Find the Best MDF Board Supplier: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for mdf board supplier

In today’s competitive landscape, sourcing high-quality MDF boards can pose significant challenges for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. With a multitude of suppliers and varying quality standards, navigating the global market for MDF board suppliers requires strategic insight and careful consideration. This guide aims to equip buyers with essential knowledge about different types of MDF boards, their applications across various industries, and key factors to consider when vetting potential suppliers.

Understanding the nuances of MDF board sourcing is crucial for making informed purchasing decisions. This comprehensive resource covers everything from identifying reliable suppliers and assessing product specifications to negotiating costs and ensuring compliance with international standards. By providing actionable insights and best practices, this guide empowers B2B buyers to optimize their supply chain, enhance product quality, and ultimately drive business growth.

For those looking to establish or strengthen their supply relationships, it is vital to grasp the key elements of successful procurement in the MDF sector. This guide will demystify the complexities of the market, enabling you to confidently engage with suppliers from diverse regions such as Thailand and Indonesia. The knowledge gained here will not only streamline your purchasing processes but also enhance your competitive edge in an ever-evolving marketplace.

Understanding mdf board supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard MDF Suppliers | Offer basic MDF boards with standard thickness and density. | Furniture manufacturing, cabinetry | Pros: Cost-effective; widely available. Cons: Limited customization options. |

| Specialty MDF Suppliers | Provide MDF boards with enhanced properties (e.g., moisture resistance, fire retardant). | High-end furniture, construction | Pros: Better durability; tailored solutions. Cons: Higher cost; longer lead times. |

| Eco-friendly MDF Suppliers | Focus on sustainable materials, often using recycled fibers. | Green building projects, eco-friendly products | Pros: Environmentally responsible; market appeal. Cons: May have limited stock; potential higher prices. |

| Custom MDF Suppliers | Offer bespoke MDF solutions tailored to specific client requirements. | Specialized manufacturing, design firms | Pros: Fully tailored products; precise specifications. Cons: Higher costs; longer production times. |

| Import MDF Suppliers | Source MDF from international markets, often at competitive prices. | Large-scale construction, export markets | Pros: Cost advantages; diverse product range. Cons: Potential quality inconsistencies; import regulations. |

What Are the Characteristics of Standard MDF Suppliers?

Standard MDF suppliers are the backbone of the MDF market, providing boards that meet industry standards for thickness and density. These boards are typically used in furniture manufacturing and cabinetry due to their affordability and availability. Buyers should consider the balance between cost and quality, as while these boards are budget-friendly, they may lack the specialized features required for high-performance applications.

How Do Specialty MDF Suppliers Stand Out?

Specialty MDF suppliers differentiate themselves by offering boards with enhanced properties, such as moisture resistance or fire retardancy. These products are ideal for high-end furniture and construction projects where durability is paramount. B2B buyers should evaluate the specific needs of their projects to determine if the investment in these advanced materials justifies the higher price point.

Why Choose Eco-friendly MDF Suppliers?

Eco-friendly MDF suppliers cater to the growing demand for sustainable building materials by utilizing recycled fibers and non-toxic adhesives. These boards are increasingly sought after for green building projects and eco-friendly product lines. While they appeal to environmentally conscious consumers, buyers should be aware that these products may come with limited stock and potentially higher costs.

What Benefits Do Custom MDF Suppliers Provide?

Custom MDF suppliers offer tailored solutions that meet specific client requirements, making them suitable for specialized manufacturing and design firms. These suppliers can produce MDF boards with precise specifications, ensuring that the end product fits perfectly within the intended design. However, buyers should be prepared for higher costs and longer lead times when opting for customization.

How Do Import MDF Suppliers Operate?

Import MDF suppliers source their products from international markets, often providing competitive pricing and a diverse range of options. This can be particularly beneficial for large-scale construction projects or export markets looking to reduce material costs. Nevertheless, B2B buyers must be cautious of potential quality inconsistencies and navigate the complexities of import regulations, which can affect delivery timelines.

Related Video: MDF and HDF

Key Industrial Applications of mdf board supplier

| Industry/Sector | Specific Application of mdf board supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Production of cabinets and shelves | High durability and smooth finish for aesthetic appeal | Sourcing for moisture resistance and custom sizes needed |

| Interior Design and Fit-Outs | Wall paneling and decorative elements | Enhanced design flexibility with various finishes | Availability of eco-friendly options and lead times |

| Construction | Temporary partitions and acoustic panels | Cost-effective solutions for space management | Compliance with local building regulations and certifications |

| Automotive | Interior components like door panels and trims | Lightweight yet strong material for better fuel efficiency | Need for precision cutting and shaping capabilities |

| Retail Fixtures | Display stands and furniture | Customization options for branding and marketing | Consideration of weight capacity and transport logistics |

How is MDF Board Used in Furniture Manufacturing?

