Find Reliable Fiber Optic Cables Supplier: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for fiber optic cables supplier

Navigating the global market for fiber optic cables suppliers presents a unique set of challenges for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. As demand for high-speed internet and reliable communication infrastructures continues to rise, sourcing quality fiber optic cables becomes crucial. This guide offers a comprehensive overview that addresses the types of fiber optic cables available, their applications across various industries, and the nuances of supplier vetting and cost considerations.

Understanding the intricacies of fiber optic technology, such as single-mode versus multi-mode fibers, is essential for making informed purchasing decisions. Buyers will find detailed insights into how to assess the quality and reliability of suppliers, ensuring they choose partners who can meet their specific needs. Additionally, this guide will provide actionable strategies for negotiating prices and managing supply chain logistics, critical factors that can influence overall project success.

By empowering B2B buyers with the knowledge and tools to navigate this complex market, we aim to facilitate smoother procurement processes and foster long-term partnerships with reputable suppliers. Whether you are looking to enhance your telecommunications infrastructure or expand into new markets, this guide serves as your roadmap to effectively sourcing fiber optic cables while maximizing value and minimizing risk.

Understanding fiber optic cables supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Mode Fiber | Smaller core diameter (8-10 µm), allows one mode of light | Long-distance telecommunications | Pros: Low signal loss, high bandwidth; Cons: Higher cost, requires precise installation. |

| Multi-Mode Fiber | Larger core diameter (50-62.5 µm), supports multiple light modes | Short-distance data centers, LANs | Pros: Cost-effective, simpler installation; Cons: Higher dispersion over long distances. |

| Specialty Fiber | Non-standard shapes (e.g., elliptical), designed for specific applications | Medical devices, sensors, industrial uses | Pros: Tailored for niche applications; Cons: Limited availability, potentially higher costs. |

| Armored Fiber | Additional protective layer to resist physical damage | Harsh environments, outdoor installations | Pros: Enhanced durability, suitable for rugged applications; Cons: Heavier, potentially more expensive. |

| Photonic Crystal Fiber | Unique structure with periodic microstructures to manipulate light | Advanced telecommunications, research | Pros: Exceptional performance in specific wavelengths; Cons: Complex design, higher manufacturing costs. |

What are the characteristics of Single-Mode Fiber?

Single-Mode Fiber (SMF) features a small core diameter, typically between 8 to 10 micrometers, which allows only one mode of light to propagate. This design minimizes signal attenuation and dispersion, making it ideal for long-distance telecommunications, such as intercontinental data transmission. When purchasing SMF, buyers should consider installation precision and the associated costs, as the need for specialized connectors and splicing techniques can increase initial investment.

How does Multi-Mode Fiber differ in application?

Multi-Mode Fiber (MMF) has a larger core diameter, usually ranging from 50 to 62.5 micrometers, allowing multiple light modes to travel simultaneously. It is commonly used for short-distance applications like data centers and local area networks (LANs). While MMF is generally more cost-effective and easier to install than SMF, it suffers from higher modal dispersion, which can limit performance over longer distances. Buyers should assess their specific distance requirements and budget constraints when selecting MMF.

What makes Specialty Fiber suitable for niche markets?

Specialty Fiber encompasses a variety of non-standard fibers tailored for specific applications, such as medical devices and industrial sensors. These fibers often feature unique shapes, like elliptical cores, to enhance performance in particular environments. While they provide significant advantages in specialized applications, buyers should be aware of their limited availability and potentially higher costs compared to standard fiber types. Understanding the specific requirements of the intended application is crucial for making an informed purchasing decision.

Why choose Armored Fiber for challenging environments?

Armored Fiber is designed with a protective layer that enhances its resistance to physical damage, making it suitable for harsh environments and outdoor installations. This type of fiber is ideal for industries such as oil and gas, where durability is paramount. While the added protection increases the fiber’s weight and cost, the long-term benefits of reduced maintenance and downtime can justify the initial investment. Buyers should evaluate the environmental conditions and potential hazards when considering Armored Fiber.

How does Photonic Crystal Fiber enhance optical performance?

Photonic Crystal Fiber (PCF) features a unique structure with periodic microstructures that manipulate light propagation, allowing for exceptional performance across specific wavelengths. This advanced fiber type is often used in cutting-edge telecommunications and research applications. However, due to its complex design and higher manufacturing costs, PCF may not be suitable for all B2B buyers. Organizations must weigh the benefits of superior optical performance against the potential for increased expenses and availability challenges.

Related Video: Understanding Fiber Optic Cables: Types, Benefits, and Applications-Part 2

Key Industrial Applications of fiber optic cables supplier

| Industry/Sector | Specific Application of fiber optic cables supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed data transmission | Enhanced bandwidth and faster internet services | Ensure compliance with international standards and regulations. |

| Healthcare | Medical imaging and diagnostics | Improved precision in diagnostics and patient care | Look for suppliers that provide specialized medical-grade fibers. |

| Industrial Automation | Networking for IoT devices | Increased efficiency and real-time data collection | Evaluate compatibility with existing systems and scalability. |

| Security Systems | Fiber optic sensors for surveillance | Enhanced security through real-time monitoring | Assess durability and resistance to environmental factors. |

| Renewable Energy | Monitoring and control systems for solar farms | Optimized performance and energy management | Consider suppliers with experience in renewable energy applications. |

How Are Fiber Optic Cables Used in Telecommunications?

