Find the Best Drilling Machine Supplier: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for drilling machine supplier

In today’s competitive landscape, sourcing the right drilling machine supplier can be a daunting task for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The intricacies of global supply chains, varying standards, and the need for advanced technology make it essential to approach this decision with a strategic mindset. This guide aims to demystify the complex world of drilling machine suppliers, providing insights into various types of drilling equipment, their applications across industries, and how to effectively vet potential suppliers.

Understanding the nuances of drilling technology—whether for oil, gas, or mineral exploration—can significantly impact operational efficiency and cost-effectiveness. As such, this guide not only covers the essential aspects of drilling machine specifications and capabilities but also delves into cost considerations, potential financing options, and the importance of after-sales support. By equipping buyers with the necessary knowledge and tools, this guide empowers them to make informed purchasing decisions that align with their specific operational needs and budgetary constraints.

Moreover, navigating the global market for drilling machines requires awareness of regional regulations and standards, which can vary significantly across continents. This guide addresses these challenges, ensuring that B2B buyers are well-prepared to engage with suppliers effectively, ultimately leading to successful partnerships and enhanced project outcomes.

Understanding drilling machine supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Drilling Suppliers | Focus on rotary drilling rigs that use a rotating drill bit to penetrate the ground. | Oil and gas extraction, mineral exploration | Pros: High efficiency, suitable for deep drilling; Cons: High initial investment. |

| Directional Drilling Suppliers | Specialize in advanced drilling techniques that allow for angled drilling paths. | Gas and oil drilling, utility installation | Pros: Reduces surface disruption, precise targeting; Cons: Higher operational complexity. |

| Core Drilling Suppliers | Provide equipment for extracting cylindrical core samples for analysis. | Geological surveys, mining exploration | Pros: Provides valuable geological data; Cons: Slower drilling speed compared to rotary. |

| Auger Drilling Suppliers | Utilize screw-like drill bits for shallow drilling applications. | Environmental studies, geotechnical investigations | Pros: Cost-effective for shallow depths; Cons: Limited to softer soils. |

| Hydraulic Drilling Suppliers | Employ hydraulic power for drilling, often used in challenging terrains. | Water well drilling, geothermal energy | Pros: Effective in tough conditions; Cons: Maintenance can be complex and costly. |

What Are the Characteristics of Rotary Drilling Suppliers?

Rotary drilling suppliers focus on providing equipment that utilizes a rotating drill bit to penetrate various types of soil and rock. This method is particularly effective for deep drilling applications, making it a staple in the oil and gas industry. Buyers should consider the supplier’s experience in the field, the efficiency of the drilling rigs, and the availability of spare parts. While the initial investment can be high, the long-term efficiency and productivity often justify the costs.

How Do Directional Drilling Suppliers Operate?

Directional drilling suppliers specialize in advanced techniques that allow for drilling at various angles rather than just vertically. This approach is essential for minimizing surface disruption and maximizing resource extraction from a single drilling site. B2B buyers should evaluate the supplier’s technological capabilities, including the precision of their drilling systems and their ability to navigate complex geological formations. While this method offers significant advantages, it also introduces greater operational complexity and requires skilled personnel.

What Role Do Core Drilling Suppliers Play?

Core drilling suppliers provide specialized equipment designed for extracting cylindrical core samples, which are critical for geological analysis and resource assessment. This technique is widely used in mining and geological surveys. Buyers need to assess the supplier’s ability to deliver high-quality core samples and the efficiency of their drilling processes. Although core drilling can be slower than other methods, the quality of data obtained is invaluable for informed decision-making.

What Are the Advantages of Auger Drilling Suppliers?

Auger drilling suppliers focus on providing equipment that uses screw-like drill bits, ideal for shallow drilling applications. This method is particularly popular in environmental studies and geotechnical investigations. B2B buyers should consider the cost-effectiveness of auger drilling for their specific needs, as it is often more affordable for projects that do not require deep penetration. However, auger drilling is limited to softer soils, which may restrict its application in more challenging terrains.

How Do Hydraulic Drilling Suppliers Address Challenging Conditions?

Hydraulic drilling suppliers utilize hydraulic power to operate drilling equipment, making them particularly effective in challenging terrains such as rocky or unstable ground. This method is commonly used for water well drilling and geothermal energy projects. Buyers should evaluate the supplier’s experience in similar conditions and the reliability of their equipment. While hydraulic drilling can be highly effective, it may also require more complex maintenance, which can lead to increased operational costs.

