Find the Best Harness Supplier: Your Complete Guide (2025)

Introduction: Navigating the Global Market for harness supplier

As businesses expand their operations globally, sourcing reliable harness suppliers can pose significant challenges, particularly for international B2B buyers. From ensuring compliance with diverse regulations to navigating the complexities of logistics, the journey to procure high-quality harnesses can be fraught with obstacles. This comprehensive guide aims to demystify the global market for harness suppliers, focusing on critical aspects such as types of harnesses available, their applications across various industries, and effective supplier vetting processes.

Understanding the nuances of cost structures and how to negotiate favorable terms is also essential for making informed purchasing decisions. This guide is tailored specifically for B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Australia. By equipping you with actionable insights and strategies, we empower your organization to make confident sourcing choices.

In a rapidly evolving marketplace, leveraging the right information can lead to significant competitive advantages. Whether you are looking for specialized harnesses for automotive, aerospace, or other industrial applications, this guide will serve as your roadmap to successfully navigate the complexities of the harness supply chain. Get ready to enhance your procurement strategy and secure the best suppliers in the global market.

Understanding harness supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Harness Suppliers | Tailored designs to specific customer needs | Aerospace, automotive, electronics | Pros: Unique solutions, optimized performance. Cons: Higher costs, longer lead times. |

| Standard Harness Suppliers | Pre-manufactured harnesses with common designs | Consumer electronics, appliances | Pros: Cost-effective, quicker delivery. Cons: Limited customization, may not fit all applications. |

| Specialty Harness Suppliers | Focus on niche markets or unique materials | Medical devices, industrial machinery | Pros: Expertise in specific applications, high-quality materials. Cons: Potentially higher prices, limited availability. |

| Bulk Harness Suppliers | Large-scale production capabilities | Construction, manufacturing | Pros: Economies of scale, lower per-unit costs. Cons: Less flexibility in design, potential quality variability. |

| International Harness Suppliers | Global reach with diverse manufacturing options | Automotive, telecommunications | Pros: Access to a wide range of products, competitive pricing. Cons: Potential language barriers, longer shipping times. |

What are the Characteristics of Custom Harness Suppliers?

Custom harness suppliers specialize in creating bespoke solutions tailored to specific client requirements. These suppliers excel in industries such as aerospace and automotive, where precision and performance are paramount. When considering a custom harness supplier, buyers should evaluate their design capabilities, lead times, and pricing structures. While the uniqueness of the products can provide significant advantages, the cost and time involved in customization can be considerable.

How Do Standard Harness Suppliers Operate?

Standard harness suppliers offer pre-manufactured harnesses that cater to widely-used applications in consumer electronics and appliances. These products are typically designed for mass production, allowing for cost savings and faster delivery times. Buyers should consider their specific needs against the limitations of standard offerings, including reduced customization options. While these suppliers provide an economical choice, they may not meet the requirements of specialized applications.

What Makes Specialty Harness Suppliers Unique?

Specialty harness suppliers focus on niche markets, often utilizing unique materials or design features to address specific industry needs, such as medical devices or industrial machinery. These suppliers often bring a wealth of expertise and high-quality materials to the table. However, buyers should be prepared for potentially higher prices and limited availability. When sourcing from specialty suppliers, it is crucial to assess their reputation and experience in the relevant field.

Why Choose Bulk Harness Suppliers?

Bulk harness suppliers are geared towards large-scale production, making them ideal for industries like construction and manufacturing. They benefit from economies of scale, which typically results in lower per-unit costs. However, buyers must be aware of the trade-offs, including less flexibility in design and the possibility of quality variability. When purchasing in bulk, it’s essential to establish clear quality assurance processes to mitigate risks.

What are the Benefits of International Harness Suppliers?

International harness suppliers provide a global perspective and a diverse range of manufacturing options, catering to industries like automotive and telecommunications. They often offer competitive pricing due to lower production costs in certain regions. However, buyers should consider potential challenges such as language barriers and longer shipping times. Establishing clear communication and logistics plans can help mitigate these issues and ensure a smooth procurement process.

Related Video: Variations In Construction Projects Explained

Key Industrial Applications of harness supplier

| Industry/Sector | Specific Application of harness supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wiring harnesses for electric vehicles | Enhanced safety and efficiency in vehicle operation | Compliance with international standards, durability in varying climates, and the ability to customize for specific vehicle models. |

| Aerospace | Electrical harnesses for aircraft systems | Improved reliability and reduced weight for better fuel efficiency | Certifications for aviation standards, resistance to extreme conditions, and traceability of materials used. |

| Industrial Machinery | Control harnesses for automation systems | Increased productivity and reduced downtime | Compatibility with existing machinery, scalability, and robust after-sales support. |

| Renewable Energy | Harnesses for solar panel installations | Optimized energy transfer and enhanced system performance | Local regulations on renewable energy, material sourcing for sustainability, and adaptability to different installation environments. |

| Telecommunications | Cable harnesses for data transmission systems | High-speed data transfer and reduced signal interference | Compliance with international communication standards, flexibility in design, and availability of technical support. |

How Are Wiring Harnesses Used in the Automotive Industry?

