Improve Quality and Cut Costs with a Raw Material Manufacturer (2025)

Introduction: Navigating the Global Market for raw material manufacturer

In today’s interconnected world, sourcing raw materials for manufacturing can be a complex and daunting task, especially for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. With fluctuating markets, diverse supplier landscapes, and varying regulatory environments, understanding how to effectively navigate the global market for raw material manufacturers is crucial. This guide aims to demystify the process, providing actionable insights that will enable you to make informed purchasing decisions tailored to your specific needs.

Throughout this comprehensive resource, we will explore various types of raw materials, their applications across different industries, and the critical factors to consider when vetting suppliers. Buyers will learn how to assess cost structures, negotiate contracts, and ensure compliance with international standards. By equipping yourself with this knowledge, you can mitigate risks, enhance supply chain efficiency, and foster long-term partnerships with reliable manufacturers.

Whether you are a buyer in Colombia looking for sustainable materials or a procurement manager in Europe seeking innovative solutions, this guide is designed to empower your decision-making process. With a focus on practical strategies and industry best practices, you will be better positioned to navigate the challenges of the global raw materials market and capitalize on emerging opportunities.

Understanding raw material manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commodity Raw Material Manufacturers | Focus on bulk production of standard materials. Often operate on a large scale. | Construction, manufacturing, energy. | Pros: Lower costs due to economies of scale. Cons: Limited customization options. |

| Specialty Raw Material Manufacturers | Produce unique materials tailored for specific applications. | Electronics, automotive, pharmaceuticals. | Pros: High-quality, customized products. Cons: Generally higher prices and longer lead times. |

| Recycled Raw Material Manufacturers | Utilize waste materials to create new raw materials. | Packaging, construction, textiles. | Pros: Environmentally friendly, often lower costs. Cons: Quality may vary significantly. |

| Local Sourcing Raw Material Manufacturers | Focus on regional production to minimize shipping costs and lead times. | Agriculture, textiles, food processing. | Pros: Reduces transportation costs and supports local economies. Cons: Limited product range compared to global suppliers. |

| Integrated Raw Material Manufacturers | Control the entire supply chain from raw material extraction to production. | Aerospace, automotive, heavy machinery. | Pros: Streamlined processes and better quality control. Cons: Higher initial investment and complexity. |

What are the Characteristics of Commodity Raw Material Manufacturers?

Commodity raw material manufacturers are essential players in the global supply chain, focusing on the mass production of standard materials such as steel, aluminum, and crude oil. Their operations are characterized by high-volume output and cost efficiency, making them ideal for industries that require large quantities of raw materials, like construction and energy. When considering purchasing from these manufacturers, buyers should evaluate factors such as pricing, delivery capabilities, and the reliability of supply, as these can significantly impact project timelines and budgets.

How do Specialty Raw Material Manufacturers Differ?

Specialty raw material manufacturers cater to niche markets by producing tailored materials for specific applications. This includes advanced materials used in electronics, automotive components, and pharmaceuticals. Buyers seeking high-quality, customized solutions will find these manufacturers beneficial, although they often come at a premium price and may require longer lead times. It’s crucial for buyers to assess their specific needs and potential trade-offs between cost and quality when engaging with these suppliers.

What are the Advantages of Recycled Raw Material Manufacturers?

Recycled raw material manufacturers focus on converting waste materials into new products, contributing to sustainability efforts while often providing cost-effective solutions. Industries such as packaging and construction increasingly rely on these manufacturers to meet environmental goals. However, buyers should be mindful of the variability in quality and consistency when sourcing recycled materials. Conducting thorough supplier assessments and quality checks is essential to ensure that the recycled materials meet the required specifications for their applications.

Why Choose Local Sourcing Raw Material Manufacturers?

Local sourcing raw material manufacturers emphasize regional production, which helps minimize shipping costs and lead times. This approach is particularly advantageous for sectors such as agriculture and textiles, where freshness and quick turnaround times are critical. While supporting local economies, buyers may encounter limitations in product variety compared to global suppliers. Evaluating the trade-offs between local sourcing benefits and product availability is vital for businesses aiming to optimize their supply chains.

What are the Features of Integrated Raw Material Manufacturers?

Integrated raw material manufacturers manage the entire supply chain, from extraction to production, ensuring better quality control and streamlined processes. This model is prevalent in industries like aerospace and heavy machinery, where precision and reliability are paramount. While the advantages include enhanced efficiency and reduced risk of supply chain disruptions, buyers should be prepared for potentially higher initial investments and the complexity of dealing with a single supplier. Understanding the manufacturer‘s capabilities and their alignment with specific project needs is crucial for successful partnerships.

