Improve Quality: The Ultimate Guide to Cable Manufacturer (2025)

Introduction: Navigating the Global Market for Cable Manufacturer

In the complex landscape of global trade, sourcing high-quality cables can pose significant challenges for international B2B buyers. Whether you are a manufacturer in Africa, a contractor in South America, or a distributor in Europe, understanding the nuances of the cable manufacturing industry is essential for making informed purchasing decisions. This guide delves into the intricate world of cable manufacturing, covering various types of cables, their applications across multiple sectors, and the essential factors to consider when selecting a supplier.

Navigating the global market requires a keen understanding of not only product specifications but also the intricacies of supplier vetting and pricing structures. With a focus on empowering buyers from regions such as Colombia, Germany, the Middle East, and beyond, this comprehensive resource equips you with actionable insights to streamline your procurement process. We will explore how to assess quality, negotiate costs, and ensure compliance with international standards, enabling your business to thrive in a competitive marketplace.

By the end of this guide, you will be well-prepared to tackle the challenges of sourcing cables effectively, making decisions that enhance your operational efficiency and drive growth. Whether you’re dealing with technical requirements or logistical considerations, our aim is to provide you with the knowledge needed to succeed in your cable sourcing endeavors.

Understanding Cable Manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Copper Cable Manufacturers | Use of copper as a primary conductor; high conductivity and reliability. | Telecommunications, power distribution, networking. | Pros: Cost-effective, widely available. Cons: Prone to corrosion, less efficient over long distances. |

| Fiber Optic Cable Manufacturers | Utilizes glass or plastic fibers for data transmission; immune to electromagnetic interference. | High-speed internet, telecommunications, data centers. | Pros: High data capacity, long-distance transmission. Cons: Higher initial cost, requires specialized installation. |

| Specialty Cable Manufacturers | Custom-made cables for specific applications, such as high-temperature or chemical-resistant cables. | Aerospace, military, industrial automation. | Pros: Tailored solutions for unique needs. Cons: Potentially longer lead times and higher costs. |

| Industrial Cable Manufacturers | Focus on rugged designs for harsh environments; often includes armored cables. | Manufacturing, oil and gas, construction. | Pros: Durable and reliable in extreme conditions. Cons: Heavier and more expensive than standard cables. |

| Virtual Cable Manufacturers | Digital cables that facilitate audio and data transmission without physical connectors; often used in software applications. | Audio production, broadcasting, online communication. | Pros: Flexibility and ease of integration. Cons: Dependent on system compatibility and can experience latency issues. |

What Are the Characteristics of Copper Cable Manufacturers?

Copper cable manufacturers produce cables primarily made from copper, known for their excellent electrical conductivity. These cables are widely used in telecommunications, power distribution, and networking applications. When purchasing copper cables, B2B buyers should consider the cable’s gauge, insulation type, and potential for corrosion, as these factors can significantly impact performance and longevity.

How Do Fiber Optic Cable Manufacturers Stand Out?

Fiber optic cable manufacturers create cables that use glass or plastic fibers to transmit data as light signals. This technology is ideal for high-speed internet and telecommunications, particularly in data centers where large volumes of data need to be transmitted over long distances. Buyers should evaluate the type of fiber (single-mode vs. multi-mode) and the cable’s compatibility with existing infrastructure to ensure optimal performance.

What Should Buyers Know About Specialty Cable Manufacturers?

Specialty cable manufacturers focus on producing custom cables designed for specific applications, such as high-temperature resistance or chemical durability. These cables are essential in sectors like aerospace, military, and industrial automation, where standard cables may not suffice. B2B buyers should assess their unique requirements, lead times, and budget constraints when considering specialty cables, as these products can come at a premium.

What Are the Key Features of Industrial Cable Manufacturers?

Industrial cable manufacturers specialize in producing robust cables designed to withstand harsh environments, including extreme temperatures, moisture, and mechanical stress. These cables are commonly used in manufacturing, oil and gas, and construction industries. When selecting industrial cables, buyers should prioritize durability ratings, certifications, and the specific environmental conditions the cables will face to ensure reliability.

How Do Virtual Cable Manufacturers Operate?

Virtual cable manufacturers provide software-based solutions for audio and data transmission, eliminating the need for physical connectors. This technology is especially useful in audio production and broadcasting. Buyers should consider system compatibility, potential latency issues, and the flexibility of virtual cables when making their purchasing decisions, as these factors can significantly affect performance in professional settings.

Related Video: Amazing Electrical Cable Manufacturing Process. How an electrical cable is made?

