Find the Best Webbing Slings Supplier: Your Complete Guide (2025)

Introduction: Navigating the Global Market for webbing slings supplier

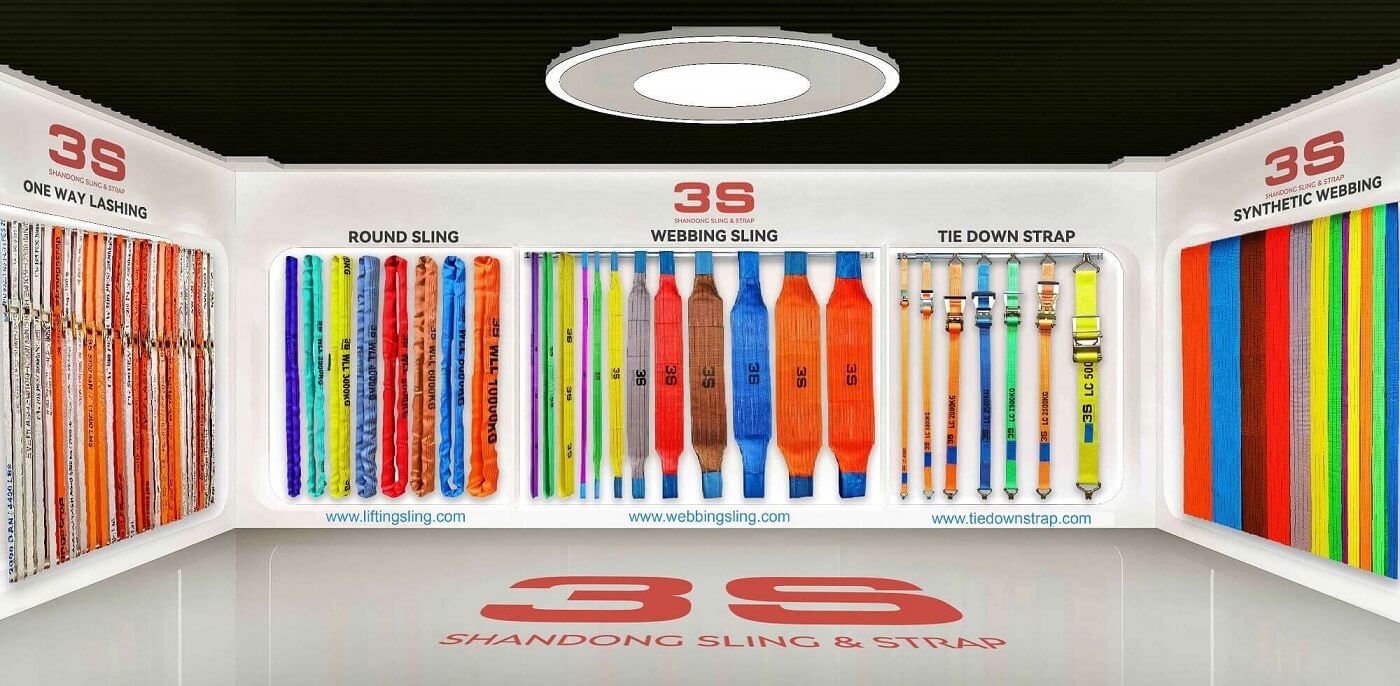

In the dynamic landscape of global trade, sourcing the right webbing slings supplier can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As industries increasingly rely on durable and reliable lifting equipment, the demand for high-quality webbing slings has surged. However, navigating the myriad of suppliers and understanding their offerings can be daunting. This guide aims to demystify the process of selecting a webbing slings supplier by providing actionable insights into the types, applications, and standards of webbing slings available in the market.

In this comprehensive resource, we will explore the various types of webbing slings, their specific applications across different industries, and essential criteria for vetting suppliers to ensure quality and compliance. Additionally, we will discuss pricing factors, logistics considerations, and how to build long-term partnerships with reliable suppliers. By equipping international B2B buyers with the necessary knowledge and strategies, this guide empowers you to make informed purchasing decisions that align with your operational needs and budget constraints.

Whether you are sourcing for construction, manufacturing, or logistics, understanding the intricacies of the webbing slings market will position you to enhance your procurement strategy and achieve operational efficiency. Let’s delve into the essential elements that will facilitate your journey toward securing the best webbing slings supplier for your business.

Understanding webbing slings supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Webbing Slings | Made from synthetic fibers; low profile design | Material handling, lifting heavy loads | Pros: Lightweight, easy to store; Cons: Limited to certain lifting angles. |

| Round Slings | Continuous loop design; high flexibility | Rigging, lifting irregular loads | Pros: Excellent load distribution; Cons: Can be less durable than flat slings. |

| Endless Webbing Slings | No seams, continuous length | Heavy lifting, construction | Pros: Higher strength; Cons: More expensive than other types. |

| Sling with Hooks | Equipped with hooks for easy attachment | Warehousing, logistics | Pros: Quick setup; Cons: Hooks can wear out over time. |

| Specialty Webbing Slings | Custom designs for specific industries | Aerospace, automotive, specialized lifting | Pros: Tailored solutions; Cons: Longer lead times and higher costs. |

What are the Characteristics of Flat Webbing Slings?

