Enhance Your Fleet: The Ultimate Ford Super Duty Custom Guide (2025)

Introduction: Navigating the Global Market for ford super duty custom

In the competitive landscape of international B2B commerce, sourcing Ford Super Duty custom vehicles poses unique challenges, particularly for buyers in Africa, South America, the Middle East, and Europe. Understanding the nuances of this market—such as vehicle specifications, compliance with local regulations, and supplier reliability—can be daunting. This guide provides a comprehensive overview of the Ford Super Duty custom segment, addressing critical aspects such as types of vehicles available, their applications across various industries, and essential criteria for vetting suppliers.

With detailed insights into pricing structures, potential cost-saving strategies, and market trends, this resource is designed to empower B2B buyers to make informed purchasing decisions. It highlights the importance of aligning procurement strategies with local market demands, ensuring that investments in Ford Super Duty customs yield optimal returns.

Whether you are a fleet manager in South Africa looking to enhance operational efficiency or a distributor in Germany aiming to meet specific client needs, this guide offers actionable insights tailored to your market. By navigating through the complexities of sourcing Ford Super Duty custom vehicles, you will be better equipped to build robust supply chains, mitigate risks, and achieve your business objectives in a globalized economy.

Understanding ford super duty custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ford Super Duty F-250 | Medium-duty capacity, versatile configurations | Construction, logistics | Pros: Strong towing capacity; Cons: Heavier fuel consumption. |

| Ford Super Duty F-350 | Enhanced payload and towing capabilities, dual-rear wheels | Heavy-duty hauling, fleet services | Pros: Excellent stability; Cons: Higher initial cost. |

| Ford Super Duty F-450 | Maximum towing capacity, commercial-grade chassis | Commercial transport, agriculture | Pros: Unmatched towing capabilities; Cons: Limited maneuverability. |

| Ford Super Duty F-550 | Super-duty chassis, designed for upfitting | Specialized transport, utility | Pros: Highly customizable; Cons: Heavy weight impacts fuel efficiency. |

| Ford Super Duty Chassis Cab | Versatile platform for custom body applications | Emergency services, delivery | Pros: Flexible for various uses; Cons: Requires additional investment for upfitting. |

What are the Key Characteristics of the Ford Super Duty F-250?

The Ford Super Duty F-250 is designed for medium-duty applications, making it a versatile choice for businesses that require a balance between payload capacity and towing capability. With configurations that range from standard to crew cab, it offers flexibility for various operational needs. B2B buyers should consider its strong towing capacity and reliability, especially for construction and logistics sectors, while being mindful of its higher fuel consumption.

How Does the Ford Super Duty F-350 Stand Out?

The F-350 is notable for its enhanced payload and towing capabilities, often equipped with dual rear wheels for improved stability and weight distribution. This model is ideal for heavy-duty hauling and fleet services, where reliability and performance are crucial. Buyers should weigh the benefits of its robust features against the higher initial investment, making it suitable for businesses with significant transport needs.

Why Choose the Ford Super Duty F-450 for Heavy-Duty Tasks?

The F-450 is engineered for maximum towing capacity, making it a top choice for commercial transport and agricultural applications. Its commercial-grade chassis supports heavy loads, making it a reliable workhorse. While its unmatched towing capabilities are a major advantage, potential buyers should consider its limited maneuverability in urban settings, which can impact its usability in certain environments.

What Makes the Ford Super Duty F-550 Ideal for Specialized Applications?

The F-550 features a super-duty chassis that is specifically designed for upfitting, allowing businesses to customize it for various specialized applications, such as utility work or emergency services. This flexibility is a significant advantage for companies needing tailored solutions. However, its heavy weight can negatively affect fuel efficiency, which buyers should factor into their overall cost considerations.

How Does the Ford Super Duty Chassis Cab Offer Customization Options?

The Ford Super Duty Chassis Cab serves as a versatile platform for businesses looking to create custom body applications, such as delivery trucks or service vehicles. Its adaptability makes it popular among emergency services and utility companies. While the potential for customization is a strong selling point, buyers must also consider the additional investment required for upfitting, which can impact the overall budget.

Related Video: Super Duty Ford F-450 Platinum 2021 Custom 4×4 Truck

Key Industrial Applications of ford super duty custom

| Industry/Sector | Specific Application of Ford Super Duty Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty towing and transport of materials | Enhanced productivity through reliable transportation of equipment and materials | Consider local regulations for vehicle modifications and emissions standards. |

| Agriculture | Farming equipment transport and utility vehicle | Efficient field operations and reduced downtime | Evaluate payload capacity and compatibility with farming tools. |

| Logistics and Transportation | Freight hauling and delivery services | Improved logistics efficiency and cost-effectiveness | Assess fuel efficiency and maintenance support in target regions. |

| Mining | Equipment and personnel transport | Increased safety and reliability in harsh environments | Ensure compliance with safety standards and operational requirements in mining. |

| Emergency Services | Ambulance and rescue operations | Rapid response capabilities in critical situations | Verify availability of specialized equipment and service support. |

How is Ford Super Duty Custom Used in Construction?

