Find Reliable Rigid Flex PCB Suppliers: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for rigid flex pcb supplier

In the rapidly evolving landscape of electronics, sourcing a reliable rigid flex PCB supplier is a critical challenge for international B2B buyers. As businesses increasingly integrate advanced technologies into their products, the demand for flexible, high-performance printed circuit boards continues to rise. This guide aims to equip decision-makers from Africa, South America, the Middle East, and Europe—regions known for their diverse industrial needs—with the insights necessary for informed procurement.

The comprehensive scope of this guide covers essential topics, including the different types of rigid flex PCBs, their applications across various industries, and strategies for effective supplier vetting. Additionally, we delve into cost factors, ensuring that buyers can navigate pricing structures and establish budgets that align with their operational goals.

By addressing these key areas, this resource empowers B2B buyers to make strategic purchasing decisions that not only meet their technical specifications but also enhance their competitive edge in the global market. Whether you’re in South Africa looking to innovate in telecommunications or in Brazil seeking to streamline manufacturing processes, understanding the intricacies of sourcing rigid flex PCBs is essential for success. With the right knowledge and tools, businesses can build fruitful partnerships that drive growth and innovation.

Understanding rigid flex pcb supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rigid-Flex PCB | Combines rigid and flexible substrates; versatile design | Consumer electronics, automotive | Pros: Cost-effective, widely available. Cons: Limited customization options. |

| High-Density Interconnect (HDI) Rigid-Flex PCB | Features microvias and advanced layer stacking; high performance | Telecommunications, medical devices | Pros: Excellent signal integrity, compact design. Cons: Higher manufacturing costs. |

| Multilayer Rigid-Flex PCB | Multiple layers of both rigid and flexible circuits; complex designs | Aerospace, military applications | Pros: High reliability, complex functionality. Cons: Longer lead times, potential for increased costs. |

| Single-Sided Rigid-Flex PCB | One layer of rigid and one layer of flexible circuitry; simpler structure | Basic consumer devices, wearables | Pros: Simplified design, lower cost. Cons: Limited functionality compared to multilayer options. |

| Custom Rigid-Flex PCB | Tailored to specific customer requirements; highly flexible design | Specialized industrial applications | Pros: Tailored solutions, unique specifications. Cons: Longer development time, potentially higher costs. |

What Are the Characteristics of Standard Rigid-Flex PCBs?

Standard rigid-flex PCBs are characterized by their integration of rigid and flexible substrates, allowing for versatile design configurations. These PCBs are particularly suitable for consumer electronics and automotive applications where space is limited, and reliability is crucial. When purchasing, buyers should consider the manufacturing capabilities of suppliers, as well as lead times and cost-effectiveness. The widespread availability of standard rigid-flex PCBs makes them a popular choice among international B2B buyers seeking reliable solutions without extensive customization.

How Do High-Density Interconnect Rigid-Flex PCBs Stand Out?

High-Density Interconnect (HDI) rigid-flex PCBs are distinguished by their microvias and advanced layer stacking, which enable superior performance in high-frequency applications. These are ideal for telecommunications and medical devices where signal integrity and compactness are paramount. Buyers should evaluate the supplier’s expertise in HDI technology and their ability to maintain high-quality standards. While these boards offer excellent performance, they come at a higher cost, making it essential for buyers to assess their budget versus performance needs.

Why Choose Multilayer Rigid-Flex PCBs for Complex Applications?

Multilayer rigid-flex PCBs comprise multiple layers of both rigid and flexible circuits, allowing for complex designs that are essential in aerospace and military applications. Their high reliability and ability to handle intricate functionalities make them a preferred choice in these industries. Buyers must consider the lead times associated with multilayer designs, as these can be longer due to their complexity. Additionally, the potential for increased costs should be weighed against the critical performance requirements of their applications.

What Are the Benefits of Single-Sided Rigid-Flex PCBs?

Single-sided rigid-flex PCBs feature one layer of rigid and one layer of flexible circuitry, providing a simpler structure ideal for basic consumer devices and wearables. Their straightforward design allows for lower costs and quicker production times, making them attractive for B2B buyers with budget constraints. However, the limited functionality compared to more complex options should be a key consideration. Buyers should ensure that their application requirements align with the capabilities of single-sided designs.

How Do Custom Rigid-Flex PCBs Meet Specialized Needs?

Custom rigid-flex PCBs are designed to meet specific customer requirements, offering a high degree of flexibility in design. These boards are particularly useful in specialized industrial applications where unique specifications are necessary. Buyers should assess the supplier’s ability to deliver tailored solutions and their experience in developing custom designs. While these boards provide the advantage of customization, they often come with longer development times and potentially higher costs, making it essential for buyers to balance their needs with budgetary constraints.