Key Industrial Applications of Cable Manufacturer

| Industry/Sector | Specific Application of Cable Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Fiber optic cables for high-speed internet | Enhanced data transmission speeds and reliability | Compliance with international standards and certifications |

| Renewable Energy | Cables for solar panel and wind turbine connections | Improved energy efficiency and system longevity | Resistance to environmental factors and durability |

| Construction & Infrastructure | Electrical cables for buildings and infrastructure | Safety, compliance with regulations, and performance | Local compliance regulations and installation support |

| Automotive | Wiring harnesses for electric vehicles | Increased safety and performance in vehicles | Compatibility with various vehicle models and standards |

| Manufacturing & Automation | Control cables for machinery and robotics | Increased productivity and reduced downtime | Customization for specific machinery requirements |

How Are Fiber Optic Cables Used in Telecommunications?

In the telecommunications sector, fiber optic cables are essential for providing high-speed internet services. They enable data transmission over long distances without significant loss of signal quality. For international B2B buyers, especially in Africa and South America, sourcing fiber optic cables that comply with local and international standards is crucial. Buyers should consider the cable’s durability and resistance to environmental factors, as well as the manufacturer‘s certification to ensure reliability and performance.

What Role Do Cables Play in Renewable Energy Systems?

Cables are vital in the renewable energy sector, particularly for connecting solar panels and wind turbines. They ensure efficient energy transfer while minimizing energy loss. Buyers from regions like the Middle East and Europe should focus on cables designed to withstand extreme weather conditions and UV exposure. Additionally, sourcing cables that meet safety standards can enhance the longevity and reliability of renewable energy installations, making them a critical investment for businesses looking to expand in this sector.

How Are Electrical Cables Utilized in Construction and Infrastructure?

In construction and infrastructure projects, electrical cables are necessary for powering buildings and systems. They must meet rigorous safety and compliance standards to prevent hazards and ensure operational efficiency. B2B buyers in Europe and Africa should prioritize sourcing from manufacturers who provide installation support and comply with local regulations. Additionally, understanding the specific requirements for different applications, such as fire resistance and load capacity, is essential for making informed purchasing decisions.

Why Are Wiring Harnesses Important for Electric Vehicles?

Wiring harnesses are crucial for the automotive industry, especially with the rise of electric vehicles (EVs). They facilitate the safe and efficient transmission of power and data throughout the vehicle. Buyers should consider sourcing harnesses that are compatible with various EV models and comply with automotive standards. The focus on lightweight and durable materials can enhance vehicle performance and safety, making it a key consideration for international B2B buyers in this rapidly evolving market.

How Do Control Cables Improve Manufacturing and Automation?

Control cables are integral to machinery and robotics in manufacturing. They enable precise control and communication between different components, which can significantly increase productivity and reduce downtime. B2B buyers should look for manufacturers that offer customization options to meet specific machinery requirements. Additionally, sourcing cables that are resistant to abrasion and chemicals can enhance their longevity and performance in industrial environments, particularly in regions with demanding operational conditions.

Related Video: Fully automated cable harness production in the automotive industry (EN)

3 Common User Pain Points for ‘Cable Manufacturer’ & Their Solutions

Scenario 1: Supply Chain Disruptions Affecting Cable Availability

The Problem: B2B buyers in regions such as Africa and South America often face significant challenges with supply chain disruptions that lead to delays in cable availability. These disruptions can stem from political instability, transportation issues, or insufficient local inventory. For manufacturers relying on timely cable delivery for production or project completion, such delays can result in financial losses and damage to client relationships.

The Solution: To mitigate supply chain risks, B2B buyers should prioritize establishing relationships with multiple cable manufacturers and suppliers. Diversifying suppliers can ensure access to alternative sources in case of disruptions. Additionally, buyers should consider implementing just-in-time inventory practices, which can help maintain a balance between supply and demand without overstocking. It’s also advisable to engage in proactive communication with suppliers regarding their inventory levels and potential delays. Utilizing digital tools for real-time tracking of shipments can also enhance visibility and allow for quick adjustments to project timelines.

Scenario 2: Difficulty in Sourcing High-Quality Cables for Specific Applications

The Problem: Many buyers struggle to find cables that meet specific technical requirements, particularly when dealing with specialized applications such as telecommunications or industrial machinery. In regions like the Middle East and Europe, stringent regulations and standards can further complicate the sourcing process, leading to frustration and potential project delays.