In the telecommunications sector, fiber optic cables are essential for high-speed data transmission. They enable the transfer of large amounts of data over long distances with minimal signal loss, making them ideal for internet service providers. This application resolves issues related to bandwidth limitations and latency, providing businesses with faster, more reliable internet services. International buyers, especially from regions like Africa and South America, should prioritize suppliers who adhere to global standards for quality and performance to ensure compatibility with their infrastructure.

What Role Do Fiber Optic Cables Play in Healthcare?

In the healthcare industry, fiber optic cables are utilized for medical imaging and diagnostics. They facilitate the transmission of light and images from endoscopes and other diagnostic equipment, leading to improved precision and accuracy in patient care. This application addresses challenges related to imaging clarity and data transfer speed. Buyers in the healthcare sector should seek suppliers that specialize in medical-grade fibers, ensuring compliance with health regulations and standards.

How Do Fiber Optic Cables Enhance Industrial Automation?

Fiber optic cables are increasingly used in industrial automation for networking IoT devices. They support the communication between machines, sensors, and control systems, enabling real-time data collection and analysis. This application enhances operational efficiency and reduces downtime by providing timely insights into production processes. For international B2B buyers, it is crucial to evaluate suppliers based on their ability to provide scalable solutions that integrate seamlessly with existing systems.

In What Ways Are Fiber Optic Cables Used in Security Systems?

In security systems, fiber optic cables are employed for surveillance through fiber optic sensors that detect motion and environmental changes. This technology provides enhanced security and monitoring capabilities, crucial for businesses that prioritize safety. It solves problems associated with traditional surveillance systems, such as signal interference and distance limitations. Buyers should assess the durability of the cables and their resistance to environmental factors, particularly in regions with extreme weather conditions.

How Are Fiber Optic Cables Applied in Renewable Energy?

Fiber optic cables are increasingly integral to monitoring and control systems in renewable energy applications, such as solar farms. They facilitate real-time data transmission for performance monitoring and energy management, helping to optimize energy production. This application addresses the need for efficient energy management systems in the growing renewable energy sector. Buyers should consider suppliers with proven experience in renewable energy applications to ensure the technology meets the specific demands of solar energy operations.

Related Video: Fiber optic cables: How they work

3 Common User Pain Points for ‘fiber optic cables supplier’ & Their Solutions

Scenario 1: Limited Knowledge on Fiber Optic Specifications

The Problem:

B2B buyers often struggle with the complex specifications and technical jargon associated with fiber optic cables. For instance, a telecommunications company in South America may be tasked with upgrading its network infrastructure but finds it overwhelming to choose between single-mode and multi-mode fibers. This confusion can lead to miscommunication with suppliers, resulting in purchasing cables that do not meet their operational needs or performance expectations.

The Solution:

To navigate this challenge, buyers should invest time in understanding the fundamental differences between fiber types and their applications. Engaging directly with suppliers for educational resources can be invaluable. For example, suppliers often provide detailed product datasheets, webinars, and technical support. Buyers should ask specific questions regarding the intended application of the fiber optics, such as distance, bandwidth, and environmental conditions. Additionally, creating a checklist of essential criteria—like core diameter, attenuation rates, and future scalability—will help in making informed decisions. Building a strong relationship with a knowledgeable supplier can also facilitate ongoing support and guidance tailored to specific projects.

Scenario 2: Concerns About Supply Chain Reliability

The Problem:

Supply chain disruptions can pose significant challenges for B2B buyers of fiber optic cables, especially in regions like Africa and the Middle East where logistics can be complicated. A buyer may place an order for a large quantity of cables only to find out that delays in shipping or production lead to missed project deadlines. This not only affects their business operations but can also strain relationships with clients relying on timely infrastructure upgrades.

The Solution:

To mitigate supply chain issues, buyers should prioritize sourcing from suppliers with a proven track record of reliability and transparency. Conducting thorough due diligence, including checking references and past performance, can help identify trustworthy partners. It is also advisable to establish clear communication channels for real-time updates on order status. Buyers might consider diversifying their supplier base to reduce dependency on a single source. In addition, implementing a just-in-time inventory system can help manage stock levels more effectively, ensuring that critical projects are not stalled due to unforeseen delays.

Scenario 3: High Costs and Budget Constraints

The Problem:

Budget constraints are a common pain point for international B2B buyers looking to procure fiber optic cables. For example, a company in Europe aiming to expand its network may find that the upfront costs of high-quality fiber optics exceed their budget, leading them to consider cheaper, lower-quality alternatives. This decision can result in future performance issues and increased maintenance costs, ultimately impacting their bottom line.

The Solution:

Buyers should conduct a comprehensive cost-benefit analysis before making purchasing decisions. It is crucial to weigh the initial costs against long-term performance and reliability. Suppliers often provide tiered pricing based on order volume, so negotiating bulk purchase discounts can significantly reduce costs. Exploring financing options or payment plans with suppliers can also help manage budget constraints. Additionally, opting for standardized products that are widely used can lead to more competitive pricing without sacrificing quality. Lastly, buyers should consider the total cost of ownership, which includes installation, maintenance, and potential downtime, ensuring that the selected solution aligns with their financial strategy and operational goals.

