Find the Best Wire Cloth Supplier: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for wire cloth supplier

In an increasingly interconnected world, sourcing high-quality wire cloth from reliable suppliers presents a significant challenge for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the complexities of navigating global supply chains can be daunting. This guide is designed to demystify the wire cloth market, offering insights into various types of wire cloth, their applications across industries, and strategic approaches for supplier vetting. By addressing crucial factors such as cost, quality, and compliance, we aim to equip you with the knowledge necessary to make informed purchasing decisions.

Understanding the nuances of the wire cloth industry is essential for businesses looking to enhance their operational efficiency and product quality. Different regions may have unique specifications and standards, which can impact sourcing strategies. This guide will explore key questions such as “What are the best types of wire cloth for my industry?” and “How do I evaluate potential suppliers effectively?” By providing actionable insights tailored to the needs of B2B buyers from diverse markets, we empower you to navigate the complexities of global procurement with confidence.

From determining the right specifications to negotiating favorable terms, this comprehensive resource is your roadmap to successful sourcing. Join us as we delve into the essential elements of finding the perfect wire cloth supplier for your business needs.

Understanding wire cloth supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Wire Cloth | Corrosion-resistant, durable, high tensile strength | Filtration, food processing, aerospace | Pros: Long lifespan, hygienic; Cons: Higher cost |

| Galvanized Wire Cloth | Coated with zinc for corrosion resistance | Construction, landscaping, fencing | Pros: Cost-effective, good durability; Cons: Limited high-temperature use |

| Copper Wire Cloth | Excellent conductivity, antimicrobial properties | Electrical applications, HVAC systems | Pros: Great for electrical applications; Cons: Prone to corrosion without proper treatment |

| Woven Wire Mesh | Various materials, customizable mesh sizes and patterns | Mining, oil & gas, industrial filtration | Pros: Versatile, tailored solutions; Cons: Longer lead times for custom orders |

| Welded Wire Fabric | Strong, rigid structure, often used in construction | Reinforcement, animal enclosures | Pros: High strength, easy installation; Cons: Less flexibility in design |

What are the Characteristics of Stainless Steel Wire Cloth?

Stainless steel wire cloth is renowned for its durability and resistance to corrosion. This type of wire cloth is ideal for industries requiring high hygiene standards, such as food processing and pharmaceuticals. When purchasing, B2B buyers should consider the specific grade of stainless steel, as different grades offer varying levels of corrosion resistance and tensile strength. It’s also important to evaluate the mesh size to ensure it meets filtration requirements.

Why Choose Galvanized Wire Cloth for Construction?

Galvanized wire cloth is coated with zinc, which enhances its resistance to rust and corrosion, making it an economical choice for outdoor applications. This type is widely used in construction, landscaping, and fencing. Buyers should assess the environment in which the wire cloth will be used, as prolonged exposure to moisture may still compromise its integrity over time. Cost-effectiveness and availability are strong advantages, but buyers should be aware of its limitations in high-temperature settings.

What are the Benefits of Using Copper Wire Cloth?

Copper wire cloth is distinguished by its excellent conductivity and antimicrobial properties, making it suitable for electrical applications and HVAC systems. When considering copper wire cloth, B2B buyers should evaluate the specific conductivity requirements of their projects. While it offers distinct advantages, such as reduced bacterial growth, buyers must also consider the potential for corrosion if not treated properly, especially in humid environments.

How Does Woven Wire Mesh Offer Versatility?

Woven wire mesh can be made from various materials and is customizable in terms of mesh sizes and patterns. This versatility makes it suitable for diverse applications, including mining, oil and gas extraction, and industrial filtration. B2B buyers should focus on the specific needs of their application, including the desired strength and openness of the mesh. Custom orders may involve longer lead times, so planning ahead is essential to avoid delays.

When to Use Welded Wire Fabric in Reinforcement?

Welded wire fabric is characterized by its strong and rigid structure, often utilized in construction for reinforcement purposes. It is also common in creating animal enclosures. Buyers should consider the weight and spacing of the wires, as these factors can affect the strength and application of the fabric. While it offers ease of installation and high strength, it is less flexible in design compared to other types, which may limit its use in certain applications.

Related Video: Variations In Construction Projects Explained

Key Industrial Applications of wire cloth supplier

| Industry/Sector | Specific Application of wire cloth supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining and Minerals | Filtration and separation in mineral processing | Enhances efficiency in extracting valuable minerals | Durability, resistance to abrasion, and customization |

| Food and Beverage | Food safety and quality control in processing | Ensures compliance with health regulations | Material safety certifications and hygiene standards |

| Oil and Gas | Well screen and filtration for drilling fluids | Increases operational efficiency and reduces downtime | Corrosion resistance and compatibility with drilling fluids |

| Construction and Architecture | Reinforcement in concrete and plaster | Improves structural integrity and longevity | Sizing and mesh specifications based on project needs |

| Environmental Protection | Wastewater treatment and air filtration | Supports sustainability initiatives and regulatory compliance | Eco-friendly materials and filtration efficiency |

How is Wire Cloth Used in Mining and Minerals Processing?

