Improve Quality & Cut Costs: Find a Sports Bra Manufacturer (2025)

Introduction: Navigating the Global Market for sports bra manufacturer

In today’s competitive landscape, sourcing high-quality sports bras that meet both comfort and performance standards presents a significant challenge for B2B buyers worldwide. As the demand for functional and stylish athletic wear continues to rise, particularly among women athletes, understanding the nuances of the sports bra manufacturing market is essential. This guide serves as a comprehensive resource for international B2B buyers, specifically targeting those from Africa, South America, the Middle East, and Europe, including countries like Mexico and Poland.

By exploring various types of sports bras—ranging from low to high support options—this guide will equip buyers with the knowledge needed to make informed decisions. Additionally, it addresses critical factors such as applications, supplier vetting processes, and cost considerations, ensuring that buyers not only find the right product but also partner with reputable manufacturers.

Navigating the global market for sports bras requires an understanding of regional preferences and trends, which can vary significantly across different continents. This guide empowers B2B buyers to leverage insights and data-driven strategies, ultimately enhancing their purchasing decisions and fostering successful business relationships in the evolving sports apparel industry. By being well-informed, buyers can align their selections with market demands, ensuring they offer products that resonate with their target audiences.

Understanding sports bra manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Sports Bras | Tight fit, minimizes movement, ideal for low-impact sports | Fitness apparel retailers | Pros: Affordable, good for beginners. Cons: May lack support for larger sizes. |

| Encapsulation Sports Bras | Individual cups for support, great for high-impact sports | Specialty athletic stores | Pros: Offers excellent support, suitable for various sizes. Cons: Higher price point. |

| Adjustable Sports Bras | Features adjustable straps and bands for a customized fit | Custom apparel manufacturers | Pros: Versatile sizing, tailored comfort. Cons: Complexity in inventory management. |

| Racerback Sports Bras | Back design prevents slipping, enhances freedom of movement | Sports teams and clubs | Pros: Great for active wear, stylish. Cons: May not suit all body types. |

| Wireless Sports Bras | No underwire, focuses on comfort, suitable for casual wear | E-commerce platforms | Pros: Comfortable for all-day wear. Cons: Less support for high-impact activities. |

What Are the Key Characteristics of Compression Sports Bras?

Compression sports bras are designed for a snug fit that minimizes breast movement during low-impact activities. They are often made from stretchy materials that provide support while allowing for a full range of motion. B2B buyers should consider the target market, as these bras are typically more suitable for smaller cup sizes. Their affordability makes them a popular choice for fitness apparel retailers looking to stock budget-friendly options.

How Do Encapsulation Sports Bras Provide Support?

Encapsulation sports bras feature individual cups that offer significant support, making them ideal for high-impact sports such as running or aerobics. They cater to a wider range of body types and sizes, which is essential for specialty athletic stores aiming to provide diverse options. Buyers should evaluate the quality of materials used, as well-constructed bras can enhance customer satisfaction and reduce return rates.

Why Choose Adjustable Sports Bras for Custom Fit?

Adjustable sports bras come equipped with features like adjustable straps and bands, allowing for a customized fit. This flexibility is particularly appealing to custom apparel manufacturers who prioritize comfort and fit in their offerings. However, managing inventory can be more complex due to the variety of adjustments available. B2B buyers should weigh the benefits of offering a tailored experience against the potential challenges in stock management.

What Makes Racerback Sports Bras Popular?

Racerback sports bras are designed to prevent slipping and enhance freedom of movement, making them a favorite among sports teams and clubs. Their stylish design also appeals to fashion-forward customers. However, B2B buyers should be aware that this design may not be suitable for all body types, potentially limiting market reach. Understanding customer preferences and fit is crucial when selecting this type of product.

How Do Wireless Sports Bras Cater to Comfort?

Wireless sports bras prioritize comfort by eliminating underwire, making them ideal for casual wear or low-impact activities. They are increasingly popular on e-commerce platforms, where customers seek versatile and comfortable options. While they provide comfort, buyers should note that these bras may offer less support for high-impact activities. Evaluating the target audience’s needs will help in selecting the right wireless options for retail.

Related Video: How To Pick The Right Sports Bra

Key Industrial Applications of sports bra manufacturer

| Industry/Sector | Specific Application of sports bra manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Apparel Retail | Custom-branded sports bras for retail chains | Enhanced brand visibility and customer loyalty | Quality certifications, customization options, and lead times |

| Fitness Centers & Gyms | Bulk purchasing for gym merchandise | Increased member satisfaction and loyalty | Pricing tiers, minimum order quantities, and material durability |

| E-commerce Platforms | Dropshipping sports bras for online stores | Lower inventory costs and flexibility in product offerings | Supplier reliability, shipping times, and product return policies |

| Athletic Teams & Clubs | Team-specific sports bras for athletes | Improved performance and team identity | Sizing accuracy, performance materials, and delivery timelines |

| Health & Wellness Programs | Sports bras as part of wellness initiatives | Promoting health and fitness, increasing participation | Compliance with health standards, educational resources, and pricing |

What Are the Key Applications of Sports Bras in the Sports Apparel Retail Sector?

