Find Reliable Table Suppliers: Your Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for table supplier

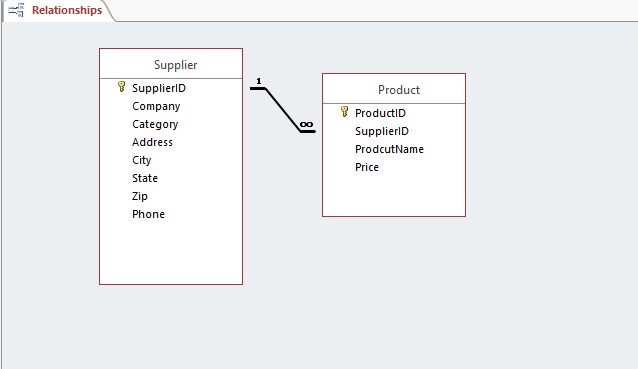

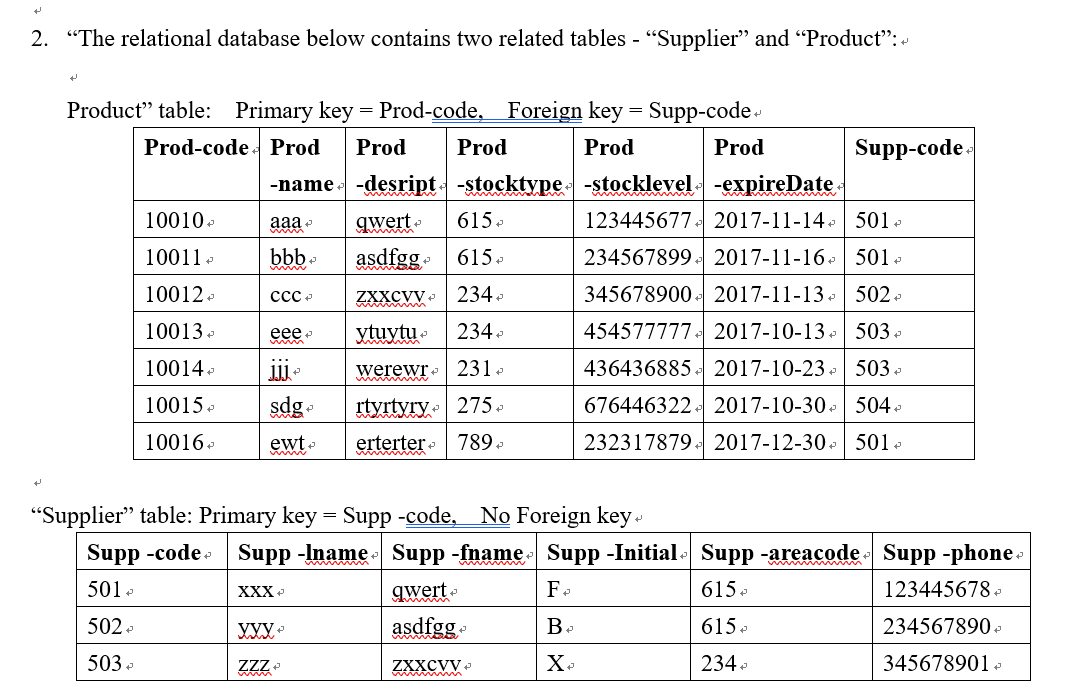

In today’s dynamic global market, sourcing the right table supplier can be a daunting task for international B2B buyers, especially when considering factors like quality, design, and cost-effectiveness. For instance, businesses in Africa, South America, the Middle East, and Europe often face challenges in finding reliable suppliers that meet their specific needs, such as sourcing ergonomic office tables that enhance productivity. This guide aims to simplify the complexities of the table supply market by providing a comprehensive overview of various types of tables, their applications across different industries, and essential strategies for vetting suppliers.

Navigating the intricate landscape of table suppliers involves understanding key elements such as material choices, manufacturing standards, and shipping logistics. This guide will delve into these aspects, offering actionable insights that empower B2B buyers to make informed purchasing decisions. With a focus on the unique challenges faced by businesses in regions like Mexico and Saudi Arabia, we will explore how to identify reputable suppliers, negotiate favorable terms, and assess total cost of ownership.

By equipping you with the knowledge to discern quality and value in your table sourcing endeavors, this guide seeks to enhance your procurement strategies and ultimately drive your business success in an increasingly competitive global market.

Understanding table supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid Wood Table Suppliers | Crafted from high-quality hardwood, durable and customizable | Furniture for hotels and restaurants | Pros: Aesthetic appeal, longevity; Cons: Higher cost, potential for warping in humid climates |

| Metal Table Suppliers | Constructed from steel or aluminum, often lightweight and stackable | Event venues, outdoor settings | Pros: Durability, ease of maintenance; Cons: Can be less comfortable, limited design flexibility |

| Glass Table Suppliers | Use tempered glass for safety, often combined with metal or wood bases | Modern offices, upscale dining | Pros: Sleek design, easy to clean; Cons: Fragility, heavier than expected |

| Folding Table Suppliers | Portable, collapsible designs, often made from plastic or lightweight materials | Trade shows, temporary events | Pros: Space-saving, easy transport; Cons: Less sturdy, limited aesthetic appeal |

| Custom Table Suppliers | Tailored designs to meet specific client needs, available in various materials | High-end retail, specialized industries | Pros: Unique designs, perfect fit; Cons: Longer lead times, potentially higher costs |

What Are the Characteristics of Solid Wood Table Suppliers?