The Solution: To address this issue, buyers should conduct thorough research to identify cable manufacturers that specialize in the required applications. Engaging with manufacturers who provide detailed product specifications, certifications, and compliance information can greatly facilitate the selection process. Furthermore, buyers should consider requesting samples or prototypes to evaluate the quality and performance of cables before committing to bulk orders. Building a collaborative relationship with manufacturers can also allow for customization options tailored to specific needs, ensuring that the cables used are not only compliant but also optimal for the intended application.

Scenario 3: Challenges with Installation and Compatibility of Cables

The Problem: Once cables are sourced, B2B buyers often encounter challenges during installation, particularly with ensuring compatibility with existing systems. This is especially common in complex environments, such as industrial plants or large-scale construction projects in Europe and South America. Incompatibility can lead to operational inefficiencies and additional costs for modifications.

The Solution: To overcome installation challenges, buyers should prioritize working closely with manufacturers who offer comprehensive technical support and guidance. Before purchasing, it is crucial to discuss installation requirements and compatibility with the manufacturer’s engineering team. Additionally, investing in training sessions for the installation team on the specific cables and systems can enhance overall efficiency. Utilizing simulation software can also help in planning the installation process by identifying potential compatibility issues in advance. Finally, establishing a feedback loop post-installation can help refine processes and address any unforeseen challenges that arise.

Strategic Material Selection Guide for Cable Manufacturer

When selecting materials for cable manufacturing, international B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. Below is an analysis of common materials used in cable manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

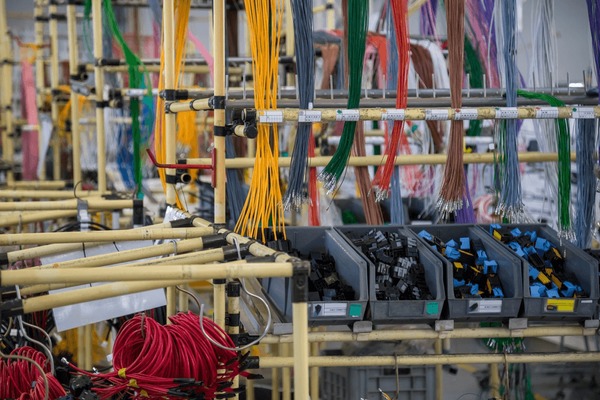

A stock image related to Cable Manufacturer.

What are the Key Properties of Copper in Cable Manufacturing?

Copper is a widely used material in cable manufacturing due to its excellent electrical conductivity and ductility. It typically has a temperature rating of up to 200°C and can withstand high pressure, making it suitable for various applications. Copper cables also exhibit good corrosion resistance, particularly when coated with protective materials.

Pros:

– High electrical conductivity ensures efficient power transmission.

– Ductility allows for easy bending and shaping during manufacturing.

– Good resistance to corrosion when properly treated.

Cons:

– Higher cost compared to aluminum and other materials.

– Susceptible to theft due to its high value.

– Requires careful handling to prevent damage during installation.

How Does Aluminum Compare as a Cable Material?

Aluminum is another common choice for cable manufacturing, particularly in overhead power lines due to its lightweight nature. It has a lower conductivity than copper but compensates with a lower cost and weight advantage. Aluminum cables typically have a temperature rating of around 90°C.

Pros:

– Lightweight, making installation easier and reducing structural load.

– Lower cost compared to copper, appealing for large-scale projects.

– Good corrosion resistance, especially when alloyed or treated.

Cons:

– Lower conductivity requires larger diameter cables to achieve the same performance as copper.

– More prone to oxidation, which can affect performance over time.

– Requires specialized connectors to ensure reliable connections.

What Role Does PVC Play in Cable Insulation?

Polyvinyl Chloride (PVC) is a popular insulating material used in cable manufacturing. It offers a temperature rating of up to 70°C and is known for its excellent mechanical properties and chemical resistance. PVC is also flame-retardant, making it suitable for various applications.

Pros:

– Cost-effective and widely available.

– Good flexibility and resistance to abrasion.

– Flame-retardant properties enhance safety in electrical applications.

Cons:

– Limited temperature range compared to other insulation materials like XLPE.

– Can release toxic fumes when burned.

– Environmental concerns regarding its production and disposal.

Why is XLPE Considered a Superior Insulation Material?

Cross-Linked Polyethylene (XLPE) is increasingly favored for high-performance cable insulation. It has a higher temperature rating of up to 90°C and excellent electrical properties. XLPE is also resistant to moisture and chemicals, making it suitable for harsh environments.

Pros:

– Superior thermal and electrical properties enhance performance.