In the furniture manufacturing sector, MDF boards are extensively used for producing cabinets, shelves, and other furniture items. Their smooth surface allows for easy painting and veneering, which enhances aesthetic appeal. International buyers, particularly from regions like Africa and South America, need to ensure that the MDF sourced is moisture-resistant to mitigate warping in humid climates. Additionally, custom sizes may be required based on specific design needs, necessitating a supplier capable of meeting these demands.

What Role Does MDF Board Play in Interior Design and Fit-Outs?

MDF boards are pivotal in the interior design and fit-out industries, particularly for applications like wall paneling and decorative elements. They provide designers with the flexibility to create unique and intricate designs that can be easily painted or laminated. Buyers from the Middle East and Europe may prioritize sourcing MDF that adheres to eco-friendly standards, as sustainability becomes increasingly important in design projects. Suppliers should offer a variety of finishes and textures to cater to diverse client preferences.

How is MDF Board Utilized in Construction?

In the construction industry, MDF boards are often utilized for temporary partitions and acoustic panels. They offer a cost-effective solution for managing space in commercial environments and help in noise reduction. B2B buyers must consider local building regulations when sourcing MDF, as compliance with fire safety and environmental standards is crucial. Additionally, suppliers should be able to provide quick turnaround times, especially for large-scale projects.

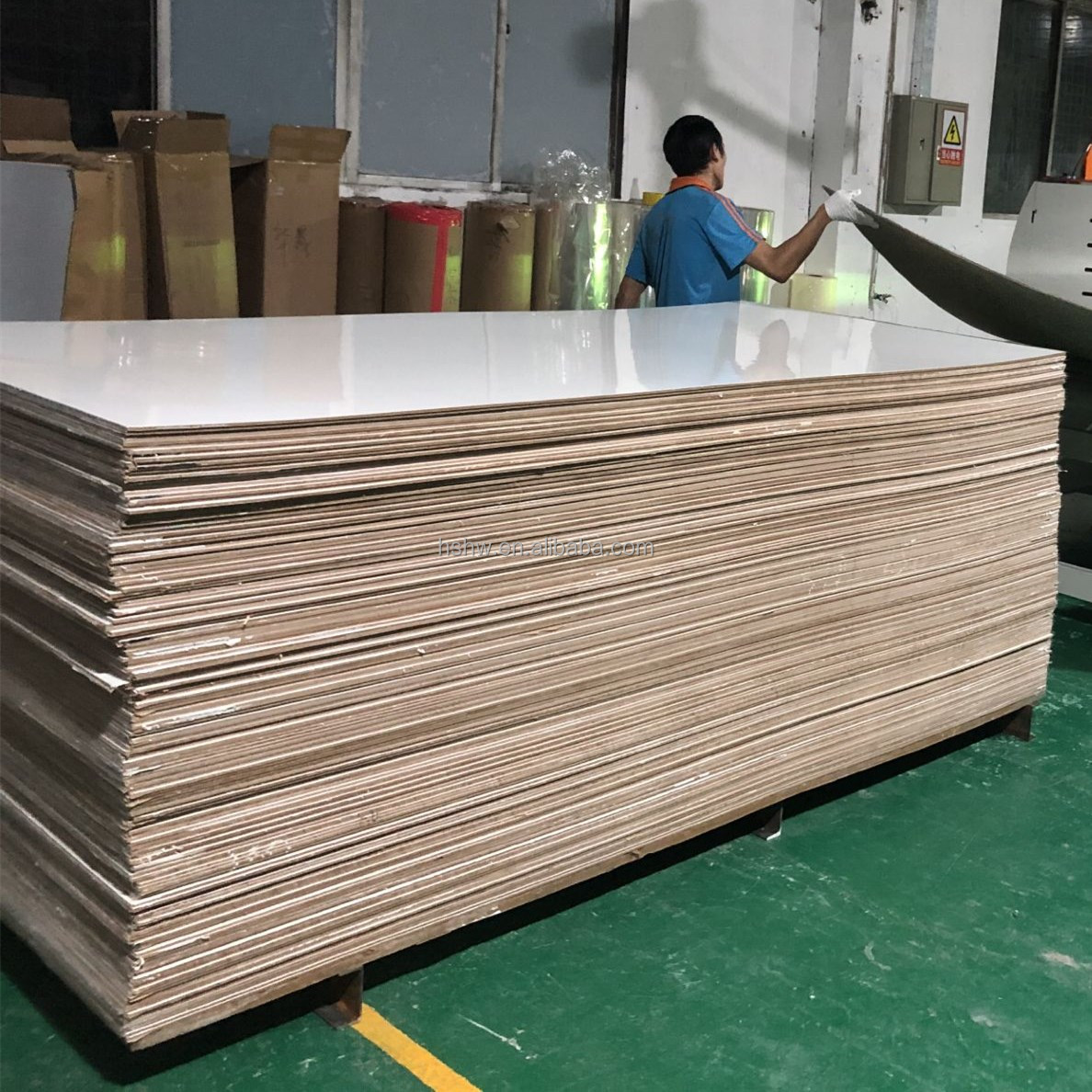

A stock image related to mdf board supplier.

