Improve Quality with the Ultimate Handles Supplier Guide (2025)

Introduction: Navigating the Global Market for handles supplier

Navigating the global market for handles suppliers presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. As businesses seek to source high-quality handles that meet specific design and functionality needs, the complexities of international supply chains can create hurdles. Understanding the nuances of selecting the right supplier is crucial for ensuring product quality, timely delivery, and cost-effectiveness.

This comprehensive guide delves into various aspects of sourcing handles, including the types available, their applications across different industries, and the critical process of supplier vetting. It also provides valuable insights into cost considerations and negotiation strategies, empowering B2B buyers to make informed decisions. By addressing key questions such as “What types of handles are best suited for my industry?” and “How can I assess the reliability of a supplier?”, this guide serves as a vital resource for businesses looking to enhance their purchasing strategies.

For buyers in regions like Italy and Poland, where craftsmanship and quality are paramount, understanding the global landscape can lead to better partnerships and improved product offerings. This guide not only equips you with the knowledge to navigate the complexities of the handles market but also positions you to leverage international opportunities effectively, ensuring your business remains competitive and responsive to market demands.

Understanding handles supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manufacturers | Produce handles from raw materials, large-scale | Furniture, construction, hardware | Pros: Customization, direct supply; Cons: Minimum order requirements, longer lead times. |

| Distributors | Resell handles from multiple manufacturers | Retail, wholesale, e-commerce | Pros: Variety of options, lower MOQ; Cons: Higher prices, less control over quality. |

| OEM Suppliers | Provide handles designed to client specifications | Automotive, electronics, appliances | Pros: Tailored solutions, integration support; Cons: Potentially higher costs, reliance on design accuracy. |

| Importers | Source handles from overseas markets | Export businesses, local retailers | Pros: Access to unique products, competitive pricing; Cons: Import duties, longer shipping times. |

| Specialty Suppliers | Focus on niche handle types (e.g., eco-friendly) | Specialty stores, artisanal markets | Pros: Unique offerings, targeted marketing; Cons: Limited availability, potentially higher costs. |

What are the key characteristics of manufacturers in the handles supply chain?

Manufacturers are the backbone of the handles supply chain, producing a wide range of products from raw materials. They typically cater to large-scale orders, making them suitable for businesses needing bulk quantities. When purchasing from manufacturers, B2B buyers should consider customization options, as many manufacturers can adapt their products to meet specific needs. However, buyers should be prepared for minimum order requirements and longer lead times, which may impact inventory management.

A stock image related to handles supplier.

How do distributors differ from other handles suppliers?

Distributors act as intermediaries, reselling handles from various manufacturers. They offer a diverse range of products, making them ideal for businesses that require flexibility and variety. Distributors often have lower minimum order quantities (MOQ), enabling smaller businesses to access a wider selection without committing to large orders. However, buyers should be cautious of potentially higher prices and less control over product quality compared to sourcing directly from manufacturers.

What advantages do OEM suppliers provide for B2B buyers?

Original Equipment Manufacturers (OEMs) create handles tailored to specific client requirements, making them a valuable partner for businesses in industries like automotive and electronics. Their ability to provide integrated solutions ensures that the handles fit seamlessly into existing products. While OEMs can offer highly customized solutions, buyers should be aware of potentially higher costs and the importance of clear communication regarding design specifications to avoid costly errors.

Why should businesses consider importing handles?

Importers specialize in sourcing handles from international markets, often providing access to unique products that are not available locally. This can be particularly beneficial for export businesses or local retailers looking to differentiate themselves. However, B2B buyers must consider the implications of import duties and longer shipping times, which can affect overall costs and delivery schedules.

What niche markets do specialty suppliers serve?

Specialty suppliers focus on specific types of handles, such as eco-friendly options or artisanal designs. They cater to niche markets and can offer unique products that appeal to specific customer segments. While these suppliers can help businesses stand out in a competitive landscape, buyers should be prepared for limited availability and potentially higher costs, which may not be suitable for all purchasing strategies.

Related Video: Different Types of Hinges – Choosing the Right Hinge for Your Application

Key Industrial Applications of handles supplier

| Industry/Sector | Specific Application of Handles Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Equipment Handles | Enhances ergonomics, reducing worker fatigue and improving efficiency. | Durability, load capacity, and compatibility with existing equipment. |

| Construction | Door and Window Handles | Increases security and ease of access in commercial and residential buildings. | Weather resistance, aesthetic design, and compliance with safety standards. |

| Logistics and Warehousing | Pallet and Container Handles | Facilitates easier handling and transportation of goods, improving operational efficiency. | Weight capacity, grip design, and material strength. |

| Automotive | Vehicle Door Handles | Enhances user experience and safety in vehicle operation. | Customization options, material durability, and compliance with automotive standards. |