Related Video: 3 Types of Inventory (Raw Materials, WIP, and Finished Goods)

Key Industrial Applications of raw material manufacturer

| Industry/Sector | Specific Application of Raw Material Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Production of Cement and Aggregates | Enhanced structural integrity and durability | Quality certifications, local availability, and transport costs |

| Automotive | Manufacturing of Plastics and Composites | Improved vehicle performance and weight reduction | Compliance with safety standards, material specifications, and lead times |

| Electronics | Supply of Metals for Circuit Boards and Components | Increased efficiency and reliability of devices | Purity levels, sourcing traceability, and supplier reputation |

| Food and Beverage | Sourcing of Packaging Materials | Extended shelf life and product safety | Regulatory compliance, sustainability practices, and customization options |

| Pharmaceuticals and Healthcare | Provision of Active Pharmaceutical Ingredients (APIs) | Enhanced efficacy and safety of medications | Quality assurance, regulatory approvals, and consistent supply |

How is Raw Material Used in the Construction Industry?

In the construction sector, raw material manufacturers play a crucial role by supplying essential components such as cement and aggregates. These materials are fundamental for building infrastructure, ensuring structural integrity and durability. International buyers, particularly from Africa and South America, should focus on sourcing high-quality materials that meet local regulations and standards. They must also consider logistics, as transport costs can significantly impact overall project budgets.

What Role Does Raw Material Play in the Automotive Industry?

The automotive industry heavily relies on raw materials like plastics and composites for manufacturing various vehicle components. These materials contribute to vehicle performance, reducing weight and enhancing fuel efficiency. For B2B buyers in Europe and the Middle East, it is vital to ensure compliance with safety and environmental regulations when sourcing these materials. Additionally, understanding the specific material requirements for different vehicle models can streamline procurement processes and minimize delays.

How Are Raw Materials Essential in Electronics Manufacturing?

In the electronics sector, raw materials, particularly metals, are critical for producing circuit boards and various components. They enhance the efficiency and reliability of electronic devices, which is increasingly important in a technology-driven market. Buyers from regions like Africa and South America should prioritize sourcing materials with high purity levels and traceability to ensure product performance. Partnering with reputable suppliers can mitigate risks associated with quality and supply chain disruptions.

Why Are Raw Materials Important in Food and Beverage Packaging?

In the food and beverage industry, the sourcing of packaging materials is vital for extending shelf life and ensuring product safety. Raw material manufacturers provide materials that comply with health regulations and sustainability practices, which are increasingly demanded by consumers. B2B buyers in Europe and the Middle East should focus on suppliers who offer customizable solutions that meet specific packaging needs while adhering to local regulations.

How Do Raw Materials Impact Pharmaceuticals and Healthcare?

Raw material manufacturers supply Active Pharmaceutical Ingredients (APIs) essential for the production of medications. These materials directly impact the efficacy and safety of pharmaceutical products, making quality assurance a top priority. International buyers from South America and Africa must ensure that suppliers have the necessary regulatory approvals and maintain consistent supply chains to meet the demands of the healthcare market. Understanding the complexities of sourcing APIs can lead to better partnerships and improved product outcomes.

3 Common User Pain Points for ‘raw material manufacturer’ & Their Solutions

Scenario 1: Supply Chain Disruptions Impacting Timelines

The Problem:

International B2B buyers often face significant delays in the supply chain when sourcing raw materials. These disruptions can stem from various factors such as geopolitical tensions, natural disasters, or logistical inefficiencies. For buyers in Africa and South America, where infrastructure may be less developed, these delays can lead to halted production lines, increased costs, and ultimately, a loss of competitive edge in their respective markets.

The Solution:

To mitigate supply chain disruptions, buyers should prioritize establishing strong relationships with multiple suppliers across different regions. This diversification can help ensure continuity in supply even if one source is affected by external factors. Additionally, implementing advanced supply chain management software can offer real-time visibility into inventory levels and shipment statuses. This technology enables buyers to make informed decisions quickly, reallocating resources or adjusting orders as necessary. Regularly assessing supplier performance and maintaining open communication channels will also foster resilience and adaptability within the supply chain.

Scenario 2: Inconsistent Quality of Raw Materials

The Problem:

Another common pain point for B2B buyers is the inconsistency in the quality of raw materials received from manufacturers. This issue can lead to production inefficiencies, increased waste, and a decline in the overall quality of the final product. Buyers in Europe and the Middle East, who often adhere to strict regulatory standards, may find that subpar materials can result in compliance issues and reputational damage.

The Solution:

To address quality concerns, buyers should implement a robust supplier evaluation process that includes quality audits and compliance checks. Establishing clear specifications and performance metrics upfront can ensure that manufacturers understand the quality standards required. Additionally, consider using third-party quality assurance services to conduct inspections before shipment. Regular feedback loops with suppliers can also help in addressing quality issues proactively, allowing for continuous improvement and a more consistent supply of high-quality materials.

Scenario 3: Transparency and Traceability Issues

The Problem:

In today’s market, B2B buyers are increasingly concerned about the ethical sourcing of raw materials and the overall transparency of their supply chains. This is particularly pressing for buyers from Africa and South America, where concerns about environmental impact and labor practices are paramount. A lack of traceability can lead to reputational risks and erode trust with end consumers who demand sustainable practices.

