Fruit Grinding Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Fruit Grinding Machines

The global demand for artisanal ciders, wines, and fresh juices has placed premium fruit processing equipment at the center of production efficiency. For commercial producers, craft breweries, and equipment distributors in the USA and Europe, sourcing the right fruit grinding machine is a critical operational decision that directly impacts yield and profitability.

However, navigating the current supply landscape is complex. The market is saturated with a vast array of specifications, ranging from manual 7L stainless steel scratchers designed for boutique operations to high-capacity electric pulpers for industrial lines.

The Core Challenge:

Buyers often struggle to balance cost-efficiency with durability. Selecting equipment with inadequate material standards—or failing to distinguish between prosumer-grade units (like those common in e-commerce listings) and rugged B2B machinery—can lead to production bottlenecks, lower extraction rates, and frequent maintenance cycles.

What This Guide Covers:

This guide cuts through the noise to provide a strategic overview of the fruit grinding machinery market. We will equip you with the technical knowledge and sourcing criteria needed to make informed purchasing decisions.

Key focus areas include:

* Material Standards: Evaluating food-grade stainless steel vs. alloy components for longevity.

* Capacity vs. Throughput: Matching machine specifications (manual flywheels vs. electric motors) to your production volume.

* ROI Analysis: Balancing upfront procurement costs with long-term operational efficiency.

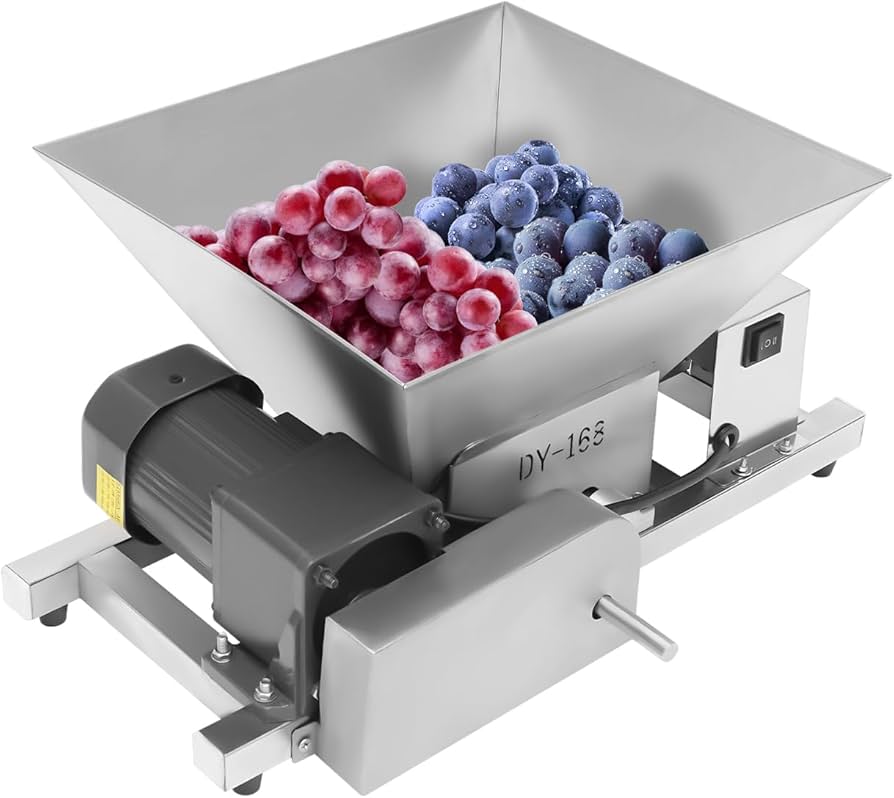

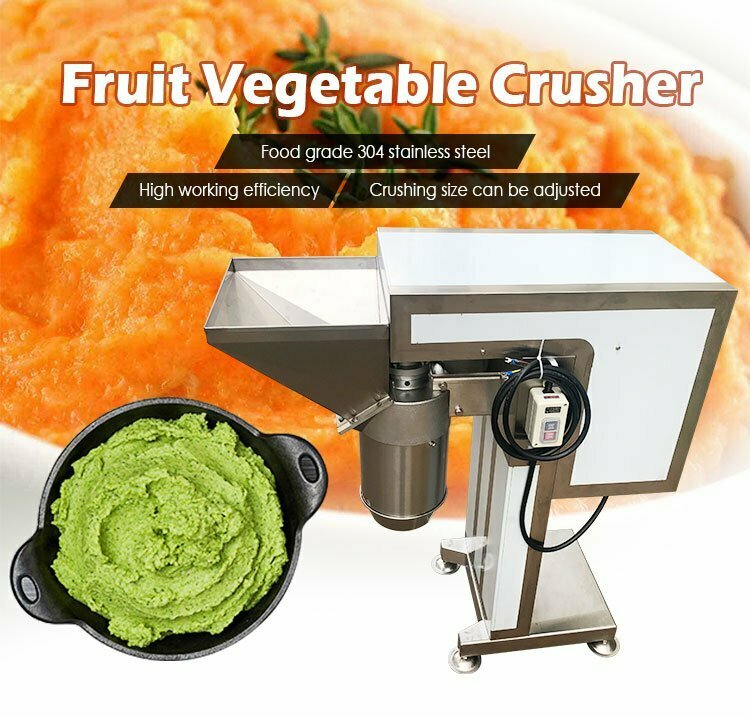

Illustrative Image (Source: Google Search)

By understanding these distinctions, businesses can secure machinery that ensures consistent mash quality and maximizes juice yield.

Top 10 Fruit Grinding Machine Manufacturers & Suppliers List

1. High-Quality Fruit Grinder Machine for Efficient Processing , Shop Now

Domain: helpermachine.com

Registered: 2023 (2 years)

Introduction: Find a reliable China manufacturer, supplier, and factory of fruit grinder machines. Explore our range of high-quality products for all your fruit ……

Illustrative Image (Source: Google Search)

2. Fruit Processing & Juice Production Machinery | ProFruit

Domain: pro-fruit.com

Registered: 2019 (6 years)

Introduction: Processing machinery – from fruit washers and crushers to belt presses and bag-in-box fillers. Efficient juice and purée production from fresh produce….

3. Fruits & Vegetables Processing Machines-WMmachinery

Domain: wmmachinery.com

Registered: 2022 (3 years)

Introduction: 15-day returnsWe designed many machines,such as Fruits&Vegetables Washing Machine;Fruits&Vegetables Juicer Machines;Fruits&Vegetables Cutting Machines;Fruits&Vegetables ……

4. Commercial Vegetable Grinding Machine – 1.5Hp – MC-303

Domain: fujimarca.com

Registered: 2005 (20 years)

Introduction: Commercial Vegetable Grinding Machine – 1.5Hp – CE Certified & Award Winning Design Fruit Juice Processing Machinery Manufacturer | JYU FONG MACHINERY CO., LTD.Missing: top suppliers…

5. industrial food production resources – Rome Grinding Solutions

Domain: romegrindingsolutions.com

Registered: 2016 (9 years)

Introduction: Unlock industry-leading solutions for food production with Rome Grinding Solutions. Stay ahead with expert insights and innovative equipment….

Illustrative Image (Source: Google Search)

6. Juice Processing Equipment – Belt Presses, Grinder, Pasteurizer

Domain: juicingsystems.com

Registered: 2019 (6 years)

Introduction: Juice processing equipment from Kreuzmayr. USA Canada dealer for Belt Presses, Grinders, Pasteurizers, De-stoners, Filling lines and more….