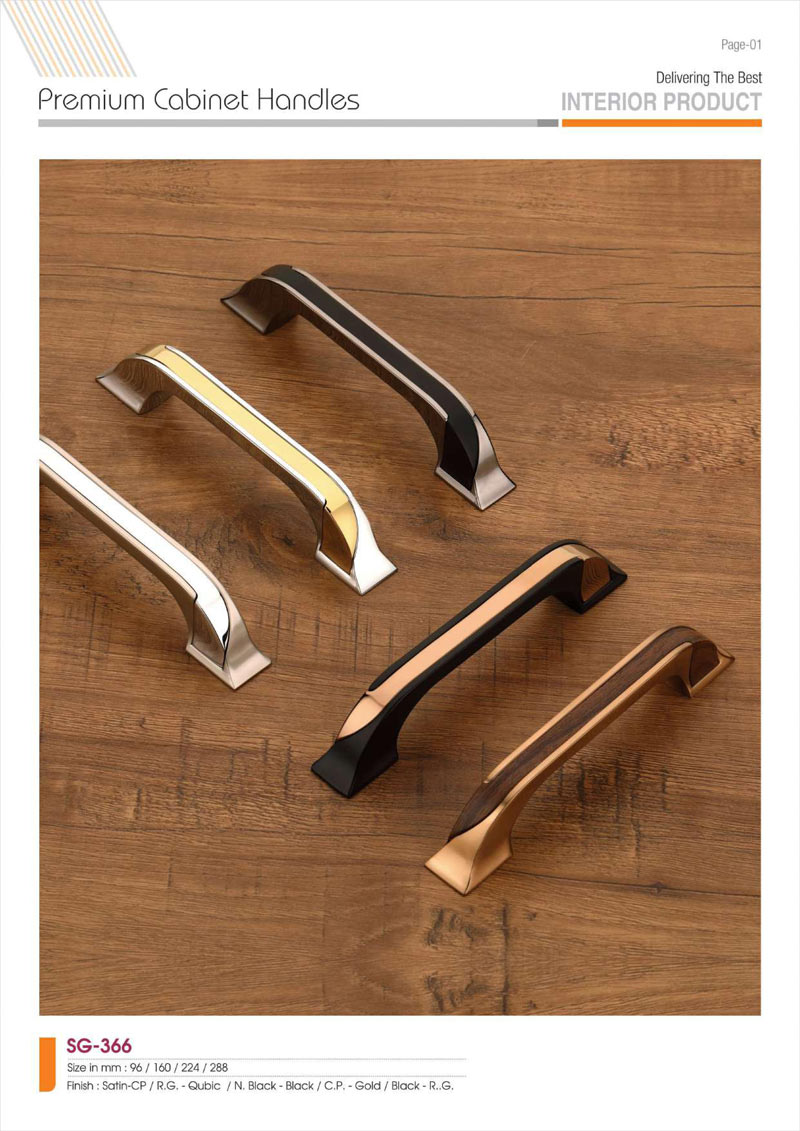

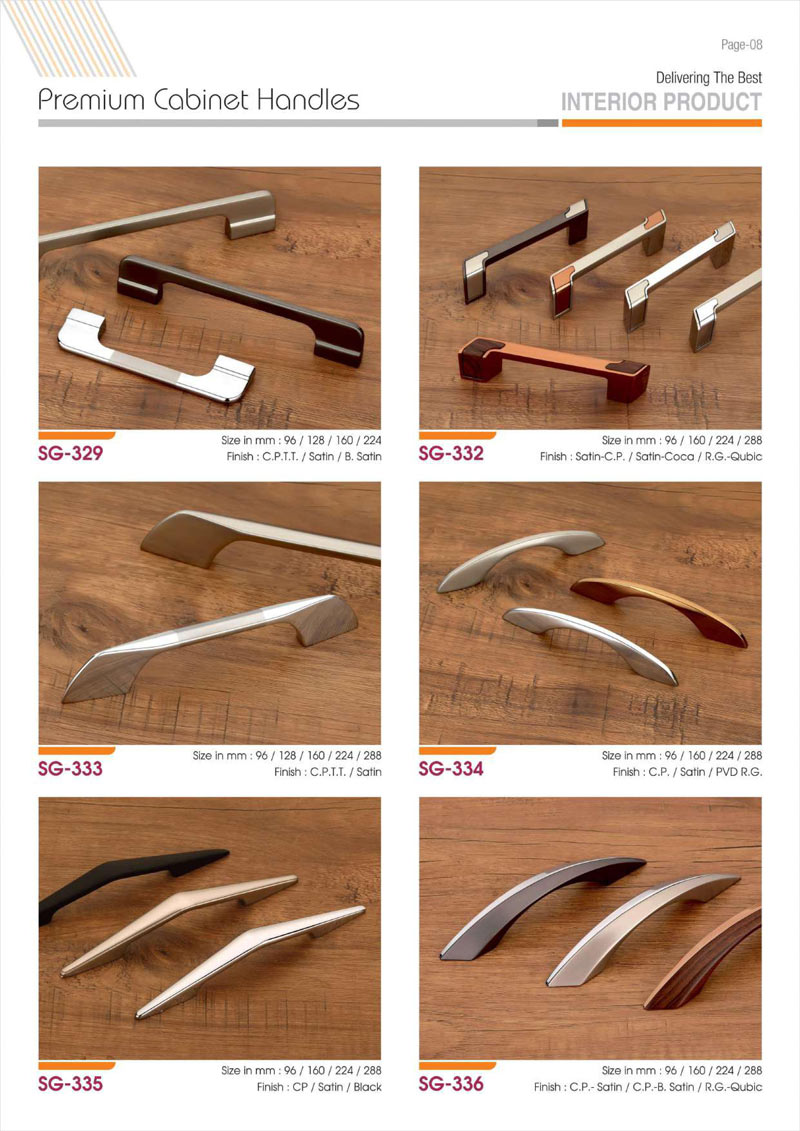

| Furniture | Cabinet and Drawer Handles | Improves functionality and aesthetic appeal in residential and commercial furniture. | Design variety, material quality, and installation ease. |

How Are Handles Used in Manufacturing Settings?