In the construction sector, the Ford Super Duty Custom is primarily utilized for heavy-duty towing and the transport of materials. With its robust towing capacity and durable build, it ensures that construction equipment and supplies are moved efficiently to and from job sites. This capability reduces downtime and enhances productivity, which is crucial for meeting project deadlines. International buyers, particularly from Africa and South America, should consider local regulations regarding vehicle modifications and emissions standards when sourcing these vehicles to ensure compliance.

What Role Does Ford Super Duty Custom Play in Agriculture?

Within agriculture, the Ford Super Duty Custom serves as a vital utility vehicle for transporting farming equipment and supplies. Its powerful engine and ample payload capacity allow for efficient field operations, significantly reducing the time farmers spend on logistics. This vehicle is especially beneficial in regions where access to remote areas is necessary for agricultural activities. Buyers should evaluate the vehicle’s compatibility with various farming tools and its ability to handle the specific demands of agricultural tasks in their respective regions.

How is Ford Super Duty Custom Beneficial for Logistics and Transportation?

In logistics and transportation, the Ford Super Duty Custom is employed for freight hauling and delivery services. Its strong build and spacious cargo area allow businesses to transport goods efficiently, leading to improved logistics efficiency and cost-effectiveness. This is particularly important for companies operating across vast distances in regions like Europe and the Middle East. When sourcing, it is essential to assess the vehicle’s fuel efficiency and the availability of maintenance support in the target regions to minimize operational disruptions.

What Advantages Does Ford Super Duty Custom Offer in Mining Operations?

In the mining industry, the Ford Super Duty Custom is used for transporting equipment and personnel to and from remote mining sites. Its rugged construction and reliability increase safety and efficiency in harsh environments where conventional vehicles may fail. This application is critical for maintaining operations without interruptions. Buyers should ensure that the vehicle complies with safety standards and operational requirements specific to the mining sector in their region, particularly in areas with stringent regulations.

How Does Ford Super Duty Custom Support Emergency Services?

The Ford Super Duty Custom is also a key asset for emergency services, including ambulance and rescue operations. Its ability to navigate challenging terrains and carry essential medical equipment enhances rapid response capabilities in critical situations. This is vital for saving lives and providing timely assistance. International buyers must verify the availability of specialized equipment and service support to ensure that the vehicle meets the specific needs of emergency response teams in their regions.

3 Common User Pain Points for ‘ford super duty custom’ & Their Solutions

Scenario 1: Difficulty in Customizing Specifications for Diverse Needs

The Problem: B2B buyers often face challenges when it comes to customizing Ford Super Duty trucks to meet specific operational requirements. For instance, a construction company in South Africa may need trucks that can handle heavy loads, while a logistics firm in Germany might prioritize fuel efficiency and advanced safety features. Misalignment between the customization options and actual business needs can lead to increased operational costs and inefficiencies.

The Solution: To effectively customize Ford Super Duty trucks, buyers should engage directly with Ford-certified dealerships or specialized upfitters who understand the unique demands of their industry. Start by conducting a thorough needs assessment, identifying key specifications such as payload capacity, towing capabilities, and desired technology features. It is also beneficial to utilize Ford’s online configurator tools to visualize different configurations. Furthermore, leveraging customer reviews and case studies from similar industries can provide insights into successful customizations. Establishing a close relationship with the dealer ensures that the specific requirements are met without incurring unnecessary costs.

Scenario 2: Challenges in Sourcing Genuine Parts for Maintenance

The Problem: International B2B buyers often struggle with sourcing genuine parts for the maintenance and repair of their Ford Super Duty trucks, especially when operating in remote areas of Africa or South America. Delays in acquiring OEM parts can lead to prolonged downtimes, affecting productivity and bottom lines. Moreover, the risk of counterfeit parts can compromise vehicle performance and safety.

The Solution: To mitigate these challenges, buyers should establish relationships with reliable suppliers who specialize in Ford parts. It’s advisable to create a network of authorized Ford dealerships and certified parts distributors that can guarantee the authenticity of the components. Additionally, utilizing platforms that offer OEM parts catalogs can streamline the ordering process. Implementing a preventive maintenance schedule and keeping a stock of essential parts can also minimize downtime. Consider collaborating with local mechanics who are familiar with Ford vehicles; they can assist in sourcing parts and performing maintenance efficiently.

Scenario 3: Navigating Compliance with Local Regulations

The Problem: B2B buyers face significant hurdles when ensuring that their Ford Super Duty trucks comply with local regulations and standards, particularly when operating across different regions such as the Middle East and Europe. Regulations regarding emissions, safety, and vehicle specifications can vary widely, leading to potential fines or operational halts if not properly addressed.