Related Video: Everything You Need to Know About Rigid-Flex PCB Design

Key Industrial Applications of rigid flex pcb supplier

| Industry/Sector | Specific Application of Rigid Flex PCB Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Wearable Devices | Compact design allows for lightweight products | Ensure supplier can meet low-volume production needs |

| Automotive | Advanced Driver Assistance Systems (ADAS) | Enhances safety through reliable performance | Look for suppliers with automotive-grade certifications |

| Medical Devices | Portable Diagnostic Equipment | Improves portability and ease of use | Verify compliance with medical standards (ISO, FDA) |

| Telecommunications | Mobile Communication Devices | Facilitates high-speed data transmission | Assess the supplier’s experience with high-frequency applications |

| Aerospace | Avionics Systems | Increases reliability and reduces weight | Consider suppliers with aerospace certifications (AS9100) |

What Are the Key Applications of Rigid Flex PCBs in Consumer Electronics?

In the consumer electronics sector, rigid flex PCBs are increasingly utilized in wearable devices such as smartwatches and fitness trackers. These applications require compact and lightweight designs to enhance user comfort and mobility. Rigid flex PCBs solve the challenge of space constraints while providing reliable electrical connections. For international buyers, especially from regions like South Africa and Brazil, sourcing from suppliers that offer low-volume production runs can be crucial for prototyping and market testing.

How Do Rigid Flex PCBs Enhance Automotive Safety?

In the automotive industry, rigid flex PCBs play a vital role in advanced driver assistance systems (ADAS), which are essential for enhancing vehicle safety. These PCBs support various sensors and cameras that require flexible interconnections to navigate complex geometries within vehicles. The reliability and durability of rigid flex PCBs are critical in this sector, as they must withstand harsh conditions. Buyers should prioritize suppliers with automotive-grade certifications to ensure compliance with industry standards and safety regulations.

What Role Do Rigid Flex PCBs Play in Medical Devices?

Rigid flex PCBs are pivotal in the development of portable diagnostic equipment in the medical sector. These devices benefit from the compact form factor and flexibility that rigid flex technology provides, allowing for easy integration into handheld devices. This innovation addresses the need for mobility and user-friendly designs in medical diagnostics. International B2B buyers should ensure that their suppliers comply with rigorous medical standards, such as ISO and FDA regulations, to guarantee product safety and effectiveness.

How Are Rigid Flex PCBs Used in Telecommunications?

In telecommunications, rigid flex PCBs are essential for mobile communication devices that require high-speed data transmission capabilities. These PCBs support the complex circuitry needed for modern smartphones and tablets, enabling seamless connectivity. The challenge lies in sourcing materials that can handle high-frequency applications without compromising performance. Buyers should assess suppliers’ experience and track record in producing high-frequency PCBs to ensure optimal functionality in their telecommunications products.

What Advantages Do Rigid Flex PCBs Provide in Aerospace Applications?

In the aerospace industry, rigid flex PCBs are integral to avionics systems, where reliability and weight reduction are paramount. These PCBs contribute to the overall efficiency of avionics by minimizing weight while maintaining robust performance under extreme conditions. For international buyers in the aerospace sector, it is essential to consider suppliers who hold aerospace certifications, such as AS9100, to ensure compliance with stringent industry standards and regulations.

Related Video: EMI Shielding Methods for Flex & Rigid Flex PCB Designs

3 Common User Pain Points for ‘rigid flex pcb supplier’ & Their Solutions

Scenario 1: Navigating Quality Control Issues with Rigid Flex PCBs

The Problem: In the competitive landscape of electronics manufacturing, quality control is paramount. B2B buyers often face challenges when sourcing rigid flex PCBs, particularly when suppliers are located in different regions, such as Africa, South America, or Europe. Miscommunications regarding specifications or inadequate quality assurance can lead to subpar products that may not meet rigorous industry standards, resulting in costly delays and reputational damage.

The Solution: To mitigate quality control issues, B2B buyers should establish clear and detailed specifications before engaging with suppliers. This includes providing comprehensive design files, tolerances, and performance requirements. Additionally, buyers should request samples and conduct thorough testing before committing to larger orders. Building a collaborative relationship with the supplier, including regular quality audits and feedback loops, can further enhance the quality assurance process. Consider leveraging third-party inspection services to ensure the products meet the expected standards, particularly when dealing with suppliers in regions where quality assurance practices may vary.

Scenario 2: Managing Lead Time and Delivery Challenges

The Problem: Delays in delivery can disrupt production schedules and lead to significant financial losses. International B2B buyers often experience longer lead times when sourcing rigid flex PCBs, especially from suppliers in regions like the Middle East or South America, where logistical issues may arise. Factors such as customs delays, shipping inefficiencies, and unexpected demand fluctuations can complicate timelines.

The Solution: To effectively manage lead times, buyers should engage in proactive planning and communication with their suppliers. Establishing a clear timeline that includes buffer periods for potential delays can help mitigate risks. Buyers should also inquire about the supplier’s production capabilities and inventory management practices to understand their ability to meet deadlines. Utilizing local suppliers or those with established logistics networks can reduce shipping times. Additionally, consider implementing a just-in-time (JIT) inventory system that aligns production schedules with delivery timelines, ensuring that you have the necessary components without overstocking.

Scenario 3: Addressing Cost Management in Rigid Flex PCB Procurement

The Problem: Cost management is a significant concern for B2B buyers, especially when dealing with the complexities of sourcing rigid flex PCBs. Fluctuating material costs, currency exchange rates, and hidden fees can lead to unexpected expenses. This unpredictability can strain budgets and affect overall project profitability.

