reputation in the industry. Utilize third-party testing labs to verify performance claims, ensuring that the cables meet the necessary standards, such as ISO/IEC 11801. Creating a checklist of quality indicators, including cable gauge, shielding type, and bandwidth, can further streamline the selection process.

Scenario 2: Lack of Technical Support and Guidance

The Problem: International B2B buyers often struggle with a lack of technical support when integrating Cat6 cables into their existing infrastructure. For instance, a buyer in Africa may face difficulties in understanding the compatibility of Cat6 cables with older equipment or the best practices for installation. This lack of guidance can lead to improper installation, poor network performance, and wasted resources.

The Solution: It is crucial for buyers to engage with suppliers who offer comprehensive technical support. When selecting a supplier, inquire about the availability of pre-sales consultations and after-sales support. Suppliers that provide installation guides, technical documentation, and access to a dedicated support team can significantly enhance the buyer’s experience. Additionally, consider suppliers that offer training sessions or webinars on network setup and optimization. Forming partnerships with suppliers who prioritize customer education can empower your team to make informed decisions, ensuring a smooth integration of Cat6 cables into your network.

Scenario 3: High Costs and Budget Constraints

The Problem: Cost is a critical factor for B2B buyers, particularly for small to medium enterprises (SMEs) in regions like Europe and South America. Buyers often find themselves facing unexpectedly high costs for Cat6 cables, which can strain their budgets. In some cases, low-cost cables turn out to be more expensive in the long run due to poor performance and the need for frequent replacements, creating a cycle of dissatisfaction and financial strain.

The Solution: To navigate budget constraints while ensuring quality, buyers should adopt a strategic sourcing approach. Begin by conducting a thorough market analysis to understand the average pricing for Cat6 cables in your region. Consider bulk purchasing or negotiating long-term contracts with suppliers to achieve better pricing. Additionally, explore alternative suppliers, including local manufacturers, who may offer competitive prices without compromising quality. Implementing a total cost of ownership (TCO) model can also provide clarity on the long-term financial implications of your choices, helping you make informed decisions that balance initial costs with future reliability and performance.

Strategic Material Selection Guide for cat6 cable supplier

When selecting materials for Cat6 cables, international B2B buyers must consider several factors that affect performance, durability, and compliance with regional standards. Here’s a detailed analysis of common materials used in Cat6 cables, focusing on their properties, advantages, disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper in Cat6 Cables?

Copper is the most widely used material for the conductors in Cat6 cables due to its excellent electrical conductivity. The key properties of copper include:

- Electrical Conductivity: Copper has a conductivity rating of about 59.6 × 10^6 S/m, making it ideal for high-speed data transmission.

- Temperature Rating: Copper can operate effectively within a temperature range of -20°C to 60°C, suitable for various environments.

- Corrosion Resistance: While copper is prone to oxidation, it can be treated or coated to enhance its resistance to corrosion.

Pros & Cons:

– Advantages: High conductivity ensures minimal signal loss, making it suitable for high-performance applications. It is also relatively easy to work with in manufacturing processes.

– Disadvantages: Copper is more expensive than alternatives like aluminum and can be susceptible to corrosion if not properly insulated.

Impact on Application: Copper’s superior conductivity supports applications requiring high bandwidth and speed, such as data centers and enterprise networks.

How Does Aluminum Compare as a Material for Cat6 Cables?

Aluminum is another option for Cat6 cables, often used in applications where cost reduction is essential. Its properties include:

- Electrical Conductivity: Aluminum has a conductivity rating of approximately 37.7 × 10^6 S/m, which is lower than copper.

- Weight: Aluminum is significantly lighter than copper, making it easier to handle during installation.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its resistance to corrosion.

Pros & Cons:

– Advantages: Lower cost and reduced weight make aluminum an attractive option for budget-conscious projects.

– Disadvantages: The lower conductivity can lead to higher attenuation, which may not meet the performance requirements of high-speed networks.

Impact on Application: While aluminum can be suitable for less demanding environments, it may not be ideal for applications requiring high data integrity and speed.

What Role Does PVC Play in Cat6 Cable Construction?

Polyvinyl Chloride (PVC) is commonly used as insulation and jacketing material for Cat6 cables. Its properties include:

- Temperature Rating: PVC can withstand temperatures from -15°C to 70°C.

