Enhance Quality & Cut Costs with Car Bumper Custom Solutions (2025)

Introduction: Navigating the Global Market for car bumper custom

Navigating the complex landscape of the global market for custom car bumpers can be a daunting task for international B2B buyers. With varying regulations, quality standards, and supplier capabilities, sourcing the right components tailored to specific needs is crucial. This guide aims to demystify the process of acquiring custom car bumpers, offering insights into the different types available, their applications across various vehicle models, and strategies for effective supplier vetting.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Kenya and Nigeria—face unique challenges. Understanding local market dynamics, import regulations, and cost considerations is essential for making informed purchasing decisions. This comprehensive guide not only outlines the types of custom car bumpers and their applications but also delves into critical factors such as pricing, quality assessment, and logistical strategies.

By equipping buyers with actionable insights and a structured approach to sourcing, this guide empowers them to navigate the global marketplace with confidence. Whether you are seeking durable bumpers for commercial vehicles or aesthetic designs for luxury cars, the information provided here will streamline your procurement process and enhance your competitiveness in the automotive industry.

Understanding car bumper custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufactured to meet original specifications of the vehicle | Automotive assembly lines, replacement parts | Pros: Guaranteed fit and quality. Cons: Higher cost compared to aftermarket options. |

| Aftermarket Bumpers | Customizable designs and materials beyond OEM specifications | Custom vehicle modifications, fleet vehicles | Pros: Greater variety and often lower prices. Cons: Potential fitment issues and varying quality. |

| Heavy-Duty Bumpers | Reinforced materials designed for off-road and rugged use | Off-road vehicles, commercial trucks | Pros: Enhanced durability and protection. Cons: Heavier, which may affect vehicle performance. |

| Lightweight Bumpers | Made from advanced materials like fiberglass or carbon fiber | Performance vehicles, racing applications | Pros: Improved fuel efficiency and speed. Cons: May not provide as much protection as heavier options. |

| Smart Bumpers | Integrated technology such as sensors and cameras | Advanced driver-assistance systems (ADAS) | Pros: Enhanced safety features and functionality. Cons: Higher complexity and cost of repairs. |

What Are OEM Bumpers and Their Key Characteristics?

OEM bumpers are produced by the original vehicle manufacturer and adhere strictly to factory specifications. This type is ideal for B2B buyers looking for reliable replacement parts that ensure a perfect fit and maintain vehicle integrity. When considering OEM bumpers, buyers should assess their budget, as these components typically come at a premium price but offer peace of mind regarding quality and compatibility.

How Do Aftermarket Bumpers Differ and What Are Their Applications?

Aftermarket bumpers provide flexibility in design and materials, allowing businesses to cater to specific customer needs. They are suitable for custom modifications or fleet vehicles where uniformity is less critical. Buyers should evaluate the reputation of aftermarket suppliers, as quality can vary significantly. Lower prices are attractive, but potential fitment issues must be considered when making bulk purchases.

What Makes Heavy-Duty Bumpers a Popular Choice for Specific Industries?

Heavy-duty bumpers are crafted from reinforced materials, making them ideal for off-road and commercial applications. They are particularly relevant for businesses in sectors like construction and agriculture, where vehicle durability is paramount. Buyers should consider the weight implications, as these bumpers can affect vehicle handling and fuel efficiency, especially in urban environments.

Why Choose Lightweight Bumpers for Performance Vehicles?

Lightweight bumpers, made from materials such as fiberglass or carbon fiber, are designed for performance-focused applications. They are favored by businesses involved in motorsports or high-performance vehicle modifications. While they enhance speed and fuel efficiency, buyers must weigh the trade-off between weight savings and the level of protection offered, especially in commercial scenarios where safety is a concern.

What Are the Benefits of Smart Bumpers in Modern Vehicles?

Smart bumpers integrate advanced technologies such as sensors and cameras, making them increasingly relevant in the context of advanced driver-assistance systems (ADAS). B2B buyers should consider the growing demand for safety features in vehicles and the associated installation costs. While smart bumpers can enhance vehicle functionality, they also introduce complexity in maintenance and repairs, which can be a significant factor for fleet managers.

Related Video: DIY Car or Truck Painting Tips! How to Paint Your Bumper to Save Money!

Key Industrial Applications of car bumper custom

| Industry/Sector | Specific Application of car bumper custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Tailored bumpers for electric vehicles | Enhances vehicle aesthetics and safety features | Material compatibility, weight considerations, compliance with regulations |

| Logistics and Transport | Reinforced bumpers for delivery vehicles | Reduces repair costs and downtime from accidents | Durability testing, customization options, lead times |

| Automotive Aftermarket | Custom bumpers for vehicle upgrades | Increases resale value and customer satisfaction | Market trends, installation compatibility, warranty policies |

| Construction and Heavy Machinery | Bumpers for construction vehicles | Protects equipment from damage, improving longevity | Impact resistance, customization for specific machinery, compliance with safety standards |

| Specialty Vehicles | Bumpers for off-road and recreational vehicles | Enhances vehicle performance and safety in rugged terrains | Material selection for extreme conditions, aesthetic customization, weight distribution |

How is Car Bumper Customization Applied in Automotive Manufacturing?