In the mining and minerals sector, wire cloth suppliers provide filtration and separation solutions crucial for mineral processing. These applications help in the efficient extraction of valuable minerals from ore. The use of durable wire cloth can significantly enhance the operational efficiency of mining operations, as it withstands the harsh conditions typical of this environment. International buyers, particularly from Africa and South America, should prioritize sourcing wire cloth that offers high abrasion resistance and is customizable to meet specific processing requirements.

What Role Does Wire Cloth Play in Food Safety and Quality Control?

In the food and beverage industry, wire cloth is instrumental in ensuring food safety and quality control during processing. Its applications range from filtering liquids to sifting dry ingredients, ensuring that contaminants are removed before products reach consumers. This is particularly important for businesses operating in Europe, where stringent health regulations must be adhered to. Buyers should focus on sourcing wire cloth that meets food safety certifications and hygiene standards to ensure compliance and protect consumer health.

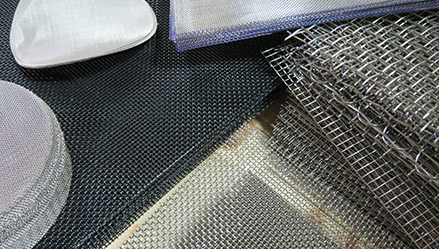

A stock image related to wire cloth supplier.

How is Wire Cloth Essential in Oil and Gas Operations?

In the oil and gas industry, wire cloth serves as a vital component in well screens and filtration systems for drilling fluids. This application helps in maintaining the integrity of drilling operations while minimizing downtime due to equipment failure. The ability of wire cloth to resist corrosion and compatibility with various drilling fluids is critical for international buyers in the Middle East, where such conditions are common. Buyers should evaluate the corrosion resistance of wire cloth to ensure it meets the demanding operational standards of their projects.

Why is Wire Cloth Important in Construction and Architecture?

Wire cloth is widely used in the construction and architecture sectors as reinforcement in concrete and plaster applications. It enhances the structural integrity and longevity of buildings, making it a vital component in construction projects. For buyers in Europe and Africa, sourcing wire cloth with the correct sizing and mesh specifications is essential to meet project requirements and ensure safety standards. This also allows for customization based on specific structural needs.

How Does Wire Cloth Contribute to Environmental Protection?

In environmental protection, wire cloth is employed in wastewater treatment and air filtration systems. These applications are increasingly important as industries strive to meet sustainability goals and regulatory compliance. For international buyers, particularly in emerging markets in Africa and South America, sourcing eco-friendly wire cloth that offers high filtration efficiency is crucial. This not only supports environmental initiatives but also enhances the overall sustainability of their operations.

Related Video: Industrial Wiring Tips and Tricks

3 Common User Pain Points for ‘wire cloth supplier’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Wire Cloth for Specific Applications

The Problem:

B2B buyers often face challenges when sourcing wire cloth that meets their specific application requirements. Industries such as food processing, pharmaceuticals, and construction require wire cloth with precise specifications—such as mesh size, material composition, and wire diameter. Buyers might encounter suppliers who provide substandard products or fail to deliver the exact specifications needed, leading to production delays, compliance issues, and increased costs. This is particularly challenging for businesses in regions like Africa and South America, where quality assurance processes might not be as stringent.

The Solution:

To effectively source quality wire cloth, B2B buyers should engage in a thorough vetting process for potential suppliers. Start by developing a clear specification sheet that outlines your requirements in detail, including material grades, mesh sizes, and any industry certifications necessary. Utilize online platforms and industry-specific forums to research suppliers and read reviews from other buyers. Building relationships with suppliers through direct communication can also foster transparency. Ask for samples before committing to larger orders, which will allow you to assess the quality firsthand. Additionally, consider establishing partnerships with suppliers who have a proven track record in your industry, ensuring they understand the unique requirements of your applications.

Scenario 2: Inconsistent Lead Times and Delivery Issues

The Problem:

Inconsistent lead times can severely disrupt production schedules, particularly for companies that rely on just-in-time inventory systems. For B2B buyers, especially in the Middle East and Europe, unexpected delays in wire cloth delivery can result in halted operations and financial losses. Moreover, navigating customs and import regulations adds another layer of complexity, often leading to unforeseen delays that can exacerbate the situation.

