Enhance Efficiency: The Complete Crane Custom Guide (2025)

Introduction: Navigating the Global Market for crane custom

In the ever-evolving landscape of global commerce, sourcing customized cranes presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With varying regulatory standards, diverse supplier capabilities, and fluctuating market demands, finding the right crane custom solution can be daunting. This comprehensive guide aims to demystify the complexities of sourcing tailored crane solutions, equipping buyers with the knowledge to make informed decisions that align with their operational needs and project specifications.

Throughout this guide, we will explore various types of cranes, their applications across different industries, and the critical factors to consider when selecting a supplier. We will delve into the intricacies of supplier vetting processes, helping you identify reliable partners who can deliver high-quality, customized solutions. Additionally, we will provide insights into cost considerations, enabling you to budget effectively while ensuring value for your investment.

Empowered with this information, B2B buyers from diverse regions, including key markets like Spain and Italy, will be better positioned to navigate the global market for crane custom solutions. By understanding the nuances of this sector, you can streamline your procurement process, mitigate risks, and ultimately enhance your operational efficiency, ensuring your projects are completed on time and within budget.

Understanding crane custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mobile Cranes | Versatile, easily transportable, and maneuverable | Construction, maintenance, and logistics | Pros: High mobility, quick setup. Cons: Limited lifting capacity compared to fixed cranes. |

| Tower Cranes | Fixed base, high lifting capacity, and height | Large construction projects | Pros: Excellent for vertical construction. Cons: Requires significant space and setup time. |

| Crawler Cranes | Track-mounted, stable on uneven ground | Heavy lifting in rough terrain | Pros: High stability and lifting power. Cons: Less mobile than wheeled cranes. |

| Overhead Cranes | Fixed installation, moves along tracks | Manufacturing and warehousing | Pros: Efficient for repetitive lifting tasks. Cons: Limited to specific areas of operation. |

| Gantry Cranes | Bridge-like structure, movable on wheels or tracks | Shipyards, rail yards, and warehouses | Pros: Cost-effective for large areas. Cons: Requires significant space for operation. |

What are the Key Characteristics of Mobile Cranes?

Mobile cranes are designed for versatility and ease of transport. They come equipped with a rotating superstructure mounted on a wheeled chassis, allowing them to navigate various terrains and job sites efficiently. This makes them ideal for construction, maintenance, and logistics operations where quick setup and mobility are critical. When purchasing a mobile crane, buyers should consider factors such as lifting capacity, boom length, and the terrain of the job site to ensure optimal performance.

How Do Tower Cranes Excel in Large Construction Projects?

Tower cranes are characterized by their fixed base and ability to reach significant heights, making them indispensable for large-scale construction projects. They provide a high lifting capacity and can handle heavy materials efficiently, making them suitable for skyscrapers and large buildings. Buyers should evaluate the crane’s height, load capacity, and the surrounding environment, as these factors will influence the crane’s operational effectiveness and safety.