In the automotive manufacturing sector, custom bumpers are critical for electric vehicles (EVs). These bumpers not only improve the vehicle’s aesthetics but also enhance safety features, which is essential in markets like Europe where stringent regulations apply. B2B buyers in this sector must consider material compatibility, weight, and compliance with local regulations to ensure their products meet both functional and legal requirements.

What Role Do Custom Bumpers Play in Logistics and Transport?

For logistics and transport companies, reinforced custom bumpers are vital for delivery vehicles. These bumpers help reduce repair costs and minimize vehicle downtime due to accidents. In regions such as Africa and South America, where road conditions can be challenging, sourcing durable bumpers that can withstand impacts is crucial. Buyers should focus on durability testing and customization options to meet specific operational needs.

Why Invest in Custom Bumpers for the Automotive Aftermarket?

In the automotive aftermarket, custom bumpers are often used for vehicle upgrades, significantly increasing resale value and enhancing customer satisfaction. B2B buyers must stay abreast of market trends to identify popular styles and features. Additionally, installation compatibility and warranty policies are key considerations when sourcing these products, particularly in competitive markets across Europe and the Middle East.

How Do Custom Bumpers Benefit Construction and Heavy Machinery?

In the construction industry, custom bumpers are designed for heavy machinery, providing essential protection against damage and extending the lifespan of equipment. Buyers in this sector should prioritize impact resistance and customization options tailored to specific machinery types. Compliance with safety standards is also paramount, especially in regions with strict regulatory frameworks.

What Are the Advantages of Custom Bumpers for Specialty Vehicles?

For specialty vehicles, such as off-road and recreational models, custom bumpers enhance both performance and safety in rugged terrains. Buyers need to consider material selection that can withstand extreme conditions, as well as aesthetic customization to appeal to niche markets. Weight distribution is another critical factor that affects vehicle handling and performance, making it essential for international B2B buyers to collaborate closely with manufacturers to meet these requirements.

Related Video: #24 Custom Steel Bumper Build

3 Common User Pain Points for ‘car bumper custom’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Custom Car Bumpers

The Problem:

B2B buyers often face significant challenges in ensuring the quality of custom car bumpers, especially when dealing with international suppliers. In regions such as Africa and South America, where access to high-quality materials may be limited, buyers can end up with subpar products that do not meet safety standards or customer expectations. This can lead to costly returns, damaged reputations, and lost sales opportunities. Buyers are frequently left questioning how to verify the reliability of manufacturers and the materials used in production.

The Solution:

To mitigate quality assurance issues, B2B buyers should implement a robust supplier vetting process. This includes requesting samples and certifications of materials used in the manufacturing process. Utilizing third-party inspection services can also provide additional assurance of quality before large-scale orders are placed. Establishing clear specifications and performance standards in contracts will further safeguard against quality discrepancies. Buyers should also engage in regular communication with suppliers to ensure that any potential issues are addressed promptly and to build a relationship based on transparency and trust.

Scenario 2: Overcoming Lead Time Challenges in Custom Orders

The Problem:

Long lead times can be a significant pain point for B2B buyers needing custom car bumpers. Many businesses operate on tight timelines and require parts quickly to meet production schedules. In regions like the Middle East and Europe, where market competition is fierce, delays can result in missed deadlines, dissatisfied customers, and financial losses. Buyers often struggle with understanding the factors that contribute to lead times and how to effectively manage them.

The Solution:

To address lead time challenges, buyers should prioritize establishing clear timelines with suppliers during the negotiation phase. This involves communicating specific delivery expectations and understanding the manufacturing process involved. Utilizing local suppliers can often reduce lead times, as they may have shorter shipping distances and more responsive production schedules. Additionally, implementing a just-in-time (JIT) inventory system can help manage stock levels more effectively, ensuring that custom bumpers are available when needed without overextending capital. Regular progress updates from suppliers can also help buyers stay informed and adjust their plans accordingly.

Scenario 3: Managing Customization Requirements and Specifications

The Problem:

B2B buyers often encounter difficulties when trying to articulate their customization needs for car bumpers. Different markets may have varying regulations, aesthetic preferences, and functional requirements, leading to confusion and miscommunication with suppliers. In regions like Kenya and Nigeria, where local preferences may differ significantly from international trends, buyers risk receiving products that do not align with market demands or legal standards, which can lead to non-compliance issues and wasted resources.

The Solution:

To effectively manage customization requirements, buyers should invest time in thoroughly researching local market trends and regulations. Creating a detailed specification document that outlines design, materials, and compliance standards can serve as a valuable tool for communicating needs to suppliers. It is also beneficial to involve local experts or consultants who understand regional preferences and legal requirements. Hosting a collaborative workshop or virtual meeting with suppliers can facilitate clearer communication and ensure that both parties are aligned on expectations. By taking these proactive steps, buyers can enhance the likelihood of receiving car bumpers that meet their specific needs and market standards.