The Solution:

To mitigate delivery issues, B2B buyers should adopt a proactive approach by establishing clear communication channels with their wire cloth suppliers. Discuss expected lead times upfront and inquire about the supplier’s logistics capabilities, including their handling of customs and import regulations. Implementing a vendor-managed inventory (VMI) system can help maintain stock levels while allowing suppliers to manage their own inventory, ensuring timely deliveries. Additionally, consider diversifying your supplier base to include local suppliers who can provide quicker turnaround times and reduce shipping delays. Regularly reviewing and adjusting contracts based on performance can also incentivize suppliers to meet delivery expectations.

Scenario 3: Lack of Technical Support and Expertise

The Problem:

Many B2B buyers struggle with a lack of technical support when selecting and using wire cloth products. This is particularly true for companies in sectors such as manufacturing and engineering, where the technical specifications of wire cloth can significantly impact the performance of machinery and end products. Buyers may find themselves unable to make informed decisions, leading to suboptimal product choices that can hinder efficiency and increase operational costs.

The Solution:

To overcome this challenge, B2B buyers should prioritize suppliers that offer comprehensive technical support and consultation services. Look for suppliers that have a dedicated team of experts who can provide guidance on material selection, installation methods, and maintenance best practices. Organizing training sessions or workshops with suppliers can enhance your team’s understanding of wire cloth applications and its technical nuances. Additionally, leveraging online resources, such as webinars or technical articles, can further empower your purchasing decisions. Establishing a feedback loop with suppliers can also facilitate ongoing support, ensuring that you receive the necessary assistance as your requirements evolve.

Strategic Material Selection Guide for wire cloth supplier

When selecting materials for wire cloth, international B2B buyers must consider several factors, including the specific application, environmental conditions, and compliance with industry standards. Below is an analysis of four common materials used in wire cloth manufacturing, highlighting their properties, advantages, disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel Wire Cloth?

Stainless Steel is one of the most widely used materials for wire cloth due to its excellent corrosion resistance and strength. It typically withstands temperatures up to 1,000°F (538°C) and is resistant to a variety of chemicals, making it suitable for diverse applications, including filtration and industrial processes.

Pros & Cons: The durability of stainless steel wire cloth is a significant advantage, as it can last longer than other materials, reducing replacement costs. However, the manufacturing process can be complex and may lead to higher initial costs compared to alternatives like plastic.

Impact on Application: Stainless steel wire cloth is ideal for applications involving harsh chemicals or high temperatures, such as in the oil and gas industry. Buyers should ensure compliance with relevant standards such as ASTM A313 or DIN 1.4301.

How Does Aluminum Wire Cloth Compare in Performance?

Aluminum wire cloth is lightweight and offers good corrosion resistance, especially in non-alkaline environments. It typically operates well at temperatures up to 600°F (316°C) and is often used in applications where weight is a critical factor.

Pros & Cons: The primary advantage of aluminum wire cloth is its low weight, making it easier to handle and install. However, it is less durable than stainless steel and may not perform well in high-stress applications, limiting its use in certain industries.

Impact on Application: Aluminum wire cloth is suitable for applications like HVAC systems and lightweight filters. Buyers in regions with specific environmental conditions, such as high humidity or saltwater exposure, should consider the material’s limitations and potential for corrosion.

What Are the Benefits of Using Polyester Wire Cloth?

Polyester wire cloth is a synthetic option that offers good chemical resistance and flexibility. It can withstand temperatures up to 250°F (121°C) and is often used in applications involving food processing or pharmaceuticals.

Pros & Cons: The flexibility of polyester wire cloth allows for easier installation and maintenance. However, it is less durable than metal options and may not be suitable for high-pressure applications.

Impact on Application: Polyester wire cloth is ideal for applications requiring a non-metallic solution, such as in food and beverage industries. Buyers should verify compliance with food safety standards, especially in regions like Europe where regulations may be stricter.

Why Choose Copper Wire Cloth for Specific Applications?

Copper wire cloth is known for its excellent conductivity and antimicrobial properties, making it suitable for applications in electronics and medical devices. It can handle temperatures up to 400°F (204°C) and is often used in specialized environments.

Pros & Cons: The key advantage of copper wire cloth is its conductivity, which is beneficial for electronic applications. However, it is prone to corrosion and may require additional coatings or treatments to enhance its durability.

Impact on Application: Copper wire cloth is particularly advantageous in applications requiring electrical conductivity, such as grounding and shielding. Buyers should be aware of the material’s susceptibility to oxidation and ensure compliance with relevant electrical standards.