The Solution:

To enhance transparency, buyers should seek out manufacturers that provide detailed documentation regarding sourcing practices and supply chain processes. Implementing blockchain technology can significantly improve traceability, as it offers an immutable record of each transaction within the supply chain. Buyers can also conduct regular audits of their suppliers to ensure compliance with sustainability standards. Engaging with suppliers who are certified by recognized sustainability organizations can further bolster credibility and help meet the growing demand for ethical sourcing practices in the market.

Strategic Material Selection Guide for raw material manufacturer

When selecting raw materials, international B2B buyers must consider a range of factors that can significantly impact product performance, manufacturing complexity, and compliance with regional standards. Below, we analyze four common materials used by raw material manufacturers, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

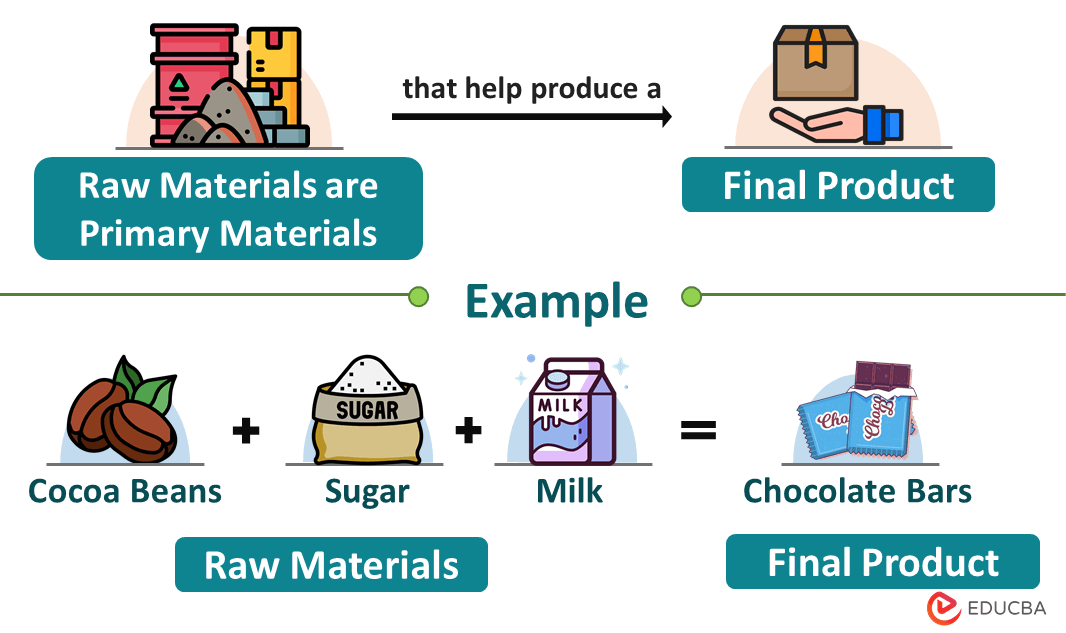

A stock image related to raw material manufacturer.

What Are the Key Properties of Steel in Raw Material Manufacturing?

Steel is a versatile material known for its strength and durability. It typically offers high-temperature resistance and excellent tensile strength, making it suitable for various applications. Its corrosion resistance can be enhanced through galvanization or alloying with elements like chromium.

Pros & Cons:

Steel’s primary advantage is its durability and ability to withstand high pressures, making it ideal for construction and manufacturing. However, it can be heavy and may require complex machining processes, which can increase manufacturing costs. Additionally, certain grades of steel may not be suitable for highly corrosive environments without proper treatment.

Impact on Application:

Steel is commonly used in construction, automotive, and machinery applications. Its compatibility with various media, including water and oil, makes it a popular choice in diverse industries.

Considerations for International Buyers:

Buyers must be aware of compliance with international standards such as ASTM and DIN. In regions like Europe, adherence to environmental regulations is crucial, while buyers in Africa and South America should consider local sourcing options to reduce costs.

How Does Aluminum Compare as a Raw Material Option?

Aluminum is lightweight and resistant to corrosion, making it an attractive option for manufacturers looking to reduce weight without sacrificing strength. It also has good thermal and electrical conductivity, which is beneficial in certain applications.

Pros & Cons:

The key advantage of aluminum is its lightweight nature, which can lead to cost savings in transportation and energy efficiency. However, it is generally more expensive than steel and may not provide the same level of strength in high-stress applications.

Impact on Application:

Aluminum is widely used in the aerospace, automotive, and packaging industries due to its excellent corrosion resistance and lightweight properties. It is compatible with various media but may require coatings in highly corrosive environments.

Considerations for International Buyers:

Buyers should consider the availability of aluminum alloys that meet specific standards, such as JIS in Japan or EN in Europe. Understanding local market conditions and tariffs can also influence procurement strategies.

What Are the Benefits and Drawbacks of Using Plastic Materials?