Strategic Material Selection Guide for car bumper custom

When selecting materials for custom car bumpers, international B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Below, we analyze four common materials used in car bumper manufacturing: polypropylene, ABS plastic, steel, and fiberglass. Each material has distinct properties, advantages, and limitations that can significantly impact the final product and its compliance with international standards.

What Are the Key Properties of Polypropylene for Car Bumpers?

Polypropylene (PP) is a thermoplastic polymer known for its resilience and flexibility. It has a temperature rating of approximately -20°C to 100°C, making it suitable for various climates. Its excellent corrosion resistance ensures durability against environmental factors such as moisture and UV radiation.

Pros: Polypropylene is lightweight, cost-effective, and easy to mold, which simplifies the manufacturing process. It also has good impact resistance, making it ideal for bumpers that must absorb shocks during collisions.

Cons: While it is durable, polypropylene can become brittle over time, especially when exposed to extreme temperatures. Its lower strength compared to metals may limit its use in high-performance vehicles.

Impact on Application: Polypropylene is compatible with various automotive paints and coatings, allowing for customization in design. However, buyers should ensure compliance with local regulations regarding recyclability and environmental impact.

How Does ABS Plastic Compare as a Material for Car Bumpers?

Acrylonitrile Butadiene Styrene (ABS) plastic is another popular choice for car bumpers due to its excellent toughness and impact resistance. It can withstand temperatures ranging from -20°C to 80°C, making it suitable for moderate climates.

Pros: ABS is known for its high strength-to-weight ratio, which enhances vehicle performance. It is also relatively easy to paint and can be finished to a high gloss, appealing to aesthetic preferences.

Cons: The primary drawback of ABS is its susceptibility to UV degradation, which can lead to color fading and surface cracking over time. Additionally, it has a higher production cost compared to polypropylene.

Impact on Application: ABS plastic is widely accepted in the automotive industry, but buyers must ensure that it meets specific standards such as ASTM D638 for tensile strength. This is particularly relevant for buyers in Europe, where stringent automotive regulations apply.

What Are the Benefits and Limitations of Steel for Custom Car Bumpers?

Steel is a traditional material used in car bumper manufacturing, known for its strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: The primary advantage of steel is its superior strength, which provides excellent protection during collisions. It is also highly recyclable, appealing to environmentally conscious buyers.

Cons: Steel bumpers are heavier than plastic alternatives, which can negatively impact fuel efficiency. Additionally, they are prone to rust and corrosion if not properly treated or coated.

Impact on Application: Steel bumpers are often preferred for off-road vehicles or heavy-duty trucks. Buyers should consider compliance with local regulations regarding weight limits and safety standards, particularly in regions like Africa and South America where road conditions vary.

Why Consider Fiberglass for Car Bumpers?

Fiberglass is a composite material that combines glass fibers with resin, offering a unique blend of strength and lightweight properties. It can handle temperatures up to 120°C, making it versatile for various climates.

Pros: Fiberglass is highly customizable and can be molded into complex shapes, allowing for innovative designs. Its resistance to corrosion and UV damage makes it suitable for long-term use.

Cons: The production process for fiberglass can be complex and costly, which may not be suitable for all manufacturers. Additionally, it can be less impact-resistant than metal options.

Impact on Application: Fiberglass bumpers are often used in custom or specialty vehicles. Buyers should ensure that the material complies with relevant standards, such as JIS K 6911 for thermosetting plastics, particularly in international markets.

Summary Table of Material Selection for Car Bumpers

| Material | Typical Use Case for car bumper custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Standard passenger vehicles | Lightweight and cost-effective | Can become brittle over time | Low |

| ABS Plastic | Mid-range vehicles | High strength-to-weight ratio | Susceptible to UV degradation | Medium |

| Steel | Heavy-duty and off-road vehicles | Superior strength and durability | Heavier, prone to rust | Medium |

| Fiberglass | Custom or specialty vehicles | Highly customizable and corrosion-resistant | Complex production process | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in custom car bumpers. Understanding these factors will help ensure compliance with international standards and align with regional preferences, ultimately enhancing product quality and market competitiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for car bumper custom

What Are the Main Stages of Manufacturing Car Bumpers?

Manufacturing custom car bumpers involves several crucial stages that ensure the final product meets the specifications required by international B2B buyers. Here’s a breakdown of the main stages:

-

Material Preparation

– The process begins with selecting the appropriate materials, typically plastic composites or metals like aluminum and steel. The choice of material affects durability, weight, and cost.

– Materials undergo rigorous inspection to ensure they meet industry standards. For instance, thermoplastic materials may need to meet specific temperature resistance requirements. -

Forming Techniques

– Injection Molding: This is the most common technique for producing plastic bumpers. It involves injecting molten plastic into a mold. This method allows for high precision and the ability to create complex shapes.