The Solution: To navigate these compliance issues, it is essential for buyers to stay informed about the regulations that apply to their specific markets. This can be achieved by consulting with local authorities or industry associations that provide guidance on vehicle compliance. Additionally, working with a logistics partner that understands the regulatory landscape can streamline the process of vehicle registration and compliance checks. Buyers should also consider investing in vehicles equipped with emissions-reducing technologies or modifications that meet regional standards. Regular training for drivers and fleet managers on compliance requirements will ensure that all operational practices align with legal obligations, thus safeguarding against potential penalties.

Strategic Material Selection Guide for ford super duty custom

When selecting materials for the Ford Super Duty Custom, international B2B buyers must consider a range of factors that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in the construction and manufacturing of the Ford Super Duty Custom, focusing on their properties, advantages, limitations, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Steel for Ford Super Duty Custom?

Steel is a primary material used in the Ford Super Duty Custom due to its exceptional strength and versatility. Its key properties include high tensile strength, good ductility, and excellent weldability. Steel is also capable of withstanding high temperatures and pressures, making it suitable for various automotive applications.

Pros & Cons: The advantages of steel include its durability and cost-effectiveness, as it is generally less expensive than alternative materials like aluminum. However, steel is prone to corrosion, which can be a significant disadvantage in humid or coastal environments. Additionally, the weight of steel can impact fuel efficiency, which is a critical consideration for many buyers.

Impact on Application: Steel is compatible with a wide range of media, including fuels and oils, making it a reliable choice for components in the Ford Super Duty Custom.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) for steel quality. In regions like South Africa and Germany, adherence to these standards can significantly affect procurement decisions.

How Does Aluminum Benefit the Ford Super Duty Custom?

Aluminum is increasingly used in the automotive industry for its lightweight properties and resistance to corrosion. Key properties of aluminum include a high strength-to-weight ratio and excellent thermal conductivity, which can enhance the vehicle’s performance.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can lead to improved fuel efficiency and handling. However, aluminum can be more expensive than steel and may require specialized manufacturing processes, increasing production complexity.

Impact on Application: Aluminum is particularly well-suited for components exposed to moisture, as it resists rust and corrosion effectively. This makes it an ideal choice for vehicles operating in humid climates.

Considerations for International Buyers: Buyers from regions like the Middle East should consider the cost implications of using aluminum, as well as compliance with local quality standards. Understanding the specific alloy grades and their properties is essential for ensuring compatibility with local regulations.

What Role Does Composite Material Play in Ford Super Duty Custom?

Composite materials, such as fiberglass or carbon fiber, are utilized in select applications within the Ford Super Duty Custom. These materials are known for their high strength-to-weight ratio and resistance to environmental factors.

Pros & Cons: The main advantage of composites is their lightweight nature, which contributes to overall vehicle efficiency. However, composites can be more expensive to manufacture and repair compared to traditional materials. Additionally, their performance can vary based on environmental conditions.

Impact on Application: Composites are often used in non-structural components, such as interior panels or body parts, where weight savings are crucial without compromising safety.

Considerations for International Buyers: Buyers should be aware of the varying standards for composite materials across regions. For instance, European buyers may need to comply with specific EU regulations regarding material safety and environmental impact.

Why is Rubber Important for Ford Super Duty Custom?

Rubber is primarily used in seals, gaskets, and suspension components within the Ford Super Duty Custom. Its key properties include flexibility, resilience, and excellent resistance to wear and tear.

Pros & Cons: The advantages of rubber include its ability to absorb shocks and vibrations, enhancing ride quality. However, rubber can degrade over time due to exposure to UV light and extreme temperatures, necessitating regular maintenance.

Impact on Application: Rubber components are crucial for maintaining the integrity of seals and preventing leaks, making them essential for the vehicle’s overall performance.

Considerations for International Buyers: Buyers should consider the climatic conditions of their regions, as extreme temperatures can affect rubber longevity. Compliance with standards such as JIS (Japanese Industrial Standards) may also be necessary for certain rubber products.

Summary Table of Material Selection for Ford Super Duty Custom

| Material | Typical Use Case for ford super duty custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High strength and cost-effective | Prone to corrosion | Low |

| Aluminum | Body panels and engine components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Composite | Interior panels and non-structural parts | High strength-to-weight ratio | Expensive and variable performance | High |

| Rubber | Seals and suspension components | Excellent shock absorption | Degrades over time | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions regarding material selection for the Ford Super Duty Custom. Understanding the properties, advantages, and limitations of each material is crucial for optimizing performance while ensuring compliance with local standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for ford super duty custom

What Are the Main Stages of the Manufacturing Process for Ford Super Duty Custom?

The manufacturing process for the Ford Super Duty Custom involves several critical stages, each designed to ensure durability, performance, and quality. Understanding these stages can help international B2B buyers make informed decisions when sourcing parts or vehicles.