Summary Table of Material Selection for Wire Cloth

| Material | Typical Use Case for wire cloth supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Filtration in oil and gas industries | Excellent corrosion resistance | Higher initial cost | High |

| Aluminum | HVAC systems and lightweight filters | Lightweight and easy to handle | Less durable under stress | Medium |

| Polyester | Food processing and pharmaceuticals | Flexible and easy to maintain | Limited durability | Low |

| Copper | Electronics and medical devices | High conductivity | Prone to corrosion | Medium |

In conclusion, selecting the right material for wire cloth requires careful consideration of the specific application, environmental conditions, and compliance with industry standards. International B2B buyers should evaluate each material’s properties, advantages, and limitations to make informed purchasing decisions that align with their operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for wire cloth supplier

What Are the Main Stages of Wire Cloth Manufacturing?

The manufacturing process for wire cloth involves several critical stages that ensure the final product meets quality standards and customer specifications. Understanding these stages can empower B2B buyers to make informed decisions when selecting a wire cloth supplier.

-

Material Preparation: The process begins with the selection and preparation of raw materials, typically stainless steel, carbon steel, or other alloys. The wire is drawn to the desired diameter using a series of dies, ensuring consistency in size and strength. Buyers should inquire about the source of raw materials, as quality can significantly influence the performance and durability of the wire cloth.

-

Forming: After preparation, the wire is formed into the desired mesh pattern. Techniques such as weaving, welding, or knitting are commonly used. Weaving involves interlacing wires at right angles, while welding creates a solid bond at intersections for enhanced strength. Understanding the forming technique can help buyers assess the suitability of the wire cloth for specific applications.

-

Assembly: Once the wire is formed, it may undergo further assembly processes, such as cutting to size or adding additional components (like frames or borders). This stage is crucial for ensuring that the wire cloth fits the intended application, whether it’s for filtration, fencing, or other uses.

-

Finishing: The final stage involves treatments that enhance the wire cloth’s properties, such as coating, galvanizing, or passivation. These processes improve corrosion resistance and extend the product’s lifespan. Buyers should consider how finishing techniques align with their operational environments, especially in regions with high humidity or exposure to chemicals.

How Do Quality Assurance Standards Impact Wire Cloth Production?

Quality assurance (QA) is integral to the wire cloth manufacturing process, ensuring that products meet both international and industry-specific standards. B2B buyers should be aware of these standards to ensure they are sourcing high-quality products.

-

International Standards: ISO 9001 is the most recognized quality management system standard globally. It ensures that suppliers maintain consistent quality through systematic processes and continuous improvement. Buyers can request certification documents to verify compliance.

-

Industry-Specific Standards: Depending on the application, other certifications may be relevant. For example, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. API specifications may be necessary for wire cloth used in the oil and gas industry. Understanding these standards helps buyers assess the suitability of products for their specific needs.

What Quality Control Checkpoints Should B2B Buyers Consider?

Quality control (QC) is a multi-faceted process that involves several checkpoints throughout the manufacturing cycle. Each stage requires careful monitoring to ensure product integrity.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Buyers should confirm that suppliers perform thorough IQC processes to ensure that only high-quality materials enter production.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves regular checks at various stages to catch defects early. This may include monitoring wire diameter, mesh size, and adherence to specifications. Buyers can request details about the frequency and type of IPQC measures employed by their suppliers.

-

Final Quality Control (FQC): Before shipment, FQC involves a comprehensive review of the finished product against specifications. This includes visual inspections, dimensional checks, and performance testing. Buyers should ask suppliers about their FQC processes to ensure that products meet required standards before delivery.

What Common Testing Methods Are Used in Wire Cloth Quality Control?

Testing methods play a vital role in verifying the performance and quality of wire cloth. B2B buyers should be familiar with these methods to better understand product reliability.

-

Tensile Strength Testing: This test measures the maximum load the wire cloth can withstand before failure. It is essential for applications requiring durability and strength. Suppliers should provide testing reports to substantiate claims regarding tensile strength.

-

Mesh Count Verification: This involves counting the number of openings per unit length to ensure it meets specifications. Buyers should request documentation that confirms mesh counts align with their requirements.

-

Corrosion Resistance Testing: Particularly for wire cloth used in harsh environments, corrosion resistance testing evaluates how well the material withstands exposure to corrosive substances. Buyers should inquire about the specific tests conducted and the results.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is critical for international B2B buyers to ensure product reliability. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and adherence to standards. Audits can reveal insights into the supplier’s operational capabilities and commitment to quality.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of IQC, IPQC, and FQC processes. These documents provide transparency and reassurance regarding product quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly useful for buyers in regions like Africa and South America, where local suppliers may not always meet international standards.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers must navigate various nuances related to quality control and certification when sourcing wire cloth from different regions. Here are some key considerations:

-

Regional Standards: Different regions may have varying standards and certifications. For instance, suppliers in Europe may be more aligned with CE marking requirements, while suppliers in the Middle East might focus on local standards. Understanding these differences can help buyers ensure compliance with regional regulations.