In the automotive sector, harness suppliers provide wiring harnesses critical for electric vehicles (EVs). These harnesses connect various electrical components, ensuring efficient power distribution and communication. By utilizing advanced materials and technologies, suppliers help manufacturers meet safety standards and enhance vehicle performance. For international buyers, particularly those from Africa and South America, understanding local regulations regarding automotive safety and environmental impact is crucial. Additionally, customization options can cater to specific models, which is essential for maintaining competitive advantages in diverse markets.

What Role Do Electrical Harnesses Play in Aerospace Applications?

In aerospace, electrical harnesses are vital for aircraft systems, including navigation, communication, and control mechanisms. Harness suppliers must meet stringent aviation regulations, ensuring reliability and safety at high altitudes. The lightweight nature of these harnesses contributes to overall fuel efficiency, a critical consideration for airlines facing rising operational costs. Buyers from Europe and the Middle East should prioritize suppliers with proven certifications and a track record of successful aerospace projects, ensuring compliance with international aviation standards.

How Do Harnesses Improve Industrial Machinery Performance?

Harness suppliers cater to the industrial machinery sector by providing control harnesses that integrate automation systems. These harnesses facilitate seamless communication between machines, enhancing productivity and minimizing downtime. For B2B buyers, particularly in South America and Africa, sourcing suppliers who offer robust after-sales support and compatibility with existing systems is essential. Additionally, scalability is a key consideration, allowing businesses to adapt their machinery as production demands change.

Why Are Harnesses Important for Renewable Energy Systems?

In the renewable energy sector, particularly solar energy, harness suppliers provide solutions that optimize energy transfer from solar panels to inverters and storage systems. The right harnesses can significantly improve system performance and longevity, making them a valuable investment for businesses. International buyers must navigate local regulations regarding renewable energy and sustainability practices. Sourcing from suppliers who prioritize environmentally friendly materials and practices is increasingly important in Europe and the Middle East, where green initiatives are gaining traction.

How Do Cable Harnesses Enhance Telecommunications Infrastructure?

In telecommunications, harness suppliers deliver cable harnesses designed for high-speed data transmission systems. These harnesses minimize signal interference and ensure reliable connections between various components. For B2B buyers, particularly in Europe, understanding compliance with international communication standards is vital. Flexibility in design and the ability to receive technical support are also crucial factors when selecting a supplier, as they can significantly impact the efficiency and reliability of telecommunications networks.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘harness supplier’ & Their Solutions

Scenario 1: Sourcing Quality Harnesses for Diverse Applications

The Problem: International B2B buyers often struggle with sourcing harnesses that meet specific application requirements while ensuring quality and compliance with local standards. For instance, a company in South America may need harnesses for automotive applications, but they are unsure whether the suppliers they are considering can provide products that adhere to both international quality standards and local regulations. This uncertainty can lead to costly delays, increased risk of product failure, and potential legal issues.

The Solution: To overcome this challenge, buyers should prioritize finding harness suppliers with a proven track record in their specific industry. Start by conducting thorough research to identify suppliers who have experience in your application area. Request samples to evaluate the quality firsthand and ask for certifications that demonstrate compliance with both international and local standards. Establish clear communication channels to discuss technical specifications and any regulatory requirements upfront. Engaging in a collaborative relationship with your supplier can also facilitate better understanding and adjustments in harness designs tailored to your specific needs.

Scenario 2: Managing Lead Times and Delivery Challenges

The Problem: In the fast-paced world of B2B transactions, lead times and delivery schedules can significantly impact operations. A buyer in Africa may face delays in receiving harnesses due to shipping logistics or production backlogs, resulting in stalled projects and lost revenue. This situation can be particularly frustrating when the buyer has already committed to a project timeline that relies on timely delivery of components.

The Solution: To mitigate lead time issues, B2B buyers should establish relationships with multiple suppliers to create a backup plan in case of delays. When sourcing harnesses, inquire about the supplier’s production capacity and historical lead times. Utilize technology, such as supply chain management software, to track orders in real time and communicate regularly with suppliers about your production schedules. Additionally, consider negotiating terms that include penalties for late delivery, which can motivate suppliers to adhere to agreed timelines. Lastly, maintaining adequate inventory levels can provide a buffer against unexpected delays.

Scenario 3: Customization and Technical Support Difficulties

The Problem: Many B2B buyers require customized harness solutions to fit unique operational needs. However, they often find that suppliers lack the technical expertise to provide the necessary customization or fail to offer adequate support during the integration phase. For example, a Middle Eastern company may need a specific harness configuration for a new piece of machinery, but their supplier may not have the technical know-how to assist in the design and implementation.