In the sports apparel retail sector, manufacturers can provide custom-branded sports bras tailored to the unique needs of retail chains. This application enhances brand visibility and fosters customer loyalty, as consumers often prefer products that resonate with their favorite brands. International buyers should consider quality certifications to ensure product standards, customization options for branding, and lead times for production to meet seasonal demands.

How Can Fitness Centers and Gyms Benefit from Sports Bra Manufacturers?

Fitness centers and gyms often purchase sports bras in bulk to offer as merchandise to their members. This application helps increase member satisfaction and loyalty, as high-quality and stylish sports bras can enhance the gym experience. Key considerations for B2B buyers include pricing tiers for bulk orders, minimum order quantities to justify sourcing costs, and the durability of materials to withstand frequent use.

What Role Do E-commerce Platforms Play in Sourcing Sports Bras?

E-commerce platforms can leverage dropshipping arrangements with sports bra manufacturers to minimize inventory costs while expanding their product offerings. This flexibility allows online retailers to cater to diverse consumer preferences without the overhead of maintaining stock. Buyers should prioritize supplier reliability, shipping times to ensure quick delivery, and product return policies to maintain customer satisfaction.

How Do Athletic Teams and Clubs Utilize Sports Bras?

Athletic teams and clubs often require team-specific sports bras designed for their athletes, which can improve performance and reinforce team identity. This application is crucial for fostering a sense of unity among team members while ensuring they have the necessary support during activities. Buyers in this sector must focus on sizing accuracy, performance materials that enhance athletic capabilities, and timely delivery to align with training schedules.

What Are the Benefits of Incorporating Sports Bras in Health and Wellness Programs?

Sports bras can be integrated into health and wellness programs as part of initiatives aimed at promoting fitness and encouraging participation. This application not only supports women’s health but also enhances overall engagement in wellness activities. When sourcing for this purpose, buyers should ensure compliance with health standards, access to educational resources for participants, and competitive pricing to make the initiative sustainable.

Related Video: What are all the Laboratory Apparatus and their uses?

3 Common User Pain Points for ‘sports bra manufacturer’ & Their Solutions

Scenario 1: Quality Assurance in Production

The Problem:

B2B buyers often face significant challenges when it comes to ensuring that the sports bras produced meet quality standards. This is particularly crucial for brands looking to establish a reputation in competitive markets like Europe and the Middle East, where consumer expectations for product quality are high. Issues such as inconsistent sizing, fabric durability, and stitch quality can lead to high return rates and damage to brand reputation. Buyers may feel overwhelmed trying to communicate these specifications to manufacturers, especially if there are language barriers or cultural differences.

The Solution:

To mitigate these issues, buyers should implement a comprehensive quality assurance (QA) protocol. Start by conducting thorough research to identify manufacturers known for their commitment to quality. Request samples and conduct wear tests to evaluate durability, fit, and comfort. Establish clear specifications and standards that include material types, stitching methods, and sizing charts tailored to your target market’s demographics. Use technology, such as 3D modeling, to visualize product specifications before production begins. Additionally, consider partnering with manufacturers who have certification from recognized quality assurance bodies, ensuring adherence to international standards.

Scenario 2: Navigating Cultural Differences in Design Preferences

The Problem:

Buyers from different regions, such as Africa and South America, often encounter challenges in design preferences and cultural nuances when sourcing sports bras. What appeals to consumers in one market might not resonate in another. For instance, while vibrant colors and bold patterns may be popular in Brazil, a more subdued palette might be preferred in the UK. Misunderstanding these preferences can lead to unsold inventory and financial losses.

The Solution:

To address this issue, conduct market research that involves direct feedback from your target audience. Utilize surveys and focus groups to gather insights on design preferences, which can guide your discussions with manufacturers. Collaborate with local designers who understand the cultural context and can translate these insights into appealing designs. Additionally, consider offering a customizable range where consumers can choose colors and styles that resonate with them. This approach not only enhances customer satisfaction but also fosters brand loyalty and increases the likelihood of repeat purchases.

Scenario 3: Supply Chain Reliability and Timeliness

The Problem:

B2B buyers often experience delays in the supply chain when sourcing sports bras from manufacturers, which can disrupt inventory management and lead to lost sales opportunities. Factors such as transportation issues, raw material shortages, or production delays can significantly impact the timely delivery of products. In regions with less developed infrastructure, these challenges can be even more pronounced.

The Solution:

To ensure a reliable supply chain, buyers should prioritize establishing strong relationships with manufacturers who have a proven track record of timely deliveries. Implementing a vendor management system can help monitor supplier performance and identify potential issues before they escalate. Diversifying your supplier base can also mitigate risks; consider sourcing from multiple manufacturers across different regions to balance supply. Additionally, developing a clear communication strategy with manufacturers can streamline operations. Regular updates on production schedules and potential disruptions allow buyers to adjust their inventory plans proactively, ensuring that they can meet customer demand without delay.