- Flame Resistance: PVC is inherently flame-retardant, making it safer in case of fire.

- Chemical Resistance: PVC is resistant to many chemicals, enhancing its durability.

Pros & Cons:

– Advantages: PVC is cost-effective and provides good insulation properties, making it suitable for general-purpose applications.

– Disadvantages: It can emit toxic fumes when burned, raising safety concerns in specific environments.

Impact on Application: PVC is widely used in indoor installations but may not be suitable for outdoor applications due to UV degradation.

How Does LSZH Material Benefit Cat6 Cable Applications?

Low Smoke Zero Halogen (LSZH) materials are increasingly popular for cable insulation, especially in environments where fire safety is paramount. Key properties include:

- Smoke Emission: LSZH materials emit minimal smoke and no halogen when burned.

- Temperature Rating: Similar to PVC, LSZH can operate effectively within a wide temperature range.

- Durability: LSZH is resistant to abrasion and impacts, enhancing cable longevity.

Pros & Cons:

– Advantages: The safety features of LSZH make it ideal for enclosed spaces like offices and public buildings.

– Disadvantages: LSZH materials can be more expensive than traditional PVC, impacting overall project costs.

Impact on Application: LSZH is increasingly preferred in regions with strict fire safety regulations, making it an essential consideration for buyers in Europe and other safety-conscious markets.

Summary Table of Material Properties

| Material | Typical Use Case for cat6 cable supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance data centers | Excellent conductivity | Higher cost, prone to corrosion | High |

| Aluminum | Budget-sensitive installations | Lightweight, cost-effective | Lower conductivity, higher attenuation | Medium |

| PVC | General indoor applications | Cost-effective, good insulation | Toxic fumes when burned | Low |

| LSZH | Enclosed spaces, public buildings | Low smoke emission, safer | Higher cost compared to PVC | High |

In conclusion, the choice of materials for Cat6 cables significantly impacts performance, safety, and compliance with international standards. Buyers should carefully evaluate their specific needs and regional regulations to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for cat6 cable supplier

What Are the Key Stages in the Manufacturing Process of CAT6 Cables?

The manufacturing process for CAT6 cables involves several critical stages that ensure the final product meets the required performance standards. Understanding these stages is essential for B2B buyers to assess the quality and reliability of potential suppliers.

