Find Top Pressure Relief Valve Suppliers: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for pressure relief valve supplier

Navigating the complexities of sourcing a reliable pressure relief valve supplier can pose significant challenges for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. The need for high-quality pressure relief valves is critical across various industries, including oil and gas, pharmaceuticals, and manufacturing, where safety and compliance are paramount. This guide aims to equip buyers with comprehensive insights into the types of pressure relief valves available, their applications, and essential supplier vetting criteria to ensure compliance with international standards.

In this resource, we delve into the nuances of pressure relief valve specifications, exploring the technological advancements that influence performance and reliability. Additionally, we will cover cost considerations, helping you understand pricing structures based on material, design, and supplier reputation. By offering a structured approach to supplier selection, this guide empowers you to make informed purchasing decisions that align with your operational needs and budget constraints.

Whether you are based in bustling cities like Ho Chi Minh City or Milan, understanding the global market for pressure relief valves is crucial for maintaining operational efficiency and safety. This guide will serve as your roadmap, helping you navigate the intricate landscape of international suppliers and ensuring you find the right partner for your business needs.

Understanding pressure relief valve supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded Relief Valves | Utilizes a spring mechanism to open at a preset pressure | Oil & gas, chemical processing | Pros: Simple design, cost-effective. Cons: Limited to specific pressure settings. |

| Pilot-Operated Relief Valves | Operates using a pilot valve for sensitive pressure control | Power generation, water treatment | Pros: High accuracy, suitable for high-pressure systems. Cons: More complex, higher maintenance. |

| Safety Relief Valves | Combines features of both safety and relief valves | HVAC systems, manufacturing | Pros: Versatile, reliable. Cons: Can be more expensive than standard valves. |

| Electronic Relief Valves | Uses electronic controls for precise pressure management | Aerospace, pharmaceuticals | Pros: Highly accurate, programmable. Cons: Higher initial investment, requires skilled operation. |

| Bursting Discs | Non-mechanical, designed to rupture at a specific pressure | Chemical manufacturing, oil refining | Pros: No moving parts, reliable failure mode. Cons: Once activated, needs complete replacement. |

What are Spring-Loaded Relief Valves and Their B2B Suitability?

Spring-loaded relief valves are among the most common types used in industrial applications. They operate by utilizing a spring mechanism that opens the valve at a predetermined pressure setting. This type is particularly suitable for industries like oil and gas and chemical processing, where cost-effectiveness and simplicity are crucial. Buyers should consider the specific pressure settings required for their operations, as these valves may not be adjustable once installed.

How Do Pilot-Operated Relief Valves Enhance Pressure Control?

Pilot-operated relief valves are designed for applications requiring sensitive pressure control. They use a pilot valve to regulate the opening and closing of the main valve, allowing for high accuracy in maintaining system pressure. This type is ideal for power generation and water treatment sectors. When purchasing, buyers should weigh the benefits of precision against the complexity and potential maintenance requirements associated with these valves.

What Makes Safety Relief Valves a Reliable Choice for B2B Applications?

Safety relief valves combine the functionalities of both safety and relief valves, making them versatile for various applications, including HVAC systems and manufacturing. Their reliability in preventing overpressure situations makes them a preferred choice among buyers. However, they may come at a higher cost compared to standard valves, so budget considerations are essential when making procurement decisions.

Why Choose Electronic Relief Valves for Precision Management?

Electronic relief valves offer advanced features such as programmability and precise pressure management, making them suitable for high-tech industries like aerospace and pharmaceuticals. While they provide exceptional accuracy, the initial investment is usually higher, and they require skilled personnel for operation. Buyers should consider their operational capabilities and budget when opting for this advanced technology.

When to Use Bursting Discs in Industrial Settings?

Bursting discs are non-mechanical devices designed to rupture at a specific pressure, providing a fail-safe method for pressure relief. Commonly used in chemical manufacturing and oil refining, they are favored for their reliability and lack of moving parts. However, once activated, they require complete replacement, which can lead to downtime. Buyers should evaluate their operational needs and maintenance capabilities before choosing this option.