Plastics, including polyethylene and polypropylene, are increasingly popular due to their versatility and low weight. They offer good chemical resistance and can be molded into complex shapes.

Pros & Cons:

The main advantage of plastics is their cost-effectiveness and ease of manufacturing. However, they may not withstand high temperatures or pressures as effectively as metals. Additionally, environmental concerns regarding plastic waste can impact buyer preferences.

Impact on Application:

Plastics are commonly used in packaging, consumer goods, and automotive components. Their compatibility with a wide range of chemicals makes them suitable for various applications, though they may degrade under UV exposure.

Considerations for International Buyers:

Buyers must navigate different regulations regarding plastic use and recycling in their respective regions. Compliance with standards like ASTM D6400 for biodegradable plastics can also be crucial in Europe.

Why is Copper a Valuable Material for Certain Applications?

Copper is known for its excellent electrical conductivity and thermal properties, making it essential in electrical applications. It also has good corrosion resistance, particularly in marine environments.

Pros & Cons:

Copper’s primary advantage is its conductivity, making it ideal for electrical wiring and components. However, it is more expensive than other materials and can be prone to corrosion in certain environments without proper treatment.

Impact on Application:

Copper is widely used in electrical wiring, plumbing, and heating applications. Its compatibility with water and various chemicals makes it a reliable choice for many industries.

Considerations for International Buyers:

International buyers should be aware of copper’s market volatility and potential supply chain issues. Compliance with standards such as ASTM B280 for copper tubing is also essential for ensuring product quality.

Summary Table of Material Selection

| Material | Typical Use Case for raw material manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, automotive, machinery | High strength and durability | Heavy, complex machining | Medium |

| Aluminum | Aerospace, automotive, packaging | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Plastic | Packaging, consumer goods, automotive components | Cost-effective and versatile | Limited high-temp/pressure resistance | Low |

| Copper | Electrical wiring, plumbing, heating applications | Excellent conductivity | Expensive, prone to corrosion | High |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions when selecting raw materials, ensuring compliance and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for raw material manufacturer

What Are the Key Stages in Manufacturing Processes for Raw Material Production?

The manufacturing process for raw materials typically encompasses several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages is essential for international B2B buyers, as they directly impact the quality and suitability of the raw materials for specific applications.

Material Preparation: How Are Raw Materials Sourced and Processed?

Material preparation involves sourcing and processing raw inputs. For example, if a manufacturer specializes in metals, they may begin with ore extraction, followed by crushing and milling to achieve the desired particle size. Buyers should inquire about the sourcing practices of their suppliers, as sustainable and ethical sourcing can enhance the value of the final product. Additionally, this stage often includes quality checks to ensure that the materials meet specified standards before moving to the next phase.

What Techniques Are Used in Forming Raw Materials?

Forming is the stage where raw materials are shaped into the desired form. Common techniques include casting, forging, extrusion, and machining. Each method has its advantages depending on the material and the intended application. For instance, casting is often used for complex shapes, while forging is preferred for strength and durability. B2B buyers should assess which forming techniques their suppliers utilize, as this can affect material properties and overall performance.

How Does Assembly Contribute to the Final Product Quality?

In some cases, assembly may be relevant, particularly for composite materials or products requiring multiple components. This stage involves combining different materials or parts to create a final product. Buyers should verify if the assembly process includes quality control measures, such as alignment checks and functional testing, to ensure that the final product meets performance expectations.

What Finishing Processes Enhance Raw Material Quality?

Finishing processes involve treatments that enhance the surface properties of raw materials, such as coating, polishing, or heat treatment. These processes can significantly affect corrosion resistance, durability, and aesthetic qualities. For B2B buyers, understanding the finishing options available is crucial, as it can influence the suitability of the materials for specific applications, such as construction, automotive, or electronics.

What International Quality Standards Should B2B Buyers Be Aware Of?

Quality assurance (QA) is an integral part of the manufacturing process, especially for international B2B transactions. Familiarity with international standards such as ISO 9001 can help buyers ensure that their suppliers maintain a consistent quality management system. ISO 9001 focuses on customer satisfaction and continual improvement, making it a crucial standard for raw material manufacturers.

Which Industry-Specific Certifications Are Important for Raw Material Suppliers?

In addition to ISO standards, various industry-specific certifications may apply, depending on the type of raw material. For example, CE marking is essential for products sold within the European Economic Area, while API certification is critical for oil and gas materials. Buyers from regions like Africa, South America, the Middle East, and Europe should verify that their suppliers hold the relevant certifications to mitigate risks associated with compliance and safety.

How Are Quality Control Checkpoints Established in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that the products meet specified standards. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the manufacturing facility to confirm they meet specifications.

- In-Process Quality Control (IPQC): Inspections conducted during the manufacturing process help identify and rectify issues early on.

- Final Quality Control (FQC): This is the last line of defense, where the finished products undergo thorough testing before shipment.

B2B buyers should inquire about the specific QC processes their suppliers implement and request detailed reports to understand how quality is maintained throughout production.