-

Language Barriers: Documentation related to QC processes and certifications may be in different languages. Buyers should ensure they can access translated documents or have a clear understanding of what each certification entails.

-

Cultural Differences: Approaches to quality control may vary based on cultural practices. Buyers should be prepared to discuss expectations clearly and establish mutual understanding with suppliers from different backgrounds.

By considering these insights into manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting wire cloth suppliers, ultimately leading to better product performance and business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire cloth supplier’

In the competitive landscape of international B2B procurement, sourcing the right wire cloth supplier is a critical task that requires careful planning and execution. This guide provides a practical checklist to streamline your sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for wire cloth. This includes specifying material types, mesh sizes, and any necessary certifications (e.g., ISO, ASTM). Defining these parameters ensures that suppliers understand your needs and can provide suitable products, ultimately reducing the risk of costly errors later.

Step 2: Research Market Trends and Supplier Reputation

Understanding the current market landscape is essential for identifying potential suppliers. Conduct thorough research to assess supplier reputation by reading reviews, seeking testimonials, and examining their portfolio of past projects. Utilize platforms like LinkedIn or industry-specific forums to gather insights on suppliers’ reliability and customer service.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; ensure they have a proven track record of delivering quality wire cloth products that meet your specifications.

- Check Experience: Look for suppliers with experience in your specific application or industry.

- Assess Financial Stability: A financially stable supplier is more likely to fulfill large orders and maintain quality over time.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess relevant certifications that guarantee quality and compliance with international standards. Certifications such as ISO 9001 for quality management systems or specific industry certifications can be a strong indicator of a supplier’s commitment to quality.

- Ask for Documentation: Request copies of certifications and any quality assurance processes they follow.

- Review Compliance History: Investigate any past compliance issues or recalls associated with the supplier.

Step 5: Request Samples for Quality Assessment

Before finalizing your order, request samples of the wire cloth to evaluate quality firsthand. This step is vital to ensure that the product meets your standards in terms of durability, finish, and functionality.

- Conduct Tests: Perform any necessary tests to evaluate the wire cloth against your specifications.

- Assess Customer Support: Gauge the supplier’s responsiveness and willingness to assist during the sample evaluation.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, delivery timelines, payment terms, and warranty policies to ensure both parties are aligned.

- Be Transparent: Clearly communicate your expectations and any potential volume commitments.

- Document Everything: Ensure all agreed terms are documented in a formal contract to avoid misunderstandings.

Step 7: Establish a Communication Plan

Effective communication is key to a successful supplier relationship. Develop a communication plan that outlines how you will interact with the supplier throughout the procurement process and beyond.

- Set Regular Check-ins: Schedule regular updates to monitor progress and address any issues promptly.

- Utilize Technology: Consider using project management tools to facilitate collaboration and ensure transparency.

By following this checklist, international B2B buyers can navigate the complexities of sourcing wire cloth suppliers effectively, ensuring that they secure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for wire cloth supplier Sourcing

What Are the Key Cost Components in Wire Cloth Supplier Sourcing?

When sourcing from wire cloth suppliers, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type and quality of wire used significantly impact costs. Stainless steel, for example, is more expensive than galvanized steel but offers superior corrosion resistance.

-

Labor: Labor costs vary by region. Suppliers in countries with higher wage standards may have elevated labor costs, which should be factored into your total expenditure.

-

Manufacturing Overhead: This includes utilities, rent, equipment depreciation, and administrative expenses. Suppliers with efficient production processes may offer lower overhead costs, which can translate into better pricing for buyers.

-

Tooling: Custom wire cloth often requires specialized tooling, which can add to the upfront costs. Understanding these costs can help in evaluating the overall pricing of customized orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can also increase costs. Suppliers with established QC protocols might charge a premium, but this investment can lead to long-term savings through reduced defects.

-

Logistics: Transportation costs are influenced by distance, mode of transport, and shipping terms. It’s vital to consider these when calculating the total cost of acquisition.

-

Margin: Supplier profit margins can vary based on competition, market demand, and the perceived value of their products. Understanding these margins can help in negotiations.

How Do Price Influencers Affect Wire Cloth Supplier Costs?

Several factors influence pricing in the wire cloth market:

-

Volume/MOQ: Larger orders often qualify for bulk discounts. Discussing minimum order quantities (MOQ) with suppliers can lead to significant savings.

-

Specifications and Customization: Custom specifications can increase costs due to the need for tailored production processes. Buyers should assess whether the added features justify the higher price.

-

Material Quality and Certifications: Suppliers offering higher-grade materials or industry certifications may charge more, but these investments can enhance product durability and compliance with regulatory standards.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with a strong track record may command higher prices due to their reliability.

-

Incoterms: The agreed Incoterms can significantly impact pricing. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will dictate who bears the shipping costs and risks, affecting the overall expenditure.