Strategic Material Selection Guide for sports bra manufacturer

What Are the Best Materials for Sports Bra Manufacturing?

Choosing the right materials for sports bras is crucial for performance, comfort, and durability. Here, we analyze four common materials used in sports bra manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Polyester Perform in Sports Bra Manufacturing?

Key Properties: Polyester is known for its excellent moisture-wicking capabilities, making it ideal for high-performance sportswear. It is lightweight, quick-drying, and resistant to shrinking and stretching.

Pros & Cons: The durability of polyester is one of its strongest points, as it withstands repeated washings and retains its shape. However, it can be less breathable than other materials, which may lead to discomfort in hot climates. Additionally, while polyester is generally cost-effective, the price can vary based on the quality of the fabric.

Impact on Application: Polyester sports bras are suitable for a wide range of activities, from yoga to high-intensity workouts. However, in humid environments, the lack of breathability may be a concern for users.

Considerations for International Buyers: Compliance with international standards such as ASTM for fabric performance is essential. Buyers from regions with high humidity, like parts of Africa and South America, should consider blends that enhance breathability.

What Role Does Nylon Play in Sports Bra Manufacturing?

Key Properties: Nylon is recognized for its strength, elasticity, and resistance to abrasion. It also has good moisture-wicking properties, making it comfortable for extended wear.

Pros & Cons: The key advantage of nylon is its durability and ability to maintain shape, which is crucial for sports bras that require consistent support. However, nylon can be more expensive than polyester and may not be as environmentally friendly, depending on the production methods used.

Impact on Application: Nylon sports bras are particularly effective for activities requiring a high degree of movement, such as running or aerobics. The elasticity helps provide support without restricting movement.

Considerations for International Buyers: Buyers should be aware of the environmental regulations in their respective countries, especially in Europe, where sustainability is increasingly prioritized. Ensuring compliance with standards like REACH can enhance marketability.

Why Is Spandex Essential in Sports Bra Manufacturing?

Key Properties: Spandex, also known as elastane, is renowned for its exceptional elasticity. It can stretch up to five times its original length, making it an ideal choice for sports bras that need to provide support while allowing freedom of movement.

Pros & Cons: The primary advantage of spandex is its ability to offer a snug fit without compromising comfort. However, it can degrade over time with exposure to heat and chlorine, which may limit its lifespan in specific applications.

Impact on Application: Spandex is often blended with other materials to enhance stretch and recovery, making it suitable for high-impact sports bras. However, its sensitivity to heat may be a concern for manufacturers in warmer climates.

Considerations for International Buyers: Buyers should consider the climate of their target markets. In regions like the Middle East, where temperatures can soar, selecting blends that enhance durability against heat is crucial.

How Does Cotton Fit into Sports Bra Manufacturing?

Key Properties: Cotton is a natural fiber known for its softness and comfort. It is breathable and hypoallergenic, making it suitable for sensitive skin.

Pros & Cons: The comfort of cotton is unmatched, but it lacks the moisture-wicking properties of synthetic fabrics. This can lead to discomfort during intense workouts. Additionally, cotton tends to absorb moisture, which can make it heavy when wet.

Impact on Application: Cotton sports bras are best suited for low-impact activities or casual wear rather than rigorous workouts. They may be preferred in markets where comfort is prioritized over performance.

Considerations for International Buyers: Buyers should be aware of cotton’s environmental impact and consider sourcing organic cotton to meet sustainability demands, particularly in Europe where eco-consciousness is significant.

Summary Table of Material Selection for Sports Bra Manufacturing

| Material | Typical Use Case for Sports Bra Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | High-performance sports bras | Excellent moisture-wicking | Less breathable in humid climates | Medium |

| Nylon | High-movement activities | Durable and elastic | More expensive, less eco-friendly | High |

| Spandex | High-impact sports bras | Exceptional elasticity | Degrades with heat exposure | Medium |

| Cotton | Low-impact and casual wear | Soft and comfortable | Absorbs moisture, less durable | Low |

This guide provides international B2B buyers with essential insights into material selection for sports bras, ensuring they make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sports bra manufacturer

What Are the Main Stages of Manufacturing Sports Bras?

The manufacturing process of sports bras involves several critical stages, each designed to ensure quality, comfort, and durability. Understanding these stages can help international B2B buyers make informed decisions when sourcing from manufacturers.

Material Preparation: How Are Fabrics Selected and Processed?

The first stage in sports bra manufacturing is material preparation. High-performance fabrics, such as moisture-wicking polyester, nylon, or spandex blends, are commonly used due to their elasticity and breathability. Suppliers often conduct thorough market research to choose fabrics that meet specific performance criteria, such as stretchability, support, and moisture management.