Solid wood table suppliers focus on high-quality hardwoods like oak, maple, and cherry, which provide durability and a classic aesthetic. These tables are often customizable in terms of size, shape, and finish, making them suitable for businesses aiming for a specific look. When purchasing, B2B buyers should consider the wood type and treatment, as these factors influence durability, especially in regions with high humidity, like parts of Africa and South America.

How Do Metal Table Suppliers Stand Out?

Metal table suppliers specialize in tables made from steel or aluminum, which are known for their strength and lightweight nature. These tables are often designed for outdoor use or event spaces due to their stackable and portable features. Buyers should evaluate the finish and coatings applied to prevent rusting, particularly in humid environments such as the Middle East. While metal tables are durable, they may sacrifice comfort and aesthetic flexibility compared to wooden options.

What Are the Benefits of Glass Table Suppliers?

Glass table suppliers offer products that typically feature tempered glass for safety, supported by metal or wooden bases. These tables are ideal for modern office spaces and upscale dining establishments, where aesthetics are crucial. Buyers should consider the weight and fragility of glass tables, as they can be cumbersome to move and may require careful handling. While they are easy to clean and visually appealing, the potential for breakage is a significant factor for B2B buyers.

Why Choose Folding Table Suppliers for Temporary Solutions?

Folding table suppliers provide portable solutions that are perfect for trade shows, conferences, and temporary events. Made from lightweight materials, these tables can be easily transported and stored, making them a practical choice for businesses that require flexibility. However, buyers should be aware that while these tables are convenient, they may lack the sturdiness of solid wood or metal options. Evaluating the locking mechanisms and materials used is essential to ensure reliability.

What Is the Advantage of Custom Table Suppliers?

Custom table suppliers cater to businesses seeking unique designs tailored to specific needs, often using various materials. This option is particularly valuable for high-end retail environments and specialized industries requiring bespoke solutions. While custom tables can perfectly fit a space and brand, buyers should anticipate longer lead times and potentially higher costs. It’s crucial to communicate design specifications clearly to avoid misunderstandings and ensure satisfaction with the final product.

Related Video: Types of Contracts • Different Contracts Explained

Key Industrial Applications of table supplier

| Industry/Sector | Specific Application of table supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Restaurant and café furniture | Enhances customer experience and ambiance | Durability, design aesthetics, and compliance with local regulations |

| Education | Classroom and conference room tables | Facilitates learning and collaboration | Ergonomic design, modular options, and supplier reliability |

| Office Spaces | Workstations and meeting room tables | Improves productivity and workspace organization | Customization options, materials, and delivery timelines |

| Healthcare | Patient care and examination tables | Supports patient comfort and clinical efficiency | Hygiene standards, adjustability, and material safety |

| Retail | Display and checkout tables | Maximizes space utilization and customer engagement | Design flexibility, durability, and ease of assembly |

How is ‘table supplier’ utilized in the Hospitality Industry?

In the hospitality sector, tables are essential for creating inviting dining environments in restaurants and cafés. Suppliers focus on providing durable and aesthetically pleasing furniture that enhances the customer experience. International B2B buyers must consider factors such as compliance with local regulations regarding materials and finishes, as well as the ability to withstand high usage in busy environments. Additionally, customization options may be necessary to align with specific branding requirements.

What are the applications of ‘table supplier’ in Education?

Educational institutions utilize tables in classrooms and conference rooms to promote effective learning and collaboration among students. Suppliers of educational tables often provide ergonomic designs that support long hours of use, as well as modular options that can be reconfigured for different teaching styles. For buyers in Africa, South America, the Middle East, and Europe, it is crucial to source products that meet local safety standards and can withstand the rigors of daily use in diverse educational settings.

How are ‘table supplier’ products used in Office Spaces?

In office environments, tables are pivotal for workstations and meeting rooms. They help improve productivity by providing organized spaces for collaboration and individual tasks. Buyers should focus on suppliers that offer customizable options to fit specific office layouts and styles. Additionally, sourcing considerations include the materials used, which should be durable and conducive to a professional atmosphere, as well as timely delivery to accommodate project timelines.

What role do ‘table supplier’ products play in Healthcare?

In healthcare settings, tables are critical for patient care and examinations. They must be designed for comfort and ease of access, ensuring that healthcare professionals can perform their duties efficiently. Buyers in this sector need to prioritize hygiene standards and adjustability features in their sourcing decisions. Furthermore, international buyers must be aware of local regulations regarding medical equipment and materials to ensure compliance and safety.

How do ‘table supplier’ products enhance Retail Experiences?

Retail environments utilize tables for displays and checkouts, playing a key role in maximizing space and enhancing customer engagement. Suppliers need to provide flexible designs that can be adapted to various retail formats and promotional needs. For B2B buyers, considerations include the durability of materials, ease of assembly, and the ability to customize tables to fit specific branding strategies. Effective sourcing can lead to improved customer experiences and increased sales.