In the manufacturing sector, handles are crucial for assembly line equipment, where they significantly enhance ergonomics. By providing a more comfortable grip, they reduce worker fatigue, leading to improved productivity and efficiency. International buyers, particularly from regions like Africa and South America, should prioritize sourcing durable handles that can withstand heavy use and are compatible with existing machinery. Additionally, considering factors such as load capacity and ease of installation is essential to ensure seamless integration into production lines.

What Role Do Handles Play in Construction Projects?

Handles are vital in construction, particularly for doors and windows, where they contribute to both security and accessibility. The right handles can improve the safety of commercial and residential buildings, making them more user-friendly. Buyers from Europe, especially in countries like Italy and Poland, should focus on sourcing weather-resistant materials that comply with local safety standards. Aesthetic design is also important, as it can enhance the overall appearance of buildings while ensuring functional effectiveness.

Why Are Handles Important in Logistics and Warehousing?

In logistics and warehousing, handles are essential for pallet and container management. They facilitate easier handling and transportation of goods, which is crucial for operational efficiency. For international B2B buyers, especially in the Middle East, sourcing handles with a robust grip design and high weight capacity can significantly reduce the risk of accidents and improve workflow. Additionally, material strength is a key consideration, as handles must endure the rigors of constant use in demanding environments.

How Do Handles Enhance Automotive Designs?

In the automotive industry, vehicle door handles are not just functional but also enhance user experience and safety. A well-designed handle can improve accessibility while ensuring that the vehicle meets safety standards. B2B buyers in Europe should look for customization options that align with their vehicle designs, as well as materials that offer durability and resistance to wear. Compliance with automotive industry standards is critical, ensuring that the handles perform reliably over time.

What Benefits Do Furniture Handles Provide?

Handles in furniture, such as cabinet and drawer handles, play a significant role in functionality and aesthetics. They enhance the user experience by providing easy access while also contributing to the overall design of the furniture. International buyers should consider sourcing a variety of designs and materials to meet diverse customer preferences. Quality and ease of installation are also vital, as they can affect the final product’s appeal and usability in both residential and commercial settings.

3 Common User Pain Points for ‘handles supplier’ & Their Solutions

Scenario 1: Difficulty in Product Specification and Consistency

The Problem:

B2B buyers often face challenges when it comes to specifying the exact requirements for handles. This can be particularly frustrating for buyers in industries such as construction, furniture, or automotive, where precise specifications are crucial. A lack of clarity in product dimensions, materials, or finishes can lead to miscommunication with suppliers, resulting in delays, increased costs, and unsatisfactory products that do not meet project standards. For instance, a furniture manufacturer in Italy may order handles that are slightly off in size, leading to production delays and potential client dissatisfaction.

The Solution:

To overcome this challenge, buyers should establish a comprehensive specification document that clearly outlines all required attributes of the handles. This document should include detailed measurements, material specifications, surface finishes, and any certifications required for compliance with local regulations. Additionally, leveraging advanced sourcing platforms that allow for visual product uploads and collaborative features can enhance communication. Using sample orders to validate specifications before full-scale production can also help minimize errors. Regular meetings with suppliers to review samples and updates on production capabilities can further ensure that all parties are aligned on expectations.

Scenario 2: Concerns Over Quality Control and Supplier Reliability

The Problem:

Quality control is a significant concern for B2B buyers, especially when sourcing handles from international suppliers. For buyers in regions like Africa or South America, the distance can exacerbate issues related to quality assurance, as they may not have immediate access to the supplier’s facilities. Instances of receiving subpar products that do not meet quality standards can lead to costly recalls or project delays, which ultimately impact a company’s reputation and profitability.

The Solution:

To mitigate quality control issues, buyers should prioritize working with suppliers who have established quality management systems and certifications, such as ISO 9001. Conducting thorough due diligence by requesting references and case studies from the supplier’s previous clients can also provide insights into their reliability. Additionally, implementing a structured quality assurance process that includes on-site inspections or third-party audits can ensure that products meet specified quality standards before shipment. Establishing a clear communication channel for quality feedback and maintaining a continuous improvement dialogue with the supplier can foster a strong partnership focused on quality enhancement.

Scenario 3: Navigating Diverse Shipping and Logistics Challenges

The Problem:

International B2B buyers often encounter logistical challenges when importing handles, such as unpredictable shipping times, customs delays, and fluctuating freight costs. For buyers in Europe, Africa, or the Middle East, these challenges can significantly impact project timelines and budget forecasts. For example, a construction company in Poland might find that delays in handle shipments push back critical project deadlines, leading to financial penalties and strained client relationships.

The Solution:

To navigate these logistical hurdles effectively, buyers should engage with logistics partners who specialize in international shipping and understand the nuances of importing goods from specific regions. Establishing a clear logistics plan that includes preferred shipping methods, expected timelines, and contingency plans for potential delays is crucial. Buyers should also consider utilizing Incoterms (International Commercial Terms) to clarify responsibilities in shipping and customs clearance. Regularly monitoring shipping progress through tracking systems and maintaining open lines of communication with suppliers can also help address any issues proactively. Building relationships with multiple logistics providers can provide flexibility and options to mitigate risks associated with shipping delays.