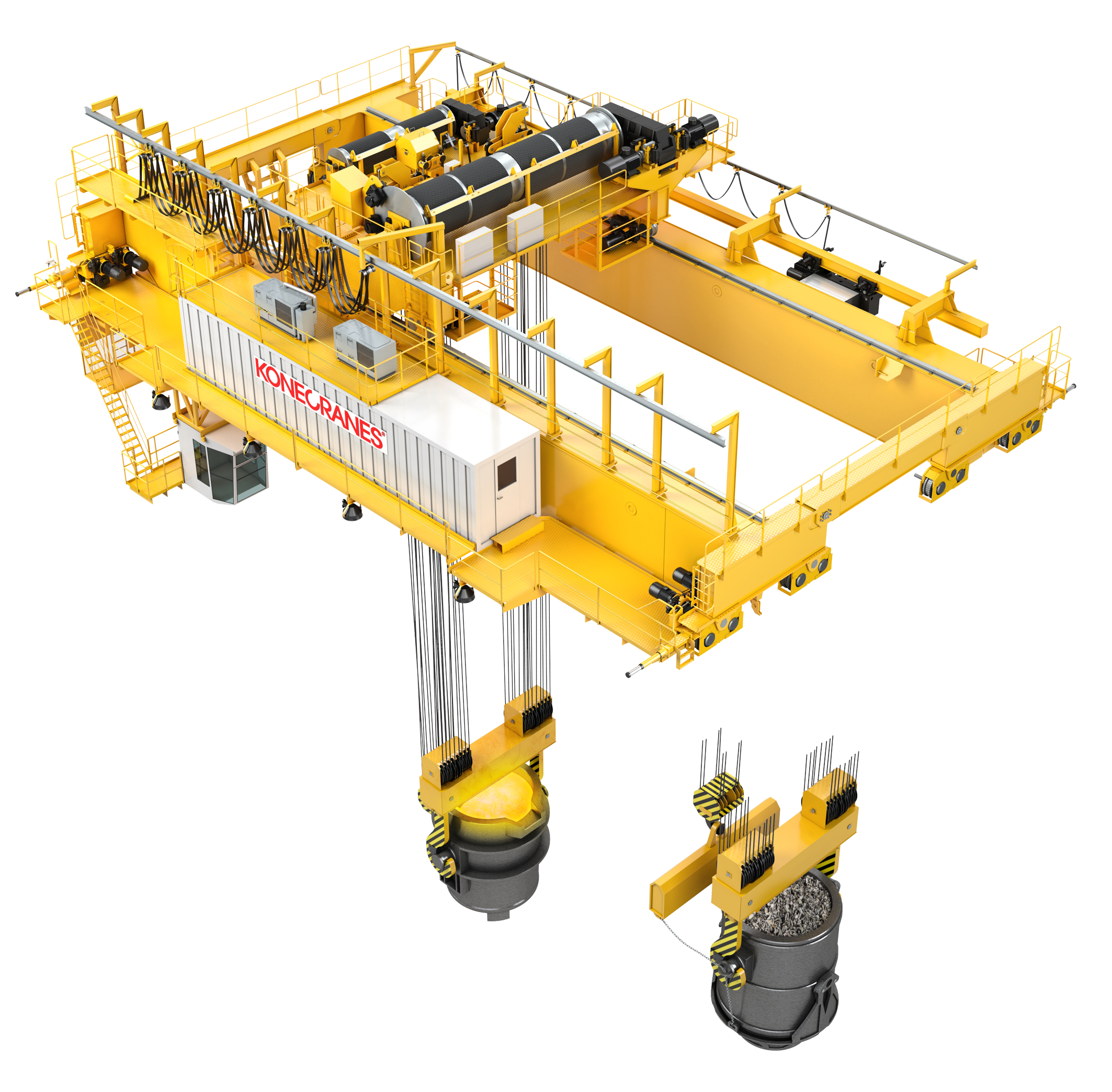

A stock image related to crane custom.

What Makes Crawler Cranes Suitable for Rough Terrain?

Crawler cranes are equipped with tracks that provide stability and mobility, making them ideal for lifting heavy loads on uneven ground. Their robust design allows them to perform well in challenging environments, such as construction sites in remote areas. When considering a crawler crane, B2B buyers should assess the crane’s lifting capacity, track width, and the specific conditions of the job site to ensure it meets their operational needs.

Why Choose Overhead Cranes for Manufacturing Operations?

Overhead cranes are fixed installations that move along tracks, providing efficient material handling in manufacturing and warehousing settings. They excel in environments where repetitive lifting tasks are common, offering high efficiency and reduced labor costs. Buyers should consider the span of the overhead system, lifting height, and load capacity when selecting an overhead crane to ensure it aligns with their production requirements.

What Are the Advantages of Gantry Cranes in Large Areas?

Gantry cranes feature a bridge-like structure and are often movable on wheels or tracks, making them ideal for operations in large areas such as shipyards and rail yards. They offer a cost-effective solution for lifting and transporting materials across expansive spaces. Buyers should evaluate the crane’s design, load capacity, and the area of operation to ensure it is suitable for their specific needs and can optimize workflow efficiency.

Related Video: Telescoping Gantry Crane, Custom Outdoor Rail Travelling Gantry Crane with Telescoping Cantilever

Key Industrial Applications of crane custom

| Industry/Sector | Specific Application of crane custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy lifting for structural components | Increases efficiency in project timelines, reduces labor costs | Compliance with local regulations, load capacity requirements |

| Manufacturing | Assembly line automation | Streamlines production processes, enhances safety | Customization for specific machinery, integration capabilities |

| Mining | Material handling and transport | Improves productivity, reduces downtime | Durability in harsh environments, maintenance support |

| Oil & Gas | Equipment installation and maintenance | Ensures safe operations, minimizes risk | Adherence to industry standards, specialized lifting capabilities |

| Logistics and Warehousing | Inventory management and storage | Optimizes space utilization, accelerates order fulfillment | Flexibility for various load types, scalability for future growth |

How is Crane Custom Used in the Construction Industry?

In the construction sector, crane custom solutions are vital for heavy lifting operations, particularly when handling large structural components such as steel beams and concrete panels. By utilizing customized cranes, companies can significantly enhance efficiency, leading to quicker project completion and reduced labor costs. International buyers should prioritize compliance with local regulations and assess load capacity requirements to ensure the crane meets the specific demands of their projects.

What are the Applications of Crane Custom in Manufacturing?

Within manufacturing, crane custom solutions are instrumental in automating assembly lines. These cranes facilitate the movement of heavy materials and components, which streamlines production processes and enhances workplace safety. For B2B buyers, it is essential to consider the customization capabilities of cranes to ensure seamless integration with existing machinery, as well as the specific requirements of their production lines.

How Does Crane Custom Benefit the Mining Sector?

In the mining industry, crane custom solutions play a crucial role in material handling and transport. They are designed to operate in rugged environments, improving productivity and reducing downtime associated with equipment failures. Buyers from regions like Africa and South America should focus on sourcing cranes that exhibit high durability and maintenance support, as these factors are critical to sustaining operations in challenging conditions.

Why is Crane Custom Important in the Oil & Gas Sector?

The oil and gas industry relies heavily on crane custom solutions for the installation and maintenance of heavy equipment. These cranes ensure safe operations in potentially hazardous environments, minimizing risks associated with lifting operations. International buyers should ensure that their sourced cranes adhere to industry standards and possess specialized lifting capabilities tailored to the specific needs of oil and gas projects.

How Can Crane Custom Enhance Logistics and Warehousing Operations?

In logistics and warehousing, crane custom solutions are essential for effective inventory management and storage optimization. By facilitating the efficient movement of goods, these cranes accelerate order fulfillment processes and maximize space utilization. For B2B buyers, flexibility to handle various load types and the ability to scale operations for future growth are key considerations when sourcing crane custom solutions.