Related Video: Sources and Uses Table

3 Common User Pain Points for ‘table supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Table Supply

The Problem: B2B buyers often face significant challenges in ensuring that the tables they order meet their specific quality standards. This issue can be particularly pronounced when dealing with suppliers from different regions, where manufacturing practices and quality control measures may vary. For instance, a furniture distributor in South America might order tables from a supplier in Europe, only to discover discrepancies in material durability and finish quality upon arrival. This not only leads to financial losses due to returns but can also damage reputations if the final products do not meet customer expectations.

The Solution: To mitigate quality assurance challenges, buyers should establish clear quality specifications before placing orders. This includes detailed descriptions of materials, finishes, and durability standards tailored to the local market demands. Additionally, conducting thorough supplier evaluations—such as requesting samples or visiting manufacturing facilities—can provide insights into their quality control processes. Utilizing third-party inspection services can also help ensure that the products meet the agreed-upon specifications before shipment. By implementing these proactive measures, buyers can significantly reduce the risk of quality discrepancies and ensure customer satisfaction.

Scenario 2: Overcoming Supply Chain Disruptions and Delays

The Problem: Supply chain disruptions can be a nightmare for B2B buyers, especially when sourcing tables internationally. Factors such as political instability, customs regulations, and transportation issues can lead to unexpected delays in delivery. For example, a hotel chain in the Middle East might find that their order of dining tables from a South American supplier is delayed due to port congestion, impacting their planned renovations and guest experiences.

The Solution: To combat supply chain disruptions, buyers should diversify their supplier base and consider sourcing from multiple regions. This strategy not only minimizes the risk associated with relying on a single supplier but also allows for greater flexibility in case of delays. Additionally, maintaining open communication with suppliers about potential delays and implementing contingency plans can help manage expectations. Utilizing supply chain management software can also provide real-time updates on order status and logistics, enabling buyers to make informed decisions quickly. Building strong relationships with logistics partners can further streamline the shipping process, ensuring timely delivery of products.

Scenario 3: Managing Customization Requests and Specifications

The Problem: Many B2B buyers have unique requirements for tables based on their specific industry needs or branding strategies. For instance, a restaurant chain may require tables that can be easily rearranged for different dining layouts, while a corporate office might need desks with integrated technology solutions. When suppliers fail to accommodate these customization requests, it can lead to mismatched products that do not fulfill the buyer’s operational requirements.

The Solution: To effectively manage customization requests, buyers should engage in thorough discussions with potential suppliers early in the procurement process. Clearly outline customization needs and ask suppliers about their capabilities to meet these specifications. Providing detailed sketches, dimensions, and functional requirements can help suppliers better understand expectations. It may also be beneficial to look for suppliers that specialize in custom solutions and have a proven track record in delivering tailored products. Setting up a prototype stage in the order process allows buyers to evaluate and modify designs before full production, ensuring that the final tables meet their precise needs. By fostering a collaborative relationship with suppliers, buyers can achieve the desired customization without compromising on quality or functionality.

Strategic Material Selection Guide for table supplier

When selecting materials for table manufacturing, it is essential to consider various factors, including performance characteristics, cost, and suitability for specific applications. Below is an analysis of four common materials used in table production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Wood for Table Manufacturing?

Wood is a traditional and widely used material in table manufacturing. Its key properties include natural aesthetic appeal, good strength-to-weight ratio, and ease of machining. Different types of wood, such as oak, maple, and walnut, offer varying levels of durability and resistance to wear.

Pros & Cons:

Wood is highly durable and can be finished to enhance its appearance. However, it can be susceptible to warping, cracking, and insect damage if not properly treated. The cost of high-quality hardwood can be significant, impacting overall manufacturing expenses.

Impact on Application:

Wood tables are suitable for indoor environments and can support a variety of media, including food and beverages. However, exposure to moisture can lead to deterioration, making them less ideal for outdoor use.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider local wood sourcing regulations and sustainability certifications. Compliance with standards such as FSC (Forest Stewardship Council) can enhance marketability in Europe and the Middle East.

How Does Metal Compare as a Material for Tables?

Metal, particularly steel and aluminum, is increasingly popular for modern table designs. Key properties include high strength, resistance to corrosion (especially with stainless steel), and the ability to withstand high temperatures.

Pros & Cons:

Metal tables are exceptionally durable and can be designed for both indoor and outdoor use. However, they can be heavier and may require more complex manufacturing processes. The cost can vary significantly based on the type of metal and finishing processes involved.

Impact on Application:

Metal tables are ideal for commercial environments, such as restaurants and cafes, where durability and ease of cleaning are paramount. They can also be used in industrial settings due to their robustness.

Considerations for International Buyers:

Buyers in the Middle East may prefer stainless steel due to its corrosion resistance in humid environments. Compliance with standards such as ASTM for metals is crucial for ensuring quality and safety.

What Are the Advantages of Using Glass in Table Designs?

Glass is often used in table designs for its aesthetic appeal and modern look. Key properties include transparency, ease of cleaning, and resistance to stains.