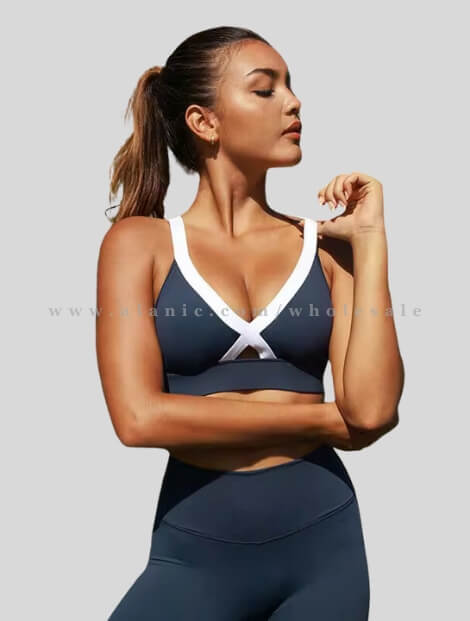

A stock image related to sports bra manufacturer.

Once materials are selected, they undergo several processes, including dyeing and finishing, to enhance their properties. The dyeing process should adhere to environmental regulations, especially for buyers from Europe, where REACH compliance is critical. Buyers should inquire about the sources of materials and the environmental impact of the dyeing processes to ensure they align with sustainability goals.

What Techniques Are Used in the Forming Stage of Sports Bra Manufacturing?

The forming stage includes cutting and shaping the fabric into the desired patterns for the sports bras. This stage typically employs advanced techniques such as digital pattern making and laser cutting, which enhance precision and minimize fabric waste.

Manufacturers should also utilize 3D prototyping to create samples that can be tested for fit and comfort. This is particularly important for B2B buyers who require a specific fit for their target demographic, as it allows for adjustments before mass production.

How Does the Assembly Process Work for Sports Bras?

Once the fabric pieces are cut, they proceed to the assembly stage. Here, sewing machines, including flatlock and coverstitch machines, are used to join the fabric pieces together. These machines provide durability and comfort, essential for activewear.

Quality manufacturers may implement automated sewing processes to increase efficiency while maintaining high standards. Additionally, skilled workers are crucial in this stage, as they ensure that the stitching is consistent and meets the design specifications. Buyers should assess the skill level of the workforce and inquire about training programs that ensure workers are up-to-date with the latest techniques.

What Finishing Techniques Are Common in Sports Bra Manufacturing?

The finishing stage is where sports bras undergo final touches to ensure they are ready for market. This can include adding tags, labels, and care instructions, as well as performing final inspections. Techniques such as heat sealing or bonding may be used to minimize chafing and enhance the comfort of the final product.

B2B buyers should pay attention to the finishing processes, as they significantly affect the product’s quality and consumer satisfaction. Manufacturers should also provide a comprehensive list of materials used in finishes to ensure compliance with international safety standards.

What Are the Key Quality Assurance Measures in Sports Bra Manufacturing?

Quality assurance (QA) is critical in the sports bra manufacturing process, ensuring that each product meets international standards and customer expectations. Understanding the QA measures can help B2B buyers verify the reliability of their suppliers.

Which International Standards Should Buyers Look For in Sports Bra Manufacturing?

International standards such as ISO 9001 are essential for manufacturers to demonstrate their commitment to quality management systems. Additionally, industry-specific certifications like CE marking in Europe and compliance with the American National Standards Institute (ANSI) guidelines can provide further assurance of product quality and safety.

For buyers from Africa and South America, it is crucial to ensure that manufacturers are compliant with local regulations and international standards, as this can significantly impact market access and consumer trust.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial stage inspects raw materials for compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages ensures that any defects are caught early, minimizing waste and rework.

-

Final Quality Control (FQC): This final inspection checks the finished products against quality standards before they are shipped to buyers.

B2B buyers should request detailed QC reports from manufacturers, which outline the processes and results of each checkpoint. This transparency helps build trust and ensures that the products meet the required standards.

What Testing Methods Are Commonly Used in Sports Bra Quality Assurance?

Manufacturers employ various testing methods to verify the performance and durability of sports bras, including:

- Tensile Strength Testing: Measures the fabric’s strength to withstand stretching.

- Moisture Management Testing: Assesses how effectively the fabric wicks moisture away from the body.

- Colorfastness Testing: Ensures that dyes do not fade or bleed during washing.

- Fit Testing: Involves wear testing by real users to assess comfort and performance in various activities.

Buyers should inquire about the specific testing methods used by their suppliers and request documentation of test results to validate product quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure the reliability of suppliers, B2B buyers should consider the following strategies:

-

Conduct Audits: Regular audits of manufacturing facilities can help assess compliance with quality standards and identify areas for improvement.

-

Request Quality Reports: Suppliers should provide comprehensive quality reports detailing their QC measures, testing results, and adherence to international standards.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased evaluation of the manufacturer’s processes and products.

-

Seek References and Reviews: Reaching out to other businesses that have worked with the manufacturer can provide insights into their reliability and quality standards.