Related Video: Vuforia Augmented Reality | Transforming How Industrial Workforces Communicate, Learn and Work

3 Common User Pain Points for ‘crane custom’ & Their Solutions

Scenario 1: Misaligned Specifications Leading to Project Delays

The Problem: One of the most significant challenges faced by B2B buyers in the crane custom sector is the misalignment between project specifications and the final crane design. Buyers often underestimate the complexity of their needs or fail to communicate specific requirements effectively. This can lead to delays in project timelines, increased costs, and frustration among stakeholders, particularly when the crane does not meet the operational demands of the project.

The Solution: To avoid misalignment, it is critical for buyers to engage in thorough pre-project planning. Start by conducting a comprehensive needs assessment that includes site conditions, load capacities, and operational workflows. Collaborate closely with crane manufacturers during the design phase, ensuring that all specifications are documented and agreed upon. Utilize digital tools like 3D modeling or virtual simulations to visualize the crane in your specific environment before finalizing the design. This proactive approach minimizes the risk of revisions and keeps your project on track.

Scenario 2: Unforeseen Regulatory Compliance Issues

The Problem: International buyers often grapple with navigating the complex web of local and international regulations governing crane operations. Different regions—especially in Africa and the Middle East—have varying safety standards and compliance requirements. Failure to adhere to these regulations can result in legal penalties, project shutdowns, or damage to reputation, leading to significant financial losses.

The Solution: Buyers should conduct thorough research on local regulations before initiating a crane custom project. Collaborate with local experts who understand the regulatory landscape and can provide insights into compliance requirements. Additionally, consider partnering with a reputable crane manufacturer that has experience in your target region. They can assist in ensuring that the design and operation of the crane align with local laws. Regular training and updates on regulatory changes should be part of the operational protocol to mitigate risks associated with compliance.

Scenario 3: Difficulty in Maintenance and After-Sales Support

The Problem: After a crane custom is delivered, many buyers encounter challenges related to maintenance and after-sales support. In regions like South America and Europe, where service networks may be limited, buyers can struggle to find qualified technicians or access spare parts, leading to prolonged downtime and reduced operational efficiency.

The Solution: To ensure reliable maintenance and support, buyers should prioritize selecting manufacturers with a robust after-sales service network. When sourcing cranes, inquire about the availability of local service centers and the manufacturer’s commitment to providing ongoing support. Establish a service agreement that outlines response times, maintenance schedules, and the availability of spare parts. Furthermore, consider investing in training for your in-house team, enabling them to handle routine maintenance tasks and minor repairs. This not only reduces reliance on external support but also enhances operational resilience.

Strategic Material Selection Guide for crane custom

When selecting materials for custom cranes, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Here, we analyze four common materials used in crane construction: steel, aluminum, composite materials, and high-strength alloys. Each material has distinct characteristics that can significantly impact the crane’s functionality and suitability for specific applications.

What Are the Key Properties of Steel in Crane Customization?

Steel is the most widely used material in crane manufacturing due to its excellent strength-to-weight ratio and versatility. It typically offers high tensile strength, making it suitable for heavy lifting applications. Steel also has good temperature and pressure ratings, allowing it to perform well in various environments. However, it is susceptible to corrosion, which can be a concern in humid or saline conditions.

Pros & Cons: The primary advantage of steel is its durability and cost-effectiveness, especially in large quantities. However, its weight can be a disadvantage in applications where mobility and ease of installation are critical. Additionally, the need for protective coatings to prevent corrosion can increase manufacturing complexity and costs.

Impact on Application: Steel cranes are highly compatible with heavy-duty lifting tasks, particularly in construction and industrial settings. Buyers should consider the specific environmental conditions where the crane will operate, as this will influence the type of protective measures required.

How Does Aluminum Compare as a Material for Custom Cranes?

Aluminum is another popular choice for crane construction, particularly in applications where weight reduction is crucial. It has a lower density than steel and offers good corrosion resistance, making it suitable for environments prone to moisture or salt exposure. However, aluminum has a lower tensile strength compared to steel, which may limit its use in extremely heavy lifting scenarios.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which facilitates easier transportation and installation. However, its higher cost compared to steel and lower strength can be significant drawbacks for certain applications, particularly in heavy industrial settings.

Impact on Application: Aluminum cranes are ideal for applications in the maritime industry or regions with high humidity, such as coastal areas in Africa or South America. Buyers should ensure that the crane’s design compensates for aluminum’s lower strength to maintain safety and performance.

What Role Do Composite Materials Play in Crane Customization?

Composite materials, often used in specialized applications, provide unique benefits such as high strength-to-weight ratios and excellent corrosion resistance. They are particularly advantageous in environments that demand lightweight structures without compromising durability. However, composites can be more expensive and complex to manufacture than traditional materials.

Pros & Cons: The primary advantage of composites is their resistance to corrosion and environmental degradation, making them suitable for long-term use in harsh conditions. The downside is the higher initial cost and the need for specialized manufacturing techniques, which may not be readily available in all regions.

Impact on Application: Composite cranes are particularly useful in sectors like aerospace or specialized construction projects where weight and performance are critical. International buyers should assess the availability of composite manufacturing capabilities in their region.

Why Are High-Strength Alloys Important for Custom Cranes?