Pros & Cons:

Glass tables can create a sense of space and light, making them suitable for contemporary interiors. However, they can be fragile and may require special handling during manufacturing and shipping. The cost of tempered glass can also be higher than other materials.

Impact on Application:

Glass tables are well-suited for decorative purposes and can be used in both residential and commercial settings. However, they may not be ideal for environments with heavy use or where durability is a concern.

Considerations for International Buyers:

When sourcing glass tables, buyers should ensure compliance with safety standards, such as those set by the European Union (EN standards). Additionally, shipping glass internationally requires careful packaging to prevent breakage.

Why is Plastic a Viable Option for Table Manufacturing?

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is gaining traction in table manufacturing. Key properties include lightweight, resistance to moisture, and ease of maintenance.

Pros & Cons:

Plastic tables are often more affordable and can be produced in various colors and designs. However, they may lack the aesthetic appeal of wood or metal and can be less durable under extreme conditions.

Impact on Application:

Plastic tables are ideal for outdoor use, such as patios and gardens, due to their resistance to weather elements. They are also easy to clean, making them suitable for casual dining environments.

Considerations for International Buyers:

Buyers in regions like South America should consider the environmental impact of plastic production and look for suppliers who adhere to recycling standards. Compliance with local regulations regarding plastic use is also crucial.

Summary Table of Material Selection for Table Suppliers

| Material | Typical Use Case for Table Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Residential and commercial furniture | Aesthetic appeal and durability | Susceptible to warping and insect damage | Medium |

| Metal | Industrial and commercial settings | High strength and corrosion resistance | Heavier and more complex manufacturing | High |

| Glass | Decorative and modern interiors | Transparency and easy maintenance | Fragility and higher shipping costs | High |

| Plastic | Outdoor and casual dining | Lightweight and affordable | Less aesthetic appeal and durability | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions when sourcing tables for various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for table supplier

What Are the Main Stages of Manufacturing Processes for Table Suppliers?

The manufacturing of tables involves several critical stages, each essential for creating high-quality products that meet international standards. Understanding these stages will help B2B buyers ensure they are partnering with suppliers who prioritize quality and efficiency.

Material Preparation: What Should Buyers Look For?

The first step in the manufacturing process is material preparation. Suppliers typically source raw materials such as wood, metal, or plastic. It’s crucial for buyers to inquire about the origin of these materials, as the quality can significantly impact the final product’s durability and aesthetics. Sustainable sourcing is increasingly important, and suppliers who demonstrate responsible procurement practices can offer a competitive advantage.

Key Techniques in Material Preparation

- Cutting: Materials are cut to specific dimensions using saws or CNC machines, ensuring precision.

- Drying and Treatment: For wooden tables, wood is often dried to reduce moisture content, preventing warping. Treatments may also be applied to enhance durability and resistance to pests.

How Are Tables Formed During Manufacturing?

The forming stage involves shaping the prepared materials into the components that will make up the table. This is where craftsmanship plays a vital role.

Common Forming Techniques

- Joinery: Techniques such as dovetail, mortise, and tenon joints are commonly used for wooden tables to ensure strength and stability.

- Molding and Casting: For metal or plastic tables, molds are created to shape the materials accurately.

- Laminating: This technique is often used for surfaces that require a veneer finish, enhancing aesthetics while maintaining strength.

What Does the Assembly Process Involve?

After forming, the next stage is assembly. This is where individual components come together to create the final product.

Assembly Techniques to Consider

- Adhesive Bonding: Strong adhesives are used to join parts, particularly in wooden furniture.

- Mechanical Fastening: Screws, bolts, and other hardware are commonly used to ensure durability and ease of disassembly.

- Final Adjustments: Quality suppliers will conduct adjustments during assembly to ensure that each table is level and stable.

What Finishing Processes Are Essential for Quality Tables?

Finishing is the final stage in the manufacturing process, significantly impacting the appearance and longevity of the table.

Key Finishing Techniques

- Sanding and Smoothing: Surfaces are sanded to create a smooth finish, essential for both aesthetics and safety.

- Staining and Painting: These processes enhance the visual appeal and protect the material from environmental factors.

- Sealing: A sealant is applied to protect surfaces from moisture and scratches, ensuring longevity.

What Are the International Quality Assurance Standards for Table Suppliers?

Quality assurance (QA) is integral to ensuring that tables meet industry standards and customer expectations. Buyers should familiarize themselves with relevant international standards.

ISO 9001: What Does It Mean for B2B Buyers?

ISO 9001 is a global standard that outlines requirements for a quality management system (QMS). Suppliers certified under this standard demonstrate their commitment to quality processes, which can give buyers confidence in their products. It’s advisable for buyers to request documentation of this certification.

Industry-Specific Certifications: Why Are They Important?

In addition to ISO 9001, other certifications may be relevant, such as CE marking for compliance with European health, safety, and environmental protection standards. For buyers in Africa and South America, understanding local certifications can also be beneficial, as they may differ from European standards.

What Are the Key Quality Control Checkpoints in Table Manufacturing?

Quality control (QC) is crucial at various stages of the manufacturing process. Understanding these checkpoints can help buyers gauge the effectiveness of a supplier’s QC measures.