The Solution: To address customization challenges, buyers should seek out harness suppliers that offer comprehensive engineering support and have a strong R&D department. Engage with potential suppliers early in the design process, allowing them to understand your requirements and provide input based on their expertise. Look for suppliers who have a history of successful custom projects and can share case studies or testimonials. Additionally, request a dedicated technical representative who can assist throughout the project lifecycle, from initial design to final integration. This proactive approach ensures that you receive the necessary support and results in a harness that meets your specific operational needs.

By addressing these common pain points, international B2B buyers can enhance their sourcing strategies, improve supplier relationships, and ultimately drive greater efficiency and success in their operations.

Strategic Material Selection Guide for harness supplier

When selecting materials for harnesses, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of each material option. This knowledge will inform better purchasing decisions that align with specific application needs and regional standards.

What Are the Key Properties of Polyvinyl Chloride (PVC) for Harnesses?

Polyvinyl Chloride (PVC) is widely used in harness manufacturing due to its excellent electrical insulation properties and resistance to chemicals. It is capable of withstanding temperatures ranging from -10°C to 60°C, making it suitable for various environments. PVC also exhibits good mechanical strength and flexibility, which are essential for harness applications.

Pros & Cons of PVC

The primary advantage of PVC is its cost-effectiveness, making it a popular choice for budget-conscious projects. However, its durability can be a concern, especially in extreme temperatures or harsh chemical environments. Moreover, PVC can be less environmentally friendly due to its production process and disposal issues.

Impact on Application

PVC is compatible with a range of media, including water, oils, and some acids, but it is not suitable for use with strong solvents. Buyers should consider the specific media that the harness will encounter to ensure compatibility.

Considerations for International Buyers

For buyers from regions like Africa and South America, understanding local regulations regarding PVC use is essential. In Europe, compliance with standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is crucial for PVC materials.

How Does Polyurethane (PU) Compare for Harness Applications?

Polyurethane (PU) is another material frequently used in harness manufacturing, known for its exceptional abrasion resistance and flexibility. It can perform well in a temperature range of -30°C to 80°C, making it suitable for more extreme applications.

Pros & Cons of PU

The key advantage of PU is its durability, which allows harnesses to withstand wear and tear over time. However, PU can be more expensive than PVC, which may be a consideration for budget-sensitive projects. Additionally, its manufacturing complexity can lead to longer lead times.

Impact on Application

PU is compatible with a variety of media, including oils and solvents, making it a versatile choice for different applications. Its superior flexibility also allows for better performance in dynamic environments.

Considerations for International Buyers

Buyers from the Middle East and Europe should be aware of the need for compliance with standards such as ISO 9001 for quality management systems when sourcing PU harnesses. Additionally, understanding local market preferences for material sustainability can influence purchasing decisions.

What Are the Benefits of Nylon for Harnesses?

Nylon is a synthetic polymer that offers excellent tensile strength and resistance to abrasion, making it a favored choice in harness applications. It can withstand temperatures ranging from -40°C to 100°C, providing a broad operational range.

Pros & Cons of Nylon

The primary advantage of nylon is its high strength-to-weight ratio, which makes it suitable for heavy-duty applications. However, nylon can absorb moisture, which may lead to dimensional changes and reduced performance in humid environments. Its cost is generally moderate, but it can be higher than PVC.

Impact on Application

Nylon is compatible with a range of media, including oils and fuels, but it is not recommended for use with strong acids or bases. Buyers should evaluate the specific environmental conditions to ensure nylon is a suitable choice.

Considerations for International Buyers

For buyers in Europe, compliance with DIN standards for nylon products is essential. In regions like Africa, understanding local sourcing capabilities and potential import tariffs on synthetic materials can impact overall costs.

How Does Steel Wire Reinforcement Enhance Harness Durability?

Steel wire reinforcement is often added to harnesses to enhance their strength and durability, particularly in high-stress applications. This material can withstand extreme temperatures and pressures, making it ideal for demanding environments.

Pros & Cons of Steel Wire

The key advantage of steel wire is its unmatched tensile strength, which significantly improves the harness’s load-bearing capacity. However, it can add weight and complexity to the manufacturing process, potentially increasing costs. Corrosion resistance is also a concern, requiring proper coatings or treatments.

Impact on Application

Steel wire is suitable for applications involving heavy loads or extreme environmental conditions. However, compatibility with corrosive media must be assessed to prevent premature failure.

Considerations for International Buyers

International buyers should be aware of the ASTM standards that govern steel wire products. Additionally, understanding local regulations regarding corrosion protection and environmental impact is crucial for compliance.