Understanding fruit grinding machine Types and Variations

Understanding Fruit Grinding Machine Types and Variations

Selecting the correct fruit grinding architecture is critical for optimizing juice yield, maintaining oxidation levels, and ensuring downstream equipment (such as belt presses or decanters) operates at peak efficiency. While entry-level manual units serve boutique operations, industrial processing requires automated, high-throughput solutions.

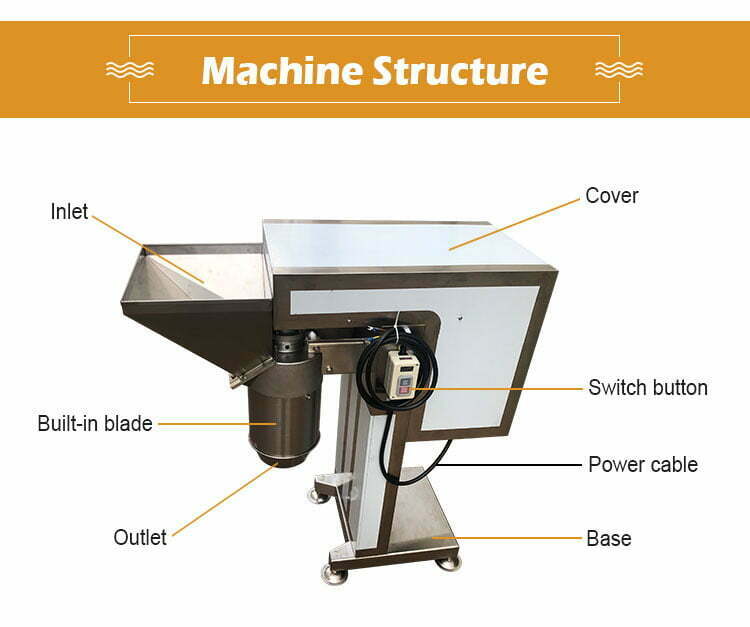

Illustrative Image (Source: Google Search)

Below is a comparative overview of the primary fruit grinding technologies available in the US and European markets.

Comparative Overview of Grinding Technologies

| Machine Type | Key Features | Typical Applications | Pros & Cons |

|---|---|---|---|

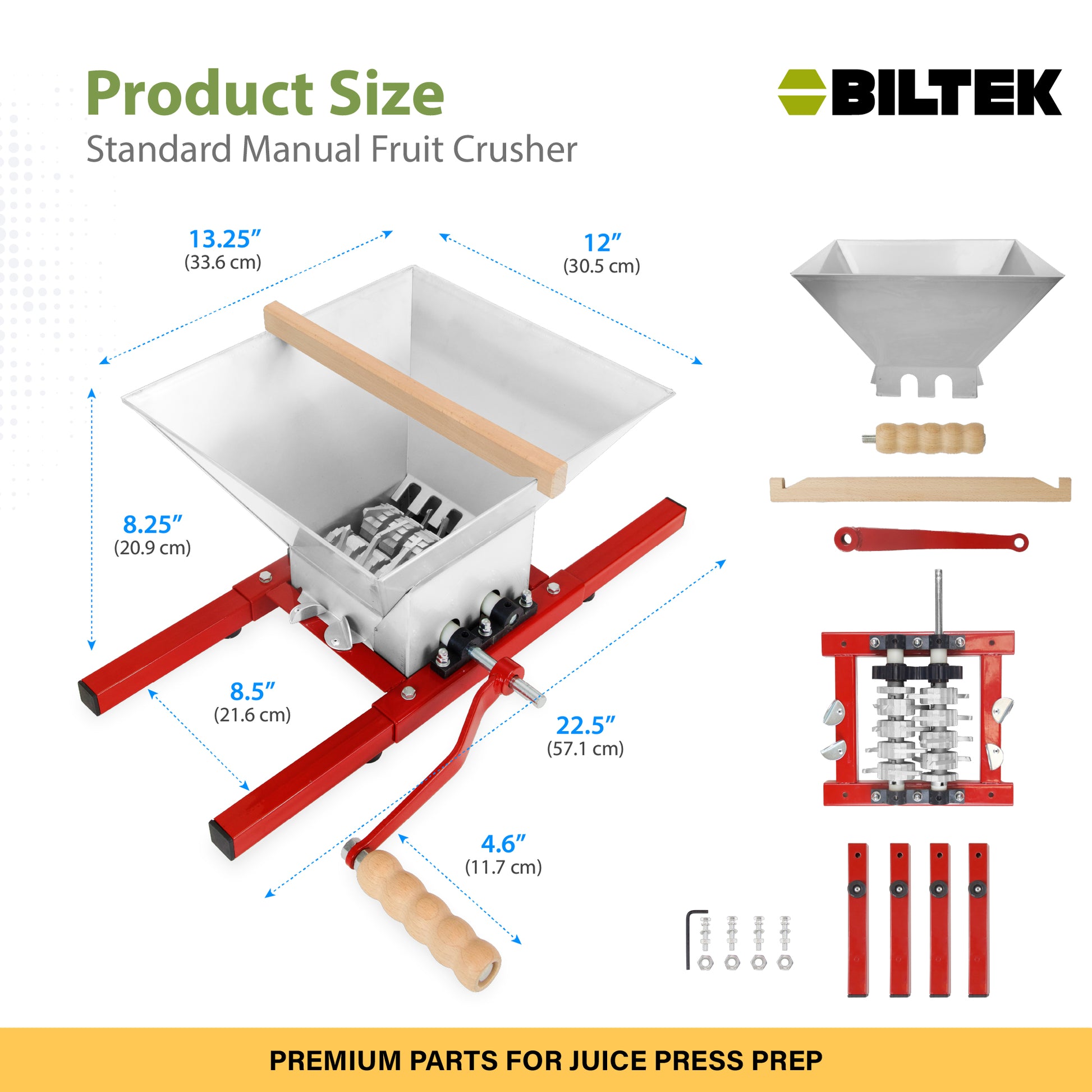

| Manual Scratter / Pulper | Hand-crank operation; large flywheel; stainless steel hopper; portable design. | R&D labs; boutique cideries; pilot batches; home brewing. | Pros: Low capital cost; zero energy consumption; gentle processing. Cons: Low throughput; labor-intensive; inconsistent particle size. |

| Electric Hammer Mill | High-speed rotating hammers; interchangeable screens; high impact force. | Large-scale juice production; industrial puree lines; hard fruits (apples, pears). | Pros: High capacity; fine mash for max yield; handles hard solids easily. Cons: Higher oxidation risk; noise; energy-intensive. |

| Disc / Grating Mill | Rotating disc with knifes/blades; precise cutting action. | Premium wine/cider production; fruits requiring specific mash structures. | Pros: Uniform particle size; lower oxidation than hammer mills. Cons: Blades require frequent sharpening; sensitive to stones/debris. |

| Screw / Auger Crusher | Slow-rotating helical screw; compression-based crushing. | Soft fruits (berries, grapes); continuous feed systems. | Pros: Very gentle; low aeration; continuous operation. Cons: Not suitable for very hard fruits; lower throughput speeds. |