1. Material Preparation

The process begins with material preparation, where high-quality raw materials are sourced and inspected. Common materials include high-strength steel for the chassis and aluminum for the body, ensuring a balance between weight and durability. Suppliers are often required to provide certifications that verify the material specifications meet Ford’s rigorous standards.

2. Forming Techniques

Once the materials are prepared, they undergo various forming techniques. These include stamping, bending, and welding. The use of advanced technologies, such as robotic welding, enhances precision and consistency, reducing the risk of defects. Buyers should inquire about the specific forming techniques used by manufacturers to ensure they align with industry best practices.

3. Assembly Process

The assembly process is where all components come together. Ford employs a modular assembly system that allows for flexibility and efficiency. Components are assembled in a systematic manner, often utilizing automated systems for tasks such as fastening and quality checks. B2B buyers should consider the assembly line configuration and workforce training, as these factors significantly impact the final product’s quality.

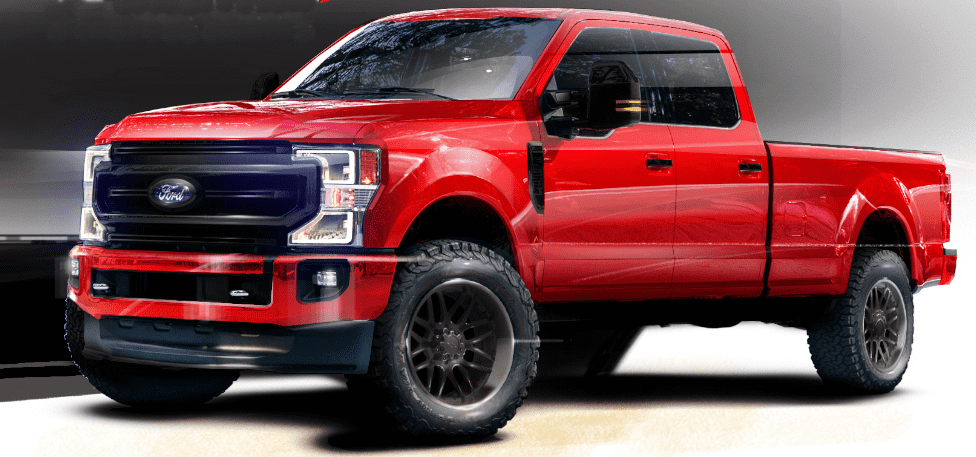

A stock image related to ford super duty custom.

4. Finishing Touches

Finishing includes painting, coating, and detailing. Ford utilizes state-of-the-art painting techniques that not only enhance aesthetics but also provide corrosion resistance. The finishing stage is critical for ensuring longevity, particularly in markets with harsh environmental conditions, such as Africa and the Middle East. Buyers should verify that manufacturers adhere to specific finishing standards to protect the vehicles in diverse climates.

How Is Quality Assurance Implemented in Ford Super Duty Custom Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that every Ford Super Duty Custom meets both internal standards and international regulations.

Relevant International Standards for Quality Assurance

Ford adheres to several international quality standards, most notably ISO 9001, which focuses on quality management systems. This certification is essential for B2B buyers looking to verify the reliability of their suppliers. Additionally, industry-specific standards such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the components being sourced.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. It ensures that all materials meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): During assembly, ongoing inspections are conducted to identify any issues early in the process. This includes monitoring critical dimensions and functionality at various stages.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection is performed. This includes thorough testing of the vehicle’s performance and safety features, ensuring compliance with regulatory requirements.

What Testing Methods Are Commonly Used in the Manufacturing of Ford Super Duty Custom?

Various testing methods are employed to ensure the Ford Super Duty Custom meets safety and performance standards.

-

Durability Testing: Vehicles undergo rigorous testing in extreme conditions to assess their durability. This includes testing for resistance to corrosion, extreme temperatures, and heavy loads.

-

Performance Testing: This involves evaluating the vehicle’s performance metrics, such as fuel efficiency, braking distance, and acceleration. These tests are crucial for meeting regulatory standards and consumer expectations.

-

Safety Testing: Safety features are rigorously tested, including crash tests and electronic stability control assessments. Compliance with safety regulations is vital, particularly for international buyers who must adhere to their local safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of supplier quality control is essential for B2B buyers, especially those operating in diverse regions with varying regulatory requirements.

Conducting Supplier Audits

One effective way to assess a supplier’s quality control processes is through audits. Buyers can perform on-site audits to evaluate the manufacturing processes, quality management systems, and compliance with international standards. It’s advisable to develop a checklist based on ISO standards and industry-specific requirements to guide the audit.

Requesting Quality Reports

Buyers should request quality reports from suppliers that detail the results of IQC, IPQC, and FQC. These reports provide insight into the quality control measures in place and any corrective actions taken in case of failures. Regularly reviewing these reports can help buyers maintain oversight of their suppliers’ performance.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These services can conduct inspections at various stages of the manufacturing process, providing additional assurance of product quality. This is particularly beneficial for buyers from regions with less stringent local regulations.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control, particularly in ensuring compliance with local regulations and standards.