By implementing these strategies, B2B buyers from Africa, South America, the Middle East, and Europe can ensure that they partner with manufacturers who prioritize quality and compliance, ultimately leading to successful business relationships and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sports bra manufacturer’

The procurement of sports bras requires careful consideration, especially for international B2B buyers looking to establish long-term relationships with manufacturers. This step-by-step checklist will guide you through the essential actions to ensure you select a reliable supplier that meets your quality, sustainability, and cost-effectiveness standards.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step to successful sourcing. This includes detailing the materials, sizes, styles, and performance features required for your sports bras. Consider factors such as moisture-wicking capabilities, breathability, and durability, which are crucial for sports apparel.

- Material Selection: Decide whether you want synthetic, natural, or blended fabrics.

- Design Features: Specify whether you need additional support structures, padding, or unique design elements.

Step 2: Research and Identify Potential Manufacturers

Once you have your specifications, conduct thorough research to identify potential manufacturers. Utilize industry directories, trade shows, and online platforms to compile a list of suppliers who specialize in sports apparel.

- Industry Reputation: Look for manufacturers with a strong presence in the sportswear market and positive reviews from past clients.

- Location Considerations: Factor in shipping logistics and tariffs that may impact overall costs, especially for buyers in Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Quality Assurance: Ask about their quality control processes and certifications, such as ISO standards.

- Production Capacity: Ensure the manufacturer can meet your order volumes and timelines.

Step 4: Verify Compliance with Ethical Standards

In today’s market, compliance with ethical manufacturing practices is non-negotiable. Verify that your potential supplier adheres to labor laws, environmental regulations, and sustainability practices.

- Certifications: Look for certifications like Fair Trade or OEKO-TEX Standard 100, which indicate ethical practices.

- Factory Audits: Consider conducting or requesting third-party audits to ensure compliance.

Step 5: Request Samples and Conduct Testing

Before finalizing your supplier, request samples of the sports bras you intend to order. Testing samples is essential to assess the quality, fit, and performance of the product.

- Functional Testing: Evaluate the bras under conditions they will be used, such as during exercise.

- Feedback Loop: Gather feedback from potential users to gauge comfort and usability.

Step 6: Negotiate Terms and Conditions

Once you are satisfied with the samples, proceed to negotiate the terms of your contract. This should include pricing, payment terms, lead times, and delivery schedules.

- Flexibility: Ensure there is room for negotiation on minimum order quantities and payment methods.

- Clear Deliverables: Specify quality expectations and consequences for non-compliance in your agreement.

Step 7: Establish a Communication Plan

Effective communication is vital for a successful partnership. Establish a clear communication plan that outlines how often you will interact with the manufacturer and through what channels.

- Regular Updates: Schedule regular check-ins to discuss production progress and any potential issues.

- Point of Contact: Designate a primary contact on both sides to streamline communication.

By following this checklist, international B2B buyers can navigate the complexities of sourcing sports bras more effectively, ensuring they partner with manufacturers who meet their business needs and values.

Comprehensive Cost and Pricing Analysis for sports bra manufacturer Sourcing

What Are the Key Cost Components in Sports Bra Manufacturing?

When sourcing sports bras, understanding the cost structure is essential. The main components include:

-

Materials: The choice of fabrics significantly impacts costs. High-performance materials like moisture-wicking polyester or elastane often command higher prices than standard cotton. For international buyers, consider sourcing from regions with lower material costs, but ensure the quality meets your market standards.

-

Labor: Labor costs can vary dramatically by region. In countries like Mexico and Poland, labor might be cheaper than in Western Europe, but you need to account for skill levels and labor regulations, which can affect production efficiency and quality.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Manufacturers in different regions may have varying overhead costs, influenced by local economic conditions and operational efficiencies.

-

Tooling: Custom designs may require specific tooling, which can increase initial costs. It’s crucial to balance the investment in tooling with the expected return from higher-priced products.

-

Quality Control (QC): Implementing a robust QC process can add to costs but is necessary to maintain product standards, especially for markets in Europe and North America, where regulatory compliance is strict.

-

Logistics: Shipping costs can fluctuate based on distance, shipping method, and current fuel prices. Choose the most efficient Incoterms to optimize costs, especially for international shipments.

-

Margin: Manufacturers typically add a profit margin to their costs, which can vary based on the supplier’s strategy and the competitive landscape.

How Do Price Influencers Affect Sports Bra Sourcing?

Several factors can influence the pricing of sports bras, impacting your sourcing decisions:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to lower per-unit costs. Establish clear expectations for MOQs with your suppliers to negotiate better pricing.

-

Specifications and Customization: Custom designs or specifications can increase costs. Understand the balance between customization and cost efficiency—sometimes, off-the-shelf products can serve your needs at a lower price point.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like OEKO-TEX or GOTS) can elevate costs but may also justify higher retail prices. Ensure that your suppliers can provide relevant certifications.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can influence pricing. Thoroughly vet suppliers to ensure they meet your quality and delivery expectations.

-

Incoterms: Choose appropriate Incoterms to clarify responsibilities in shipping and logistics. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of goods.