What are the Applications of MDF Board in the Automotive Sector?

MDF boards find applications in the automotive industry, particularly for interior components like door panels and trims. The lightweight nature of MDF contributes to improved fuel efficiency without compromising strength. Buyers in this sector require suppliers that can deliver precision-cut MDF to meet specific design criteria. Additionally, the ability to withstand various environmental conditions is essential, making sourcing from reliable suppliers critical.

How is MDF Board Important for Retail Fixtures?

A stock image related to mdf board supplier.

In retail, MDF boards are widely used for creating display stands and furniture that showcase products effectively. The ability to customize MDF for branding purposes allows retailers to create unique shopping experiences. When sourcing MDF for retail applications, considerations around weight capacity and logistics are vital, particularly for international shipments. Suppliers should be equipped to handle bulk orders and provide timely delivery to ensure retail operations are not disrupted.

3 Common User Pain Points for ‘mdf board supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of MDF Boards

The Problem: One of the most pressing challenges for B2B buyers sourcing MDF boards is the inconsistency in product quality. Buyers often face situations where the MDF boards received do not meet the specifications outlined in the purchase agreement. This can lead to project delays, increased costs, and dissatisfaction from end-users. For companies in industries like furniture manufacturing or interior design, where quality is paramount, such discrepancies can damage reputation and profitability.

The Solution: To mitigate the risk of inconsistent quality, buyers should establish a robust supplier evaluation process. This involves assessing potential MDF board suppliers based on their manufacturing capabilities, quality certifications (such as ISO 9001), and customer reviews. It’s crucial to request samples before placing a bulk order to verify that the product meets the necessary standards. Additionally, maintaining clear communication about specifications and quality expectations in the contract can help hold suppliers accountable. Implementing regular quality audits during production can also ensure that the boards conform to agreed-upon standards throughout the manufacturing process.

Scenario 2: Long Lead Times for MDF Board Deliveries

The Problem: International B2B buyers frequently encounter long lead times when ordering MDF boards, which can hinder project timelines and operational efficiency. For example, a furniture manufacturer in South America may place an order with a supplier in Europe only to face unexpected delays due to shipping or production issues. These delays can disrupt supply chains, resulting in missed deadlines and increased costs.

The Solution: To combat long lead times, buyers should prioritize establishing relationships with local or regional MDF board suppliers who can provide faster delivery times. It’s also beneficial to negotiate terms that include expedited shipping options. Buyers can implement a just-in-time inventory strategy, which allows them to order smaller quantities more frequently, thus reducing the risk of stockouts. Additionally, maintaining a buffer stock of MDF boards can help mitigate the impact of delays and ensure continuity in production.

Scenario 3: Lack of Customization Options from Suppliers

The Problem: Another significant pain point for B2B buyers is the limited customization options available when sourcing MDF boards. Many suppliers offer standard sizes and finishes, which may not meet the specific requirements of a project. For example, a company specializing in bespoke furniture might need MDF boards in unique dimensions or specific finishes, but suppliers may be unable or unwilling to accommodate these requests.

The Solution: To address the lack of customization, buyers should seek out MDF board suppliers that specialize in custom solutions. This involves conducting thorough research to identify suppliers with a proven track record of flexibility and innovation. When approaching potential suppliers, buyers should clearly communicate their specific needs, including dimensions, finishes, and any other custom requirements. Engaging in collaborative discussions can lead to tailored solutions that not only meet project specifications but also enhance the overall quality of the final product. Establishing long-term partnerships with these suppliers can also foster a greater willingness to adapt to unique requests in the future.

Strategic Material Selection Guide for mdf board supplier

When selecting materials for MDF board production, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with regional standards and preferences. Below, we analyze four common materials used in MDF boards, focusing on their properties, pros and cons, and implications for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Common MDF Board Materials?

1. Wood Fiber

Wood fiber is the primary raw material used in MDF production. It is derived from wood chips and sawmill waste, making it an eco-friendly option.

- Key Properties: Wood fiber offers good tensile strength and flexibility, making it suitable for various applications. It has a moderate temperature resistance and is generally non-corrosive.

- Pros & Cons: The main advantage of wood fiber is its sustainability and cost-effectiveness. However, it may not be as durable as other materials, especially in high-moisture environments.

- Impact on Application: Wood fiber is compatible with paints and adhesives, making it ideal for furniture and cabinetry.

- Considerations for International Buyers: Buyers should ensure that the wood fiber complies with local regulations regarding sustainability, such as the Forest Stewardship Council (FSC) certification.

2. Urea-Formaldehyde Resin

Urea-formaldehyde resin is commonly used as a binding agent in MDF production.

- Key Properties: This resin provides excellent adhesion and is resistant to heat and moisture. However, it can emit volatile organic compounds (VOCs), which may be a concern in certain markets.