Flat webbing slings are constructed from high-strength synthetic fibers, such as polyester or nylon, designed to provide a low-profile lifting solution. These slings are ideal for applications where space is limited or where a low lifting height is required. B2B buyers should consider the weight capacity and length when purchasing flat webbing slings, as these factors directly impact their effectiveness in material handling and lifting operations.

How Do Round Slings Differ from Flat Slings?

Round slings feature a continuous loop design, offering exceptional flexibility and the ability to lift irregularly shaped loads. They excel in applications requiring load distribution, making them suitable for lifting heavy machinery or construction materials. Buyers should evaluate the sling’s load rating and ensure it meets their specific lifting needs, as the versatility of round slings can significantly enhance operational efficiency.

Why Choose Endless Webbing Slings for Heavy Lifting?

Endless webbing slings are characterized by their seamless construction, providing a continuous length that enhances their strength and durability. These slings are particularly effective in heavy lifting scenarios, such as in construction and industrial applications. B2B buyers should weigh the benefits of increased strength against the higher cost compared to other sling types, ensuring that their investment aligns with long-term operational goals.

What are the Advantages of Slings with Hooks?

Slings equipped with hooks offer a convenient solution for quick attachment and detachment, making them ideal for warehousing and logistics applications. Their ease of use can streamline operations, but buyers should be mindful of the wear and tear on the hooks over time. Selecting high-quality hooks and regularly inspecting them can mitigate potential safety risks and ensure continued effectiveness in lifting operations.

When to Consider Specialty Webbing Slings?

Specialty webbing slings are designed for specific industries, such as aerospace or automotive, where unique lifting requirements exist. These slings can be customized to meet the precise needs of a business, providing tailored solutions that enhance safety and efficiency. However, buyers should be prepared for potentially longer lead times and higher costs associated with these custom designs, making it essential to assess the return on investment for specialized applications.

Related Video: Rigger and Signalman – Perform safe lifting with shackle and webbing slings

Key Industrial Applications of webbing slings supplier

| Industry/Sector | Specific Application of webbing slings supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting heavy materials and equipment | Enhances safety and efficiency in lifting operations | Compliance with local safety standards and certifications |

| Manufacturing | Material handling during assembly processes | Streamlines production and reduces downtime | Durability and load capacity tailored to specific machinery |

| Shipping and Logistics | Securing cargo in shipping containers | Minimizes damage during transport and ensures compliance | Weight capacity, weather resistance, and length options |

| Oil and Gas | Rigging for offshore platforms | Increases operational safety and reliability | Resistance to environmental factors and certification for marine use |

| Events and Entertainment | Rigging for stage setups and events | Ensures safety and stability of installations | Customization options and compliance with safety regulations |

How Are Webbing Slings Used in the Construction Industry?

In the construction sector, webbing slings are essential for lifting heavy materials and equipment, such as beams, concrete blocks, and machinery. Their flexibility allows for easy handling and positioning, which is crucial on dynamic job sites. International buyers should ensure that the slings meet local safety regulations and certifications, as compliance can vary significantly across regions like Africa and Europe. Additionally, it’s important to consider the load capacity and durability of the slings to withstand harsh working conditions.

What Role Do Webbing Slings Play in Manufacturing?

Webbing slings are widely used in manufacturing for material handling during assembly processes. They facilitate the movement of components from one station to another, thereby streamlining production and reducing downtime. For buyers, it is vital to assess the durability and load capacity of the slings to match the specific requirements of their machinery. Moreover, sourcing slings that are resistant to wear and tear will ensure longevity, which can significantly reduce operational costs in the long run.

How Are Webbing Slings Utilized in Shipping and Logistics?

In the shipping and logistics industry, webbing slings are crucial for securing cargo in shipping containers. They help minimize damage during transport and ensure compliance with international shipping standards. For B2B buyers, key considerations include the weight capacity, weather resistance, and length options of the slings. Ensuring that the slings are suitable for various types of cargo and can withstand different environmental conditions is essential for maintaining the integrity of shipments.

Why Are Webbing Slings Important in Oil and Gas Operations?

In the oil and gas sector, webbing slings are used for rigging on offshore platforms, where safety and reliability are paramount. These slings must be able to endure harsh marine environments, which makes sourcing slings with resistance to environmental factors critical. International buyers should prioritize suppliers that offer products certified for marine use, ensuring that the slings can handle the specific stresses encountered in offshore operations.

How Are Webbing Slings Applied in Events and Entertainment?

Webbing slings are indispensable in the events and entertainment industry, particularly for rigging stage setups and installations. They provide the necessary safety and stability to support lighting, sound equipment, and other stage elements. Buyers in this sector should focus on customization options to meet unique design requirements and ensure compliance with safety regulations to avoid potential liabilities. Selecting a supplier that understands the specific needs of the entertainment industry can enhance both safety and performance in live events.