The Solution: To gain better control over costs, B2B buyers should conduct a comprehensive market analysis to understand the pricing landscape for rigid flex PCBs. Engaging in negotiations with multiple suppliers can help identify the best price points and terms. It is also essential to clarify all potential costs upfront, including shipping, tariffs, and taxes, to avoid surprises later on. Implementing a long-term partnership with a reliable supplier may allow for better pricing agreements and discounts on bulk orders. Furthermore, consider alternative materials or designs that may offer cost savings without compromising quality. Regularly reviewing and adjusting procurement strategies in response to market changes can also help maintain budget adherence.

Strategic Material Selection Guide for rigid flex pcb supplier

What Are the Key Materials for Rigid Flex PCBs?

When selecting materials for rigid flex printed circuit boards (PCBs), international B2B buyers must consider various factors that impact performance, cost, and manufacturing complexity. Below, we analyze four common materials used in the production of rigid flex PCBs, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Which Materials Are Commonly Used in Rigid Flex PCBs?

1. Polyimide (PI)

Key Properties:

Polyimide is known for its excellent thermal stability, withstanding temperatures up to 400°C. It also exhibits high mechanical strength and flexibility, making it suitable for dynamic applications.

Pros & Cons:

The durability of polyimide is a significant advantage, particularly in harsh environments. However, it can be more expensive compared to other materials and may complicate the manufacturing process due to its specific processing requirements.

Impact on Application:

Polyimide is compatible with various media, including chemicals and solvents, making it ideal for applications in the aerospace and automotive industries.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and JIS, particularly in industries that demand high reliability. The higher cost may be justified in applications requiring superior performance.

2. FR-4 (Flame Retardant 4)

Key Properties:

FR-4 is a composite material made from woven glass fabric and epoxy resin, offering good electrical insulation and mechanical strength. It typically operates effectively at temperatures up to 130°C.

Pros & Cons:

FR-4 is widely used due to its balance of cost and performance. However, it is less flexible than polyimide and may not be suitable for applications requiring extensive bending.

Impact on Application:

FR-4 is commonly used in consumer electronics and telecommunications, where moderate thermal and mechanical stress is expected.

Considerations for International Buyers:

FR-4 is generally compliant with global standards, making it a safe choice for various applications. Its cost-effectiveness is appealing for buyers in developing markets like South Africa and Brazil.

3. Liquid Crystal Polymer (LCP)

Key Properties:

LCP offers excellent thermal stability and low moisture absorption, making it suitable for high-frequency applications. It can endure temperatures up to 260°C.

Pros & Cons:

The key advantage of LCP is its superior electrical performance, particularly in high-speed applications. However, the material can be more challenging to process, leading to increased manufacturing costs.

Impact on Application:

LCP is ideal for applications in telecommunications and medical devices, where performance and reliability are critical.

Considerations for International Buyers:

Buyers must consider the higher costs associated with LCP and ensure that their suppliers can meet stringent quality standards. Compliance with regional regulations is essential, especially in the medical sector.

4. Polyethylene Terephthalate (PET)

Key Properties:

PET is known for its excellent chemical resistance and good electrical insulation properties, withstanding temperatures up to 120°C.

Pros & Cons:

While PET is cost-effective and offers decent performance, it may not provide the same level of thermal stability and mechanical strength as other materials like polyimide or LCP.

Impact on Application:

PET is commonly used in lower-stress applications, such as consumer electronics and packaging.

Considerations for International Buyers:

Given its lower cost, PET may be attractive for buyers in emerging markets. However, they should be mindful of its limitations in high-performance applications and ensure that it meets local compliance standards.

Summary Table of Material Selection for Rigid Flex PCBs

| Material | Typical Use Case for rigid flex pcb supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) | Aerospace, Automotive | Excellent thermal stability | Higher cost, complex manufacturing | High |

| FR-4 | Consumer Electronics, Telecommunications | Cost-effective, good performance | Less flexible | Medium |

| Liquid Crystal Polymer (LCP) | Telecommunications, Medical Devices | Superior electrical performance | Higher processing costs | High |

| Polyethylene Terephthalate (PET) | Consumer Electronics, Packaging | Cost-effective, decent performance | Limited thermal stability | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions when sourcing rigid flex PCBs, ensuring that they choose materials that align with their specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rigid flex pcb supplier

What Are the Key Stages in the Manufacturing Process of Rigid Flex PCBs?

The manufacturing process of rigid flex printed circuit boards (PCBs) involves several critical stages that ensure the final product meets the necessary performance and reliability standards. Understanding these stages is essential for B2B buyers looking for quality suppliers. The main stages include:

-

Material Preparation

– Material Selection: The process begins with choosing the right materials, such as polyimide substrates for flexibility, copper for conductors, and adhesives that provide robust bonding.

– Layer Stack-Up: The stack-up configuration is crucial, as it determines the electrical performance and mechanical stability of the PCB. Buyers should verify that suppliers can customize stack-ups based on specific project requirements. -

Forming

– Copper Foil Lamination: The selected copper foil is laminated onto the substrate using heat and pressure. This stage is vital for ensuring good adhesion and uniform thickness.