– Stamping: For metal bumpers, stamping is often used. This process involves pressing a sheet of metal into a mold under high pressure, which shapes the bumper according to design specifications.

– Thermoforming: This method is sometimes employed for creating bumpers from thermoplastic sheets. The sheets are heated and then formed over a mold. -

Assembly

– Once individual components are formed, they are assembled. This can include attaching additional features such as lights, sensors, or mounting brackets.

– Automation plays a significant role in this stage, enhancing consistency and reducing labor costs. -

Finishing

– The final stage involves surface treatment, which may include painting, coating, or polishing to enhance aesthetics and protect against environmental factors.

– Quality control checks during this phase ensure that the finish meets the required specifications for color, gloss, and texture.

How Is Quality Assurance Implemented in Car Bumper Manufacturing?

Quality assurance (QA) is vital for ensuring that custom car bumpers meet both functional and aesthetic standards. Here’s how it’s typically implemented:

-

International Standards and Certifications

– Adhering to international quality standards like ISO 9001 is crucial. This standard emphasizes a systematic approach to managing quality across processes and is recognized globally.

– Industry-specific certifications such as CE marking (for products sold in the European Economic Area) and Automotive Product Information (API) are also essential. These certifications indicate compliance with safety, health, and environmental protection standards. -

Key Quality Control Checkpoints

– Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production process. It ensures that only materials that meet quality standards are used.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor the quality of products at different stages. This helps to identify and rectify issues early.

– Final Quality Control (FQC): Once the bumpers are fully assembled and finished, a thorough inspection is conducted to ensure they meet all specifications and standards before they are shipped. -

Common Testing Methods for Car Bumpers

– Impact Testing: Measures the bumper’s ability to absorb energy during a collision.

– UV Resistance Testing: Assesses how well the bumper can withstand prolonged exposure to sunlight without degrading.

– Corrosion Testing: For metal bumpers, this testing evaluates resistance to rust and other forms of corrosion.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for risk mitigation. Here are some actionable steps:

-

Conduct Supplier Audits

– Perform on-site audits to evaluate the supplier’s manufacturing processes and quality assurance protocols. This not only helps verify compliance with international standards but also builds a relationship with the supplier. -

Request Quality Assurance Documentation

– Ask for detailed quality control reports, including results from IQC, IPQC, and FQC. Documentation should also include certifications and compliance reports to ensure the supplier meets both local and international standards. -

Utilize Third-Party Inspection Services

– Engaging third-party inspection companies can provide an unbiased evaluation of the supplier’s quality control measures. These companies can conduct inspections at various stages of production and provide detailed reports. -

Check for Certifications and Compliance

– Ensure that the supplier holds relevant certifications (ISO, CE, API) that validate their commitment to quality. Regularly updated certifications can indicate a supplier’s dedication to maintaining high standards.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is crucial for B2B buyers operating in diverse markets. Here are key considerations:

-

Regional Standards and Compliance

– Different regions may have varying standards for automotive components. Buyers should familiarize themselves with the specific requirements applicable in their target markets, such as the European Union’s stringent regulations versus those in African countries. -

Cultural and Communication Factors

– Effective communication is essential when dealing with suppliers from different cultural backgrounds. Misunderstandings can lead to quality issues. It’s advisable to establish clear expectations and guidelines regarding quality standards from the outset. -

Logistics and Supply Chain Considerations

– Quality control doesn’t end at manufacturing. Buyers must also consider logistics and shipping processes. Ensure that suppliers have measures in place to protect products during transit to prevent damage. -

Feedback and Continuous Improvement

– Encourage an open line of communication with suppliers regarding product performance and quality. Regular feedback can lead to continuous improvement and innovation in manufacturing processes.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing custom car bumpers, ensuring they receive products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car bumper custom’

Introduction

Sourcing custom car bumpers can be a complex process, especially for B2B buyers in international markets such as Africa, South America, the Middle East, and Europe. This step-by-step checklist aims to streamline your procurement process, ensuring you find the right supplier who meets your specific needs, adheres to quality standards, and supports your business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical specifications. This includes dimensions, materials (e.g., plastic, fiberglass, or metal), weight, and design features that meet regulatory standards in your target market. Having a detailed specification helps avoid misunderstandings with suppliers and ensures that the final product aligns with your quality expectations.

- Consider local regulations: Be aware of any regional compliance requirements regarding automotive parts.

- Include design elements: If you have specific branding or aesthetic requirements, detail these in your specifications.

Step 2: Conduct Market Research on Suppliers

Understanding the landscape of potential suppliers is crucial for making informed decisions. Investigate suppliers’ market presence, customer reviews, and their specialization in custom car bumpers. This research will help you identify reputable suppliers who have experience in your target market.

- Utilize online platforms: Websites like Alibaba and ThomasNet can provide valuable insights into supplier capabilities.