Related Video: RRC Equipment Education – Synthetic Webbing Slings

3 Common User Pain Points for ‘webbing slings supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Webbing Slings

The Problem:

B2B buyers often face the challenge of inconsistent quality in webbing slings, which can lead to safety hazards and financial losses. Suppliers may provide products that do not meet the required safety standards or specifications, especially when sourced from different regions. This inconsistency can be particularly concerning for buyers in industries such as construction or logistics, where the reliability of lifting equipment is crucial. Buyers may find themselves in a position where they have to frequently return products or deal with the repercussions of equipment failure, leading to project delays and increased costs.

The Solution:

To mitigate this issue, it is essential for buyers to establish a robust quality assurance process when sourcing webbing slings. Start by identifying reputable suppliers with a proven track record of quality. Request certifications and test reports that validate the slings’ compliance with international safety standards, such as ISO 4878. Additionally, consider implementing a pilot program where you order a small batch of slings for testing before committing to larger orders. This will allow you to evaluate the quality firsthand and ensure it meets your specific needs. Regular audits and on-site inspections can also help maintain quality over time, fostering a long-term relationship built on trust and reliability.

Scenario 2: Difficulty in Customizing Webbing Slings to Specific Needs

The Problem:

B2B buyers often require customized webbing slings tailored to unique operational needs, such as specific weight capacities or lengths. However, many suppliers may offer limited options or lack the flexibility to accommodate such requests. This can result in buyers resorting to generic products that do not fit their specific applications, which can lead to inefficiencies and potential safety risks in their operations.

The Solution:

To effectively address customization needs, buyers should engage directly with suppliers early in the sourcing process. Clearly communicate your specific requirements, including load capacities, sizes, and any unique features necessary for your operations. It’s beneficial to ask suppliers about their manufacturing capabilities and willingness to produce custom solutions. Building a collaborative relationship can often lead to better outcomes, as suppliers may be more inclined to accommodate specific requests when they understand the buyer’s operational context. Additionally, consider working with suppliers who have experience in your industry, as they are more likely to understand your needs and offer tailored solutions.

Scenario 3: Lack of Support and Expertise in Selecting the Right Webbing Slings

The Problem:

Many B2B buyers, especially those new to sourcing lifting equipment, struggle with selecting the appropriate webbing slings for their applications. The lack of technical knowledge can lead to purchasing mistakes, where buyers may choose slings that are either over-specified or under-specified for their needs. This confusion can result in safety risks, increased operational costs, and legal liabilities.

The Solution:

To overcome this knowledge gap, buyers should seek suppliers that provide comprehensive support and expertise. During the selection process, ask suppliers about their consultative services, including the availability of technical support and training for your team. Look for suppliers who can offer detailed guidance on factors such as load limits, sling types, and materials, tailored to your specific applications. Additionally, consider attending workshops or training sessions offered by suppliers, which can enhance your team’s understanding of webbing slings and their proper use. By equipping yourself and your team with the necessary knowledge, you can make informed decisions that enhance safety and efficiency in your operations.

Strategic Material Selection Guide for webbing slings supplier

When selecting materials for webbing slings, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in webbing slings, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyester Webbing Slings?

Polyester is one of the most widely used materials for webbing slings due to its excellent balance of strength and flexibility. It typically has a temperature rating of up to 100°C (212°F) and is resistant to UV light, making it suitable for outdoor applications. Polyester webbing also exhibits low stretch under load, which enhances load control.

Pros & Cons:

The primary advantage of polyester is its high strength-to-weight ratio, making it durable yet lightweight. However, it can be susceptible to damage from chemicals like acids and solvents, which may limit its application in certain environments. Additionally, while polyester is generally cost-effective, prices can vary based on quality and supplier.

Impact on Application:

Polyester webbing slings are ideal for lifting and rigging applications in construction, logistics, and manufacturing. However, buyers must ensure compatibility with the specific media they will encounter, particularly in chemical handling scenarios.

How Does Nylon Compare as a Material for Webbing Slings?

Nylon is another popular choice for webbing slings, known for its exceptional elasticity and strength. It can withstand temperatures up to 120°C (248°F) and has good abrasion resistance, making it suitable for dynamic loads.

Pros & Cons:

The key advantage of nylon is its ability to absorb shock, which is beneficial in applications involving heavy lifting or sudden load changes. However, nylon is more prone to UV degradation and has a higher cost compared to polyester. Its moisture absorption can also affect its performance in wet conditions.

Impact on Application:

Nylon webbing slings are often used in environments where shock loads are common, such as in the transportation of heavy machinery. Buyers should consider the potential for UV exposure and moisture when selecting nylon slings for outdoor or humid applications.

What Are the Benefits of Using Polypropylene for Webbing Slings?

Polypropylene is a lightweight and economical option for webbing slings, often used for lighter loads. It has a lower temperature rating of around 80°C (176°F) and is resistant to moisture, making it suitable for marine applications.