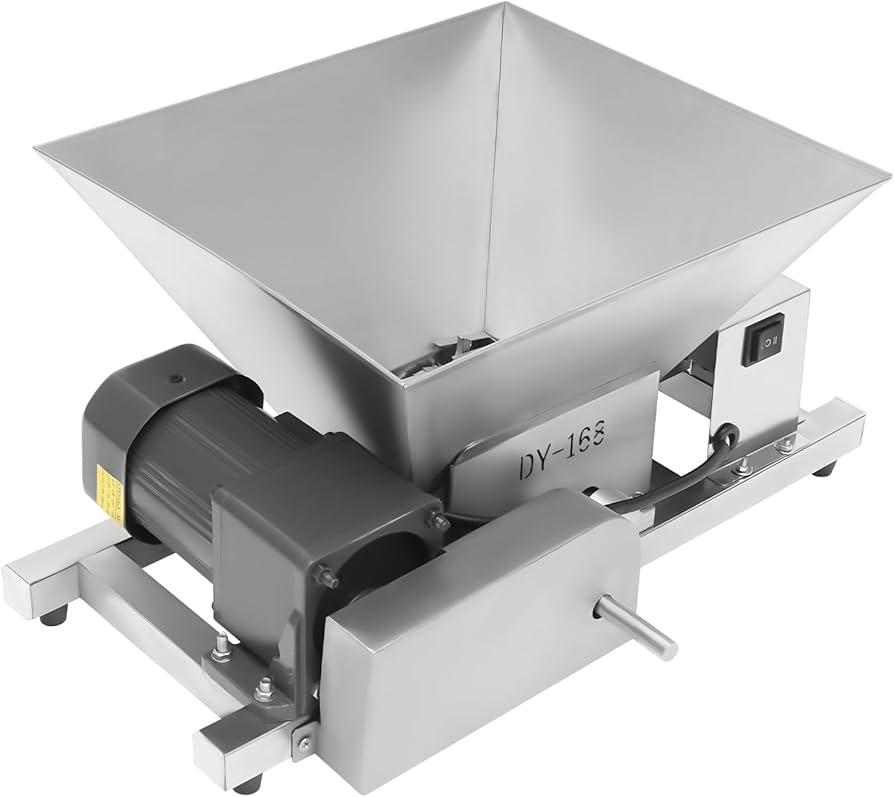

1. Manual Scratters and Pulpers

Based on current market data, including popular models like the EJWOX and VEVOR series, manual scratters represent the entry point for professional fruit processing. These units typically feature a 7L (1.8 Gallon) stainless steel hopper and a manual flywheel mechanism.

- Mechanism: The operator rotates a side-mounted flywheel, driving internal rollers or blades that tear and crush the fruit against a stainless steel wall or opposing roller.

- B2B Use Case: While not suitable for industrial lines, these are essential for product development teams and micro-wineries testing small batches (5–50 gallons) where setting up a full production line is inefficient.

- Material Standards: Professional buyers should look for food-grade stainless steel (SS304) hoppers and cast-iron or aluminum supports to ensure longevity and hygiene compliance.

2. Electric Hammer Mills

The hammer mill is the industry standard for high-volume fruit processing in the USA and Europe. It utilizes a set of swinging hammers mounted on a rapidly spinning rotor.

- Mechanism: Fruit is fed into a chamber where it is impacted by hammers until the particles are small enough to pass through a calibrated discharge screen.

- Throughput: Industrial models can process anywhere from 1 to 50 tons per hour.

- Yield Optimization: By changing the screen size, operators can control the “mash” consistency. A finer mash generally yields more juice but may increase sediment in the press; a coarser mash drains better but may lower extraction rates.

3. Disc and Grating Mills

Unlike the smashing action of a hammer mill, disc mills utilize sharp blades to slice the fruit. This is particularly prevalent in the European cider and wine markets where “structure” in the mash is desired to aid the pressing process.

Illustrative Image (Source: Google Search)

- Mechanism: A heavy steel disc with mounted knives rotates against the fruit feed.

- Quality Control: This method creates a precise cut rather than a bruise. This minimizes cellular damage outside of the cut zone, potentially reducing enzymatic browning (oxidation) and preserving the aromatic profile of delicate varietals.

- Maintenance: These units require stricter maintenance schedules to keep blades sharp, as dull blades will tear rather than cut, reducing efficiency.

4. Screw / Auger Crushers

Screw crushers are preferred for continuous production lines handling soft fruits or destemmed grapes.

- Mechanism: A large auger pushes fruit through a tapering channel or against a resistance plate, crushing the fruit via compression.

- Integration: These units are often integrated directly into the intake hoppers of progressive cavity pumps or destemming units.

- Advantages: The slow rotation speed introduces very little heat and air into the product, making it the superior choice for high-quality juice lines where preventing oxidation is the primary KPI.

Key Industrial Applications of fruit grinding machine

Key Industrial Applications of Fruit Grinding Machines

While manual crushers and small-scale 7L grinders are ubiquitous in the home-brewing market, industrial-grade fruit grinding machines serve as the critical first step in large-scale food processing lines. In the US and European markets, where efficiency and yield are paramount, these machines are utilized to prepare raw material for pressing, extraction, or cooking.

The following table outlines the primary sectors utilizing fruit grinding technology and their specific applications.

Industry Application Matrix

| Industry Sector | Primary Application | Typical Fruit Inputs | End Product |

|---|---|---|---|

| Commercial Beverage & Juice | Mash Preparation: Pulverizing whole fruits to optimize consistency for hydraulic or belt presses. | Apples, Pears, Carrots, Pineapples | Cold-pressed juices, cloudy juices, cider bases. |

| Wineries & Cideries | Must Creation: Crushing fruit to break skins and release pulp without pulverizing seeds (which cause bitterness). | Grapes, Apples, Pears, Cherries | Wine, hard cider, fruit wines, brandy mash. |

| Food Preserves & Sauces | Texture Standardization: Grinding fruit into uniform particulate sizes for consistent cooking and setting. | Berries, Stone fruits, Tomatoes | Jams, jellies, applesauce, tomato paste, chutneys. |

| Dairy & Confectionery | Inclusion Processing: Creating fruit purees or chunks for integration into other substrates. | Strawberries, Peaches, Mangoes | Fruit-on-the-bottom yogurt, ice cream swirls, bakery fillings. |

| Nutraceuticals & By-products | Extraction Prep: Grinding peels and pomace to increase surface area for chemical extraction. | Citrus peels, Apple pomace, Grape skins | Pectin, essential oils, dietary fiber supplements. |

Operational Benefits for Industrial Processing

For B2B buyers in the USA and Europe, the value of a high-performance fruit grinder lies in its ability to maximize ROI through yield and versatility.

Illustrative Image (Source: Google Search)

1. Optimization of Juice Yield

The primary industrial function of a grinder is to increase the surface area of the fruit. By reducing whole fruit to a specific mash consistency—neither too coarse nor too fine—operators can increase juice extraction rates by 15% to 30% during the pressing stage.

* Too coarse: Juice remains trapped in the cellular structure.

* Too fine: The mash becomes “sludge,” clogging filter cloths and increasing sediment in the final product.

* Industrial Solution: Adjustable knifes and rollers allow operators to dial in the exact particle size required for their specific press type (e.g., bladder press vs. belt press).

2. Seed Integrity and Quality Control

Unlike simple home blenders, industrial fruit mills (particularly those used for stone fruits and grapes) are designed to strip flesh while leaving seeds and pits intact.

* Significance: Crushed seeds release tannins and amygdalin, which can spoil the flavor profile of wines and juices.

* Mechanism: Soft-touch rubber rollers or centrifugal designs with adjustable clearances ensure the fruit is crushed, not sheared.

3. Sanitary Design and Compliance

To meet strict FDA (USA) and CE (Europe) safety standards, industrial grinders are constructed from food-grade stainless steel (typically 304 or 316 grade).

* Corrosion Resistance: Essential for handling acidic fruits (citrus, apples, tomatoes) without metal leaching.

* Cleanability: Designs feature quick-release hoppers and wash-down motor enclosures to facilitate rapid sanitation cycles (CIP – Clean In Place), reducing downtime between batches.