- Leverage industry networks: Engage with industry associations or trade shows to gather recommendations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, case studies, and references from buyers in similar industries or regions. This vetting process will help you assess the supplier’s reliability and ability to meet your demands.

- Check for certifications: Ensure the supplier has relevant quality certifications (e.g., ISO 9001) that demonstrate their commitment to quality management.

- Request samples: If possible, obtain samples of previous work to assess craftsmanship and material quality.

Step 4: Assess Pricing and Payment Terms

Understanding pricing structures and payment terms is vital for maintaining budget control. Compare quotes from multiple suppliers to ensure competitiveness while considering the quality of materials and services offered.

- Inquire about bulk discounts: Many suppliers offer better pricing for larger orders, which can significantly affect your overall costs.

- Clarify payment methods: Ensure that the payment terms are flexible and secure, accommodating your financial preferences.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a potential supplier, negotiate the terms and conditions of the contract. This includes delivery timelines, warranties, and after-sales support. Clear agreements help prevent disputes and ensure both parties are aligned on expectations.

A stock image related to car bumper custom.

- Document everything: Ensure all negotiated terms are included in the contract to protect your interests.

- Discuss penalties for delays: Establish consequences for non-compliance with delivery schedules to incentivize timely performance.

Step 6: Plan for Logistics and Shipping

Effective logistics planning is crucial for the timely delivery of your custom car bumpers. Consider the shipping methods, delivery times, and costs involved in transporting the goods to your location.

- Evaluate shipping options: Determine whether air freight or sea freight is more suitable based on urgency and budget.

- Understand customs regulations: Familiarize yourself with import duties and regulations in your country to avoid unexpected delays.

Step 7: Establish Quality Control Procedures

Implementing quality control procedures is essential for ensuring that the final product meets your specifications and standards. Consider conducting inspections at various stages of production and before shipment.

- Schedule inspections: Arrange for third-party inspections if possible, to provide an unbiased assessment of quality.

- Create a feedback loop: Develop a system for providing feedback to the supplier for continuous improvement in future orders.

By following these steps, international B2B buyers can navigate the complexities of sourcing custom car bumpers effectively, ensuring a smooth procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for car bumper custom Sourcing

What Are the Key Cost Components in Car Bumper Custom Sourcing?

When sourcing custom car bumpers, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials like plastic, fiberglass, and metal vary in price due to their availability and manufacturing processes. For instance, high-grade plastics that provide better durability and aesthetics will come at a premium.

-

Labor: Labor costs depend on the geographical location of the manufacturing facility. Regions with higher labor costs, such as Europe, may yield higher prices compared to those in parts of Africa or South America, where labor might be more cost-effective.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Companies with advanced manufacturing technologies may pass on these costs to buyers, impacting the final price.

-

Tooling: Custom bumpers often require specialized molds or tooling, which can be a significant upfront investment. This cost is typically amortized over the production run, influencing the per-unit cost depending on the volume ordered.

-

Quality Control (QC): Implementing stringent QC measures adds to the cost but is critical for ensuring product reliability. Certifications such as ISO can also affect pricing, as suppliers may charge more for compliance with international standards.

-

Logistics: Shipping costs vary based on the distance from the supplier to the buyer, chosen Incoterms, and the mode of transportation. For international buyers, understanding these factors is crucial to avoid unexpected expenses.

-

Margin: Suppliers generally add a profit margin to cover their business risks and operational costs. This margin can vary widely based on competition, supplier reputation, and perceived product value.

How Do Price Influencers Impact Custom Car Bumper Costs?

Several factors can influence the price of custom car bumpers, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to economies of scale, reducing the per-unit cost. International buyers should inquire about MOQs and negotiate terms to maximize cost savings.

-

Specifications and Customization: Customized features or unique designs can lead to higher costs. Buyers should clearly define specifications to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications can significantly increase costs but may also enhance durability and compliance with safety standards, which can be crucial for certain markets.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers may charge more due to their reliability, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Choosing the right Incoterm can help manage costs effectively.

What Tips Can International B2B Buyers Use for Effective Negotiation?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips for negotiating better prices:

-

Conduct Thorough Market Research: Understanding market rates and competitor pricing can provide leverage in negotiations. Buyers should gather data on different suppliers to make informed decisions.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, maintenance, and potential resale value. A higher upfront cost might be justified if the product offers better longevity or lower maintenance.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing and terms. Suppliers may offer discounts or favorable terms to repeat customers.

-

Be Clear and Specific in Requirements: Providing precise specifications and expectations can minimize misunderstandings that lead to cost overruns. Clear communication fosters trust and can facilitate negotiations.

-

Consider the Timing of Orders: Prices can fluctuate based on demand and supply cycles. Timing purchases during off-peak seasons can result in lower prices.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing, prices can vary widely based on specific circumstances, supplier negotiations, and market conditions. Always consult multiple suppliers and seek detailed quotes to ensure accuracy in budgeting.

Alternatives Analysis: Comparing car bumper custom With Other Solutions

A stock image related to car bumper custom.