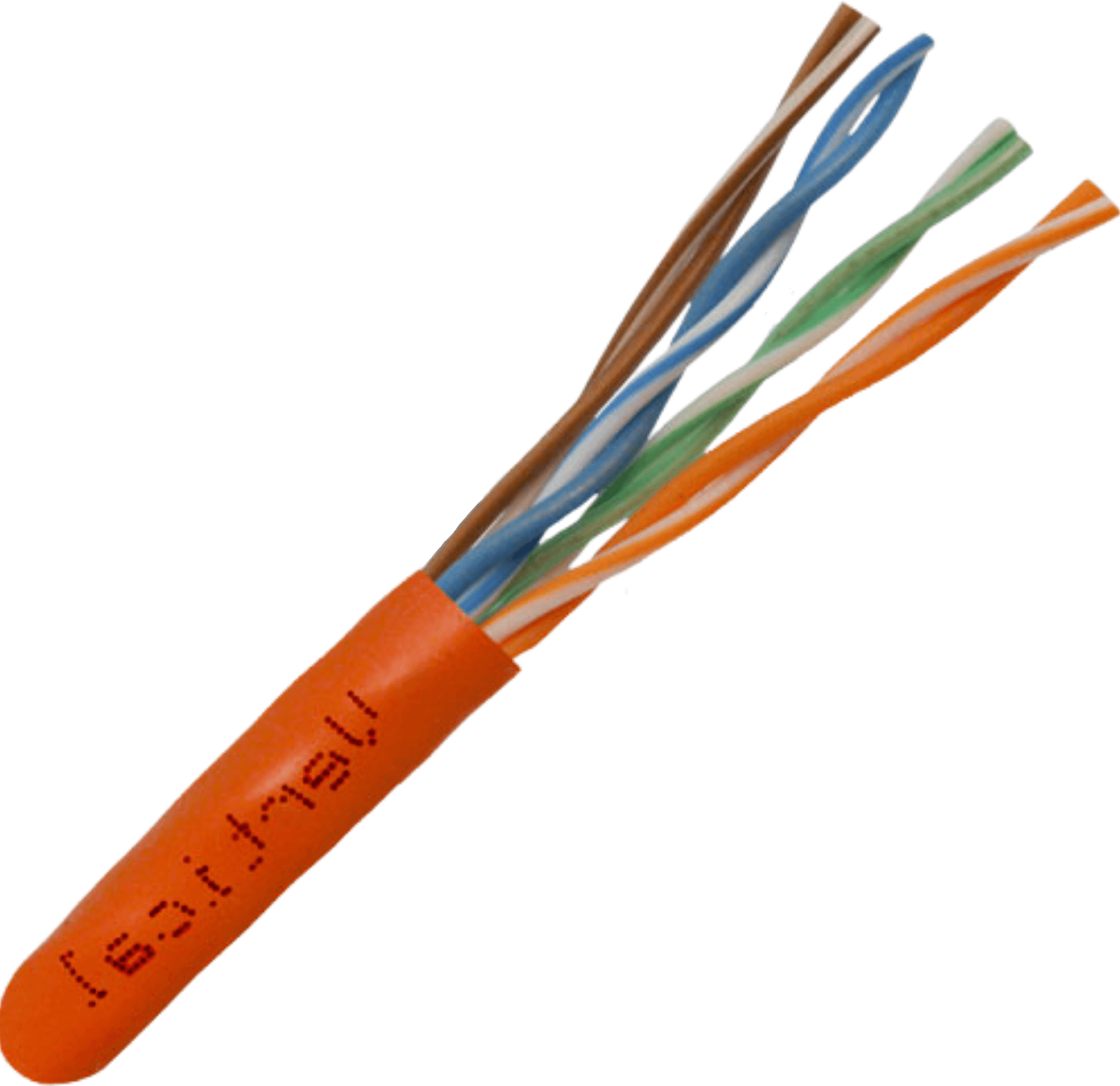

A stock image related to cat6 cable supplier.

1. Material Preparation

A stock image related to cat6 cable supplier.

The first stage in the manufacturing of CAT6 cables is material preparation. This involves sourcing high-quality raw materials, primarily copper for the conductors, insulation materials, and protective sheathing. Suppliers often opt for oxygen-free copper (OFC) due to its superior conductivity and lower resistance.

In addition to copper, the insulation materials must comply with international safety standards, such as low smoke zero halogen (LSZH) compounds that minimize toxic fumes in case of fire. B2B buyers should inquire about the specific types of materials used and request certifications to ensure compliance with safety regulations.

2. Forming

Once the materials are prepared, the forming process begins. This stage includes drawing the copper into fine wires and applying insulation. The conductors are typically twisted into pairs to reduce electromagnetic interference (EMI) and crosstalk.

For CAT6 cables, it is vital that the twisting of pairs is consistent and meets the industry standards. Buyers should look for suppliers that utilize automated machinery to ensure precision during this phase, as any deviation can impact the cable’s performance.

3. Assembly

During the assembly stage, the twisted pairs are grouped and encased in an outer sheath. The assembly process may also include the addition of a separator to maintain the integrity of the twisting and further reduce crosstalk.

Moreover, connectors like RJ45 are attached to the ends of the cables. It’s crucial that the assembly process is performed in a controlled environment to avoid contamination and damage. B2B buyers can request information on the assembly techniques and quality checks performed during this stage.

4. Finishing

The final stage in the manufacturing process is finishing. This involves testing the cables for various electrical parameters, such as bandwidth, attenuation, and return loss. Finishing also includes labeling and packaging the cables for shipment.

Buyers should ensure that the suppliers have robust testing protocols in place and utilize advanced testing equipment to guarantee that the cables meet or exceed the required specifications.

How Do Quality Assurance Processes Ensure Reliability in CAT6 Cables?

Quality assurance (QA) is a critical aspect of CAT6 cable manufacturing, ensuring that the final products meet international standards and customer expectations. Understanding the QA processes can help international B2B buyers make informed purchasing decisions.