– Excellent resistance to moisture and chemicals extends cable life.

– Lightweight and flexible, facilitating easier installation.

Cons:

– Higher manufacturing complexity and cost.

– Requires specific processing conditions, making it less accessible for some manufacturers.

– Limited compatibility with certain types of connectors.

What Should International Buyers Consider When Selecting Cable Materials?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local and international standards such as ASTM, DIN, and JIS. Understanding the specific requirements for electrical and mechanical properties in their region is crucial. Additionally, considerations around environmental regulations and material sourcing can impact long-term sustainability and cost-effectiveness.

| Material | Typical Use Case for Cable Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring in residential and commercial buildings | High conductivity ensures efficient power transmission | Higher cost compared to alternatives | High |

| Aluminum | Overhead power lines and large-scale electrical distribution | Lightweight reduces structural load | Lower conductivity requires larger cables | Medium |

| PVC | Insulation for low to medium voltage cables | Cost-effective and widely available | Limited temperature range compared to XLPE | Low |

| XLPE | High-performance insulation for power cables | Superior thermal and electrical properties | Higher manufacturing complexity and cost | High |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for cable manufacturing, allowing them to make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Cable Manufacturer

What Are the Main Stages of Manufacturing for Cable Manufacturers?

The manufacturing process for cables involves several key stages that ensure the final product meets the necessary specifications and quality standards. Understanding these stages is crucial for B2B buyers looking to source high-quality cable products.

-

Material Preparation: This initial stage involves selecting and preparing raw materials, which typically include copper or aluminum conductors and various insulating materials. The quality of these materials directly influences the performance and durability of the final product. Suppliers should provide documentation of material certifications, ensuring they meet international standards.

-

Forming: In this stage, the prepared materials are shaped into their desired forms. This includes processes such as drawing (to reduce the diameter of wires) and stranding (twisting multiple wires together). Advanced machinery, such as extrusion lines, is often used to create insulation layers around the conductors. B2B buyers should inquire about the technology used in forming processes, as modern equipment can enhance precision and consistency.

-

Assembly: Once the individual components are formed, they are assembled into the final cable structure. This may involve combining multiple conductors, adding shielding, and applying outer jackets. Automation plays a critical role in this stage, ensuring that assembly is efficient and minimizes human error. Buyers should assess the assembly process, focusing on how it aligns with their specific requirements for cable types and applications.

-

Finishing: The final stage involves applying any necessary coatings, labels, and packaging. This step is essential for ensuring that the cables are ready for distribution and meet safety regulations. Buyers should ensure that the manufacturer adheres to industry-specific packaging requirements, particularly if the cables will be shipped internationally.

How Is Quality Assurance Implemented in Cable Manufacturing?

Quality assurance (QA) is an integral part of the cable manufacturing process, ensuring that products meet both international and industry-specific standards. For B2B buyers, understanding these QA processes can help in evaluating potential suppliers.

-

International Standards Compliance: Many cable manufacturers adhere to ISO 9001 standards, which provide a framework for quality management systems. Compliance with these standards ensures that the manufacturer has established processes for continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for the European market or API (American Petroleum Institute) for oil and gas applications may be relevant.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection checks the quality of raw materials before they enter the production process.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that production adheres to specified standards.

– Final Quality Control (FQC): Once the cables are completed, a final inspection is performed to verify that they meet all specifications and quality standards. -

Common Testing Methods: Various testing methods are employed to assess the quality and performance of cables, including:

– Electrical Testing: Verifying electrical conductivity, insulation resistance, and dielectric strength.

– Mechanical Testing: Evaluating tensile strength and flexibility to ensure durability.

– Environmental Testing: Assessing the cable’s performance under different environmental conditions, such as temperature and humidity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure compliance and quality assurance:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. These audits should include evaluations of their adherence to international standards and their internal QC practices.

-

Request Documentation and Reports: Buyers should ask suppliers for documentation that demonstrates compliance with quality standards, including certificates of compliance, test reports, and quality management system documentation.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing and QC processes. These services can conduct independent audits and testing to verify the quality of the cables before shipment.

-

Understand QC Nuances for International Markets: Different regions may have specific regulations and standards that impact cable manufacturing. B2B buyers should familiarize themselves with these requirements, particularly when sourcing from international suppliers. For example, European buyers may need to ensure compliance with RoHS (Restriction of Hazardous Substances) regulations, while buyers in the Middle East may need to consider local safety standards.

What Are the Key Considerations for International B2B Buyers?