Summary Table of Material Selection for Harness Suppliers

| Material | Typical Use Case for harness supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride | Electrical insulation harnesses | Cost-effective | Less durable in extreme conditions | Low |

| Polyurethane | Flexible, wear-resistant harnesses | High durability | Higher cost and complexity | Med |

| Nylon | Heavy-duty harnesses | High strength-to-weight ratio | Moisture absorption issues | Med |

| Steel Wire | High-stress applications | Unmatched tensile strength | Weight and corrosion concerns | High |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding material selection for harnesses, ensuring compliance with regional standards and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for harness supplier

What Are the Main Stages of the Manufacturing Process for Harnesses?

The manufacturing process for harnesses is intricate and involves several critical stages, each ensuring that the final product meets high standards of quality and performance. Understanding these stages is essential for B2B buyers looking to source reliable harness suppliers.

Material Preparation: What Materials Are Used in Harness Manufacturing?

The first stage is material preparation, which involves selecting the right materials based on the harness’s intended application. Common materials include:

- Conductors: Copper or aluminum wires are typically used for electrical harnesses due to their excellent conductivity.

- Insulation: PVC, rubber, or silicone materials provide protection against electrical interference and environmental factors.

- Connectors and Terminals: These components are often made from brass or other alloys to ensure durability and corrosion resistance.

B2B buyers should inquire about the sourcing of these materials and any certifications that guarantee their quality and compliance with international standards.

How Is the Forming Process Conducted?

The forming stage involves shaping the prepared materials into the desired configuration. This can include:

- Cutting: Wires are cut to specific lengths using precision cutting machines.

- Stripping: Insulation is stripped from the wire ends to allow for proper connections.

- Crimping: Connectors are attached to wire ends using crimping tools to ensure a secure fit.

Buyers should assess the machinery used in this stage, as advanced technologies can enhance precision and reduce waste.

What Does the Assembly Stage Entail?

During the assembly stage, all components are brought together to form the complete harness. This process may involve:

- Wiring Layout: Arranging wires according to the design specifications.

- Soldering and Welding: Ensuring electrical connections are robust and reliable.

- Securing: Utilizing ties, clips, or heat-shrink tubing to keep the harness organized and protected.

Buyers should seek suppliers that utilize automated assembly processes, as this can improve consistency and reduce human error.

How Is the Finishing Process Performed?

The final stage, finishing, includes several steps that enhance the harness’s performance and longevity:

- Testing: Conducting initial tests to ensure functionality.

- Labeling: Clearly marking the harness for identification and safety compliance.

- Packaging: Ensuring that the harness is packaged correctly to prevent damage during transport.

B2B buyers should verify that suppliers have robust quality control measures in place during this stage to maintain product integrity.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in harness manufacturing, especially for international buyers. Adhering to recognized standards ensures that the products meet safety and performance requirements.

Which International Standards Are Most Relevant?

Suppliers should comply with international standards such as:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality.

- CE Marking: For products sold in Europe, CE marking indicates compliance with EU safety and environmental requirements.

- API Standards: For harnesses used in the oil and gas industry, adherence to API standards is crucial.

B2B buyers should request documentation proving compliance with these standards, ensuring that their suppliers maintain high-quality benchmarks.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step verifies the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product before it is shipped.

Buyers should engage with suppliers that have established QC protocols and can provide reports on their findings.

How Can B2B Buyers Verify Supplier Quality Control?

Ensuring that suppliers maintain rigorous quality control measures is vital for B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe.

What Methods Can Be Used to Verify Supplier QC?

B2B buyers can use several methods to verify the quality control processes of their harness suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality control measures directly.

- Quality Control Reports: Requesting detailed QC reports can provide insights into the supplier’s testing procedures and outcomes.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the supplier’s quality standards.

Buyers should prioritize suppliers that are transparent about their QC processes and willing to provide the necessary documentation.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is crucial for international B2B buyers, particularly when sourcing from different regions. Buyers should consider:

- Cultural Differences: Awareness of varying quality perceptions and practices can aid in establishing effective communication with suppliers.

- Regulatory Compliance: Different regions may have specific regulations affecting harness manufacturing and quality standards. Buyers should be well-informed about these to avoid compliance issues.

- Language Barriers: Effective communication is essential for understanding QC measures. Buyers should ensure that language differences do not hinder clarity.

By being aware of these nuances, B2B buyers can make informed decisions and establish fruitful partnerships with harness suppliers globally.

Conclusion: Why Is Understanding Manufacturing Processes and QC Essential for B2B Buyers?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, comprehending the manufacturing processes and quality assurance measures of harness suppliers is vital. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet the required safety and performance standards. By focusing on the details outlined in this guide, buyers can enhance their sourcing strategies and foster successful business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘harness supplier’

Introduction

This sourcing guide aims to equip international B2B buyers with a structured approach to procuring harness suppliers. Whether you’re based in Africa, South America, the Middle East, or Europe, following this checklist will help you make informed decisions, reduce risks, and ensure you partner with reliable suppliers that meet your specific needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential. This includes understanding the type of harnesses you need, such as their materials, dimensions, and performance standards. Providing detailed specifications helps suppliers determine whether they can meet your needs and allows for more accurate quotes.