- Pros & Cons: The main advantage is its strong bonding capability, which enhances the durability of MDF boards. The downside is the potential health risks associated with VOC emissions, making it less suitable for indoor applications in sensitive environments.

- Impact on Application: Ideal for applications requiring strong, durable boards, such as flooring and wall panels.

- Considerations for International Buyers: Compliance with regulations like the European Union’s E1 standard for formaldehyde emissions is crucial for market acceptance.

3. Medium Density Fiberboard (MDF) with Additives

Additives such as fire retardants or anti-fungal agents can be mixed with MDF to enhance performance.

- Key Properties: These additives improve fire resistance and mold prevention, making the MDF suitable for a wider range of applications.

- Pros & Cons: The key advantage is increased safety and longevity, particularly in humid or high-risk environments. However, the manufacturing process can become more complex and costly.

- Impact on Application: Particularly beneficial for commercial applications such as office furniture and public spaces where safety is a concern.

- Considerations for International Buyers: Buyers should verify that the additives used meet local safety standards, such as ASTM or DIN regulations.

4. Recycled Wood Material

Recycled wood materials are increasingly being used in MDF production to promote sustainability.

- Key Properties: This material offers similar properties to virgin wood fiber but with a lower environmental impact. It has good strength and durability.

- Pros & Cons: The primary advantage is its eco-friendliness and reduced cost. However, the quality can vary based on the source of the recycled material.

- Impact on Application: Suitable for a wide range of applications, including furniture and decorative panels.

- Considerations for International Buyers: Ensure compliance with recycling standards and certifications, which can vary significantly by region.

Summary Table of MDF Board Materials

| Material | Typical Use Case for MDF Board Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood Fiber | Furniture, cabinetry | Eco-friendly and cost-effective | Less durable in high-moisture environments | Low |

| Urea-Formaldehyde Resin | Flooring, wall panels | Strong bonding capability | VOC emissions may pose health risks | Medium |

| MDF with Additives | Office furniture, public spaces | Increased safety and longevity | More complex and costly manufacturing process | High |

| Recycled Wood Material | Decorative panels, furniture | Eco-friendly and reduced cost | Quality can vary based on source | Medium |

Understanding these materials and their implications can help international B2B buyers make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mdf board supplier

What Are the Main Stages of MDF Board Manufacturing?

MDF (Medium Density Fiberboard) is a versatile engineered wood product used widely in furniture, cabinetry, and flooring. The manufacturing process consists of several key stages that ensure the quality and durability of the final product.

Material Preparation: How Is MDF Board Made?

The first step in MDF production involves preparing the raw materials. Wood fibers, typically sourced from wood shavings and sawdust, are cleaned and screened to remove impurities. This is crucial because contaminants can affect the quality of the board. The wood fibers are then subjected to a drying process to reduce moisture content to an optimal level, which is usually around 8-12%. This preparation stage ensures that the fibers are suitable for the subsequent forming process.

Forming Process: What Techniques Are Used?

Once the materials are prepared, the next stage is forming. The dried wood fibers are mixed with adhesives, usually urea-formaldehyde or phenol-formaldehyde, and other additives to enhance properties like water resistance and fire retardancy. This mixture is then formed into mats using a mat forming machine. The mats are compressed under high pressure and temperature in a hot press, which fuses the fibers together. The resulting board is then cooled and cut to size.

Assembly and Finishing: How Is Quality Enhanced?

Following the forming process, the MDF boards undergo assembly, where they may be layered or bonded with additional materials for specific applications. This is often done for products requiring enhanced strength or aesthetic features. After assembly, the boards are sanded and finished to meet surface quality standards. This finishing can include painting, veneering, or laminating, which not only improves aesthetics but also provides additional protective layers.

What Quality Assurance Measures Are Essential in MDF Production?

Quality assurance is critical in ensuring that MDF boards meet industry standards and customer expectations. Various international standards and industry-specific certifications guide this process.

Which International Standards Should B2B Buyers Look For?

For MDF suppliers, adhering to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and continuous improvement, ensuring that suppliers maintain high-quality processes. Additionally, compliance with the CE marking indicates that the products meet European safety, health, and environmental requirements.

What Are the Checkpoints in Quality Control?

Quality control (QC) in MDF production involves multiple checkpoints, which typically include:

- Incoming Quality Control (IQC): This phase assesses raw materials before they enter the production line. Suppliers should check for moisture content, fiber quality, and adherence to specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at various stages to ensure the product meets defined standards. This includes monitoring adhesive application and mat density.

- Final Quality Control (FQC): Once the boards are produced, they undergo thorough testing for dimensional accuracy, surface finish, and physical properties like strength and density.

What Common Testing Methods Are Employed?

B2B buyers should be aware of common testing methods that verify the quality of MDF boards. These include:

- Density Testing: To ensure the board meets specified density requirements.

- Moisture Content Testing: Critical for assessing the board’s stability and performance.