When sourcing cables from international manufacturers, several key considerations can impact the purchasing decision:

-

Supplier Reputation and Experience: Researching the supplier’s reputation and industry experience can provide assurance of their capabilities. Look for manufacturers with a proven track record and positive reviews from other B2B clients.

-

Customization Capabilities: Many projects require specialized cables tailored to specific applications. Ensure that the manufacturer can accommodate custom specifications without compromising quality.

-

Lead Times and Delivery: Understanding the manufacturer’s lead times for production and delivery is crucial for project planning. Confirm that they can meet your timelines, especially for large orders or urgent projects.

-

Pricing and Payment Terms: While price is an essential factor, it should not be the sole consideration. Evaluate the overall value offered by the supplier, including quality, service, and support. Establish clear payment terms to avoid misunderstandings.

By carefully evaluating these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Cable Manufacturer’

A stock image related to Cable Manufacturer.

In the quest for sourcing reliable cable manufacturers, international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, need a structured approach. This checklist will guide you through the essential steps to ensure that you select a manufacturer that meets your technical and business requirements.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical requirements. This includes the type of cables (e.g., power, data, or specialty cables), materials, and specific performance standards needed for your applications.

– Consider factors such as voltage ratings, insulation types, and environmental conditions where the cables will be used.

– Providing detailed specifications helps manufacturers understand your needs and prevents miscommunication.

Step 2: Conduct Market Research on Suppliers

Research potential cable manufacturers to understand their reputation and market presence. Use industry directories, trade shows, and online platforms to gather information.

– Look for reviews, testimonials, and case studies from other clients, particularly those in your region or industry.

– This will help you identify suppliers that are not only capable but also reliable and responsive.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assess their production capacity, quality assurance processes, and compliance with international standards.

– This step ensures that the supplier can meet your demands and deliver consistent quality.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the manufacturers you consider have the necessary certifications for quality and safety, such as ISO 9001 or UL certification.

– Compliance with local and international regulations is critical, especially for electrical products.

– Request documentation to verify their certifications and understand their commitment to quality control.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the cables you intend to buy. Testing these samples will help you assess their quality and performance under actual conditions.

– Evaluate the samples for durability, flexibility, and electrical performance.

– This hands-on approach minimizes risks and ensures that the product meets your specifications.

Step 6: Negotiate Pricing and Terms

Once you have shortlisted potential suppliers, initiate discussions about pricing, payment terms, and delivery schedules.

– Be clear about your budget but also consider the total cost of ownership, which includes shipping, customs, and potential tariffs.

– Negotiating favorable terms can lead to long-term partnerships and better pricing for future orders.

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Define how you will communicate with your supplier and establish regular check-ins.

– Use project management tools or dedicated communication platforms to track progress and address any issues promptly.

– This proactive approach fosters transparency and builds a strong working relationship.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process and establish partnerships with reliable cable manufacturers, ensuring high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for Cable Manufacturer Sourcing

What Are the Key Cost Components in Cable Manufacturing?

When sourcing cables from manufacturers, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The choice of materials significantly affects the cost. For instance, copper and aluminum are common conductors, but variations in purity and sourcing can lead to price fluctuations. Buyers should assess the quality and specifications of the materials used.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with higher labor costs may result in higher overall prices. Understanding local wage standards is essential for evaluating cost-effectiveness.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs. Manufacturers often calculate these costs into the unit price, so it’s important for buyers to inquire about overhead allocations.

-

Tooling: Investment in tooling can be significant, especially for custom cable designs. Buyers should ask about the tooling costs that might be passed on to them, particularly if they require unique specifications.

-

Quality Control (QC): Ensuring product quality is vital, and rigorous QC processes can add to costs. Buyers should consider the level of QC that the manufacturer employs and how it aligns with their quality requirements.

-

Logistics: Shipping and handling costs can vary widely depending on the manufacturer’s location and the Incoterms used. Buyers need to factor in these costs to understand the total pricing.

-

Margin: Manufacturers typically include a profit margin, which can vary based on market conditions and competition. Understanding the industry standard for margins can aid in negotiations.

How Do Price Influencers Affect Cable Manufacturing Costs?

Several factors can influence the pricing of cable manufacturing, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes often leads to discounts. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Custom cables with specific features or certifications typically incur higher costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO or UL) can increase costs but may be essential for compliance and safety in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a proven track record may charge more, but they often offer better quality assurance.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial as they dictate responsibility for shipping costs and risks. This can significantly impact the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Cable Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance cost-efficiency:

-

Negotiate Effectively: Leverage the volume of your orders and long-term partnerships to negotiate better pricing. Understanding the manufacturer’s cost structure can provide leverage during negotiations.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial price. TCO includes maintenance, operational costs, and potential downtime, which can be significantly affected by the quality of the cables sourced.