Incoming Quality Control (IQC)

During IQC, raw materials are inspected upon arrival to ensure they meet specified quality standards. Buyers should ask suppliers about their IQC processes and the criteria used for material acceptance.

In-Process Quality Control (IPQC)

IPQC involves monitoring the manufacturing process to catch defects early. This may include regular inspections and measurements during the forming and assembly stages. Suppliers who employ rigorous IPQC protocols can minimize the risk of defects in the final product.

Final Quality Control (FQC)

FQC is the last line of defense before products are shipped. This inspection checks the finished tables against quality standards, including dimensions, finishes, and structural integrity. Buyers should inquire about the FQC processes and request reports to understand how defects are managed.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that a supplier adheres to stringent QC measures is essential for international buyers. Here are some actionable steps to verify a supplier’s quality control practices.

Conducting Audits: What Should Buyers Look For?

Buyers can conduct on-site audits to assess the supplier’s manufacturing processes and quality control measures. During the audit, focus on:

- Documentation: Review quality manuals, inspection reports, and certificates.

- Process Observations: Observe the manufacturing process to ensure compliance with stated practices.

- Employee Training: Evaluate the training programs for employees involved in QC.

Requesting Quality Reports: Why Are They Important?

Suppliers should be willing to provide quality reports that detail the results of IQC, IPQC, and FQC. These reports can give insight into the supplier’s commitment to quality and help identify any recurring issues.

Engaging Third-Party Inspectors: When Is It Necessary?

For added assurance, buyers can engage third-party inspection services. These independent entities can conduct unbiased inspections and provide detailed reports on the supplier’s quality control processes. This step is particularly beneficial for buyers in regions with varying quality standards.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certifications is essential for B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

Regional Variations in Standards

Quality standards can differ significantly between regions. Buyers in Europe may prioritize CE certification, while those in Africa may focus on local certifications that comply with regional regulations. It’s important to understand these differences when evaluating potential suppliers.

Cultural Considerations in Quality Assurance

Cultural attitudes towards quality assurance can also vary. In some regions, suppliers may place less emphasis on formal certifications, relying instead on reputation and word-of-mouth. Buyers should consider these cultural factors when assessing supplier quality.

By understanding the manufacturing processes and quality assurance measures that table suppliers implement, international B2B buyers can make informed decisions. This knowledge not only helps in selecting reliable suppliers but also ensures the procurement of high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘table supplier’

Introduction

Sourcing tables from reliable suppliers is essential for international B2B buyers looking to enhance their product offerings. This checklist serves as a practical guide to help you navigate the complexities of finding the right table suppliers, particularly for those operating in diverse markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can ensure a streamlined and effective procurement process.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s crucial to establish clear technical specifications for the tables you require. Consider factors such as materials, dimensions, weight capacity, and design aesthetics. This clarity will help you communicate your needs effectively and filter out suppliers that do not meet your criteria.

- Material Requirements: Specify whether you need wood, metal, or composite materials.

- Design Preferences: Determine if you want modern, traditional, or custom designs.

Step 2: Conduct Market Research on Suppliers

Understanding the landscape of potential suppliers is vital. Research various manufacturers and distributors that specialize in tables. Look for companies with a proven track record in your target regions and industries.

- Industry Directories: Utilize online platforms and trade directories to find reputable suppliers.

- Customer Reviews: Check reviews and testimonials from previous clients to gauge reliability.

Step 3: Verify Supplier Certifications

Before entering into agreements, ensure that your potential suppliers possess the necessary certifications and compliance documents. This step is critical for maintaining quality and adhering to industry standards.

- ISO Certifications: Look for ISO certifications that indicate quality management systems.

- Local Regulations: Ensure compliance with local safety and quality regulations specific to your region.

Step 4: Request Product Samples

Requesting samples is an effective way to assess the quality of the tables. This step allows you to evaluate the craftsmanship and material quality before making a bulk purchase.

- Sample Evaluation: Assess the samples for durability, finish, and overall aesthetics.

- Cost of Samples: Inquire about any associated costs and shipping timelines for the samples.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted potential suppliers, initiate negotiations on pricing, payment terms, and delivery schedules. This is where you can establish a mutually beneficial relationship.

- Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

- Payment Terms: Discuss payment methods and any advance payment requirements.

Step 6: Establish Clear Communication Channels

Effective communication is vital for successful sourcing. Ensure that you have established clear lines of communication with your chosen supplier.

- Language Considerations: If language barriers exist, consider hiring a translator or using bilingual staff.

- Regular Updates: Set expectations for regular updates on production and shipping timelines.

Step 7: Finalize Agreements and Contracts

After negotiations, finalize your agreements with legally binding contracts. This step protects both parties and clarifies all terms of the transaction.

- Legal Review: Consider having legal counsel review the contract to ensure all terms are fair and enforceable.

- Include Exit Clauses: Make sure to include clauses that outline the steps to take in case of disputes or contract termination.

By following this step-by-step checklist, you can enhance your sourcing strategy and establish productive partnerships with table suppliers that meet your specific needs.

Comprehensive Cost and Pricing Analysis for table supplier Sourcing

What Are the Key Cost Components in Table Supplier Sourcing?

