Improve Quality & Cut Costs: Aluminum Profile China Guide (2025)

Introduction: Navigating the Global Market for aluminum profile china

Navigating the global market for aluminum profiles from China presents a unique set of challenges for international B2B buyers. Sourcing high-quality aluminum profiles that meet specific application requirements can be daunting, especially when considering factors such as material specifications, production capabilities, and supplier reliability. This guide aims to demystify the complexities of purchasing aluminum profiles from China by providing a comprehensive overview of the types available, their various applications across industries, and essential criteria for vetting suppliers effectively.

Buyers from regions like Africa, South America, the Middle East, and Europe—such as Saudi Arabia and France—will find this guide particularly beneficial. It empowers decision-makers to make informed purchasing choices by outlining key considerations including pricing structures, quality assurance processes, and logistical aspects that can impact delivery timelines. By understanding the nuances of the aluminum profile market in China, buyers can mitigate risks associated with international procurement and enhance their operational efficiency.

This guide is structured to equip you with actionable insights and strategic approaches, ensuring that you can confidently navigate the intricacies of sourcing aluminum profiles. Whether you are looking for specific alloy compositions or need guidance on compliance with international standards, this resource serves as your roadmap to successful procurement in the global aluminum market.

Understanding aluminum profile china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Profiles | Uniform shapes; available in various dimensions | Construction, framing, furniture | Pros: Versatile, widely available. Cons: Limited customization options. |

| Custom Profiles | Tailored dimensions and shapes | Specialized machinery, custom builds | Pros: Exact specifications, unique designs. Cons: Higher costs, longer lead times. |

| Anodized Profiles | Enhanced corrosion resistance, aesthetic finish | Architecture, automotive, electronics | Pros: Durable, visually appealing. Cons: More expensive than standard profiles. |

| Thermal Break Profiles | Insulated design to reduce heat transfer | Windows, doors, energy-efficient buildings | Pros: Energy-saving, improved insulation. Cons: Complex manufacturing, higher cost. |

| Structural Profiles | High strength-to-weight ratio | Heavy-duty construction, bridges | Pros: Strong, lightweight. Cons: Requires precise engineering, may need specialized handling. |

What Are Standard Aluminum Profiles and Their Applications?

Standard aluminum profiles are widely used in various industries due to their uniform shapes and dimensions. These profiles are ideal for general construction applications, framing structures, and furniture manufacturing. B2B buyers appreciate their versatility and availability, making them a go-to choice for many projects. However, one limitation is their lack of customization, which may not suit specialized applications.

How Do Custom Aluminum Profiles Benefit B2B Buyers?

Custom aluminum profiles are designed to meet specific requirements, allowing for tailored dimensions and shapes. This flexibility is particularly beneficial for specialized machinery and custom builds where standard profiles may fall short. While they offer unique design possibilities, B2B buyers should consider the higher costs and longer lead times associated with these profiles.

What Are the Advantages of Anodized Aluminum Profiles?

Anodized aluminum profiles undergo an electrochemical process that enhances their corrosion resistance and provides a visually appealing finish. These profiles are commonly used in architecture, automotive, and electronics industries where aesthetics and durability are critical. While they are more expensive than standard profiles, their long lifespan and low maintenance make them a worthwhile investment for B2B buyers.

Why Choose Thermal Break Aluminum Profiles?

Thermal break profiles are specifically designed to minimize heat transfer, making them ideal for energy-efficient buildings, windows, and doors. This feature not only helps in reducing energy costs but also improves overall insulation. However, the manufacturing process is more complex, which can lead to higher costs. B2B buyers should weigh the energy savings against the initial investment when considering these profiles.

What Makes Structural Aluminum Profiles Unique?

Structural aluminum profiles are characterized by their high strength-to-weight ratio, making them suitable for heavy-duty construction applications such as bridges and large buildings. Their lightweight nature allows for easier handling and installation, but they require precise engineering to ensure safety and effectiveness. Buyers in the construction sector should consider the technical specifications and potential handling requirements when sourcing these profiles.

Related Video: Laser Cutting Aluminum Profile – China Aluminum Extrusion Supplier

Key Industrial Applications of aluminum profile china

| Industry/Sector | Specific Application of aluminum profile china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural frames for buildings | Lightweight and corrosion-resistant solutions | Compliance with local building codes and standards |

| Automotive | Lightweight chassis components | Improved fuel efficiency and performance | Compatibility with existing manufacturing processes |

| Electronics | Heat sinks and enclosures for electronic devices | Enhanced thermal management and durability | Precision in dimensions and surface finish requirements |

| Renewable Energy | Solar panel frames | Increased efficiency and longevity of solar installations | Resistance to environmental factors and custom designs |

| Transportation & Logistics | Cargo containers and pallets | Strength and reduced weight for better payloads | Certification for safety standards and load capacities |

How is Aluminum Profile China Used in Construction?

In the construction industry, aluminum profiles are extensively utilized for structural frames of buildings and facades. Their lightweight nature and resistance to corrosion make them ideal for both residential and commercial projects. For international buyers, particularly in regions like the Middle East and Africa, sourcing aluminum profiles that meet local building codes is crucial. This ensures not only compliance but also the durability of structures in various environmental conditions.