-

Explore Alternative Suppliers: Diversifying your supplier base can lead to competitive pricing. Evaluate manufacturers from different regions to compare costs and quality.

-

Request Detailed Quotes: Ask for itemized quotes that break down costs for materials, labor, and logistics. This transparency can help identify areas for potential savings.

-

Stay Informed About Market Trends: Keep abreast of material price trends and economic factors affecting the cable industry. This knowledge can aid in timing purchases to coincide with favorable pricing.

Disclaimer on Pricing

Prices for cable manufacturing can vary widely based on numerous factors outlined above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing Cable Manufacturer With Other Solutions

When considering a cable manufacturer for your B2B needs, it is essential to evaluate various alternatives that can fulfill similar functions. This analysis helps international buyers identify which solution best aligns with their operational requirements, budget constraints, and long-term goals. Below, we compare a traditional cable manufacturer against two viable alternatives: Fiber Optic Solutions and Wireless Communication Technologies.

Comparison Table of Cable Manufacturer and Alternatives

| Comparison Aspect | ‘Cable Manufacturer’ | Fiber Optic Solutions | Wireless Communication Technologies |

|---|---|---|---|

| Performance | High durability; suitable for long-distance transmission | Superior bandwidth and speed; minimal signal loss | Flexible and easy to deploy; dependent on environmental factors |

| Cost | Moderate initial investment; lower long-term maintenance costs | Higher upfront costs; lower operational costs over time | Variable costs; ongoing subscription fees for services |

| Ease of Implementation | Requires skilled labor for installation | Installation can be complex; specialized training may be needed | Quick setup; minimal technical expertise required |

| Maintenance | Regular inspections needed; repairs can be time-consuming | Low maintenance; infrequent issues arise | Requires regular updates and monitoring for optimal performance |

| Best Use Case | Industrial applications, data centers, and commercial buildings | High-speed internet, telecommunications, and data transfer | Short-range communication, IoT devices, and mobile networks |

What Are the Advantages and Disadvantages of Fiber Optic Solutions?

Fiber optic solutions utilize glass or plastic fibers to transmit data as light signals, providing exceptional bandwidth and transmission speed. The primary advantage of fiber optics is their ability to handle vast amounts of data over long distances with minimal signal degradation. This makes them ideal for telecommunications and internet service providers. However, the initial investment for fiber optic infrastructure can be significantly higher than that of traditional copper cables. Additionally, installation requires specialized skills, which may result in higher labor costs.

What Are the Pros and Cons of Wireless Communication Technologies?

Wireless communication technologies offer flexibility and ease of deployment, making them an attractive alternative for businesses that require mobility and quick setup. They are perfect for connecting IoT devices, enabling mobile communications, and providing internet access in remote areas. However, wireless solutions can be impacted by environmental factors such as physical obstructions and interference, potentially affecting performance. Furthermore, ongoing subscription fees for service can accumulate over time, making them less economical in the long run for some organizations.

How Should B2B Buyers Choose the Right Solution?

When choosing the right solution for your business, it is crucial to assess your specific needs, including the scale of your operations, budget, and desired performance levels. For businesses that require reliable, high-speed connections over long distances, fiber optic solutions may provide the best value despite the higher initial costs. On the other hand, if flexibility and rapid deployment are your priorities, wireless technologies might be the better choice. Ultimately, understanding the strengths and weaknesses of each option will enable you to make an informed decision that aligns with your strategic goals.

Essential Technical Properties and Trade Terminology for Cable Manufacturer

What Are the Essential Technical Properties for Cable Manufacturing?

When sourcing cables, international B2B buyers must understand key technical specifications that define the quality and suitability of the products for their intended applications. Here are some critical properties to consider:

-

Material Grade

– The material grade determines the cable’s conductivity, flexibility, and durability. Common materials include copper and aluminum. Copper cables are preferred for their superior conductivity, while aluminum is lighter and more cost-effective. Buyers should assess material grades based on their specific electrical and mechanical requirements. -

Conductor Size (AWG)

– The American Wire Gauge (AWG) system indicates the diameter of the conductor. Smaller gauge numbers correspond to thicker wires, which can carry more current. It is crucial for buyers to select the appropriate AWG to prevent overheating and ensure efficient power transmission. -