What Are the Best Buyer Tips for Negotiating Wire Cloth Pricing?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms that can lead to better pricing or additional value, such as extended warranties or free shipping.

-

Focus on Cost-Efficiency: Evaluate suppliers not just on price but on overall value. Assess long-term partnerships that could yield better pricing through loyalty and consistent ordering.

-

Consider Total Cost of Ownership (TCO): Look beyond the purchase price. Factor in costs related to maintenance, downtime, and potential replacements. A higher upfront cost may lead to lower TCO over time if the quality is superior.

-

Understand Pricing Nuances: Be aware of the economic conditions in both your region and the supplier’s. Currency fluctuations, tariffs, and trade regulations can affect pricing. Keeping abreast of these factors can provide leverage during negotiations.

-

Request Indicative Prices: Given the variability in wire cloth pricing based on specifications and market conditions, always request indicative prices before committing to an order. This will help you budget accurately and make informed decisions.

By understanding the cost components, price influencers, and effective negotiation strategies, international B2B buyers can navigate the complexities of wire cloth sourcing with confidence.

Alternatives Analysis: Comparing wire cloth supplier With Other Solutions

Exploring Alternatives to Wire Cloth Suppliers

When considering wire cloth for industrial applications, international B2B buyers must explore various alternatives that may offer comparable functionality. Understanding the strengths and weaknesses of each option can lead to better decision-making tailored to specific operational needs. In this section, we will compare wire cloth suppliers with two viable alternatives: perforated metal sheets and synthetic filter media.

Comparison Table of Wire Cloth Supplier and Alternatives

| Comparison Aspect | Wire Cloth Supplier | Perforated Metal Sheets | Synthetic Filter Media |

|---|---|---|---|

| Performance | High tensile strength, versatile | Good airflow, limited filtration | Excellent filtration efficiency, lightweight |

| Cost | Moderate to high depending on material | Generally lower cost | Varies widely, often higher for specialized applications |

| Ease of Implementation | Requires specific fabrication techniques | Easily customizable, quick to install | May require specialized installation techniques |

| Maintenance | Low maintenance, durable | Low maintenance, but can corrode | Regular replacement needed, depending on application |

| Best Use Case | Heavy-duty applications requiring strength | Ventilation and noise reduction | Water treatment, air filtration, and food processing |

In-Depth Analysis of Alternatives

What are the advantages and disadvantages of using perforated metal sheets?

Perforated metal sheets serve as a practical alternative to wire cloth, particularly in applications where airflow is essential. They provide good structural support while allowing for the passage of air and light. The cost of perforated sheets is typically lower than that of wire cloth, making them an attractive option for budget-conscious projects. However, their filtration capabilities are limited compared to wire cloth, which may not suit applications requiring precise particle separation. Additionally, while they are generally low-maintenance, they can be susceptible to corrosion if not properly treated, which may lead to increased long-term costs.

How does synthetic filter media compare to wire cloth suppliers?

Synthetic filter media is another alternative that excels in specific applications, particularly in filtration processes. They offer outstanding filtration efficiency, often outperforming wire cloth in trapping smaller particles and contaminants. This makes them ideal for industries such as water treatment and food processing. However, the cost can be higher, especially for specialized synthetic materials. Installation may also require specific techniques or equipment, which could complicate the implementation process. Furthermore, synthetic media typically have a shorter lifespan than wire cloth, necessitating regular replacements that can increase operational costs over time.

How can B2B buyers select the right solution for their needs?

Choosing the right solution among wire cloth suppliers, perforated metal sheets, and synthetic filter media hinges on several factors. B2B buyers should assess their specific application requirements, including performance criteria, budget constraints, and maintenance capabilities. For example, if the need is for high tensile strength and durability in harsh environments, wire cloth may be the best option. Conversely, if the priority is on cost-effectiveness and airflow, perforated metal sheets could be more suitable. Lastly, for applications demanding high filtration efficiency, synthetic filter media might prove to be the most effective choice. By carefully weighing these aspects, buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for wire cloth supplier

What Are the Key Technical Properties of Wire Cloth?

When sourcing wire cloth, understanding its technical specifications is crucial for making informed purchasing decisions. Below are several essential properties that international B2B buyers should consider:

1. Material Grade

The material grade of wire cloth, often made from stainless steel, carbon steel, or other alloys, plays a pivotal role in determining its durability, corrosion resistance, and overall performance. For instance, 304 stainless steel offers good corrosion resistance for a variety of applications, while 316 stainless steel is preferable for harsher environments, such as marine settings. Selecting the appropriate material grade ensures longevity and functionality, which can reduce replacement costs over time.