What Common Testing Methods Are Used in Quality Assurance?

Quality assurance in raw material manufacturing often involves a variety of testing methods, including:

- Mechanical Testing: Assesses properties such as tensile strength, hardness, and ductility.

- Chemical Analysis: Determines the composition of materials to ensure they meet specifications.

- Non-Destructive Testing (NDT): Techniques like ultrasound and X-ray are used to detect internal flaws without damaging the materials.

Buyers should request information on the testing methods their suppliers use and the frequency of these tests to ensure that the materials meet their quality requirements.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the quality of raw materials, B2B buyers should engage in the following practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This helps buyers assess compliance with international standards and industry-specific certifications.

-

Reviewing Quality Reports: Requesting quality reports and certificates of conformity from suppliers can help verify that products meet required specifications.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the Nuances of Quality Control and Certification for International Buyers?

When dealing with international suppliers, B2B buyers must consider nuances such as language barriers, varying compliance standards, and cultural differences in business practices. Buyers from Africa, South America, the Middle East, and Europe should ensure that their suppliers not only comply with local regulations but also understand the requirements of the buyer’s home market. Establishing clear communication and expectations regarding quality control and certifications can help mitigate risks and foster successful partnerships.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting raw material suppliers, ultimately leading to better product outcomes and enhanced business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘raw material manufacturer’

In the competitive landscape of international trade, particularly for raw materials, having a structured sourcing strategy is essential for B2B buyers. This practical sourcing guide will provide you with a checklist that streamlines the procurement process, ensuring you select the right raw material manufacturer that meets your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to outline your specific technical requirements. This includes the type of raw materials needed, quality standards, and any industry-specific regulations. Clearly defined specifications help in narrowing down potential suppliers and ensuring that the materials you receive meet your production needs.

Step 2: Conduct Market Research

Understanding the market landscape is essential for informed decision-making. Research the current trends in raw material pricing, availability, and supplier reputation in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize online databases, trade publications, and industry reports to gather relevant data, which will enable you to make comparisons and identify the best options.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, thorough evaluation is critical. Request detailed company profiles, product catalogs, and customer references to gain insights into their operational capabilities. Pay attention to their experience in your specific industry and their ability to meet your technical specifications. This step helps mitigate risks associated with quality and reliability.

Step 4: ✅ Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO, ASTM, or industry-specific standards. These certifications indicate that the manufacturer adheres to recognized quality management practices. Verification of certifications can also protect your business from legal liabilities and ensure compliance with international trade regulations.

Step 5: Request Samples and Conduct Quality Testing

Before finalizing any orders, request samples of the raw materials you intend to procure. Conduct quality testing to ensure that the samples meet your specifications and quality standards. This step is vital as it provides an opportunity to assess the material’s performance and suitability for your applications, reducing the risk of future production issues.

Step 6: Negotiate Terms and Conditions

Once you have identified a potential supplier, it’s time to discuss pricing, delivery schedules, and payment terms. Clear negotiation helps establish a mutually beneficial relationship and ensures that both parties have aligned expectations. Be sure to address any additional costs, such as shipping and customs duties, especially when dealing with international suppliers.

Step 7: Establish a Communication Plan

Effective communication is key to successful supplier relationships. Set up a communication plan that outlines how often you will check in with the supplier, preferred communication channels, and points of contact on both sides. A well-defined communication strategy fosters transparency and can help quickly resolve any potential issues during the procurement process.

By following this checklist, B2B buyers can enhance their sourcing strategy, ensuring they select the right raw material manufacturers that align with their business objectives and operational requirements.

Comprehensive Cost and Pricing Analysis for raw material manufacturer Sourcing

What Are the Key Cost Components in Raw Material Manufacturing?

When sourcing from raw material manufacturers, understanding the cost structure is essential for making informed purchasing decisions. The primary components of cost include:

-

Materials: This is typically the largest cost component, depending on the type of raw material. Prices can fluctuate based on market conditions, availability, and sourcing location. Buyers should consider local versus imported materials and their associated costs.

-

Labor: Labor costs can vary significantly by region. In countries with lower wage standards, manufacturers may offer competitive pricing. However, it is crucial to ensure that labor practices comply with international standards to avoid ethical dilemmas.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Manufacturers with efficient operations may pass these savings onto buyers.

-

Tooling: Custom tooling can be a significant upfront investment. Buyers should evaluate whether they need specialized tooling for their orders and how this affects overall costs.

-

Quality Control (QC): Implementing stringent QC processes can incur additional costs but ultimately ensures product reliability and compliance with international standards. Buyers should assess the manufacturer’s QC protocols.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and the complexity of the supply chain. Import duties and tariffs can also add to the total logistics expenses.

-

Margin: Manufacturers will typically include a profit margin in their pricing. Understanding the market dynamics can help buyers negotiate better deals.

How Do Price Influencers Impact Raw Material Sourcing?

Several factors can influence the final price of raw materials:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to discounts. Buyers should negotiate MOQs that align with their needs without overcommitting.