– Etching: The unwanted copper is removed through chemical etching, leaving behind the desired circuit patterns. Buyers should inquire about the etching methods used, as advanced techniques can enhance precision. -

Assembly

– Component Placement: Automated pick-and-place machines are used for placing components accurately on the PCB. This stage is critical for ensuring high-density component layouts.

– Soldering: Techniques such as reflow soldering or wave soldering are employed to secure components. Buyers should confirm that suppliers use reliable soldering methods to ensure durability. -

Finishing

– Surface Finish: The final finish, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to enhance solderability and prevent oxidation.

– Testing and Inspection: Before shipping, the finished PCBs undergo rigorous testing to ensure they meet the required specifications.

How Do Quality Assurance Standards Impact Rigid Flex PCB Suppliers?

Quality assurance (QA) is paramount in the manufacturing of rigid flex PCBs. For international buyers, understanding the standards and checkpoints in place can significantly influence supplier selection.

-

International Quality Standards

– ISO 9001 Certification: This standard ensures that the supplier has a quality management system that consistently meets customer and regulatory requirements. Buyers should request ISO certification documentation to assess compliance.

– Industry-Specific Certifications: Depending on the application, certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas applications might be relevant. Buyers should ensure suppliers hold the necessary certifications for their target markets. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): Materials are inspected upon arrival to confirm they meet specified standards. Buyers can request reports or documentation related to IQC processes.

– In-Process Quality Control (IPQC): During manufacturing, various checkpoints ensure that processes are followed correctly. This might include visual inspections and automated testing.

– Final Quality Control (FQC): Before shipment, the finished products undergo rigorous testing to ensure functionality and reliability. Buyers should inquire about the types of tests performed, such as electrical testing, thermal cycling, and mechanical stress tests.

What Common Testing Methods Are Used in Rigid Flex PCB Manufacturing?

Testing is a crucial part of the manufacturing process, helping to ensure that the rigid flex PCBs meet performance standards. Here are some common testing methods:

- Electrical Testing: This includes continuity tests and short-circuit tests to verify that electrical paths are functioning correctly.

- Thermal Cycling Tests: These tests assess the PCB’s ability to withstand temperature fluctuations, which is particularly important for applications in extreme environments.

- Mechanical Stress Testing: This involves subjecting the PCBs to physical stress to evaluate their durability and resistance to flexing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insights into the supplier’s manufacturing processes and quality assurance practices. Buyers should schedule visits or request audit reports.

-

Request Quality Assurance Documentation: Suppliers should provide documentation related to their quality management systems, including certifications, inspection reports, and testing protocols.

-

Engage Third-Party Inspection Services: Utilizing independent inspection services can offer an unbiased evaluation of the supplier’s quality control measures. This is especially useful for buyers who are unable to visit suppliers in person.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing from international suppliers, B2B buyers should be aware of certain nuances in quality control that may vary by region:

- Regulatory Compliance: Different countries have varying regulatory requirements for electronic components. Buyers must ensure that suppliers comply with local regulations in their respective markets.

- Cultural Differences: Understanding cultural differences in business practices can aid in effective communication with suppliers. For instance, negotiation styles and quality expectations may vary.

- Logistics and Shipping Considerations: Quality control does not end at manufacturing. Buyers should consider how products are handled during shipping and storage, as these factors can impact the final quality.

In conclusion, understanding the manufacturing processes and quality assurance standards for rigid flex PCBs is crucial for B2B buyers. By focusing on key stages, quality control checkpoints, testing methods, and supplier verification practices, buyers can make informed decisions and ensure they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rigid flex pcb supplier’

In the competitive landscape of electronics manufacturing, sourcing a reliable rigid flex PCB supplier is critical for product performance and success. This guide provides a step-by-step checklist designed for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By following these actionable insights, you can streamline your sourcing process and ensure you select a supplier that meets your technical and business needs.

Step 1: Define Your Technical Specifications

Understanding your product requirements is the foundation of a successful sourcing process. Specify the technical parameters of your rigid flex PCBs, including dimensions, layer count, materials, and thermal performance. This clarity helps you communicate effectively with potential suppliers and ensures that they can meet your specific needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential rigid flex PCB suppliers. Utilize online directories, industry trade shows, and referrals from trusted contacts to create a shortlist. Pay attention to suppliers’ experience, specializations, and geographical presence, as these factors can influence lead times and shipping costs, particularly for buyers in regions like Africa or South America.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that the suppliers hold relevant certifications such as ISO 9001 or IPC standards. These certifications indicate adherence to industry best practices and quality management systems. A supplier with the right certifications is more likely to deliver consistent and reliable products, reducing the risk of defects and costly delays.

Step 4: Request Samples and Prototypes

Obtaining samples or prototypes is crucial to assess the quality of a supplier’s work. Evaluate the samples for adherence to your specifications, quality of materials used, and overall craftsmanship. This step not only helps you gauge the supplier’s capabilities but also provides insight into their responsiveness and willingness to accommodate your needs.

Step 5: Assess Production Capabilities

Understanding a supplier’s production capacity is essential, especially for large-scale projects. Inquire about their manufacturing processes, lead times, and the technology they use. Consider factors such as their ability to handle your volume requirements and their flexibility in scaling production as your business grows.

