Find the Best Upholstery Fabric Supplier: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for upholstery fabric supplier

In an increasingly interconnected world, sourcing the right upholstery fabric supplier can be a daunting task for international B2B buyers, particularly when navigating diverse markets across Africa, South America, the Middle East, and Europe. The challenge lies not just in finding suppliers who offer quality materials but also in understanding regional preferences, compliance with local regulations, and the nuances of cultural aesthetics. This guide addresses these complexities by providing a comprehensive overview of the upholstery fabric market, including various types of fabrics, their applications, and effective strategies for supplier vetting.

As you embark on your journey to procure upholstery fabrics, this guide will empower you with actionable insights that facilitate informed purchasing decisions. Learn how to assess the quality of materials, compare costs, and identify reputable suppliers that align with your business needs. We will also delve into critical aspects such as sustainability practices and the importance of transparent communication with suppliers.

By equipping yourself with knowledge and strategies specific to your region—be it Italy’s rich textile heritage or South Africa’s vibrant market—you can enhance your sourcing efforts and ensure that your upholstery products meet the highest standards. This guide aims to be your go-to resource in navigating the global upholstery fabric landscape, turning challenges into opportunities for growth and innovation in your business.

Understanding upholstery fabric supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Fiber Suppliers | Use of organic materials like cotton, linen, and wool | High-end furniture, eco-friendly designs | Pros: Sustainable, breathable; Cons: Higher cost, less durability. |

| Synthetic Fiber Suppliers | Made from man-made materials such as polyester and nylon | Mass production, budget-friendly items | Pros: Cost-effective, durable; Cons: Less breathable, may have environmental concerns. |

| Specialty Fabric Suppliers | Focus on niche markets like outdoor fabrics or performance textiles | Hospitality, automotive, marine sectors | Pros: Tailored solutions, high performance; Cons: Limited availability, potentially higher prices. |

| Upholstery Wholesalers | Bulk suppliers with a wide range of fabric options | Retailers, manufacturers, interior designers | Pros: Competitive pricing, large inventory; Cons: May lack personalized service. |

| Custom Fabric Suppliers | Offer bespoke designs and patterns tailored to client needs | Luxury furniture, bespoke projects | Pros: Unique offerings, high customization; Cons: Longer lead times, higher costs. |

What Are the Characteristics of Natural Fiber Suppliers?

Natural fiber suppliers focus on providing upholstery fabrics made from organic materials like cotton, linen, and wool. These fabrics are often sought after for their aesthetic appeal and sustainability, making them popular in high-end furniture design and eco-friendly projects. Buyers should consider the durability and maintenance requirements of these fabrics, as they may require special care to maintain their quality over time. Additionally, the cost can be a significant factor, as natural fibers tend to be more expensive than synthetic options.

How Do Synthetic Fiber Suppliers Benefit B2B Buyers?

Synthetic fiber suppliers specialize in upholstery fabrics made from man-made materials such as polyester and nylon. These fabrics are known for their durability and resistance to wear and tear, making them ideal for mass production and budget-friendly items. B2B buyers often favor synthetic fabrics for their cost-effectiveness and ease of maintenance. However, it’s essential to weigh the environmental impact of these materials, as they may not align with sustainability goals. Understanding the specific applications and performance characteristics of synthetic fabrics can aid buyers in making informed decisions.

What Are the Unique Offerings of Specialty Fabric Suppliers?

Specialty fabric suppliers cater to niche markets by providing unique upholstery solutions such as outdoor fabrics or performance textiles. These suppliers are crucial for industries like hospitality, automotive, and marine sectors, where specific performance characteristics are required. When purchasing from specialty suppliers, B2B buyers should consider the fabric’s resistance to environmental factors, such as UV rays and moisture. While these fabrics may come at a premium price, their tailored solutions and high performance can justify the investment for businesses looking for durability and functionality.

Why Choose Upholstery Wholesalers for Bulk Purchases?

Upholstery wholesalers are ideal for businesses looking to purchase fabrics in bulk. They typically offer a wide range of fabric options, making them a one-stop shop for retailers, manufacturers, and interior designers. The competitive pricing and large inventory are significant advantages for B2B buyers. However, businesses should be aware that wholesalers may lack personalized service, which can be a drawback when seeking specific guidance or custom solutions. It’s essential to evaluate the wholesaler’s reputation and customer service capabilities before committing to large orders.

What Are the Advantages of Working with Custom Fabric Suppliers?

Custom fabric suppliers provide bespoke designs and patterns tailored to the specific needs of clients. This option is particularly appealing for luxury furniture makers and bespoke projects, allowing businesses to differentiate themselves in the market. While the unique offerings and high levels of customization can enhance a brand’s appeal, buyers should be prepared for longer lead times and potentially higher costs. It’s crucial for B2B buyers to communicate their requirements clearly to ensure the final product meets their expectations and aligns with their budget.

Related Video: How To Choose Upholstery Fabric

Key Industrial Applications of upholstery fabric supplier

| Industry/Sector | Specific Application of Upholstery Fabric Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel Furniture Upholstery | Enhances guest experience and aesthetic appeal | Durability, stain resistance, and design flexibility |

| Automotive | Car Interior Upholstery | Improves vehicle comfort and brand image | Material performance, compliance with safety standards |

| Healthcare | Medical Furniture Upholstery | Ensures hygiene and patient comfort | Antimicrobial properties, ease of cleaning, durability |

| Office Furniture | Office Chairs and Desks Upholstery | Increases employee satisfaction and productivity | Ergonomics, durability, and design compatibility |

| Retail | Display Furniture Upholstery | Attracts customers and enhances product presentation | Customization options, material quality, and cost-effectiveness |

How Is Upholstery Fabric Used in the Hospitality Industry?