-

Specifications and Customization: Custom orders may increase costs due to additional processing or material requirements. Clearly defining specifications can help manage expectations and pricing.

-

Materials and Quality Certifications: Premium materials or those certified for specific standards (like ISO) generally come at a higher price. Buyers should weigh the importance of certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record, while newer suppliers might offer competitive rates to build their market presence.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly impact costs. Understanding the responsibilities and risks associated with different Incoterms is crucial for accurate cost estimation.

What Buyer Tips Can Enhance Cost-Efficiency in Raw Material Sourcing?

To maximize cost-efficiency and ensure a favorable purchasing process, B2B buyers should consider the following strategies:

-

Effective Negotiation: Approach negotiations with a clear understanding of your requirements and the supplier’s cost structure. Leverage volume commitments to secure better rates.

-

Focus on Total Cost of Ownership (TCO): Rather than just looking at the initial purchase price, consider the TCO, which includes shipping, handling, storage, and potential wastage. This holistic view can reveal more cost-effective options.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local regulations, and trade agreements that can affect pricing. This understanding can help in forecasting costs more accurately.

-

Seek Multiple Quotations: Getting quotes from several suppliers provides leverage in negotiations and can uncover hidden costs. Always compare apples to apples regarding specifications and quality.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and improved communication, ultimately resulting in cost savings.

Disclaimer on Indicative Prices

Prices for raw materials can fluctuate due to various factors, including market demand, geopolitical influences, and currency exchange rates. It is advisable for buyers to conduct thorough research and obtain updated quotes to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing raw material manufacturer With Other Solutions

Understanding Alternatives to Raw Material Manufacturers

In the rapidly evolving landscape of international trade, B2B buyers often face the challenge of selecting the right source for raw materials. While traditional raw material manufacturers provide a reliable option, various alternative solutions can offer distinct advantages depending on the buyer’s specific needs. This analysis compares raw material manufacturers with two viable alternatives: synthetic material production and recycled material sourcing. Each option presents unique benefits and drawbacks that can significantly influence purchasing decisions.

Comparison Table

| Comparison Aspect | Raw Material Manufacturer | Synthetic Material Production | Recycled Material Sourcing |

|---|---|---|---|

| Performance | High quality, consistent supply | Variable quality, tailored properties | Quality can vary, but often meets standards |

| Cost | Generally higher upfront costs | Potentially lower costs due to scalability | Often lower costs due to reduced processing needs |

| Ease of Implementation | Established processes, but can be complex | Requires specialized knowledge and technology | Often simpler due to existing infrastructure |

| Maintenance | Regular quality checks, monitoring needed | Continuous innovation, upkeep of technology | Minimal maintenance, focus on collection and processing |

| Best Use Case | Industries requiring high-quality, specific materials | Custom applications needing unique material properties | Sustainable projects and companies focused on eco-friendly practices |

What are the Pros and Cons of Synthetic Material Production?

Synthetic material production involves creating materials through chemical processes, often resulting in tailored properties that meet specific industry needs. The primary advantage of this approach is its ability to deliver materials with unique characteristics that raw materials may not offer. Additionally, synthetic materials can sometimes be produced at lower costs due to economies of scale. However, the drawbacks include a reliance on complex manufacturing processes and potential environmental concerns associated with chemical production. B2B buyers should weigh these factors carefully, especially in industries sensitive to sustainability.

Why Consider Recycled Material Sourcing?

Recycled material sourcing has gained traction as a viable alternative, particularly among environmentally conscious companies. This method involves reprocessing waste materials to create new products, which can significantly reduce costs and environmental impact. One of the primary advantages is the lower cost associated with sourcing recycled materials, as they often require less energy to produce compared to raw materials. However, the quality of recycled materials can vary, and they may not always meet the stringent requirements of certain industries. B2B buyers focused on sustainability and cost-efficiency may find this option appealing, but should also consider the quality and reliability of the recycled inputs.

How Can B2B Buyers Choose the Right Solution?

Choosing the right solution between raw material manufacturers and alternatives like synthetic production or recycled sourcing ultimately depends on the specific needs of the business. Buyers should conduct a thorough analysis of their material requirements, budget constraints, and sustainability goals. If high quality and consistency are paramount, raw material manufacturers may be the best fit. Conversely, for businesses looking to innovate with custom materials or reduce costs, synthetic production could be advantageous. Finally, companies committed to sustainability should consider recycled material sourcing as a viable option that aligns with eco-friendly initiatives. By assessing these factors, B2B buyers can make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for raw material manufacturer

What Are the Essential Technical Properties for Raw Material Manufacturers?

When sourcing raw materials, understanding the technical properties is crucial for ensuring that the materials meet your production needs. Here are some key specifications that every B2B buyer should consider:

1. Material Grade

Material grade refers to the classification of raw materials based on their chemical composition and physical properties. For example, steel is available in various grades, each with different tensile strength, corrosion resistance, and ductility. Knowing the specific grade needed for your application helps in selecting the right material, ultimately affecting product quality and performance.