High-strength alloys, such as those made from titanium or specialized steel blends, offer superior performance in extreme conditions. They provide excellent tensile strength and resistance to deformation under load, making them suitable for heavy-duty applications. However, the cost of high-strength alloys can be significantly higher than traditional materials.

Pros & Cons: The main advantage of high-strength alloys is their ability to perform under extreme conditions, providing safety and reliability. The primary disadvantage is the high cost and potential challenges in sourcing these materials, particularly in developing regions.

Impact on Application: These materials are ideal for cranes used in heavy industrial operations, such as mining or oil extraction, where durability and strength are paramount. Buyers should ensure that they comply with local standards and regulations regarding the use of high-strength materials.

Summary Table of Material Selection for Crane Customization

| Material | Typical Use Case for crane custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy lifting in construction | Durable and cost-effective | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications in maritime | Lightweight and corrosion-resistant | Higher cost and lower strength | High |

| Composite | Specialized construction projects | Excellent corrosion resistance | High cost and complex manufacturing | High |

| High-Strength Alloys | Heavy industrial operations | Superior performance under extreme conditions | High cost and sourcing challenges | High |

In conclusion, selecting the right material for custom cranes involves evaluating the specific application requirements, environmental conditions, and regional manufacturing capabilities. By understanding the properties, advantages, and limitations of each material, international B2B buyers can make informed decisions that align with their operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for crane custom

What Are the Key Stages in the Manufacturing Process of Custom Cranes?

The manufacturing process for custom cranes involves several critical stages that ensure each unit meets the specific requirements of the buyer. The main stages include:

1. Material Preparation

The first step in crane manufacturing is selecting and preparing the materials. High-strength steel is often the primary material due to its durability and load-bearing capacity. Suppliers typically conduct metallurgical testing to verify material properties. B2B buyers should ensure that suppliers provide material certifications and traceability documents, which confirm compliance with international standards.

2. Forming Techniques

Forming is where the raw materials are shaped into components. Common techniques include:

- Welding: Essential for joining parts and ensuring structural integrity. Automated welding processes, such as robotic welding, enhance precision and repeatability.

- Bending: Used for creating frames and supports. Advanced CNC bending machines are employed for accuracy.

- Casting: Some components may be cast to achieve complex shapes that are difficult to fabricate. Ensure that the supplier uses quality-controlled foundries.

Understanding these techniques helps buyers assess the capabilities of a manufacturer and their ability to meet specific design requirements.

3. Assembly Procedures

After forming, the crane components undergo assembly. This stage is crucial as it impacts the final product’s functionality. Key considerations include:

- Jigs and Fixtures: These are used to maintain accuracy during assembly. Buyers should inquire about the types of jigs used to ensure they meet international standards.

- Quality Control Checkpoints: During assembly, manufacturers should perform in-process inspections (IPQC) to catch defects early. B2B buyers can ask for records of these inspections.

4. Finishing Processes

The final stage involves finishing processes such as painting, galvanizing, or powder coating to protect against corrosion and wear. The finishing process not only enhances aesthetics but also prolongs the crane’s lifespan. Buyers should seek suppliers that adhere to environmental regulations, particularly regarding paint application and waste management.

How Is Quality Assurance Implemented in Crane Manufacturing?

Quality assurance (QA) is critical in crane manufacturing, ensuring that each unit is safe, reliable, and compliant with standards. Understanding the QA processes can help buyers choose the right supplier.

What Are the International Standards for Crane Manufacturing?

Several international standards govern the manufacturing of cranes. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Particularly relevant for European buyers, this certification indicates compliance with EU safety, health, and environmental protection legislation.

- API Standards: For cranes used in oil and gas, compliance with American Petroleum Institute (API) standards is crucial.

Buyers should verify that the supplier holds valid certifications and regularly undergoes audits to maintain these standards.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. The key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival for compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues in real-time.

- Final Quality Control (FQC): The completed crane undergoes thorough inspection and testing before delivery. This includes load testing and functional checks.

B2B buyers should request detailed reports from these checkpoints to ensure the manufacturing process meets their quality expectations.

Which Testing Methods Are Commonly Used in Crane Quality Assurance?

Various testing methods are employed to ensure cranes meet safety and performance standards. Common testing methods include:

- Load Testing: Essential for verifying that the crane can handle the specified loads. This is often done under controlled conditions to simulate operational stress.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to identify internal defects without damaging the components.

- Functional Testing: Assessing the crane’s operational capabilities, including movement, speed, and control systems.

Buyers should ensure that suppliers provide documentation of testing results, including methodologies and compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is essential for mitigating risks associated with crane procurement. Here are actionable steps B2B buyers can take:

- Conduct Supplier Audits: On-site audits allow buyers to assess the manufacturing environment, equipment, and adherence to quality standards firsthand.

- Request Quality Assurance Documentation: Suppliers should provide records of their QA processes, including inspection reports, testing results, and certifications.

- Engage Third-Party Inspection Services: Utilizing independent inspectors can provide an unbiased assessment of the supplier’s capabilities and quality adherence.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Key nuances include:

- Understanding Regional Standards: Different regions may have varying standards and certifications. Buyers should familiarize themselves with local regulations and ensure that suppliers comply.

- Cultural and Language Barriers: Effective communication is vital. Buyers may consider engaging local representatives or consultants who understand the regional market and can facilitate communication with suppliers.