Related Video: Pressure Safety and Pressure Relief Valve| PRV and PSV

Key Industrial Applications of pressure relief valve supplier

| Industry/Sector | Specific Application of Pressure Relief Valve Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pressure relief in upstream and downstream operations | Enhanced safety and compliance with regulations | Certification standards, material compatibility, and performance under extreme conditions. |

| Chemical Manufacturing | Pressure relief in reactors and storage tanks | Prevention of hazardous overpressure situations | Reliability, response time, and compatibility with various chemicals. |

| Water Treatment | Pressure relief in filtration and treatment systems | Protection of equipment and continuity of service | Corrosion resistance, maintenance requirements, and operational pressures. |

| Power Generation | Pressure relief in steam and gas turbines | Increased efficiency and operational safety | Temperature ratings, material durability, and response characteristics. |

| Food & Beverage | Pressure relief in processing and storage | Ensures product safety and compliance with health standards | Hygiene standards, ease of cleaning, and material safety certifications. |

How Are Pressure Relief Valves Used in the Oil & Gas Industry?

In the oil and gas sector, pressure relief valves are critical for maintaining safety during both upstream and downstream operations. These valves help prevent overpressure situations that can lead to catastrophic failures, ensuring compliance with stringent safety regulations. International buyers from regions like Africa and the Middle East must ensure that the suppliers meet specific certification standards and can provide valves that perform reliably in extreme environmental conditions.

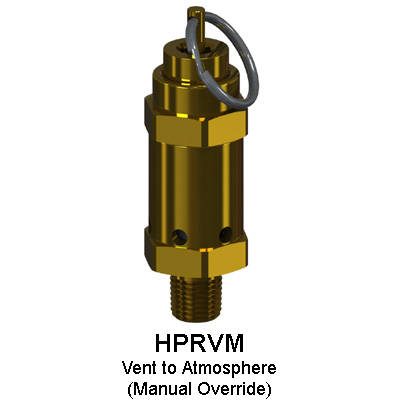

A stock image related to pressure relief valve supplier.

What Role Do Pressure Relief Valves Play in Chemical Manufacturing?

A stock image related to pressure relief valve supplier.

In chemical manufacturing, pressure relief valves are essential for protecting reactors and storage tanks from overpressure. These valves automatically release excess pressure, thereby preventing potential explosions or leaks of hazardous materials. Buyers in South America and Europe should focus on sourcing valves that offer high reliability and fast response times, as well as compatibility with the diverse range of chemicals processed in their facilities.

How Are Pressure Relief Valves Beneficial in Water Treatment?

Pressure relief valves are utilized in water treatment facilities to protect filtration and treatment systems from excessive pressure build-up. This not only safeguards the equipment but also ensures the continuous delivery of clean water. For international buyers, especially in developing regions, it is crucial to consider valves that are resistant to corrosion and require minimal maintenance, ensuring long-term reliability in harsh environments.

Why Are Pressure Relief Valves Important in Power Generation?

In power generation, pressure relief valves are vital for steam and gas turbines to avoid overpressure conditions that can damage equipment and reduce efficiency. These valves help maintain optimal operational conditions, contributing to overall energy efficiency. Buyers from Europe and the Middle East should prioritize sourcing valves that can withstand high temperatures and have a proven track record in similar applications to ensure safety and performance.

How Do Pressure Relief Valves Ensure Safety in Food & Beverage Processing?

In the food and beverage industry, pressure relief valves are crucial for ensuring the safety of processing and storage systems. These valves help maintain safe pressure levels, preventing contamination and ensuring compliance with health regulations. Buyers, particularly in Africa and South America, should ensure that the valves sourced adhere to hygiene standards, are easy to clean, and are made from materials that meet food safety certifications.

Related Video: How to set a Hydraulic Pressure Relief Valve safely and easily

3 Common User Pain Points for ‘pressure relief valve supplier’ & Their Solutions

Scenario 1: High Failure Rates of Pressure Relief Valves

The Problem:

B2B buyers in industries such as oil and gas or manufacturing often face the challenge of high failure rates in pressure relief valves, leading to costly downtimes and safety hazards. This issue is particularly pressing in regions with stringent safety regulations, such as Europe and parts of the Middle East. Buyers may struggle to find reliable suppliers who can guarantee the durability and performance of their products under extreme conditions. The implications of valve failure can be severe, resulting in financial losses and potential legal liabilities.

The Solution:

To mitigate this issue, buyers should prioritize sourcing valves from suppliers with a proven track record of reliability and industry-specific expertise. Conduct thorough supplier evaluations that include reviews of product performance data, customer testimonials, and certifications relevant to your industry. Request detailed technical specifications, including materials used and testing methods. Additionally, consider implementing a proactive maintenance schedule and regular inspections to identify potential issues before they escalate. Engaging in long-term relationships with reputable suppliers can also facilitate better support and innovation in product design tailored to your operational needs.