2. Tolerance

Tolerance is the allowable deviation from a specified dimension. In manufacturing, tighter tolerances often lead to higher costs but can significantly enhance product functionality. Understanding the tolerance requirements ensures that the materials you procure will fit precisely into your production processes, minimizing waste and enhancing efficiency.

3. Purity Level

Purity level indicates the absence of contaminants in raw materials. For industries such as pharmaceuticals or electronics, high purity is essential to ensure product safety and performance. B2B buyers must confirm the purity specifications to avoid costly recalls or failures in their final products.

4. Mechanical Properties

Mechanical properties, including hardness, elasticity, and tensile strength, dictate how a material will behave under various loads. These properties are critical for applications that require durability and resistance to wear and tear. Understanding the mechanical properties helps B2B buyers choose materials that will perform reliably in their specific applications.

5. Thermal Properties

Thermal properties, such as thermal conductivity and heat resistance, are vital for materials used in environments with extreme temperatures. For instance, if you’re sourcing materials for automotive or aerospace applications, knowing the thermal characteristics will ensure the materials can withstand operational conditions without failure.

Which Trade Terms Should B2B Buyers Understand?

Navigating the world of raw materials involves understanding specific trade terminology that can impact procurement and logistics. Here are some common terms you should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, knowing whether a supplier is an OEM can help in assessing the reliability and quality of the materials provided. OEMs often have stringent quality control processes, ensuring that the materials meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is crucial for budget management and inventory planning. If your production needs do not meet the MOQ, you may face increased costs or find it challenging to secure the materials you require.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications for the materials needed. Crafting a detailed RFQ can lead to better pricing and terms, allowing B2B buyers to negotiate more effectively with suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and delivery responsibilities, facilitating smoother transactions across borders.

5. Lead Time

Lead time refers to the time it takes for a supplier to deliver materials after an order is placed. Understanding lead times is essential for effective supply chain management. Buyers should factor in lead times when planning production schedules to avoid delays that could impact business operations.

Conclusion

Being well-versed in the essential technical properties and trade terminology related to raw material manufacturing is vital for international B2B buyers. By understanding these specifications and terms, buyers can make informed decisions, enhance procurement strategies, and ensure a smoother operational workflow.

Navigating Market Dynamics and Sourcing Trends in the raw material manufacturer Sector

What Are the Current Market Dynamics Affecting Raw Material Manufacturers?

The raw material manufacturing sector is experiencing significant transformations driven by globalization, technological advancements, and shifting consumer demands. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate these dynamics to optimize their sourcing strategies. Key trends influencing the market include increased digitization and automation, which streamline operations and enhance supply chain transparency. The rise of e-commerce platforms has also made it easier for buyers to source materials directly from manufacturers, allowing for more competitive pricing and reduced lead times.

Emerging technologies such as blockchain and IoT are reshaping how raw materials are tracked and verified, ensuring greater accountability and traceability in the supply chain. Buyers in Colombia, Brazil, and other regions can leverage these technologies to mitigate risks associated with sourcing, such as counterfeiting and supply chain disruptions. Additionally, the demand for local sourcing is on the rise, driven by geopolitical tensions and a growing emphasis on reducing carbon footprints. As such, international buyers should consider diversifying their supplier base to include local manufacturers, which can result in cost savings and shorter delivery times.

How Is Sustainability Shaping the Raw Material Manufacturing Sector?

Sustainability is no longer a niche concern; it has become a core principle in the raw material manufacturing sector. For international B2B buyers, particularly those in Africa and South America, understanding the environmental impact of their sourcing decisions is crucial. The industry is witnessing a shift toward sustainable practices, with manufacturers increasingly adopting eco-friendly processes and materials. This includes utilizing renewable resources, reducing waste, and minimizing carbon emissions in production.

Ethical sourcing has also gained prominence, as buyers demand transparency regarding labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential criteria for selecting suppliers. Buyers should prioritize manufacturers who hold these certifications, as they not only reduce risks but also enhance brand reputation. Furthermore, integrating sustainability into procurement strategies can lead to long-term cost savings and improved relationships with customers who prioritize corporate social responsibility.

What Is the Historical Context of Raw Material Manufacturing for B2B Buyers?

The raw material manufacturing sector has evolved significantly over the past few decades, influenced by technological innovations and changing global trade dynamics. Historically, the industry was characterized by labor-intensive processes and limited automation. However, the advent of advanced manufacturing technologies, such as CNC machining and 3D printing, has transformed production methods, leading to greater efficiency and precision.

In recent years, the emphasis on sustainability and ethical sourcing has further shaped the industry’s evolution. B2B buyers are now more informed and proactive in their sourcing decisions, seeking manufacturers who align with their values and sustainability goals. This historical context is vital for understanding current market trends and making informed purchasing decisions in a rapidly changing global landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of raw material manufacturer

-

How do I solve the challenge of sourcing high-quality raw materials for my business?