Related Video: drilltronic : radial arm machine to drilling and tapping with vaps

Key Industrial Applications of drilling machine supplier

| Industry/Sector | Specific Application of drilling machine supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Exploration and development of oil and gas fields | Enhanced resource extraction efficiency and reduced costs | Supplier reliability, technology compatibility, and after-sales support |

| Mining | Mineral exploration and extraction | Improved accuracy in resource identification and extraction | Equipment durability, local service availability, and compliance with safety standards |

| Construction | Foundation drilling and site preparation | Increased project timelines and reduced labor costs | Adaptability to local soil conditions and compliance with local regulations |

| Geothermal Energy | Drilling for geothermal wells | Sustainable energy solutions and reduced operational costs | Expertise in thermal drilling techniques and environmental impact considerations |

| Environmental Studies | Soil sampling and environmental assessments | Accurate data for environmental impact assessments | Supplier experience in specialized drilling techniques and data analysis capabilities |

How Are Drilling Machine Suppliers Used in the Oil and Gas Sector?

In the oil and gas industry, drilling machine suppliers provide essential equipment for the exploration and development of hydrocarbon resources. These machines are utilized to create wells that access oil and natural gas deposits buried deep underground. By using advanced drilling technologies, suppliers can enhance drilling efficiency, reduce operational costs, and ensure the safety of the drilling process. International B2B buyers must consider supplier reliability and the compatibility of technology with existing systems, particularly in regions like Africa and the Middle East where resource extraction is critical.

What Are the Applications of Drilling Machines in Mining?

Drilling machines play a pivotal role in the mining sector, particularly for mineral exploration and extraction. Suppliers provide specialized drilling equipment that allows for precise drilling, which is crucial for identifying mineral deposits and optimizing extraction processes. By improving the accuracy of resource identification, businesses can significantly enhance their operational efficiency and reduce waste. Buyers from South America and Europe should focus on equipment durability and the availability of local service to mitigate downtime during critical operations.

How Do Drilling Suppliers Support Construction Projects?

In construction, drilling machine suppliers are instrumental in foundation drilling and site preparation. Their equipment ensures that the groundwork is laid accurately and efficiently, which is vital for the structural integrity of buildings and infrastructure. The use of advanced drilling techniques can lead to quicker project timelines and lower labor costs. B2B buyers in Europe, particularly in urban areas, should prioritize suppliers who can adapt their equipment to local soil conditions and comply with regional construction regulations.

What Role Do Drilling Suppliers Play in Geothermal Energy Development?

Drilling machine suppliers are crucial in the geothermal energy sector, where they provide equipment for drilling geothermal wells. This process is essential for tapping into sustainable energy resources, allowing businesses to reduce reliance on fossil fuels and lower operational costs. International buyers, especially from regions focused on renewable energy, should evaluate suppliers based on their expertise in thermal drilling techniques and their understanding of environmental impact considerations.

How Are Drilling Machines Used in Environmental Studies?

In environmental studies, drilling machines are employed for soil sampling and conducting environmental assessments. This application is critical for gathering accurate data on soil composition and contamination levels, which informs environmental impact assessments. Suppliers must demonstrate experience in specialized drilling techniques and the capability to analyze data effectively. B2B buyers should consider suppliers who can provide comprehensive solutions that address both drilling and data analysis needs, ensuring compliance with local environmental regulations.

Related Video: Drilling Machine | Construction ,Parts , Working , Animation

3 Common User Pain Points for ‘drilling machine supplier’ & Their Solutions

Scenario 1: Navigating Complex Geological Conditions

The Problem:

B2B buyers often encounter significant challenges when sourcing drilling machines suitable for complex geological conditions. These conditions can include varying rock formations, fault lines, and moisture levels, which can drastically affect drilling efficiency and safety. A drilling machine that performs well in one type of terrain may fail or incur higher costs in another, leading to operational delays and potential safety hazards. This unpredictability can be particularly frustrating for international buyers who may not have firsthand experience with local geological variations.

The Solution:

To effectively navigate these challenges, B2B buyers should prioritize suppliers that offer machines specifically designed for diverse geological conditions. Engage with suppliers who provide detailed geological assessments as part of their service. When evaluating drilling equipment, inquire about the machine’s adaptability and the technology used for real-time monitoring and adjustment of drilling parameters.

Moreover, consider suppliers who can provide trial runs or demonstrations in similar geological conditions to your project site. This hands-on experience can help you assess the machine’s performance and reliability. Additionally, leveraging data-driven monitoring technologies can significantly enhance drilling efficiency by allowing for real-time adjustments based on geological feedback. Buyers should seek partnerships with suppliers that offer robust training and support services, ensuring that their teams are well-equipped to operate the machinery effectively across varying conditions.

Scenario 2: Overcoming High Operational Costs

The Problem:

Many B2B buyers face the issue of escalating operational costs associated with drilling projects. This can stem from inefficient drilling practices, equipment breakdowns, and unanticipated delays. Particularly in regions like Africa and South America, where logistical challenges can compound these issues, the pressure to maintain profitability becomes even greater. Buyers are often left searching for solutions that can reduce costs without compromising safety or efficiency.