Strategic Material Selection Guide for fiber optic cables supplier

When selecting materials for fiber optic cables, international B2B buyers must consider various factors that directly impact performance, durability, and compliance with industry standards. Below, we analyze four common materials used in fiber optic cable manufacturing: glass, plastic, aramid yarn, and PVC. Each material has distinct properties, advantages, and limitations that buyers should evaluate based on their specific application needs and regional standards.

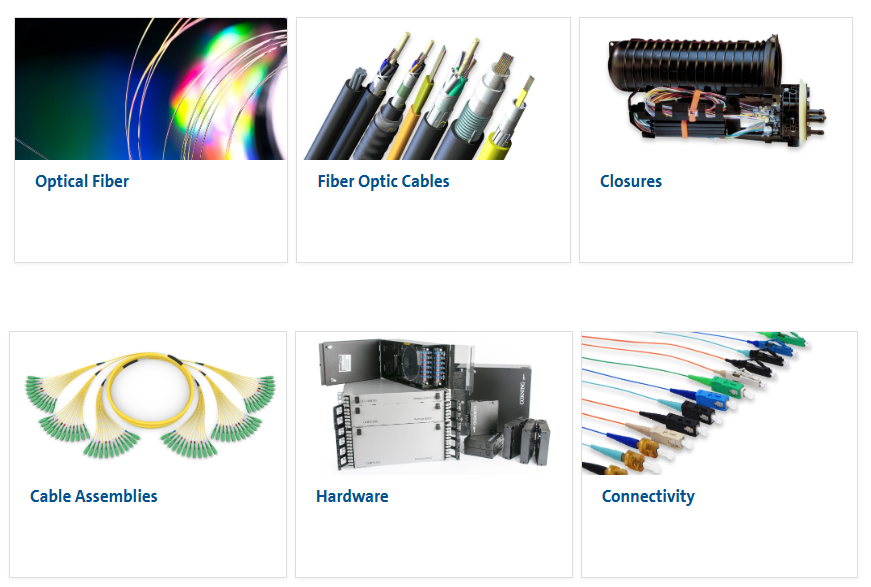

A stock image related to fiber optic cables supplier.

What Are the Key Properties of Glass Fiber in Fiber Optic Cables?

Key Properties: Glass fiber, primarily made from silica, boasts high transparency and low attenuation, making it ideal for long-distance communication. It has excellent temperature resistance (up to 85°C) and can withstand high pressures.

Pros & Cons: The durability of glass fibers is notable, as they are resistant to corrosion and environmental factors. However, they are more fragile than plastic fibers, making them susceptible to breakage during installation and handling. The manufacturing process can also be complex, leading to higher production costs.

Impact on Application: Glass fiber is particularly suited for high-bandwidth applications, such as telecommunications and data centers, where signal integrity is critical. Its compatibility with various media types enhances its versatility.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN, which govern material quality and safety. Understanding local regulations regarding telecommunications infrastructure is essential.

How Does Plastic Fiber Compare in Fiber Optic Cable Manufacturing?

Key Properties: Plastic optical fibers (POFs) are made from polymer materials, typically PMMA (polymethyl methacrylate). They are lightweight, flexible, and can operate effectively at lower temperatures (up to 70°C).

Pros & Cons: The main advantage of plastic fibers is their ease of installation and lower cost compared to glass fibers. They are more robust and less prone to breakage, making them suitable for applications where flexibility is required. However, they have higher attenuation rates, limiting their use in long-distance communications.

Impact on Application: POFs are ideal for short-distance applications, such as in-home networking and automotive systems, where flexibility and ease of installation are prioritized over long-range performance.

Considerations for International Buyers: Buyers from Africa and South America should be aware of the growing demand for cost-effective solutions in local markets. Ensuring that the plastic fibers meet international safety and performance standards is crucial.

What Role Does Aramid Yarn Play in Fiber Optic Cable Design?

Key Properties: Aramid yarn, known for its high tensile strength and thermal stability, is often used as a protective layer in fiber optic cables. It enhances the cable’s durability against physical stress and environmental factors.

Pros & Cons: The primary benefit of aramid yarn is its ability to provide excellent mechanical protection without adding significant weight. However, it can be more expensive than other protective materials, impacting overall cable costs.

Impact on Application: Aramid yarn is particularly beneficial in outdoor applications where cables are exposed to harsh conditions, such as UV radiation and extreme temperatures. Its strength helps maintain cable integrity over time.

Considerations for International Buyers: Buyers in regions like Turkey and Saudi Arabia should consider the local climate when selecting cables with aramid yarn. Compliance with local environmental regulations is also essential for outdoor installations.

Why Is PVC a Common Choice for Fiber Optic Cable Jackets?

Key Properties: Polyvinyl chloride (PVC) is widely used for cable jackets due to its excellent insulation properties and resistance to moisture and chemicals. It can operate effectively in a range of temperatures (up to 70°C).

Pros & Cons: PVC is cost-effective and easy to process, making it a popular choice for manufacturers. However, it is less environmentally friendly compared to other materials and can become brittle over time, especially in extreme conditions.

Impact on Application: PVC jackets are suitable for indoor applications where exposure to harsh environmental conditions is minimal. They provide adequate protection for most standard fiber optic installations.