In the hospitality sector, upholstery fabric suppliers play a crucial role in enhancing the aesthetic appeal and comfort of hotel furniture. High-quality upholstery not only improves guest experiences but also aligns with the brand image of the establishment. Buyers in this sector should prioritize fabrics that offer durability and stain resistance, as these attributes are essential for maintaining a pristine appearance in high-traffic areas. Additionally, design flexibility is vital to accommodate various interior themes and styles prevalent in different regions, particularly in Europe and Africa.

What Are the Applications of Upholstery Fabric in the Automotive Industry?

In the automotive industry, upholstery fabric suppliers provide materials for car interiors, including seats, headliners, and door panels. The primary focus is on improving vehicle comfort and enhancing the overall brand image of the manufacturer. International B2B buyers must consider the performance of materials, such as resistance to wear and tear, as well as compliance with safety standards. Furthermore, the growing trend towards sustainability in automotive design means that eco-friendly materials are increasingly sought after, particularly in markets like South America and Europe.

How Is Upholstery Fabric Beneficial in the Healthcare Sector?

Healthcare facilities utilize upholstery fabric for medical furniture, such as examination tables and waiting room chairs. The primary concern in this sector is hygiene and patient comfort. Suppliers must provide fabrics with antimicrobial properties that are easy to clean and maintain, ensuring a safe environment for patients and staff alike. Buyers should also consider the durability of the fabric, as healthcare settings often require long-lasting solutions that withstand frequent use and cleaning processes.

What Role Does Upholstery Fabric Play in Office Furniture?

Upholstery fabric suppliers are essential for the office furniture sector, particularly for items like chairs and desks. The right upholstery can significantly enhance employee satisfaction and productivity by providing ergonomic support and aesthetic appeal. Buyers should focus on sourcing materials that combine durability with style, ensuring they meet the demands of a modern workplace. Additionally, compatibility with existing office design and the ability to customize colors and patterns are key considerations for international buyers, especially in the Middle East and Europe.

How Does Upholstery Fabric Enhance Retail Environments?

In retail, upholstery fabric is used for display furniture and seating areas, playing a pivotal role in attracting customers and enhancing product presentation. Suppliers must offer customization options to align with the brand’s visual identity, while also ensuring high-quality materials that can withstand wear from customer interactions. Cost-effectiveness is another critical factor, as retailers seek to maximize their investment in creating inviting shopping environments. International buyers should also be aware of regional design preferences, particularly in South America and Africa, to effectively cater to local markets.

Related Video: Printed Fabric Production

3 Common User Pain Points for ‘upholstery fabric supplier’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Upholstery Fabrics

The Problem: Many B2B buyers, especially from emerging markets in Africa and South America, often struggle to find upholstery fabric suppliers that offer high-quality materials. This challenge is exacerbated by a lack of local suppliers, leading to reliance on international vendors. Buyers may encounter issues such as inconsistent fabric quality, limited color choices, and long lead times, which can result in delays in production and increased costs.

The Solution: To mitigate these issues, buyers should adopt a multi-faceted approach to sourcing. First, conduct thorough research to identify reputable upholstery fabric suppliers with a proven track record in quality. Use platforms like LinkedIn, industry trade shows, and fabric expos to connect with suppliers. It’s also beneficial to request samples before placing bulk orders. This allows buyers to evaluate the fabric’s texture, durability, and color accuracy firsthand. Furthermore, establishing long-term relationships with selected suppliers can lead to better pricing, priority on orders, and access to exclusive materials.

Scenario 2: Managing Fabric Compliance and Regulations

The Problem: International B2B buyers often face challenges in ensuring that the upholstery fabrics they source comply with local regulations regarding safety, environmental impact, and material sourcing. For instance, buyers in Europe may require fabrics to meet specific fire safety standards, while those in the Middle East might have different requirements. Non-compliance can lead to legal issues and damage to brand reputation.

The Solution: To effectively navigate compliance challenges, buyers should familiarize themselves with the regulations in their target markets before sourcing upholstery fabrics. Engaging legal experts or compliance consultants can provide clarity on local standards. Additionally, buyers should request certifications from suppliers that demonstrate compliance with relevant regulations, such as Oeko-Tex or ISO standards. It’s also advisable to maintain an updated compliance checklist for each fabric type and supplier, which can streamline the sourcing process and ensure that all materials meet necessary criteria.

Scenario 3: Overcoming Communication Barriers with Suppliers

The Problem: Communication issues often arise when B2B buyers engage with upholstery fabric suppliers, particularly when dealing with suppliers from different cultural backgrounds or languages. Misunderstandings can lead to incorrect orders, delays, and frustration on both sides. This is particularly prevalent for buyers from Africa and the Middle East, where linguistic differences may complicate negotiations and specifications.

The Solution: To enhance communication with upholstery fabric suppliers, buyers should establish clear and structured communication protocols. This includes providing detailed specifications in writing, using visual aids like charts or images, and confirming understanding through follow-up questions. Employing bilingual staff or utilizing translation services can also bridge language gaps. Additionally, setting regular check-in meetings can help ensure that both parties remain aligned throughout the sourcing process. By prioritizing clear communication, buyers can significantly reduce the risk of errors and build stronger partnerships with their suppliers.