- Logistical Considerations: Shipping and transportation can impact quality. Buyers should discuss packaging and handling procedures with suppliers to prevent damage during transit.

By considering these factors, international B2B buyers can navigate the complexities of crane procurement and ensure they receive high-quality, reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crane custom’

Introduction

Sourcing custom cranes for your business can be a complex process, especially for international buyers navigating diverse markets like Africa, South America, the Middle East, and Europe. This practical sourcing guide provides a structured checklist to help you streamline the procurement process, ensuring you make informed decisions that align with your operational needs and budget.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is fundamental to sourcing the right custom crane. This includes determining load capacity, lift height, and operational environment (indoor or outdoor). Clearly defined specifications will help you communicate your requirements to potential suppliers effectively and ensure that the cranes meet your operational needs.

- Consider factors like power source (electric, hydraulic) and mobility (fixed, mobile) based on your project requirements.

Step 2: Research Potential Suppliers

Before you begin contacting suppliers, conduct thorough research to identify potential manufacturers or distributors. Utilize online platforms, industry trade shows, and local directories to create a shortlist of candidates. This step is crucial in finding reputable suppliers who have a track record in delivering quality cranes.

- Look for suppliers with experience in your specific industry or region to ensure they understand your unique challenges.

Step 3: Evaluate Supplier Credentials

When you’ve identified potential suppliers, it’s essential to evaluate their credentials. Request documentation such as ISO certifications, safety compliance records, and quality assurance processes. This step ensures that the suppliers adhere to international standards and regulations, which is critical for safety and reliability.

- Verify their reputation by checking online reviews, testimonials, and case studies from previous clients.

Step 4: Request Detailed Quotations

Once you’ve narrowed down your options, request detailed quotations from your shortlisted suppliers. A comprehensive quote should outline pricing, lead times, payment terms, and warranty conditions. This transparency allows you to make informed comparisons between different suppliers.

- Ensure that the quotation includes potential additional costs such as shipping, installation, and maintenance.

Step 5: Conduct Site Visits or Virtual Tours

If possible, arrange site visits to the suppliers’ facilities to inspect their production capabilities and quality control processes. If travel is impractical, request virtual tours or video demonstrations. This step provides a deeper insight into the supplier’s operations and helps build trust in their ability to deliver.

- Pay attention to the technology and equipment used in manufacturing to gauge the quality of the cranes being produced.

Step 6: Negotiate Terms and Conditions

Negotiating favorable terms is crucial for maximizing value in your procurement process. Discuss not only pricing but also delivery schedules, payment terms, and after-sales support. A good negotiation can lead to better pricing and service terms that can save you money in the long run.

- Ensure that you understand the implications of the terms you agree upon, especially regarding warranties and service agreements.

Step 7: Finalize Your Purchase Agreement

Once you are satisfied with the terms and conditions, finalize your purchase agreement. Ensure that all specifications, delivery timelines, and payment terms are clearly documented. This contract serves as a safeguard for both parties and minimizes misunderstandings.

- Include clauses for contingencies, such as delays or defects, to protect your investment.

By following this checklist, international B2B buyers can navigate the complexities of sourcing custom cranes with confidence, ensuring that they secure the best solutions for their operational needs.

Comprehensive Cost and Pricing Analysis for crane custom Sourcing

What Are the Key Cost Components in Crane Custom Sourcing?

When evaluating the costs associated with crane custom sourcing, it’s essential to break down the cost structure into specific components. The primary elements include:

-

Materials: The cost of raw materials varies significantly based on the type of crane and its specifications. High-quality steel, advanced electronics, and specialized components can drive up material costs.

-

Labor: Labor costs encompass both direct and indirect expenses. Skilled labor is crucial for custom fabrication, and regions with higher labor costs may impact overall pricing.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Manufacturing overhead can differ based on the supplier’s location and operational efficiency.

-

Tooling: Custom cranes often require specialized tools for production. The initial investment in tooling can be substantial but is typically amortized over large production runs.

-

Quality Control (QC): Rigorous QC processes ensure that the cranes meet safety and performance standards. The costs associated with QC can vary based on certification requirements and the complexity of the crane design.

-

Logistics: Transportation costs are a significant factor, particularly for international buyers. Freight, insurance, and customs duties must be factored into the total cost.

-

Margin: Suppliers will add a profit margin, which can vary widely based on market conditions, competition, and the supplier’s pricing strategy.

How Do Price Influencers Affect Crane Custom Costs?

Several factors influence the pricing of custom cranes, and understanding these can help buyers negotiate better deals:

-

Volume/MOQ: Purchasing in larger volumes often leads to reduced unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQ) to optimize pricing.

-

Specifications/Customization: Highly specialized cranes with unique features will generally cost more. Buyers should clearly define their requirements to avoid unnecessary customization costs.

-

Materials: The choice of materials directly affects pricing. Opting for standard materials over specialized ones can lead to cost savings.

-

Quality/Certifications: Compliance with international standards and certifications can increase costs. However, investing in quality can reduce long-term risks and maintenance costs.

-

Supplier Factors: The supplier’s reputation, experience, and location can all influence pricing. Established suppliers may charge a premium for their reliability and service.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is crucial for determining responsibilities for shipping, insurance, and customs duties. Choosing the right terms can lead to significant cost savings.

What Are the Best Buyer Tips for Cost-Efficient Crane Custom Sourcing?