What are the Benefits of Aluminum Profiles in the Automotive Sector?

Aluminum profiles are increasingly being used in automotive manufacturing for lightweight chassis components. This application is vital as it contributes to improved fuel efficiency and overall vehicle performance. For B2B buyers in South America and Europe, it’s essential to consider the compatibility of these profiles with existing manufacturing processes and the specific requirements of vehicle models. Such considerations can significantly enhance production efficiency and reduce costs.

How Do Electronics Manufacturers Benefit from Aluminum Profiles?

In the electronics sector, aluminum profiles serve as heat sinks and enclosures for various devices. They facilitate effective thermal management, ensuring that electronics operate efficiently and have a longer lifespan. B2B buyers should prioritize precision in dimensions and surface finish when sourcing these profiles, as these factors directly influence the performance of electronic devices. In Europe, where technology standards are stringent, sourcing from reputable suppliers in China can provide the necessary quality assurance.

Why are Aluminum Profiles Important for Renewable Energy Applications?

Aluminum profiles are critical in renewable energy, particularly for solar panel frames. They enhance the efficiency and longevity of solar installations by providing a robust and lightweight support structure. For buyers in Africa and the Middle East, sourcing aluminum profiles that can withstand harsh environmental conditions is vital. Additionally, customization options can help tailor solutions to specific project needs, maximizing energy output.

What Role Do Aluminum Profiles Play in Transportation and Logistics?

In the transportation and logistics sector, aluminum profiles are commonly used for cargo containers and pallets. Their strength and reduced weight allow for better payloads, leading to cost savings in shipping and handling. International buyers must ensure that the sourced profiles comply with safety standards and load capacities, particularly in Europe and South America, where regulations can be stringent. Proper certification can enhance operational efficiency and safety in logistics operations.

Related Video: How it’s Made: Aluminum Extrusion Profiles | Lynch Metals

3 Common User Pain Points for ‘aluminum profile china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges with Aluminum Profiles from China

The Problem: One of the most pressing concerns for B2B buyers sourcing aluminum profiles from China is the inconsistency in product quality. Buyers often face issues with the strength, thickness, and finish of the aluminum profiles, which can lead to project delays, increased costs, and dissatisfaction from end clients. For instance, a manufacturer in Europe might receive a batch of profiles that don’t meet the required specifications, resulting in wasted time and resources to rectify the situation.

The Solution: To mitigate quality assurance challenges, it is crucial to establish a robust supplier evaluation process. Start by conducting thorough due diligence on potential suppliers, including reviewing their certifications, production capabilities, and quality control measures. Request samples before placing a bulk order to assess the quality firsthand. Additionally, consider utilizing third-party inspection services to conduct quality checks during production and prior to shipment. This proactive approach ensures that the aluminum profiles meet your specifications and can save both time and costs in the long run.

Scenario 2: Overcoming Communication Barriers in Sourcing Aluminum Profiles from China

The Problem: International buyers often encounter significant communication barriers when sourcing aluminum profiles from Chinese manufacturers. Misunderstandings related to product specifications, lead times, and payment terms can lead to frustration and contractual disputes. For instance, a buyer in South America may request specific dimensions only to receive profiles that are not only incorrect but also delivered late, impacting project timelines.

The Solution: To enhance communication effectiveness, establish clear, detailed specifications and expectations from the outset. Utilize visual aids such as CAD drawings or samples to convey your requirements accurately. Engage a local intermediary or sourcing agent who understands both the language and the cultural nuances of doing business in China. This intermediary can facilitate better communication and help bridge any gaps. Regular updates via video calls can also ensure that both parties are aligned throughout the sourcing process, minimizing the risk of miscommunication.

Scenario 3: Managing Supply Chain Disruptions When Importing Aluminum Profiles

The Problem: Supply chain disruptions are a common headache for B2B buyers, particularly when importing aluminum profiles from China. Factors such as geopolitical tensions, shipping delays, and increased freight costs can all lead to unexpected interruptions in supply, which can be detrimental to project timelines and budgets. A construction firm in the Middle East, for example, may find that delays in aluminum profile shipments halt their project progress, leading to potential penalties and financial losses.

The Solution: To manage potential supply chain disruptions, diversify your supplier base by establishing relationships with multiple manufacturers. This strategy allows you to pivot quickly if one supplier experiences delays. Implementing a just-in-time inventory system can also help maintain operations without overcommitting capital to excess stock. Furthermore, stay informed about global shipping trends and potential disruptions by subscribing to industry news and reports. Consider working with logistics companies that specialize in international shipping to better navigate complexities and optimize your supply chain management. By taking these steps, you can enhance resilience against disruptions and ensure smoother project execution.

Strategic Material Selection Guide for aluminum profile china

What Are the Key Properties of Common Materials for Aluminum Profiles from China?

When selecting aluminum profiles from China, international B2B buyers need to consider various materials that can affect product performance. The following analysis covers four common materials used in aluminum profiles, highlighting their properties, advantages, disadvantages, and implications for specific applications.