4. Versatility Across Viscosities

Modern industrial grinders are equipped with high-torque motors capable of processing fruits with varying densities without stalling. A single unit can often transition from soft berries to hard root vegetables or crisp apples simply by adjusting the feed rate or screen size, allowing contract manufacturers to switch product lines efficiently.

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘fruit grinding machine’ & Their Solutions

Based on current market offerings and common operational challenges in the USA and European markets, here are three critical user pain points regarding fruit grinding machinery, structured for a B2B context.

3 Common User Pain Points for Fruit Grinding Machines & Their Solutions

Commercial fruit processing requires equipment that balances throughput with hygiene. While manual “scratter” style crushers (often found in entry-level searches) suit home brewing, B2B operations frequently encounter specific scalability issues.

1. Production Bottlenecks & Labor Fatigue

The Scenario: A mid-sized cidery or juice bar attempts to scale production using manual or low-capacity electric crushers.

The Problem: Manual hand-crank units (common in entry-level listings) rely entirely on operator physical exertion. This leads to rapid fatigue, inconsistent feed rates, and a “stop-and-go” workflow that creates bottlenecks upstream from the press. Even smaller electric units may lack the hopper capacity to handle continuous commercial dumping, requiring constant supervision.

The Solution:

* Motorization: Upgrade to fully motorized grinders with high-torque motors (1.5HP+) capable of continuous operation without overheating.

* Hopper Design: Select machines with large, funnel-shaped stainless steel hoppers that allow for crate-dumping rather than single-fruit feeding.

* Throughput Matching: Ensure the grinder’s hourly output (e.g., 1,000 kg/h) matches or slightly exceeds the capacity of the hydraulic press to maintain a continuous production line.

2. Inconsistent Mash Texture & Low Juice Yield

The Scenario: The grinding machine produces chunks that are too large (leaving juice locked in the fruit) or a paste that is too fine (clogging the press cloths/screens).

The Problem: Many standard grinders utilize fixed rollers or blades designed for a “general” consistency. However, apples require a different grind profile than grapes or stone fruits. Inconsistent particle size results in inefficient pressing, leading to significant revenue loss through wasted yield.

The Solution:

* Adjustable Cutting Mechanisms: Utilize grinders with adjustable knives or roller spacing. This allows operators to dial in the specific “pomace” consistency required for the fruit type (e.g., a coarser grind for soft apples to prevent sauce-like consistency).

* Replaceable Blades: Choose machinery with easily replaceable, serrated stainless steel blades. Sharp blades cut fruit cleanly rather than tearing it, which preserves cellular integrity for better cold-pressing results.

Illustrative Image (Source: Google Search)

3. Sanitation Compliance & Material Corrosion

The Scenario: Equipment begins to show signs of corrosion or becomes difficult to clean after exposure to high-acid fruits (citrus, apples, pineapples), risking FDA or EFSA non-compliance.

The Problem: Lower-tier grinders often utilize cast iron components, painted steel, or wood (beech) baskets. While aesthetically pleasing for traditionalists, wood is porous and difficult to sanitize to commercial standards, harboring bacteria. Painted steel eventually chips, risking physical contamination of the product.

The Solution:

* Full Stainless Steel Construction: Mandate AISI 304 or 316 food-grade stainless steel for all contact parts (hopper, blades, chute).

* Hygienic Design: Look for “tool-free” disassembly features. The ability to remove the hopper and rollers without wrenches allows for rapid, frequent deep cleaning and prevents cross-contamination between batches.

Quick Reference: Problem vs. Feature Checklist

| Pain Point | Commercial Feature Requirement | Benefit |

|---|---|---|

| Labor Fatigue | High-torque Electric Motor & Large Hopper | Increases throughput; reduces labor costs. |

| Low Yield | Adjustable Rollers/Blades | Maximizes juice extraction; prevents press clogging. |

| Sanitation Risks | 100% Stainless Steel (No Wood/Iron) | Ensures FDA/EFSA compliance; prevents corrosion. |

Strategic Material Selection Guide for fruit grinding machine

Strategic Material Selection Guide for Fruit Grinding Machines

For B2B buyers in the USA and Europe, material selection is not merely a question of aesthetics; it is a calculation of sanitation compliance (FDA/EFSA), acid resistance, and total cost of ownership (TCO). Fruit grinding environments are inherently aggressive due to the presence of organic acids (citric, malic, tartaric) and high moisture levels.

The following analysis categorizes materials based on component function, drawing distinctions between entry-level commercial units and industrial-grade processing equipment.

1. Primary Contact Surfaces: The Stainless Standard

For hoppers, crushing drums, and blades, Stainless Steel (AISI 304 and 316) is the non-negotiable standard for the US and European markets.

Illustrative Image (Source: Google Search)

- AISI 304 (18/8): The industry baseline. It offers excellent corrosion resistance against most fruit juices. It is the material of choice for the majority of commercial “fruit scratter” and pulper drums (as seen in higher-end VEVOR and EJWOX commercial lines).

- AISI 316 (Marine Grade): Required for high-acidity processing (e.g., citrus or unripe grapes) or environments using harsh chemical sanitizers. It contains molybdenum, increasing resistance to pitting and crevice corrosion.

- Surface Finish: For B2B applications, a polished or electropolished finish is preferred over brushed finishes to minimize bacterial adhesion and facilitate Clean-in-Place (CIP) protocols.

2. Structural Components: Coated Steel vs. Cast Iron

The frame and stand bear the mechanical load. While contact surfaces must be stainless, structural components often utilize different materials to manage costs.

- Powder-Coated Steel: Frequently seen in the “green” painted housings of manual and semi-automatic crushers (e.g., EJWOX 7L models).

- Strategic View: Cost-effective and durable if the coating remains intact. However, in a B2B setting, chips in the coating can lead to rust and contamination. Buyers should look for food-safe epoxy coatings.

- Cast Iron: heavy-duty and stable, often used for flywheels.

- Strategic View: Provides necessary inertia for manual or belt-driven grinding but is heavy and prone to oxidation if untreated. It must never contact the fruit pulp directly.

3. Traditional Materials: The Role of Beech Wood

References indicate a continued market presence for Solid Beech Wood (e.g., basket presses and hopper accents).

- Application: Primarily used in traditional cider pressing or boutique “farm-to-table” operations where aesthetic authenticity appeals to the consumer.

- B2B Limitation: Wood is porous. In strict HACCP (Hazard Analysis Critical Control Point) environments, wood is difficult to sanitize and may harbor spoilage organisms (wild yeast/bacteria). It is generally not recommended for high-volume industrial processing lines in the EU/USA unless specific traditional exemptions apply.

4. Rollers and Gears: Aluminum and Polymers

- Cast Aluminum: Often used for internal crushing rollers in mid-range units.

- Requirement: Must be anodized or food-grade. Uncoated aluminum can react with fruit acids, leaching metal and altering flavor profiles.

- Nylon/Polymers: Used for gears or gentle crushing teeth.

- Benefit: Reduces noise and eliminates metal-on-metal contamination risks.

- Risk: High wear rates compared to stainless steel.