Considerations for International Buyers: Buyers should be aware of the increasing regulations around the use of PVC due to environmental concerns. Ensuring compliance with local regulations regarding material safety and environmental impact is vital.

Summary Table of Material Selection for Fiber Optic Cables

| Material | Typical Use Case for Fiber Optic Cables Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Long-distance telecommunications | Low attenuation and high bandwidth | Fragile and higher manufacturing cost | High |

| Plastic | Short-distance networking | Cost-effective and flexible | Higher attenuation limits distance | Low |

| Aramid Yarn | Outdoor installations | Excellent mechanical protection | Higher cost compared to alternatives | Med |

| PVC | Indoor applications | Cost-effective and moisture-resistant | Environmental concerns and brittleness | Low |

This analysis provides a comprehensive overview of material options for fiber optic cables, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fiber optic cables supplier

What Are the Key Stages in the Manufacturing Process of Fiber Optic Cables?

The manufacturing of fiber optic cables involves several critical stages that ensure the final product meets the stringent requirements of performance and quality. Understanding these stages is essential for international B2B buyers looking to procure reliable fiber optic solutions.

1. Material Preparation: What Raw Materials Are Used?

The primary materials for fiber optic cables include high-purity silica glass for the fibers and various polymers for the protective layers. The manufacturing process begins with the preparation of these raw materials, which are sourced from reputable suppliers to ensure quality. The silica is typically refined to achieve ultra-high purity levels, essential for minimizing signal loss during transmission.

2. Forming: How Are Fiber Optics Created?

The next stage involves forming the optical fibers. This is done through methods such as:

– Modified Chemical Vapor Deposition (MCVD): A process where silica is deposited onto a rotating rod to create a preform.

– Outside Vapor Deposition (OVD): Silica is deposited on the outside of a rotating substrate to form a preform that will be drawn into fiber.

– Vapor Axial Deposition (VAD): A method that produces high-quality fibers by depositing silica vapor onto a rotating rod.

Once the preform is made, it is heated and drawn into fibers at controlled temperatures and speeds to maintain consistent diameter and optical properties.

3. Assembly: How Are Fiber Optics Bundled and Protected?

After the fibers are drawn, they are assembled into cables. This involves:

– Stranding: The individual fibers are grouped and twisted together to form a cable core.

– Jacketing: A protective outer layer is added, typically made from durable materials that provide resistance to environmental factors such as moisture, UV light, and physical abrasion.

This stage is crucial for ensuring that the fiber optic cables can withstand harsh conditions while maintaining their integrity.

4. Finishing: What Final Touches Are Added?

The finishing process involves testing the cables for performance and reliability. Cables are often marked with information such as type, length, and manufacturing date, facilitating easy identification during installation and maintenance.

What Are the International Quality Assurance Standards for Fiber Optic Cable Suppliers?

Quality assurance is critical in the fiber optic cable industry, ensuring that products meet both local and international standards. For B2B buyers, understanding these standards can help in selecting reliable suppliers.

1. ISO 9001: What Does This Standard Entail?

ISO 9001 is an internationally recognized standard that outlines requirements for a quality management system (QMS). Suppliers certified under this standard demonstrate their commitment to quality through documented processes, continuous improvement, and customer satisfaction. Buyers should look for this certification when evaluating potential suppliers.

2. CE Marking: How Does It Affect Fiber Optic Products?

CE marking indicates that a product complies with EU safety, health, and environmental protection standards. For fiber optic cables, CE marking ensures that they are safe to use in various applications across Europe, making it a crucial factor for buyers in the region.

3. API Standards: Are They Relevant?

For certain applications, especially in the oil and gas sector, API (American Petroleum Institute) standards may apply. These standards ensure that products are suitable for the demanding environments found in these industries. Buyers should verify whether the supplier’s products meet relevant API standards if applicable.

What Are the Quality Control Checkpoints in Fiber Optic Manufacturing?

Quality control (QC) is integral to the manufacturing process of fiber optic cables, encompassing several checkpoints that help identify defects and maintain high standards.

1. Incoming Quality Control (IQC): How Are Raw Materials Inspected?

IQC involves inspecting all incoming materials before they enter the production line. This step ensures that only high-quality raw materials are used, which is essential for the overall quality of the final product. Buyers should inquire about the supplier’s IQC processes and the criteria used for acceptance.

2. In-Process Quality Control (IPQC): What Monitoring Happens During Production?

IPQC involves continuous monitoring during the manufacturing process. Techniques such as real-time measurements of fiber diameter, refractive index, and attenuation are employed to ensure that the products remain within specified tolerances. Buyers can ask for data and reports from these checks to assess the supplier’s commitment to quality.

3. Final Quality Control (FQC): What Testing Is Conducted Before Shipment?

FQC is the last step before the product is shipped. It typically includes various tests such as:

– Optical performance testing: Measures loss and bandwidth.

– Mechanical testing: Assesses tensile strength and flexibility.

– Environmental testing: Evaluates the cable’s performance under extreme conditions.

Buyers should request FQC reports to ensure that the products meet their specifications before delivery.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for B2B buyers, especially when sourcing from international markets.