1. 6061 Aluminum Alloy

Key Properties:

6061 aluminum alloy is known for its excellent mechanical properties and good corrosion resistance. It has a temperature rating of up to 150°C and can withstand moderate to high pressure, making it suitable for structural applications.

Pros & Cons:

The primary advantage of 6061 is its versatility; it can be easily machined and welded. However, it is more expensive than some other alloys and may not be the best choice for applications requiring extreme strength.

Impact on Application:

This alloy is ideal for applications in the automotive and aerospace sectors, where weight reduction and strength are critical. It is compatible with various media, including water and mild chemicals.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and EN. The alloy’s popularity means that it is widely available, but buyers should verify the quality and certification of suppliers.

2. 6063 Aluminum Alloy

Key Properties:

6063 aluminum alloy is characterized by its excellent extrudability and surface finish. It has a lower strength compared to 6061 but offers good corrosion resistance and a temperature rating of around 140°C.

Pros & Cons:

The main advantage is its aesthetic appeal, making it suitable for architectural applications. However, its lower strength limits its use in structural components.

Impact on Application:

This alloy is commonly used in window frames, door frames, and other architectural structures. It is not recommended for high-stress applications but performs well in environments exposed to moisture.

Considerations for International Buyers:

International buyers should be aware of local building codes and standards, especially in Europe, where architectural aesthetics are often regulated. Ensuring the alloy meets local compliance standards is crucial.

3. 7075 Aluminum Alloy

Key Properties:

7075 aluminum alloy is one of the strongest aluminum alloys available, with a temperature rating of up to 120°C. It has excellent fatigue resistance and is often used in high-stress applications.

Pros & Cons:

The key advantage is its high strength-to-weight ratio, making it ideal for aerospace and military applications. However, it is more expensive and less corrosion-resistant compared to other alloys.

Impact on Application:

7075 is suitable for components that undergo significant stress, such as aircraft frames and military vehicles. Its compatibility with aggressive media is limited, requiring protective coatings in certain environments.

Considerations for International Buyers:

Buyers in the aerospace sector, particularly in regions like the Middle East, must ensure suppliers meet stringent quality standards such as AS9100. The higher cost may be justified by performance in critical applications.

4. 1050 Aluminum Alloy

Key Properties:

1050 aluminum alloy is known for its excellent corrosion resistance and high thermal conductivity. It has a lower strength rating but can operate effectively at temperatures up to 200°C.

Pros & Cons:

The significant advantage is its cost-effectiveness and ease of fabrication. However, its low strength makes it unsuitable for structural applications.

Impact on Application:

This alloy is often used in electrical applications and heat exchangers, where conductivity is essential. It is compatible with various media, including water and some chemicals.

Considerations for International Buyers:

Buyers in Africa and South America should focus on the alloy’s compliance with local electrical standards. Its affordability makes it an attractive option for projects with budget constraints.

Summary Table of Material Selection for Aluminum Profiles

| Material | Typical Use Case for aluminum profile china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum Alloy | Structural applications in automotive and aerospace | Versatile and easy to machine | Higher cost, moderate strength | High |

| 6063 Aluminum Alloy | Architectural applications (window and door frames) | Aesthetic finish and good extrudability | Lower strength | Medium |

| 7075 Aluminum Alloy | High-stress components in aerospace and military | High strength-to-weight ratio | Expensive, less corrosion-resistant | High |

| 1050 Aluminum Alloy | Electrical and heat exchanger applications | Cost-effective, high conductivity | Low strength | Low |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum profile china

What Are the Main Stages of Manufacturing Aluminum Profiles in China?

The manufacturing of aluminum profiles involves several critical stages that ensure quality and precision. Understanding these stages can help international B2B buyers identify reliable suppliers and assess their capabilities.

Material Preparation: How Is Aluminum Sourced and Processed?

Aluminum profiles typically begin with the sourcing of raw materials, primarily bauxite ore, which is processed to extract aluminum oxide through the Bayer process. This involves crushing the bauxite and treating it with sodium hydroxide to produce alumina. Once the alumina is obtained, it is subjected to electrolysis in a reduction cell to produce aluminum metal.

International buyers should inquire about the source of the bauxite and the supplier’s environmental practices, as these factors can influence the sustainability and quality of the final product.

Forming: What Techniques Are Used to Shape Aluminum Profiles?

Once the aluminum is produced, the next step is forming it into profiles. This is typically done through extrusion, where heated aluminum billets are forced through a die to create the desired shape. This process allows for complex geometries and is highly efficient, producing profiles with consistent dimensions.

Buyers should be aware of the different extrusion techniques, such as direct and indirect extrusion, as well as the potential impact on the material properties of the profiles. Additionally, some suppliers may offer customized profiles tailored to specific applications, which can be a significant advantage for buyers with unique requirements.

Assembly: How Are Aluminum Profiles Joined and Finished?

After the profiles are extruded, they often require assembly, especially in applications like construction or manufacturing. Common joining techniques include welding, riveting, and mechanical fastening.