- Consider industry standards: Ensure your specifications align with relevant industry standards to facilitate compliance and quality assurance.

- Include customization requirements: If your project demands unique features, include these in your specifications to avoid misunderstandings later.

Step 2: Research Potential Suppliers

Begin by compiling a list of potential harness suppliers. Utilize online directories, industry trade shows, and referrals from trusted contacts to identify candidates. This step is crucial to ensure you have a diverse pool of suppliers to evaluate.

- Use platforms like Alibaba or ThomasNet: These platforms can provide insights into supplier capabilities and reviews from previous buyers.

- Check industry-specific forums: Engaging with communities can yield recommendations for reputable suppliers.

Step 3: Evaluate Supplier Certifications and Compliance

Before advancing negotiations, verify that suppliers possess the necessary certifications and comply with relevant regulations. This step protects your business from quality issues and ensures legal compliance.

- Look for ISO certifications: These indicate adherence to international quality management standards.

- Assess regional compliance: Ensure suppliers meet local regulations in your target market, especially if you’re operating in Europe with stringent standards.

Step 4: Request Samples for Quality Assessment

Request samples of the harnesses to evaluate their quality firsthand. This step is critical in determining whether the supplier can meet your specifications and quality expectations.

- Conduct tests: Perform necessary tests to assess durability, functionality, and overall performance.

- Evaluate packaging and presentation: The way samples are presented can also reflect the supplier’s professionalism and attention to detail.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with shortlisted suppliers to finalize terms and conditions. This includes pricing, payment terms, delivery schedules, and after-sales support. Clear agreements can prevent disputes down the line.

- Discuss minimum order quantities: Understanding these can help you manage inventory effectively.

- Clarify warranty and support services: Ensure there are clear terms for product support and warranty claims.

Step 6: Conduct a Final Supplier Audit

Before finalizing your choice, conduct a comprehensive audit of the supplier’s operations. This step helps ensure that they can consistently meet your requirements and maintain quality.

- Evaluate production capabilities: Assess whether they have the capacity to fulfill your orders on time.

- Review financial stability: A supplier’s financial health is crucial for long-term partnerships.

Step 7: Establish a Communication Plan

Effective communication is vital for a successful supplier relationship. Develop a communication plan that outlines points of contact, preferred communication channels, and regular check-in schedules.

- Set expectations: Clearly define response times and escalation procedures for issues that may arise.

- Use project management tools: Consider using tools like Slack or Trello to facilitate ongoing communication and track progress.

By following this comprehensive checklist, international B2B buyers can streamline the sourcing process for harness suppliers and build strong, effective partnerships.

Comprehensive Cost and Pricing Analysis for harness supplier Sourcing

What Are the Key Cost Components in Harness Supplier Sourcing?

When sourcing harness suppliers, understanding the cost structure is vital for making informed decisions. The main components influencing the total cost include:

-

Materials: The choice of materials directly affects the price. High-quality materials such as specialized plastics or metals will increase costs but may provide longer durability and better performance.

-

Labor: Labor costs can vary significantly based on the supplier’s location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and other indirect expenses. Efficient manufacturers often have lower overhead, allowing them to offer better pricing.

-

Tooling: Custom tooling can be a significant upfront cost, especially for specialized harness designs. Buyers should assess whether the tooling costs are justifiable based on their production volume.

-

Quality Control (QC): Rigorous QC processes ensure the final product meets specifications, but they also add to the overall cost. It’s important to balance quality assurance with cost efficiency.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier and the chosen shipping method. Consideration of local tariffs and customs duties is essential for international shipments.

-

Margin: Suppliers typically build in a profit margin that reflects their business model and market conditions. Understanding the supplier’s margin can provide insight into pricing flexibility during negotiations.

How Do Price Influencers Affect Harness Supplier Pricing?

Several factors influence the pricing structure for harness suppliers. Recognizing these can help international buyers negotiate better deals:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit prices. Establishing a good relationship with suppliers can sometimes allow for negotiation on MOQ.

-

Specifications and Customization: Custom designs typically incur higher costs. Clearly defining requirements from the outset can help avoid unexpected costs later in the process.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or CE) often increase costs. Buyers should evaluate whether the added expense aligns with their project needs.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can influence pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms (International Commercial Terms) can significantly impact total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) define the responsibilities of buyers and sellers, affecting overall pricing.

What Negotiation Tips Can Help Achieve Cost-Efficiency?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, here are actionable negotiation strategies:

-

Understand Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider the TCO, which includes maintenance, operational efficiency, and potential replacement costs. This broader perspective can justify higher initial expenditures if long-term savings are anticipated.