The Solution:

Implementing a comprehensive approach to drilling parameter optimization can dramatically reduce operational costs. Buyers should collaborate with suppliers who utilize advanced technologies such as machine learning algorithms to optimize drilling parameters in real time. By focusing on factors such as weight on bit (WOB), rotation speed (RPM), and drilling fluid properties, these technologies can help maximize drilling efficiency and minimize wear and tear on machinery.

Additionally, consider integrating predictive maintenance schedules into your operations. Suppliers who provide equipment with built-in monitoring systems can alert teams to potential issues before they escalate into costly breakdowns. Establishing a solid feedback loop with your supplier for continuous improvement can also help in adjusting operational practices based on historical data and performance metrics, further driving down costs.

Scenario 3: Ensuring Compliance with Local Regulations

The Problem:

International buyers often grapple with the complexities of complying with local regulations when sourcing drilling machines. Each region may have different environmental and safety standards, and failing to adhere to these can result in legal penalties and project delays. This is particularly relevant in areas with strict environmental protections, such as parts of Europe and the Middle East, where non-compliance can halt operations entirely.

The Solution:

To mitigate compliance risks, B2B buyers should thoroughly research local regulations and seek suppliers who are knowledgeable about these requirements. When engaging with potential drilling machine suppliers, ask for documentation that proves their equipment meets or exceeds local standards. This includes certifications related to emissions, noise levels, and safety features.

Moreover, establish a partnership with suppliers who are willing to provide ongoing support and updates regarding regulatory changes. Some suppliers may also offer compliance consulting as part of their service, helping you navigate the complexities of local laws. Regular training sessions for your operational teams on compliance protocols can also ensure that everyone is aware of the necessary standards, thereby minimizing the risk of infractions and promoting a culture of safety and responsibility.

Strategic Material Selection Guide for drilling machine supplier

What are the Key Properties of Common Materials Used in Drilling Machines?

When selecting materials for drilling machines, it is essential to consider their properties, which directly influence performance and durability. Here, we analyze four common materials: steel, tungsten carbide, high-density polyethylene (HDPE), and aluminum. Each material has unique characteristics that can significantly impact the efficiency and effectiveness of drilling operations.

Steel: The Backbone of Drilling Equipment

Steel is a widely used material in the manufacturing of drilling machines due to its strength and versatility. Key properties include high tensile strength, good ductility, and the ability to withstand high temperatures and pressures. Steel’s corrosion resistance can be enhanced through galvanization or coating, making it suitable for various environments.

Pros: Steel is durable and cost-effective, providing a balance between performance and affordability. It is readily available and easy to manufacture into complex shapes.

Cons: While steel is strong, it can be susceptible to corrosion if not properly treated, especially in harsh environments. Its weight can also be a disadvantage in applications requiring lightweight materials.

For international buyers, especially those in regions like Africa and South America where environmental conditions may vary, it is crucial to consider compliance with standards such as ASTM and DIN for corrosion resistance and structural integrity.

Tungsten Carbide: The Hardness Champion

Tungsten carbide is known for its exceptional hardness and wear resistance, making it ideal for drilling applications that involve abrasive materials. It can withstand high temperatures and pressures, which is critical in deep drilling operations.

Pros: Its hardness allows for longer tool life and reduced downtime, leading to cost savings in the long run. Tungsten carbide is also effective in maintaining sharp cutting edges.

Cons: The primary drawback is its high cost, which can be a barrier for some buyers. Additionally, tungsten carbide is brittle, making it susceptible to chipping under high-impact conditions.

For B2B buyers in Europe and the Middle East, understanding the specific applications and the cost-benefit ratio of tungsten carbide tools is essential, especially when considering compliance with local standards for tool manufacturing.

High-Density Polyethylene (HDPE): The Lightweight Alternative

HDPE is increasingly used in non-structural components of drilling machines, such as liners and protective casings. Its key properties include excellent chemical resistance, low moisture absorption, and lightweight characteristics.

Pros: HDPE is resistant to many chemicals and does not corrode, making it suitable for various drilling environments. Its lightweight nature reduces transportation and handling costs.

Cons: While it is durable, HDPE is not as strong as metals and may not be suitable for load-bearing applications. Its performance can be affected by extreme temperatures.

International buyers from regions like Africa and South America should consider HDPE’s compliance with environmental regulations and its suitability for specific drilling media, especially in chemical-rich environments.

Aluminum: The Lightweight Structural Material

Aluminum is celebrated for its lightweight and corrosion-resistant properties. It is often used in drilling machine components where weight savings are essential without sacrificing too much strength.

Pros: Aluminum’s lightweight nature enhances mobility and reduces fuel consumption in drilling operations. It is also resistant to corrosion, making it suitable for various environments.

Cons: While aluminum is strong, it is not as durable as steel or tungsten carbide, especially in high-stress applications. It can also be more expensive than traditional steel.

For B2B buyers in Europe and the Middle East, adhering to standards such as JIS and ASTM for aluminum alloys is crucial to ensure compatibility with existing equipment and performance expectations.