Understanding Regional Standards

Buyers must familiarize themselves with the quality standards specific to their regions. For example, European buyers may prioritize CE marking, while Middle Eastern buyers may require compliance with local safety regulations. Understanding these nuances helps buyers effectively communicate their requirements to suppliers.

Navigating Import Regulations

When sourcing vehicles or components internationally, buyers must also consider import regulations that may affect the quality of the products received. This includes understanding tariffs, trade agreements, and local compliance requirements, which can influence the overall cost and quality assurance processes.

Building Long-Term Supplier Relationships

Establishing strong relationships with suppliers can enhance quality assurance. Open communication about quality expectations and continuous feedback can lead to improvements in manufacturing processes and product quality. Buyers should prioritize suppliers who are willing to engage in collaborative quality initiatives.

By understanding the manufacturing processes and quality assurance protocols for the Ford Super Duty Custom, international B2B buyers can make informed decisions and ensure they partner with reliable suppliers who meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ford super duty custom’

Introduction

Navigating the procurement of a Ford Super Duty Custom can be complex, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This step-by-step checklist is designed to streamline your sourcing process, ensuring that you make informed decisions while maximizing value and minimizing risks.

Step 1: Define Your Technical Specifications

Before you start reaching out to suppliers, it’s vital to have a clear understanding of your specific requirements. Define the model, engine type, transmission, and any customization options that are critical for your operations.

- Why it matters: Clear specifications help in avoiding miscommunication and ensure that you receive quotes that meet your needs.

- What to look for: Consider factors like payload capacity, towing capabilities, and any industry-specific modifications required.

Step 2: Conduct Market Research

Understanding the market landscape is essential before making any purchases. Research various suppliers, their offerings, and market trends related to the Ford Super Duty Custom.

- Why it matters: This step helps you identify potential suppliers and gauge the competitive pricing landscape.

- What to look for: Pay attention to customer reviews, market share, and the geographical reach of different suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is crucial. Request company profiles, case studies, and references from buyers in similar industries or regions.

- Why it matters: A reliable supplier can significantly reduce operational risks and enhance your procurement process.

- What to look for: Check for industry certifications, years of experience, and client testimonials to assess their credibility.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers comply with industry regulations and standards. This is particularly important for international transactions.

- Why it matters: Compliance with regulations can prevent legal issues and ensure product quality.

- What to look for: Request documentation of certifications such as ISO standards, as well as compliance with local import/export regulations.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline pricing, terms, and delivery timelines.

- Why it matters: Detailed quotes help you compare offers effectively and ensure transparency in pricing.

- What to look for: Check for any hidden fees, warranty details, and the terms of after-sales support.

Step 6: Assess Logistics and Supply Chain Capabilities

Understanding the logistics and supply chain capabilities of your suppliers is crucial for timely delivery.

- Why it matters: Delays in delivery can disrupt your operations and impact customer satisfaction.

- What to look for: Inquire about shipping methods, lead times, and the supplier’s ability to handle customs clearance in your region.

Step 7: Finalize Payment Terms and Conditions

Before concluding any deal, ensure that the payment terms are clearly defined and agreeable to both parties.

- Why it matters: Clear payment terms can help avoid disputes and ensure smooth transactions.

- What to look for: Assess options such as upfront payments, credit terms, and payment methods that suit your business model.

By following this checklist, B2B buyers can navigate the complexities of procuring a Ford Super Duty Custom more effectively, ensuring that they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for ford super duty custom Sourcing

What Are the Key Cost Components for Ford Super Duty Custom Sourcing?

When sourcing Ford Super Duty customs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials can significantly influence the overall price. High-quality materials will generally increase costs but can lead to better performance and durability, which is essential for heavy-duty applications.

-

Labor: Labor costs vary by region and can be a major factor in the final pricing. Skilled labor is necessary for custom modifications, which can further increase the cost. It’s advisable to consider the labor market conditions in both the supplier’s country and your own.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce these costs, benefiting buyers in terms of pricing.

-

Tooling: Customization often requires specialized tooling. The costs associated with tool design and manufacturing can be substantial, particularly for one-off projects or unique specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the customizations meet necessary standards. While this adds to costs, it can prevent issues down the line, ultimately saving money.

-

Logistics: Shipping costs depend on the distance, mode of transport, and urgency. Understanding Incoterms is essential, as they define responsibilities regarding shipping, insurance, and tariffs.

-

Margin: Supplier profit margins can vary widely. Buyers should be aware of the market rates and negotiate accordingly to ensure they are not overpaying.

How Do Price Influencers Affect Ford Super Duty Custom Pricing?

Numerous factors can influence the pricing of Ford Super Duty customs:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. If you anticipate ongoing needs, consider negotiating for bulk pricing.