1. Conducting Supplier Audits: What Should Buyers Look For?

Performing audits can help buyers gain insights into a supplier’s QMS and QC practices. During audits, buyers should assess:

– Compliance with international standards.

– Effectiveness of IQC, IPQC, and FQC processes.

– Documentation practices and traceability of materials.

2. Requesting Quality Reports: What Documentation Is Essential?

Buyers should always request detailed quality reports, including IQC, IPQC, and FQC data. These reports should provide a clear picture of the quality levels maintained throughout the manufacturing process.

3. Engaging Third-Party Inspectors: How Can They Help?

A stock image related to fiber optic cables supplier.

Using third-party inspectors can provide an unbiased evaluation of a supplier’s QC practices. These inspectors can conduct comprehensive assessments and provide certification that the products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of several nuances that may affect quality control and assurance processes in different regions.

1. Regional Standards: How Do They Differ?

Quality standards can vary significantly from one region to another. For instance, while ISO standards are widely accepted globally, specific countries may have additional regulations. Buyers should familiarize themselves with local regulations in regions such as Africa, South America, the Middle East, and Europe.

2. Language Barriers: How Can They Impact Communication?

Language differences can lead to miscommunication regarding specifications and quality expectations. Buyers should ensure that they communicate clearly with suppliers and consider using professionals who can bridge the language gap.

3. Cultural Considerations: What Role Do They Play in Quality Assurance?

Cultural attitudes towards quality can vary significantly across regions. For example, some cultures may prioritize speed over quality, leading to potential issues in manufacturing processes. Buyers should engage in discussions about quality expectations and practices to ensure alignment.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting fiber optic cable suppliers, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiber optic cables supplier’

In the competitive landscape of fiber optic cable procurement, international B2B buyers must adopt a structured approach to ensure they select the right suppliers. This step-by-step checklist serves as a practical guide to help you navigate the complexities of sourcing fiber optic cables from reliable suppliers, particularly in regions like Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Understanding your project’s technical requirements is crucial before engaging with suppliers. Clearly define the type of fiber optic cables you need, including specifications like core diameter, mode (single-mode or multi-mode), and performance metrics such as attenuation and bandwidth. This clarity will streamline discussions and help suppliers provide tailored solutions.

Step 2: Conduct Market Research for Suppliers

Thorough market research is essential to identify potential suppliers. Utilize online platforms, trade shows, and industry forums to gather information about suppliers with a solid reputation. Pay attention to customer reviews and case studies that highlight their experience and service quality, particularly in your geographical area.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and references from existing customers, especially those in similar industries or regions. This step will help you assess their reliability and expertise in handling orders that meet your technical requirements.

Step 4: ✅ Verify Supplier Certifications

Ensure that your potential suppliers hold the necessary certifications, such as ISO 9001 for quality management or industry-specific certifications. These certifications serve as proof of their commitment to quality and compliance with international standards, which is particularly important when sourcing from different regions.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the fiber optic cables to conduct quality tests. Evaluate the samples for performance indicators such as signal loss and flexibility. This hands-on approach allows you to verify that the products meet your specifications and industry standards.

Step 6: Assess Pricing and Payment Terms

Once you’ve narrowed down your options, compare pricing structures and payment terms. Look for transparency in pricing and be wary of suppliers offering significantly lower prices, as this may indicate compromised quality. Discuss payment terms that align with your budget and financial planning, ensuring they are reasonable and flexible.

Step 7: Establish Communication Protocols

Effective communication is key to a successful supplier relationship. Establish clear protocols for updates on order status, delivery timelines, and any issues that may arise. Having an open line of communication will facilitate smoother transactions and help resolve potential challenges promptly.

By following this checklist, international B2B buyers can enhance their sourcing strategies for fiber optic cables, ensuring they partner with suppliers who meet their technical needs and business standards. This systematic approach not only mitigates risks but also fosters long-term relationships in the evolving telecommunications landscape.

Comprehensive Cost and Pricing Analysis for fiber optic cables supplier Sourcing

What Are the Key Cost Components for Fiber Optic Cables Suppliers?

When sourcing fiber optic cables, international B2B buyers should consider various cost components that contribute to the overall pricing structure. Understanding these elements can help in making informed purchasing decisions.

-

Materials: The primary materials used in fiber optic cables include glass and plastic fibers, which are typically derived from silica. The cost of these raw materials can fluctuate based on global supply and demand, impacting the final price of the cables. Buyers should be aware of how market trends affect material costs.

-

Labor: Labor costs can vary significantly depending on the geographical location of the supplier. Regions with higher wage standards, such as parts of Europe, may have higher production costs compared to suppliers in Africa or South America. Buyers should consider the labor market conditions when evaluating supplier pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment depreciation, and administrative costs. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Specialized tools and machinery are often required for the production of fiber optic cables. The initial investment in these tools can be substantial, influencing the pricing structure. Suppliers may pass on these costs to buyers, especially if they require custom cable solutions.

-

Quality Control (QC): Ensuring that fiber optic cables meet industry standards requires rigorous testing and quality assurance processes. The costs associated with QC can vary based on the level of certification required (e.g., ISO certifications), affecting the final price offered to buyers.

-

Logistics: Transportation and shipping costs are critical components of the overall pricing. The distance from the supplier to the buyer, as well as chosen Incoterms, can significantly impact logistics expenses. Understanding these costs can help buyers negotiate better shipping terms.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition and the supplier’s business model. Buyers should be aware of standard margins in the industry to evaluate pricing fairness.