2. Wire Diameter

Wire diameter is a critical factor that influences the strength and flexibility of wire cloth. Measured in millimeters or inches, the diameter affects the mesh opening size and the overall weight of the material. A thicker wire typically provides greater strength but may limit flexibility, making it essential to align the wire diameter with the intended application. Buyers should consider the trade-off between strength and flexibility to meet their specific requirements.

3. Mesh Count

Mesh count refers to the number of openings per linear inch in the wire cloth. Higher mesh counts lead to finer openings, suitable for filtration applications, while lower counts are ideal for applications requiring larger openings. Understanding the mesh count is vital for ensuring the wire cloth meets the intended purpose, whether for sieving, filtration, or safety barriers.

4. Tolerance

Tolerance indicates the allowable deviation in dimensions from the specified measurements. In wire cloth manufacturing, tighter tolerances are often necessary for applications that require precision, such as in the aerospace or medical sectors. Buyers should specify their tolerance requirements to ensure the final product meets the necessary standards for quality and performance.

5. Coating Options

Coatings, such as PVC or epoxy, enhance the wire cloth’s resistance to environmental factors, including moisture and chemicals. These coatings can also provide additional benefits such as reduced friction and improved aesthetics. Understanding the available coating options can help buyers select wire cloth that is not only functional but also suited for specific environmental conditions.

What Are the Common Trade Terms Used in Wire Cloth Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in the wire cloth market. Here are several key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end product. In the wire cloth industry, buyers may source from OEMs to ensure that the wire cloth meets specific design and quality standards, especially in industries like automotive or aerospace.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, particularly those in smaller markets or startups, as it can impact cash flow and inventory management. Negotiating MOQs can sometimes yield flexibility, particularly for larger orders or long-term contracts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific quantities of products. It allows buyers to compare prices, terms, and conditions from various suppliers, facilitating informed decision-making. A well-prepared RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs. Familiarity with Incoterms helps buyers manage risks and understand their obligations in global sourcing.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for effective inventory management and project planning. B2B buyers should communicate their timelines clearly to suppliers to avoid delays that could impact operations.

By grasping these essential technical properties and trade terms, international B2B buyers can navigate the wire cloth market more effectively, ensuring they make informed decisions that align with their operational needs and objectives.

Navigating Market Dynamics and Sourcing Trends in the wire cloth supplier Sector

What Are the Current Market Dynamics and Key Trends in the Wire Cloth Supplier Sector?

The wire cloth supplier sector is experiencing significant transformations driven by global economic shifts, technological advancements, and evolving customer demands. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers that can offer not only quality but also adaptability and innovation. One of the most notable trends is the rise of digital procurement platforms. These platforms streamline the sourcing process, allowing buyers to access a broader range of suppliers and compare prices and quality more effectively.

Moreover, the demand for customized wire cloth solutions is on the rise. Buyers are seeking materials tailored to specific applications, which has prompted suppliers to invest in flexible production capabilities. This trend is particularly evident in industries such as construction, automotive, and filtration, where the specifications for wire cloth can vary greatly. Additionally, the focus on local sourcing is becoming more pronounced. Buyers are increasingly prioritizing suppliers in close proximity to reduce lead times and transportation costs, which is particularly relevant for regions like Europe and the Middle East.

How Is Sustainability Influencing Sourcing Decisions in the Wire Cloth Supplier Sector?

Sustainability and ethical sourcing are becoming paramount in the wire cloth supplier sector. As international buyers become more environmentally conscious, the pressure on suppliers to minimize their ecological footprint is increasing. This includes adopting sustainable manufacturing practices, reducing waste, and utilizing recycled materials. For instance, wire cloth made from recycled metals not only meets environmental standards but also appeals to buyers looking to enhance their corporate responsibility profiles.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly interested in understanding the origins of materials and the labor practices involved in their production. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming critical in supplier evaluations. Buyers from regions like Africa and South America, where ethical sourcing can significantly impact community development, are particularly attentive to these factors. Therefore, suppliers that can demonstrate a commitment to sustainability and ethical practices are likely to gain a competitive edge in the market.

What Is the Evolution of the Wire Cloth Supplier Sector and Its Relevance to B2B Buyers?

The wire cloth supplier sector has a rich history that reflects broader industrial trends. Originally, wire cloth was primarily used in agriculture and construction. However, as industries evolved, so did the applications of wire cloth, expanding into sectors such as aerospace, medical, and food processing. This evolution has led to innovations in material composition and manufacturing techniques, including the development of specialty alloys and advanced weaving methods.

For B2B buyers, understanding this historical context is crucial as it informs current market offerings and future developments. The ongoing push for innovation and customization is rooted in this history, providing buyers with a variety of options to meet their specific needs. By staying informed about the evolution of wire cloth applications, international buyers can better anticipate market shifts and make more strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of wire cloth supplier

-

How do I solve the issue of finding a reliable wire cloth supplier?