-

Specifications and Customization: The more complex the specifications or the greater the level of customization, the higher the costs. Be clear about your requirements to avoid unexpected charges.

-

Materials Quality and Certifications: The choice of materials, especially if they require certifications (e.g., ISO, CE), can impact pricing. High-quality materials may lead to a higher initial investment but can reduce maintenance costs and improve lifespan.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge a premium, but their experience can lead to better overall value.

-

Incoterms: Understanding Incoterms is critical as they dictate who pays for shipping, insurance, and customs duties. This can affect your total landed cost.

What Are the Best Tips for Negotiating Ford Super Duty Custom Prices?

-

Do Your Research: Understand the market rates for both the vehicle and the necessary customizations. This knowledge will empower you during negotiations.

-

Leverage Volume Discounts: If planning future orders, negotiate for discounts based on anticipated volume. Suppliers may be more willing to offer lower prices for guaranteed business.

-

Explore Total Cost of Ownership: Consider long-term costs, including maintenance, potential downtime, and resale value. Sometimes a higher upfront cost can lead to lower total costs over time.

-

Be Clear About Specifications: Clearly outline your requirements to avoid misunderstandings that can lead to increased costs. A well-defined scope can streamline the process and reduce unnecessary expenses.

-

Consider Different Suppliers: Don’t settle for the first quote. Obtain multiple quotes to compare pricing and services. This competition can help you secure better terms.

Important Note on Indicative Prices

Prices for Ford Super Duty customs can fluctuate based on various factors, including market conditions and supplier capabilities. Always request detailed quotes and clarify the terms before finalizing any agreements.

Alternatives Analysis: Comparing ford super duty custom With Other Solutions

Introduction: What Are the Viable Alternatives to Ford Super Duty Custom?

When considering heavy-duty vehicles like the Ford Super Duty Custom, it is essential to evaluate alternatives that may suit specific business needs. The right choice can significantly affect operational efficiency, cost management, and long-term sustainability. This analysis will compare the Ford Super Duty Custom against two noteworthy alternatives: the Chevrolet Silverado HD and the Ram 2500. Each alternative offers unique features that may appeal to international B2B buyers across various markets, including Africa, South America, the Middle East, and Europe.

Comparison Table of Ford Super Duty Custom and Alternatives

| Comparison Aspect | Ford Super Duty Custom | Chevrolet Silverado HD | Ram 2500 |

|---|---|---|---|

| Performance | Up to 450 HP, towing capacity of 37,000 lbs | Up to 445 HP, towing capacity of 36,000 lbs | Up to 410 HP, towing capacity of 19,680 lbs |

| Cost | Starting at $40,000 | Starting at $38,000 | Starting at $36,000 |

| Ease of Implementation | Requires specialized knowledge for custom builds | User-friendly interface, less customization required | Moderate customization options, familiar interface |

| Maintenance | Higher due to specialized parts | Moderate, widely available parts | Moderate, reliable but less availability in some regions |

| Best Use Case | Heavy-duty commercial use, construction, towing | Versatile for personal and commercial use | Ideal for off-road and rugged terrain |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of the Chevrolet Silverado HD?

The Chevrolet Silverado HD is an excellent alternative for businesses looking for a balance between performance and cost. Its towing capacity is slightly lower than the Ford Super Duty Custom but still robust enough for most commercial applications. The Silverado’s user-friendly interface simplifies the implementation process, making it accessible for businesses without specialized knowledge. However, its performance may not match the Ford’s in extreme conditions, and while parts are generally available, they may not have the same level of specialization as those for the Ford.

How Does the Ram 2500 Compare to the Ford Super Duty Custom?

The Ram 2500 is designed with rugged terrain in mind, making it suitable for businesses operating in challenging environments. Its lower starting price is attractive for budget-conscious buyers. However, its towing capacity is significantly less than the Ford Super Duty Custom, which could limit its effectiveness for heavy-duty tasks. Maintenance costs are moderate, but parts availability can be an issue in some regions, particularly in Africa and South America. While the Ram offers good performance for off-road capabilities, its overall versatility may not meet the demands of all commercial applications.

Conclusion: How Can B2B Buyers Choose the Right Heavy-Duty Vehicle?

Selecting the right vehicle for your business requires careful consideration of various factors, including performance needs, budget constraints, and specific operational requirements. The Ford Super Duty Custom excels in heavy-duty applications with its superior towing capacity and powerful engine. However, the Chevrolet Silverado HD and Ram 2500 present viable alternatives that offer unique advantages in cost and usability. B2B buyers should assess their specific needs, including the terrain they will navigate and the load they will carry, to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for ford super duty custom

What Are the Essential Technical Properties of Ford Super Duty Custom?