Finishing processes, such as anodizing, powder coating, or painting, are also crucial for enhancing the corrosion resistance and aesthetic appeal of aluminum profiles. Buyers should inquire about the finishing options available, as these can significantly affect the durability and performance of the profiles in different environments.

What Quality Assurance Measures Are in Place for Aluminum Profiles?

Quality assurance (QA) is a vital component of aluminum profile manufacturing, ensuring that products meet international standards and customer specifications.

Which International Standards Should B2B Buyers Be Aware Of?

International standards play a crucial role in maintaining quality across the manufacturing process. The most relevant standards for aluminum profiles include:

- ISO 9001: This quality management standard ensures that manufacturers have robust processes in place to consistently produce quality products.

- CE Marking: Particularly important for products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: For industries such as oil and gas, adherence to American Petroleum Institute (API) standards is essential.

Buyers should ensure that their suppliers are compliant with these standards, as this can significantly reduce the risk of product failure and liability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are conducted to monitor the quality of the aluminum profiles.

- Final Quality Control (FQC): This final inspection ensures that the finished products meet all specifications and standards before they are shipped.

B2B buyers should request detailed QC reports from suppliers, as these documents can provide insights into the manufacturing process and any potential issues encountered.

Which Testing Methods Are Commonly Used in Aluminum Profile Manufacturing?

Various testing methods are employed to ensure the quality and performance of aluminum profiles:

- Mechanical Testing: This includes tensile strength tests, yield strength tests, and hardness tests to evaluate the material properties.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection can identify internal defects without damaging the product.

- Corrosion Testing: Accelerated corrosion tests help evaluate how the aluminum profiles will perform in different environmental conditions.

Understanding these testing methods can help buyers assess the reliability of their suppliers and the quality of the products they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control measures of potential suppliers is essential for B2B buyers looking to ensure product reliability and compliance.

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control practices. Buyers should:

- Request Documentation: Ask suppliers for their quality management system documentation, including ISO certifications, QC reports, and testing results.

- Conduct On-Site Audits: If feasible, visiting the manufacturing facility allows buyers to observe the production processes and QC measures in action.

- Engage Third-Party Inspectors: Hiring third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must be aware of specific nuances when it comes to quality control:

- Cultural Differences: Different regions may have varying approaches to quality management and compliance. Understanding these differences can help buyers navigate negotiations and expectations.

- Regulatory Compliance: Ensure that suppliers are aware of and compliant with the regulations in the buyer’s country, as this can impact product acceptance and marketability.

- Language Barriers: Clear communication is essential for quality assurance. Buyers should ensure that there are no language barriers that could lead to misunderstandings regarding specifications or quality requirements.

By taking these steps, international B2B buyers can effectively assess and verify the quality assurance practices of their aluminum profile suppliers in China, ensuring they make informed purchasing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum profile china’

The following practical sourcing guide is designed to assist international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, in effectively procuring aluminum profiles from China. This checklist will help streamline the sourcing process and ensure that you make informed decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical specifications of the aluminum profiles you need. This includes dimensions, alloy types, finishes, and any specific performance standards required for your application. Having precise specifications will facilitate accurate quotes and help prevent misunderstandings later in the process.

- Considerations:

- Determine the application of the aluminum profiles to identify suitable alloys.

- Document any industry standards that must be met.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in China. Utilize online platforms, trade fairs, and industry recommendations to compile a list of potential partners. Supplier reputation is critical, as it can directly impact the quality of the aluminum profiles you receive.

- Tips:

- Look for suppliers with certifications such as ISO 9001 to ensure quality management systems are in place.

- Pay attention to suppliers’ years of experience and customer reviews.

Step 3: Verify Supplier Certifications

Once you have shortlisted suppliers, verify their certifications and compliance with international standards. This step ensures that the supplier adheres to quality and safety regulations, which is crucial for maintaining your product’s integrity.

- Key Certifications:

- ISO 9001 for quality management.

- CE marking for compliance with EU regulations, if applicable.

Step 4: Request Samples

Before placing large orders, request samples of the aluminum profiles. This allows you to assess the quality, finish, and dimensions firsthand. Evaluating samples can prevent costly errors in your procurement process.

- What to Evaluate:

- Surface finish and color consistency.

- Dimensional accuracy compared to your specifications.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your chosen suppliers regarding pricing, payment terms, and delivery schedules. Clear communication during this phase can lead to more favorable terms and potentially lower costs.

- Negotiation Points:

- Ask about bulk order discounts and payment methods.

- Discuss lead times and shipping options to align with your production schedule.

Step 6: Conduct a Factory Audit

If feasible, perform a factory audit to evaluate the supplier’s production capabilities and quality control processes. This step is particularly important for larger orders to ensure the supplier can meet your demands consistently.

- Audit Checklist:

- Inspect the manufacturing equipment and processes.

- Review quality control measures and staff qualifications.

Step 7: Establish a Clear Contract

Finally, draft a clear contract that outlines all terms of the agreement, including specifications, pricing, delivery schedules, and penalties for non-compliance. A well-defined contract protects both parties and ensures accountability.