What Are the Best Buyer Tips for Negotiating Sports Bra Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, consider these actionable tips:

-

Negotiate Strategically: Leverage volume discounts and long-term contracts to negotiate lower prices. Understand the supplier’s cost structure to identify areas where you can push for concessions.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, duties, and potential tariffs. This comprehensive view can lead to smarter sourcing decisions.

-

Be Aware of Pricing Nuances: International sourcing can involve hidden costs such as currency fluctuations and import duties. Stay informed about these factors to avoid surprises that affect your budget.

-

Research Market Trends: Understanding regional market trends can provide leverage in negotiations. For example, if a particular fabric is trending, suppliers may be less inclined to lower prices due to increased demand.

-

Build Strong Relationships: Establishing a solid relationship with suppliers can lead to better pricing, priority service, and more favorable terms over time. Regular communication and feedback can foster trust and collaboration.

Conclusion

Sourcing sports bras involves a complex interplay of costs and pricing influences. By understanding these factors and employing strategic negotiation techniques, international B2B buyers can optimize their sourcing decisions, ensuring both quality and cost-effectiveness in their procurement processes. Always remember that prices may vary, and it’s wise to obtain multiple quotes to gauge the market accurately.

Alternatives Analysis: Comparing sports bra manufacturer With Other Solutions

When considering options for sourcing sports bras, international B2B buyers have several alternatives to traditional sports bra manufacturers. Each option comes with distinct advantages and disadvantages, making it essential to evaluate them based on various factors. Below is a comparison of sports bra manufacturers against two viable alternatives: custom apparel printing services and local textile suppliers.

Comparison Table of Sports Bra Manufacturing Alternatives

| Comparison Aspect | Sports Bra Manufacturer | Custom Apparel Printing Services | Local Textile Suppliers |

|---|---|---|---|

| Performance | High durability and support | Varies by print quality and fabric | Moderate durability, often lower support |

| Cost | Moderate to high per unit | Generally lower, but varies with volume | Low to moderate, depending on materials |

| Ease of Implementation | Requires minimum order quantity | Easy to set up with online platforms | May require negotiation and longer lead times |

| Maintenance | Minimal maintenance required | Dependent on fabric choice | May require quality checks |

| Best Use Case | Bulk orders for retail or branding | Small batch production and customization | Local markets or sustainable sourcing |

What Are the Pros and Cons of Custom Apparel Printing Services?

Custom apparel printing services provide an accessible alternative for businesses looking to offer unique sports bras. The primary advantage is the ability to customize designs quickly and with minimal upfront investment, making it ideal for small orders or limited runs. However, the performance of these bras can be inconsistent, depending heavily on the quality of materials used. While the costs are generally lower than traditional manufacturing, the durability and support may not meet the standards expected by serious athletes, which could limit their market appeal.

How Do Local Textile Suppliers Compare for Sports Bra Production?

Local textile suppliers can be an excellent choice for businesses seeking to produce sports bras with a focus on sustainability and regional sourcing. The advantages include potentially lower costs and shorter shipping times, as well as the opportunity to foster local economies. However, the trade-off often comes in the form of reduced performance, as many local suppliers may not specialize in high-performance sports fabrics. Additionally, the process can be more cumbersome, requiring negotiation on prices and quality assurance checks, which can complicate the supply chain.

Conclusion: How Can B2B Buyers Choose the Right Solution?

For international B2B buyers looking for sports bras, the choice between traditional manufacturers, custom apparel printing services, and local textile suppliers largely depends on their specific needs. If high performance and bulk production are priorities, partnering with established sports bra manufacturers is advisable. Alternatively, for businesses focusing on unique designs or smaller quantities, custom printing services may offer the flexibility required. Finally, local textile suppliers can be a viable option for those prioritizing sustainability and regional sourcing, albeit with some trade-offs in performance and quality. Assessing these factors will help buyers make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for sports bra manufacturer

What Are the Key Technical Properties of Sports Bras That Manufacturers Should Focus On?

When sourcing sports bras, international B2B buyers need to understand the essential technical properties that define product quality and performance. Here are some critical specifications to consider:

1. Material Composition

The choice of material significantly impacts the comfort, durability, and performance of a sports bra. Common materials include polyester, nylon, and spandex, each offering unique benefits. For instance, polyester is known for its moisture-wicking properties, while spandex provides excellent stretch and recovery. Understanding material composition helps buyers select products that meet specific customer needs, such as breathability for high-intensity workouts.

2. Support Level

Support level is categorized into three types: low, medium, and high. Low support bras are suitable for activities like yoga, while medium support is ideal for running or cycling, and high support is necessary for high-impact sports. This classification is crucial for buyers to ensure they are offering products that cater to their target market’s activity levels.

3. Size Tolerance

Size tolerance refers to the acceptable range of variation in dimensions and fit. For sports bras, maintaining precise size tolerances is vital for ensuring a proper fit across different body types. Inconsistent sizing can lead to dissatisfaction and increased return rates, making it essential for manufacturers to adhere to strict sizing standards.