Scenario 2: Difficulty in Customizing Pressure Relief Valves

The Problem:

International B2B buyers often encounter the challenge of finding customizable pressure relief valves that meet specific operational requirements. For instance, businesses in South America may need valves that can handle varying pressure levels due to fluctuating environmental conditions. Suppliers may offer standard products that do not align with unique specifications, leading to inefficiencies and increased costs in the manufacturing process.

The Solution:

Buyers should seek suppliers that specialize in custom solutions and are willing to collaborate closely throughout the design process. Before initiating discussions, prepare a clear list of your requirements, including pressure ratings, materials, and size specifications. Engage suppliers early in your project to allow for iterative design and testing phases, ensuring that the final product aligns perfectly with your needs. Utilizing 3D modeling or simulations can also help visualize how the valve will perform in your specific application, reducing the risk of costly modifications later on.

Scenario 3: Complex Compliance and Regulatory Challenges

The Problem:

Navigating the complex landscape of compliance and regulatory standards for pressure relief valves can be overwhelming for B2B buyers, especially in regions like Africa and Europe where regulations can vary significantly. Buyers may find it challenging to ensure that the valves they procure meet local standards, resulting in potential legal complications and increased costs for re-certification or replacement.

The Solution:

To address compliance challenges, buyers should partner with suppliers who have comprehensive knowledge of local and international regulations governing pressure relief valves. Conduct due diligence by reviewing the supplier’s certifications and ensuring they adhere to relevant industry standards such as ASME, API, or ISO. Establish a clear communication channel with the supplier to stay updated on changes in regulations and compliance requirements. Additionally, consider investing in training for your procurement team on regulatory matters to enhance their understanding and ability to make informed decisions when sourcing valves.

Strategic Material Selection Guide for pressure relief valve supplier

What Are the Key Materials Used for Pressure Relief Valves?

When selecting materials for pressure relief valves, international B2B buyers must consider various factors, including the properties of the materials, their suitability for specific applications, and compliance with regional standards. Here, we analyze four common materials used in pressure relief valves: stainless steel, brass, plastic, and carbon steel.

How Does Stainless Steel Perform in Pressure Relief Valves?

Stainless steel is a widely used material for pressure relief valves due to its excellent corrosion resistance and strength. It typically offers high-temperature and pressure ratings, making it suitable for various industrial applications. The most common grades include 304 and 316, with 316 providing superior resistance to chloride-induced corrosion.

Pros: Stainless steel is durable and can withstand harsh environments, making it ideal for chemical processing and oil & gas applications. Its longevity reduces the need for frequent replacements.

Cons: The primary drawback is the cost, as stainless steel is generally more expensive than other materials. Additionally, its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel valves are compatible with aggressive media, such as acids and chlorides, making them a preferred choice in industries like pharmaceuticals and petrochemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A312 (for pipe) and ASTM A276 (for bars) is crucial. Buyers from Europe and the Middle East should also consider EN standards for quality assurance.

What Are the Benefits of Brass in Pressure Relief Valves?

Brass is another popular material, particularly in applications where moderate pressure and temperature ratings are sufficient. It offers good corrosion resistance and is relatively easy to machine.

Pros: Brass is cost-effective compared to stainless steel and provides good thermal conductivity. Its ease of machining allows for intricate designs, making it suitable for smaller valves.

Cons: While brass is resistant to many chemicals, it can corrode in the presence of ammonia or certain chlorides. Its temperature rating is lower than that of stainless steel, limiting its use in high-temperature applications.

Impact on Application: Brass valves are commonly used in water and gas applications, making them suitable for residential and commercial plumbing systems.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B16 (for fittings) and check local regulations regarding lead content, especially in drinking water applications.

Why Choose Plastic for Pressure Relief Valves?

Plastic materials, such as PVC and CPVC, are increasingly used in pressure relief valves, particularly in environments where corrosion is a significant concern. They are lightweight and resistant to a wide range of chemicals.

Pros: Plastic valves are highly resistant to corrosion and are generally less expensive than metal options. They are also lightweight, which can reduce shipping costs.

Cons: The primary limitation is their lower pressure and temperature ratings compared to metals. Plastic valves may not be suitable for high-pressure applications or extreme temperatures.

Impact on Application: Plastic valves are ideal for chemical processing and water treatment applications, where corrosive media are present.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 (for PVC) is essential. Buyers should also consider the environmental impact of plastic disposal in their regions.

What Role Does Carbon Steel Play in Pressure Relief Valves?

Carbon steel is often used for pressure relief valves in heavy-duty applications, particularly in the oil and gas sector. It offers good strength and is generally less expensive than stainless steel.