Insulation Type

– Different insulation materials (e.g., PVC, XLPE, Teflon) offer varying levels of resistance to heat, chemicals, and environmental factors. The choice of insulation affects both safety and performance. Understanding insulation types helps buyers select cables that meet industry standards and specific application requirements. -

Voltage Rating

– This specification indicates the maximum voltage the cable can handle safely. Selecting a cable with an appropriate voltage rating is essential to prevent electrical failures and ensure compliance with safety regulations. Buyers should consult with manufacturers to align voltage ratings with their operational needs. -

Temperature Rating

– The temperature rating defines the maximum operating temperature for the cable. Cables used in extreme conditions require higher temperature ratings. Buyers should consider the operating environment to ensure the longevity and reliability of the cables. -

Tensile Strength

– This property measures the cable’s resistance to being pulled apart. High tensile strength is crucial for applications involving heavy loads or where cables are subject to mechanical stress. Buyers should evaluate tensile strength to ensure cables can withstand the physical demands of their installations.

What Common Trade Terminology Should B2B Buyers Know?

Understanding industry jargon can significantly enhance the purchasing process. Here are some common terms that every B2B buyer should be familiar with:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For cable buyers, understanding OEM relationships can help identify quality sources and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ specifies the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budget management and inventory planning, particularly for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

– An RFQ is a document used to solicit price quotes from suppliers. Buyers should prepare detailed RFQs that specify technical requirements and quantities to ensure accurate pricing and prevent misunderstandings. -

Incoterms (International Commercial Terms)

– These are standardized international trade terms that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms helps buyers negotiate shipping costs and understand liability during transit. -

Lead Time

– Lead time refers to the amount of time between placing an order and receiving it. Understanding lead time is essential for planning and ensuring timely project execution, especially in industries where delays can impact operations. -

Certification Standards

– Various certification standards (e.g., ISO, UL) indicate compliance with safety and quality regulations. Buyers should prioritize suppliers who adhere to relevant certification standards to mitigate risks associated with product quality and safety.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure cables that meet their specific needs while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the Cable Manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Cable Manufacturing Sector?

The cable manufacturing sector is witnessing significant shifts driven by technological advancements, increasing demand for connectivity, and evolving industry standards. Global drivers such as the push for higher bandwidth capabilities, the proliferation of IoT devices, and the expansion of renewable energy projects are reshaping the landscape. Emerging technologies, including fiber optics and enhanced copper solutions, are at the forefront, catering to the growing needs of telecommunications and energy sectors.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe should closely monitor these trends. For instance, in Africa, there is a burgeoning demand for reliable power and telecommunications infrastructure, leading to increased sourcing of high-quality cables. Similarly, in South America, renewable energy projects are on the rise, creating a robust market for specialized cables designed for solar and wind energy systems. Meanwhile, European buyers are increasingly focused on compliance with stringent regulations regarding safety and environmental impact, driving the need for certified products.

Moreover, there is a notable shift towards digital sourcing platforms that facilitate easier access to manufacturers and suppliers globally. These platforms often provide real-time data analytics, helping buyers make informed decisions based on market trends and supplier performance. Buyers should leverage these technologies to streamline their procurement processes and enhance supply chain visibility.

How Does Sustainability and Ethical Sourcing Impact the Cable Manufacturing Industry?

Sustainability has become a critical focus for the cable manufacturing sector, particularly for B2B buyers concerned about environmental impact and corporate social responsibility. The production and disposal of cables often involve materials that can be harmful to the environment, prompting a shift towards sustainable practices. Manufacturers are increasingly adopting eco-friendly materials, such as recyclable plastics and low-impact copper sources, to minimize their carbon footprint.

Ethical sourcing is also gaining traction, with buyers demanding transparency throughout the supply chain. This includes ensuring that raw materials are sourced from suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and the Responsible Business Alliance (RBA) code of conduct are becoming vital for manufacturers aiming to appeal to conscientious buyers.

For international buyers, particularly those in Europe and North America, selecting suppliers with robust sustainability practices can enhance their brand reputation and meet regulatory requirements. In regions like Africa and South America, where sustainable development is increasingly prioritized, ethical sourcing can serve as a competitive advantage, enabling businesses to align with global sustainability goals while fostering local economic growth.

What Is the Evolution of the Cable Manufacturing Sector and Its Relevance to B2B Buyers?

The cable manufacturing sector has evolved significantly over the past few decades, transitioning from traditional materials and manufacturing processes to advanced technologies and sustainable practices. Initially dominated by copper-based cables, the market has seen a substantial shift towards fiber optic cables, driven by the demand for higher data transmission speeds and greater bandwidth capacity.