Relevant International Standards for CAT6 Cable Quality

Several international standards govern the quality of CAT6 cables. The ISO 9001 certification is pivotal, as it indicates that a supplier has implemented a quality management system that meets customer and regulatory requirements. Additionally, CAT6 cables should comply with standards from organizations like the Telecommunications Industry Association (TIA) and the Institute of Electrical and Electronics Engineers (IEEE).

For European buyers, compliance with CE marking indicates adherence to health, safety, and environmental protection standards. B2B buyers should always verify these certifications before engaging with suppliers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically conducted at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint examines raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor the production stages. This includes verifying the twisting of pairs, insulation thickness, and the assembly of connectors.

-

Final Quality Control (FQC): At this stage, the finished cables undergo rigorous testing to ensure they meet performance specifications. This includes electrical tests for bandwidth, attenuation, and crosstalk, as well as physical inspections for defects.

Buyers should inquire about the specific QC measures employed by their suppliers and request access to quality reports and test results.

What Testing Methods Are Commonly Used for CAT6 Cables?

Various testing methods are utilized to evaluate the performance and reliability of CAT6 cables. Understanding these methods helps B2B buyers assess the quality assurance practices of potential suppliers.

-

Fluke Testing: This method employs a Fluke tester to measure cable performance parameters such as length, resistance, and crosstalk. Fluke testing is considered the industry standard for cable certification.

-

Ethernet Testing: Conducted to ensure the cables can handle the specified data rates, this test simulates actual network conditions.

-

Environmental Testing: This involves exposing cables to extreme conditions (e.g., temperature fluctuations, humidity) to assess their durability and performance over time.

B2B buyers should request detailed testing reports from suppliers, including the specific methods used and the results obtained.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the reliability of CAT6 cable suppliers, international buyers should take proactive steps to verify the quality control measures in place.

1. Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Buyers should establish a schedule for audits, focusing on key areas such as material sourcing, production techniques, and testing protocols.

2. Review Quality Assurance Reports

Buyers should request comprehensive quality assurance reports that detail the outcomes of testing and inspections throughout the manufacturing process. These reports can offer valuable insights into the consistency and reliability of the supplier’s products.

3. Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can evaluate materials, manufacturing practices, and finished products to ensure compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control when sourcing CAT6 cables.

-

Understanding Local Regulations: Different regions may have varying regulatory requirements for electrical products. Buyers should familiarize themselves with local standards to ensure compliance.

-

Cultural Considerations: When dealing with suppliers from different cultures, communication can sometimes be challenging. Establishing clear expectations regarding quality standards and delivery timelines is crucial.

-

Supply Chain Reliability: Given the global nature of the supply chain, buyers should assess the reliability of their suppliers in terms of logistics and delivery times, which can affect project timelines.

By understanding the manufacturing processes and quality assurance practices of CAT6 cable suppliers, B2B buyers can make informed decisions that align with their business needs and ensure the procurement of high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cat6 cable supplier’

The following checklist provides a structured approach for international B2B buyers aiming to procure Cat6 cables from reliable suppliers. This guide will help streamline the sourcing process, ensuring that buyers make informed decisions aligned with their technical and business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before reaching out to suppliers. Determine the required cable type (e.g., unshielded twisted pair vs. shielded twisted pair), length, and performance standards (e.g., minimum bandwidth of 250 MHz). This clarity helps to avoid misunderstandings later and ensures that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential Cat6 cable suppliers. Look for manufacturers with a solid reputation in the industry and those who specialize in telecommunications equipment. Utilize online directories, trade shows, and industry publications to gather a list of candidates.

- Key Considerations:

- Supplier experience and history in the market.

- Reviews and ratings from previous customers.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, it’s essential to check for relevant certifications. Certifications such as ISO 9001 for quality management systems and RoHS compliance for environmental standards indicate a supplier’s commitment to quality and safety.

- Why It Matters:

- Certifications ensure the product meets international standards, reducing the risk of purchasing subpar materials.

Step 4: Request Sample Products

Always request samples of the Cat6 cables to evaluate their quality firsthand. Testing samples can help identify potential issues related to performance, durability, and compatibility with your existing systems.

- What to Test:

- Transmission speed and data loss.

- Physical integrity (e.g., insulation quality, connector fit).

Step 5: Evaluate Pricing and Payment Terms

Compare pricing structures among shortlisted suppliers to ensure competitive rates. Look beyond the initial cost; consider total cost of ownership, including shipping, taxes, and potential import duties.