Pros: Carbon steel valves are durable and can handle high-pressure applications. They are also cost-effective, making them a popular choice for large-scale projects.

Cons: The main drawback is their susceptibility to corrosion, which can lead to failure if not properly coated or maintained. This limits their use in corrosive environments.

Impact on Application: Carbon steel valves are commonly used in oil and gas pipelines, where high strength is required, but additional corrosion protection measures must be taken.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A105 (for forged steel) and consider local environmental regulations regarding corrosion protection.

Summary Table of Material Selection for Pressure Relief Valves

| Material | Typical Use Case for Pressure Relief Valve Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil & gas | Excellent corrosion resistance and durability | Higher cost and complex manufacturing | High |

| Brass | Water and gas applications | Cost-effective and easy to machine | Limited temperature and pressure rating | Medium |

| Plastic | Chemical processing, water treatment | Highly corrosion-resistant and lightweight | Lower pressure and temperature ratings | Low |

| Carbon Steel | Oil and gas pipelines | Durable and cost-effective for high-pressure use | Susceptible to corrosion without proper coating | Medium |

This guide provides essential insights into material selection for pressure relief valves, enabling international B2B buyers to make informed decisions based on their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure relief valve supplier

What Are the Main Stages of Manufacturing Pressure Relief Valves?

Manufacturing pressure relief valves involves several critical stages that ensure the final product meets stringent safety and operational standards. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe (including markets like Vietnam and Italy) make informed decisions.

-

Material Preparation

– The first step involves selecting high-quality raw materials such as stainless steel, brass, or specialized alloys that can withstand high pressure and corrosion. Suppliers must ensure that all materials meet relevant international standards (e.g., ASTM or ISO).

– Material testing is conducted to verify properties like tensile strength, hardness, and corrosion resistance, ensuring that the materials will perform adequately under operational conditions. -

Forming

– This stage includes processes like forging, casting, or machining to create the valve components. Techniques such as CNC machining are often employed for precision and consistency.

– Advanced forming techniques can include hydroforming or stamping, which allow for complex geometries that improve valve performance and reduce weight. -

Assembly

– During assembly, individual components such as the valve body, spring, and seat are brought together. This stage requires a clean environment to prevent contamination, which can compromise the valve’s integrity.

– Automated assembly systems may be used for high-volume production, while skilled labor is critical for custom or low-volume orders. -

Finishing

– Finishing processes include surface treatments like polishing, coating, or plating to enhance durability and resistance to environmental factors.

– Final inspections are conducted to ensure that all components fit correctly and that the valve operates smoothly.

How Is Quality Assurance Implemented in Pressure Relief Valve Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of pressure relief valves, ensuring that products meet safety and performance standards. Here are the key aspects of QA in this industry:

What International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001

– This standard outlines requirements for a quality management system (QMS) and is crucial for manufacturers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. -

CE Marking

– For products sold in the European Union, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly relevant for pressure relief valves used in critical applications. -

API Standards

– The American Petroleum Institute (API) provides standards specifically for valves used in the oil and gas industry, ensuring performance and safety.

What Are the Key Quality Control Checkpoints in Valve Manufacturing?

Quality control (QC) is maintained at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC)

– This initial checkpoint involves inspecting raw materials upon arrival. Suppliers should implement strict criteria for acceptance to ensure only high-quality materials enter the production line. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, ongoing inspections are conducted to monitor compliance with specifications. This includes monitoring machining tolerances, assembly accuracy, and operational checks on components. -

Final Quality Control (FQC)

– The final inspection stage involves comprehensive testing of the completed valves. This may include pressure testing, leak testing, and functional testing to ensure that each valve performs as intended under simulated operational conditions.

What Common Testing Methods Are Used for Pressure Relief Valves?

Several testing methods are standard in the industry to ensure quality and reliability:

- Hydrostatic Testing: Valves are subjected to water pressure to check for leaks and structural integrity.

- Pneumatic Testing: Air is used to test the valve under pressure, allowing for detection of leaks and performance issues.

- Functional Testing: This ensures that the valve opens and closes at the designated pressure settings and that it performs according to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability:

-

Conduct Supplier Audits

– Regular audits can provide insights into the supplier’s manufacturing processes, quality management systems, and compliance with industry standards. -

Request Quality Assurance Reports

– Suppliers should provide documentation of their quality control processes, including inspection and testing reports. This transparency is crucial for building trust. -

Third-Party Inspections

– Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality assurance practices. This is particularly important for buyers who may not have the resources for in-depth evaluations.