Summary Table of Material Selection for Drilling Machines

| Material | Typical Use Case for drilling machine supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, drill bits | Durable and cost-effective | Susceptible to corrosion if untreated | Medium |

| Tungsten Carbide | Cutting tools, drill bits | Exceptional hardness and wear resistance | High cost and brittleness | High |

| High-Density Polyethylene (HDPE) | Liners, protective casings | Lightweight and chemically resistant | Not suitable for load-bearing applications | Low |

| Aluminum | Non-structural components, frames | Lightweight and corrosion-resistant | Less durable than steel and tungsten carbide | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on material properties, advantages, limitations, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for drilling machine supplier

What Are the Main Stages of Manufacturing Drilling Machines?

The manufacturing process of drilling machines involves several critical stages that ensure high-quality output and reliability. Understanding these stages can help international B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process is material preparation. Raw materials, typically high-strength steel and specialized alloys, are selected based on the specific requirements of the drilling machine. Suppliers often utilize advanced technologies such as laser cutting and water jet cutting to precisely shape these materials. Additionally, metallurgical testing is conducted to ensure the materials meet required specifications, focusing on tensile strength, hardness, and ductility.

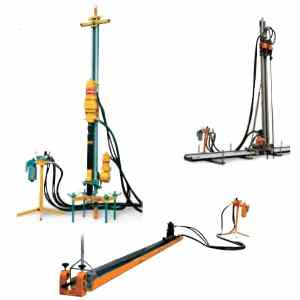

A stock image related to drilling machine supplier.

What Techniques Are Used in the Forming Stage?

Once materials are prepared, the next stage is forming. This involves processes such as forging, casting, and machining.

- Forging is commonly used for critical components like drill bits and gears, as it enhances the strength and durability of the materials.

- Casting is employed for complex shapes that are difficult to achieve through forging.

- Machining includes turning, milling, and grinding, which refine the dimensions and surface finishes of components.

These techniques are vital for creating components that can withstand the rigors of drilling operations.

How Is the Assembly Process Structured?

The assembly stage brings together various components to create a complete drilling machine. This process typically involves:

- Sub-assembly: Components such as the motor, gearbox, and drill bit are assembled separately before being combined into the main structure.

- Final assembly: This includes integrating all sub-assemblies into the drilling machine, followed by alignment and calibration to ensure optimal performance.

During this stage, skilled technicians perform manual inspections to catch any defects early in the process, which is critical for maintaining quality.

What Finishing Techniques Are Applied to Enhance Performance?

Finishing processes are essential for improving the performance and longevity of drilling machines. Techniques such as surface hardening, coating, and painting are commonly used.

- Surface hardening improves wear resistance, which is crucial in harsh drilling environments.

- Coating can protect against corrosion and reduce friction, enhancing operational efficiency.

- Painting not only provides a protective layer but also ensures that the machine meets aesthetic and branding requirements.

These finishing touches are essential for ensuring that the drilling machines can perform effectively in diverse environments.

What International Quality Assurance Standards Are Relevant for Drilling Machine Suppliers?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for drilling machines. Compliance with international standards not only assures product quality but also enhances credibility among buyers.

How Does ISO 9001 Certification Impact Supplier Quality?

ISO 9001 is a widely recognized quality management standard that outlines the criteria for establishing an effective quality management system (QMS). Suppliers with ISO 9001 certification demonstrate their commitment to consistent quality, customer satisfaction, and continuous improvement. Buyers should prioritize suppliers with this certification, as it indicates adherence to global quality standards.

What Are the Industry-Specific Standards for Drilling Machines?

In addition to ISO 9001, drilling machine suppliers may also need to comply with industry-specific standards such as:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Spec 7-1: Pertains to drilling and production equipment, ensuring that products meet specific performance criteria.

These certifications can significantly impact a supplier’s marketability and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integral to the manufacturing of drilling machines. Understanding the QC checkpoints can help buyers evaluate supplier reliability.

How Are Incoming Quality Control (IQC) Processes Conducted?

Incoming Quality Control (IQC) involves inspecting raw materials and components as they arrive at the manufacturing facility. This step is crucial for identifying defects before they enter the production line. Common IQC methods include visual inspections, dimensional checks, and material testing.

What Role Does In-Process Quality Control (IPQC) Play?

In-Process Quality Control (IPQC) monitors the manufacturing process itself. Techniques like statistical process control (SPC) are employed to track production metrics in real-time. Any deviations from established parameters can prompt immediate corrective actions, preventing defective products from reaching the next stage of production.

Why Is Final Quality Control (FQC) Essential?

Final Quality Control (FQC) is the last checkpoint before the drilling machine is shipped to the buyer. This stage involves comprehensive testing, including:

- Functional testing to ensure that the machine operates according to specifications.

- Performance testing to evaluate efficiency and reliability under simulated working conditions.