Step 6: Evaluate Pricing and Payment Terms

Compare pricing among your shortlisted suppliers, but remember that the cheapest option may not always be the best. Analyze the total cost of ownership, including shipping, customs duties, and any potential tariffs. Furthermore, discuss payment terms and conditions to ensure they align with your cash flow management strategies.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Make sure to establish clear lines of communication with your chosen supplier, including language preferences and time zone considerations. Regular updates and open dialogue will help preempt potential issues and ensure a smoother collaboration.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing rigid flex PCBs more effectively. Each step is crucial for building a successful partnership that meets both technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for rigid flex pcb supplier Sourcing

What Are the Key Cost Components in Rigid Flex PCB Supplier Sourcing?

When sourcing rigid flex PCBs, understanding the cost structure is crucial for B2B buyers. The total cost typically consists of several components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

- Materials: The choice of materials significantly impacts pricing. High-quality substrates, copper, and adhesives will elevate costs but may enhance performance and longevity.

- Labor: Labor costs vary based on the region and the skill level required for PCB fabrication. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality standards are met.

- Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. These can vary widely based on the supplier’s location and operational efficiency.

- Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should inquire about tooling fees and whether they are amortized over a certain volume of orders.

- Quality Control (QC): Rigorous QC processes ensure product reliability. Suppliers with advanced QC measures may charge higher prices, but this investment often leads to fewer defects and lower long-term costs.

- Logistics: Shipping and handling costs can add up, particularly for international shipments. Factors like distance, shipping method, and customs duties play a role in determining logistics expenses.

- Margin: Suppliers will include a margin based on their business model and market conditions. Understanding the typical margins in the industry can help buyers gauge the fairness of quoted prices.

How Do Price Influencers Impact Rigid Flex PCB Costs?

Several factors influence the pricing of rigid flex PCBs. Understanding these can aid buyers in negotiating better deals.

- Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should assess their needs and consider negotiating MOQs to optimize pricing.

- Specifications and Customization: Custom designs or specific requirements can drive up costs. Buyers must balance customization needs with budget constraints.

- Materials and Quality Certifications: The use of premium materials and certifications (such as ISO or IPC standards) can increase costs but also enhance product reliability and compliance with industry standards.

- Supplier Factors: The supplier’s reputation, experience, and production capabilities can affect pricing. Established suppliers may charge a premium for their reliability and quality assurance.

- Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can influence who bears the cost of shipping, insurance, and customs, thereby affecting the total cost.

What Buyer Tips Can Help in Negotiating Rigid Flex PCB Prices?

International B2B buyers must adopt strategic approaches to ensure cost-efficiency when sourcing rigid flex PCBs.

- Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. A well-prepared buyer can leverage market knowledge and supplier competition to secure better deals.

- Consider Total Cost of Ownership (TCO): Evaluate the total cost, including initial purchase price, maintenance, and potential downtime. Sometimes, a higher initial investment in quality can lead to lower TCO.

- Understand Pricing Nuances: Prices can vary significantly based on geography. For buyers from Africa, South America, the Middle East, and Europe, it’s essential to understand local market conditions, currency fluctuations, and trade regulations that may affect pricing.

- Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Suppliers are more likely to offer favorable terms to repeat customers.

- Request Detailed Quotes: Always ask for detailed quotations that break down costs. This transparency helps in understanding the pricing structure and identifying areas for negotiation.

Disclaimer on Indicative Prices

It’s important to note that the prices for rigid flex PCBs can fluctuate based on market conditions, material availability, and technological advancements. Buyers should always seek updated quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing rigid flex pcb supplier With Other Solutions

When evaluating solutions for printed circuit boards, it is crucial for international B2B buyers to consider various alternatives to rigid flex PCB suppliers. The choice of technology can significantly impact product design, manufacturing efficiency, and overall costs. Below is a comparative analysis of rigid flex PCBs against two viable alternatives: traditional rigid PCBs and flexible PCBs.

| Comparison Aspect | Rigid Flex PCB Supplier | Traditional Rigid PCB | Flexible PCB |

|---|---|---|---|

| Performance | High performance with flexibility for compact designs | Excellent for stable environments, limited flexibility | Good flexibility and lightweight, but lower durability |

| Cost | Higher initial cost but potential long-term savings | Generally lower upfront costs | Mid-range costs, depending on complexity |

| Ease of Implementation | Moderate complexity due to design requirements | Straightforward implementation | Requires specialized assembly techniques |

| Maintenance | Low maintenance with high reliability | Low maintenance, but less adaptable | Can be more vulnerable to wear and tear |

| Best Use Case | Advanced electronics requiring space optimization | Standard applications with stable conditions | Wearable devices and applications needing bending |

What Are the Advantages and Disadvantages of Traditional Rigid PCBs?

Traditional rigid PCBs are often favored for their lower initial costs and straightforward manufacturing processes. They are suitable for applications where the components do not require flexibility, such as consumer electronics and automotive systems. However, their lack of adaptability can be a significant drawback in designs that require space optimization or complex geometries.