What Nuances Should International Buyers Consider in QC and Certification?

Different regions may have varying requirements for quality assurance and certification. Buyers from Africa, South America, the Middle East, and Europe should be aware of these nuances:

- Regional Standards: Familiarize yourself with local regulations and certifications that may differ from international standards. For instance, the European Union may have stricter environmental and safety requirements compared to other regions.

- Cultural Differences: Understanding the cultural context can help in negotiations and establishing strong relationships with suppliers. This is especially important in regions with different business practices.

Conclusion

Navigating the manufacturing processes and quality assurance protocols of pressure relief valves is critical for international B2B buyers. By understanding each stage of manufacturing, the standards involved, and how to verify quality control practices, buyers can make informed decisions that ensure safety and performance in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure relief valve supplier’

Introduction

Navigating the procurement process for pressure relief valves is critical for ensuring safety and compliance in various industrial applications. This guide provides a practical checklist for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. By following these steps, you can systematically evaluate suppliers and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first step in sourcing pressure relief valves. Identify key parameters such as pressure ratings, materials, and application environments. This clarity helps in filtering potential suppliers who can meet your exact needs.

- Pressure Ratings: Specify the pressure range your application requires.

- Materials: Consider the environment; for example, corrosive environments may require specific alloys.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Utilize online directories, trade shows, and industry publications to compile a list of candidates.

- Supplier Reviews: Look for testimonials and case studies to gauge reliability.

- Industry Presence: Check if they have experience in your region or sector, as local regulations may vary.

Step 3: Verify Supplier Certifications and Compliance

Ensuring that suppliers have the necessary certifications is crucial for quality assurance and regulatory compliance. Check for certifications such as ISO 9001 or industry-specific approvals.

- Quality Assurance: Certifications indicate adherence to international standards.

- Regulatory Compliance: Ensure that suppliers are compliant with local safety regulations applicable in your region.

Step 4: Request Technical Documentation

Before finalizing a supplier, request detailed technical documentation, including product datasheets and installation guidelines. This information is vital for assessing whether the products meet your specifications.

- Datasheets: Verify technical specifications align with your requirements.

- Installation Guidelines: Ensure that you have clear instructions for safe installation.

Step 5: Evaluate Supplier Response and Support

Assess the responsiveness and support offered by potential suppliers. A good supplier should be willing to answer queries and provide technical support throughout the purchasing process.

- Communication: Quick and clear responses indicate reliability.

- Technical Support: Availability of technical assistance post-purchase is essential for troubleshooting.

Step 6: Check for Warranty and After-Sales Service

Evaluate the warranty and after-sales services offered by suppliers. A robust warranty indicates confidence in their products, while good after-sales support ensures you can address any issues post-purchase.

- Warranty Terms: Understand what is covered and for how long.

- Service Availability: Confirm whether they offer maintenance or repair services.

Step 7: Compare Pricing and Payment Terms

Finally, compare pricing and payment terms among shortlisted suppliers. While cost is important, ensure that you are also considering the overall value, including product quality and support.

- Total Cost of Ownership: Factor in shipping, duties, and maintenance when evaluating costs.

- Flexible Payment Terms: Look for suppliers offering favorable payment terms that suit your cash flow needs.

By following this step-by-step checklist, you can streamline your sourcing process for pressure relief valves, ensuring that you choose a supplier that meets your technical needs while providing reliable support and service.

Comprehensive Cost and Pricing Analysis for pressure relief valve supplier Sourcing

What Are the Key Cost Components for Sourcing Pressure Relief Valves?

When sourcing pressure relief valves, understanding the comprehensive cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials used in manufacturing pressure relief valves significantly impact costs. Common materials include stainless steel, brass, and plastic. High-grade materials that meet specific industry standards can lead to higher prices but may offer better durability and performance.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. In regions like Africa and South America, labor costs may vary widely, affecting the overall price of the valves.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, leading to lower prices for buyers.

-

Tooling: Tooling costs are associated with the equipment required to manufacture the valves. This can be a significant upfront investment, especially for customized or high-spec products.

-

Quality Control (QC): Ensuring that valves meet quality standards involves additional costs related to testing and inspection. High-quality certifications can enhance the product’s value but may also increase the price.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors like distance, transportation mode, and customs duties can significantly affect the final cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. This margin can vary based on market competition and the supplier’s positioning.

How Do Price Influencers Affect Pressure Relief Valve Costs?

Several factors influence the pricing of pressure relief valves, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing based on their purchasing capacity.