FQC not only confirms that the product meets quality standards but also builds trust with buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from diverse regions, verifying a supplier’s quality control practices is essential. Here are several strategies to consider:

What Auditing Processes Should Buyers Implement?

Conducting supplier audits is a proactive way to assess quality control practices. Buyers should look for:

- Documentation review: Analyze quality manuals, inspection reports, and compliance certificates.

- On-site inspections: Visit the manufacturing facility to observe processes firsthand and engage with quality control staff.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing and QC practices. These services can conduct independent audits, testing, and certification processes, offering buyers additional assurance.

Why Are Quality Reports Important for Continuous Monitoring?

Requesting regular quality reports from suppliers is a best practice for maintaining oversight. These reports should include data on defect rates, compliance with standards, and results from internal audits. Continuous monitoring allows buyers to identify trends and address potential issues proactively.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers must navigate various nuances in quality control when sourcing drilling machines.

How Do Cultural Differences Impact Quality Expectations?

Cultural attitudes toward quality and compliance can vary significantly across regions. Buyers should be aware of these differences and communicate their quality expectations clearly to avoid misunderstandings.

What Are the Import Regulations and Standards Buyers Should Consider?

A stock image related to drilling machine supplier.

Each country has specific import regulations and standards that may affect the quality assurance process. Buyers should familiarize themselves with these requirements to ensure that the products they import comply with local laws and standards.

By understanding the manufacturing processes and quality assurance measures in place for drilling machines, international B2B buyers can make informed decisions, ensuring they select reliable suppliers capable of meeting their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drilling machine supplier’

This practical sourcing guide aims to assist international B2B buyers in effectively procuring drilling machine suppliers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. As the demand for drilling machines grows due to resource exploration and development, it is essential to approach sourcing with a structured strategy. Below is a step-by-step checklist to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is vital to clearly define your technical specifications. This includes understanding the type of drilling machine required, such as rotary, percussive, or auger drilling machines, along with their intended applications.

– Consider factors such as:

– Drilling depth requirements

– Type of materials to be drilled

– Necessary power and torque specifications

Step 2: Research the Market Landscape

Conduct thorough market research to identify potential suppliers. This helps in understanding the competitive landscape and the capabilities of different suppliers.

– Focus on:

– Industry reports and trade publications

– Online supplier directories and platforms

– Recommendations from industry peers and networking events

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet suppliers thoroughly to ensure they meet your standards. Request detailed company profiles, case studies, and references from buyers in similar industries or regions.

– Look for:

– Proven track records and successful projects

– Customer testimonials and reviews

– Technical support and service capabilities

Step 4: Verify Supplier Certifications and Compliance

Confirm that potential suppliers have the necessary certifications and comply with industry standards. This is crucial for ensuring the quality and safety of the drilling machines.

– Key certifications to check include:

– ISO certifications relevant to manufacturing and safety

– Compliance with local regulations and international standards

Step 5: Assess the Financial Stability of Suppliers

Evaluate the financial health of your shortlisted suppliers. A financially stable supplier is more likely to deliver on time and provide ongoing support.

– Consider reviewing:

– Financial statements and credit ratings

– Length of time in business and market reputation

Step 6: Request Detailed Proposals

Once you have narrowed down your suppliers, request detailed proposals. These proposals should outline pricing, lead times, warranty conditions, and after-sales support.

– Ensure the proposal includes:

– Breakdown of costs (including shipping and installation)

– Timeline for delivery and installation

– Terms of service and warranty coverage

Step 7: Negotiate Terms and Finalize the Contract

After reviewing proposals, engage in negotiations to finalize terms that are favorable for both parties. This is an opportunity to clarify expectations and ensure mutual understanding.

– Key points to negotiate include:

– Payment terms and conditions

– Penalties for delays or non-compliance

– Support and maintenance agreements

By following this step-by-step checklist, international B2B buyers can make informed decisions when sourcing drilling machine suppliers, ensuring that they partner with reliable and capable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for drilling machine supplier Sourcing

What Are the Key Cost Components in Drilling Machine Supplier Pricing?

Understanding the cost structure of drilling machine suppliers is essential for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact the overall cost. High-grade steel and specialized alloys for durability can raise prices, but they enhance machine longevity and performance.

-

Labor: Skilled labor is often required for manufacturing complex drilling machines. Labor costs can vary greatly depending on the region. For instance, suppliers in Europe may have higher labor costs compared to those in South America or Africa.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can lower overhead, which can be passed on to buyers.

-

Tooling: The investment in tooling and machinery required for production is a substantial cost. Custom tooling can add to the initial expense but is often necessary for specialized drilling machines.

-

Quality Control (QC): Rigorous quality assurance processes are critical in maintaining standards, especially for machines used in demanding environments. Enhanced QC measures can increase costs but also reduce long-term operational risks.

-

Logistics: Shipping and handling costs can fluctuate based on distance, method of transport, and geopolitical factors. Buyers should factor in these costs when evaluating supplier quotes.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on competition and market conditions.