- Strength Testing: This includes bending and tensile strength tests to evaluate the board’s durability.

- Formaldehyde Emission Testing: To ensure compliance with health and safety regulations, especially for products sold in markets with strict emission standards.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers must establish confidence in their suppliers’ QC processes. Here are effective strategies for verifying quality:

What Audits and Reports Should Be Considered?

Conducting audits is one of the most effective ways to assess a supplier’s quality control measures. Buyers can request to see:

- Quality Management System Documentation: This includes manuals and procedures that outline how the supplier maintains quality.

- Inspection Reports: These reports detail the results of IQC, IPQC, and FQC, providing insights into the supplier’s quality assurance practices.

How Can Third-party Inspections Enhance Trust?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. These inspections can be scheduled at various stages of production and are particularly beneficial for buyers from regions such as Africa, South America, and the Middle East, where local regulations may differ significantly from European standards.

What Nuances Should International B2B Buyers Be Aware Of?

Understanding the nuances of quality control and certification can significantly impact purchasing decisions. For buyers from Africa, South America, the Middle East, and Europe, it’s essential to consider:

- Local Regulations vs. International Standards: Different regions may have varying standards for MDF boards. Buyers should familiarize themselves with both local regulations and international standards to ensure compliance.

- Supply Chain Transparency: Establishing a transparent supply chain can help mitigate risks related to quality. Buyers should inquire about the sourcing of raw materials and the overall manufacturing process.

- Sustainability Certifications: With increasing emphasis on sustainability, buyers should look for suppliers that adhere to environmental certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification).

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing MDF boards from suppliers worldwide, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mdf board supplier’

This guide aims to provide international B2B buyers with a practical checklist for sourcing MDF board suppliers. It focuses on actionable insights that will streamline the procurement process and ensure that you select the right supplier for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing MDF boards. Consider the thickness, density, and grade of the MDF required for your projects. Specific industries may have unique standards, so understanding these nuances will help you communicate your needs effectively to potential suppliers.

- What to Include: Dimensions, moisture resistance, and any certifications required for your specific application.

- Why It’s Important: Well-defined specifications will help filter out suppliers who cannot meet your requirements, saving time and reducing the risk of procurement errors.

Step 2: Conduct Market Research

Before reaching out to suppliers, conduct comprehensive market research to identify potential vendors. Look for suppliers with a strong reputation, especially those with experience in your target regions, such as Africa, South America, the Middle East, and Europe.

- Where to Look: Industry directories, trade shows, and online platforms specializing in B2B transactions.

- Why It’s Important: Understanding the market landscape allows you to make informed decisions and identify the most competitive suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; dig deeper.

- What to Check: Financial stability, production capacity, and past performance reviews.

- Why It’s Important: A reliable supplier can significantly affect your supply chain efficiency, so it’s essential to ensure they have a proven track record.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold the necessary certifications relevant to MDF production. This includes ISO certifications, environmental compliance, and safety standards.

- What to Look For: Documentation that proves adherence to industry standards and regulations.

- Why It’s Important: Certifications are indicators of quality and reliability, and they can also affect your own compliance with regulations.

Step 5: Request Sample Products

Always request samples of the MDF boards before finalizing any orders. This allows you to assess the quality firsthand and ensure it meets your specifications.

- What to Consider: Durability, finish, and how well the product fits into your intended application.

- Why It’s Important: Samples can reveal potential issues that may not be apparent through documentation alone, helping you avoid costly mistakes.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms of the contract, including pricing, delivery schedules, and payment terms. Be clear about expectations to avoid misunderstandings later.

- Key Areas to Address: Minimum order quantities, penalties for late deliveries, and warranty conditions.

- Why It’s Important: Clear terms help establish a strong partnership and protect your interests throughout the procurement process.

Step 7: Establish Communication Protocols

After finalizing the deal, establish effective communication protocols with your supplier. Regular updates on order status and potential challenges are crucial for a smooth collaboration.

- What to Set Up: Regular check-ins, preferred communication channels, and escalation procedures for issues.

- Why It’s Important: Strong communication fosters trust and helps resolve any issues quickly, ensuring that your supply chain remains efficient.

By following these steps, you can streamline the sourcing process for MDF boards, ensuring that you partner with a supplier who meets your quality and service expectations.

Comprehensive Cost and Pricing Analysis for mdf board supplier Sourcing

What Are the Key Cost Components for Sourcing MDF Boards?

When sourcing MDF (Medium Density Fiberboard) boards, understanding the complete cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: This is often the largest expense, influenced by the type and quality of wood fibers used. Higher-quality materials can increase the price but may offer better durability and performance.

-

Labor: Labor costs include wages for workers involved in the production process. These costs can vary significantly depending on the region, with countries in Africa and South America generally having lower labor costs compared to Europe.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Investment in tooling is critical, particularly for customized orders. The upfront cost may be high, but it can lead to greater efficiency and lower per-unit costs in large orders.