Strategic Material Selection Guide for handles supplier

When selecting materials for handles, it is crucial for international B2B buyers to understand the characteristics, advantages, and limitations of various materials. This knowledge will aid in making informed decisions that align with specific application requirements and regional standards.

What are the Key Properties of Plastic Handles?

Plastic, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), is widely used for handles due to its lightweight nature and versatility. These materials typically exhibit good temperature resistance (up to 80°C) and moderate pressure ratings, making them suitable for a variety of applications. However, their resistance to UV light and chemicals can vary significantly based on the specific type of plastic used.

Pros & Cons: The primary advantage of plastic handles is their cost-effectiveness and ease of manufacturing, which allows for mass production. However, they may not offer the same level of durability as metal options, especially in high-stress environments. Additionally, they can be less suitable for applications involving extreme temperatures or heavy loads.

Impact on Application: Plastic handles are often used in household appliances, furniture, and lightweight industrial equipment. Buyers should consider compatibility with specific media, especially if the handle will be exposed to chemicals or solvents.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local regulations regarding plastic materials, as certain plastics may be restricted. Understanding standards such as ASTM for the U.S. or EN standards in Europe can help in selecting compliant materials.

How Do Metal Handles Compare in Performance?

Metal handles, particularly those made from stainless steel and aluminum, are known for their strength and durability. Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 500°C), making it ideal for industrial applications. Aluminum, while lighter, is also resistant to corrosion but may not handle high temperatures as effectively.

Pros & Cons: The key advantage of metal handles is their longevity and robustness, making them suitable for heavy-duty applications. However, they tend to be more expensive than plastic options and may require more complex manufacturing processes, which can increase lead times.

Impact on Application: Metal handles are commonly used in industrial machinery, automotive applications, and outdoor equipment. Their ability to withstand harsh environments makes them a preferred choice for applications where reliability is critical.

Considerations for International Buyers: Buyers in Europe, particularly in countries like Italy and Poland, should be aware of the EU regulations on metal materials and ensure that their suppliers meet these standards. Compliance with ISO standards can also be a crucial factor in the procurement process.

What Are the Benefits of Wood Handles?

Wood handles offer a unique aesthetic appeal and are often used in high-end consumer products, such as kitchen utensils and furniture. Common types of wood used include oak, maple, and walnut, which provide a warm feel and good grip. Wood can handle moderate temperatures but may not be suitable for high-pressure applications.

Pros & Cons: The main advantage of wood handles is their ergonomic comfort and visual appeal. However, wood can be prone to warping, splintering, or degradation when exposed to moisture or extreme temperatures, which limits its application in certain environments.

Impact on Application: Wood handles are ideal for consumer goods and items where aesthetics are important. They may not be suitable for industrial applications where durability is paramount.

Considerations for International Buyers: Buyers should consider sustainability certifications for wood materials, such as FSC (Forest Stewardship Council) certification, especially in regions like Europe where environmental regulations are stringent. Understanding local preferences for wood types can also influence purchasing decisions.

Summary of Material Selection for Handles

| Material | Typical Use Case for handles supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Household appliances, furniture | Cost-effective and lightweight | Less durable under stress | Low |

| Metal | Industrial machinery, automotive | High strength and durability | Higher cost and manufacturing complexity | High |

| Wood | Kitchen utensils, furniture | Aesthetic appeal and comfort | Prone to moisture damage | Medium |

In conclusion, selecting the right material for handles is essential for ensuring product performance and compliance with regional standards. By understanding the properties, advantages, and limitations of each material, international B2B buyers can make informed decisions that align with their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for handles supplier

What Are the Main Stages of Manufacturing for Handles Suppliers?

The manufacturing process for handles involves several critical stages that ensure the final product meets both functional and aesthetic requirements. Understanding these stages helps international B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The first step in the manufacturing process is material preparation. Depending on the type of handle being produced—metal, plastic, or wood—suppliers will source raw materials that meet specific quality standards. For instance, stainless steel may be chosen for its corrosion resistance, while high-density polyethylene (HDPE) might be selected for its durability and lightweight properties.

Suppliers often perform material tests to check for impurities and ensure compliance with international quality standards. Buyers should inquire about the origins of materials and request certification documents that verify quality and sustainability.

2. Forming Processes

Once materials are prepared, the next stage is forming. Various techniques are employed depending on the material type:

- Metal Handles: Common methods include die casting, forging, and machining. Die casting is popular for producing complex shapes, while forging enhances the strength of the handle.

- Plastic Handles: Injection molding is the primary technique used, allowing for mass production of intricate designs with a high level of precision.

- Wood Handles: Typically, wood handles are shaped using CNC machining or traditional woodworking techniques, which may include sanding and routing.

Buyers should assess the supplier’s capabilities in these forming processes and inquire about the machinery used, as this can affect production efficiency and product quality.

3. Assembly

After forming, the handles often require assembly. This stage may involve attaching different components, such as grips or fasteners, and may be performed manually or via automated processes.

An essential aspect of assembly is ensuring that all parts fit correctly and function as intended. Buyers should ask suppliers about their assembly techniques, as well as any automation they employ to enhance precision and reduce labor costs.

4. Finishing Techniques

The finishing stage is crucial for both the aesthetic appeal and durability of handles. Common finishing techniques include:

- Coating: Powder coating or painting provides a protective layer against corrosion and enhances visual appeal.