How Do Price Influencers Affect Fiber Optic Cable Costs?

Several factors influence the pricing of fiber optic cables, which buyers should consider during the procurement process.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk purchases. Understanding MOQ policies can help buyers optimize their orders to achieve cost savings.

-

Specifications and Customization: Custom cable specifications can lead to higher costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and recognized certifications (like RoHS or CE) can increase costs but also enhance the product’s reliability and performance. Buyers should balance quality with budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and proven track record.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects shipping costs and responsibility for logistics. Buyers should clearly define these terms to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing Fiber Optic Cables?

To navigate the complex landscape of fiber optic cable pricing, international B2B buyers can employ several strategies:

-

Negotiate: Always negotiate terms and pricing with suppliers. Understanding the cost components allows buyers to identify areas where discounts may be possible.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term costs associated with installation, maintenance, and potential downtime. A lower initial price may not always equate to a better deal.

-

Consider Regional Pricing Nuances: Prices can vary significantly across regions, particularly between Europe and developing markets in Africa and South America. Buyers should research local market conditions to make informed decisions.

-

Stay Informed About Market Trends: Keeping abreast of global supply chain issues, material shortages, and geopolitical factors can provide insights into potential price changes.

Disclaimer on Indicative Prices

Prices for fiber optic cables can vary widely based on the factors mentioned above. Buyers should request quotes from multiple suppliers and consider all cost components before making a decision.

Alternatives Analysis: Comparing fiber optic cables supplier With Other Solutions

In the realm of telecommunications and data transmission, selecting the right medium is crucial for ensuring optimal performance and cost-effectiveness. While fiber optic cables are a leading choice for many businesses due to their high-speed capabilities and low signal loss, it is essential to explore alternative solutions. This analysis will compare fiber optic cables with two viable alternatives: copper cables and wireless communication technologies.

Comparison Table of Fiber Optic Cables Supplier and Alternatives

| Comparison Aspect | Fiber Optic Cables Supplier | Copper Cables | Wireless Communication Technologies |

|---|---|---|---|

| Performance | High bandwidth, low latency | Moderate bandwidth, higher latency | Variable bandwidth, subject to interference |

| Cost | Higher upfront cost | Lower initial investment | Variable cost based on technology |

| Ease of Implementation | Requires specialized installation | Easier to install, less specialized skills needed | Simple setup, no physical cabling required |

| Maintenance | Low, durable over time | Moderate, prone to corrosion | Low, but dependent on network conditions |

| Best Use Case | Long-distance, high-speed data | Short distances, lower speed applications | Mobile connectivity, flexible environments |

What are the Advantages and Disadvantages of Copper Cables?

Copper cables have been a longstanding alternative to fiber optics, especially in older installations. Their main advantage lies in their lower initial cost and ease of installation. Businesses can often utilize existing infrastructure, making them a quick solution for short-distance applications, such as local area networks (LANs).

However, copper cables come with significant drawbacks, including limited bandwidth and higher susceptibility to interference. Over longer distances, signal degradation becomes a critical issue, leading to latency and reduced data integrity. Thus, while copper may serve well in specific scenarios, it does not match the performance capabilities of fiber optics for high-demand applications.

How Do Wireless Communication Technologies Compare?

Wireless communication technologies provide a flexible alternative that can be advantageous for businesses requiring mobility and adaptability. The setup is often straightforward, with minimal physical infrastructure needed, allowing for rapid deployment.

Despite these benefits, wireless solutions can suffer from variable performance due to environmental factors, such as interference from other electronic devices and physical obstructions. Bandwidth can be inconsistent, especially in densely populated areas. Moreover, security can be a concern, as wireless signals are more susceptible to interception compared to the more secure fiber optic cables.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When considering the right solution for data transmission, B2B buyers should evaluate their specific needs, including distance, bandwidth requirements, and budget constraints. Fiber optic cables are ideal for long-distance and high-speed applications, particularly in industries such as telecommunications and data centers. Conversely, copper cables may be suitable for short-range, cost-sensitive projects, while wireless technologies provide flexibility for dynamic environments.

Ultimately, the decision should be guided by a thorough assessment of each solution’s strengths and weaknesses relative to the intended application. By doing so, businesses can ensure they choose the most effective and sustainable option for their communication needs.

Essential Technical Properties and Trade Terminology for fiber optic cables supplier

What Are the Essential Technical Properties of Fiber Optic Cables?

When selecting fiber optic cables, international B2B buyers must understand the critical technical properties that can significantly impact performance and application suitability. Here are some key specifications:

1. Material Grade: What Types of Materials Are Used in Fiber Optic Cables?

Fiber optic cables are primarily made from glass (silica) or plastic. The choice of material affects the cable’s performance characteristics, such as bandwidth and attenuation. Glass fibers are typically preferred for long-distance transmission due to their lower attenuation rates, while plastic fibers may be used for shorter distances due to their flexibility and ease of installation. Buyers should consider the specific application requirements to determine the suitable material grade.

