Improve Quality with Top Artificial Turf Manufacturers (2025)

Introduction: Navigating the Global Market for artificial turf manufacturer

In an increasingly competitive landscape, sourcing high-quality artificial turf manufacturers can be a daunting task for international B2B buyers. With the growing demand for durable and aesthetically pleasing synthetic grass solutions across various sectors—from sports fields and landscaping to playgrounds and commercial properties—understanding the nuances of the global market is essential. This guide serves as a comprehensive resource for buyers in regions such as Africa, South America, the Middle East, and Europe, addressing the critical questions and challenges they face when selecting the right supplier.

Throughout this guide, we will explore the diverse types of artificial turf available, their specific applications, and the key factors to consider when vetting potential suppliers. Additionally, we will delve into cost considerations, helping you navigate pricing structures and negotiate favorable terms. By equipping you with actionable insights and industry best practices, this guide aims to empower informed purchasing decisions, ensuring that you find a manufacturer that meets your quality standards and operational requirements.

As the artificial turf industry continues to evolve, staying informed about market trends and supplier capabilities is vital. This guide will help you cut through the noise and make strategic choices that not only enhance your projects but also contribute to long-term success in your business endeavors.

Understanding artificial turf manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nylon Turf Manufacturers | High durability, UV resistance, and excellent resilience | Sports fields, commercial landscaping | Pros: Long-lasting, vibrant colors; Cons: Higher cost compared to other types. |

| Polyethylene Turf Manufacturers | Soft texture, realistic appearance, and lower pile height | Residential lawns, playgrounds | Pros: Cost-effective, safe for children; Cons: Less durable than nylon. |

| Polypropylene Turf Manufacturers | Budget-friendly, lightweight, and low maintenance | Temporary installations, event spaces | Pros: Affordable, easy to install; Cons: Shorter lifespan, less realistic. |

| Infill Turf Manufacturers | Incorporates infill materials for improved performance | Sports fields, pet areas | Pros: Enhances drainage and stability; Cons: Requires maintenance of infill. |

| Eco-Friendly Turf Manufacturers | Made from recycled materials, promoting sustainability | Green spaces, eco-conscious projects | Pros: Environmentally friendly, reduces waste; Cons: May have limited availability. |

What Are the Characteristics of Nylon Turf Manufacturers?

Nylon turf manufacturers produce some of the most durable artificial grass options available. Known for their resilience and ability to withstand heavy foot traffic, nylon turfs are ideal for high-use areas such as sports fields and commercial landscapes. When considering nylon turf, B2B buyers should evaluate the long-term cost-effectiveness, as the initial investment may be higher but can lead to savings over time due to its longevity.

How Do Polyethylene Turf Manufacturers Stand Out?

Polyethylene turf manufacturers focus on creating softer and more lifelike surfaces, making their products suitable for residential lawns and playgrounds. The lower pile height of polyethylene turf enhances its realistic appearance while providing a safe environment for children. Buyers should consider the balance between cost and durability, as polyethylene tends to be less durable than nylon but offers a more budget-friendly option for residential projects.

What Should Buyers Know About Polypropylene Turf Manufacturers?

Polypropylene turf manufacturers offer an economical choice for businesses looking for temporary or lightweight solutions. This type of turf is easy to install and is often used in event spaces or for short-term projects. However, B2B buyers should be aware that polypropylene turf has a shorter lifespan and may not provide the realistic look of other materials. It’s essential to assess the intended use and duration before making a purchase.

Why Consider Infill Turf Manufacturers?

Infill turf manufacturers create products that incorporate materials like rubber or sand to enhance performance. This type of turf is particularly beneficial for sports fields and areas designated for pets, as the infill improves drainage and stability. Buyers need to consider the maintenance requirements associated with the infill, as regular upkeep is necessary to ensure optimal performance and longevity.

What Are the Benefits of Eco-Friendly Turf Manufacturers?

Eco-friendly turf manufacturers focus on sustainability by producing artificial grass from recycled materials. This type of turf is gaining popularity among environmentally conscious businesses and projects aiming to reduce waste. While eco-friendly options may have limited availability, they represent a growing market segment. Buyers should evaluate the environmental impact alongside performance metrics when considering these products for green spaces or eco-centric developments.