- Contract Essentials:

- Include detailed specifications and quality standards.

- Specify dispute resolution mechanisms to handle potential issues.

By following this step-by-step checklist, B2B buyers can enhance their sourcing strategy for aluminum profiles from China, ensuring quality products and reliable supplier partnerships.

Comprehensive Cost and Pricing Analysis for aluminum profile china Sourcing

What Are the Key Cost Components in Sourcing Aluminum Profiles from China?

When sourcing aluminum profiles from China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw aluminum, which fluctuates based on global market prices and sourcing from bauxite-rich regions. Buyers should consider the quality of the aluminum, as higher-grade materials can significantly influence overall pricing.

-

Labor: China’s competitive labor costs are a significant factor. However, the level of expertise required for specific manufacturing processes can vary, affecting labor costs. Skilled labor may command higher wages, particularly for custom or high-precision profiles.

-

Manufacturing Overhead: This encompasses factory operation costs, including utilities, equipment maintenance, and administrative expenses. Understanding these costs helps buyers gauge the efficiency of potential suppliers.

-

Tooling Costs: Custom molds and dies required for specialized profiles can add substantial upfront costs. Buyers should inquire about tooling costs and whether they can be amortized over larger orders.

-

Quality Control (QC): Ensuring product quality is vital, especially for industries requiring strict compliance with standards. QC costs may include inspections, testing, and certifications, which can be negotiated into the overall contract.

-

Logistics: Shipping costs from China to the destination country can vary based on freight methods (air vs. sea), distance, and shipping volume. Buyers should also consider customs duties and import taxes that may apply.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can help buyers negotiate more effectively.

How Do Price Influencers Affect Aluminum Profile Sourcing?

Several factors can influence the price of aluminum profiles sourced from China:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Larger orders typically reduce the per-unit cost, allowing for better margins.

-

Specifications and Customization: Custom profiles or unique specifications can lead to increased costs due to specialized tooling and manufacturing processes. Clear communication of requirements can help manage these costs.

-

Quality and Certifications: Profiles that require specific certifications (e.g., ISO, ASTM) may incur additional costs for testing and documentation. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will determine who bears the cost of shipping and insurance. Understanding these terms is essential for calculating the total landed cost.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

Effective negotiation is key for international buyers looking to maximize cost efficiency in aluminum profile sourcing:

-

Bulk Ordering: Leverage larger order volumes to negotiate better pricing. Suppliers are often more willing to offer discounts for bulk purchases.

-

Long-Term Partnerships: Building relationships with suppliers can lead to favorable terms and pricing over time. Consider establishing long-term contracts for consistent supply.

-

Transparency in Requirements: Clearly articulate your needs regarding specifications, quality, and delivery timelines. This can help suppliers provide more accurate quotes and minimize unexpected costs.

-

Total Cost of Ownership: Focus not just on the purchase price but also on the total cost of ownership, including shipping, duties, and maintenance. This broader view can lead to smarter sourcing decisions.

Why Is It Important to Understand Pricing Nuances for International B2B Buyers?

International B2B buyers must navigate various pricing nuances when sourcing from China. Factors like currency fluctuations, trade policies, and regional economic conditions can all impact costs. Additionally, understanding local market dynamics in regions such as Africa, South America, the Middle East, and Europe can provide insights into negotiating better deals.

Buyers should also be aware of indicative prices that may fluctuate based on the market, ensuring they remain adaptable and informed throughout the sourcing process. By understanding these complexities, buyers can make strategic decisions that align with their business objectives and budget constraints.

Alternatives Analysis: Comparing aluminum profile china With Other Solutions

Exploring Alternatives to Aluminum Profile China

In the global B2B market, buyers are often faced with numerous material options that can fulfill their structural and design needs. While “aluminum profile China” is a popular choice due to its lightweight, corrosion resistance, and versatility, it’s essential to evaluate other viable alternatives to make informed purchasing decisions. This section compares aluminum profiles sourced from China with two alternatives: steel profiles and fiberglass composites.