-

Leverage Market Research: Being informed about market rates and competitor pricing can empower buyers during negotiations. Knowing the standard pricing for similar products will help in assessing whether a supplier’s quote is competitive.

-

Cultivate Long-Term Relationships: Building a rapport with suppliers can lead to better pricing and terms. Suppliers often prefer to work with reliable clients, which can lead to discounts for bulk orders or loyalty incentives.

-

Be Prepared to Walk Away: Having alternative suppliers in mind can provide leverage in negotiations. If a supplier knows you have other options, they may be more inclined to offer favorable terms.

-

Clarify Payment Terms: Flexible payment terms can ease cash flow constraints and make large orders more manageable. Discussing payment schedules upfront can help avoid misunderstandings later.

Conclusion and Pricing Disclaimer

When sourcing harness suppliers, a deep understanding of the cost structure and pricing influencers is essential for making strategic purchasing decisions. Prices fluctuate based on various factors, and while this analysis provides a framework, it’s important to seek quotes and conduct thorough due diligence. Always remember that indicative prices may vary, and it’s crucial to negotiate effectively to secure the best possible deal for your specific requirements.

Alternatives Analysis: Comparing harness supplier With Other Solutions

In the dynamic landscape of B2B solutions, buyers must consider various alternatives to meet their specific needs. When evaluating a harness supplier, it is essential to compare it with other viable options to determine the most effective and efficient solution for your operations. Below is a detailed comparison of a harness supplier against two alternatives: wire harness manufacturing and modular connector systems.

Comparison Table

| Comparison Aspect | Harness Supplier | Wire Harness Manufacturing | Modular Connector Systems |

|---|---|---|---|

| Performance | High reliability for specific applications | Tailored performance for complex designs | Flexible configuration for diverse uses |

| Cost | Moderate initial investment, potential for bulk discounts | Higher upfront costs due to customization | Generally lower cost due to standardization |

| Ease of Implementation | Straightforward integration with existing systems | Requires detailed planning and design | Simple installation and scalability |

| Maintenance | Low maintenance, durable materials used | Moderate maintenance; depends on complexity | Low maintenance; easy to replace components |

| Best Use Case | Ideal for specialized applications needing custom solutions | Best for intricate systems needing bespoke design | Suitable for general use where flexibility is key |

What Are the Advantages and Disadvantages of Wire Harness Manufacturing?

Wire harness manufacturing provides tailored solutions for complex electronic systems. The primary advantage is its ability to meet specific design requirements, which can significantly enhance performance in intricate applications. However, this customization comes at a cost—higher upfront investments and longer lead times due to the design and production process. Moreover, ongoing maintenance can be moderate, as the complexity of the harness may require specialized knowledge for repairs or adjustments.

How Do Modular Connector Systems Compare?

Modular connector systems offer a flexible and cost-effective alternative. These systems are designed for ease of use, enabling quick installation and scalability, making them ideal for projects that may evolve over time. The standardization of components typically leads to lower costs, which is advantageous for budget-conscious buyers. However, modular systems may not provide the same level of performance as custom harnesses in specialized applications, potentially limiting their effectiveness in certain scenarios.

How Can B2B Buyers Choose the Right Solution?

When selecting the right solution, B2B buyers should assess their specific operational requirements and constraints. Consider factors such as the complexity of your project, budget limitations, and the need for customization versus flexibility. A harness supplier may be the best fit for specialized applications, while wire harness manufacturing could be ideal for intricate designs. Conversely, modular connector systems may serve well in environments requiring adaptability and cost-efficiency.

In summary, understanding the strengths and weaknesses of each alternative will empower buyers to make informed decisions tailored to their unique business needs.

Essential Technical Properties and Trade Terminology for harness supplier

What Are the Key Technical Properties for Harness Suppliers?

When sourcing harnesses, understanding the essential technical specifications is crucial for ensuring product quality and performance. Here are some critical properties to consider:

1. Material Grade

The material grade refers to the type and quality of materials used in harness production, such as copper for wires or PVC for insulation. Selecting the right material grade impacts conductivity, durability, and resistance to environmental factors. For B2B buyers, choosing the appropriate material ensures compliance with industry standards and enhances the longevity of the harness in various applications.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. For harnesses, this might relate to wire thickness or insulation thickness. High precision in manufacturing tolerances is crucial for ensuring compatibility with other components and systems. Buyers should prioritize suppliers who can maintain tight tolerances to prevent failures in critical applications.

3. Temperature Rating

This specification indicates the maximum and minimum temperatures at which the harness can operate effectively. Different applications, especially in automotive and industrial sectors, require harnesses that can withstand extreme temperatures. Understanding the temperature rating helps buyers select products that will function optimally in their specific environments, minimizing the risk of failure.