Comparative Analysis: Material Suitability for Commercial Grinding

The table below compares common materials based on durability, regulatory compliance (FDA/EC 1935/2004), and operational suitability.

| Material | Primary Component | Acid Resistance | Sanitation (CIP) | Durability | Best B2B Application |

|---|---|---|---|---|---|

| Stainless Steel (304) | Hoppers, Drums, Blades | High | Excellent | High | Standard commercial processing (Apples, Pears, Berries). |

| Stainless Steel (316) | Hoppers, Blades | Very High | Superior | High | High-acid fruits (Citrus) or heavy chemical cleaning regimes. |

| Powder-Coated Steel | Frames, Stands, Flywheels | Low (relies on coating) | Moderate | Moderate | Structural support for SME/Pilot scale units; cost-sensitive projects. |

| Solid Beech Wood | Baskets, Hoppers | Moderate | Low (Porous) | Moderate | Boutique/Artisanal production where traditional aesthetic is a USP. |

| Cast Aluminum | Crushing Rollers | Moderate (if treated) | Moderate | Moderate | Mid-tier crushers; lightweight mobile units. |

| Food-Grade Nylon | Gears, Crushing Teeth | High | High | Low/Med | Noise reduction; gentle crushing for soft fruits (grapes). |

Strategic Recommendation: For facilities targeting the USA and Europe, prioritize Full Stainless Steel (All-In-One) construction for any machine component contacting the product. While powder-coated frames (like the green EJWOX models) are acceptable for batch processing or pilot lines, fully stainless chassis reduce long-term maintenance costs and eliminate paint-chip contamination risks in continuous industrial operations.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for fruit grinding machine

In-depth Look: Manufacturing Processes and Quality Assurance

For distributors and industrial buyers targeting markets in the USA and Europe, understanding the manufacturing lifecycle of fruit grinding machines—from manual 7L crushers to semi-automated units—is critical for ensuring inventory reliability and compliance.

1. Material Selection and Preparation

The longevity and safety of a fruit grinder are dictated by raw material sourcing. Manufacturers targeting Western markets must adhere to strict food-contact substance (FCS) regulations.

- Hopper and Teeth (Stainless Steel): High-grade AISI 304 stainless steel is the standard for hoppers and grinding teeth to prevent oxidation caused by acidic fruit juices (apples, grapes, berries). Lower-cost manufacturers may attempt to use SS201, which has lower corrosion resistance; buyers should require material certification.

- Grinding Rollers (Aluminum/Nylon): For crushers utilizing rollers, cast aluminum or high-density food-grade nylon is used. These materials must be non-porous to prevent bacterial growth.

- Basket and Frame:

- Wood Components: As seen in premium manual presses (e.g., Beech wood baskets), the wood must be steamed and treated to resist warping under moisture pressure without using toxic varnishes.

- Structural Frames: usually cast iron or heavy-gauge steel, requiring powder coating to prevent rust in humid processing environments.

2. Manufacturing Workflow Steps

The production line typically follows a four-stage protocol to ensure structural integrity and mechanical efficiency.

| Stage | Process Description | Critical Quality Checkpoint |

|---|---|---|

| 1. Precision Fabrication | Laser Cutting & Stamping: Stainless steel sheets are laser-cut for the hopper to ensure smooth edges. CNC Machining: Grinding teeth and gears are machined to tight tolerances to prevent jamming during high-torque crushing. |

Dimensional Accuracy: Verification of tolerances to $\pm0.05mm$ to ensure seamless assembly. |

| 2. Surface Treatment | Passivation: Stainless steel parts undergo passivation to remove free iron and enhance corrosion resistance. Powder Coating: Frames are coated with food-safe, electrostatic paint (often green or red) to resist chipping. |

Adhesion Testing: Cross-hatch testing on painted surfaces to ensure coating does not flake into the product. |

| 3. Assembly | Bearing Pressing: Sealed bearings are pressed into the housing to support the flywheel/handle shaft. Alignment: Rollers and teeth are aligned to ensure uniform crushing without metal-on-metal contact. |

Torque Verification: Fasteners are tightened to specific torque settings to withstand vibration during operation. |

| 4. Finishing | Deburring: All metal edges, particularly around the hopper and chute, are polished to remove sharp burrs that could injure operators or contaminate pulp. | Visual Inspection: 100% check for surface imperfections or sharp edges. |

3. Quality Assurance (QA) Protocols

To meet the expectations of the European and American markets, manufacturers must implement rigorous QA testing beyond basic visual inspections.

Illustrative Image (Source: Google Search)

Functional Load Testing

Before packaging, a statistical sample of machines undergoes “wet testing” using synthetic loads or actual fruit to verify:

* Throughput Efficiency: Confirming the machine handles the rated capacity (e.g., 7L hopper volume) without clogging.

* Mechanical Stress: The flywheel and handle mechanism are tested under resistance to ensure the shaft does not shear under heavy load (e.g., crushing hard apples or quince).

Material Compliance Testing

- PMI (Positive Material Identification): XRF analyzers are used to verify the chemical composition of stainless steel components, ensuring no heavy metal leaching (Lead, Cadmium).

- Food Grade Lubricants: Verification that all moving parts (gears/bearings) are lubricated with NSF H1 registered lubricants, safe for incidental food contact.

4. Regulatory Standards and Certification

For B2B buyers importing into the USA and EU, the manufacturing facility should hold specific certifications to avoid customs and liability issues.

- ISO 9001:2015: Ensures the manufacturer has a consistent Quality Management System (QMS) in place.

- FDA Compliance (USA): All food contact surfaces (steel, paint, wood) must meet FDA CFR 21 requirements.

- CE Marking (Europe):

- Machinery Directive (2006/42/EC): Essential for safety regarding moving parts (finger guards on hoppers).

- EC 1935/2004: Framework regulation for materials and articles intended to come into contact with food.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fruit grinding machine’

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Fruit Grinding Machine’

Sourcing fruit grinding machinery for the US and European markets requires strict adherence to food safety standards, material durability, and throughput efficiency. Whether sourcing manual units for resale to home brewers (similar to EJWOX or VEVOR models) or industrial electric grinders for commercial processing, follow this checklist to mitigate risk and ensure quality.

Phase 1: Requirement Definitions & Specifications

Before engaging suppliers, define the precise operational scope. B2B buyers must distinguish between consumer-grade manual crushers (often 7L capacity, manual flywheels) and commercial electric grinders.

Illustrative Image (Source: Google Search)

| Specification | Entry-Level/Resale (Consumer) | Commercial/Industrial (Pro) |

|---|---|---|

| Capacity | 1.8 – 5 Gallons (7L – 20L) | 500kg – 5,000kg per hour |

| Power Source | Manual (Hand Crank/Flywheel) | Electric (0.5HP – 5HP Motor) |

| Material Grade | Stainless Steel Hopper / Beech Wood | Full SUS304 or SUS316 Stainless Steel |

| Target End-User | Home brewers, small cider pressers | Juice factories, wineries, commercial kitchens |

| Key Component | Adjustable rollers, portable stand | High-torque blades, automated feed |

Phase 2: Supplier Qualification Checklist

When vetting manufacturers (OEMs) or distributors, verify the following to ensure they meet Western market standards.

- Manufacturing Capabilities:

- [ ] Does the factory offer OEM/ODM services? (Crucial if branding units like EJWOX or VEVOR for private label).

- [ ] Can they customize hopper sizes or handle designs?

- Certifications (USA & EU Focus):

- [ ] ISO 9001: Quality management system.

- [ ] CE Marking: Mandatory for machinery sold in the EEA (European Economic Area).

- [ ] FDA Compliance: Documentation proving all food-contact parts (hoppers, blades, rollers) are food-grade and non-toxic.

- [ ] UL/ETL: Required for electric motor components in the US market.

- Market Experience:

- [ ] Request references from current buyers in North America or Western Europe.

- [ ] Verify experience with “Drop Test” packaging standards (essential for e-commerce resale).

Phase 3: Product Inspection & Quality Assurance

Do not rely on photos. Implement a rigorous sampling and inspection protocol.