- Payment Terms:

- Inquire about payment options such as letters of credit or payment on delivery, which can offer additional security.

Step 6: Assess Customer Support and Warranty

Evaluate the level of customer support offered by the supplier, including response times, technical assistance, and after-sales service. A robust warranty policy is also a critical factor, as it provides assurance regarding product reliability and supplier accountability.

- What to Look For:

- Duration and coverage of the warranty.

- Availability of technical support for troubleshooting.

Step 7: Check References and Case Studies

Lastly, ask for references from other businesses that have procured Cat6 cables from the supplier. Case studies can provide insights into the supplier’s reliability and service quality, particularly in contexts similar to your own operations.

- Why References Matter:

- They offer real-world evidence of the supplier’s capabilities and customer satisfaction levels.

By following this checklist, international B2B buyers can effectively navigate the sourcing process for Cat6 cables, ensuring they partner with suppliers that meet their technical requirements and business standards.

Comprehensive Cost and Pricing Analysis for cat6 cable supplier Sourcing

What Are the Key Cost Components in Sourcing Cat6 Cables?

When sourcing Cat6 cables, understanding the cost structure is crucial for B2B buyers. The primary components influencing the cost include:

-

Materials: The primary material for Cat6 cables is copper, with variations in quality affecting price. The use of oxygen-free copper improves conductivity and reduces signal loss, which can increase costs. Additionally, the quality of insulation and shielding materials will impact overall pricing.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and testing the cables. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to countries with lower labor costs, like those in Africa and South America.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and administrative costs. Efficient manufacturing processes can help minimize these costs, making it essential to evaluate potential suppliers’ operational efficiencies.

-

Tooling: Initial costs for molds, dies, and other manufacturing tools can be substantial. Custom tooling for specialized cable types or configurations can further increase costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the cables meet international standards, such as ISO or IEC certifications. While this may add to upfront costs, it is crucial for long-term reliability and performance.

-

Logistics: Shipping costs can vary significantly based on the distance between the supplier and the buyer, the mode of transport, and the quantity ordered. International buyers should consider these factors when calculating total costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition and demand. Understanding typical margins in specific regions can help buyers negotiate better.

How Do Price Influencers Affect Cat6 Cable Sourcing?

Several factors can influence the pricing of Cat6 cables:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract significant discounts. Buyers should negotiate MOQs to align with their inventory needs while optimizing cost-efficiency.

-

Specifications and Customization: Custom cables or specialized specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Higher quality standards and certifications generally correlate with higher prices. Buyers should balance their quality needs against budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can affect pricing. Established suppliers with proven track records may charge a premium but offer more reliability.

-

Incoterms: The terms of delivery can significantly impact costs. For example, “FOB” (Free on Board) pricing may include shipping to the port, while “CIF” (Cost, Insurance, and Freight) includes shipping and insurance. Understanding these terms is essential for accurate cost assessment.

What Negotiation Tips Can International Buyers Use for Cost Efficiency?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following strategies to enhance their purchasing efficiency:

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes installation, maintenance, and operational costs. This approach helps in making informed decisions based on long-term value rather than short-term savings.

-

Leverage Competitive Bids: Engage multiple suppliers to foster competition. This can lead to more favorable pricing and terms.

-

Build Relationships: Establishing long-term partnerships with suppliers can lead to better pricing, more favorable terms, and improved service over time.

-

Stay Informed: Keep abreast of market trends, material costs, and technology advancements. This knowledge enables better negotiation and purchasing strategies.

-

Be Cautious with Pricing Nuances: Be aware that prices can fluctuate based on global economic conditions, raw material costs, and currency exchange rates, particularly for international transactions.

Conclusion

While sourcing Cat6 cables, it is essential to understand the comprehensive cost structure and pricing dynamics. By analyzing cost components, recognizing price influencers, and employing effective negotiation strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember to request indicative prices and be prepared for variations based on market conditions.