Pros & Cons:

The main advantage of polypropylene is its cost-effectiveness, making it an attractive option for low-budget projects. However, it has lower strength compared to polyester and nylon, which limits its use to lighter applications. Additionally, polypropylene is less durable under UV exposure.

Impact on Application:

Polypropylene slings are commonly used in packaging and light lifting tasks. Buyers in regions with high UV exposure should be cautious about using polypropylene in outdoor applications.

What Makes Aramid Fiber a Unique Choice for Webbing Slings?

Aramid fibers, such as Kevlar, are known for their high strength and heat resistance, withstanding temperatures up to 200°C (392°F). They are lightweight yet incredibly strong, making them suitable for specialized applications.

Pros & Cons:

The key advantage of aramid fibers is their exceptional tensile strength and resistance to cutting and abrasion. However, they are significantly more expensive than other materials and may require specialized manufacturing processes. Their performance can also be affected by moisture and certain chemicals.

Impact on Application:

Aramid webbing slings are ideal for high-risk environments, such as aerospace and military applications. Buyers must ensure compliance with specific industry standards and consider the cost implications when selecting aramid slings.

Summary Table of Material Selection for Webbing Slings

| Material | Typical Use Case for webbing slings supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Lifting and rigging in construction | High strength-to-weight ratio | Susceptible to chemical damage | Medium |

| Nylon | Heavy lifting with shock loads | Excellent shock absorption | Prone to UV degradation | High |

| Polypropylene | Packaging and light lifting tasks | Cost-effective | Lower strength and UV sensitivity | Low |

| Aramid Fiber | Aerospace and military applications | Exceptional tensile strength | High cost and moisture sensitivity | High |

This guide provides a strategic overview of material selection for webbing slings, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for webbing slings supplier

What Are the Key Stages in the Manufacturing Process of Webbing Slings?

The manufacturing process of webbing slings involves several key stages, each critical to ensuring the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers assess suppliers more effectively.

Material Preparation: What Materials Are Used in Webbing Slings?

The first step in manufacturing webbing slings is the selection and preparation of materials. Typically, high-strength synthetic fibers such as polyester and nylon are used due to their durability and resistance to abrasion. Suppliers often source these materials from reputable manufacturers who provide certificates of origin and compliance with international standards.

Once the materials are sourced, they undergo various treatments to enhance their properties. For example, UV stabilization may be applied to prevent degradation from sunlight exposure, which is particularly important for slings used outdoors. Buyers should inquire about the specific materials used and any treatments applied, as this can significantly affect the sling’s performance and lifespan.

How Are Webbing Slings Formed and Assembled?

After material preparation, the next stage is forming the webbing into slings. This involves weaving the synthetic fibers into a flat, strong strip. Techniques such as Jacquard weaving can be employed to create slings with specific patterns or load ratings. The weaving process must be closely monitored to ensure uniformity in thickness and strength.

Once the webbing is formed, the assembly process begins. This typically involves sewing the webbing into loops or attaching hardware such as hooks, rings, or connectors. The stitching must be done using high-strength thread and should follow specific patterns to ensure load distribution and integrity. B2B buyers should look for suppliers that utilize automated sewing machines, as this can enhance precision and reduce human error.

What Are the Finishing Processes for Webbing Slings?

The final manufacturing stage is finishing, which involves several quality-enhancing processes. This may include trimming excess material, applying protective coatings, and labeling the slings with load capacity and safety information. Some suppliers also conduct a final inspection to check for defects or inconsistencies.

Buyers should ensure that their suppliers adhere to strict finishing standards, as this can impact both the aesthetic and functional qualities of the slings. A thorough understanding of the finishing processes can help B2B buyers make informed decisions when selecting a supplier.

What Quality Assurance Measures Are Commonly Used in Webbing Sling Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of webbing slings to ensure safety and reliability. International standards and industry-specific regulations guide QA processes, providing a framework for consistent product quality.

A stock image related to webbing slings supplier.

Which International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that adhere to internationally recognized standards, such as ISO 9001, which outlines a framework for quality management systems. Compliance with this standard indicates that a supplier has established processes for continuous improvement and customer satisfaction.

Additionally, industry-specific certifications such as the CE mark in Europe or API standards in the oil and gas sector may also be relevant. These certifications often require rigorous testing and documentation, providing buyers with confidence in the quality of the products.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are critical at various stages of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues early on, preventing defects from progressing to later stages.

- Final Quality Control (FQC): A comprehensive inspection of finished products ensures they meet all quality and safety standards before shipping.

B2B buyers should ask potential suppliers about their QC processes and the frequency of inspections at each checkpoint.

What Testing Methods Are Used to Ensure Sling Quality?

Testing methods for webbing slings vary, but common approaches include:

- Tensile Testing: This assesses the maximum load a sling can withstand before breaking, ensuring it meets specified load ratings.

- Fatigue Testing: This evaluates how well the sling performs under repeated loading cycles, which is crucial for applications that involve frequent use.

- Environmental Testing: This simulates exposure to conditions such as UV light, chemicals, or extreme temperatures to assess the durability of the slings.