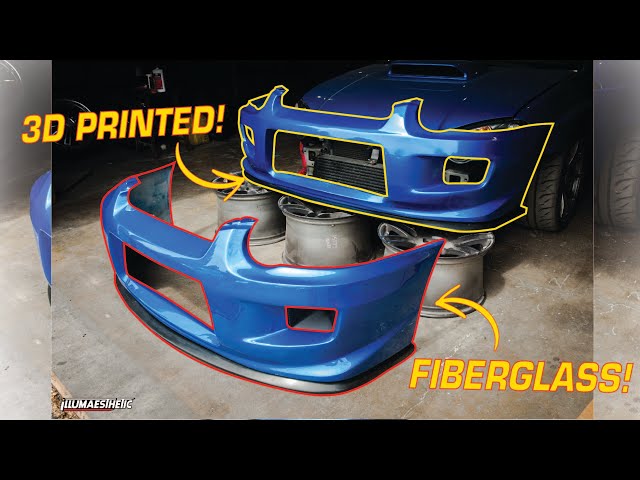

In the dynamic automotive industry, businesses often seek effective solutions for car bumpers that meet their unique requirements. While custom car bumpers offer a tailored approach, there are alternative solutions worth considering. This analysis will compare car bumper custom against two viable alternatives: pre-manufactured bumpers and 3D-printed bumpers, helping international B2B buyers make informed decisions.

Comparison Table of Car Bumper Custom vs. Alternatives

| Comparison Aspect | Car Bumper Custom | Pre-Manufactured Bumpers | 3D-Printed Bumpers |

|---|---|---|---|

| Performance | High durability and fit | Standard performance | Variable, depends on design |

| Cost | Higher initial investment | Lower upfront cost | Moderate, varies by design |

| Ease of Implementation | Requires skilled labor | Quick installation | Moderate, requires setup |

| Maintenance | Custom parts may need special care | Standard maintenance | Variable, depends on material |

| Best Use Case | Unique design specifications | Mass production needs | Prototyping or unique designs |

What Are the Advantages and Disadvantages of Pre-Manufactured Bumpers?

Pre-manufactured bumpers are designed for mass production, making them a cost-effective option for businesses looking to quickly outfit vehicles with standard parts. Their primary advantage lies in the lower upfront costs and ease of installation, making them an attractive choice for businesses with tight budgets or those looking to scale operations rapidly. However, the downside is the lack of customization, which may not meet the specific aesthetic or functional needs of all vehicles. As such, they are best suited for companies looking for quick replacements or standard models rather than bespoke solutions.

How Do 3D-Printed Bumpers Compare to Custom Bumpers?

3D-printed bumpers offer a modern solution that allows for high levels of customization and rapid prototyping. The ability to create complex designs that may not be feasible with traditional manufacturing methods is a significant advantage. Moreover, 3D printing can reduce waste and allow for material experimentation. However, the performance of 3D-printed bumpers can vary significantly based on the material used and the design intricacies, which may not always provide the durability required for heavy-duty applications. Therefore, businesses in niche markets or those requiring unique designs may find 3D printing beneficial, while others may face challenges with performance consistency.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When considering the right solution for car bumpers, B2B buyers should evaluate their specific requirements, including performance, budget constraints, and the need for customization. If durability and a perfect fit are paramount, investing in custom bumpers may be justified despite the higher cost. On the other hand, for businesses focused on rapid deployment and cost efficiency, pre-manufactured bumpers could be the ideal choice. Finally, if innovation and unique design are key factors, 3D-printed bumpers may provide the flexibility needed to meet those goals. By carefully analyzing these aspects, buyers can select the solution that aligns best with their operational objectives and market demands.

Essential Technical Properties and Trade Terminology for car bumper custom

What Are the Key Technical Properties of Custom Car Bumpers?

When engaging in the procurement of custom car bumpers, understanding the technical specifications is crucial for ensuring quality, compatibility, and safety. Here are some essential technical properties that B2B buyers should consider:

1. Material Grade

The material grade refers to the specific type of material used in manufacturing the bumper. Common materials include thermoplastics, fiberglass, and metal alloys. Each material offers different benefits such as weight reduction, impact resistance, and cost-effectiveness. For instance, thermoplastics are lightweight and can be molded into complex shapes, making them popular for custom bumpers. Selecting the right material grade is essential for achieving durability while keeping production costs manageable.

2. Tolerance Levels

Tolerance levels define the acceptable variations in dimensions during the manufacturing process. This specification is critical because it ensures that the bumper fits correctly with other vehicle components. Tight tolerances are often required for high-performance vehicles, where even minor discrepancies can lead to functional issues. By understanding tolerance requirements, buyers can prevent costly rework and ensure product consistency.

3. Impact Resistance

Impact resistance measures how well a bumper can withstand sudden forces, such as collisions. This property is vital for safety regulations in the automotive industry. Bumpers with high impact resistance can absorb energy and reduce damage to the vehicle’s frame and occupants. Evaluating impact resistance can help buyers choose bumpers that meet legal safety standards and enhance vehicle performance.