Alternatives Analysis: Comparing cat6 cable supplier With Other Solutions

When considering networking solutions, it is essential to evaluate the various options available to meet specific business needs. In the realm of high-speed data transmission, Cat6 cables are a popular choice, but other alternatives may also be viable depending on the context. This analysis will compare Cat6 cable suppliers with two alternative solutions: Fiber Optic Cables and Cat5e Cables.

| Comparison Aspect | Cat6 Cable Supplier | Fiber Optic Cables | Cat5e Cables |

|---|---|---|---|

| Performance | Up to 1 Gbps, supports up to 10 Gbps (CAT6A) | Up to 100 Gbps | Up to 1 Gbps |

| Cost | Moderate, typically higher than Cat5e | Higher initial investment | Lower initial cost |

| Ease of Implementation | Relatively easy with standard connectors | Requires specialized installation | Easy installation, widely available |

| Maintenance | Low maintenance, durable | Low maintenance, but fragile | Low maintenance |

| Best Use Case | Office networks, data centers | Long-distance communication, high-speed data networks | Small to medium networks |

What Are the Advantages and Disadvantages of Fiber Optic Cables?

Fiber optic cables are known for their superior performance, offering data transmission speeds that can reach up to 100 Gbps over long distances. They are less susceptible to electromagnetic interference and can transmit signals over greater distances without degradation. However, their installation can be complex and often requires specialized skills, leading to higher upfront costs. Additionally, fiber optic cables can be more fragile than traditional copper cables, necessitating careful handling during installation and maintenance.

How Do Cat5e Cables Compare to Cat6?

Cat5e cables are a cost-effective alternative to Cat6 cables, providing data transmission speeds of up to 1 Gbps. They are widely used in small to medium-sized networks and are easier to install due to their compatibility with standard RJ45 connectors. However, they do not support the same bandwidth and speed as Cat6 cables, which may become a limitation for businesses planning to expand their network capabilities in the future. While Cat5e is suitable for basic networking needs, it may not be adequate for high-performance applications that require faster speeds and improved reliability.

Conclusion: How Can B2B Buyers Choose the Right Networking Solution?

In deciding between Cat6 cables, fiber optic cables, and Cat5e cables, B2B buyers should consider their specific networking requirements, budget constraints, and long-term scalability. For businesses needing high-speed and reliable connections with future-proof capabilities, Cat6 or fiber optic cables would be the best choice despite the higher costs. Conversely, for smaller operations or those with limited data transmission needs, Cat5e cables may suffice. Ultimately, the selection should align with the organization’s current needs while also considering potential growth and technological advancements.

Essential Technical Properties and Trade Terminology for cat6 cable supplier

What Are the Key Technical Properties of Cat6 Cables?

When sourcing Cat6 cables, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade: Cat6 cables typically use stranded or solid copper conductors. Solid copper is preferable for permanent installations, while stranded copper is better for flexible applications. The quality of copper affects conductivity and signal strength, making it a vital consideration for B2B buyers.

-

Transmission Speed: Cat6 cables support data rates of up to 1 Gbps (Gigabit Ethernet) at a maximum distance of 100 meters. Higher-grade variants like Cat6a can handle speeds up to 10 Gbps for distances up to 55 meters. Understanding these specifications helps buyers choose the right cable for their network demands.

-

Frequency: The operational frequency for Cat6 cables is 250 MHz, which allows for high data throughput. This is important for businesses with extensive data transfer needs, as higher frequencies can accommodate more simultaneous data streams.

-

Cable Structure: Cat6 cables feature a twisted pair design, which enhances performance by reducing electromagnetic interference (EMI). The inclusion of a cross separator within the cable helps maintain the integrity of each pair, ensuring optimal performance. Buyers should assess the cable structure to ensure reliability in their specific environments.

-

Shielding: Cat6 cables can be unshielded (UTP) or shielded (STP). Shielded cables offer better protection against interference, making them suitable for environments with high EMI. This choice is essential for international buyers who may encounter different regional interference challenges.

-

Length and Tolerance: Standard lengths for Cat6 cables vary, but maintaining the tolerance within specified limits ensures that the cable performs optimally. Exceeding the maximum length can lead to signal degradation, which is critical for maintaining a high-quality network.

What Are Common Trade Terminologies Used by Cat6 Cable Suppliers?