To effectively source high-quality raw materials, start by conducting thorough market research to identify reputable manufacturers. Utilize trade shows and industry events to meet potential suppliers face-to-face. Establish clear criteria for quality, such as certifications and compliance with international standards. Consider requesting samples before placing larger orders to assess the material’s suitability. Building a long-term relationship with a trusted supplier can also ensure consistent quality and supply reliability. -

What are the key factors to consider when selecting a raw material manufacturer?

When selecting a raw material manufacturer, focus on their production capabilities, quality control processes, and industry reputation. Evaluate their experience in your specific sector and their ability to meet your customization needs. Financial stability is crucial, as it impacts their ability to fulfill large orders. Additionally, consider their logistics capabilities, including shipping options and timelines, which can significantly affect your supply chain efficiency. -

What is the typical minimum order quantity (MOQ) for raw materials?

Minimum order quantities (MOQs) vary widely among raw material manufacturers and can depend on factors such as material type, production processes, and supplier policies. Generally, MOQs can range from a few hundred to several thousand units. When negotiating with suppliers, clarify your requirements and see if they can accommodate smaller orders, especially if you are testing new materials or are a smaller business. Flexibility in MOQs can facilitate smoother transactions and help build lasting partnerships. -

How can I ensure the reliability of a raw material supplier?

To ensure a supplier’s reliability, conduct a comprehensive due diligence process that includes checking references, reading reviews, and verifying their credentials. Request information about their production processes, quality assurance protocols, and delivery timelines. Establishing a trial order can help assess their responsiveness and reliability before committing to larger purchases. Regular communication and visits to their facilities can also strengthen the relationship and provide insights into their operations. -

What payment terms should I negotiate with raw material suppliers?

When negotiating payment terms, consider options like letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60 days). Choose terms that balance your cash flow needs with the supplier’s requirements for security. It’s important to clarify what happens in case of delays or quality issues, including potential penalties or refunds. Establishing clear, mutually beneficial payment terms helps build trust and facilitates smoother transactions. -

How do I handle quality assurance for imported raw materials?

Implement a robust quality assurance process by establishing clear specifications and standards for the materials you are importing. Request certifications and compliance documents from suppliers to ensure adherence to industry standards. Consider hiring third-party inspection services to verify quality before shipment. Additionally, maintaining open lines of communication with your supplier can help address potential issues early and ensure that corrective actions are taken promptly. -

What logistics considerations should I keep in mind when importing raw materials?

Logistics play a crucial role in the import process. Assess shipping methods and costs, as well as potential customs duties and tariffs that may apply to your materials. Understand the timelines for shipping and customs clearance to avoid unexpected delays. Collaborate with logistics providers experienced in international trade to streamline the import process and ensure compliance with local regulations. Proper logistics planning can minimize risks and ensure timely delivery of raw materials. -

How can I customize raw materials to meet my specific business needs?

Customization options for raw materials often depend on the manufacturer’s capabilities. Discuss your specific requirements with potential suppliers, including material composition, size, and packaging. Many manufacturers offer tailored solutions to meet unique business needs, but it’s crucial to communicate your expectations clearly from the outset. Request samples of customized materials to evaluate their performance before committing to larger orders. Establishing a collaborative relationship with your supplier can facilitate the customization process effectively.

Important Disclaimer & Terms of Use

A stock image related to raw material manufacturer.

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for raw material manufacturer

Why is Strategic Sourcing Essential for Raw Material Buyers?

In today’s global marketplace, strategic sourcing emerges as a critical element for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By prioritizing a well-defined sourcing strategy, companies can optimize their supply chains, reduce costs, and enhance the quality of raw materials sourced. This proactive approach not only mitigates risks associated with price volatility and supply disruptions but also fosters long-term partnerships with reliable suppliers.

How Can Buyers Leverage Market Trends for Competitive Advantage?

Understanding regional market dynamics and trends is vital for informed decision-making. Buyers in countries like Colombia and Brazil should monitor fluctuations in demand and supply, as well as geopolitical factors that could impact sourcing. By aligning their sourcing strategies with these insights, businesses can better position themselves to capitalize on opportunities and navigate challenges in the raw materials market.

What Does the Future Hold for Raw Material Sourcing?

Looking ahead, the landscape for raw material manufacturers is set to evolve with advancements in technology and sustainability practices. Buyers should remain vigilant and adaptable to these changes, incorporating innovative solutions such as digital procurement platforms and sustainable sourcing initiatives. This forward-thinking mindset will not only enhance operational efficiency but also align with global sustainability goals.

Call to Action: How Can You Enhance Your Sourcing Strategy?

As you refine your sourcing strategy, consider leveraging local suppliers to foster regional economic growth while ensuring quality and reliability. Engage with industry experts, attend trade fairs, and utilize digital tools to enhance your sourcing capabilities. By doing so, you will not only optimize your procurement processes but also secure a competitive edge in the ever-evolving raw materials market. Embrace the future of strategic sourcing today!