When sourcing tables from suppliers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials significantly impact the overall cost. Common materials used in table production include wood, metal, and composite materials. Premium materials may increase the price but can enhance durability and aesthetics.

-

Labor: Labor costs vary by region and can be influenced by local wage rates and skill levels. In regions like Africa and South America, labor may be less expensive, while Europe and the Middle East might have higher labor costs due to stricter labor regulations and standards.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, impacting the final pricing.

-

Tooling: Custom designs often require specific tooling, which can be a significant upfront cost. Buyers should consider whether the investment in specialized tooling is justified by the volume of orders.

-

Quality Control (QC): Implementing rigorous QC measures can add to costs but is essential for ensuring product quality, especially for international shipments where standards may differ.

-

Logistics: Shipping costs can vary widely depending on the distance, method of transportation, and any tariffs or customs duties applicable. Understanding the logistics landscape is vital for accurate cost forecasting.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on competition, brand reputation, and market demand.

How Do Pricing Influencers Affect Table Supplier Costs?

Several factors influence the pricing of tables, and international buyers should be aware of these to negotiate effectively:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate MOQs accordingly.

-

Specifications and Customization: Custom tables with unique designs or specifications will generally cost more. Buyers should weigh the benefits of customization against the added costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like FSC for wood) can increase costs. Buyers need to decide the level of quality necessary for their target market.

-

Supplier Factors: The supplier’s reputation, experience, and location can also influence pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities. Understanding these terms can help buyers avoid unexpected expenses.

What Buyer Tips Can Help Optimize Table Sourcing Costs?

To navigate the complexities of table sourcing and minimize costs, buyers should consider the following strategies:

-

Effective Negotiation: Approach negotiations with clear objectives and a solid understanding of the market. Leverage multiple quotes to create competitive pressure on suppliers.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes all costs associated with purchasing, shipping, handling, and maintenance. A lower initial price may not always equate to better value if long-term costs are high.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing variations and cultural differences in negotiation styles. Building strong relationships with suppliers can lead to better pricing and terms.

-

Stay Informed About Market Trends: Regularly update knowledge on material costs, labor rates, and global supply chain issues to anticipate pricing changes and adjust sourcing strategies accordingly.

Disclaimer on Indicative Prices

Please note that the prices provided in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and consult with suppliers to get accurate pricing information tailored to your needs.

Alternatives Analysis: Comparing table supplier With Other Solutions

When evaluating suppliers for tables, it’s crucial for international B2B buyers to consider various alternatives that might meet their operational needs. The market offers several solutions, each with unique advantages and drawbacks. This comparison will focus on the ‘table supplier’ against two viable alternatives: custom furniture manufacturers and modular furniture systems.

Comparison Table of Table Supplier and Alternatives

| Comparison Aspect | Table Supplier | Custom Furniture Manufacturer | Modular Furniture System |

|---|---|---|---|

| Performance | High durability and design versatility | Tailored to specific requirements, often high quality | Flexible and adaptable to various spaces |

| Cost | Moderate to high, depending on materials | Typically higher due to bespoke nature | Generally lower, cost-effective options available |

| Ease of Implementation | Straightforward ordering process | Longer lead times due to design and manufacturing | Quick setup, often no tools required |

| Maintenance | Minimal maintenance required | May require special care based on materials | Low maintenance, easy to clean |

| Best Use Case | Standard office or commercial spaces | High-end projects requiring unique designs | Dynamic environments needing frequent reconfiguration |

How Does Custom Furniture Manufacturing Compare to Table Suppliers?

Custom furniture manufacturers excel in providing tailored solutions that meet specific business needs. These suppliers work closely with clients to create unique designs that align with branding and functional requirements. However, this level of customization often comes with a higher price tag and longer lead times, which may not suit businesses needing quick solutions or operating on a tight budget. Custom furniture is best for high-end projects where aesthetics and brand identity are paramount.

What Are the Advantages of Modular Furniture Systems Over Traditional Table Suppliers?

Modular furniture systems are designed for flexibility and adaptability, making them an excellent choice for businesses that frequently change their layouts. These systems allow for easy reconfiguration without the need for professional assembly, which can significantly reduce setup time. Moreover, they are often more cost-effective, providing a variety of options to fit different budgets. However, they might lack the durability and aesthetic appeal of traditional table suppliers, making them less ideal for upscale environments.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right supplier for tables involves careful consideration of various factors such as performance, cost, ease of implementation, and maintenance. For businesses in Africa, South America, the Middle East, and Europe, understanding the specific requirements of their operational environment is essential. If customization and unique design are critical, a custom furniture manufacturer may be the best fit. Conversely, for flexibility and cost-effectiveness, modular furniture systems present a compelling alternative. Ultimately, B2B buyers should align their choice with their business goals, budget constraints, and the specific use cases of the furniture to ensure optimal outcomes.

Essential Technical Properties and Trade Terminology for table supplier

What Are the Key Technical Properties of Tables That Buyers Should Consider?

When sourcing tables from suppliers, understanding the technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to keep in mind:

1. Material Grade

The material used in table manufacturing significantly affects its durability, aesthetics, and functionality. Common materials include solid wood, engineered wood, metal, and plastic. Each material has different grades that indicate quality and suitability for various applications. For instance, solid hardwood tables are often more durable and offer a premium feel, making them ideal for high-end markets. In contrast, engineered wood may be more cost-effective for bulk orders.