How Do Flexible PCBs Compare to Rigid Flex PCBs?

Flexible PCBs offer a lightweight and compact solution that is ideal for applications like wearables and portable devices. They can bend and twist, making them suitable for tight spaces. However, they often come with durability concerns, as they may wear out faster than their rigid counterparts. Additionally, the assembly process can be more complex, potentially leading to increased labor costs.

Conclusion: Which PCB Solution Should You Choose for Your Needs?

Choosing the right PCB solution depends on specific project requirements, including design complexity, performance needs, and budget constraints. Rigid flex PCBs provide a balance of performance and flexibility but come at a higher cost, making them ideal for advanced applications where space is a premium. Traditional rigid PCBs are best for stable environments with less need for adaptability, while flexible PCBs are perfect for innovative designs requiring a lightweight and compact form factor. International B2B buyers should carefully assess these factors to select the most suitable PCB solution for their projects, taking into account both current needs and future scalability.

Essential Technical Properties and Trade Terminology for rigid flex pcb supplier

What Are the Key Technical Properties of Rigid Flex PCBs?

When sourcing rigid flex PCBs, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that B2B buyers should consider:

1. Material Grade

The material grade of a rigid flex PCB significantly impacts its performance and reliability. Common materials include polyimide and FR-4, each offering different thermal and electrical properties. High-grade materials ensure durability in harsh environments, making them ideal for applications in sectors like aerospace and medical devices. Buyers should prioritize material grades that align with their specific operational needs to avoid costly failures.

2. Layer Count

The layer count refers to the number of conductive layers within the PCB. Rigid flex PCBs can range from single-layer to multi-layer designs. A higher layer count allows for more complex circuit designs and increased functionality but also raises production costs. Understanding the required layer count is essential for balancing performance and budget constraints.

3. Tolerance

Tolerance defines the permissible limits of variation in a PCB’s dimensions and features, such as hole sizes and trace widths. Common tolerances range from ±0.05 mm to ±0.1 mm. Tight tolerances are vital for high-frequency applications, where signal integrity is paramount. B2B buyers should evaluate their application requirements to determine the necessary tolerance levels for optimal performance.

4. Thermal Management

Thermal management properties are crucial for ensuring that the PCB can dissipate heat effectively, thereby prolonging its lifespan and maintaining performance. Rigid flex PCBs often incorporate thermal vias and heat sinks. Buyers should assess the thermal characteristics of their applications to select a PCB that can handle operational heat loads without failure.

5. Flexibility and Bend Radius

Flexibility refers to the ability of the PCB to bend without compromising its functionality. The bend radius is the minimum radius to which the PCB can be bent. This property is particularly important for applications requiring dynamic movement, such as wearable technology. Buyers should inquire about the flexibility and bend radius specifications to ensure compatibility with their design requirements.

Which Trade Terms Should B2B Buyers Understand When Dealing with Rigid Flex PCB Suppliers?

Familiarizing oneself with industry terminology is essential for effective communication and negotiation with suppliers. Here are some common terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rigid flex PCBs, understanding OEM relationships can help buyers identify quality standards and ensure compatibility with their existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers, as it directly affects inventory levels and cash flow. Understanding MOQ requirements can aid in budget planning and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should prepare detailed RFQs that outline their technical specifications and requirements to receive accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can help buyers negotiate better shipping terms and understand their cost responsibilities.

5. DFM (Design for Manufacturability)

DFM refers to the principles used to design a product that is easy to manufacture. By incorporating DFM principles into their designs, B2B buyers can reduce production costs and lead times, enhancing the overall efficiency of the manufacturing process.

Understanding these technical properties and trade terms equips B2B buyers from Africa, South America, the Middle East, and Europe with the knowledge needed to make strategic purchasing decisions in the rigid flex PCB market.

Navigating Market Dynamics and Sourcing Trends in the rigid flex pcb supplier Sector

What are the Current Market Dynamics and Sourcing Trends in the Rigid Flex PCB Sector?

The rigid flex PCB sector is experiencing significant growth driven by the increasing demand for compact, lightweight electronic devices across various industries, including automotive, telecommunications, and consumer electronics. Key trends shaping the market include the rising adoption of Internet of Things (IoT) devices and the proliferation of smart technology, which necessitate advanced circuit designs that rigid flex PCBs provide. International buyers from regions such as Africa, South America, the Middle East, and Europe must stay informed about these trends to leverage opportunities in their local markets.

Another emerging trend is the shift towards automation and advanced manufacturing processes. Technologies like 3D printing and automated assembly are enhancing production efficiency and reducing lead times, which is crucial for B2B buyers seeking competitive pricing and rapid product delivery. Additionally, the integration of artificial intelligence in manufacturing processes is allowing suppliers to predict market demands more accurately, enabling international buyers to align their sourcing strategies accordingly.

Furthermore, geopolitical factors and trade regulations are influencing sourcing dynamics. For instance, buyers must navigate tariffs and trade agreements that may impact costs and supply chain reliability. Understanding these market dynamics is essential for international B2B buyers to make informed sourcing decisions and establish resilient supply chains.

A stock image related to rigid flex pcb supplier.