Familiarizing yourself with industry jargon can enhance communication and negotiation with suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce components or products that are then marketed by another company. When sourcing Cat6 cables, identifying OEMs can help ensure quality and reliability, as they often adhere to strict manufacturing standards.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for businesses looking to optimize their supply chain.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request quotes from suppliers for specific products. Utilizing RFQs can help international buyers secure competitive pricing for Cat6 cables while ensuring they meet technical specifications.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms (such as FOB, CIF, and DDP) is critical for understanding shipping costs, insurance, and delivery responsibilities, especially for buyers from diverse regions.

-

Lead Time: This refers to the time it takes from placing an order to receiving the product. Knowing the lead time helps businesses plan their procurement and installation schedules effectively.

-

Warranty: A warranty provides assurance regarding the quality and performance of the cables. Understanding the warranty terms can help buyers gauge the long-term reliability of their investments.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing Cat6 cables, ensuring they meet their specific network requirements while also optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the cat6 cable supplier Sector

What Are the Current Market Dynamics and Key Trends for Cat6 Cable Suppliers?

The cat6 cable supplier market is experiencing significant growth, driven by the increasing demand for high-speed internet and data transfer capabilities across various sectors. Key global drivers include the expansion of cloud computing, the rise of IoT devices, and the growing need for reliable network infrastructure in emerging markets such as Africa and South America. Businesses in these regions are investing heavily in upgrading their telecommunications systems to support digital transformation initiatives, making cat6 cables an essential component.

Emerging trends include a shift towards high-performance cabling solutions, such as Cat6a and Cat7 cables, which offer enhanced data transmission speeds and reduced interference. International B2B buyers are increasingly looking for suppliers that provide not only quality products but also innovative solutions that can meet specific project requirements. This demand for customization has led to the emergence of flexible manufacturing processes and just-in-time delivery models, allowing suppliers to cater to diverse client needs more effectively.

Moreover, the trend toward smart buildings and smart cities is influencing sourcing decisions, as businesses seek cabling solutions that support advanced networking capabilities. Buyers from Europe and the Middle East are particularly focused on integrating sustainable practices into their sourcing strategies, looking for suppliers who can demonstrate commitment to quality and environmental standards.

How Important Is Sustainability and Ethical Sourcing in the Cat6 Cable Supplier Sector?

Sustainability and ethical sourcing are becoming increasingly important in the cat6 cable supplier sector, driven by growing awareness of environmental issues and corporate responsibility among B2B buyers. The production of cat6 cables often involves materials that can have significant environmental impacts, such as copper and plastics. Therefore, suppliers are under pressure to adopt sustainable practices throughout their supply chains.

Buyers are actively seeking suppliers who utilize eco-friendly materials, such as low-smoke, zero-halogen (LSZH) cabling, which minimizes toxic emissions during fires. Certifications like RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management) are becoming essential credentials for suppliers aiming to attract environmentally conscious buyers.

Additionally, ethical sourcing practices ensure that materials are procured responsibly, without exploitative labor practices, thus enhancing the supplier’s reputation and fostering trust among international clients. Buyers from regions like Europe are leading the charge in demanding transparency in supply chains, making it imperative for suppliers to disclose sourcing practices and material origins.

What Is the Brief Evolution of Cat6 Cable Technology in the B2B Context?

The evolution of cat6 cable technology reflects the increasing demands for higher bandwidth and faster data transmission rates. Introduced in the early 2000s, cat6 cables were developed to support 1 Gbps speeds over distances of up to 100 meters, making them a significant upgrade over their predecessor, cat5e cables. As businesses began to rely more heavily on internet connectivity for daily operations, the need for more robust cabling solutions became evident.

The introduction of cat6a (augmented) cables further enhanced performance, supporting 10 Gbps speeds while maintaining the same distance limitations. This evolution was crucial for data centers and enterprises that required fast and reliable network infrastructure to support cloud services and virtual environments. Today, cat6 cables are widely recognized as a standard for modern networking, particularly in sectors that demand high performance, including finance, healthcare, and telecommunications.

As the market continues to evolve, international B2B buyers should remain vigilant about advancements in cabling technology and the implications for their network infrastructure. Understanding these trends will empower buyers to make informed sourcing decisions that align with their business needs and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of cat6 cable supplier

-

How do I choose the right Cat6 cable supplier for my business needs?