2. Dimensions and Tolerance

Dimensions refer to the physical size of the table, including length, width, and height. Tolerance indicates the allowable variation in these dimensions. Accurate measurements are essential to ensure that the tables fit the intended space and meet the specific needs of the buyer. For instance, a restaurant in Saudi Arabia may require tables that fit perfectly in a designated area, and deviations could lead to logistical issues.

3. Load Capacity

This property defines how much weight a table can support without compromising its structural integrity. Understanding load capacity is particularly important for B2B buyers in sectors like hospitality and education, where tables may need to accommodate heavy items or multiple users. A table with inadequate load capacity could result in safety hazards and additional costs for replacements or repairs.

4. Surface Finish

The surface finish not only affects the table’s appearance but also its resistance to scratches, stains, and moisture. Common finishes include varnish, lacquer, and oil. For buyers in humid regions like parts of Africa and the Middle East, selecting a finish that provides moisture resistance is vital to prolong the table’s lifespan and maintain its aesthetic appeal.

5. Sustainability Certifications

In today’s market, sustainability is a growing concern for buyers. Certifications like FSC (Forest Stewardship Council) or GREENGUARD indicate that materials are sourced responsibly and meet environmental standards. Buyers from Europe, in particular, are increasingly prioritizing eco-friendly products, making it essential for suppliers to provide this information.

What Are Common Trade Terms That B2B Buyers Should Know?

Understanding industry terminology is key to navigating the purchasing process effectively. Here are several common trade terms that international buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. For table suppliers, being an OEM means they can customize tables to meet specific requirements of their clients, allowing buyers to differentiate their offerings in the market.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can impact inventory management and cash flow. For instance, a startup in South America may not have the budget for a high MOQ but needs to negotiate a lower amount to maintain financial flexibility.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to potential suppliers requesting pricing and terms for specific products. Submitting an RFQ allows buyers to compare costs and features across different suppliers, ensuring they make the best-informed decision.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international trade. Understanding these terms helps buyers from Africa, the Middle East, and Europe clarify shipping responsibilities, risk management, and costs associated with transporting tables.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. For B2B buyers, understanding lead times is essential for planning inventory and ensuring that products are available when needed, especially in industries with high demand fluctuations.

6. Warranty

A warranty is a promise from the supplier regarding the quality and durability of the product. Knowing the warranty terms is essential for buyers to safeguard their investment and ensure recourse in case of defects or issues with the tables.

By familiarizing themselves with these essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance their procurement process and meet their specific business needs.

Navigating Market Dynamics and Sourcing Trends in the table supplier Sector

What Are the Key Market Dynamics and Trends in the Table Supplier Sector?

The global table supplier market is witnessing significant shifts driven by various factors, including technological advancements, changing consumer preferences, and economic conditions. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be particularly aware of these dynamics to make informed sourcing decisions.

One of the most notable trends is the integration of digital tools in sourcing processes. Platforms that facilitate online procurement are gaining traction, allowing buyers to streamline their purchasing operations, compare prices, and review supplier credentials more efficiently. For instance, e-commerce platforms tailored for B2B transactions are enabling suppliers to reach broader markets, thus increasing competition and driving innovation.

A stock image related to table supplier.

Moreover, sustainability is becoming a pivotal concern for buyers, with a growing emphasis on ethical sourcing practices. Suppliers that prioritize environmentally friendly materials and processes are likely to gain a competitive edge. Additionally, fluctuations in global trade policies and logistics challenges, particularly due to the ongoing impacts of the pandemic, have highlighted the need for agile supply chains. As a result, buyers are encouraged to diversify their supplier base to mitigate risks associated with over-reliance on a single source.

How Can Sustainability and Ethical Sourcing Impact Your Table Supplier Choices?

Sustainability and ethical sourcing are no longer optional considerations for B2B buyers; they are essential components of a responsible procurement strategy. The environmental impact of the table supplier sector is significant, with deforestation and pollution being major concerns. Buyers should actively seek suppliers who demonstrate a commitment to sustainable practices, such as using reclaimed wood or non-toxic finishes.

The importance of ethical supply chains cannot be overstated. Buyers must ensure that their suppliers adhere to fair labor practices and support local communities. Certifications such as FSC (Forest Stewardship Council) and LEED (Leadership in Energy and Environmental Design) provide assurance that materials used are sourced responsibly and sustainably. By prioritizing suppliers with these certifications, buyers not only contribute to environmental preservation but also enhance their brand reputation among increasingly eco-conscious consumers.

Furthermore, implementing a sustainable procurement strategy can lead to long-term cost savings. For example, investing in energy-efficient production processes can reduce operational costs while minimizing environmental footprints. As international trade regulations become more stringent concerning environmental practices, aligning with sustainable suppliers can also ensure compliance and reduce the risk of penalties.

What Is the Historical Context of the Table Supplier Market for B2B Buyers?