1. Material Verification

* [ ] Acid Resistance Test: Fruit acids (malic, citric) are corrosive. Verify the stainless steel is truly 304-grade and not cheaper 201-grade, which will rust.

* [ ] Wood Quality (If applicable): If sourcing traditional presses with wood baskets (e.g., beech wood), ensure the wood is treated, smoothed, and free of chemical sealants that could leach.

2. Functional Testing

* [ ] Load Testing: Test the machine at full capacity. For manual crushers, the flywheel mechanism must rotate smoothly without grinding against the hopper walls.

* [ ] Particle Consistency: Process a sample batch (apples or pears). The output should be a consistent pulp suitable for pressing, not a puree (which clogs presses) or large chunks (which reduce yield).

* [ ] Stability: Ensure the stand or base does not tip during vigorous cranking or operation.

Illustrative Image (Source: Google Search)

Phase 4: Commercial Terms & Logistics

- Spare Parts Availability:

- [ ] Negotiate a percentage of spare parts (gears, handles, blades) to be included with the shipment. These are high-wear components.

- Warranty:

- [ ] Standard B2B warranty should be 12 months minimum. Clarify if the warranty covers the motor (for electric units) or structural integrity.

- Packaging for Retail (Resale Buyers):

- [ ] Ensure packaging is “Retail Ready.” Manual crushers are heavy (often 15-30 lbs). Box strength must be rated for heavy handling to prevent shipping damage.

- Incoterms:

- [ ] Define clear Incoterms (e.g., FOB Shanghai or DDP New York) to establish liability during transit.

Phase 5: Final Compliance Check (Pre-Shipment)

- [ ] User Manuals: Must be in fluent English (and local languages for EU). Must include safety warnings regarding moving parts/rollers.

- [ ] Labeling: Ensure products have permanent data plates indicating model number, manufacturer, and safety warnings (CE/UL logos where applicable).

Comprehensive Cost and Pricing Analysis for fruit grinding machine Sourcing

Comprehensive Cost and Pricing Analysis for Fruit Grinding Machine Sourcing

Sourcing fruit grinding machines for the US and European markets requires a clear understanding of the price-to-performance ratio, particularly when navigating between manual entry-level units and industrial-grade machinery. This analysis breaks down current market pricing, the Bill of Materials (BOM), and logistics considerations.

1. Market Pricing Overview by Tier

Pricing for fruit crushers varies significantly based on automation levels, material grade, and throughput capacity. Below is a tiered pricing structure based on current B2B and B2C market data.

| Category | Specifications | Target Application | Estimated Unit Price (FOB) |

|---|---|---|---|

| Entry-Level (Manual) | 7L capacity, Stainless Steel hopper, Manual flywheel. | Homebrewing, Small Batch Cider. | $85 – $130 |

| Semi-Automatic | Electric motor (0.5HP – 1HP), 500kg/h throughput. | Small Orchards, Pilot Production. | $450 – $1,200 |

| Industrial | High-torque motor, Conveyor integration, 2+ Tons/h. | Commercial Juice/Cider Plants. | $3,500 – $15,000+ |

Note on Entry-Level Benchmarks:

Based on current market listings (e.g., EJWOX and VEVOR), a standard 7L Stainless Steel Manual Crusher retails between $100.69 and $159.99. Wholesale sourcing for these specific units generally offers a 30-40% margin reduction depending on MOQ (Minimum Order Quantity).

2. Cost Breakdown Structure

To negotiate effectively, buyers must understand the cost drivers behind the quoted price.

A. Material Costs (40-50% of Total Cost)

- Stainless Steel (SS304/316): The primary cost driver. For US and EU markets, food-contact surfaces must be SS304 or SS316 to meet FDA and EFSA standards. Cheaper units may utilize SS201 or carbon steel, which poses corrosion risks and compliance failures.

- Aluminum & Cast Iron: Often used for flywheels and stands (as seen in EJWOX models). Fluctuations in global aluminum prices directly impact the BOM.

- Wood Components: Some traditional presses/crushers use Beech wood. While aesthetically pleasing, wood requires treatment to be food-safe, adding processing costs.

B. Labor and Manufacturing (20-30% of Total Cost)

- Machining: CNC machining for roller teeth and gear mechanisms ensures consistency but raises machine-hour costs.

- Assembly & Finishing: Polishing stainless steel to remove burrs (sanitary welding) is labor-intensive but critical for food safety compliance.

- Quality Control: Testing for alignment of grinding rollers and motor stability (for electric units).

C. Compliance and Certification (5-10% of Total Cost)

- US Market: Costs associated with UL certification (for electric motors) and FDA-compliant material sourcing.

- EU Market: CE marking is mandatory. The cost of technical file creation and conformity assessment is amortized into the unit price.

3. Logistics and Landed Cost Analysis

For buyers in the USA and Europe sourcing from overseas, the FOB price is only a fraction of the total expenditure.

- Volumetric Weight: Fruit crushers, especially those with stands (like the 7L models), have a high dimensional weight relative to their actual weight. This increases air freight costs significantly; sea freight is recommended for orders exceeding 10 units.

- Packaging: Reinforced packaging is required to prevent hopper deformation during transit. Expect a 2-3% surcharge for “drop-test approved” packaging suitable for Amazon FBA or direct-to-consumer shipping.

- Duties and Tariffs:

- EU: Check TARIC codes for steel machinery.

- USA: Be aware of Section 301 tariffs if sourcing from China, which can add significant percentage points to the landed cost.

4. Strategic Cost Optimization Tips

- Material Substitution (Non-Contact Parts): Request SS304 only for food-contact zones (hopper, blades). Allow powder-coated carbon steel or cast aluminum for the frame and flywheel to reduce costs by 10-15% without compromising food safety.

- KD (Knock-Down) Packaging: Ensure the supplier ships the unit disassembled (hopper detached from stand). This reduces shipping volume by up to 40%, lowering per-unit freight costs.

- Bundle Sourcing: As indicated by market trends, crushers are frequently bought with fruit presses. Sourcing both from a single manufacturer allows for container optimization and better leverage on MOQ pricing.

- Standardize Components: For electric models, insist on standard off-the-shelf motors rather than proprietary custom motors. This lowers the initial purchase price and simplifies after-sales maintenance/warranty claims in the US/EU.

Alternatives Analysis: Comparing fruit grinding machine With Other Solutions

Alternatives Analysis: Comparing Fruit Grinding Machines With Other Solutions

For B2B buyers in the USA and Europe, selecting fruit processing equipment is a balance between capital expenditure (CapEx), labor efficiency, and juice yield. While a dedicated electric fruit grinding machine (often paired with a hydropress) is the standard for commercial cider, wine, and juice production, distinct alternatives exist depending on production volume.

Below is a comparison of the dedicated Electric Fruit Grinding Machine against two common alternatives: Manual Batch Crushers and Integrated Whole-Fruit Juicers.