Understanding these testing methods allows B2B buyers to gauge the reliability of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Ensuring that a supplier adheres to stringent quality control practices is essential for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

What Audits and Reports Should Buyers Request?

B2B buyers should request copies of quality management system audits and reports from suppliers. These documents provide insights into the supplier’s adherence to international standards and their internal quality assurance processes. Regular audits, especially from third-party organizations, can further validate a supplier’s commitment to quality.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing and QC processes. These services can conduct on-site inspections and testing, ensuring that the products meet the required standards before shipment. This is particularly important for international buyers who may not have the capacity to conduct their inspections.

What Nuances Should International Buyers Be Aware Of When It Comes to QC?

International B2B buyers should be aware of regional differences in quality standards and certifications. For example, while CE marking is crucial for products sold in Europe, it may not be recognized in Africa or South America. Understanding these nuances can help buyers navigate the complexities of sourcing webbing slings from different regions.

Additionally, language barriers and variations in documentation practices can pose challenges. It is advisable for buyers to establish clear communication channels with suppliers and to request documentation in a language they understand.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for webbing slings is vital for B2B buyers. By focusing on material preparation, manufacturing techniques, quality standards, and verification methods, buyers can make informed decisions that ensure safety and reliability in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘webbing slings supplier’

In the competitive landscape of international B2B procurement, sourcing webbing slings requires a systematic approach to ensure quality, compliance, and value. This checklist provides actionable steps for buyers from regions such as Africa, South America, the Middle East, and Europe, enabling them to make informed decisions when selecting suppliers.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, it’s essential to establish clear technical specifications for the webbing slings you need. This includes understanding the load capacity, material type (such as polyester or nylon), and safety standards relevant to your industry. Defining these parameters early helps streamline communication with potential suppliers and ensures that you receive products that meet your operational requirements.

Step 2: Conduct Market Research for Suppliers

Identifying potential suppliers is a critical step in the sourcing process. Use online directories, industry trade shows, and trade associations to compile a list of manufacturers and distributors specializing in webbing slings. Look for suppliers with a proven track record in your target regions, such as Africa and Europe, to ensure they understand local regulations and market needs.

Step 3: Verify Supplier Certifications

Ensure that any potential supplier holds relevant certifications that demonstrate compliance with international safety and quality standards, such as ISO 9001 or EN standards. Certifications provide assurance of the supplier’s commitment to quality and safety, which is particularly crucial for products like webbing slings that are used in lifting and rigging applications.

Step 4: Request Samples for Evaluation

Once you have narrowed down your list of suppliers, request samples of their webbing slings. Evaluating samples allows you to assess the quality, durability, and performance of the products firsthand. Pay attention to details such as stitching quality, material feel, and overall craftsmanship, as these factors can significantly impact the safety and efficacy of the slings in your operations.

Step 5: Evaluate Pricing and Payment Terms

Cost is a critical factor in any procurement decision. Compare pricing among your shortlisted suppliers, but also consider the total cost of ownership, which includes shipping, taxes, and potential tariffs. Additionally, clarify payment terms and conditions, as favorable terms can improve cash flow and reduce financial risk.

Step 6: Assess Supplier Communication and Support

Effective communication is vital for a successful supplier relationship. During your interactions, evaluate the responsiveness and clarity of the supplier’s communication. Reliable suppliers should provide prompt answers to inquiries and demonstrate a willingness to support your needs throughout the sourcing process.

Step 7: Review Logistics and Delivery Capabilities

Finally, consider the logistics and delivery capabilities of your potential suppliers. Assess their ability to meet your timelines and the shipping methods they offer. Suppliers with robust logistics networks can ensure timely delivery, which is crucial for maintaining your operational schedules and avoiding project delays.

By following this checklist, B2B buyers can strategically approach the sourcing of webbing slings, ensuring that they partner with reliable suppliers who meet their specific needs while adhering to industry standards.

Comprehensive Cost and Pricing Analysis for webbing slings supplier Sourcing

What Are the Key Cost Components in Sourcing Webbing Slings?

Understanding the cost structure of webbing slings is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for webbing slings include polyester and nylon, each with varying price points based on quality and durability. High-performance materials may increase costs but can offer better safety and longevity.

-

Labor: Labor costs vary widely depending on the region of production. In regions with lower labor costs, such as parts of Africa and South America, suppliers may offer more competitive pricing. However, the skill level and expertise required for manufacturing high-quality slings can also affect labor costs.

-

Manufacturing Overhead: This includes expenses related to running production facilities, such as utilities, rent, and administrative costs. Efficient manufacturing processes can help keep these overheads low, which is beneficial for pricing.

-

Tooling: Initial tooling costs for custom or specialized slings can be significant. If a supplier requires specific molds or machinery, this may be factored into the cost of the slings, especially for low-volume orders.

-

Quality Control (QC): Rigorous quality control processes are essential in ensuring product safety and reliability. While this adds to the cost, it can prevent higher costs associated with product failures or recalls.

-

Logistics: Transportation costs for shipping slings from the supplier to the buyer can vary based on distance, volume, and the choice of shipping method. Incoterms also play a crucial role in determining who bears these costs.