- Polishing: This technique is particularly important for metal handles to achieve a smooth, shiny surface.

- Sealing: For wood handles, sealing is necessary to protect against moisture and wear.

Buyers should inquire about the finishing options available and whether they can customize finishes to align with their branding or product requirements.

How Is Quality Assurance Implemented in Handle Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the handles produced meet specific standards and customer expectations.

What Are the International Standards for Handle Manufacturing?

International standards such as ISO 9001 provide a framework for quality management systems (QMS) that suppliers must adhere to. ISO 9001 certification indicates that a supplier has established processes to ensure consistent quality in their products and services.

Industry-specific certifications may also apply, such as:

- CE Marking: Required for products sold in the European Economic Area, ensuring compliance with safety and environmental standards.

- API Standards: Relevant for handles used in oil and gas applications, focusing on performance and safety.

B2B buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers with these certifications, as they reflect a commitment to quality and compliance with international regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring materials meet specified standards is crucial for maintaining product quality.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to identify any defects early in the process. This proactive approach helps minimize waste and reduces the risk of subpar products reaching the market.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to ensure they meet all specifications. This may include dimensional checks, functional tests, and aesthetic evaluations.

B2B buyers should ask suppliers about their QC processes and request detailed reports to gain insight into how quality is maintained throughout production.

What Common Testing Methods Are Used for Handles?

Various testing methods are employed to ensure the quality and durability of handles:

-

Mechanical Testing: This includes tensile tests to evaluate the strength and elasticity of materials, especially for metal handles.

-

Environmental Testing: Handles may be subjected to conditions simulating exposure to moisture, heat, or chemicals to assess their resistance to wear and tear.

-

Functional Testing: This involves assessing the usability and performance of handles under real-world conditions, such as load-bearing tests.

Buyers should be aware of these testing methods and ask suppliers for testing certifications that demonstrate compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are partnering with reliable handles suppliers, B2B buyers should take several steps to verify quality control practices:

Conducting Supplier Audits

Buyers can arrange for on-site audits to assess a supplier’s manufacturing processes, QC systems, and overall operational efficiency. This hands-on approach allows buyers to verify compliance with international standards and gain confidence in the supplier’s capabilities.

Requesting Quality Assurance Reports

Suppliers should be able to provide comprehensive QA reports, including details on materials used, testing outcomes, and any certifications obtained. These documents are essential for buyers to evaluate the supplier’s commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These services can conduct audits and testing, providing buyers with an additional layer of assurance regarding product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing handles from suppliers in different regions, buyers should be aware of the nuances in quality control and certification:

-

Regional Standards: Each region may have different regulatory requirements. For example, CE marking is essential for products sold in Europe, while other regions may have their specific standards.

-

Cultural Considerations: Understanding local business practices and attitudes towards quality can impact supplier relationships. For instance, in some cultures, personal relationships may play a significant role in business dealings, affecting negotiation and compliance.

By being aware of these factors, B2B buyers can navigate the complexities of international sourcing and ensure they choose suppliers that align with their quality expectations and standards.

In conclusion, comprehending the manufacturing processes and quality assurance practices for handles suppliers is vital for international B2B buyers. By focusing on key stages of manufacturing, understanding quality control checkpoints, and verifying supplier capabilities, buyers can make informed decisions that enhance their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘handles supplier’

In the competitive landscape of international B2B procurement, sourcing handles from reliable suppliers is crucial for ensuring product quality and operational efficiency. This practical sourcing guide will provide a step-by-step checklist to help B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outlining your product requirements is the first step in the sourcing process. Consider the materials, dimensions, and finishes necessary for your handles. This clarity will not only help suppliers understand your needs but also streamline the evaluation process.

- Materials: Specify if you need stainless steel, plastic, or another material.

- Dimensions: Provide exact measurements to avoid compatibility issues.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in handles. Utilize platforms like Alibaba, ThomasNet, or industry-specific directories to find reputable companies. This step is essential to build a shortlist of suppliers that align with your specifications.

- Read Reviews: Look for feedback from other buyers in your region to gauge reliability.

- Check Market Presence: A supplier with a strong market presence is often more trustworthy.

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding with a supplier, verify their certifications and compliance with industry standards. This ensures that the handles meet safety and quality regulations, which is particularly important for international transactions.

- ISO Certifications: Look for suppliers with ISO 9001 or equivalent certifications.

- Local Regulations: Ensure they comply with any regional regulations relevant to your market.

Step 4: Request Samples and Prototypes

Obtaining samples is a critical step to assess the quality and functionality of the handles. It allows you to evaluate whether the supplier’s offerings meet your specifications before placing a bulk order.

- Quality Check: Inspect the samples for durability and finish.

- Functionality Test: Ensure the handles operate as intended in your application.

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, initiate negotiations on pricing, payment terms, and delivery timelines. Effective negotiation can lead to better pricing and favorable terms, which are crucial for maintaining your budget and cash flow.

- Bulk Discounts: Inquire about pricing breaks for larger orders.

- Payment Terms: Discuss payment methods that minimize risk, such as letters of credit.

Step 6: Establish Communication Channels

Open lines of communication are vital for ensuring a smooth procurement process. Establish clear contact points and preferred communication methods to facilitate ongoing discussions.

- Regular Updates: Set expectations for regular updates on production status.