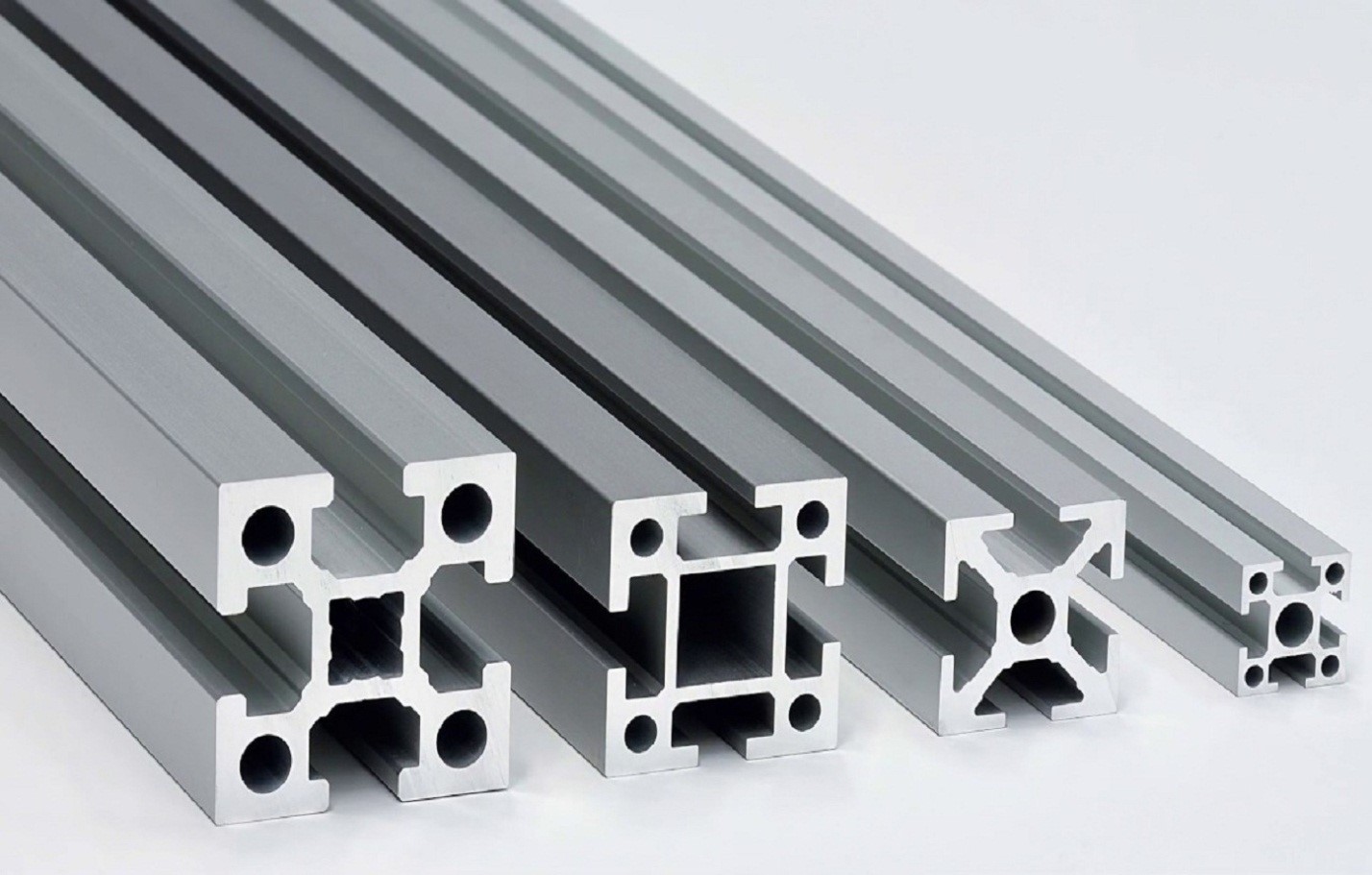

A stock image related to aluminum profile china.

Comparison Table of Alternatives

| Comparison Aspect | Aluminum Profile China | Steel Profiles | Fiberglass Composites |

|---|---|---|---|

| Performance | High strength-to-weight ratio; good corrosion resistance | Very strong; can rust if not treated | Lightweight; good chemical resistance |

| Cost | Generally lower due to mass production | Higher due to raw material costs | Moderate; cost-effective for specific applications |

| Ease of Implementation | Easy to fabricate and install | Requires skilled labor for welding and cutting | Can be complex to mold and shape |

| Maintenance | Low maintenance; resistant to corrosion | Moderate; requires protective coatings | Very low; resistant to environmental wear |

| Best Use Case | Construction, automotive, electronics | Heavy-duty construction, infrastructure | Marine applications, automotive, and construction where weight is critical |

Detailed Breakdown of Alternatives

Steel Profiles: Are They Worth the Investment?

Steel profiles are known for their unmatched strength and durability, making them a preferred choice in heavy-duty applications such as construction and infrastructure. However, they can be prone to rust if not properly treated, which can lead to higher maintenance costs over time. While steel tends to be more expensive than aluminum profiles, its superior strength makes it indispensable for projects requiring high load-bearing capacities. Buyers should consider the long-term costs associated with maintenance and protective coatings when evaluating steel as an option.

Fiberglass Composites: A Lightweight Option with Unique Advantages

Fiberglass composites are increasingly popular due to their lightweight nature and excellent resistance to corrosion and chemicals. These materials are particularly suited for marine applications and environments where exposure to harsh elements is common. However, the complexity involved in shaping and molding fiberglass can lead to higher initial fabrication costs. While they offer significant weight savings compared to metals, buyers must assess whether the specific performance characteristics of fiberglass composites align with their project requirements.

Conclusion: How to Choose the Right Material for Your Needs

When selecting between aluminum profile China, steel profiles, and fiberglass composites, B2B buyers must consider several factors, including the intended application, budget constraints, and long-term maintenance requirements. Aluminum profiles are an excellent choice for projects that prioritize weight and corrosion resistance, while steel is better suited for heavy-duty applications. Fiberglass composites may offer the best of both worlds in specific environments but require careful consideration of fabrication processes. Ultimately, understanding the unique attributes of each material will empower buyers to make choices that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for aluminum profile china

What Are the Key Technical Properties of Aluminum Profiles from China?