4. Surface Finish

The surface finish refers to the texture and smoothness of the bumper’s exterior. This property not only affects aesthetic appeal but also plays a role in durability and maintenance. A high-quality surface finish can resist scratches and corrosion, making it easier to clean and maintain. Buyers should consider their target market’s preferences for aesthetics and functionality when selecting surface finishes.

5. Weight

The weight of the bumper is a critical factor that influences fuel efficiency and vehicle handling. Lighter bumpers contribute to reduced overall vehicle weight, which can lead to improved performance and lower fuel consumption. Buyers should assess the balance between weight and strength to ensure they are making an informed decision that aligns with industry trends towards sustainability.

What Are Common Trade Terms Used in Custom Car Bumper Manufacturing?

Familiarizing yourself with industry jargon can enhance communication and streamline procurement processes. Here are some common terms relevant to custom car bumper manufacturing:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are used as components in another company’s product. In the context of car bumpers, an OEM produces bumpers that are used by automotive manufacturers. Understanding OEM relationships can help buyers identify reliable suppliers and ensure that they are purchasing parts that meet specific vehicle standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to produce or sell. This term is particularly important for buyers from regions like Africa and South America, where smaller batch sizes may be necessary. Knowing the MOQ can help buyers plan their inventory and budget more effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for a price quote for specific products or services. Issuing an RFQ allows buyers to compare pricing and terms from multiple suppliers, facilitating informed decision-making. It’s a crucial step in the sourcing process for custom car bumpers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping costs and risks associated with international trade, particularly for buyers in Europe and the Middle East.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This metric is important for supply chain management and inventory planning. Buyers should inquire about lead times to ensure they align with production schedules and market demands.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of custom car bumper procurement more effectively, ensuring quality products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the car bumper custom Sector

What Are the Current Market Dynamics and Key Trends in the Car Bumper Custom Sector?

The car bumper custom sector is experiencing a significant transformation driven by various global trends that international B2B buyers should consider. One of the primary drivers is the increasing demand for customization, as consumers seek unique vehicle aesthetics and enhanced functionality. This trend is particularly strong in regions like Africa and South America, where buyers are looking for products that reflect their cultural identity and preferences.

Additionally, the rise of electric vehicles (EVs) has introduced new materials and designs in bumper manufacturing. Bumpers are now being tailored not only for aesthetics but also for aerodynamic efficiency and safety features. This shift is prompting suppliers to invest in advanced technologies such as 3D printing and computer-aided design (CAD), which allow for more rapid prototyping and lower production costs. B2B buyers in the Middle East and Europe can benefit from these technologies by sourcing more innovative and cost-effective solutions.

Moreover, supply chain resilience is becoming a critical focus. The COVID-19 pandemic highlighted vulnerabilities in global supply chains, prompting buyers to seek suppliers with diversified sourcing strategies. This trend is particularly relevant for African and South American markets, where establishing reliable supply channels can mitigate risks associated with geopolitical tensions and economic fluctuations.

How Can Sustainability and Ethical Sourcing Impact the Car Bumper Custom Sector?

Sustainability is increasingly influencing purchasing decisions in the car bumper custom sector. Buyers are becoming more aware of the environmental impact of manufacturing processes and are seeking suppliers that prioritize ethical sourcing and sustainable practices. This includes the use of recycled materials and low-impact production methods, which can significantly reduce the carbon footprint associated with bumper manufacturing.

Ethical supply chains are essential for fostering trust and transparency in B2B transactions. Certifications such as ISO 14001 (Environmental Management) and materials that meet green standards are crucial for buyers who want to ensure their suppliers adhere to sustainable practices. B2B buyers from Europe, in particular, are often mandated by regulatory frameworks to source products that comply with environmental standards, making it imperative to partner with certified suppliers.

Furthermore, the demand for eco-friendly materials, such as bio-based plastics and composites, is rising. These materials not only contribute to sustainability but also often provide superior performance characteristics. By aligning with suppliers that utilize these materials, B2B buyers can enhance their brand reputation while meeting consumer demand for greener products.

How Has the Car Bumper Custom Sector Evolved Over Time?

The evolution of the car bumper custom sector has been marked by significant technological advancements and changing consumer preferences. Initially, bumpers were primarily designed for safety, made from heavy metals and rigid plastics. However, with the advent of new materials and manufacturing techniques, the focus has shifted towards customization, lightweight designs, and enhanced functionality.

The integration of technology into bumper design, such as sensors for parking assistance and collision detection, has also transformed the sector. As consumer expectations have evolved, manufacturers have adapted to meet these demands, paving the way for a more dynamic and innovative market.

In summary, understanding the current market dynamics, sustainability initiatives, and the historical context of the car bumper custom sector provides international B2B buyers with the insights needed to make informed sourcing decisions. By leveraging emerging trends and prioritizing ethical practices, businesses can position themselves competitively in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of car bumper custom

-

How do I solve quality issues when sourcing custom car bumpers?