- Crisis Management: Discuss how to handle potential delays or issues.

Step 7: Plan for Logistics and Import Regulations

Understand the logistics involved in importing handles from your chosen supplier. Familiarize yourself with shipping methods, customs duties, and import regulations to avoid unexpected delays and costs.

- Shipping Options: Evaluate air versus sea freight based on urgency and cost.

- Customs Documentation: Ensure all necessary paperwork is ready to facilitate smooth customs clearance.

By following this checklist, B2B buyers can streamline their sourcing process for handles, ensuring they partner with reliable suppliers who meet their specific requirements while navigating the complexities of international procurement effectively.

Comprehensive Cost and Pricing Analysis for handles supplier Sourcing

What Are the Key Cost Components in Handles Supplier Sourcing?

Understanding the cost structure involved in sourcing handles is essential for international B2B buyers. The primary cost components can be broken down into several categories:

-

Materials: The type of material used for handles—such as metal, plastic, or wood—significantly affects costs. High-quality materials may incur a higher upfront cost but can lead to greater durability and lower replacement rates.

-

Labor: Labor costs vary widely based on geographical location and the skill level required for production. In regions like Africa and South America, labor may be less expensive, which can lower overall costs, but quality and skill must be considered.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Suppliers in Europe may have higher overhead due to stricter regulations and higher operational costs, impacting pricing.

-

Tooling: Custom tooling for specific handle designs can be a significant expense. Buyers should consider whether the tooling costs are amortized over larger production runs to minimize initial investment.

-

Quality Control (QC): Ensuring the handles meet international quality standards often requires investment in quality control processes. This is crucial for maintaining consistency and avoiding costly returns.

-

Logistics: Shipping and handling costs can vary significantly based on distance and shipping methods. Buyers should factor in logistics when comparing suppliers from different regions.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Understanding typical margins in your target supplier regions can help in negotiations.

How Do Price Influencers Affect Handles Supplier Pricing?

Several factors can influence the pricing of handles, which international buyers should consider when sourcing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQ to align with their budget while ensuring they meet supplier requirements.

-

Specifications and Customization: Custom-designed handles can increase costs due to additional tooling and labor requirements. It is vital to balance customization with budget constraints.

-

Materials and Quality Certifications: Handles made from premium materials or those that come with certifications (like ISO) may command higher prices. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to attract business.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping and delivery, which can impact the total cost.

What Are the Best Negotiation and Cost-Efficiency Tips for International Buyers?

To maximize cost efficiency when sourcing handles, international buyers should consider the following strategies:

-

Conduct Market Research: Understand the pricing landscape within your specific industry and region. This knowledge equips you with leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Instead of just evaluating the purchase price, consider the total cost throughout the product’s lifecycle, including maintenance, replacement, and logistics.

-

Build Long-term Relationships: Developing a strong relationship with suppliers can lead to better pricing and more favorable terms over time. Loyalty can result in discounts and priority service.

-

Be Clear About Requirements: Clearly communicate your specifications and requirements to avoid misunderstandings that can lead to unexpected costs.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow pressures and allow for better budget management.

Why Are Indicative Prices Important in Handles Sourcing?

While discussing costs, it’s essential to note that prices can fluctuate based on market conditions, supplier changes, and material costs. Always request detailed quotes from suppliers and verify their validity periodically. This approach ensures you have the most accurate cost projections for your sourcing strategy.

By understanding these aspects of cost and pricing in handles supplier sourcing, international B2B buyers can make informed decisions that align with their operational goals and budgetary constraints.

Alternatives Analysis: Comparing handles supplier With Other Solutions

Understanding Alternatives in Handles Supply Solutions

In the B2B landscape, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe, evaluating alternatives to traditional handles suppliers is crucial. Different solutions can offer varying benefits in terms of performance, cost, and implementation. This analysis compares the conventional handles supplier model with two viable alternatives: custom manufacturing and modular handle systems.

Comparison Table

| Comparison Aspect | Handles Supplier | Custom Manufacturing | Modular Handle Systems |

|---|---|---|---|

| Performance | Standardized options | Tailored to specific needs | Flexible configurations |

| Cost | Generally lower | Higher due to customization | Moderate, depending on complexity |

| Ease of Implementation | Quick and straightforward | Longer lead times | Easy installation |

| Maintenance | Low maintenance required | Variable, based on design | Low, with interchangeable parts |

| Best Use Case | Bulk orders for uniformity | Unique applications | Projects needing adaptability |

What Are the Advantages and Disadvantages of Custom Manufacturing?

Custom manufacturing provides tailored solutions that can meet specific requirements in terms of design and functionality. This approach is particularly beneficial for businesses with unique needs that standardized handles cannot satisfy. However, the trade-off is often higher costs and longer lead times, which can impact cash flow and project timelines. Additionally, the complexity of designs may lead to increased maintenance challenges, especially if the manufacturing process is not well-optimized.

How Do Modular Handle Systems Enhance Flexibility?

Modular handle systems offer a versatile alternative, allowing businesses to customize their handle solutions while maintaining the ability to adapt over time. These systems are designed for easy installation and provide interchangeable parts that can be swapped out as needed. This flexibility is especially beneficial for projects that require rapid adjustments or upgrades. However, while the initial costs can be moderate, businesses must consider potential expenses related to additional components that might be needed for future adaptations.