When considering a Ford Super Duty Custom for your business needs, understanding its technical specifications is crucial. These properties not only affect performance but also influence procurement decisions. Here are some key specifications to consider:

-

Material Grade: The Ford Super Duty Custom often utilizes high-strength steel and aluminum in its construction. High-strength steel enhances durability while reducing weight, which can improve fuel efficiency. For B2B buyers, sourcing vehicles made from superior materials can translate to lower maintenance costs and extended service life.

-

Towing Capacity: The towing capacity of the Super Duty Custom can reach up to 37,000 pounds, depending on the configuration. This specification is vital for businesses in logistics or construction, as it directly impacts the vehicle’s ability to transport heavy loads. Understanding your specific towing requirements can help you select the right model.

-

Payload Capacity: The payload capacity typically ranges between 4,200 and 7,850 pounds. Knowing the payload capacity is essential for businesses that frequently carry heavy materials or equipment. It allows you to maximize efficiency and ensure compliance with local regulations regarding weight limits.

-

Engine Specifications: The Super Duty Custom is equipped with powerful engine options, such as the 6.7L Power Stroke V8 Turbo Diesel. This engine not only provides significant horsepower but also enhances torque, crucial for towing and hauling. B2B buyers should assess engine performance to match their operational needs, ensuring that the vehicle can handle specific tasks without compromising efficiency.

-

Fuel Economy Ratings: Understanding the fuel economy ratings (typically around 15-20 MPG combined) is vital for cost analysis. Businesses aiming to minimize operational costs should consider vehicles that offer better fuel efficiency, as this can lead to substantial savings over time.

-

Safety Ratings: The Ford Super Duty Custom often comes equipped with advanced safety features, which can include adaptive cruise control, lane-keeping assist, and automatic emergency braking. High safety ratings are not just about compliance; they can reduce insurance costs and enhance driver confidence.

What Common Trade Terms Should B2B Buyers of Ford Super Duty Custom Know?

Navigating the procurement process requires familiarity with industry terminology. Here are some essential trade terms relevant to the Ford Super Duty Custom:

-

OEM (Original Equipment Manufacturer): This term refers to the company that makes the original parts and components of the vehicle. Understanding OEM parts is crucial for maintenance and repairs, as they ensure compatibility and quality.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in negotiating bulk purchases, which can lead to cost savings.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. Crafting a clear RFQ can streamline the purchasing process and ensure that you receive competitive offers.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risk management, and delivery obligations.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for inventory management and project planning.

-

Warranty Terms: Warranty terms outline the conditions under which a product is covered for repairs or replacements. Understanding warranty terms can help businesses assess the long-term value of their investment in vehicles like the Ford Super Duty Custom.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions, ultimately optimizing their fleet management and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the ford super duty custom Sector

What Are the Current Market Dynamics and Key Trends Affecting the Ford Super Duty Custom Sector?

The Ford Super Duty custom sector is experiencing robust growth driven by increasing demand for heavy-duty vehicles across various industries such as construction, agriculture, and logistics. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are looking for versatile, high-performance trucks that can handle demanding tasks while offering customization options. Key market dynamics include the integration of advanced technologies such as telematics and fleet management systems, which enhance operational efficiency and vehicle performance.

Another significant trend is the growing preference for electric and hybrid variants in response to environmental regulations and the push for sustainability. Buyers are increasingly seeking vehicles that not only meet their operational needs but also align with their corporate responsibility goals. Furthermore, the availability of aftermarket customization options is becoming a critical factor for international buyers, as they look to tailor vehicles to specific operational requirements. This trend reflects a shift from traditional purchasing to a more strategic sourcing approach, where companies prioritize long-term partnerships with manufacturers and suppliers that offer ongoing support and customization capabilities.

How Can Sustainability and Ethical Sourcing Impact the Ford Super Duty Custom Supply Chain?

A stock image related to ford super duty custom.

Sustainability is becoming a pivotal consideration for international B2B buyers in the Ford Super Duty custom sector. The environmental impact of vehicle production, operation, and disposal is under scrutiny, prompting buyers to demand greater transparency in the supply chain. Ethical sourcing practices are essential for reducing the carbon footprint associated with vehicle manufacturing. This includes the use of sustainable materials, such as recycled metals and eco-friendly plastics, as well as ensuring that suppliers adhere to ethical labor practices.

Moreover, certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are increasingly important for companies looking to enhance their sustainability profile. Buyers are encouraged to collaborate with manufacturers who prioritize sustainability in their operations, as this not only reduces environmental impact but also can lead to cost savings in the long run. By opting for greener alternatives, companies can improve their brand image and attract customers who value corporate responsibility.

What Is the Evolution of the Ford Super Duty Custom Sector?

The Ford Super Duty custom sector has evolved significantly over the past few decades, transitioning from basic utility vehicles to highly sophisticated machines equipped with cutting-edge technology and customization options. Initially designed for heavy-duty work, these trucks now incorporate features such as advanced safety systems, enhanced towing capabilities, and luxurious interior options. This evolution reflects changing consumer preferences and the need for vehicles that can perform in both rugged and urban environments.