Strategic Material Selection Guide for upholstery fabric supplier

What are the Key Properties of Common Upholstery Fabrics?

When selecting upholstery fabrics, understanding the key properties of various materials is crucial for ensuring product performance. Below, we analyze four common upholstery materials: polyester, leather, cotton, and vinyl. Each material has unique characteristics that can significantly impact the final product’s suitability for different applications.

How Does Polyester Perform as an Upholstery Fabric?

Polyester is a synthetic fabric known for its durability and resistance to fading, stains, and wrinkles. It typically has a temperature rating that allows it to withstand moderate heat without degrading. Polyester is often treated with additional coatings to enhance its resistance to moisture and mildew, making it suitable for various environments.

Pros: Polyester is cost-effective, easy to clean, and available in a wide range of colors and patterns. Its durability makes it a popular choice for high-traffic areas.

Cons: While polyester is strong, it may not breathe as well as natural fibers, leading to discomfort in warmer climates. Additionally, its synthetic nature can sometimes be perceived as less luxurious compared to natural fabrics.

Impact on Application: Polyester is compatible with various media, including foam and cushioning materials, making it ideal for residential and commercial upholstery.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards for flame resistance and durability. In Europe, adherence to the REACH regulation for chemical safety is essential.

What are the Advantages and Disadvantages of Leather Upholstery?

Leather is a classic upholstery material known for its elegance and durability. It has a high temperature and pressure rating, making it suitable for heavy use in both residential and commercial settings.

Pros: Leather is naturally resistant to stains and spills, and it ages beautifully, developing a patina over time. It is also breathable, providing comfort in various climates.

Cons: The primary drawback of leather is its high cost compared to other materials. Additionally, it requires regular maintenance to keep it looking its best, which can be a consideration for some buyers.

Impact on Application: Leather is often used in high-end furniture and automotive interiors, where aesthetics and durability are paramount.

Considerations for International Buyers: Buyers should be aware of the ethical sourcing of leather and compliance with regulations regarding animal welfare. In Europe, certifications like the EU Ecolabel may be relevant.

Why is Cotton a Popular Choice for Upholstery Fabrics?

Cotton is a natural fiber that offers breathability and comfort, making it a popular choice for upholstery. It typically has a moderate temperature rating and performs well under normal pressure conditions.

Pros: Cotton is soft, durable, and easy to dye, allowing for a wide variety of styles and colors. It is also biodegradable, appealing to environmentally conscious consumers.

Cons: Cotton can be prone to wrinkling and fading, especially when exposed to sunlight. It may also require more frequent cleaning compared to synthetic options.

Impact on Application: Cotton is ideal for residential upholstery, particularly in settings that prioritize comfort and aesthetics.

Considerations for International Buyers: Buyers should check for compliance with standards like ASTM D4157 for abrasion resistance. In regions like South America, awareness of local climate conditions is vital, as humidity can affect cotton’s performance.

What Role Does Vinyl Play in Upholstery Fabric Selection?

Vinyl is a synthetic material that is highly resistant to moisture, making it an excellent choice for environments where spills are common. It has a high-pressure rating and can withstand wear and tear effectively.

Pros: Vinyl is easy to clean, affordable, and available in various colors and textures. It is also resistant to fading and cracking, making it suitable for outdoor furniture.

Cons: While vinyl is durable, it may not provide the same level of comfort as natural fabrics. Additionally, it can be less breathable, which might be a concern in warmer climates.

Impact on Application: Vinyl is commonly used in commercial settings, such as restaurants and healthcare facilities, where hygiene and durability are priorities.

Considerations for International Buyers: Buyers should ensure that vinyl products meet local health and safety regulations, particularly in the Middle East, where standards may vary significantly.

Summary Table of Upholstery Fabric Materials

| Material | Typical Use Case for upholstery fabric supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Residential and commercial upholstery | Durable and easy to clean | Less breathable than natural fibers | Low |

| Leather | High-end furniture and automotive interiors | Elegant and durable | High cost and requires maintenance | High |

| Cotton | Residential upholstery | Soft, breathable, and biodegradable | Prone to wrinkling and fading | Medium |

| Vinyl | Commercial settings (restaurants, healthcare) | Moisture-resistant and easy to clean | Less breathable and comfort | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for upholstery fabric supplier

What Are the Main Stages of Manufacturing Upholstery Fabrics?

Understanding the manufacturing processes of upholstery fabrics is crucial for B2B buyers, especially when evaluating potential suppliers. The production of upholstery fabrics typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage includes the selection and treatment of raw materials. Commonly used fibers include cotton, polyester, wool, and blends. Each fiber type has unique properties, influencing the fabric’s durability, texture, and appearance. Buyers should inquire about the sourcing of these materials, as sustainable and ethical sourcing practices can significantly impact quality and brand reputation.

-

Forming: In this stage, fibers are transformed into fabric through techniques such as weaving, knitting, or non-woven processes. Weaving, which includes methods like jacquard and damask, is prominent for upholstery due to its strength and aesthetic appeal. Buyers should assess the supplier’s machinery and technology to ensure they employ modern techniques that enhance fabric durability and design flexibility.

-

Assembly: After forming, the fabric may undergo processes such as dyeing, printing, and finishing treatments. Dyeing can be done using various methods like reactive or disperse dyeing, depending on the fiber type. It’s vital for buyers to understand the dyeing processes employed, as they affect colorfastness and overall fabric performance.