-

Quality Control (QC): Implementing stringent QC measures ensures that the MDF boards meet industry standards. While this adds to the overall cost, it is crucial for maintaining product integrity and customer satisfaction.

-

Logistics: Transportation costs can significantly impact the final price, particularly for international shipments. Factors such as distance, mode of transport, and local tariffs play a vital role in logistics expenses.

-

Margin: Suppliers will also include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect MDF Board Pricing?

Several factors can influence the pricing of MDF boards, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it essential to negotiate based on your purchasing needs.

-

Specifications and Customization: Custom MDF boards that meet specific design or performance criteria often come with higher costs. Understanding your requirements can help you balance quality and cost effectively.

-

Material Quality and Certifications: Boards that comply with international certifications, such as CARB or E0, often attract higher prices due to their lower emissions and environmental impact. Buyers should weigh the benefits of certified products against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more, but they can also provide peace of mind regarding product consistency.

-

Incoterms: International Commercial Terms (Incoterms) determine the responsibilities of buyers and sellers in shipping. Understanding these terms can help mitigate unforeseen costs related to customs duties and shipping insurance.

What Are the Best Buyer Tips for Sourcing MDF Boards Internationally?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, here are some actionable tips to enhance cost-efficiency:

-

Negotiate Pricing: Always engage in negotiations. Suppliers expect some bargaining, and you may secure better terms by discussing volume commitments or long-term partnerships.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs, including maintenance and disposal. Opting for higher-quality MDF boards may result in lower TCO due to their durability.

-

Research Market Prices: Stay informed about market trends and pricing benchmarks. This knowledge can empower you during negotiations and help you identify fair pricing.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures influenced by local demand, supply chain dynamics, and economic conditions. Understanding these nuances can help you make more strategic sourcing decisions.

Disclaimer on Indicative Prices

Prices for MDF boards can fluctuate based on market conditions, supplier pricing strategies, and other external factors. It is advisable to request updated quotes from multiple suppliers to ensure competitive pricing and make informed purchasing decisions.

Alternatives Analysis: Comparing mdf board supplier With Other Solutions

Understanding Alternatives to MDF Board Suppliers

When sourcing materials for manufacturing or construction, international B2B buyers often face the challenge of selecting the right supplier or product. While MDF (Medium Density Fiberboard) is a popular choice due to its versatility and cost-effectiveness, there are viable alternatives that may better suit specific needs. This section compares MDF board suppliers with other solutions, helping buyers make informed decisions based on performance, cost, and other critical factors.

Comparison Table of MDF Board Suppliers and Alternatives

| Comparison Aspect | MDF Board Supplier | Plywood Supplier | Particle Board Supplier |

|---|---|---|---|

| Performance | Good for flat surfaces; can warp in humid conditions | Stronger, more durable; resistant to moisture | Less durable; prone to damage under heavy loads |

| Cost | Generally low-cost | Moderate to high cost | Low-cost |

| Ease of Implementation | Easy to cut and shape; requires minimal tools | Requires specialized tools for cutting | Easy to work with; minimal tools needed |

| Maintenance | Low maintenance; may require sealing | Low maintenance; can be refinished | Low maintenance; prone to chipping |

| Best Use Case | Ideal for furniture, cabinetry, and decorative applications | Best for structural applications and furniture | Suitable for low-cost furniture and temporary structures |

In-Depth Analysis of Alternatives

What are the advantages and disadvantages of plywood suppliers?

Plywood is a strong alternative to MDF, composed of multiple layers of wood veneer glued together. Its primary advantage is durability; it resists warping and moisture better than MDF, making it suitable for outdoor furniture and structural applications. However, plywood can be more expensive and may require specialized tools for cutting and installation. Buyers should consider the end-use application to determine if the investment in plywood is justified.

How does particle board compare to MDF board suppliers?

Particle board, made from wood chips and resin, is another cost-effective alternative to MDF. It is lightweight and easy to work with, making it suitable for low-cost furniture and temporary structures. However, its durability is a significant downside; particle board is more prone to damage under heavy loads and can swell when exposed to moisture. For buyers focused on budget and short-term solutions, particle board may be an attractive option, but it may not hold up as well in the long run compared to MDF or plywood.

How to Choose the Right Solution for Your Needs

When selecting a solution, B2B buyers should evaluate their specific requirements, including budget, intended use, and environmental factors. If durability and moisture resistance are crucial, plywood may be the better choice despite its higher cost. Conversely, if cost is the primary concern and the application is less demanding, MDF or particle board could suffice. Ultimately, understanding the unique properties and limitations of each material will empower buyers to make a decision that aligns with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for mdf board supplier

What Are the Key Technical Properties of MDF Boards That B2B Buyers Should Know?