As the market continues to develop, manufacturers are focusing on innovation and sustainability, responding to both regulatory pressures and consumer demand for greener vehicles. The introduction of electric models, such as the Ford F-150 Lightning, signifies a pivotal moment in the industry, paving the way for future advancements in the heavy-duty vehicle segment. For international B2B buyers, understanding this evolution is crucial for making informed purchasing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of ford super duty custom

-

How do I source Ford Super Duty custom trucks internationally?

To source Ford Super Duty custom trucks internationally, start by identifying reputable suppliers or manufacturers in the regions you are targeting. Utilize online platforms such as Alibaba or trade directories specific to automotive suppliers. Ensure that the suppliers have experience in exporting vehicles and understand the regulations in your country. It’s crucial to request product samples or specifications to ensure they meet your standards. Additionally, establish clear communication regarding customization options to align with your business needs. -

What is the minimum order quantity (MOQ) for Ford Super Duty custom trucks?

The MOQ for Ford Super Duty custom trucks can vary significantly based on the manufacturer and the level of customization required. Typically, manufacturers may set a MOQ ranging from 5 to 20 units for special orders. It’s advisable to negotiate with suppliers, especially if you are a first-time buyer. Some manufacturers may offer lower MOQs for established relationships or larger orders in the future, so maintaining an open dialogue is essential. -

What payment terms should I expect when buying Ford Super Duty custom trucks?

Payment terms for purchasing Ford Super Duty custom trucks often include options such as a deposit followed by balance payment upon delivery or a letter of credit. Suppliers may request a deposit of 30% to 50% upfront to cover initial production costs. It’s important to clarify payment methods accepted, such as wire transfers, PayPal, or other secure payment options. Always ensure that payment terms are documented in the contract to avoid disputes later. -

How can I ensure the quality of Ford Super Duty custom trucks?

To ensure the quality of Ford Super Duty custom trucks, conduct thorough supplier vetting, including checking certifications and customer reviews. Request quality assurance documentation and inquire about their manufacturing processes. If possible, arrange for a pre-shipment inspection to verify the vehicles meet your specifications. Building a strong relationship with the supplier can also facilitate better quality control and adherence to your standards. -

What customization options are available for Ford Super Duty trucks?

Customization options for Ford Super Duty trucks can include modifications such as engine upgrades, specialized cargo beds, enhanced suspension systems, and interior fittings tailored to specific needs. Work closely with your supplier to discuss available options and ensure that your specifications align with local regulations. It’s also beneficial to research popular customizations in your target market to better serve your customers. -

What logistics considerations should I keep in mind when importing Ford Super Duty custom trucks?

When importing Ford Super Duty custom trucks, consider logistics aspects such as shipping methods (e.g., container shipping, roll-on/roll-off), customs duties, and taxes. Partner with a freight forwarder experienced in vehicle transport to navigate international shipping regulations. Ensure that all necessary documentation, such as invoices, packing lists, and customs declarations, is prepared to avoid delays. Additionally, be aware of the lead times associated with production and shipping to plan your inventory accordingly. -

What are the common challenges faced in international trade of Ford Super Duty trucks?

Common challenges in the international trade of Ford Super Duty trucks include navigating complex customs regulations, potential tariffs, and language barriers. Currency fluctuations can also impact pricing and costs. It is essential to stay informed about trade agreements between your country and the supplier’s country, as these can affect duties and import regulations. Collaborating with experienced trade consultants can mitigate these risks and streamline the importing process. -

How can I effectively communicate with suppliers from different regions?

Effective communication with suppliers from different regions requires clarity and cultural sensitivity. Use clear, concise language and confirm understanding by summarizing key points in your communications. Utilize professional translation services if language barriers exist. Establish a regular communication schedule through emails, calls, or video conferences to maintain a strong relationship. Building rapport can also foster better collaboration and understanding of each other’s business practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ford super duty custom

How Can Strategic Sourcing Enhance Your Ford Super Duty Custom Experience?

In conclusion, strategic sourcing plays a pivotal role in optimizing the procurement of Ford Super Duty Custom vehicles and parts for international B2B buyers. By focusing on supplier relationships, understanding local market dynamics, and leveraging technology, businesses can significantly reduce costs while ensuring product quality and reliability. Engaging with reputable suppliers who provide OEM parts and services can streamline maintenance and enhance operational efficiency.

International buyers from Africa, South America, the Middle East, and Europe should prioritize building partnerships with suppliers that offer comprehensive support, including technical assistance and aftermarket services. This approach not only fosters trust but also enables businesses to adapt to evolving market demands.

As we look to the future, embracing a collaborative and strategic sourcing mindset will be essential in navigating the complexities of global supply chains. By staying informed and proactive, B2B buyers can position themselves for success in an increasingly competitive landscape. Start exploring your sourcing options today to unlock the full potential of your Ford Super Duty Custom investment.