Top Hum Wire Caging Machine Manufacturers Reviewed

Are you tired of sifting through countless suppliers to find the perfect hum wire caging machine manufacturer? You’re not alone! Many businesses struggle to identify the right partner, leading to costly delays and frustrations. Finding the best factory can make all the difference in ensuring high-quality production, reliable service, and competitive pricing. Imagine the peace of mind that comes from knowing you have a trusted supplier backing your operations.

In this article, we’ll compare the top 30 manufacturers, showcasing their strengths and what sets them apart. Whether you’re looking for innovation, reliability, or affordability, we’ve got you covered. Ready to discover the best options for your business? Keep reading to find the ideal manufacturer that meets your needs!

Top 16 Hum Wire Caging Machine Manufacturer Manufacturers

Cagemachine – Reinforcement Welding Machines

Domain: cagemachine.com

Registered: 2001 ( 24 years )

Introduction: Apilion manufactures fully and semi-automatic reinforcement welding machines for producing various concrete products, including pipes, piles, poles, and trusses.

PMW Industries – Precision Industrial Machinery Solutions

Domain: pmw-industries.com

Registered: 1999 ( 26 years )

Introduction: PMW Industries specializes in manufacturing machines and molds for various industrial applications, focusing on precision and efficiency.

Ahct – High Productivity Cage Welding Machines

Domain: ahct.in

Registered: 2012 ( 13 years )

Introduction: Cage welding machines designed for high productivity and efficiency in the manufacturing of wire mesh and cages.

Tjkmachinery Group – Steel Wire Cage Welding Machines

Domain: tjkmachinery-group.com

Registered: 2016 ( 9 years )

Introduction: Automatic Steel Wire Cage Welding Machine, Pile Cage Making Machine

Progress M – Cage Welding Machines

Domain: progress-m.com

Registered: 2000 ( 25 years )

Introduction: VTA series cage welding machines are used to manufacture cylindrical and where required, oval or rectangular cages. The machines offer various configuration options and levels of automation for efficient production.

Wirecageusa – Industrial Security Cages and Safety Solutions

Domain: wirecageusa.com

Registered: 2021 ( 4 years )

Introduction: Wire Security Cages and related safety products for industrial applications, including machine guarding, pallet rack safety, and guardrails.

WireCrafters – Wire Cages and Storage Solutions

Domain: wirecrafters.com

Registered: 1996 ( 29 years )

Introduction: WireCrafters offers a variety of products including wire cages and partitions, storage lockers, protective railings, pallet rack safety systems, and bicycle storage solutions.

Bartell Machinery – Stranding and Cabling Equipment

Domain: bartellmachinery.com

Registered: 1999 ( 26 years )

Introduction: Bartell Machinery offers a range of stranding, bunching, and cabling equipment for wire and cable manufacturing, including various types of stranders and cablers designed for high productivity and reliability.

Itech Bending Machine – Rebar Cage Welding Solutions

Domain: itechbendingmachine.com

Registered: 2020 ( 5 years )

Introduction: Reinforcement Rebar pile cage welding machine Cut&bend Equipment is an essential tool for the construction industry, designed to automate the production of rebar cages used in construction, particularly for bored piles, diaphragm walls, and foundation reinforcement.

Awcwire – Mil-Spec Wire & Custom Cable Solutions

Domain: awcwire.com

Registered: 1997 ( 28 years )

Introduction: Allied Wire & Cable is a distributor of military specification (Mil-Spec) wire and cable, custom cable solutions, and other related products.

McMaster-Carr – Wire Cages and Storage Solutions

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: Wire cages offered by McMaster-Carr are designed for various storage and organizational needs, providing a durable and versatile solution for different applications.

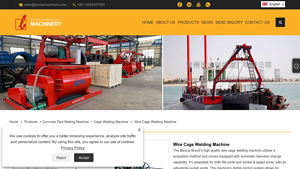

Baolaimachinery – Wire Cage Welding Machines

Domain: baolaimachinery.com

Registered: 2024 ( 1 years )

Introduction: Wire Cage Welding Machine for manufacturing wire cages used in concrete pipe production.

Schnellgroup – Cage Assembling Machines Solutions

Domain: schnellgroup.com

Registered: 2000 ( 25 years )

Introduction: Schnell cage assembling machines are designed for high productivity and quality in the production of construction reinforcement, including pile cage making machines and cage welding machines.

Riverdale – Premium Animal Safety Wire Mesh

Domain: riverdale.com

Registered: 1995 ( 30 years )

Introduction: Riverdale Cage Wire is the highest-quality wire mesh designed to keep animals safe and secure while minimizing the risk of escape or injury. It is available in various finishes and can be used for both large and small animals in commercial and consumer applications.