How Do Price Influencers Impact Drilling Machine Costs?

Several factors can influence the pricing of drilling machines, making it crucial for buyers to understand them:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can be beneficial for companies looking to source multiple machines.

-

Specifications and Customization: Custom-built machines tailored to specific needs can significantly increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of materials not only affects durability but also compliance with industry standards. Machines that meet high-quality certifications may carry a premium price but offer better reliability.

-

Supplier Factors: Supplier reputation, experience, and geographical location can affect pricing. Established suppliers with proven track records may charge more due to their reliability and support services.

-

Incoterms: The shipping terms agreed upon can influence overall costs. Understanding the implications of terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost assessment.

What Are the Best Buyer Tips for Negotiating Drilling Machine Prices?

To maximize value when sourcing drilling machines, buyers should consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially regarding bulk orders or long-term partnerships. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential downtime. A slightly higher upfront cost may lead to lower long-term expenses.

-

Understand Pricing Nuances for International Transactions: Different regions may have unique pricing structures influenced by local labor costs, material availability, and economic conditions. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors to make informed decisions.

-

Be Aware of Indicative Prices: Prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Always verify current pricing and inquire about potential future price changes.

By understanding these cost components, price influencers, and negotiation strategies, international B2B buyers can make informed decisions that lead to successful sourcing of drilling machines tailored to their operational needs.

Alternatives Analysis: Comparing drilling machine supplier With Other Solutions

Introduction: Exploring Alternatives to Drilling Machine Suppliers

In the competitive landscape of resource extraction and geological drilling, businesses often seek solutions that enhance efficiency and reduce costs. While drilling machine suppliers offer specialized equipment, various alternative methods and technologies can achieve similar goals. This analysis will compare drilling machine suppliers with two viable alternatives: Automated Drilling Systems and Geological Data Analytics Platforms. Each option presents unique advantages and challenges, making it essential for international B2B buyers to carefully consider their specific needs.

Comparison Table of Drilling Solutions

| Comparison Aspect | Drilling Machine Supplier | Automated Drilling Systems | Geological Data Analytics Platforms |

|---|---|---|---|

| Performance | High efficiency, reliability in various conditions | Enhanced speed and precision through automation | Provides insights that optimize drilling parameters |

| Cost | High initial investment; ongoing operational costs | Moderate initial costs; potential long-term savings | Lower upfront costs; subscription or usage fees |

| Ease of Implementation | Requires training and setup time | Integration can be complex; requires technical expertise | Quick to implement; relies on existing data |

| Maintenance | Regular maintenance needed; spare parts may be costly | Lower maintenance due to automation; software updates required | Minimal maintenance; relies on software capabilities |

| Best Use Case | Large-scale drilling operations needing heavy machinery | Environments requiring precision and speed | Projects needing data-driven insights for optimization |

Detailed Breakdown of Alternatives

Automated Drilling Systems

Automated drilling systems leverage advanced robotics and AI to enhance drilling performance. The primary advantage of these systems is their ability to operate with greater speed and precision, significantly reducing drilling time and minimizing human error. However, the initial investment can be moderate to high, depending on the technology and the scale of operation. Integration into existing workflows may require technical expertise, which could lead to longer implementation times. These systems are best suited for operations where high efficiency and precision are paramount, such as offshore drilling or deep mineral extraction.

Geological Data Analytics Platforms

Geological data analytics platforms utilize big data and machine learning to provide insights into drilling operations. These platforms analyze historical and real-time data to optimize drilling parameters, which can lead to significant cost savings and improved efficiency. One of the key benefits is the lower upfront cost compared to purchasing heavy machinery; however, there may be ongoing subscription or usage fees. Implementation is relatively quick, especially for companies that already have access to geological data. These platforms are ideal for projects focused on optimizing existing operations and improving decision-making through data-driven insights.

Conclusion: Choosing the Right Drilling Solution

When evaluating the best solution for drilling needs, B2B buyers must consider various factors, including performance requirements, budget constraints, and the operational environment. While drilling machine suppliers provide robust equipment essential for large-scale operations, alternatives such as automated drilling systems and geological data analytics platforms offer innovative approaches that may better suit specific project goals. By assessing the unique advantages and disadvantages of each option, buyers from Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational objectives and resource management strategies.

Essential Technical Properties and Trade Terminology for drilling machine supplier

What Are the Essential Technical Properties for Drilling Machines?

Understanding the technical specifications of drilling machines is crucial for B2B buyers, particularly when sourcing from international suppliers. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the type of materials used in the construction of drilling machines, such as steel or composite materials. High-grade materials are essential for durability and resistance to wear and tear, which directly affects the lifespan and performance of the equipment. Buyers should prioritize suppliers who utilize high-quality materials to ensure long-term reliability and reduced maintenance costs.