-

Margin: Suppliers will include a profit margin that can vary based on their market positioning, production capacity, and competitive landscape.

How Do Price Influencers Impact Webbing Sling Costs?

Several factors influence the pricing of webbing slings, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized slings, tailored to specific applications or certifications, usually come at a premium. Buyers must weigh the benefits of customization against additional costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or EN standards) may lead to increased costs. However, they also enhance safety and compliance, which can justify the investment.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more but offer better service and quality assurance.

-

Incoterms: The agreed-upon Incoterms dictate the responsibilities of both parties regarding shipping costs and risks. Understanding these terms can help buyers manage their total costs effectively.

What Are the Best Practices for Negotiating Prices on Webbing Slings?

Negotiating prices can lead to significant cost savings for international B2B buyers. Here are some tips:

-

Research Market Rates: Familiarize yourself with prevailing market prices for webbing slings in your region. This knowledge can strengthen your negotiating position.

-

Leverage Volume: If possible, consolidate orders to meet or exceed MOQs, which can lead to reduced per-unit costs.

-

Discuss Long-Term Relationships: Suppliers are often willing to negotiate better terms for buyers who commit to long-term relationships or repeated orders.

-

Evaluate Total Cost of Ownership (TCO): Consider the TCO, which includes not just the purchase price but also logistics, maintenance, and potential downtime costs. This broader perspective can help justify higher upfront costs for better quality or service.

-

Understand Pricing Nuances in Different Regions: Pricing strategies may vary significantly between regions. For instance, a supplier in Turkey may have different pricing dynamics than one in South America or Africa, influenced by local economic factors.

Disclaimer on Indicative Prices

Prices for webbing slings can fluctuate due to various factors, including raw material costs and market demand. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing and to stay updated on market trends.

Alternatives Analysis: Comparing webbing slings supplier With Other Solutions

Introduction: Understanding Alternative Solutions to Webbing Slings

When evaluating webbing slings as a lifting solution, it is essential for international B2B buyers to consider various alternatives that might suit their operational needs. This analysis will focus on comparing webbing slings suppliers with two viable alternatives: steel wire ropes and chain slings. Each option offers unique benefits and potential drawbacks, making it imperative to assess them based on specific criteria such as performance, cost, and ease of implementation.

Comparison Table: Evaluating Webbing Slings Against Alternatives

| Comparison Aspect | Webbing Slings Supplier | Steel Wire Ropes | Chain Slings |

|---|---|---|---|

| Performance | High flexibility, suitable for various loads | Excellent strength, less flexible | Very strong, limited flexibility |

| Cost | Generally lower cost | Moderate to high cost | Moderate cost |

| Ease of Implementation | Easy to handle and deploy | Requires specialized equipment for setup | Moderate, requires proper training |

| Maintenance | Low maintenance, inspect for wear | Moderate maintenance, check for rust | Low maintenance, regular inspection needed |

| Best Use Case | Lightweight loads, lifting in tight spaces | Heavy industrial applications | Heavy lifting in harsh environments |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Steel Wire Ropes?

Steel wire ropes are renowned for their exceptional strength and durability, making them an ideal choice for heavy industrial applications. Their ability to handle substantial loads without stretching or deforming is a significant advantage. However, they require specialized equipment for installation and may involve higher costs due to material and maintenance. Additionally, wire ropes are susceptible to rust and corrosion, necessitating regular inspections and maintenance to ensure safety.

How Do Chain Slings Compare in Terms of Functionality?

Chain slings offer unmatched strength and are highly effective in heavy lifting scenarios, particularly in harsh environments such as construction sites or manufacturing plants. They are resilient and can handle extreme conditions, but their inflexibility can limit their use in tight spaces. Chain slings also require proper training for safe usage, which may add to the implementation time and cost. Regular inspections are necessary to ensure that they remain safe for use, although they typically have low maintenance requirements.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right lifting solution involves understanding the specific requirements of your operations. Webbing slings are ideal for lighter loads and scenarios requiring flexibility and ease of use. In contrast, steel wire ropes and chain slings excel in heavy-duty applications where strength is paramount. B2B buyers should carefully evaluate their operational needs, considering factors like load weight, environmental conditions, and cost constraints. By aligning these factors with the characteristics of each solution, buyers can make informed decisions that enhance safety and efficiency in their lifting operations.

Essential Technical Properties and Trade Terminology for webbing slings supplier

When sourcing webbing slings, understanding essential technical properties and trade terminology is crucial for making informed purchasing decisions. This knowledge helps in evaluating product quality, ensuring compliance with safety standards, and facilitating smooth transactions with suppliers.

What Are the Key Technical Properties of Webbing Slings?

1. Material Grade: What Should Buyers Look For?

Webbing slings are typically made from nylon, polyester, or a blend of both. The material grade determines the sling’s strength, stretch, and resistance to environmental factors. For instance, polyester slings offer lower stretch and better UV resistance, making them suitable for outdoor use. Buyers should assess the material grade based on the intended application and environmental conditions to ensure optimal performance.