Selecting the right Cat6 cable supplier involves evaluating their product quality, reputation, and service offerings. Look for suppliers who provide detailed specifications and certifications for their cables, ensuring compliance with international standards. Additionally, consider their experience in the market, customer reviews, and the range of products they offer, including customization options. Establishing clear communication with potential suppliers can also help assess their reliability and responsiveness to inquiries. -

What specifications should I look for in a high-quality Cat6 cable?

When sourcing Cat6 cables, key specifications to consider include the maximum data transmission speed (up to 1 Gbps), the frequency rating (at least 250 MHz), and the type of shielding (unshielded twisted pair or shielded twisted pair). It’s also important to check the cable’s construction quality, including the gauge of the copper wire (usually 23 AWG) and the insulation material. Ensure that the supplier provides clear documentation on these specifications to confirm product quality. -

What are the typical minimum order quantities (MOQ) for Cat6 cables from suppliers?

Minimum order quantities for Cat6 cables can vary widely among suppliers, often ranging from 100 to 1,000 units. Some suppliers may offer flexibility for smaller orders, especially for new customers or bulk purchase agreements. It’s advisable to discuss your specific needs with suppliers, as they may accommodate your requirements based on your business size and potential for future orders. -

How can I verify the credibility of a Cat6 cable supplier?

Verifying a supplier’s credibility involves several steps. Start by checking their business licenses, certifications, and industry affiliations. Request references from previous clients and seek testimonials regarding their product quality and service reliability. Additionally, consider conducting a factory visit or arranging a third-party audit if feasible. Online platforms and trade shows can also provide insights into their reputation within the industry. -

What payment terms are standard when sourcing Cat6 cables internationally?

Standard payment terms for international transactions typically include options like advance payment, letter of credit, or payment upon delivery. It’s important to clarify these terms upfront with your chosen supplier to avoid misunderstandings. Some suppliers may require a deposit before production, while others may offer flexible payment plans based on the order size and relationship length. Ensure that you understand the implications of currency exchange rates and transaction fees. -

How do I ensure quality assurance for Cat6 cables before accepting delivery?

To ensure quality assurance, request samples of the Cat6 cables before placing a full order. Conduct tests to verify performance metrics such as speed, frequency, and shielding effectiveness. Additionally, establish a quality control agreement with the supplier, specifying the testing methods and acceptable standards. Upon delivery, inspect the cables for physical defects and verify that they meet the agreed-upon specifications before acceptance. -

What logistics considerations should I keep in mind when importing Cat6 cables?

When importing Cat6 cables, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder with experience in electronic goods to navigate international shipping efficiently. Be aware of potential tariffs and taxes that may apply upon arrival in your country. It’s also wise to have a clear understanding of the delivery timeline to align with your project schedules. -

Can I customize Cat6 cables to meet specific requirements?

Yes, many suppliers offer customization options for Cat6 cables, including length, color, and connector types. Customization can be particularly beneficial for businesses with unique installation needs or branding requirements. Discuss your specifications with the supplier and inquire about any additional costs or lead times associated with custom orders. Ensure that the customized cables still adhere to the necessary performance standards to maintain quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cat6 cable supplier

Why is Strategic Sourcing Important for Cat6 Cable Suppliers?

In the competitive landscape of Cat6 cable procurement, strategic sourcing emerges as a critical approach for international B2B buyers. By leveraging comprehensive supplier evaluations, companies can ensure they secure cables that meet stringent performance standards while also optimizing costs. This proactive strategy not only fosters stronger supplier relationships but also enhances overall supply chain resilience.

What Are the Key Takeaways for International Buyers?

As businesses in Africa, South America, the Middle East, and Europe (including countries like Australia and France) pursue high-quality Cat6 cables, it is vital to focus on suppliers that offer transparent specifications and adhere to international standards. Understanding the specifications—such as transmission speeds, shielding types, and environmental compliance—will empower buyers to make informed decisions. Additionally, engaging with suppliers who demonstrate innovation in product development and customer service can lead to long-term partnerships that drive mutual growth.

How Can Buyers Prepare for the Future?

Looking ahead, international B2B buyers should remain vigilant about emerging technologies and market trends that could influence the performance and pricing of Cat6 cables. By staying informed and adaptable, buyers can better navigate the evolving landscape of telecommunications infrastructure. Take action today by exploring reputable suppliers that align with your strategic sourcing goals and setting the stage for a robust and efficient network infrastructure.