When sourcing MDF (Medium Density Fiberboard) boards, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications that international B2B buyers should consider:

1. Material Grade

Material grade refers to the density and quality of the MDF board. Common grades include standard, moisture-resistant, and fire-retardant. For instance, moisture-resistant MDF is ideal for humid environments, making it suitable for kitchen and bathroom applications. Selecting the right material grade can significantly impact the durability and performance of the final product.

2. Thickness Tolerance

Thickness tolerance indicates the allowable deviation from the specified thickness of the MDF board. For instance, a standard tolerance may be ±0.5 mm. This specification is crucial for ensuring a precise fit in applications such as cabinetry and furniture, where uniformity is essential for aesthetics and functionality.

3. Surface Finish

The surface finish of MDF can be raw, primed, or veneered. A primed surface is often preferred for painting, while veneered boards offer a more aesthetically pleasing appearance. Understanding the surface finish helps buyers select the appropriate MDF type for their specific projects, ensuring they meet design and functional requirements.

4. Formaldehyde Emissions

MDF boards are manufactured using adhesives that can emit formaldehyde. Buyers should be aware of the emission levels, which are categorized by standards such as E1 or E0. Selecting low-emission MDF is not only beneficial for health but may also be a regulatory requirement in some markets, particularly in Europe.

5. Weight Load Capacity

The weight load capacity indicates how much weight the MDF board can support without compromising structural integrity. This property is particularly important for applications like shelving and furniture, where excessive weight can lead to sagging or breakage. Understanding this capacity ensures that buyers choose the right MDF for their intended use.

Which Trade Terminology Should B2B Buyers Understand When Dealing with MDF Suppliers?

In addition to technical specifications, familiarity with industry jargon is vital for successful transactions. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. For MDF suppliers, being an OEM means they can produce custom boards tailored to specific requirements, which is crucial for buyers needing unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding the MOQ helps buyers plan their procurement strategies, ensuring they meet supplier requirements while avoiding excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. For MDF boards, an RFQ should include details about specifications, quantities, and desired delivery timelines. This process helps buyers compare offers and negotiate favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, risk, and costs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping logistics and total landed costs.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for project planning, particularly in industries with strict timelines. Buyers should inquire about lead times when negotiating contracts to ensure timely delivery.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the MDF supply chain more effectively, leading to smarter purchasing decisions and better project outcomes.

Navigating Market Dynamics and Sourcing Trends in the mdf board supplier Sector

What Are the Current Market Dynamics and Key Trends in the MDF Board Supplier Sector?

The MDF (Medium Density Fiberboard) board supplier sector is experiencing significant growth driven by the rise of the construction and furniture industries globally. In particular, emerging markets in Africa, South America, and the Middle East are witnessing a surge in demand for MDF boards due to rapid urbanization and increased disposable income. Simultaneously, Europe remains a strong market, with a focus on innovative designs and sustainable materials.

Technological advancements in manufacturing processes, such as the adoption of automated machinery and digital supply chain management, are transforming sourcing strategies. International B2B buyers are increasingly leaning towards online platforms for procurement, streamlining communication and enhancing transparency. Moreover, the integration of AI and data analytics in inventory management is helping suppliers predict demand more accurately, reducing lead times and enhancing customer satisfaction.

Another notable trend is the increasing preference for customized solutions. Buyers are seeking MDF products that can be tailored to specific requirements, from thickness to surface finishes, thereby pushing suppliers to innovate continuously. As global supply chains evolve, buyers must remain vigilant about geopolitical factors, tariffs, and trade agreements that could impact sourcing strategies.

How Does Sustainability and Ethical Sourcing Impact the MDF Board Supplier Sector?

Sustainability has become a central theme in the MDF board supplier sector. The environmental impact of MDF production, particularly regarding deforestation and resource depletion, has led to increased scrutiny from consumers and regulatory bodies. As a result, international B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing raw materials from certified forests and using eco-friendly adhesives and finishes.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly demanding transparency in sourcing, which includes understanding the origin of materials and the labor practices involved in production. Certifications such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) are becoming essential for suppliers aiming to attract conscientious buyers.

Furthermore, as global awareness of climate change grows, there is a significant push towards using ‘green’ materials. Suppliers offering MDF boards with low volatile organic compounds (VOCs) and improved recyclability are more likely to capture the attention of environmentally aware B2B buyers. Embracing sustainability not only enhances brand reputation but can also lead to cost savings through efficient resource management.

How Has the MDF Board Supplier Sector Evolved Over Time?

The MDF board supplier sector has evolved significantly since its inception in the 1960s. Initially, MDF was primarily used in furniture and cabinetry due to its smooth finish and versatility. Over the years, advancements in technology have led to improved manufacturing processes, resulting in stronger, more durable products that cater to a wider range of applications, including flooring, wall panels, and decorative mouldings.

In recent decades, the focus has shifted towards sustainability and ethical sourcing, reflecting broader societal changes. With the rise of environmental awareness, suppliers have had to adapt by implementing greener production methods and obtaining certifications that appeal to conscientious buyers. This evolution underscores the sector’s responsiveness to market demands and highlights the importance of aligning business practices with global sustainability goals.