Security Caging – Secure Storage Solutions

Domain: securitycaging.com

Registered: 2019 ( 6 years )

Introduction: Security Caging offers a variety of secure storage products including wire mesh partitions, pallet rack safety systems, guard rails, machine guarding, DEA compliant caging, tenant storage lockers, TA-50 military lockers, mezzanine systems, and customizable cage doors with various locking options.

Bizearch – Concrete Pole Factory Solutions

Domain: bizearch.com

Registered: 2006 ( 19 years )

Introduction: Turnkey design and built for Concrete pole factory, including machinery and moldings for Pre-stressed Spun Concrete Pole / Pile / Pipe, Decorative Concrete Pole.

Category Information

Hum wire caging machine manufacturers specialize in producing equipment designed for the fabrication and assembly of wire cages, which are essential in various industries, including agriculture, construction, and retail. These machines automate the process of cutting, bending, and welding wire to create durable cages for animals, storage, or structural support. The efficiency and precision of these machines significantly enhance production capabilities, ensuring consistent quality and reducing labor costs.

The significance of wire caging machines lies in their ability to meet the growing demand for reliable and robust wire products. As industries expand and evolve, the need for customized wire solutions becomes crucial. Manufacturers of these machines not only contribute to increased productivity but also support innovation in design and functionality, enabling businesses to adapt to market changes and consumer needs effectively.

Application Information

Hum wire caging machine manufacturers produce equipment primarily used in industries requiring robust and secure containment solutions. One key application area is the agricultural sector, where wire cages are employed for protecting livestock and poultry, ensuring their safety from predators while allowing for proper ventilation and movement. Another significant area is the construction and landscaping industries, where wire caging is utilized for creating protective barriers around plants, trees, and construction sites.

These cages help prevent damage from wildlife and environmental factors. Additionally, the manufacturing sector often uses wire caging machines for producing enclosures for storage and transportation, enhancing security and organization within warehouses and shipping facilities. Overall, these machines serve critical roles in ensuring safety, security, and efficient operations across various industries.

Production Process Information

Manufacturing a hum wire caging machine involves several key stages. First, the design phase is crucial, where engineers create blueprints based on the specific needs of customers. This includes determining the size, functionality, and materials required for the machine. Next, the production phase begins. This involves sourcing high-quality materials, such as steel and electrical components, and then fabricating them into parts using various machinery. Once the parts are made, they are assembled into the final product.

Quality control is essential during this stage to ensure that each machine operates safely and efficiently. Finally, after assembly, the machines undergo testing to ensure they meet industry standards. Once approved, they are packaged and shipped to customers. Throughout this process, manufacturers must also consider customer support and maintenance services to ensure long-term satisfaction with the product.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a wire caging machine manufacturer?

When searching for a wire caging machine manufacturer, consider their experience and reputation in the industry. Look for manufacturers with a proven track record of producing high-quality machines and positive customer reviews. Additionally, check if they offer comprehensive customer support, including installation and maintenance services. It’s also beneficial to see if they have a range of models to choose from, allowing you to find a machine that fits your specific needs.

How can I verify the quality of the machines offered by a manufacturer?

To verify the quality of machines from a manufacturer, request samples or visit their factory to see the production process firsthand. Ask for certifications and quality assurance processes they follow, such as ISO standards. Additionally, reading reviews and testimonials from other customers can provide insight into the machine’s performance and durability. If possible, reach out to current users to get their feedback on the machine’s reliability and functionality.

What are the typical lead times for ordering a wire caging machine?

Lead times can vary significantly based on the manufacturer and the complexity of the machine. Generally, you can expect a lead time of anywhere from a few weeks to several months. It’s essential to discuss this upfront with the manufacturer to understand their production schedule and any potential delays. If you have a tight timeline, consider manufacturers who can accommodate rush orders or have machines readily available for immediate shipment.

Are there any warranties or guarantees offered on wire caging machines?

Most reputable manufacturers offer warranties on their machines, which can range from one year to several years, depending on the manufacturer and the specific machine. A warranty typically covers defects in materials and workmanship, giving you peace of mind about your investment. Always ask about the warranty terms and what it covers before making a purchase, and consider manufacturers who provide extended warranty options for added security.

How can I ensure good communication with my chosen manufacturer?

Good communication is key to a successful partnership with your manufacturer. Before making a decision, assess their responsiveness during your initial inquiries. A reliable manufacturer should be prompt in answering your questions and providing detailed information about their products. It’s also helpful to establish preferred communication channels, whether through email, phone, or messaging apps, and to clarify who your main point of contact will be throughout the process. This will help ensure that you stay informed and any issues can be addressed quickly.