Finding a trustworthy wire cloth supplier involves thorough research and due diligence. Start by leveraging online directories and industry-specific platforms to identify potential suppliers. Check for certifications and compliance with international standards, such as ISO. Engage in discussions with suppliers to assess their responsiveness and willingness to provide references from existing clients. Additionally, consider attending trade shows in your region, as these events offer opportunities to meet suppliers face-to-face and evaluate their products firsthand. -

What factors should I consider when selecting the best wire cloth for my application?

When selecting wire cloth, consider the material type, mesh size, and wire diameter, as these affect the cloth’s strength and filtration capabilities. Evaluate the specific requirements of your application, such as temperature tolerance and corrosion resistance. Additionally, assess whether you need customized specifications, as many suppliers offer tailored solutions. It’s also important to review the supplier’s track record in producing wire cloth suitable for your industry, ensuring they understand your unique needs. -

What is the typical minimum order quantity (MOQ) for wire cloth orders?

The minimum order quantity (MOQ) for wire cloth can vary significantly between suppliers, ranging from a few square meters to several rolls, depending on the material and customization options. When sourcing internationally, it’s crucial to clarify MOQ during initial discussions, as some suppliers may be more flexible for repeat customers or larger orders. If your requirements fall below the MOQ, inquire about the possibility of combining orders with other buyers or exploring alternative suppliers that accommodate smaller quantities. -

How can I negotiate favorable payment terms with my wire cloth supplier?

Negotiating payment terms requires clear communication and understanding of your supplier’s policies. Start by expressing your payment preferences, such as net 30 or net 60 days. Building a solid relationship with the supplier can enhance your negotiating power, especially if you demonstrate a commitment to future orders. Consider offering a larger upfront payment in exchange for better terms or discounts. Always ensure that payment terms are documented in your contract to avoid misunderstandings later. -

What quality assurance measures should I expect from a wire cloth supplier?

A reputable wire cloth supplier should implement rigorous quality assurance (QA) measures. Expect them to provide detailed specifications for their products, including material certifications and test results. Inquire about their QA processes, such as inspections during production and post-manufacturing testing. Additionally, request samples before placing a large order to assess the quality firsthand. Establishing a clear QA agreement in your contract will ensure that both parties have aligned expectations regarding product standards. -

How can I ensure timely logistics and delivery from my wire cloth supplier?

To ensure timely logistics and delivery, discuss shipping options and timelines upfront with your supplier. Consider using suppliers who have established logistics networks or partnerships with reliable freight forwarders. Request a shipping schedule that aligns with your project timelines and ask for regular updates on the order status. Additionally, factor in customs clearance times, especially for international shipments, and verify that your supplier has experience navigating these processes effectively. -

What are the best practices for vetting international wire cloth suppliers?

Vetting international suppliers involves multiple steps. Start by researching their company background, including years in business and customer reviews. Utilize platforms like LinkedIn to gauge their reputation in the industry. Request references from existing clients and follow up to understand their experiences. It’s also advisable to conduct a factory visit if possible, or use third-party inspection services to verify the supplier’s capabilities and adherence to quality standards. Lastly, ensure they comply with international trade regulations relevant to your region.

A stock image related to wire cloth supplier.

- How can I communicate effectively with a wire cloth supplier located in a different country?

Effective communication with international suppliers hinges on clarity and consistency. Use clear, concise language and avoid jargon that may not translate well. Utilize email for detailed discussions, ensuring that all agreements are documented. Video calls can enhance understanding and build relationships, providing a more personal touch. Be aware of time zone differences and cultural nuances that may affect communication styles. Finally, establishing a single point of contact can streamline communication and prevent misunderstandings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wire cloth supplier

As the global market for wire cloth continues to evolve, strategic sourcing remains a pivotal approach for international B2B buyers. By understanding the nuances of supplier capabilities and regional market dynamics, businesses can optimize their procurement processes. Key takeaways include the importance of establishing strong relationships with suppliers, leveraging technology for better supply chain visibility, and conducting thorough market research to identify the most reliable partners.

B2B buyers from Africa, South America, the Middle East, and Europe must prioritize collaboration with suppliers who not only meet quality standards but also align with their ethical sourcing values. This alignment can enhance brand reputation and ensure compliance with international regulations. Additionally, as sustainability becomes a focal point in procurement decisions, buyers should seek suppliers that demonstrate a commitment to environmentally friendly practices.

Looking ahead, the landscape of wire cloth supply will likely be shaped by advancements in manufacturing technologies and shifts in global trade policies. To stay competitive, B2B buyers should continuously monitor these trends and be proactive in adjusting their sourcing strategies. Engage with suppliers today to secure a strong position in this dynamic market and unlock new opportunities for growth and innovation.