2. Tolerance

Tolerance indicates the allowable deviation from specified dimensions. In drilling operations, precise tolerances are vital for ensuring that the drilling equipment performs accurately and efficiently. Poor tolerances can lead to equipment failure or subpar drilling results, which can be costly. B2B buyers should verify that suppliers adhere to industry standards for tolerances, ensuring optimal performance.

3. Weight on Bit (WOB)

Weight on Bit (WOB) is a critical parameter that influences the rate of penetration (ROP) during drilling. It is the force applied to the drill bit to enhance its penetration into the geological formation. A well-calibrated WOB can optimize drilling efficiency and minimize costs. Buyers should inquire about the ability of the drilling machine to adjust WOB dynamically based on geological conditions to maximize efficiency.

4. Rotational Speed (RPM)

Rotational speed is the rate at which the drill bit turns. Different drilling applications require varying RPM settings to achieve optimal performance. Higher RPMs can improve penetration rates but may increase wear on the equipment. Buyers should ensure that the drilling machine can provide adjustable RPM settings to adapt to different drilling conditions and optimize performance.

5. Hydraulic Pressure

Hydraulic pressure is crucial for the operation of hydraulic drilling machines, affecting the machine’s ability to perform efficiently under varying conditions. High hydraulic pressure can enhance drilling power and effectiveness but also requires careful management to avoid equipment failure. B2B buyers should assess the hydraulic capabilities of potential suppliers to ensure they meet the demands of their specific applications.

What Are Common Trade Terms in the Drilling Machine Industry?

Familiarity with industry terminology is essential for effective communication and negotiation with suppliers. Here are some common trade terms used in the drilling machine industry:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of drilling machines, understanding whether a supplier is an OEM can indicate the quality and reliability of the products. B2B buyers should consider purchasing from established OEMs to ensure high standards of production.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum quantity of units that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and upfront costs. Buyers should negotiate MOQs with suppliers to align with their operational needs and financial constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. It is a critical step in the procurement process, allowing buyers to compare offerings from different suppliers. When issuing an RFQ for drilling machines, buyers should be clear and detailed about their requirements to receive accurate quotations.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. They define aspects such as shipping, insurance, and delivery obligations. B2B buyers should familiarize themselves with relevant Incoterms to ensure clear agreements and avoid misunderstandings during international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the goods. Understanding lead times is crucial for project planning and inventory management. B2B buyers should ask suppliers for estimated lead times to ensure that drilling machines are delivered when needed, minimizing potential project delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing drilling machines, ensuring they choose the right suppliers and equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the drilling machine supplier Sector

What Are the Key Drivers Influencing the Drilling Machine Supplier Market?

The global drilling machine supplier market is experiencing significant transformations driven by technological advancements and changing industry demands. Key factors include the increasing need for efficient resource extraction and the push towards automation and digitalization in drilling operations. Enhanced drilling techniques and tools, such as data-driven intelligent monitoring and real-time optimization models, are becoming essential for improving drilling performance and reducing operational costs. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, must stay attuned to these trends to remain competitive.

Emerging technologies such as machine learning and AI are being integrated into drilling processes, allowing for more precise parameter optimization and enhanced safety measures. The rise of smart drilling solutions that leverage IoT capabilities is further reshaping the sector. Buyers from regions like Europe and the Middle East, where regulatory standards are stringent, are increasingly seeking suppliers that can provide advanced technological solutions and comply with local regulations. Moreover, the global emphasis on sustainability is prompting a shift towards suppliers who prioritize environmentally friendly practices.

How Can International Buyers Ensure Sustainable and Ethical Sourcing?

In today’s market, sustainability and ethical sourcing are paramount for international B2B buyers in the drilling machine sector. The environmental impact of drilling operations is under scrutiny, necessitating a focus on sustainable practices. Buyers should prioritize suppliers that demonstrate commitment to reducing carbon footprints and minimizing ecological disruption. This includes sourcing materials that are certified as ‘green’ and adopting technologies that reduce waste and energy consumption.

Ethical supply chains are also gaining importance, as buyers seek to ensure that their suppliers adhere to fair labor practices and responsible sourcing policies. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for evaluating potential suppliers. By aligning with suppliers who prioritize sustainability, buyers not only contribute to environmental conservation but also enhance their brand reputation, fulfilling the growing demand for corporate social responsibility.

What Historical Trends Have Shaped the Current Drilling Machine Supplier Market?

The evolution of the drilling machine supplier market has been significantly influenced by technological advancements and the increasing complexity of resource extraction. Historically, drilling technology was primarily mechanical, focusing on basic penetration techniques. However, as resource demands surged in the 20th century, innovations in drilling methods, such as rotary drilling and horizontal drilling, emerged, enabling access to previously unreachable resources.