In conclusion, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of these dynamics and trends when sourcing MDF boards. Understanding market forces, prioritizing sustainability, and recognizing the evolution of the sector are key to making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of mdf board supplier

-

How do I evaluate the quality of MDF boards from a supplier?

To assess the quality of MDF boards, request product samples and conduct a thorough inspection. Check for uniform thickness, density, and surface smoothness. Additionally, inquire about the supplier’s certifications, such as ISO or environmental standards, which indicate adherence to quality control processes. Testing for moisture resistance and formaldehyde emissions can also provide insights into durability and safety. Engaging in quality audits or site visits can further help in evaluating the supplier’s manufacturing practices. -

What are the best practices for negotiating prices with MDF board suppliers?

When negotiating prices, start by researching market rates and understanding your supplier’s cost structure. Clearly outline your requirements, including specifications and order quantities, to establish a basis for negotiation. Leverage your purchasing volume for better pricing and consider long-term partnerships for additional discounts. Be prepared to discuss payment terms and delivery timelines, as these can influence overall costs. Finally, maintaining open communication can foster a collaborative negotiation atmosphere. -

What customization options are available for MDF boards?

Many MDF board suppliers offer customization options, including specific sizes, thicknesses, and finishes. You can also request custom formulations for enhanced properties, such as moisture resistance or fire retardancy. Before placing an order, communicate your exact requirements and confirm the supplier’s capabilities to meet them. Some suppliers may also provide design services to help you visualize the final product, making it essential to discuss these possibilities early in the engagement. -

What is the minimum order quantity (MOQ) for MDF boards from suppliers?

Minimum order quantities for MDF boards vary significantly among suppliers, often depending on their production capacity and your specific requirements. Generally, MOQs can range from a few hundred to several thousand square meters. When sourcing, ask potential suppliers about their MOQs upfront to avoid unexpected costs. If your needs are smaller, consider negotiating for a trial order or seeking suppliers who cater to smaller businesses. -

What payment terms should I expect when sourcing MDF boards internationally?

Payment terms for international transactions typically include options like advance payment, letters of credit, or open account terms. Expect to negotiate terms based on your relationship with the supplier and the order size. Many suppliers may require a deposit, with the balance payable upon shipment or delivery. It’s crucial to clarify all payment details, including currency and transaction fees, to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure compliance with international shipping regulations for MDF boards?

To ensure compliance with international shipping regulations, familiarize yourself with the import/export laws of both your country and the supplier’s country. Request documentation from your supplier, such as certificates of origin and compliance with safety standards. Engaging a freight forwarder experienced in handling MDF products can also help navigate logistics and customs procedures. Always stay updated on any changes in regulations that may affect your shipments to avoid delays. -

What quality assurance measures should I look for in MDF board suppliers?

When vetting MDF board suppliers, inquire about their quality assurance processes. Look for suppliers that implement regular quality checks at various stages of production and have certifications such as ISO 9001. Ask about their testing methods for product durability, surface quality, and safety standards. Additionally, consider suppliers who are open to third-party inspections, as this can provide added assurance of product quality before shipment. -

How can I manage logistics effectively when importing MDF boards?

To manage logistics effectively when importing MDF boards, start by selecting a reliable shipping partner familiar with handling bulky goods. Coordinate closely with your supplier to align production schedules with shipping times. Use technology, such as tracking systems, to monitor shipments in real-time. Additionally, plan for potential delays by factoring in customs clearance times and local transportation logistics. Establishing clear communication channels with all parties involved can also streamline the process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mdf board supplier

What Are the Key Takeaways for B2B Buyers in Sourcing MDF Boards?

In conclusion, strategic sourcing is paramount for B2B buyers navigating the complex landscape of MDF board procurement. Understanding the nuances of supplier capabilities, regional market dynamics, and compliance with international standards can significantly enhance your sourcing strategy. Buyers should prioritize relationships with suppliers who demonstrate reliability, quality assurance, and innovative practices that align with sustainability goals.

How Can International Buyers Leverage Strategic Sourcing?

For buyers in Africa, South America, the Middle East, and Europe, the focus should be on building strong partnerships that not only fulfill immediate needs but also foster long-term collaboration. By leveraging technology and data analytics, companies can optimize their sourcing processes, ensuring they remain competitive in a rapidly evolving marketplace.

What Is the Future Outlook for MDF Board Suppliers?

Looking forward, the MDF board industry is poised for growth, driven by increasing demand for sustainable materials and innovative applications. International buyers are encouraged to stay informed about emerging trends, such as eco-friendly product lines and advancements in manufacturing technology. Engage with suppliers actively and explore opportunities for joint ventures or partnerships that can enhance your value chain.

By embracing strategic sourcing, B2B buyers can position themselves for success in the global MDF market, ensuring they not only meet current demands but also anticipate future needs.