4. Moisture Management

Moisture management properties dictate how well a fabric can wick away sweat and dry quickly. This feature is essential for maintaining comfort during physical activities. Buyers should look for bras with advanced moisture-wicking technologies, as these can enhance user experience and increase product value.

5. Breathability

Breathability refers to the ability of the fabric to allow air circulation, which is crucial during intense workouts. Fabrics with mesh panels or special weave techniques can enhance breathability. B2B buyers should prioritize breathable fabrics to ensure their products support athletes’ performance and comfort.

6. Durability and Care Instructions

Durability encompasses how well the sports bra can withstand wear and tear over time, including resistance to fading, stretching, and deformation. Understanding care instructions is also essential, as proper maintenance prolongs the life of the product. Buyers should seek manufacturers who provide clear guidelines on care to enhance customer satisfaction.

What Are Common Trade Terminology and Jargon in the Sports Bra Manufacturing Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation between buyers and manufacturers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of sports bras, buyers often work with OEMs to create custom designs or private-label products. Understanding OEM relationships can help buyers leverage manufacturing capabilities and streamline sourcing.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a manufacturer requires for a production run. This term is critical for buyers to ensure that they are ordering sufficient quantities to meet their sales forecasts while avoiding excess inventory. Knowing the MOQ helps in financial planning and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. It typically outlines details such as specifications, quantities, and delivery timelines. Using RFQs effectively can help buyers compare prices and select the best supplier based on their budget and needs.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to ensure clarity on shipping, insurance, and delivery responsibilities.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. It includes production time, shipping, and any potential delays. Knowing the lead time helps buyers plan their inventory and meet customer demand effectively.

6. Certification Standards

Certification standards refer to the various quality assurance benchmarks that products must meet to ensure safety and performance. Common certifications include OEKO-TEX® and GOTS (Global Organic Textile Standard). Buyers should look for manufacturers who comply with relevant certifications to guarantee product quality and sustainability.

A stock image related to sports bra manufacturer.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when sourcing sports bras, ultimately enhancing their product offerings and meeting customer expectations effectively.

Navigating Market Dynamics and Sourcing Trends in the sports bra manufacturer Sector

What Are the Key Market Dynamics and Trends Influencing Sports Bra Manufacturers?

The sports bra manufacturing sector is experiencing significant transformation driven by various global factors. The rising awareness of health and fitness, particularly in regions like Africa and South America, is spurring demand for high-quality activewear. In Europe, particularly in countries such as Poland, there is a growing trend towards inclusivity and body positivity, which manufacturers are beginning to embrace through diverse sizing and styles. Furthermore, technological advancements in fabric technology—such as moisture-wicking, breathable materials, and smart textiles—are becoming essential in product development.

International B2B buyers should also be aware of the increasing adoption of e-commerce platforms that facilitate direct-to-consumer sales, enabling brands to reach wider audiences. This trend is particularly evident in the Middle East, where online shopping is becoming a preferred method for purchasing activewear. Additionally, the rise of social media marketing, particularly on platforms like Instagram and TikTok, is influencing consumer purchasing decisions, urging manufacturers to align their marketing strategies accordingly.

Moreover, the ongoing impact of global supply chain challenges necessitates a focus on local sourcing and production. International buyers should consider partnerships with manufacturers who have established robust supply chains to mitigate risks associated with delays and material shortages.

How Is Sustainability Impacting B2B Sourcing for Sports Bra Manufacturers?

Sustainability has become a cornerstone of modern manufacturing practices, particularly in the sportswear sector. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact. This includes the use of recycled materials, such as polyester derived from plastic bottles, and the adoption of water-saving production techniques.

Ethical sourcing is another critical aspect that buyers should consider. Transparency in the supply chain is essential, as consumers are more inclined to support brands that adhere to fair labor practices and prioritize workers’ rights. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices.

Furthermore, adopting a circular economy approach—where products are designed for longevity and eventual recycling—can enhance brand reputation and consumer loyalty. Manufacturers that invest in sustainable practices not only contribute positively to the environment but also tap into a growing market of eco-conscious consumers, particularly in Europe and South America.

What Is the Historical Context of the Sports Bra Manufacturing Sector?

The sports bra manufacturing sector has evolved significantly since its inception in the 1970s. Originally designed as a functional garment, sports bras have transformed into a fashion statement, reflecting broader societal changes regarding women’s fitness and body image. Over the decades, manufacturers have innovated to enhance comfort, support, and style, leading to an explosion of options available today.

The rise of athleisure in the 2010s further propelled the market, blurring the lines between workout gear and everyday wear. International B2B buyers should recognize how this evolution has shaped consumer expectations and influenced sourcing trends. Understanding the historical context can provide valuable insights into current market dynamics and help buyers make informed decisions when partnering with manufacturers.

Frequently Asked Questions (FAQs) for B2B Buyers of sports bra manufacturer

-

How do I choose the right sports bra manufacturer for my business needs?