Comparison Matrix: Production & Efficiency

| Feature | Electric Fruit Grinding Machine (Primary Solution) | Alternative 1: Manual Fruit Crusher | Alternative 2: Integrated Whole-Fruit Juicer |

|---|---|---|---|

| Throughput | High (Hundreds of kg/hour) | Low (7L–10L per batch) | Medium to High (Continuous feed) |

| Labor Intensity | Low (Automated feeding/grinding) | High (Manual cranking required) | Low (Single-step operation) |

| Pulp Consistency | Consistent, adjustable grain size | Variable (Dependent on operator speed) | Fine pulp (often highly aerated) |

| Yield Potential | Excellent (when paired with a press) | Moderate | Good (but lower clarity) |

| CapEx | Moderate to High ($500 – $3,000+) | Low ($100 – $180) | Moderate ($300 – $1,500) |

| Maintenance | Motor/Electrical maintenance | Minimal (Mechanical cleaning) | High (Complex screen/blade cleaning) |

| Best For | Commercial cideries, wineries, juice bars | Pilot batches, R&D, Agritourism | On-demand service, immediate consumption |

Alternative 1: Manual Fruit Crushers (Batch Processing)

Manual crushers represent the entry-level alternative to electric grinding. Based on current market data, these units typically feature a 1.8-gallon (7L) to 4.75-gallon capacity and rely on a hand-crank flywheel mechanism.

Illustrative Image (Source: Google Search)

- Market Context: Common models (e.g., EJWOX, VEVOR) utilize stainless steel hoppers and solid beech wood components. They are widely available and cost-effective, often retailing between $100 and $160.

- Operational Analysis:

- Pros: Zero electricity costs, highly portable, and gentle on the fruit (low oxidation). They are ideal for “agritourism” (u-pick farms) where the customer experience of crushing fruit is part of the value proposition.

- Cons: Labor costs prohibit commercial scaling. Processing 100lbs of apples requires significant physical exertion and time. The “scratter” mechanism in manual units often produces larger chunks than electric grinders, potentially reducing juice yield during the pressing phase unless double-ground.

Verdict: A viable alternative only for micro-batch testing, R&D labs, or interactive customer experiences. Not suitable for volume production.

Alternative 2: Integrated Whole-Fruit Juicers (Centrifugal/Masticating)

Unlike a grinder—which prepares fruit for a separate pressing stage—integrated juicers combine grinding and extraction into a single step.

- Operational Analysis:

- Pros: Speed and footprint. These machines eliminate the need for a separate press, significantly reducing the floor space required in a facility. They offer “drop-and-go” efficiency for citrus and soft fruits.

- Cons:

- Quality Control: High-speed centrifugal alternatives introduce heat and oxygen, which can degrade shelf-life and alter the flavor profile of ciders and premium juices.

- Yield & Waste: Integrated systems often produce wetter pomace (waste) compared to the high-pressure extraction achieved by a grinder-and-hydropress combination.

- Versatility: While excellent for citrus (e.g., electric citrus squeezers), they struggle with hard pomaceous fruits (apples, pears) at scale compared to heavy-duty grinders.

Verdict: Best suited for front-of-house service (HoReCa) where immediate serving speed outweighs total yield efficiency. For bottled production or fermentation (cider/wine), the separate grinder approach remains superior for flavor preservation.

Strategic Recommendation

For B2B operations aiming for commercial scale, the Electric Fruit Grinding Machine remains the superior choice over manual alternatives due to labor ROI. While manual crushers (like the 7L EJWOX models) offer a low barrier to entry, the labor cost to process commercial volumes exceeds the CapEx savings within the first few production runs.

Illustrative Image (Source: Google Search)

Choose Manual Crushers only for pilot testing. Choose Integrated Juicers for immediate consumption environments. Stick to Dedicated Grinders for production, bottling, and fermentation lines.

Essential Technical Properties and Trade Terminology for fruit grinding machine

Essential Technical Properties and Trade Terminology

When sourcing fruit grinding machines for the US and European markets, buyers must evaluate specific technical parameters to ensure equipment meets production throughput requirements and local safety standards. Below are the critical technical properties and commercial terminology required for procurement.

Key Technical Properties

For B2B buyers, the distinction between “batch capacity” (common in manual units) and “continuous throughput” (electric industrial units) is vital.

| Property | Technical Definition | B2B Relevance (USA/EU) |

|---|---|---|

| Throughput / Output | The volume of fruit processed per hour, measured in kg/h or tons/h. | Determines if the unit fits a home-brew scale (e.g., 50-100 kg/h) or industrial line (1–5 tons/h). |

| Hopper Capacity | The volume of the feed chute, typically measured in Liters (L) or Gallons. | Larger hoppers (e.g., >7L) reduce labor intensity for manual loading. Essential for batch processing efficiency. |

| Material Grade | The specific type of metal used in contact parts. | SS304 (AISI 304) is the industry standard for food hygiene and fruit acid resistance. SS316 is preferred for highly acidic citrus or industrial saline environments. |

| Power Rating | Motor power output (kW or HP) and voltage configuration. | USA: 110V/60Hz (light commercial) or 220V/480V (industrial). EU: 220V/50Hz or 380V (3-phase). Note: Manual units rely on flywheel inertia. |

| Crushing Mechanism | The internal geometry used to pulp the fruit. | Scratter/Roller: Uses interlocking teeth to tear fruit (ideal for apples/pears). Hammer Mill: High-speed impact for fine purees. |

| Particle Size Adjustment | The ability to alter the gap between rollers or grate size. | Critical for controlling the “pomace” consistency. Coarser grinds are required for cider pressing; finer grinds for purees. |

Trade & Commercial Terminology

Understanding these terms is essential for negotiating contracts with manufacturers and ensuring compliance with import regulations.

Illustrative Image (Source: Google Search)

Procurement Terms

- MOQ (Minimum Order Quantity): The lowest quantity a supplier will sell.

- Heavy Machinery: Often 1 unit.

- Small/Manual Crushers: Often 50–100 units for custom branding; 1–5 units for stock items.

- OEM (Original Equipment Manufacturer): The buyer purchases a standard machine but requests their own branding (logo, manual, packaging). Common for distributors selling under private labels (e.g., similar to “EJWOX” or “VEVOR” rebrands).

- ODM (Original Design Manufacturer): The supplier modifies the design (e.g., changing the hopper shape or flywheel material) based on the buyer’s specs.

- Lead Time: The duration between order confirmation and shipment.

- RTS (Ready to Ship): Stock items (typically 3–7 days).

- Production Order: Requires manufacturing (typically 25–45 days).

Regulatory & Shipping Terms

- HS Code: The Harmonized System code used for customs classification.

- Common Code: 8438.60 (Machinery for the preparation of fruits, nuts, or vegetables).

- CE Marking: Mandatory for Europe. Certifies the machine meets EU safety, health, and environmental protection requirements.

- FDA Compliance: Mandatory for USA. All food contact surfaces (stainless steel, plastics, lubricants) must be FDA-compliant food-grade materials.

- Incoterms (International Commercial Terms):

- FOB (Free on Board): Supplier is responsible until goods are loaded on the vessel at the export port. Buyer handles ocean freight and import.

- DDP (Delivered Duty Paid): Supplier handles everything, including shipping, customs, and duties, delivering directly to the buyer’s warehouse. Preferred by smaller B2B buyers.

Navigating Market Dynamics and Sourcing Trends in the fruit grinding machine Sector

Navigating Market Dynamics and Sourcing Trends in the Fruit Grinding Machine Sector

The market for fruit grinding and crushing machinery is undergoing a distinct shift. While industrial-scale processing remains stable, there is a surge in demand for “prosumer” grade equipment driven by the home brewing, cider-making, and organic juice movements in the USA and Europe.

Current Market Dynamics

B2B buyers must recognize that the end-user profile has expanded from commercial wineries to residential artisans. Analysis of current retail performance indicates three primary market drivers:

- The Rise of the “Home Artisan”: High sales volumes for manual, 1.8-gallon (7L) crushers indicate a robust market for home-based production. Consumers are seeking equipment that bridges the gap between kitchen appliances and industrial machinery.