How is Sustainability Impacting the Rigid Flex PCB Supply Chain?

Sustainability is becoming a pivotal concern in the rigid flex PCB sector, with environmental impacts driving the demand for greener manufacturing practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through reduced waste, energy-efficient processes, and lower carbon footprints. This trend is particularly prominent among international buyers from Europe, where stringent environmental regulations are in place.

Moreover, ethical sourcing is gaining traction, as businesses seek to ensure that their supply chains are free from labor exploitation and environmentally harmful practices. Buyers should consider suppliers that hold certifications such as ISO 14001 for environmental management and R2 (Responsible Recycling) for responsible recycling practices. These certifications not only indicate compliance with international standards but also enhance a company’s reputation among environmentally conscious consumers.

The use of eco-friendly materials is another aspect of sustainability that buyers should consider. Rigid flex PCB suppliers are increasingly offering materials that are recyclable or derived from sustainable sources. By prioritizing suppliers with sustainable practices, international B2B buyers can contribute to a more ethical supply chain while also meeting the growing demand for environmentally friendly products.

What is the Historical Context of Rigid Flex PCB Development?

The evolution of rigid flex PCBs can be traced back to the late 20th century when the demand for more compact electronic components began to rise. Initially, these PCBs were primarily used in military and aerospace applications due to their durability and reliability under extreme conditions. Over time, advancements in materials science and manufacturing techniques led to wider adoption across various sectors, including consumer electronics and medical devices.

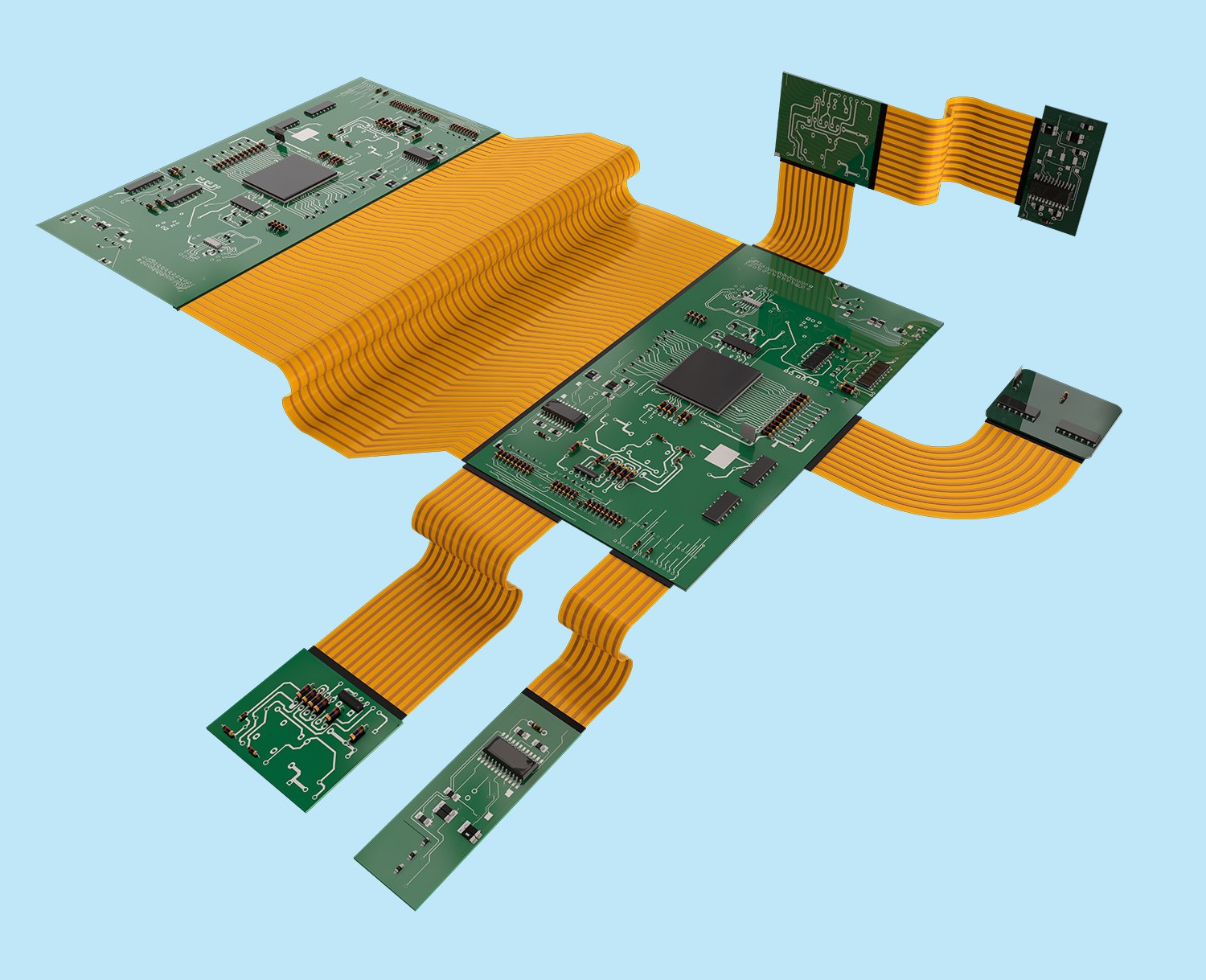

A stock image related to rigid flex pcb supplier.