-

Finishing: The final stage involves applying treatments that enhance the fabric’s characteristics, such as water resistance, stain repellency, or fire retardancy. Buyers should verify the types of finishes used and their compliance with industry standards, especially if the upholstery will be used in high-traffic or specialized environments.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the upholstery fabric manufacturing process. International standards and industry-specific certifications ensure that products meet safety and quality benchmarks, which is crucial for B2B buyers looking to maintain their brand integrity.

-

ISO 9001 Certification: This international standard focuses on quality management systems. Suppliers with ISO 9001 certification demonstrate a commitment to continuous improvement and customer satisfaction. Buyers should request proof of certification to ensure the supplier adheres to these quality management principles.

-

CE Marking: Particularly relevant for fabrics used in the European market, CE marking indicates compliance with health, safety, and environmental protection standards. Buyers in Europe should prioritize suppliers with CE certification, as it reflects adherence to stringent regulatory requirements.

-

API Standards: For buyers in the Middle East or industries requiring specific quality benchmarks, the American Petroleum Institute (API) standards may be relevant, especially for fabrics used in specialized applications. Understanding the specific API standards applicable to upholstery fabrics can help buyers ensure their suppliers meet necessary criteria.

How Are Quality Control Checkpoints Structured?

Quality control (QC) is integrated at various stages of the manufacturing process to ensure that the final product meets the required standards. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers should have a robust IQC process to verify the quality and specifications of fibers and materials before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC ensures that each stage meets quality criteria. This can include monitoring weaving tension, dye consistency, and finish application. Buyers should ask suppliers how they conduct IPQC and what metrics they monitor.

-

Final Quality Control (FQC): After production, FQC involves a comprehensive inspection of the finished fabric. This includes checking for defects, color consistency, and adherence to specifications. Buyers should request FQC reports to assess the quality of the final product before shipment.

What Common Testing Methods Are Used in Upholstery Fabric Manufacturing?

To ensure that upholstery fabrics meet industry standards, suppliers typically employ several testing methods:

-

Abrasion Resistance Testing: This test measures the durability of the fabric against wear and tear. The Martindale test is commonly used for upholstery fabrics. Buyers should inquire about the results of this testing, as higher abrasion resistance indicates longer-lasting fabrics.

-

Colorfastness Testing: This test evaluates how well a fabric retains its color under various conditions, including exposure to light and washing. Testing methods like the AATCC (American Association of Textile Chemists and Colorists) standards help ensure that fabrics maintain their appearance over time.

-

Flame Retardancy Testing: For upholstery fabrics used in commercial settings or public spaces, flame retardancy is critical. Testing methods such as the NFPA (National Fire Protection Association) standards can provide reassurance that the fabric meets necessary safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers uphold their quality claims, B2B buyers should actively engage in the verification process. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and QC practices. Buyers should establish a schedule for audits, either conducted internally or by third-party inspection services, to verify compliance with standards.

-

Request Quality Assurance Reports: Suppliers should provide documentation detailing their QC processes, testing methods, and results. Buyers should review these reports thoroughly to assess the supplier’s commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing capabilities and quality control measures. This is particularly important for buyers operating in regions like Africa and South America, where local regulations may vary.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, should be aware of the nuances in QC and certification processes that may impact their purchasing decisions:

-

Regional Compliance Requirements: Different regions may have specific regulations governing textile manufacturing. Buyers should familiarize themselves with local laws and standards that may affect their sourcing decisions.

-

Cultural and Economic Considerations: Buyers from diverse regions may encounter varying levels of supplier capabilities. It’s essential to assess not just the certifications but also the practical implementation of quality controls in manufacturing processes.

-

Establishing Trust: Building a relationship with suppliers through transparent communication about quality expectations and compliance can foster trust. Buyers should prioritize suppliers who are willing to share their QC practices and certifications openly.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing upholstery fabrics, ensuring they select suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘upholstery fabric supplier’

Introduction

Navigating the complexities of sourcing upholstery fabric suppliers requires a structured approach. This checklist is designed to guide international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, through the essential steps to ensure they select the right suppliers for their specific needs. By following this practical sourcing guide, buyers can mitigate risks and enhance their procurement efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for aligning your needs with supplier capabilities. Consider factors such as fabric type, durability, colorfastness, and environmental certifications. Having detailed requirements will help you communicate effectively with potential suppliers and avoid misunderstandings.

- Fabric Type: Identify whether you need natural, synthetic, or blended fabrics based on the intended application.

- Durability Standards: Specify wear and tear resistance to ensure longevity in high-use environments.

Step 2: Conduct Market Research

Before reaching out to suppliers, perform thorough market research to understand current trends, pricing, and availability. This knowledge will empower you to make informed decisions and help you identify reputable suppliers within your target regions.

- Trend Analysis: Investigate popular upholstery trends in your target market to align your sourcing with consumer demand.

- Price Benchmarking: Compare prices from multiple suppliers to establish a competitive range.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; consider their market reputation and previous client feedback.

- Supplier Credentials: Verify their business licenses, certifications, and any industry awards to assess credibility.

- Client References: Contact previous clients to gain insights into their reliability and service quality.

Step 4: Request Samples for Quality Assessment

Always request fabric samples before finalizing your supplier. Evaluating physical samples allows you to assess the quality, texture, and appearance of the fabric firsthand, ensuring it meets your specifications.

- Testing Durability: Consider performing basic tests on samples to check for wear, color retention, and stain resistance.

- Color Matching: Ensure that the colors in samples match your design requirements, as discrepancies can affect your project.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements on these aspects can prevent future disputes and ensure a smooth procurement process.