2. WLL (Working Load Limit): Why Is It Critical?

The Working Load Limit (WLL) refers to the maximum load that a webbing sling can safely handle during operation. It is a vital specification that must be clearly marked on the sling. Buyers should always choose slings with a WLL that exceeds their lifting requirements to maintain safety margins and avoid potential accidents.

3. Safety Factor: How Does It Affect Your Purchase?

The safety factor is the ratio of the breaking strength of the sling to its WLL. A higher safety factor indicates greater reliability under load. Industry standards typically recommend a safety factor of at least 5:1 for lifting applications. Understanding this concept helps buyers select slings that provide adequate safety and performance in their specific operational context.

4. Tolerance: What Does It Mean for Sling Specifications?

Tolerance refers to the permissible limit of variation in the manufacturing of webbing slings. It affects dimensions, strength, and overall performance. Tight tolerances ensure consistency and reliability, which are crucial for applications that require precise lifting. Buyers should inquire about the manufacturer’s tolerance standards to ensure compliance with their operational needs.

5. Length and Width: How Do They Impact Performance?

The length and width of a webbing sling directly influence its lifting capacity and usability. Longer slings can distribute loads more evenly, while wider slings reduce pressure on the load, minimizing the risk of damage. Buyers must consider the specific lifting scenarios and choose appropriate dimensions to enhance safety and efficiency.

What Are Common Trade Terms Used in the Webbing Sling Industry?

1. OEM (Original Equipment Manufacturer): What Does It Imply?

OEM refers to companies that manufacture products to be sold under another company’s brand. When dealing with webbing slings, sourcing from an OEM can ensure high-quality products tailored to specific requirements. Buyers should assess the reputation of OEMs to guarantee product reliability.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their demand forecasts to avoid excess inventory costs or supply shortages.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document used to solicit price quotes from suppliers. Including detailed specifications and requirements in an RFQ helps suppliers provide accurate pricing and delivery timelines. This process is essential for comparing offers and making informed purchasing decisions.

4. Incoterms (International Commercial Terms): What Should Buyers Know?

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps buyers understand cost allocation, risk, and logistics involved in transporting webbing slings. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which outline who bears the shipping costs and risks at various stages of the transport process.

5. Certification Standards: Why Are They Essential?

Certification standards, such as ISO or EN standards, ensure that webbing slings meet specific safety and quality requirements. Buyers should prioritize suppliers that provide certified products, as this guarantees compliance with industry regulations and enhances safety during use.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed choices, ensuring they select the right webbing slings for their operational needs while fostering effective supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the webbing slings supplier Sector

What Are the Key Market Dynamics and Trends Impacting Webbing Slings Suppliers?

The webbing slings supplier sector is witnessing significant transformation driven by global economic shifts and technological advancements. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, must be aware of these dynamics to make informed sourcing decisions. One of the primary drivers is the increasing demand for lightweight and high-strength materials that enhance safety and efficiency in lifting applications. Additionally, the rise of e-commerce platforms has streamlined the procurement process, enabling buyers to access a wider range of suppliers and products online.

Emerging technologies, such as automated inventory management systems and data analytics, are reshaping how suppliers operate, allowing for better demand forecasting and inventory control. For buyers, this means shorter lead times and improved supply chain reliability. Furthermore, as global trade policies evolve, international tariffs and regulations must be closely monitored to mitigate risks associated with sourcing from various regions.

A stock image related to webbing slings supplier.

Another notable trend is the growing preference for customized solutions. Buyers are increasingly looking for suppliers who can offer tailored products that meet specific operational requirements. This trend is particularly relevant in regions like Europe and Turkey, where industry standards are stringent, and compliance is non-negotiable. By understanding these market dynamics, international B2B buyers can better navigate the complexities of sourcing webbing slings and leverage opportunities for competitive advantage.

How Is Sustainability Influencing Sourcing Decisions in the Webbing Slings Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the webbing slings supplier sector. The environmental impact of production processes and materials used in webbing slings is under scrutiny as industries strive to meet sustainability goals. Buyers are increasingly prioritizing suppliers that adopt eco-friendly practices, such as using recycled materials and minimizing waste during manufacturing. This shift not only reflects a commitment to environmental stewardship but also aligns with the growing consumer demand for sustainable products.

Ethical sourcing is another critical factor. Buyers are keen to ensure that their suppliers adhere to fair labor practices and contribute positively to their local communities. This is particularly important in regions like Africa and South America, where ethical concerns can significantly influence purchasing decisions. Suppliers that obtain certifications such as ISO 14001 for environmental management or Fair Trade certifications can enhance their appeal to conscious buyers.

The market is also seeing a rise in “green” materials, such as bio-based webbing slings that offer similar performance characteristics as traditional products but with a lower environmental footprint. By focusing on sustainability and ethical sourcing, B2B buyers can not only fulfill their corporate social responsibility (CSR) commitments but also improve their brand reputation in increasingly eco-conscious markets.

What Has Been the Evolution of the Webbing Slings Supplier Sector?