When considering aluminum profiles from China for your business needs, understanding the technical specifications is crucial. Here are several key properties to consider:

1. Material Grade

Aluminum profiles are classified into various grades, often indicated by the series number (e.g., 6061, 6063). Each grade has unique properties such as strength, corrosion resistance, and weldability. For instance, 6063 is commonly used for architectural applications due to its excellent extrudability and surface finish. Choosing the right grade ensures that the profile meets your specific application requirements.

2. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. It is critical in ensuring that the aluminum profiles fit precisely into their intended applications. Standard tolerances for aluminum extrusions can range from ±0.1 mm to ±0.5 mm, depending on the profile’s complexity and intended use. Accurate tolerances minimize the risk of assembly issues, enhancing overall product quality.

3. Surface Finish

The surface finish of aluminum profiles can significantly impact their aesthetic appeal and performance. Common finishes include anodized, powder-coated, and mill finish. Anodized finishes provide enhanced corrosion resistance and durability, while powder coating offers a wide range of colors and textures. Selecting the appropriate finish not only affects appearance but also influences the material’s longevity and maintenance requirements.

4. Weight Load Capacity

Understanding the weight load capacity of aluminum profiles is essential for structural applications. This property is determined by factors such as the profile’s geometry and material thickness. Profiles designed for heavy loads must be engineered to withstand specific stress levels without deformation. Accurately assessing weight capacity helps in ensuring safety and compliance with industry standards.

5. Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. However, the level of corrosion resistance can vary based on the alloy and surface treatment. For applications in harsh environments, such as coastal areas, selecting profiles with enhanced corrosion resistance is vital to prevent premature failure and reduce maintenance costs.

What Are Common Trade Terms in the Aluminum Profile Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms used in the trade:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. In the aluminum profile industry, an OEM partner can provide customized solutions tailored to specific client needs. Understanding OEM relationships can help you identify the right manufacturers for your projects.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is critical for international buyers, as it can impact inventory management and cost efficiency. Being aware of MOQs helps you plan your purchases effectively and negotiate better terms.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers, submitting an RFQ is a vital step in sourcing aluminum profiles, as it allows you to compare options and make informed decisions based on cost and delivery terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for clarifying who is responsible for shipping, insurance, and tariffs. Proper knowledge of Incoterms can prevent misunderstandings and ensure smoother transactions.

5. Extrusion

Extrusion is the manufacturing process used to create aluminum profiles by forcing molten aluminum through a shaped die. This process allows for the production of complex shapes and is widely used in various applications, from construction to automotive. Knowing about extrusion helps you appreciate the capabilities and limitations of aluminum profiles.

By understanding these essential properties and trade terms, international B2B buyers can navigate the aluminum profile market more effectively, ensuring they make informed purchasing decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the aluminum profile china Sector

What Are the Current Market Dynamics and Key Trends in the Aluminum Profile Sector?

The global aluminum profile market is experiencing notable growth, driven by increasing demand in sectors such as construction, automotive, and aerospace. As urbanization accelerates in regions like Africa and South America, the need for lightweight yet durable materials is on the rise. In Europe and the Middle East, sustainability initiatives are prompting industries to seek out aluminum solutions that meet stringent environmental regulations. This shift is fueled by innovations in B2B technologies, including automation and digital procurement platforms, enabling international buyers to streamline sourcing processes and enhance supply chain efficiency.

Emerging trends indicate a significant shift towards customization and flexibility in aluminum profiles. Manufacturers in China are leveraging advanced manufacturing technologies, such as 3D printing and CNC machining, to produce tailored solutions that meet specific client requirements. For international buyers, this means more opportunities to acquire unique, high-quality products that can differentiate their offerings in competitive markets. Additionally, the rise of e-commerce platforms in the B2B sector is reshaping how buyers interact with suppliers, making it easier to compare products and prices across different manufacturers.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Aluminum Procurement?

Sustainability is becoming a critical factor for international buyers in the aluminum profile sector. The environmental impact of aluminum production, particularly concerning energy consumption and greenhouse gas emissions, is prompting companies to adopt more sustainable practices. As a result, ethical sourcing is not just a trend but a necessity for businesses aiming to build a responsible brand image.

Buyers should prioritize suppliers that adhere to recognized sustainability standards and certifications. Look for “green” certifications such as ISO 14001 for environmental management and the Aluminium Stewardship Initiative (ASI) certification, which ensures responsible production practices. Additionally, sourcing recycled aluminum can significantly reduce the carbon footprint associated with new aluminum production, as recycling requires only 5% of the energy needed to produce primary aluminum. By integrating these considerations into procurement strategies, international buyers can contribute to a more sustainable aluminum industry while also meeting consumer demand for environmentally friendly products.

How Has the Aluminum Profile Market Evolved Over Time?