- Payment Terms: Discuss options such as advance payment, credit terms, or payment on delivery to find a mutually beneficial arrangement.

- Delivery Timelines: Set clear expectations regarding lead times and logistics to avoid delays.

Step 6: Establish a Communication Plan

Effective communication is key to a successful supplier relationship. Set up regular check-ins and define communication channels to address any issues promptly.

- Contact Points: Identify key contacts on both sides for seamless communication.

- Feedback Mechanism: Establish a process for providing and receiving feedback to enhance collaboration.

Step 7: Monitor Supplier Performance Post-Procurement

After the initial order, regularly assess the supplier’s performance against your expectations. This ongoing evaluation helps maintain quality standards and strengthens your business relationship.

- Quality Control: Implement a system for ongoing quality checks on the delivered fabric.

- Supplier Audits: Schedule periodic evaluations to ensure compliance with your specifications and service level agreements.

By following this checklist, B2B buyers can streamline their sourcing process and build strong partnerships with upholstery fabric suppliers that meet their needs.

Comprehensive Cost and Pricing Analysis for upholstery fabric supplier Sourcing

What Are the Key Cost Components in Upholstery Fabric Supplier Sourcing?

When sourcing upholstery fabrics, understanding the cost structure is essential for informed decision-making. The primary cost components include:

-

Materials: The type and quality of fabric significantly influence costs. Natural fibers like cotton or linen often come at a premium compared to synthetic options such as polyester. Additionally, special treatments or finishes can elevate material costs.

-

Labor: Labor costs vary by region and can be impacted by local wage standards. For instance, suppliers in Europe may have higher labor costs compared to those in South America or Africa, affecting overall pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. A supplier’s operational efficiency can affect these costs, so it’s crucial to evaluate their production processes.

-

Tooling: Initial setup costs for machinery and tools required to produce specific fabric designs or patterns are factored into pricing. Custom orders may incur higher tooling costs, influencing the overall price.

-

Quality Control (QC): Rigorous quality checks ensure that the fabric meets industry standards. Suppliers with robust QC processes may charge more, but this investment can reduce returns and increase customer satisfaction.

-

Logistics: Shipping costs vary based on distance, mode of transport, and the volume of goods. Import tariffs and customs duties should also be considered, especially for international transactions.

-

Margin: Suppliers add a profit margin to cover risks and ensure sustainability. Understanding a supplier’s pricing strategy can help negotiate better terms.

How Do Price Influencers Affect Upholstery Fabric Costs?

Several factors can influence the final price of upholstery fabrics, impacting international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Understanding the MOQ can help you negotiate better pricing, especially if you can commit to higher volumes.

-

Specifications and Customization: Custom fabrics tailored to specific designs or uses can significantly increase costs. It’s essential to balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Fabrics that meet specific certifications (e.g., fire resistance, sustainability) may command higher prices. Buyers should weigh the benefits of certification against additional costs.

-

Supplier Factors: Established suppliers with a strong reputation may charge more due to their reliability and service levels. However, newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will determine who is responsible for shipping and insurance, impacting the overall cost. Clarity on these terms is crucial to avoid unexpected expenses.

What Are the Best Tips for Negotiating Upholstery Fabric Prices?

Effective negotiation is key to achieving cost efficiency when sourcing upholstery fabrics. Here are actionable tips for international B2B buyers:

-

Conduct Market Research: Understand the typical pricing landscape for upholstery fabrics in your region. This knowledge equips you to negotiate effectively and identify fair pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with the fabric, including maintenance, durability, and potential waste. A higher upfront cost may lead to lower overall expenses.

-

Build Strong Relationships with Suppliers: Establishing a rapport can lead to better pricing and terms. Suppliers may be more willing to negotiate with long-term partners.

-

Be Transparent About Your Needs: Clearly communicate your requirements and budget constraints to suppliers. This openness can foster collaboration and result in tailored solutions that meet your needs.

-

Consider Payment Terms: Negotiating favorable payment terms can enhance cash flow and reduce financial strain. Look for options like extended payment periods or discounts for upfront payments.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing in upholstery fabric sourcing, actual prices can vary widely based on market conditions, supplier negotiations, and specific project requirements. Always seek multiple quotes and conduct thorough due diligence before finalizing any agreements.

Alternatives Analysis: Comparing upholstery fabric supplier With Other Solutions

Understanding Alternatives to Upholstery Fabric Suppliers

In today’s global marketplace, B2B buyers must carefully evaluate their options when sourcing upholstery fabrics. While traditional upholstery fabric suppliers are a popular choice, several alternative solutions can also meet the diverse needs of businesses across Africa, South America, the Middle East, and Europe. This section explores these alternatives and provides actionable insights for international buyers looking to make informed decisions.

Comparison Table of Upholstery Fabric Supplier and Alternatives

| Comparison Aspect | Upholstery Fabric Supplier | Alternative 1: Upholstery Foam Manufacturer | Alternative 2: Sustainable Fabric Producers |

|---|---|---|---|

| Performance | High durability and variety in textures and patterns | Offers comfort and support, but limited aesthetic options | Eco-friendly options with varying durability |

| Cost | Moderate to high, depending on fabric type and quality | Generally lower cost due to simplified production | Often higher initial costs, but potential savings in long-term sustainability |

| Ease of Implementation | Requires sourcing and logistics management | Easy to source locally in many regions | May require additional sourcing and certification checks |

| Maintenance | Varies by fabric type; some require special care | Generally low maintenance, easy to clean | Maintenance varies; eco-friendly fabrics may require specific care |

| Best Use Case | Ideal for high-end furniture and custom projects | Suitable for applications needing cushioning, like sofas | Best for environmentally-conscious projects and brands |

What Are the Pros and Cons of Upholstery Foam Manufacturers?