4. Voltage Rating

The voltage rating defines the maximum voltage the harness can safely handle without breaking down. This is particularly important in electrical applications where exceeding the voltage rating can lead to hazardous situations. Buyers should ensure that the voltage rating aligns with their operational requirements to guarantee safety and efficiency.

5. Wire Gauge

Wire gauge indicates the thickness of the wires used in the harness. A lower gauge number denotes a thicker wire, which can carry more current. Buyers must consider the wire gauge in relation to their specific power requirements to prevent overheating and ensure optimal performance.

What Trade Terminology Should B2B Buyers Know When Sourcing Harnesses?

Familiarity with trade terminology can significantly enhance communication and negotiation with suppliers. Here are some common terms that international buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In harness sourcing, an OEM supplier provides components that are integral to the final product. Buyers should assess whether they are working directly with OEMs to ensure quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget management and inventory planning. Buyers should negotiate MOQs based on their needs, as large orders can lead to cost savings but may also lead to excess inventory if not managed correctly.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a clear and detailed RFQ can help buyers receive accurate quotes and compare offers effectively. Including specifications and quantities in the RFQ will facilitate better responses from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage logistics and cost expectations. Key Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which define who is responsible for shipping costs and risk during transit.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for project planning and inventory management. Buyers should inquire about lead times during negotiations to ensure that they can meet their production schedules without delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing harnesses, ensuring they select the right products and suppliers for their needs.

Navigating Market Dynamics and Sourcing Trends in the harness supplier Sector

What Are the Key Market Dynamics and Trends in the Harness Supplier Sector?

The harness supplier sector is currently witnessing significant transformations driven by global demand for more efficient and reliable electrical systems. With the rise of automation, electric vehicles, and renewable energy solutions, international B2B buyers are increasingly seeking suppliers that can provide advanced harness solutions tailored to their specific needs. Emerging technologies such as IoT, AI, and smart manufacturing are reshaping sourcing strategies, emphasizing the importance of connectivity and data integration in harness design and production.

In regions such as Africa and South America, the adoption of these technologies is accelerating, spurred by infrastructure development and a growing emphasis on modernization. Buyers from the Middle East and Europe, particularly Germany, are also focusing on suppliers that can offer innovative materials and customization capabilities. A notable trend is the increasing reliance on digital platforms for sourcing, which enhances transparency and efficiency. B2B buyers should consider adopting robust sourcing tools and analytics to streamline their procurement processes and identify the best suppliers based on performance metrics and reliability.

How Is Sustainability Shaping Sourcing Decisions in the Harness Supplier Sector?

Sustainability has emerged as a crucial factor influencing sourcing decisions in the harness supplier sector. The environmental impact of harness production, including resource extraction and waste generation, has prompted buyers to prioritize suppliers with sustainable practices. Ethical supply chains are not just a trend; they are becoming a necessity as consumers and regulatory bodies demand greater accountability.

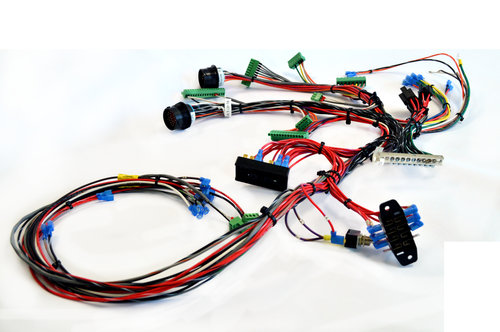

A stock image related to harness supplier.

International buyers are encouraged to seek suppliers that hold certifications like ISO 14001 for environmental management and those utilizing recycled or eco-friendly materials. The use of bioplastics and other green materials in harness manufacturing can significantly reduce the carbon footprint, aligning with global sustainability goals. Additionally, transparent reporting on environmental performance can enhance a supplier’s credibility and appeal to conscientious buyers. By prioritizing sustainability, B2B buyers can not only mitigate risks but also enhance their brand reputation in increasingly eco-aware markets.

What Is the Historical Context of the Harness Supplier Sector?

The harness supplier sector has evolved significantly over the past few decades, transitioning from traditional manufacturing practices to advanced, technology-driven processes. Initially, harnesses were predominantly used in the automotive industry, but their applications have expanded to various sectors, including aerospace, telecommunications, and renewable energy.

The introduction of computerized design tools and automation in production has allowed for greater precision and customization, meeting the diverse demands of international buyers. As industries continue to innovate, the harness supplier sector is poised for further growth, driven by the need for more complex and efficient wiring solutions. Understanding this evolution helps B2B buyers appreciate the technological advancements that enhance product quality and supplier capabilities today.

Frequently Asked Questions (FAQs) for B2B Buyers of harness supplier

-

How do I choose the right harness supplier for my business needs?