-

Specifications and Customization: Custom-engineered valves tailored to specific applications usually come at a premium. Buyers should assess whether off-the-shelf solutions can meet their needs to avoid unnecessary costs.

-

Quality and Certifications: Valves that comply with international quality standards (e.g., ISO, ASME) often command higher prices. Buyers must weigh the benefits of certified products against the potential cost implications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge more but can provide peace of mind regarding product performance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for assessing total costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, which can significantly affect the final price.

What Are the Best Practices for Negotiating Pressure Relief Valve Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing pressure relief valves:

-

Conduct Thorough Market Research: Understanding the average price range for pressure relief valves in specific regions (e.g., Europe, the Middle East) can empower buyers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and longevity. A higher upfront cost might lead to lower TCO if the valve performs better over time.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better terms and pricing flexibility. Suppliers may offer discounts or favorable payment terms to repeat customers.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations. This approach also helps identify competitive pricing and product offerings.

-

Be Aware of Pricing Nuances: International buyers must navigate currency fluctuations, import duties, and other regional factors that may affect pricing. Staying informed can help buyers make better purchasing decisions.

Disclaimer on Indicative Prices

Prices for pressure relief valves can vary widely based on specifications, supplier, and market conditions. The information provided herein serves as a guideline, and buyers should engage directly with suppliers for accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing pressure relief valve supplier With Other Solutions

In the realm of industrial safety and equipment reliability, pressure relief valves (PRVs) play a crucial role in preventing equipment failure and ensuring operational safety. However, businesses often find themselves evaluating various alternatives to conventional pressure relief valve suppliers. This analysis explores other viable solutions, focusing on their performance, cost, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | Pressure Relief Valve Supplier | Alternative 1: Safety Fuses | Alternative 2: Rupture Disks |

|---|---|---|---|

| Performance | High reliability under pressure fluctuations | Moderate reliability; effective in specific conditions | High reliability; quick pressure relief |

| Cost | Varies widely based on specifications | Generally lower cost | Moderate cost; can be less expensive than PRVs |

| Ease of Implementation | Installation may require specialized knowledge | Easy installation | Requires careful installation to ensure effectiveness |

| Maintenance | Regular inspections required | Minimal maintenance | No ongoing maintenance, but requires monitoring |

| Best Use Case | General industrial applications | Situations with infrequent overpressure | High-pressure systems requiring immediate relief |

What Are the Pros and Cons of Using Safety Fuses as an Alternative?

Safety fuses, also known as thermal fuses, provide a simple and effective solution for overpressure situations. They are designed to melt at a specific temperature, thereby allowing pressure to escape. The primary advantage of safety fuses is their lower cost and straightforward installation process, making them accessible for various applications. However, their performance can be inconsistent in fluctuating pressure environments, and they may not be suitable for all industrial applications, particularly those requiring high reliability.

How Do Rupture Disks Compare to Pressure Relief Valve Suppliers?

Rupture disks are another alternative that provides an immediate response to overpressure. They are designed to burst at a predetermined pressure level, allowing for a rapid release of excess pressure. This solution is particularly advantageous in high-pressure systems where quick relief is essential. Rupture disks are generally low-maintenance as they do not require regular inspections like PRVs. However, their installation can be more complex, and once they rupture, they must be replaced entirely, which may lead to increased downtime.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate pressure relief mechanism, B2B buyers must consider several factors including the specific operational environment, the nature of the processes involved, and budget constraints. Understanding the performance characteristics of each alternative can guide businesses in making informed decisions that align with their safety standards and operational efficiency. It’s essential to conduct a thorough risk assessment to determine the best fit for their unique applications, ensuring that safety and compliance are prioritized without compromising on cost-effectiveness.

Essential Technical Properties and Trade Terminology for pressure relief valve supplier

What Are the Key Technical Properties of Pressure Relief Valves?

When sourcing pressure relief valves, understanding the technical specifications is crucial for ensuring optimal performance and compliance with industry standards. Here are several key properties to consider:

- Material Grade

– The material used in manufacturing pressure relief valves significantly affects their durability and corrosion resistance. Common materials include stainless steel, brass, and various alloys. Selecting the right material is essential for the valve’s application, especially in industries like oil and gas or chemical processing, where exposure to harsh environments is common.