Upholstery foam manufacturers provide a viable alternative, particularly for buyers focused on comfort and support. One of the main advantages of choosing upholstery foam is cost-effectiveness; it tends to be less expensive than traditional upholstery fabrics. Additionally, foam can be sourced locally, making it easier to implement for businesses aiming for quick turnaround times. However, the aesthetic options are limited, which may not suit projects requiring a particular visual style. Moreover, foam does not offer the same durability as high-quality upholstery fabrics, making it less ideal for high-end furniture applications.

How Do Sustainable Fabric Producers Compare?

Sustainable fabric producers cater to the growing demand for eco-friendly materials in the upholstery market. These alternatives often boast organic or recycled materials, appealing to brands looking to enhance their environmental credentials. While the initial costs may be higher, the long-term benefits, such as reduced environmental impact and potential brand loyalty, can outweigh these concerns. However, sourcing sustainable fabrics may involve additional steps, including verifying certifications and ensuring compliance with environmental standards. Maintenance can also vary significantly depending on the type of sustainable fabric used, potentially complicating care for buyers.

Conclusion: How Can B2B Buyers Choose the Right Upholstery Solution?

When selecting the right upholstery solution, B2B buyers must consider their specific needs, including performance, cost, and the desired aesthetic. While upholstery fabric suppliers offer a diverse range of high-quality options, alternatives like upholstery foam manufacturers and sustainable fabric producers can provide cost-effective and eco-friendly solutions, respectively. Ultimately, the decision should align with the buyer’s project requirements, target market preferences, and long-term business goals. By weighing these factors, international buyers can make informed choices that enhance their product offerings and contribute to their brand’s success.

Essential Technical Properties and Trade Terminology for upholstery fabric supplier

What Are the Key Technical Properties of Upholstery Fabrics?

Understanding the technical properties of upholstery fabrics is crucial for B2B buyers to ensure they select materials that meet their specific needs. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the quality and type of fiber used in the fabric. Common materials include polyester, cotton, linen, and leather. The grade impacts durability, maintenance requirements, and aesthetics. For instance, high-grade materials typically offer superior longevity and resistance to wear, making them ideal for high-traffic areas.

2. Fabric Weight

Fabric weight is measured in grams per square meter (GSM) and indicates how heavy or dense the fabric is. Heavier fabrics tend to be more durable and are often used for commercial upholstery, while lighter fabrics may be better suited for residential applications. Understanding the weight can help buyers assess the fabric’s suitability for specific projects.

3. Abrasion Resistance

Abrasion resistance measures how well a fabric withstands wear from friction. This is often tested using the Martindale method, where the fabric is rubbed against a standard abrasive surface. A higher rating indicates better durability, which is essential for upholstery that will see frequent use. B2B buyers should prioritize fabrics with high abrasion resistance for longevity.

4. Colorfastness

Colorfastness refers to the fabric’s ability to retain its color when exposed to various elements, such as sunlight, washing, and abrasion. Fabrics with high colorfastness ratings are crucial for maintaining the appearance of upholstery over time. This property is especially important in regions with intense sunlight or humid conditions, which can accelerate fading.

5. Fire Resistance

Fire resistance is an essential property for upholstery fabrics, particularly in commercial settings. Fabrics may be treated with flame-retardant chemicals or made from inherently fire-resistant fibers. Understanding fire safety standards relevant to your region, such as BS 5852 in the UK or NFPA 701 in the US, is critical for compliance and safety.

What Are Common Trade Terms Used in Upholstery Fabric Supply?

Navigating the trade terminology in the upholstery fabric industry is vital for effective communication and negotiation. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then sold under another company’s brand. For upholstery fabric suppliers, understanding OEM relationships can help buyers ensure they are sourcing high-quality materials that meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For upholstery fabrics, this term is significant as it can impact inventory costs and purchasing decisions. Knowing the MOQ helps buyers plan their orders strategically, especially when looking to reduce waste and optimize inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers inviting them to submit price quotes for specific products or services. In the context of upholstery fabrics, an RFQ should detail the required materials, specifications, and quantities. This process allows buyers to compare prices and terms from various suppliers effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), is essential for B2B buyers to understand shipping costs and responsibilities, which can significantly impact the total cost of procurement.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for project planning, especially in markets where timely delivery can affect business operations. Buyers should discuss lead times upfront to avoid disruptions in their supply chain.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the upholstery fabric supplier Sector

What Are the Current Market Dynamics and Key Trends in Upholstery Fabric Supply?

The upholstery fabric supplier sector is witnessing significant transformations driven by globalization, technological advancements, and shifting consumer preferences. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek competitive advantages, understanding these market dynamics becomes crucial. Key trends include the rising demand for customized upholstery solutions, which are increasingly being facilitated by digital tools and platforms that allow for real-time design and ordering processes.

Moreover, there is a notable shift towards the use of innovative materials, including synthetic fibers and blended fabrics that offer enhanced durability and aesthetic appeal. This trend is particularly prominent in European markets, where designers are prioritizing both functionality and style. In contrast, markets in Africa and South America are seeing a growing interest in locally-sourced materials that reflect cultural heritage, offering unique selling propositions for suppliers.