Conclusion: How Can B2B Buyers Choose the Right Handle Solution?

When choosing between a traditional handles supplier, custom manufacturing, and modular handle systems, B2B buyers should evaluate their specific needs carefully. Factors such as project timelines, budget constraints, and performance requirements play a crucial role in the decision-making process. Buyers in Africa, South America, the Middle East, and Europe should conduct thorough research and consider the long-term implications of each solution to ensure they select the most suitable option for their operations.

Essential Technical Properties and Trade Terminology for handles supplier

When engaging with handles suppliers, understanding the essential technical properties and trade terminology is critical for international buyers. This knowledge not only aids in making informed purchasing decisions but also facilitates clearer communication with suppliers, ultimately enhancing the efficiency of procurement processes.

What Are the Key Technical Properties of Handles?

1. Material Grade

The material grade refers to the specific type of material used in the manufacture of handles, such as stainless steel, aluminum, plastic, or wood. Each material has unique properties that affect durability, weight, and aesthetic appeal. For instance, stainless steel handles are corrosion-resistant and ideal for outdoor use, making them a popular choice in regions with high humidity, such as parts of South America and Africa. Understanding material grades can help buyers select the most suitable handles for their specific applications.

2. Load Capacity

Load capacity indicates the maximum weight that a handle can safely support. This is crucial for applications in industrial settings or heavy-use environments. For instance, a handle used in manufacturing or shipping must be able to withstand significant forces without failure. Buyers should assess their needs and ensure that the handles they procure meet or exceed the required load capacity, ensuring safety and longevity.

3. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the handle. This specification is vital for ensuring that handles fit properly and function as intended within their applications. Inaccurate tolerances can lead to installation issues or functional failures, which can be particularly detrimental in B2B contexts where reliability is paramount. Clear communication about tolerance requirements can prevent costly mistakes and delays.

4. Surface Finish

The surface finish of a handle affects its appearance, texture, and resistance to wear and corrosion. Common finishes include polished, brushed, or powder-coated options. Buyers should consider the environmental conditions where the handles will be used, as certain finishes may provide better resistance to scratches or weathering. Selecting the right surface finish can enhance product longevity and customer satisfaction.

5. Dimensions

Handles come in various sizes and shapes, and precise dimensions are crucial for compatibility with existing products. Buyers need to specify the required dimensions clearly, including length, width, and depth, to avoid issues during installation. Understanding dimensional requirements can help streamline the sourcing process and ensure that the right products are delivered.

What Are Common Trade Terms in the Handles Supply Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of handles, an OEM supplier may provide custom handles designed specifically for a brand’s unique specifications. Buyers should consider working with OEMs for tailored solutions that meet their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is essential for buyers, as it can impact budget and inventory management. For international buyers, especially from regions with fluctuating demand, negotiating favorable MOQs can ensure they maintain flexibility in procurement.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. It is an essential step in the procurement process, allowing buyers to compare pricing, quality, and terms from multiple suppliers. Crafting a detailed RFQ can lead to better pricing and more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is crucial for international transactions, as they dictate who is responsible for shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs and ensure smoother logistics.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. It is a critical factor in supply chain management, especially for international buyers who may face longer shipping durations. By discussing lead times upfront, buyers can better plan their inventory and production schedules, minimizing disruptions.

By mastering these technical properties and trade terms, international B2B buyers can engage more effectively with handles suppliers, ensuring they make informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the handles supplier Sector

What Are the Current Market Dynamics and Key Trends in the Handles Supplier Sector?

The handles supplier sector is experiencing a transformative phase driven by globalization, technological advancements, and shifting consumer preferences. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the market. One significant trend is the increasing demand for customized and ergonomic designs tailored to specific industries, which requires suppliers to be agile and responsive. Furthermore, the integration of digital platforms for sourcing and procurement is becoming commonplace, allowing buyers to streamline their purchasing processes while gaining access to a broader range of suppliers.

Another driver is the rise of e-commerce, which has expanded the reach of handles suppliers beyond traditional markets. This shift not only enables suppliers to showcase their offerings more effectively but also allows buyers to compare options and negotiate better terms. As a result, international B2B buyers should leverage online marketplaces and supplier directories to enhance their sourcing strategies. Additionally, sustainability is becoming a critical consideration, with buyers increasingly prioritizing suppliers that demonstrate environmental responsibility in their operations.

How Is Sustainability Influencing the Handles Supplier Sector?

Sustainability and ethical sourcing are now at the forefront of purchasing decisions in the handles supplier sector. Environmental impact considerations are prompting buyers to seek suppliers who prioritize eco-friendly materials and practices. This trend is particularly relevant for buyers from regions like Europe, where stringent regulations regarding environmental sustainability are in place.

To align with these values, suppliers are increasingly obtaining certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wooden handles. Such certifications signal a commitment to sustainable practices and can be a deciding factor for buyers concerned about their environmental footprint. Additionally, opting for recycled or sustainably sourced materials not only reduces environmental impact but can also appeal to a growing segment of eco-conscious consumers.

By prioritizing suppliers with robust sustainability practices, international B2B buyers can enhance their brand reputation and meet the expectations of their clientele, which is increasingly demanding transparency and ethical practices in supply chains.

What Is the Historical Context of the Handles Supplier Sector?