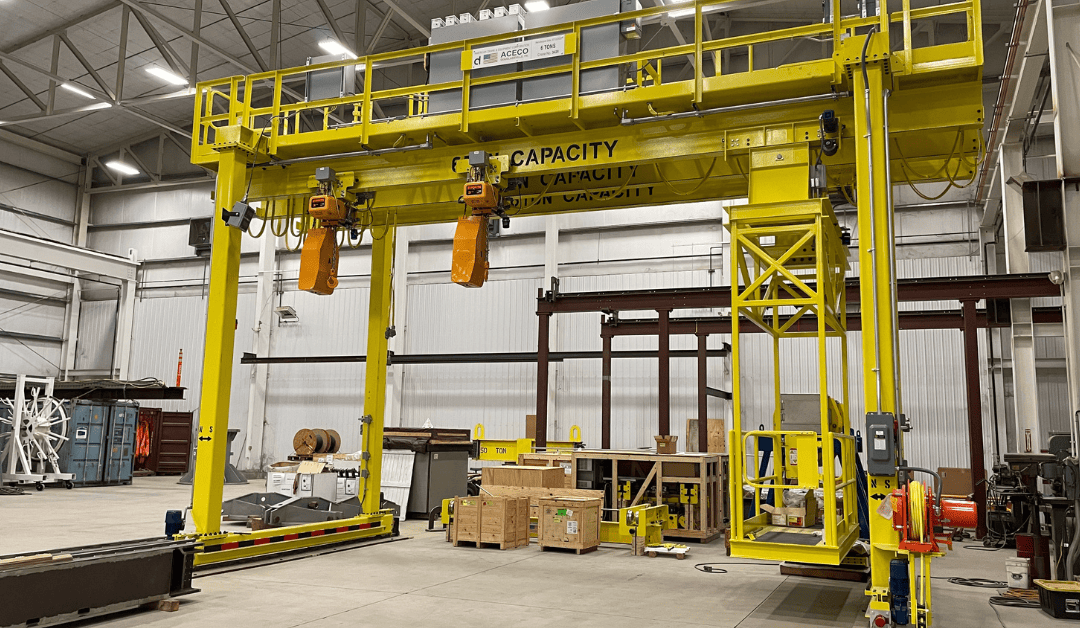

A stock image related to crane custom.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are several actionable strategies to enhance cost-efficiency in crane custom sourcing:

-

Negotiate Effectively: Leverage competition among suppliers to negotiate better terms. Being prepared with data on market pricing can strengthen your position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, operational, and disposal costs. A lower upfront price may lead to higher long-term expenses.

-

Understand Pricing Nuances: Familiarize yourself with regional market dynamics. For example, European suppliers might have different pricing structures compared to those in Africa or South America due to labor and material costs.

-

Explore Alternative Suppliers: Diversifying your supplier base can lead to competitive pricing. However, ensure that alternative suppliers meet the necessary quality and certification standards.

-

Plan for Logistics: Factor in logistics from the outset. Working with suppliers who have experience in international shipping can mitigate unforeseen costs.

Disclaimer on Indicative Prices

It’s important to note that the prices discussed in this analysis are indicative and can vary based on numerous factors, including market fluctuations, geopolitical influences, and specific buyer-supplier agreements. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to make informed purchasing decisions.

Alternatives Analysis: Comparing crane custom With Other Solutions

Exploring Alternatives to Crane Custom: What Are Your Options?

When considering crane custom solutions, it’s essential to evaluate other available options that may fulfill similar operational needs. This analysis will compare crane custom against two viable alternatives: modular cranes and automated guided vehicles (AGVs). Each solution has its own strengths and weaknesses, and understanding these can help international B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Crane Custom | Modular Cranes | Automated Guided Vehicles (AGVs) |

|---|---|---|---|

| Performance | High lifting capacity, tailored design for specific tasks | Good flexibility and scalability | Efficient for repetitive tasks, limited lifting capacity |

| Cost | Higher initial investment; long-term ROI through efficiency | Moderate cost; initial setup can vary | Lower upfront costs; operational costs can add up |

| Ease of Implementation | Requires site-specific planning and engineering | Quick setup; adaptable to various environments | Easy to integrate with existing systems; minimal training required |

| Maintenance | Regular maintenance required; specialized knowledge needed | Generally low maintenance; parts are widely available | Minimal maintenance; requires software updates |

| Best Use Case | Heavy lifting in construction, shipbuilding, and large warehouses | Dynamic environments needing quick adjustments | Warehousing, manufacturing, and assembly lines for small loads |

What Are the Pros and Cons of Modular Cranes?

Modular cranes offer a flexible solution, particularly in settings where space and load requirements may change frequently. They can be assembled and disassembled quickly, making them ideal for temporary projects or facilities that require reconfiguration. However, their performance may not match that of crane custom solutions in terms of lifting capacity, especially for heavy-duty applications. Additionally, while modular cranes are often more cost-effective upfront, they may not provide the same long-term ROI as crane custom due to potential limitations in heavy lifting scenarios.

How Do Automated Guided Vehicles (AGVs) Compare?

Automated Guided Vehicles (AGVs) are increasingly popular in environments like warehouses and manufacturing facilities. They excel in moving smaller loads efficiently and can operate autonomously, reducing labor costs. The integration of AGVs is relatively straightforward, requiring minimal training for staff. However, their lifting capacity is often less than that of crane custom solutions, making them unsuitable for heavy-duty applications. Moreover, while AGVs have lower initial costs, their operational expenses can accumulate, especially in high-traffic environments.