The webbing slings supplier sector has evolved considerably over the past few decades, transitioning from traditional manufacturing methods to incorporating advanced technologies and materials. Initially, webbing slings were primarily made from natural fibers, which provided limited strength and durability. The introduction of synthetic materials, such as polyester and nylon, revolutionized the industry by offering superior performance and longevity.

As safety regulations became more stringent, suppliers began to innovate, developing slings that could withstand higher loads and resist wear and tear. The advent of modern manufacturing techniques, such as computer-aided design (CAD) and automated weaving processes, has further enhanced the precision and quality of webbing slings.

Today, the focus is not only on performance but also on sustainability and ethical practices, reflecting broader industry trends. This evolution has positioned the webbing slings supplier sector as a critical component of supply chains across various industries, from construction to logistics, making it essential for international B2B buyers to stay abreast of these developments.

Frequently Asked Questions (FAQs) for B2B Buyers of webbing slings supplier

-

How do I choose the right webbing slings supplier for my business needs?

Choosing the right supplier involves assessing their industry experience, product quality, and customer service. Look for suppliers with certifications such as ISO 9001, which indicates quality management systems. Request samples to evaluate the durability and specifications of their webbing slings. Additionally, check references or testimonials from other B2B buyers to gauge reliability. Consider suppliers who can accommodate your specific industry requirements, as well as those who offer customization options. -

What are the key factors to consider when vetting a webbing slings supplier?

Key factors include the supplier’s track record, compliance with international safety standards, and capacity to meet your volume needs. Evaluate their manufacturing processes and quality assurance protocols to ensure product reliability. Communication is also crucial; a responsive supplier can facilitate smoother transactions and quicker resolutions to issues. Lastly, consider their logistical capabilities, especially for international shipping to regions like Africa, South America, and the Middle East. -

What customization options are typically available for webbing slings?

Most suppliers offer various customization options, including length, width, and color of the webbing slings. You can also request specific load capacities and safety features tailored to your operational requirements. Some suppliers may provide additional services like branding or labeling, which can enhance your product presentation. When discussing customization, ensure that the supplier can maintain quality and safety standards throughout the production process. -

What is the minimum order quantity (MOQ) for webbing slings, and why does it matter?

The MOQ for webbing slings varies by supplier, typically ranging from 100 to 500 units. Understanding MOQ is crucial as it affects your purchasing strategy and cash flow. Suppliers often set MOQs to ensure cost-effectiveness in production and to cover setup costs. If your needs are below the MOQ, discuss flexibility with the supplier or consider partnering with other businesses to meet the requirement. -

What payment terms should I expect when sourcing from international webbing slings suppliers?

Payment terms can vary significantly among suppliers, but common options include upfront payments, 30% deposits with the balance upon delivery, or net 30/60 terms. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. It’s also wise to discuss currency exchange rates and potential fees to avoid unexpected costs during the transaction process. -

How can I ensure quality assurance when sourcing webbing slings?

To ensure quality, request detailed product specifications and certifications from the supplier. Conduct third-party inspections during production or before shipment to verify compliance with safety standards. Establishing a clear communication line with the supplier about quality expectations can help prevent issues. Consider suppliers who offer warranties or guarantees, which can provide added security for your investment. -

What logistics considerations should I keep in mind when importing webbing slings?

Logistics plays a vital role in international sourcing. Consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Collaborate with suppliers who have experience in your target market, as they can provide insights into local regulations and shipping best practices. It’s also essential to plan for lead times, as international shipping can introduce delays that affect your inventory levels. -

How do I handle disputes or issues with my webbing slings supplier?

Handling disputes effectively requires a proactive approach. Begin by maintaining open communication to address any concerns promptly. If an issue arises, document all correspondence and agreements for reference. Many suppliers have dispute resolution protocols; familiarize yourself with these processes. If necessary, seek legal advice or mediation, especially for larger contracts, to ensure a fair resolution without damaging the business relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for webbing slings supplier

In the evolving landscape of supply chain management, strategic sourcing remains pivotal for B2B buyers, particularly those seeking webbing slings. Understanding the specific needs of your operations, whether in Africa, South America, the Middle East, or Europe, is essential for optimizing sourcing strategies. Key takeaways include the importance of evaluating supplier capabilities, ensuring compliance with international safety standards, and fostering long-term relationships that enhance supply chain resilience.

What are the benefits of establishing partnerships with webbing slings suppliers? By engaging with reputable suppliers, businesses can access high-quality products tailored to their unique requirements, facilitating operational efficiency and safety. Furthermore, leveraging technology for supplier evaluation and management can streamline procurement processes and reduce costs.

Looking ahead, the demand for innovative and sustainable webbing sling solutions will continue to rise. International B2B buyers are encouraged to proactively seek suppliers who not only meet current standards but also invest in future advancements. By embracing strategic sourcing practices, businesses can position themselves competitively in a global marketplace. Now is the time to refine your sourcing strategy, ensuring your company is well-equipped to navigate the challenges and opportunities of the coming years.