Choosing the right harness supplier requires a thorough assessment of your specific requirements. Start by evaluating the supplier’s experience in your industry and their track record with similar projects. Check for certifications that ensure quality and compliance with international standards. Additionally, consider their ability to customize products to meet your specifications, production capacity, and lead times. Engaging in direct communication to gauge their responsiveness and willingness to collaborate can also provide insight into their reliability. -

What are the key factors to consider when vetting a harness supplier?

When vetting a harness supplier, focus on several critical factors: product quality, production capabilities, compliance with safety standards, and financial stability. Research their reputation through customer reviews and industry references. Ensure they have a robust quality assurance process in place, including testing protocols for durability and safety. It’s also important to evaluate their logistics capabilities, especially if you are sourcing internationally, as this can impact delivery times and costs. -

What is the minimum order quantity (MOQ) for harnesses, and how does it affect pricing?

The minimum order quantity (MOQ) for harnesses can vary significantly between suppliers, often ranging from 50 to 500 units or more. Understanding the MOQ is crucial as it directly impacts pricing and inventory management. Suppliers typically offer better pricing per unit at higher quantities due to economies of scale. If your demand is lower, inquire about sample orders or smaller batch production options. Always factor in your budget and storage capabilities when negotiating MOQs with potential suppliers. -

What are the payment terms I should expect from harness suppliers?

Payment terms with harness suppliers can vary, but common practices include a percentage upfront (typically 30-50%) with the balance due upon delivery or after a specified period post-delivery. It’s essential to discuss payment methods as well, including options for letters of credit, wire transfers, or escrow services. Be cautious of suppliers requiring full payment upfront, as this could indicate financial instability. Negotiate terms that provide sufficient security for both parties, especially in international transactions. -

How can I ensure quality assurance in my harness orders?

To ensure quality assurance in your harness orders, establish clear specifications and standards at the outset. Request detailed product samples before committing to larger orders. Additionally, inquire about the supplier’s quality control processes, including inspections and certifications. Conducting on-site audits or hiring third-party inspection services can also help verify compliance with your quality standards. Regular communication throughout the production process allows for timely adjustments and minimizes the risk of defects. -

What are the logistics considerations when sourcing harnesses internationally?

When sourcing harnesses internationally, logistics play a crucial role in ensuring timely delivery and cost efficiency. Consider factors such as shipping methods, customs regulations, and import duties specific to your country. Collaborate with suppliers who have experience in international shipping to navigate complexities. It’s advisable to work with a freight forwarder to streamline logistics and mitigate risks associated with delays or damages during transit. Always have a contingency plan in place for potential disruptions. -

How can I customize harness designs to fit my specific needs?

Customizing harness designs typically involves collaborating closely with your supplier from the design phase. Clearly communicate your requirements, including materials, dimensions, and functionality. Many suppliers offer design services or can work with your existing designs to create tailored solutions. Be prepared to provide prototypes or sketches to illustrate your vision. Establishing a strong partnership with the supplier can facilitate smoother customization processes and ensure that the final product meets your expectations.

A stock image related to harness supplier.

- What should I do if there are issues with my harness order?

If issues arise with your harness order, promptly communicate with the supplier to address the problem. Document any discrepancies or defects with photographs and detailed descriptions. Most reputable suppliers will have a process for resolving issues, whether through replacements, refunds, or adjustments. Maintain records of all correspondence and agreements for reference. Building a good relationship with your supplier can often lead to quicker resolutions and a more positive outcome.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for harness supplier

What Are the Key Takeaways for B2B Buyers in Harness Sourcing?

In navigating the landscape of harness suppliers, international B2B buyers should prioritize strategic sourcing as a means to enhance operational efficiency and drive competitive advantage. The integration of supplier capabilities, adherence to quality standards, and alignment with sustainability practices are critical elements in this process. By establishing robust partnerships with harness suppliers, businesses can leverage innovative solutions that cater to their specific industry needs, whether in Africa, South America, the Middle East, or Europe.

How Can Strategic Sourcing Impact Your Business?

The value of strategic sourcing extends beyond mere cost savings; it fosters a collaborative environment that encourages innovation and responsiveness to market demands. Buyers should focus on cultivating relationships with suppliers who not only meet technical specifications but also share a commitment to ethical practices and continuous improvement. This holistic approach not only mitigates risks but also positions your business for long-term growth in an increasingly competitive global marketplace.

What Is the Future of Harness Sourcing?

As we look ahead, the importance of agility in sourcing strategies will only intensify. Buyers are encouraged to stay informed about emerging trends, such as digital transformation and supply chain resilience, which are reshaping the harness industry. Engaging with suppliers who are forward-thinking and adaptable will ensure that your business remains at the forefront of innovation. Now is the time to take action—evaluate your sourcing strategies, explore new supplier partnerships, and harness the potential of strategic sourcing to drive your business forward.