Additionally, the ongoing disruptions in global supply chains, exacerbated by the COVID-19 pandemic, have prompted buyers to diversify their supplier base. This diversification strategy not only mitigates risk but also allows buyers to tap into emerging markets that may offer cost advantages or unique product offerings. Engaging with suppliers who utilize advanced technologies such as AI and IoT for inventory management and production forecasting can also enhance efficiency and responsiveness in the sourcing process.

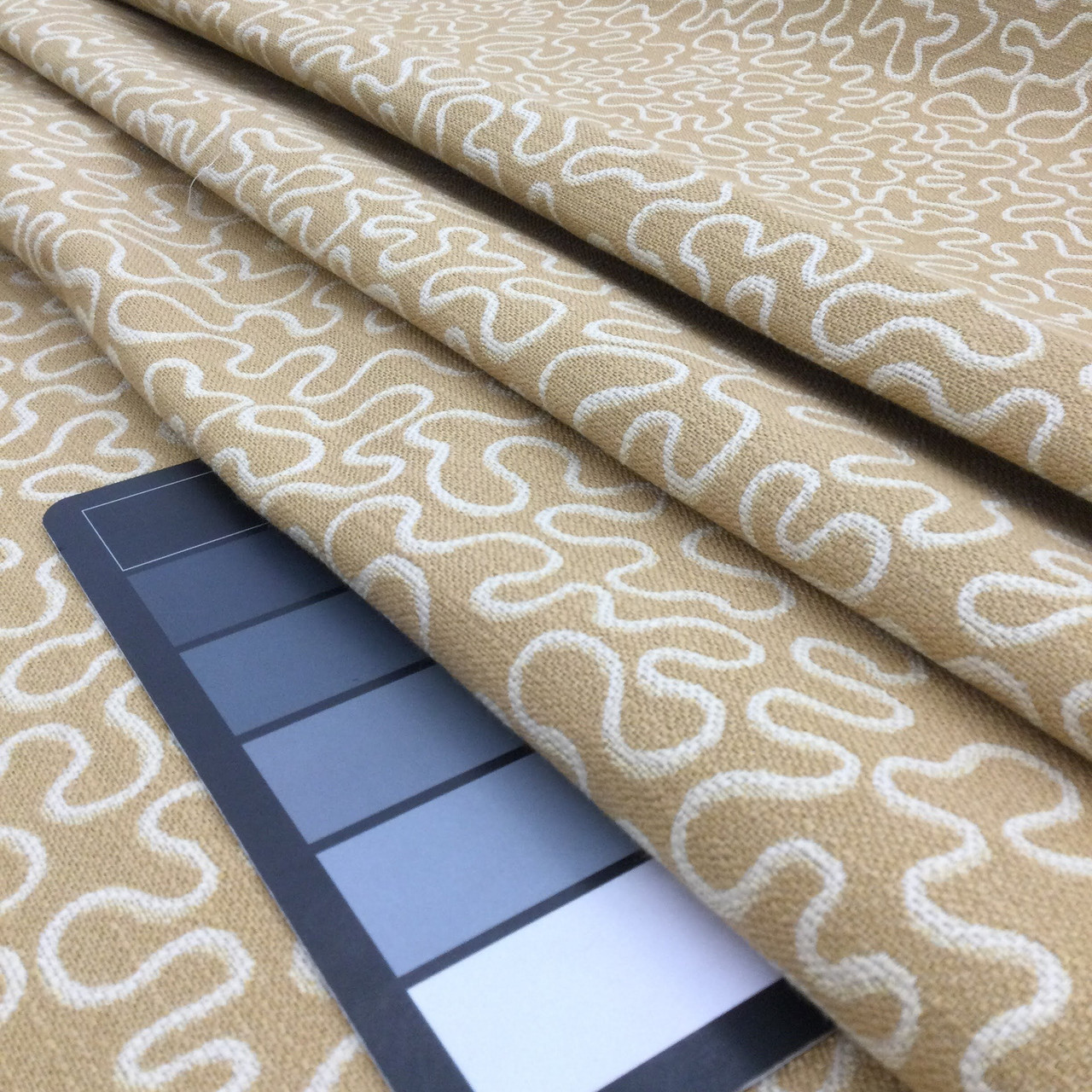

A stock image related to upholstery fabric supplier.

How Is Sustainability Influencing Sourcing Decisions in the Upholstery Fabric Sector?

Sustainability and ethical sourcing are increasingly becoming non-negotiable factors in the decision-making processes of B2B buyers in the upholstery fabric sector. The environmental impact of fabric production is significant, from water consumption to chemical usage, prompting buyers to seek suppliers who prioritize sustainable practices. This includes using organic or recycled materials, which not only reduce environmental footprints but also appeal to a growing segment of eco-conscious consumers.

Ethical supply chains are equally important, with buyers needing assurance that their suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 provide a level of trust and transparency that can be crucial in supplier selection. For buyers in Europe and the Middle East, where regulatory frameworks are becoming more stringent regarding sustainability, aligning with certified suppliers can also ensure compliance and enhance brand reputation.

Investing in ‘green’ materials, such as water-based dyes and biodegradable fabrics, can not only meet regulatory standards but also create competitive differentiation. By prioritizing sustainability, B2B buyers can appeal to a broader market that values ethical consumption, ultimately leading to stronger business relationships and improved customer loyalty.

How Has the Upholstery Fabric Supplier Sector Evolved Over Time?