2. Core Diameter: Why Is Core Diameter Important in Fiber Optics?

The core diameter of fiber optic cables can be categorized into single-mode (typically 8-10 microns) and multi-mode (usually 50-62.5 microns). Single-mode fibers allow only one mode of light to propagate, making them ideal for long-distance communication with minimal signal loss. In contrast, multi-mode fibers can carry multiple light modes, making them suitable for short-distance applications. Understanding core diameter helps buyers select the right fiber type for their specific communication needs.

3. Attenuation: How Does Attenuation Affect Signal Quality?

Attenuation refers to the loss of signal strength as it travels through the fiber. It is measured in decibels per kilometer (dB/km). Lower attenuation values are critical for long-distance applications to ensure signal integrity over longer runs. Buyers should always request attenuation specifications to ensure the cable meets their operational requirements.

4. Numerical Aperture (NA): What Role Does Numerical Aperture Play?

Numerical aperture measures the light-gathering ability of the fiber and indicates how much light can enter the fiber. A higher NA allows for greater light input, making installation easier and improving performance in environments with less precise alignment. This is particularly relevant for multi-mode fibers, where NA can affect bandwidth and transmission distances.

5. Operating Temperature Range: Why Is Temperature Consideration Crucial?

Fiber optic cables have specified operating temperature ranges, typically from -40°C to +85°C. Operating outside this range can lead to performance degradation or failure. Buyers should ensure that the selected cables can withstand the environmental conditions of their application, particularly in regions with extreme temperatures.

What Are Common Trade Terms Used in Fiber Optic Cable Procurement?

Understanding trade terminology is crucial for B2B buyers to navigate the procurement process effectively. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean in Fiber Optics?

An OEM refers to a company that manufactures products that are sold under another company’s brand. In the context of fiber optic cables, it often means that the cables are produced by one company and then branded by another. Buyers should understand the implications of OEM products regarding quality and warranty.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important for Buyers?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to understand as it impacts inventory management and cash flow. If the MOQ is too high, it may force buyers to purchase more than they need, leading to excess inventory.

3. RFQ (Request for Quotation): How Should Buyers Use RFQs?

An RFQ is a document issued by a buyer to request price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Using RFQs helps ensure that buyers receive competitive pricing and can compare offers effectively.

4. Incoterms (International Commercial Terms): What Are Incoterms in Fiber Optic Trade?

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for buyers to manage logistics and avoid unexpected costs.

5. Lead Time: Why Is Lead Time a Key Factor in Procurement?

Lead time refers to the time it takes from placing an order to receiving the product. It includes manufacturing and shipping time. Buyers should consider lead time when planning projects to ensure timely delivery and avoid delays in operations.

By familiarizing themselves with these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing fiber optic cables, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the fiber optic cables supplier Sector

What Are the Current Market Dynamics and Key Trends in the Fiber Optic Cables Sector?

The fiber optic cables market is experiencing significant growth driven by a surge in demand for high-speed data transmission and the expansion of telecommunications infrastructure. Global drivers include the increasing adoption of cloud computing, the Internet of Things (IoT), and the need for enhanced network security. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, it is crucial to stay informed about these trends to make informed sourcing decisions.

Emerging technologies such as 5G networks are reshaping market dynamics, necessitating the upgrade of existing fiber optic infrastructure. This transition opens up new opportunities for suppliers who can provide advanced solutions, including high-capacity single-mode and multimode fiber cables. Additionally, the rise of smart cities and industrial automation is prompting investments in fiber optic networks, particularly in urban areas of Turkey and Saudi Arabia, where digital transformation initiatives are gaining momentum.

Buyers should also consider the shift towards direct sourcing models, which are increasingly favored for their cost-effectiveness and efficiency. Collaborating directly with manufacturers allows buyers to negotiate better terms and ensure product quality. Furthermore, understanding regional market variations is essential, as factors such as local regulations and import tariffs can significantly impact sourcing strategies.

How Can Sustainability and Ethical Sourcing Impact Your Fiber Optic Cable Procurement?

Sustainability is becoming a central concern in the fiber optic cables sector. As international B2B buyers, recognizing the environmental impact of sourcing decisions is critical. The production of fiber optic cables involves significant energy use and raw materials, which can lead to environmental degradation if not managed responsibly.

Prioritizing ethical sourcing means selecting suppliers who adhere to sustainable practices, such as minimizing waste and using eco-friendly materials. Look for suppliers who possess certifications such as ISO 14001 (Environmental Management) or other green credentials that demonstrate a commitment to sustainability.

Incorporating recycled materials into the production process is also gaining traction among suppliers, offering an avenue for buyers to reduce their carbon footprint. Additionally, engaging with suppliers who invest in renewable energy sources can further enhance the sustainability of your supply chain. By integrating sustainability into procurement strategies, B2B buyers can not only comply with regulatory demands but also appeal to environmentally conscious customers and stakeholders.

What Is the Brief Evolution of the Fiber Optic Cables Industry?

The evolution of the fiber optic cables industry dates back to the 1970s when the first optical fibers were developed, primarily for telecommunications. Early adoption was limited due to high costs and technological constraints. However, advancements in manufacturing techniques and materials science, particularly the use of high-purity silica, significantly reduced production costs and improved performance.