Selecting the right sports bra manufacturer requires thorough research and consideration of several factors. Start by evaluating the manufacturer’s experience in producing sports bras, including their production capacity and quality control measures. Look for manufacturers that specialize in the type of sports bras you want to offer, whether for high-impact sports or casual wear. Request samples to assess the quality and fit, and check customer reviews or references to gauge reliability. Additionally, consider the manufacturer’s ability to communicate effectively and respond to your specific needs and queries. -

What are the key factors to consider when sourcing sports bras from manufacturers in different regions?

When sourcing sports bras internationally, key factors include understanding local manufacturing capabilities, trade regulations, and shipping logistics. For buyers in Africa, South America, the Middle East, and Europe, consider the proximity to your market to reduce shipping costs and lead times. Evaluate the quality standards adhered to in each region, as these can vary widely. Additionally, assess the political and economic stability of the region, which could impact your supply chain, and ensure that the manufacturer complies with international labor laws and ethical standards. -

What are the minimum order quantities (MOQs) typically required by sports bra manufacturers?

Minimum order quantities (MOQs) for sports bras can vary significantly depending on the manufacturer and the complexity of the design. Typically, MOQs range from 100 to 1,000 units per style. However, some manufacturers may offer lower MOQs for specific styles or during promotional periods. It’s crucial to discuss MOQs upfront to understand the manufacturer’s flexibility and how it aligns with your business model. If you are a startup or entering a new market, look for manufacturers willing to negotiate MOQs to facilitate your entry into the market. -

How can I ensure quality assurance when sourcing sports bras from manufacturers?

To ensure quality assurance when sourcing sports bras, establish a robust vetting process. Request detailed information on the manufacturer’s quality control protocols, including certifications (e.g., ISO) and testing procedures. Conduct factory audits or hire third-party inspection services to verify compliance with your standards. Additionally, specify quality benchmarks in your contract, such as materials used, stitching techniques, and performance tests. Regular communication during the production process can also help address any concerns promptly and maintain quality standards. -

What customization options are typically available when ordering sports bras?

Most manufacturers offer a range of customization options for sports bras, including fabric selection, colors, sizes, and branding elements like logos and labels. Some may provide additional features such as padding, adjustable straps, or moisture-wicking materials. When discussing customization, provide clear specifications and samples of preferred designs to the manufacturer. Understand that extensive customization may impact production timelines and costs, so it’s important to balance your design aspirations with practical considerations. -

What payment terms should I expect when working with sports bra manufacturers?

Payment terms can vary widely among sports bra manufacturers, but common practices include a deposit upfront (typically 30-50%) with the balance due upon completion or before shipping. Some manufacturers may offer credit terms for established relationships. Always clarify payment methods accepted, which could include wire transfers, letters of credit, or payment platforms. It’s advisable to negotiate terms that align with your cash flow and risk management strategies, especially when dealing with international transactions. -

How do I handle logistics and shipping when sourcing sports bras from international manufacturers?

Logistics and shipping are crucial when sourcing sports bras internationally. Start by discussing shipping options with your manufacturer, including incoterms (e.g., FOB, CIF) to clarify responsibilities for costs and risks. Evaluate various shipping methods (air, sea, or land) based on your budget and timeline. Consider working with freight forwarders who can streamline the process and navigate customs regulations. Additionally, factor in lead times and potential delays to ensure timely delivery to your market. -

What are the best practices for establishing a long-term relationship with a sports bra manufacturer?

Building a long-term relationship with a sports bra manufacturer requires transparency and consistent communication. Establish clear expectations regarding quality, delivery timelines, and pricing from the outset. Regularly provide feedback on products and share insights about market trends to foster collaboration. Consider visiting the manufacturer’s facility to strengthen personal connections and understand their operations better. Lastly, ensure that any agreements are documented to avoid misunderstandings and to build trust over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sports bra manufacturer

What Are the Key Takeaways for Strategic Sourcing in Sports Bra Manufacturing?

In conclusion, effective strategic sourcing in the sports bra manufacturing sector is pivotal for international B2B buyers aiming to enhance their supply chain resilience and product quality. Key takeaways include the importance of evaluating suppliers not just on price but also on their ability to deliver innovative designs, sustainable materials, and ethical production practices. As the global demand for high-performance activewear continues to rise, understanding regional market trends and consumer preferences in Africa, South America, the Middle East, and Europe is essential.

How Can B2B Buyers Enhance Their Sourcing Strategy?

International buyers should prioritize building long-term relationships with manufacturers who can adapt to market changes and provide customized solutions. Emphasizing collaboration and transparency during negotiations can lead to better pricing and service agreements, ensuring that your brand remains competitive.

What Is the Future Outlook for Sports Bra Manufacturers?

Looking ahead, the sports bra market is poised for growth, driven by increasing health awareness and active lifestyles. By investing in strategic sourcing now, B2B buyers can position themselves favorably for future success. Embrace innovation and sustainability in your sourcing strategies to meet the evolving demands of consumers and differentiate your offerings in the marketplace. Engage with reliable manufacturers today to secure your supply chain for tomorrow’s opportunities.