The upholstery fabric supplier sector has evolved significantly over the past few decades, transitioning from traditional manufacturing processes to a more dynamic and technology-driven landscape. Initially dominated by local artisans and small-scale manufacturers, the industry began to globalize in the late 20th century, with increased outsourcing to regions that offered lower production costs.

The advent of digital technologies has further transformed the sector, allowing for more efficient supply chain management and enhanced customer interaction. Today, suppliers can leverage data analytics to understand market trends better, optimize inventory, and improve customer service. This evolution has positioned the upholstery fabric sector to not only respond to changing buyer needs but also to anticipate future demands, making it a critical area for international B2B buyers to explore.

As the market continues to evolve, staying informed about these trends and dynamics will be essential for buyers looking to forge successful partnerships and ensure their sourcing strategies align with global best practices.

Frequently Asked Questions (FAQs) for B2B Buyers of upholstery fabric supplier

-

How do I evaluate the quality of upholstery fabric from international suppliers?

To evaluate the quality of upholstery fabric, request samples from potential suppliers. Examine the fabric’s texture, durability, and colorfastness. Additionally, inquire about the materials used and their certifications, such as OEKO-TEX or GOTS, which indicate compliance with environmental standards. Establish a testing protocol to assess how the fabric performs under various conditions, including wear and tear, cleaning processes, and exposure to sunlight. Engaging a third-party quality assurance company can also provide unbiased evaluations. -

What are the key factors to consider when choosing an upholstery fabric supplier?

When selecting an upholstery fabric supplier, consider their reputation, product range, and manufacturing capabilities. Assess their experience in international trade and familiarity with your target market. Evaluate their customer service and communication responsiveness, as these will be crucial during the sourcing process. Look into their compliance with international standards, delivery timelines, and ability to meet your customization needs. Finally, check for reviews or testimonials from other B2B buyers to gauge their reliability. -

What customization options should I expect from upholstery fabric suppliers?

Most upholstery fabric suppliers offer customization options, including color selection, patterns, and fabric composition. Some may also provide the ability to create unique designs tailored to your specific needs. Inquire about their minimum order quantities (MOQs) for custom fabrics and the lead times required for production. Discuss any additional costs associated with customization, as well as the potential for future orders at similar specifications, which can lead to better pricing and terms. -

What are the typical minimum order quantities (MOQs) for upholstery fabrics?

Minimum order quantities can vary significantly among upholstery fabric suppliers, typically ranging from 50 to 500 yards, depending on the type of fabric and supplier capabilities. For custom orders, MOQs may be higher due to the costs associated with production runs. It’s essential to communicate your needs clearly and negotiate MOQs that align with your business model. Some suppliers may offer flexibility on MOQs for first-time orders or ongoing partnerships, so explore these options. -

How do payment terms work with international upholstery fabric suppliers?

Payment terms with international suppliers can differ widely based on their policies and the buyer’s relationship with them. Common arrangements include advance payment, letters of credit, or payment upon delivery. It’s essential to clarify payment methods, currency, and any fees involved. Consider using escrow services for larger transactions to protect both parties. Establishing a good credit history with suppliers can also lead to more favorable payment terms in future transactions. -

What quality assurance practices should I look for in upholstery fabric suppliers?

Quality assurance practices are vital to ensure that the upholstery fabrics meet your expectations and industry standards. Look for suppliers that have established quality control measures, such as regular inspections during production, testing for compliance with international standards, and certifications. Request details about their quality assurance processes, including the use of third-party testing labs. Establishing clear quality expectations upfront can help avoid issues later in the supply chain. -

What logistics considerations are important when importing upholstery fabrics?

Logistics play a crucial role in the successful importation of upholstery fabrics. Consider shipping methods, costs, and estimated delivery times when negotiating with suppliers. Familiarize yourself with import regulations and tariffs in your country to avoid unexpected fees. Collaborating with a reputable freight forwarder can streamline the shipping process and ensure compliance with all regulations. Additionally, factor in storage solutions and inventory management to accommodate incoming shipments. -

How can I build a long-term relationship with my upholstery fabric supplier?

Building a long-term relationship with your upholstery fabric supplier involves consistent communication and mutual trust. Regularly share feedback about their products and services, and express appreciation for their efforts. Consider placing larger or repeat orders to demonstrate commitment. Engage in discussions about future trends and potential collaborations, which can provide both parties with insights into market demands. Attending industry trade shows together can also strengthen your partnership and open doors for new opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for upholstery fabric supplier

In the evolving landscape of upholstery fabric supply, strategic sourcing emerges as a vital approach for international B2B buyers. By leveraging supplier relationships, companies can not only secure high-quality materials but also optimize costs and enhance supply chain resilience. For buyers in Africa, South America, the Middle East, and Europe, particularly in regions like Italy and South Africa, understanding local market dynamics and cultural nuances is crucial for successful partnerships.

How can B2B buyers enhance their sourcing strategies? Prioritize transparency and sustainability in your supplier selection process. Seek suppliers that demonstrate ethical practices and are committed to sustainable production, as this aligns with global trends and consumer preferences. Additionally, consider diversifying your supplier base to mitigate risks associated with geopolitical and economic fluctuations.

A stock image related to upholstery fabric supplier.

Looking ahead, the upholstery fabric market is poised for growth, driven by innovation and evolving consumer demands. Now is the time for international buyers to engage proactively with suppliers, exploring new fabrics and technologies that can elevate their product offerings. By embracing strategic sourcing, you not only secure a competitive edge but also contribute to a more sustainable and ethical industry. Take the next step today—invest in your sourcing strategy to unlock new opportunities and drive your business forward.