The late 20th and early 21st centuries saw the introduction of computer-aided designs and simulation technologies, transforming the planning and execution of drilling operations. The integration of data analytics and real-time monitoring systems has further enhanced operational efficiency, allowing for better decision-making based on comprehensive geological data. For B2B buyers, understanding this historical context is crucial, as it highlights the ongoing evolution of supplier capabilities and the importance of investing in advanced technologies that can drive future success in drilling operations.

Conclusion

Navigating the complexities of the drilling machine supplier market requires international B2B buyers to stay informed about market dynamics, prioritize sustainability, and understand the historical context that shapes current trends. By adopting a strategic approach to sourcing, buyers can ensure they align with suppliers that not only meet operational needs but also contribute to a sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of drilling machine supplier

-

How do I select the right drilling machine supplier for my project?

When choosing a drilling machine supplier, assess their industry experience, product range, and technical expertise. Look for suppliers who understand your specific geological conditions and project requirements. Request case studies or references from previous clients to gauge their reliability and performance. Additionally, consider their after-sales support and training services, as well as their ability to provide spare parts and maintenance. This comprehensive evaluation will help ensure you select a supplier who can meet your operational needs effectively. -

What certifications should I look for in a drilling machine supplier?

Ensure your drilling machine supplier holds relevant industry certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications indicate compliance with international standards, which is crucial for safety and efficiency in drilling operations. Additionally, check for any specific certifications related to the machinery, such as API (American Petroleum Institute) for oil and gas drilling equipment, which ensures the equipment meets rigorous industry standards. -

What is the minimum order quantity (MOQ) for drilling machines?

The minimum order quantity for drilling machines can vary significantly based on the supplier and the specific type of equipment. Many suppliers may set an MOQ to ensure production efficiency and cost-effectiveness. It’s advisable to inquire directly with potential suppliers to understand their policies. Some may offer flexible options for smaller orders or provide leasing agreements, which can be beneficial for businesses looking to minimize upfront investment. -

How can I negotiate payment terms with a drilling machine supplier?

Negotiating payment terms involves clear communication about your financial capabilities and project timelines. Common terms include advance payments, payment upon delivery, or installment payments based on project milestones. It’s beneficial to establish a mutually agreeable payment schedule that aligns with your cash flow. Additionally, consider leveraging your purchasing volume to negotiate better terms, such as discounts for early payments or extended payment periods. -

What should I know about logistics when sourcing drilling machines internationally?

When sourcing drilling machines internationally, consider the logistics involved in shipping, customs, and local regulations. Work closely with your supplier to understand shipping options and timelines. Ensure all necessary documentation, such as import permits and customs declarations, is prepared to avoid delays. Collaborating with a freight forwarder experienced in heavy machinery can also streamline the process, ensuring timely delivery to your project site while adhering to local regulations. -

How can I ensure the quality of drilling machines from a supplier?

To ensure quality, request detailed specifications and test reports for the drilling machines you intend to purchase. Engage in quality assurance processes by conducting factory visits or audits, if feasible. Additionally, consider suppliers who offer warranties or guarantees on their products, as this can provide added assurance of quality. Establishing a clear communication channel for ongoing support and addressing any potential issues will further enhance the quality assurance process. -

What customization options are available for drilling machines?

Many drilling machine suppliers offer customization options to meet specific project requirements. Customizations may include modifications to the drilling depth, type of drill bits, or specialized features for unique geological conditions. Discuss your specific needs with potential suppliers to explore available options. It’s beneficial to work closely with the supplier during the design and manufacturing phases to ensure that the customized equipment meets your operational goals effectively. -

How do I vet a drilling machine supplier before making a purchase?

Vetting a drilling machine supplier involves several steps. Start by researching their reputation in the industry through online reviews and testimonials. Check their business history, financial stability, and compliance with local and international regulations. Request references from previous clients, particularly those within your industry. Finally, evaluate their technical support and service capabilities to ensure they can provide assistance throughout the equipment’s lifecycle. This thorough vetting process will help mitigate risks associated with your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drilling machine supplier

In conclusion, strategic sourcing of drilling machines is pivotal for international B2B buyers aiming to enhance operational efficiency and reduce costs. By carefully evaluating suppliers based on technological advancements, such as intelligent monitoring and machine learning for drilling parameter optimization, businesses can significantly improve their drilling performance. Understanding the complexities of geological conditions and the need for tailored solutions allows buyers to make informed decisions that align with their specific project requirements.

What are the future trends in drilling machine technology for B2B buyers? As the industry evolves, buyers should anticipate innovations that focus on sustainability and digital transformation, including enhanced data analytics capabilities and eco-friendly drilling practices. By staying ahead of these trends, businesses can not only optimize their drilling operations but also contribute to global sustainability goals.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Poland and Vietnam, are encouraged to leverage strategic sourcing as a means to foster competitive advantage. Engage with suppliers who are committed to innovation and sustainability, ensuring that your drilling operations are not only efficient but also responsible. The time to act is now—embrace strategic sourcing to secure your position in the evolving drilling landscape.