To resolve quality concerns when sourcing custom car bumpers, start by conducting thorough supplier vetting. Request samples before committing to large orders to assess material quality and craftsmanship. Establish clear quality assurance (QA) standards and communicate them to the supplier. Regularly monitor production processes through audits or third-party inspections, particularly if suppliers are located overseas. Additionally, consider incorporating quality control metrics in your contract to ensure accountability throughout the production process. -

What is the best approach to finding reliable suppliers for custom car bumpers?

Finding reliable suppliers involves a multi-step approach. Start by leveraging industry-specific platforms, trade shows, and B2B marketplaces to identify potential suppliers. Conduct background checks, review customer testimonials, and seek references from other businesses in your network. Consider engaging a local sourcing agent familiar with the customs and trade practices in regions like Africa or South America. Lastly, initiate small test orders to evaluate the supplier’s reliability and responsiveness before scaling up your purchases. -

What customization options are available for car bumpers?

Customization options for car bumpers can vary widely based on supplier capabilities. Common options include material selection (plastic, fiberglass, or metal), color choices, design modifications, and additional features like integrated sensors or lighting. Some suppliers may also offer branding opportunities, allowing you to incorporate logos or specific designs. When discussing customization, clearly outline your requirements and ask for a portfolio of previous work to ensure the supplier can meet your expectations. -

What are the typical minimum order quantities (MOQ) for custom car bumpers?

Minimum order quantities (MOQ) for custom car bumpers can differ significantly between suppliers and depend on the complexity of the customization. Generally, MOQs can range from 50 to 500 units. It’s advisable to negotiate MOQs based on your specific needs, especially if you are a smaller business. Some suppliers may offer flexibility or tiered pricing based on order volume, so be sure to discuss your production requirements upfront to find a mutually beneficial arrangement. -

What payment terms should I expect when ordering custom car bumpers?

Payment terms for custom car bumpers often include a deposit upfront, typically ranging from 30% to 50% of the total order value, with the balance due upon delivery or before shipment. Be sure to clarify the payment methods accepted, such as bank transfers or letters of credit, as these can vary by region. It’s also wise to establish clear terms regarding refunds or exchanges in case of quality issues or delivery delays. Always have a written agreement to avoid misunderstandings. -

How can I ensure timely logistics for importing custom car bumpers?

To ensure timely logistics when importing custom car bumpers, start by selecting suppliers with a proven track record of on-time delivery. Discuss shipping options and timelines during the negotiation phase, including air freight for faster delivery or sea freight for cost savings. Consider working with logistics companies experienced in international trade, who can assist with customs clearance and documentation. Additionally, keep an open line of communication with your supplier to address any potential delays proactively. -

What are the common challenges in international trade for custom car bumpers?

Common challenges in international trade for custom car bumpers include navigating complex customs regulations, tariffs, and import/export restrictions. Additionally, language barriers can lead to miscommunication with suppliers. It’s crucial to stay informed about trade policies specific to your region and engage legal or trade experts if necessary. Other challenges may involve fluctuating shipping costs and potential quality discrepancies due to different manufacturing standards, so thorough planning and supplier vetting are essential. -

How do I evaluate the performance of my custom car bumper supplier?

To evaluate your custom car bumper supplier’s performance, establish key performance indicators (KPIs) such as on-time delivery rates, quality defect rates, and responsiveness to inquiries. Regularly review these metrics against agreed-upon standards. Schedule periodic reviews and feedback sessions to address any issues and discuss improvement opportunities. Engaging in open communication fosters a collaborative relationship, helping you and the supplier align better and enhance overall performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for car bumper custom

What Are the Key Takeaways for B2B Buyers in Car Bumper Customization?

In the ever-evolving landscape of automotive manufacturing, strategic sourcing remains a pivotal element for international B2B buyers. By prioritizing the selection of reliable suppliers, businesses can significantly enhance product quality and reduce lead times. Engaging with manufacturers who understand the specific requirements of diverse markets—such as those in Africa, South America, the Middle East, and Europe—ensures that custom car bumpers not only meet regulatory standards but also cater to regional preferences.

How Can Buyers Position Themselves for Future Success?

As the automotive industry shifts towards sustainability and innovation, buyers must remain vigilant in adapting their sourcing strategies. Leveraging technology, such as digital procurement platforms, can streamline the sourcing process and foster stronger supplier relationships. Additionally, understanding local market dynamics will empower buyers to make informed decisions, optimizing cost structures while enhancing supply chain resilience.

What Should B2B Buyers Do Next?

Looking ahead, it is crucial for international B2B buyers to embrace a proactive approach to sourcing custom car bumpers. This involves continuous market research, fostering collaborations with innovative suppliers, and staying attuned to industry trends. By taking these steps, businesses can not only secure a competitive edge but also contribute to a more sustainable automotive future. Engage with suppliers today to unlock new opportunities and drive growth in your automotive ventures.