How to Choose the Right Solution for Your Needs?

When selecting between crane custom and its alternatives, B2B buyers should consider several factors. First, assess the specific lifting and operational needs of your project. If heavy lifting is a primary requirement, crane custom may be the best choice despite its higher upfront cost. Conversely, if flexibility and lower initial investment are priorities, modular cranes or AGVs might be more suitable. Furthermore, consider the available space for installation, the ease of maintenance, and the long-term operational costs associated with each solution. Ultimately, the right choice will depend on aligning the solution with your operational goals and financial strategy.

Essential Technical Properties and Trade Terminology for crane custom

What Are the Key Technical Properties of Custom Cranes?

When sourcing custom cranes, understanding their technical properties is crucial for ensuring optimal performance and safety. Here are some essential specifications to consider:

1. Material Grade

The material grade refers to the specific quality of materials used in the crane’s construction, such as steel or aluminum. Higher grades indicate superior strength and durability, which are essential for heavy lifting applications. For B2B buyers, selecting the right material grade impacts the crane’s lifespan, maintenance costs, and overall safety standards.

2. Load Capacity

Load capacity is the maximum weight a crane can safely lift and move. This specification is critical for buyers to ensure that the crane meets their operational needs without compromising safety. Understanding load capacity helps businesses avoid overloading, which can lead to accidents and costly downtime.

3. Tolerance

Tolerance defines the permissible limit of variation in a physical dimension. In crane manufacturing, tight tolerances are necessary for ensuring precise movement and stability. For B2B purchasers, knowing the required tolerances can influence the crane’s performance and the reliability of its operations, especially in sectors like construction and manufacturing.

4. Reach and Height

Reach refers to the horizontal distance the crane can extend, while height indicates how high it can lift loads. Both parameters are essential for determining the crane’s suitability for specific jobs. Buyers must evaluate their operational environment to select cranes with appropriate reach and height capabilities to maximize efficiency.

5. Stability Rating

The stability rating indicates how well a crane can maintain its position while lifting loads. This property is particularly important for mobile cranes that operate on various terrains. For international buyers, a high stability rating reduces the risk of tipping and enhances safety, making it a vital consideration when selecting equipment.

What Are Common Trade Terms Used in Crane Customization?

Understanding industry jargon can significantly improve communication with suppliers and streamline the procurement process. Here are some common terms associated with crane customization:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the crane industry, choosing OEM parts ensures compatibility and adherence to quality standards, which is essential for maintaining operational efficiency and safety.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory planning. Understanding this term can also provide leverage when negotiating prices, especially for bulk orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers, issuing an RFQ can streamline the procurement process by providing clear requirements and enabling comparisons across different vendors. This practice is particularly useful in international trade, where pricing can vary significantly.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, insurance obligations, and risk management throughout the supply chain. This knowledge is crucial for international transactions, particularly when dealing with suppliers from diverse regions like Africa, South America, the Middle East, and Europe.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead time is essential for B2B buyers to plan their operations effectively. This metric can vary significantly based on the complexity of the crane customization, so it’s important to discuss this upfront with suppliers to avoid delays in project timelines.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing custom cranes, ultimately leading to enhanced operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the crane custom Sector

What Are the Current Market Dynamics and Sourcing Trends in the Crane Custom Sector?

The crane custom sector is currently experiencing significant transformations driven by technological advancements and shifting market demands. Global drivers such as urbanization, infrastructure development, and the rise of renewable energy projects are fueling the need for specialized cranes tailored to specific applications. B2B buyers from Africa, South America, the Middle East, and Europe should be aware that these regions are witnessing increased investment in construction and logistics, creating a favorable environment for sourcing customized cranes.

Emerging technologies, particularly in automation and IoT (Internet of Things), are reshaping the landscape. Smart cranes equipped with sensors and data analytics capabilities are becoming more prevalent, allowing for enhanced operational efficiency and safety. B2B buyers should consider suppliers that offer innovative solutions that integrate with existing machinery to optimize performance and reduce downtime.

Additionally, sourcing trends are leaning towards localized manufacturing to mitigate supply chain disruptions exacerbated by geopolitical tensions and the COVID-19 pandemic. As a result, international buyers are encouraged to establish relationships with regional manufacturers who can provide customized solutions while ensuring a faster turnaround time. It’s also essential to evaluate the suppliers’ capabilities in producing cranes that meet international safety standards and certifications, which are crucial for compliance in various markets.

How Can Sustainability and Ethical Sourcing Impact Your B2B Crane Custom Procurement?

Sustainability and ethical sourcing are becoming pivotal considerations for B2B buyers in the crane custom sector. The environmental impact of crane production and operation is significant, with traditional manufacturing processes contributing to carbon emissions and resource depletion. International buyers should prioritize suppliers who adopt sustainable practices, including the use of recycled materials and energy-efficient manufacturing processes.

Moreover, ethical supply chains are increasingly important, especially in regions with stringent regulations regarding labor practices and environmental stewardship. Buyers should seek manufacturers that are transparent about their sourcing practices and can provide documentation of compliance with international labor standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability.

By aligning procurement strategies with sustainability goals, B2B buyers not only contribute to global environmental efforts but also enhance their brand reputation. Companies that demonstrate a commitment to green practices often find favor with clients and partners who are increasingly prioritizing sustainability in their operations.