-

Pressure Rating

– Pressure rating indicates the maximum pressure at which the valve can operate safely. It is typically expressed in pounds per square inch (PSI) or bar. Understanding the pressure rating is vital for ensuring that the valve can handle the operational conditions of your system without risking failure or safety hazards. -

Tolerance

– Tolerance refers to the acceptable limits of variation in the valve’s dimensions and performance characteristics. High tolerance levels are essential for applications requiring precision, such as in aerospace or medical industries, where even minor deviations can lead to significant issues. -

Flow Capacity

– Flow capacity, often measured in gallons per minute (GPM) or liters per minute (LPM), determines how much fluid the valve can handle. This is crucial for ensuring that the valve can effectively relieve pressure without causing system disruptions. Buyers should assess the flow requirements of their systems to select the appropriate valve size and type. -

Temperature Range

– The operational temperature range of a pressure relief valve defines the temperatures at which it can function effectively. This property is particularly important in applications involving steam or high-temperature fluids, as exceeding these limits can lead to valve failure. -

Actuation Mechanism

– Pressure relief valves can be actuated either mechanically or electronically. Mechanical valves are typically simpler and more cost-effective, while electronic valves offer enhanced precision and responsiveness. Understanding the actuation mechanism helps buyers align their choice with operational needs and maintenance capabilities.

Which Trade Terminology Should B2B Buyers Understand?

In addition to technical specifications, familiarizing yourself with industry jargon can enhance communication and negotiation processes. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding the role of OEMs can help buyers identify reliable suppliers who adhere to high manufacturing standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for budgeting and inventory management, especially for businesses that may not require large quantities. -

RFQ (Request for Quotation)

– An RFQ is a document sent by a buyer to suppliers requesting pricing and terms for specific products or services. Knowing how to craft an effective RFQ can lead to better pricing and more favorable terms. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps mitigate risks related to shipping and delivery responsibilities. -

Lead Time

– Lead time is the time it takes from placing an order to receiving the goods. Understanding lead times is essential for planning and ensuring that production schedules are met without delays. -

Certification Standards

– These are industry-specific standards that pressure relief valves must meet for quality and safety. Familiarizing yourself with relevant certifications (such as API, ASME, or CE) ensures that the products meet regulatory requirements and industry best practices.

By grasping these essential technical properties and trade terms, international B2B buyers from diverse regions can make informed decisions when sourcing pressure relief valves, ultimately contributing to the efficiency and safety of their operations.

Navigating Market Dynamics and Sourcing Trends in the pressure relief valve supplier Sector

What Are the Current Market Dynamics and Sourcing Trends in the Pressure Relief Valve Supplier Sector?

The global pressure relief valve market is witnessing robust growth, driven by increasing industrial activities, stringent safety regulations, and the rising demand for automation across various sectors. In regions like Africa and South America, the expanding manufacturing and energy sectors are pivotal in shaping market dynamics. Conversely, Europe and the Middle East are leaning towards advanced technologies and innovative solutions, which is prompting suppliers to enhance their product offerings. Key trends include the adoption of IoT (Internet of Things) technologies for real-time monitoring and predictive maintenance, which enhances operational efficiency and safety.

Moreover, B2B buyers are increasingly favoring suppliers that offer integrated solutions rather than standalone products. This shift towards comprehensive service offerings allows companies to optimize their procurement processes, thereby reducing lead times and enhancing overall supply chain efficiency. In addition, the emphasis on digital transformation is leading to the emergence of e-procurement platforms, facilitating easier access to a wider range of suppliers and products, especially for international buyers.

How Is Sustainability Impacting Sourcing Decisions for Pressure Relief Valves?

Sustainability is becoming a cornerstone of sourcing strategies in the pressure relief valve supplier sector. International B2B buyers are increasingly aware of the environmental impacts of their procurement choices, driving demand for suppliers that prioritize sustainable practices. This includes the use of eco-friendly materials and production processes that minimize waste and energy consumption.

Ethical sourcing is also gaining traction, as buyers seek to ensure that their suppliers adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming critical criteria in supplier selection. Additionally, suppliers who invest in green technologies and sustainable materials are likely to gain a competitive edge in the market.

The integration of sustainability into sourcing decisions not only aligns with corporate social responsibility objectives but also enhances brand reputation, ultimately leading to increased customer loyalty and market share.

What Is the Evolution of the Pressure Relief Valve Supplier Sector?

The pressure relief valve industry has evolved significantly over the decades, transitioning from basic mechanical devices to sophisticated systems integrated with advanced technology. Initially, the market was characterized by simple designs primarily focused on functionality and safety. However, with the advent of automation and Industry 4.0, there has been a marked shift towards smart pressure relief valves equipped with sensors and connectivity features.