The aluminum profile market has a rich history, evolving significantly since the first commercial production of aluminum in the 19th century. Initially used primarily for its lightweight and corrosion-resistant properties, aluminum profiles have become essential in diverse applications, from building facades to automotive components.

In the late 20th century, advancements in production techniques, such as extrusion and rolling, enabled manufacturers to produce a wider variety of profiles, catering to specific industry needs. Today, China stands as a global leader in aluminum production, leveraging its extensive resources and manufacturing capabilities to supply an increasingly demanding international market. The historical evolution of aluminum profiles underscores their adaptability and the ongoing innovation within the sector, making them a vital component for contemporary engineering and design solutions.

By understanding these dynamics, international buyers can make informed decisions and strategically source aluminum profiles that align with their business goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum profile china

-

How do I select the right aluminum profile supplier in China?

To select the right aluminum profile supplier in China, start by researching potential suppliers online through platforms like Alibaba or Global Sources. Look for suppliers with verified credentials, positive reviews, and a history of successful transactions. Request samples to evaluate the quality of their aluminum profiles. Additionally, consider suppliers who can provide customization options that meet your specific needs, and verify their production capacity to ensure they can handle your order volume. -

What is the minimum order quantity (MOQ) for aluminum profiles from China?

The minimum order quantity (MOQ) for aluminum profiles from Chinese suppliers can vary significantly, often ranging from 100 kg to several tons. Smaller suppliers may have lower MOQs, while larger manufacturers may require higher volumes. Always inquire about the MOQ when negotiating with suppliers, as some may be flexible, especially for first-time buyers or larger orders. Understanding your project requirements will help you choose a supplier that aligns with your needs. -

What customization options are available for aluminum profiles sourced from China?

Many Chinese suppliers offer a wide range of customization options for aluminum profiles, including varying dimensions, shapes, surface treatments, and finishes. Common customizations include anodizing, powder coating, and machining. When contacting suppliers, provide detailed specifications and drawings to ensure they understand your requirements. This will enable them to give you accurate quotes and timelines for your customized aluminum profiles. -

What payment terms should I expect when sourcing aluminum profiles from China?

Payment terms when sourcing aluminum profiles from China typically include options like T/T (telegraphic transfer), L/C (letter of credit), or PayPal. Many suppliers may require a deposit (usually 30%) upfront, with the balance payable before shipment. It’s crucial to clarify payment terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially for large transactions. -

How can I ensure quality assurance when purchasing aluminum profiles from China?

To ensure quality assurance, request a detailed quality control plan from your supplier. Ask for third-party inspections before shipment, which can include checks for dimensions, surface quality, and mechanical properties. Establish clear quality standards in your purchase agreement, and consider visiting the supplier’s facility if feasible. Utilizing certifications, such as ISO 9001, can also indicate a supplier’s commitment to quality management practices. -

What logistics considerations should I be aware of when importing aluminum profiles from China?

When importing aluminum profiles from China, consider logistics factors such as shipping methods, lead times, and customs clearance. Sea freight is the most cost-effective method for large shipments, while air freight is faster but more expensive. Ensure your supplier provides all necessary shipping documents, including the bill of lading and customs declarations. Familiarize yourself with your country’s import regulations to avoid delays at customs. -

What are the common applications for aluminum profiles in international markets?

Aluminum profiles are widely used in various industries, including construction, automotive, and electronics. In construction, they are used for window frames, doors, and structural components. In the automotive sector, aluminum profiles contribute to lightweight vehicle designs, improving fuel efficiency. Understanding the applications relevant to your industry will help you communicate effectively with suppliers and ensure you select the right products for your projects. -

How do I handle language barriers when sourcing aluminum profiles from China?

Language barriers can be challenging when sourcing aluminum profiles from China. To mitigate this, consider using suppliers who have English-speaking staff or hiring a local agent who can facilitate communication. Utilize translation tools or services for written correspondence. Ensure that technical specifications and contractual terms are clearly understood by both parties to avoid miscommunications that could impact your order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum profile china

In the realm of international trade, particularly for aluminum profiles sourced from China, strategic sourcing has emerged as an essential practice for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. By leveraging China’s advanced manufacturing capabilities and competitive pricing, businesses can enhance their supply chain resilience and optimize their operational efficiency.

How Can B2B Buyers Enhance Their Sourcing Strategies?

To maximize value, international buyers should focus on building strong relationships with suppliers, ensuring quality control, and understanding the dynamics of pricing fluctuations influenced by global market trends. Additionally, embracing sustainable practices, such as sourcing recycled aluminum, can not only reduce environmental impact but also mitigate risks associated with raw material price volatility.

What Does the Future Hold for Aluminum Profile Sourcing?

Looking ahead, the demand for aluminum profiles is expected to grow due to their versatility and application across multiple industries, including construction, automotive, and aerospace. B2B buyers are encouraged to stay proactive by continuously evaluating supplier performance and exploring innovations in production techniques.

In conclusion, as the global market evolves, strategic sourcing of aluminum profiles from China presents significant opportunities for buyers. Now is the time to act—invest in robust sourcing strategies that align with your business goals and sustainability commitments, ensuring a competitive edge in an increasingly interconnected world.