How Has the Crane Custom Sector Evolved Over Time?

The crane custom sector has undergone substantial evolution over the decades, transitioning from basic mechanical designs to highly sophisticated machines capable of handling complex tasks. Initially, cranes were primarily utilized in construction and heavy lifting, but advancements in technology have expanded their applications to sectors such as renewable energy, mining, and logistics.

In the past, the focus was predominantly on the mechanical capabilities of cranes. Today, however, customization is driven by specific industry needs, regulatory requirements, and advancements in materials science. This evolution has led to the development of cranes that are lighter, more durable, and equipped with advanced features like remote operation and enhanced safety systems.

For international B2B buyers, understanding this historical context is essential as it informs current trends and future innovations. By recognizing the trajectory of the crane custom sector, buyers can make informed decisions that align with both their immediate operational needs and long-term strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of crane custom

-

How do I determine the right specifications for a custom crane?

To determine the right specifications for a custom crane, start by assessing your operational needs, including the type of materials to be lifted, the weight capacity required, and the working environment. Consult with your engineering team to identify crucial factors like lift height, reach, and mobility requirements. Consider industry standards and local regulations that may affect crane design. Engaging with suppliers early in the process can also provide valuable insights into design feasibility and potential innovations that meet your specific needs. -

What is the best customization option for a crane in the construction industry?

The best customization option for cranes in the construction industry typically involves features that enhance efficiency and safety, such as adjustable boom lengths, specialized attachments (like buckets or hooks), and advanced control systems. Additionally, considering features like weather-resistant materials for outdoor use and modular designs for easy transport can significantly benefit construction operations. Collaborating with manufacturers who specialize in construction equipment can help ensure that the crane meets the unique challenges of your projects. -

How can I vet suppliers for custom cranes effectively?

Vetting suppliers for custom cranes involves several key steps. First, research potential manufacturers’ experience and reputation in the industry, focusing on their track record for quality and reliability. Request references from previous clients and inspect case studies of similar projects. Evaluate their certifications and compliance with international standards, particularly if sourcing from regions like Europe or the Middle East. Finally, consider visiting their facilities or arranging virtual meetings to assess their production capabilities and commitment to quality assurance. -

What are the typical minimum order quantities (MOQs) for custom cranes?

Minimum order quantities (MOQs) for custom cranes can vary significantly depending on the manufacturer and the complexity of the design. Generally, MOQs can range from one unit for highly specialized custom designs to larger quantities for standardized models. When negotiating with suppliers, clarify whether the MOQ can be adjusted based on specific requirements or if there are opportunities for pilot orders. This flexibility can be crucial for international buyers, especially in markets with fluctuating demand. -

What payment terms should I expect when ordering custom cranes internationally?

Payment terms for ordering custom cranes internationally can vary widely among suppliers. Common practices include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment. Some manufacturers may offer payment upon delivery or after installation, depending on the relationship and trust built over time. Ensure to negotiate terms that are favorable and protect your interests, such as including provisions for delays or quality issues. It’s also advisable to use secure payment methods that offer buyer protection. -

What quality assurance measures should be in place for custom crane production?

Quality assurance measures for custom crane production should include thorough inspections at various stages of manufacturing, including raw material quality checks, in-process inspections, and final testing. Reputable manufacturers often follow ISO standards and have documented quality control processes. Request documentation regarding their QA protocols and any certifications they hold. Additionally, consider engaging third-party inspectors for an independent assessment to ensure the crane meets your specifications and safety standards. -

How can I manage logistics for importing custom cranes to my region?

Managing logistics for importing custom cranes requires careful planning and coordination. Start by understanding the import regulations and tariffs in your region, particularly in Africa or South America, which can significantly affect costs. Collaborate with logistics providers experienced in heavy equipment transport to ensure proper handling and compliance with local laws. Additionally, factor in lead times for manufacturing and shipping, and consider potential delays caused by customs clearance. Establishing a clear communication channel with your supplier can also help mitigate logistical challenges. -

What are the common challenges faced when sourcing custom cranes internationally?

Common challenges when sourcing custom cranes internationally include language barriers, cultural differences, and varying quality standards. Buyers may also encounter difficulties in navigating import regulations and customs processes. To overcome these challenges, it is essential to engage with suppliers who have experience in your target market and can provide local support. Building strong relationships and maintaining open lines of communication can help address issues promptly and ensure a smoother procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for crane custom

In today’s competitive landscape, strategic sourcing for custom cranes is not merely a procurement task but a critical element for operational success. B2B buyers from Africa, South America, the Middle East, and Europe must prioritize understanding their unique market demands, which can significantly influence sourcing decisions. By leveraging local suppliers and fostering partnerships, buyers can enhance supply chain resilience, reduce lead times, and ultimately lower costs.

What are the key benefits of strategic sourcing in the crane industry? It empowers businesses to align procurement strategies with long-term objectives, ensuring that they not only meet current needs but also anticipate future requirements. Moreover, investing in technology and data analytics can provide insights into market trends and supplier performance, enabling informed decision-making.

As we look ahead, the importance of adaptability and innovation in sourcing strategies cannot be overstated. B2B buyers are encouraged to continuously evaluate their supply chains, embracing sustainability practices and digital transformation to stay competitive. Now is the time to take action—forge strategic partnerships, invest in local capabilities, and remain agile to navigate the evolving landscape of custom crane procurement.