The advent of digital technologies and the Internet of Things (IoT) has further accelerated this evolution, necessitating innovations in cable design and functionality. Modern cables are not only designed for connectivity but also for enhanced durability and environmental sustainability.

For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions. As manufacturers continue to innovate, buyers must evaluate products based on their technological compatibility, sustainability credentials, and compliance with industry standards. This knowledge will empower buyers to select suppliers that align with their strategic goals and meet the demands of their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of Cable Manufacturer

- How do I solve issues with cable performance?

To troubleshoot cable performance issues, first ensure that the cables are properly connected and compatible with your equipment. Check for any visible damage or wear on the cables. If problems persist, consider testing the cables with different devices to isolate the issue. It may also be beneficial to consult the manufacturer’s specifications and support resources for guidance. If necessary, reach out to the supplier for further assistance or to explore warranty options.

-

What is the best type of cable for industrial applications?

The best type of cable for industrial applications often depends on the specific environment and requirements. For harsh conditions, look for cables that are rated for high durability and resistance to environmental factors like temperature, moisture, and chemicals. Common choices include armored cables for physical protection and heavy-duty flexible cables for dynamic applications. Always consult with your supplier for recommendations based on your unique operational needs. -

How can I verify the reliability of a cable manufacturer?

To verify the reliability of a cable manufacturer, conduct thorough research that includes checking their certifications, such as ISO or IEC standards. Request references or case studies from other clients, particularly those in your industry. Additionally, assess their quality assurance processes and warranty offerings. Engaging in direct communication to discuss their production capabilities and lead times can also provide insight into their reliability. -

What customization options are available when sourcing cables?

Many cable manufacturers offer customization options to meet specific business needs. Common customizations include variations in length, color, material, and connector types. Some manufacturers can even design cables for unique applications, such as high-temperature or low-voltage requirements. When discussing options with a supplier, be clear about your technical specifications and application needs to ensure they can accommodate your requests.

-

What are the typical minimum order quantities (MOQ) for cables?

Minimum order quantities (MOQ) for cables can vary widely depending on the manufacturer and the type of cable being ordered. Generally, MOQs can range from a few hundred to several thousand units. For specialized or custom cables, the MOQ may be higher. It’s important to discuss your requirements with potential suppliers to understand their MOQs and explore options for smaller orders if needed. -

What payment terms should I expect when sourcing cables internationally?

Payment terms for international cable sourcing typically include options such as advance payment, letters of credit, or payment upon delivery. The specific terms can vary based on the supplier’s policies, the order size, and your negotiation. It’s advisable to clarify payment terms upfront to avoid misunderstandings and ensure compliance with local regulations. Establishing clear terms also helps in building trust and facilitating smooth transactions. -

How do I ensure quality assurance in cable manufacturing?

Ensuring quality assurance in cable manufacturing involves several steps. First, verify that the manufacturer adheres to international quality standards. Request documentation related to quality control processes, such as testing protocols and inspection reports. Additionally, consider conducting on-site audits or third-party inspections to assess the manufacturing process. Establishing a clear communication channel with the supplier can also facilitate quality oversight throughout the production cycle. -

What logistics considerations should I keep in mind when importing cables?

When importing cables, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with the import/export requirements of your region. Be aware of potential tariffs or duties that may apply, and ensure that all necessary documentation is prepared in advance. It’s also wise to plan for delays by allowing extra time in your supply chain for unforeseen circumstances.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Cable Manufacturer

In the evolving landscape of cable manufacturing, strategic sourcing has emerged as a pivotal factor for international B2B buyers. Buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize partnerships with manufacturers that offer not only quality products but also robust supply chain management and competitive pricing. Engaging with reputable suppliers can enhance product reliability and ensure compliance with local regulations, fostering smoother operations and reducing risks associated with international trade.

How can B2B buyers leverage strategic sourcing for competitive advantage?

By adopting a strategic approach to sourcing, businesses can gain insights into market trends, optimize procurement processes, and enhance negotiation outcomes. This proactive stance enables buyers to stay ahead of market fluctuations and respond effectively to consumer demands.

As we look to the future, the demand for high-quality cables will continue to rise, driven by advancements in technology and infrastructure development. International buyers should seize this opportunity by evaluating their sourcing strategies and aligning them with manufacturers that demonstrate innovation and sustainability. Take action today—assess your current suppliers and explore new partnerships that can elevate your business in this dynamic market.