The introduction of advanced materials such as polyimide and improved lamination processes has significantly enhanced the performance and flexibility of rigid flex PCBs. This historical context is essential for B2B buyers to understand the technological advancements that have shaped current offerings in the market. As these products continue to evolve, international buyers can leverage this knowledge to make informed decisions and select suppliers that are at the forefront of innovation in the rigid flex PCB sector.

Frequently Asked Questions (FAQs) for B2B Buyers of rigid flex pcb supplier

-

How can I evaluate a rigid flex PCB supplier’s reliability?

To assess a supplier’s reliability, review their track record by examining customer testimonials and case studies. Request references from previous clients, particularly those in your industry, to gain insights into their experiences. Furthermore, verify certifications such as ISO 9001, which indicate adherence to quality management standards. Conducting site visits can also provide a firsthand view of their manufacturing capabilities and quality control processes. -

What are the key factors to consider when selecting a rigid flex PCB supplier?

Key factors include the supplier’s experience in your specific industry, their manufacturing capabilities, and the technology they use. Additionally, consider their ability to meet your design specifications, lead times, and flexibility in order quantities. It’s also crucial to evaluate their communication practices and customer service responsiveness, as these can significantly impact project success. -

How do I negotiate payment terms with a rigid flex PCB supplier?

Start by understanding common payment practices in your target region, as they can vary significantly. Propose terms that align with your cash flow needs, such as partial payments upfront and the remainder upon delivery or after successful testing. Be transparent about your budget constraints and seek flexibility in payment schedules. Establishing a good rapport with the supplier can lead to more favorable terms over time. -

What minimum order quantities (MOQ) should I expect from rigid flex PCB suppliers?

MOQs can vary widely among suppliers, often depending on the complexity and technology of the PCBs. Typically, you might encounter MOQs ranging from 50 to several hundred units. If your project requires a lower quantity, discuss the possibility of exceptions or inquire about the costs associated with smaller runs. Some suppliers may offer prototype services that allow you to order smaller quantities for testing. -

How can I ensure quality assurance from my rigid flex PCB supplier?

To ensure quality, inquire about the supplier’s quality assurance processes, including testing protocols and inspection methods. Request documentation of their quality certifications and ask about their defect rates. Establish clear quality expectations in your contract and consider including penalty clauses for failure to meet these standards. Regular communication and updates during production can also help maintain quality oversight. -

What are the logistics considerations when importing rigid flex PCBs?

Logistics considerations include shipping methods, customs regulations, and potential tariffs that may apply to your imports. Choose a supplier experienced in international shipping to navigate these complexities effectively. It’s advisable to work with a freight forwarder who understands the specifics of PCB shipments. Additionally, factor in lead times for production and shipping to ensure timely delivery aligned with your project timelines. -

How can I customize rigid flex PCBs to meet my specific needs?

Customization options often include size, layer count, materials, and specific electrical characteristics. Discuss your design requirements with potential suppliers early in the sourcing process to ensure they can accommodate your specifications. Many suppliers provide design support services to help optimize your PCB design for manufacturability and performance. Be prepared to share detailed design files and prototypes to facilitate the customization process. -

What are the common challenges faced when sourcing rigid flex PCBs internationally?

Common challenges include language barriers, cultural differences, and varying business practices that may impact negotiations and project timelines. Quality control can also be a concern, as distance may hinder oversight. To mitigate these risks, establish clear communication channels, use detailed contracts, and consider working with local agents or representatives who understand the nuances of the region. Building strong relationships with suppliers can also enhance collaboration and trust.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rigid flex pcb supplier

What are the Key Takeaways for B2B Buyers in Rigid Flex PCB Sourcing?

In the competitive landscape of rigid flex PCB suppliers, international B2B buyers must prioritize strategic sourcing to maximize value. Understanding the unique demands of your industry—whether in telecommunications, automotive, or consumer electronics—will enable you to identify suppliers that not only meet technical specifications but also align with your long-term business objectives. Key takeaways include emphasizing quality assurance, fostering supplier relationships, and leveraging global sourcing strategies to mitigate risks associated with supply chain disruptions.

How Does Strategic Sourcing Enhance Supply Chain Resilience?

Strategic sourcing is essential for enhancing supply chain resilience, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By diversifying your supplier base and establishing partnerships with reliable manufacturers, you can ensure continuity of supply and better manage costs. Furthermore, investing in local suppliers can enhance responsiveness and reduce lead times, which is crucial in today’s fast-paced market.

What Does the Future Hold for Rigid Flex PCB Buyers?

Looking ahead, the demand for rigid flex PCBs is set to grow, driven by advancements in technology and increasing adoption in various sectors. International B2B buyers are encouraged to stay informed about industry trends and innovations that could impact sourcing decisions. Engage proactively with suppliers to explore collaborative opportunities and ensure you remain competitive. By prioritizing strategic sourcing, you position your business not only to thrive today but also to adapt and flourish in the evolving landscape of tomorrow.