By the 1990s, the internet boom led to a rapid increase in demand for fiber optic cables, as they provided a solution for high-bandwidth data transmission. This trend accelerated into the 2000s with the proliferation of broadband services and the introduction of fiber-to-the-home (FTTH) solutions. Today, fiber optic technology is integral to global communication networks, supporting everything from internet services to medical applications, and continues to evolve with innovations such as photonic crystal fibers and specialized sensors.

Understanding this historical context can help B2B buyers appreciate the advancements in fiber optic technology and the reliability of suppliers who have adapted to the industry’s changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of fiber optic cables supplier

-

How do I ensure quality when sourcing fiber optic cables from suppliers?

To ensure quality when sourcing fiber optic cables, start by verifying the supplier’s certifications, such as ISO 9001 or relevant industry standards. Request product samples to evaluate performance and reliability. Additionally, consider conducting factory audits or third-party inspections to assess production processes. Establish clear quality assurance protocols in your purchase agreements, including testing methods and acceptable tolerances. Collaborating with suppliers who have a proven track record in the market can also help mitigate risks associated with quality issues. -

What types of fiber optic cables are best for long-distance communication?

For long-distance communication, single-mode fiber optic cables are generally the best choice. They have a smaller core diameter, allowing only one mode of light to propagate, which minimizes signal loss and dispersion over long distances. This makes them ideal for applications requiring high bandwidth and long-range data transmission, such as telecommunications and internet backbones. However, multi-mode fibers can be suitable for shorter distances, particularly within buildings or campuses, where cost-effectiveness is a priority. -

What is the minimum order quantity (MOQ) for fiber optic cables from suppliers?

The minimum order quantity (MOQ) for fiber optic cables can vary significantly based on the supplier, product type, and customization options. Typically, MOQs can range from a few hundred meters for standard products to several kilometers for specialized cables. It is essential to discuss MOQs with potential suppliers early in the negotiation process. If you’re looking for smaller quantities, consider suppliers who offer flexible terms or stock products ready for immediate shipment. -

How can I customize fiber optic cables to meet specific project requirements?

Customizing fiber optic cables involves specifying parameters such as cable type (single-mode or multi-mode), core diameter, outer sheath material, and length. Many suppliers offer customization options to accommodate unique project requirements, including connectors, colors, and additional protective features. When discussing customization, provide detailed specifications and expected performance criteria to ensure that the final product meets your needs. It’s advisable to engage with the supplier’s engineering team to explore available options and solutions. -

What payment terms should I expect when sourcing fiber optic cables internationally?

Payment terms for international sourcing of fiber optic cables typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, particularly for customized orders. It’s important to negotiate terms that align with your cash flow and project timelines. Additionally, be aware of any currency exchange risks and consider using secure payment methods to protect your transaction. -

What logistics considerations should I keep in mind when importing fiber optic cables?

When importing fiber optic cables, consider logistics factors such as shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder experienced in handling telecommunications equipment to navigate international shipping regulations. Ensure compliance with local import regulations, including any necessary certifications and documentation. Additionally, factor in storage requirements upon arrival, especially if you’re importing large quantities that may require special handling. -

How do I vet potential fiber optic cable suppliers effectively?

Vetting potential suppliers involves assessing their experience, reputation, and product offerings. Start by checking online reviews, industry certifications, and references from other clients. Request detailed information about their manufacturing processes, quality control measures, and compliance with international standards. Engage in discussions to gauge their responsiveness and willingness to address your specific needs. Attending industry trade shows or networking events can also provide insights into potential suppliers and their capabilities. -

What are the common applications of fiber optic cables in various industries?

Fiber optic cables are widely used across various industries, including telecommunications for internet connectivity, healthcare for medical imaging and diagnostics, and manufacturing for automation systems. They are also utilized in broadcasting for high-quality video transmission, and in data centers to support high-speed data transfer. Understanding the specific applications relevant to your industry can help guide your sourcing decisions and ensure you select the appropriate fiber optic solutions for your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fiber optic cables supplier

Why is Strategic Sourcing Crucial for Fiber Optic Cables?

In the rapidly evolving telecommunications landscape, effective strategic sourcing of fiber optic cables is pivotal for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By engaging with reliable suppliers, businesses can not only reduce costs but also improve supply chain efficiency and ensure the quality of the technology that underpins their operations. Understanding the nuances of fiber optic technology—such as the differences between single-mode and multi-mode fibers, and the impact of attenuation on performance—will empower buyers to make informed decisions.

How Can Buyers Leverage Market Trends?

As the demand for high-speed internet and advanced communication systems grows, the fiber optic cable market is set to expand significantly. Buyers should keep an eye on emerging trends, including advancements in manufacturing techniques and the introduction of innovative materials that enhance performance and reduce costs. By aligning purchasing strategies with these trends, businesses can secure a competitive edge.

What Steps Should Buyers Take Next?

International B2B buyers are encouraged to take proactive steps in their sourcing strategy. This includes conducting thorough market research, leveraging supplier relationships, and considering long-term contracts to mitigate risks associated with price volatility. Engaging with industry experts and attending trade shows can also provide valuable insights into potential suppliers and technological advancements.

In conclusion, the strategic sourcing of fiber optic cables is not merely a procurement activity; it is a vital component of a company’s growth strategy. By making informed choices and staying ahead of market trends, businesses can ensure they are well-positioned to capitalize on the opportunities that the digital age presents.