The table supplier sector has evolved significantly over the past few decades, transitioning from traditional craft-based production to a more industrialized approach. Historically, table manufacturing was dominated by local artisans who emphasized craftsmanship and bespoke designs. However, the rise of globalization and technological advancements has led to mass production methods that prioritize efficiency and cost-effectiveness.

As a result, international B2B buyers now have access to a diverse range of suppliers, each offering varying qualities and price points. This evolution has also fostered competition, pushing suppliers to innovate and adapt to changing market demands. Understanding this historical context can help buyers appreciate the current landscape and make strategic sourcing decisions that align with their operational goals and values.

By navigating these market dynamics and sourcing trends effectively, international B2B buyers can enhance their procurement strategies and build resilient supply chains that meet both their business needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of table supplier

-

How do I evaluate the reliability of a table supplier?

To assess the reliability of a table supplier, start by reviewing their business credentials, including registration and certifications. Look for customer testimonials and case studies that highlight their experience, especially with international clients. It’s also beneficial to request samples or visit their production facilities if possible. Engaging in direct communication can provide insights into their responsiveness and customer service. Additionally, check their online presence and industry reputation through platforms like LinkedIn or trade associations relevant to your region. -

What are the key factors to consider when selecting a table supplier?

When selecting a table supplier, consider product quality, pricing, and the supplier’s ability to meet your specific needs, including design and customization options. Assess their production capacity and lead times to ensure they can fulfill your order volume and timeline. Evaluate their logistics capabilities, especially if you are importing from overseas, to understand shipping costs and delivery times. Lastly, consider their after-sales support and warranty policies, which can be crucial for long-term partnerships. -

What customization options should I look for in a table supplier?

Customizable features can significantly enhance your product offering. Look for suppliers that provide options for materials, sizes, colors, and finishes. Some suppliers may also allow for branding, such as engraving or printing your logo. Discuss your specific needs during initial conversations to see how flexible they are with design changes. It’s also useful to ask about their process for handling custom orders, including lead times and minimum order quantities (MOQs). -

What are the typical minimum order quantities (MOQs) for table suppliers?

Minimum order quantities (MOQs) can vary widely among suppliers, often depending on production capabilities and product type. Generally, MOQs for tables may range from a few pieces for smaller suppliers to hundreds for larger manufacturers. Always confirm the MOQ before proceeding, as this can impact your initial investment. If you’re a smaller buyer, consider negotiating lower MOQs or seeking suppliers that specialize in small-batch production. -

What payment terms are common when dealing with international table suppliers?

Payment terms can vary significantly by supplier and region. Common arrangements include advance payments, typically 30% upfront and 70% upon delivery, or net 30/60 days after receipt. Consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Always clarify payment terms in the contract to avoid misunderstandings. Understanding regional practices, particularly in Africa or South America, can also help in negotiations. -

How can I ensure quality assurance (QA) when sourcing tables internationally?

Implementing a robust quality assurance process is essential when sourcing tables from international suppliers. Request detailed specifications and samples before finalizing your order. Consider conducting third-party inspections during production and before shipment to verify compliance with your standards. Establish clear quality metrics in your agreement, and maintain open lines of communication to address any issues promptly. Developing a relationship with the supplier can also foster better adherence to quality expectations.

A stock image related to table supplier.

-

What logistics considerations should I keep in mind when importing tables?

Logistics is a critical factor when importing tables. Evaluate shipping options, including freight forwarders and customs brokers, to find the most efficient and cost-effective methods. Understand the import regulations and tariffs for your specific country, as these can significantly impact your total costs. Additionally, plan for potential delays in shipping and customs clearance, especially in regions with complex import processes. Having a contingency plan can help mitigate disruptions. -

How do I handle disputes with a table supplier?

Dispute resolution should be clearly outlined in your contract to avoid complications. Start by communicating directly with the supplier to resolve issues amicably. If necessary, escalate the matter to a higher authority within the supplier’s organization. If disputes arise over quality or delivery, document all communications and evidence to support your case. Consider mediation or arbitration as a next step if direct negotiations fail, as these can be more efficient than legal proceedings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for table supplier

What Are the Key Takeaways for International B2B Buyers?

In today’s global marketplace, strategic sourcing is not just a procurement function; it is a critical component of competitive advantage. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics while leveraging global supplier networks can lead to significant cost savings and improved product quality. The ability to identify reliable table suppliers who align with your business goals will enhance operational efficiency and foster long-term partnerships.

How Can Strategic Sourcing Impact Your Business?

Investing time in strategic sourcing can streamline your supply chain, reduce risks associated with supplier reliability, and improve negotiation leverage. By conducting thorough market research and supplier evaluations, buyers can better anticipate trends and shifts in demand, ensuring they remain agile and responsive to market needs. Furthermore, building relationships with table suppliers who understand the cultural and economic nuances of your target markets can lead to tailored solutions that drive business growth.

What Should You Do Next?

As you consider your sourcing strategies, prioritize suppliers that demonstrate a commitment to sustainability, innovation, and responsiveness. Engaging with suppliers from diverse regions not only enriches your supply chain but also opens doors to new opportunities and markets. Take the initiative to reach out, ask questions, and explore partnerships that align with your vision for the future. The journey towards optimizing your table sourcing strategy starts today—embrace it to secure a competitive edge in the evolving global landscape.