This evolution has been driven by the need for enhanced safety measures in high-pressure environments, as well as the demand for operational efficiency and real-time data analytics. As industries continue to innovate, suppliers are expected to keep pace by offering increasingly intelligent solutions that cater to the complex needs of modern manufacturing and energy sectors. The ongoing research and development in materials and design are also paving the way for more durable and efficient products, making it essential for B2B buyers to stay updated on the latest advancements in the field.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure relief valve supplier

-

How do I select the right pressure relief valve supplier for my business needs?

Selecting the right supplier involves assessing their industry experience, product range, and compliance with international standards. Look for suppliers that have certifications such as ISO 9001, and evaluate their reputation through customer reviews and case studies. Additionally, consider their ability to provide customized solutions tailored to your specific requirements, as well as their logistical capabilities in your region. -

What are the key factors to consider when evaluating pressure relief valve quality?

Quality can be assessed based on the supplier’s adherence to relevant industry standards (e.g., API, ASME). Ensure that the valves undergo rigorous testing, including pressure testing and material inspections. Ask for documentation like test certificates and quality assurance reports. Additionally, consider the supplier’s warranty policy, which can be indicative of their confidence in product quality. -

What customization options are available when sourcing pressure relief valves?

Many suppliers offer customization options such as size, materials, and pressure settings to meet specific operational needs. When discussing your requirements, inquire about the supplier’s ability to modify designs and whether they can accommodate unique specifications. Customization can enhance efficiency and safety, making it a crucial factor in supplier selection. -

What is the typical minimum order quantity (MOQ) for pressure relief valves?

MOQs vary widely by supplier and product type. Some suppliers may have a low MOQ, making them suitable for small businesses, while others may require larger orders to optimize costs. It’s essential to communicate your needs upfront to find a supplier willing to accommodate your order size without compromising on quality. -

What payment terms should I expect when sourcing pressure relief valves internationally?

Payment terms can differ significantly among suppliers. Common arrangements include advance payment, letter of credit, or payment upon delivery. It’s advisable to negotiate terms that align with your cash flow and risk tolerance. Be cautious of suppliers who demand full payment upfront, as this can indicate potential issues with reliability. -

How can I ensure reliable logistics and timely delivery from my pressure relief valve supplier?

To ensure timely delivery, evaluate the supplier’s logistics capabilities, including their partnerships with freight forwarders and shipping carriers. Discuss lead times and delivery schedules clearly during negotiations. Additionally, consider suppliers who have experience in international shipping to your region, as they will be familiar with customs regulations and potential delays. -

What certifications should a pressure relief valve supplier have?

Look for suppliers that hold relevant certifications such as ISO 9001 for quality management and specific industry certifications like API or ASME for pressure equipment. These certifications indicate adherence to international quality standards and best practices, ensuring that the products meet safety and performance requirements. -

How do I verify the credibility of a pressure relief valve supplier before making a purchase?

To verify a supplier’s credibility, conduct thorough research, including checking their business registration, customer testimonials, and industry affiliations. Request references from previous clients and assess their responsiveness during initial communications. Utilizing platforms such as LinkedIn can also provide insights into their professional network and reputation in the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pressure relief valve supplier

What Are the Key Takeaways for B2B Buyers in Pressure Relief Valves?

In the realm of pressure relief valves, strategic sourcing is not merely a procurement task; it is a pivotal element that influences operational efficiency and safety. International B2B buyers should prioritize suppliers who demonstrate reliability, compliance with industry standards, and the ability to deliver tailored solutions that meet specific regional needs. Establishing long-term partnerships with reputable suppliers can lead to cost savings, enhanced product quality, and improved supply chain resilience, particularly in emerging markets across Africa, South America, the Middle East, and Europe.

How Can Buyers Prepare for Future Trends in Pressure Relief Valves?

As the global market evolves, buyers must remain proactive in adapting to technological advancements and regulatory changes in the pressure relief valve industry. Continuous engagement with suppliers for insights on innovations and market trends is essential. Buyers should also consider the importance of sustainability and eco-friendly practices in their sourcing decisions, as these factors increasingly influence purchasing behavior.

What Should International Buyers Do Next?

Looking ahead, international B2B buyers are encouraged to leverage the insights gained from this guide to refine their sourcing strategies. By focusing on strategic partnerships and staying informed about market dynamics, buyers can ensure they remain competitive and compliant in a rapidly changing landscape. Take the initiative today to assess your current supplier relationships and explore new opportunities that align with your organizational goals.