The handles supplier sector has evolved significantly over the past few decades. Initially dominated by local artisans and small-scale manufacturers, the market began to expand in the late 20th century as globalization took hold. This shift allowed for the establishment of larger, more standardized production processes, enabling suppliers to meet the growing demand for handles across various industries, from furniture to construction.

With the advent of technology, the sector has witnessed the introduction of innovative materials and designs, enhancing functionality and aesthetics. Today, the handles supplier market is characterized by a blend of traditional craftsmanship and modern manufacturing techniques, allowing for greater customization and efficiency. Understanding this evolution is crucial for B2B buyers, as it provides insights into the capabilities and offerings of potential suppliers, helping them make informed sourcing decisions.

By staying attuned to these dynamics, international B2B buyers can navigate the complexities of the handles supplier sector and forge strategic partnerships that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of handles supplier

-

How do I solve quality assurance issues when sourcing handles suppliers?

To effectively manage quality assurance when sourcing handles suppliers, start by conducting thorough research on potential suppliers’ reputations. Request samples before making large orders to assess their product quality firsthand. Implement a clear quality control checklist based on your specifications and industry standards. Consider hiring third-party inspection services to verify product quality before shipment, particularly if you are importing from regions like Asia or Europe. Establishing long-term relationships with reliable suppliers can also help maintain consistent quality over time. -

What is the best way to assess the reliability of a handles supplier?

Assessing a handles supplier’s reliability involves several steps. Begin by checking their business credentials, such as certifications, years of operation, and industry reputation. Look for reviews or testimonials from other international buyers, particularly those from your region. Request references and follow up with them to gain insights into their experiences. Additionally, ensure the supplier has a robust supply chain management system, which can help mitigate risks associated with delays and quality issues, especially when dealing with international logistics. -

What are the common payment terms for handles suppliers?

Payment terms can vary significantly among handles suppliers, but common options include Letters of Credit (LC), wire transfers, and payment upon delivery. For international transactions, it’s prudent to negotiate terms that protect your interests, such as a 30% upfront payment followed by 70% upon delivery. Be cautious with suppliers who demand full payment upfront, as this can be a red flag. Always clarify the currency and method of payment to avoid unexpected fees or exchange rate fluctuations. -

What is the minimum order quantity (MOQ) for handles suppliers?

The minimum order quantity (MOQ) for handles can differ widely based on the supplier’s production capabilities and the type of handles you require. Generally, MOQs can range from 100 to several thousand units. When sourcing from suppliers in regions like Asia, MOQs might be higher due to economies of scale, while suppliers in Europe may offer more flexibility. If you are unsure about committing to a large order, consider negotiating for a lower MOQ or requesting a trial order to test the market. -

How can I customize handles to fit my specific needs?

Customizing handles to meet your specific needs typically involves discussing your requirements with the supplier during the initial stages of sourcing. Provide detailed specifications, including materials, dimensions, colors, and finishes. Many suppliers offer design services, so take advantage of their expertise. Be prepared for additional costs associated with customization, including tooling and setup fees. Request prototypes to evaluate the designs before final production, ensuring that the final product aligns with your expectations. -

What logistics considerations should I be aware of when importing handles?

When importing handles, logistics play a crucial role in ensuring timely delivery. Familiarize yourself with international shipping regulations and customs requirements for your specific region. Choose reliable freight forwarders who can provide comprehensive services, including handling customs clearance and documentation. Be aware of shipping times and potential delays, especially during peak seasons. Consider using Incoterms to define responsibilities and costs related to transportation and delivery, which can mitigate misunderstandings with suppliers.

A stock image related to handles supplier.

-

How can I effectively communicate with handles suppliers across different cultures?

Effective communication with handles suppliers from diverse cultural backgrounds is essential for successful collaboration. Start by being clear and concise in your communication, avoiding jargon or idiomatic expressions that may not translate well. Use professional language and confirm understanding by summarizing key points. Be respectful of cultural differences in negotiation styles and decision-making processes. Utilizing a translation service or hiring bilingual staff can enhance communication, particularly when dealing with suppliers in non-English-speaking countries. -

What are the potential risks of sourcing handles from international suppliers?

Sourcing handles from international suppliers comes with several risks, including quality inconsistencies, communication barriers, and potential supply chain disruptions. To mitigate these risks, conduct comprehensive due diligence on suppliers, including site visits if possible, or utilizing trusted third-party services. Establish clear contracts outlining terms, conditions, and quality standards. Additionally, diversify your supplier base to avoid over-reliance on a single source, which can help maintain continuity in case of unforeseen issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for handles supplier

In today’s global marketplace, effective strategic sourcing for handles suppliers is paramount for international B2B buyers. By prioritizing supplier relationships and understanding regional dynamics, businesses can enhance their supply chain resilience and optimize costs. Key takeaways include the importance of evaluating suppliers not just on price but also on quality, reliability, and sustainability practices.

Moreover, leveraging technology and data analytics can provide insights into market trends and supplier performance, which is crucial for making informed decisions. As buyers in Africa, South America, the Middle East, and Europe navigate diverse markets, adopting a tailored approach to strategic sourcing will yield significant competitive advantages.

Looking forward, international B2B buyers must remain agile and proactive. Engage with suppliers who demonstrate innovation and adaptability to meet evolving customer needs. As you refine your sourcing strategies, consider the long-term partnerships that can drive mutual growth and success. Start exploring new supplier relationships today to secure a sustainable and robust supply chain for tomorrow.