- Material Standards: There is an uncompromising demand for food-grade hygiene. Stainless steel hoppers and grinding teeth are now the baseline expectation for durability and sanitation. However, “traditional” aesthetics remain relevant; units featuring solid beech wood components (baskets/stands) command strong pricing, appealing to the heritage aspect of wine and cider making.

- Portability and Manual Operation: Despite the availability of electric options, manual flywheel-operated crushers dominate the best-seller lists. This suggests a consumer preference for equipment that is portable, energy-independent, and suitable for outdoor use (e.g., directly in the orchard).

Sourcing Trends and Seasonality

For distributors targeting US and European markets, procurement strategies must align with agricultural cycles and consumer purchasing behaviors.

| Sourcing Factor | Trend / Requirement | Strategic Implication |

|---|---|---|

| Peak Demand | August – November | Inventory must be secured by Q2 to meet the harvest season rush for apples and grapes. |

| Price Sensitivity | Retail range: $95 – $160 | Wholesale sourcing must target unit costs that allow for competitive retail pricing against dominant brands like EJWOX. |

| Bundle Potential | High | Grinders are rarely bought in isolation. Sourcing trends favor bundling crushers with 3–5 gallon fruit presses. |

| Key Features | “Heavy-Duty,” “Large Flywheel” | Procurement specs should prioritize torque and stability over speed. |

Sustainability in Fruit Processing

Sustainability is no longer a buzzword but a technical requirement for European and American buyers.

Illustrative Image (Source: Google Search)

- Energy Independence: The resurgence of manual fruit crushers aligns with low-carbon lifestyle trends. These machines require zero electricity, appealing to off-grid users and eco-conscious consumers.

- Reduction of Food Waste: A primary driver for purchasing fruit grinders is the processing of “ugly” or surplus fruit. Marketing narratives and product descriptions should highlight the machine’s role in converting unmarketable harvest into value-added products (cider/juice), thereby reducing agricultural waste.

- Longevity and Repairability: The market favors simple mechanical designs (flywheels, gears) over complex electronics. These units offer longer lifecycles and easier repairability, reducing the frequency of replacement and landfill contribution.

Historical Context and Evolution

Understanding the lineage of fruit crushing aids in product positioning.

- Stone and Trough: Historically, crushing was a communal activity utilizing large stone wheels, prioritizing volume over precision.

- The Wooden Era: The introduction of wooden screw presses and crushers allowed for household-level production. The current popularity of beech wood baskets in modern units is a direct homage to this era, signaling “authenticity” to the buyer.

- The Stainless Revolution: Modern manufacturing introduced stainless steel hoppers to the traditional wooden frame. This hybrid design—currently the market leader—combines the sanitary benefits of modern metallurgy with the nostalgic appeal of traditional cider making.

Strategic Takeaway: When sourcing for Western markets, prioritize equipment that balances modern hygiene standards (stainless steel internals) with the tactile, manual experience of traditional brewing (flywheels and wood accents).

Frequently Asked Questions (FAQs) for B2B Buyers of fruit grinding machine

Frequently Asked Questions (FAQs) for B2B Buyers of Fruit Grinding Machines

1. What is the difference between manual batch crushers and continuous electric grinders?

Manual crushers (often 7L/1.8-gallon capacity with flywheel handles) are designed for micro-breweries, R&D pilot testing, or low-volume artisanal production. They require physical labor and operate in batches. Continuous electric grinders are required for commercial throughput, utilizing high-torque motors to process tons per hour, ensuring consistency and reducing labor costs for medium-to-large scale operations in the USA and Europe.

2. Which material standards are required for compliance in US and European markets?

For commercial food processing, the machine’s contact parts must be constructed from food-grade Stainless Steel (typically Grade 304 or 316).

* USA: Must meet FDA food safety requirements.

* Europe: Must comply with CE machinery directives and EC 1935/2004 regarding materials in contact with food.

Avoid equipment using cast iron or non-certified alloys to prevent contamination and regulatory fines.

Illustrative Image (Source: Google Search)

3. Can a single machine handle both hard pome fruits and soft stone fruits?

Most industrial grinders are optimized for specific textures, but versatile models exist.

* Hard Fruits (Apples, Pears): Require sharp blades or heavy-duty rollers to tear through skin and flesh.

* Soft Fruits (Berries, Grapes): Require a gentler “crushing” or “destemming” action to avoid pulverizing seeds (which releases bitter tannins).

B2B buyers should look for machines with adjustable roller spacing or interchangeable hoppers/screens to handle multiple fruit types.

4. How does grind consistency affect juice yield and pressing efficiency?

The “scratter” or pulp consistency directly dictates yield.

* Too Fine: Creates a “sauce” that clogs press cloths and prevents juice drainage.

* Too Coarse: Leaves juice trapped inside large chunks of fruit.

High-quality commercial grinders offer adjustable particle size control to produce the optimal “pomace” structure for your specific hydraulic or belt press, maximizing extraction volume.

5. What maintenance is required for stainless steel fruit grinders?

While stainless steel resists corrosion, acidic fruit juices require strict sanitation protocols.

* Daily: Wash-down to remove sugar and acid residue using high-pressure water.

* Periodic: Lubrication of external bearings (away from food zones) and inspection of cutter blades/rollers for dullness.

* Design: Look for “tool-free” disassembly features that allow operators to access the crushing chamber quickly for deep cleaning.

6. Are manual crushers viable for commercial cider production?

Generally, no. A manual unit (e.g., 7L capacity) is a bottleneck for commercial production lines. However, they are frequently purchased by B2B buyers for:

1. Recipe Testing: Small-batch experimentation without dirtying the main line.

2. Agritourism: “U-Press” stations where customers grind their own fruit.

For core production, automated electric milling is necessary to maintain margins.

7. How do I determine the correct capacity (throughput) for my facility?

Calculate your peak harvest window processing needs.

* Formula: Total Harvest Weight ÷ Harvest Window Hours = Required Hourly Throughput.

* Buffer: Always purchase a machine with 20% higher capacity than your calculation to account for loading times and potential bottlenecks.

Common commercial ratings range from 500 kg/h for small cideries to 10+ tons/h for industrial plants.

8. What power specifications should I verify before importing?

Voltage standards differ significantly between target markets.

* USA: Industrial units often require 110V (small) or 220V/480V 3-phase (large).

* Europe: typically 230V (single phase) or 400V (3-phase).

Ensure the motor specification matches your facility’s grid to avoid the cost of step-up/step-down transformers.

Strategic Sourcing Conclusion and Outlook for fruit grinding machine

Strategic Sourcing Conclusion and Outlook

The market for fruit grinding machinery is evolving, driven by a resurgence in artisanal cider production, home brewing, and small-scale organic processing across the USA and Europe. For distributors and retailers, this category represents a convergence of traditional durability and modern hygiene standards. Data indicates sustained demand for 7L manual crushers and stainless steel units, signaling a robust “prosumer” segment that bridges the gap between hobbyist and commercial equipment.

Key Sourcing Takeaways:

- Material Integrity: Prioritize units constructed from food-grade 304 stainless steel and solid beech wood. Compliance with EU and FDA food safety standards is a critical selling point for Western buyers.

- Portfolio Balance: Stocking a mix of manual fly-wheel units for entry-level enthusiasts and electric automated grinders for small-batch commercial efficiency ensures broad market coverage.

- Versatility: Value lies in multi-fruit capability. Machines proven to handle apples, grapes, and berries without clogging offer higher ROI and lower return rates.

Outlook:

As the “farm-to-table” movement matures, demand will shift toward equipment that balances portability with high-yield output. Strategic sourcing should focus on suppliers offering modular designs and readily available replacement parts to support long-term product lifecycles and brand loyalty.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.