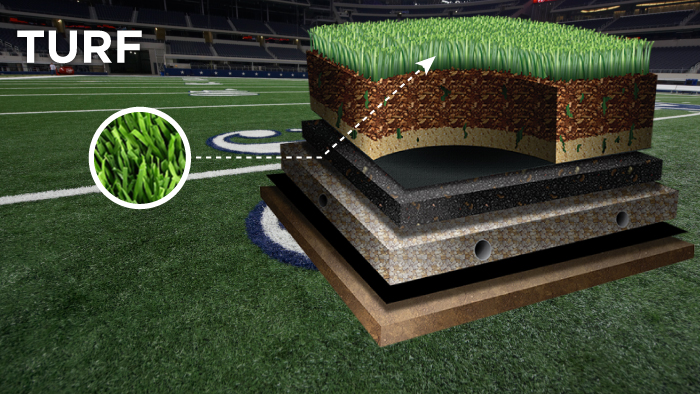

Related Video: Artificial Turf Manufacturer CGT Shares how to install high-quality football field meets FIFA

Key Industrial Applications of artificial turf manufacturer

| Industry/Sector | Specific Application of artificial turf manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Facilities | Football and Rugby Fields | Enhanced playability and reduced maintenance costs | Durability, weather resistance, and compliance with sports standards |

| Landscaping | Residential and Commercial Gardens | Aesthetic appeal and water conservation | Environmental impact, UV stability, and infill options |

| Playgrounds and Recreational Areas | Children’s Play Areas | Safety features and reduced injury risks | Non-toxic materials, cushioning properties, and color options |

| Event Venues | Temporary Event Setups | Quick installation and easy dismantling | Customization options, portability, and weather resistance |

| Equestrian Facilities | Horse Arenas | Improved footing and reduced injury to horses | Drainage capabilities, cushioning, and material durability |

How is Artificial Turf Used in Sports Facilities?

In sports facilities, artificial turf is predominantly utilized for football and rugby fields. These surfaces provide consistent playability, reducing the risk of injuries associated with natural grass, especially in adverse weather conditions. For international buyers, particularly from regions with varying climates such as Africa and Europe, sourcing durable turf that meets specific sports standards is crucial. Buyers should prioritize products that offer excellent drainage, wear resistance, and low maintenance to ensure long-term performance and cost-effectiveness.

What Role Does Artificial Turf Play in Landscaping?

In landscaping, artificial turf is employed in both residential and commercial gardens to enhance aesthetic appeal while conserving water. This is particularly valuable in regions experiencing water scarcity, such as parts of South America and the Middle East. When sourcing turf for landscaping projects, buyers should consider the environmental impact, UV stability, and the availability of different infill options to ensure that the product aligns with their sustainability goals and design preferences.

How is Artificial Turf Beneficial for Playgrounds and Recreational Areas?

For playgrounds and recreational areas, artificial turf provides a safe surface for children to play on, significantly reducing the risk of injuries. The cushioning properties of the turf are essential in creating a safer environment. Buyers from Europe and Africa should focus on sourcing non-toxic materials that meet safety standards for children’s play areas. Additionally, color options and design flexibility can enhance the attractiveness of the space, making it more inviting for families.

Why is Artificial Turf Ideal for Event Venues?

Artificial turf finds its application in temporary event setups, where quick installation and easy dismantling are essential. Event venues benefit from the aesthetic appeal of turf, which can be customized to fit the theme of the event. For international buyers, especially in regions with diverse event types, considering customization options, portability, and weather resistance is crucial to ensure that the turf can withstand various conditions while maintaining its appearance.

How Does Artificial Turf Enhance Equestrian Facilities?

In equestrian facilities, artificial turf is used in horse arenas to provide improved footing and reduce the risk of injury to horses. The right turf can enhance performance while ensuring the safety of both horses and riders. Buyers from regions with high equestrian activity, such as parts of Europe and Australia, should prioritize turf that offers excellent drainage capabilities and cushioning. Durability is also a key consideration, as equestrian surfaces endure heavy use and require consistent performance over time.

Related Video: How To Install Synthetic Turf

3 Common User Pain Points for ‘artificial turf manufacturer’ & Their Solutions

Scenario 1: Sourcing Quality Artificial Turf Amidst Varied Standards

The Problem:

International B2B buyers often face the challenge of inconsistent quality standards when sourcing artificial turf. This is particularly pronounced in regions like Africa and South America, where local suppliers may not adhere to international quality benchmarks. The lack of standardized testing for durability, safety, and environmental impact can lead to significant discrepancies in product performance. Buyers may receive subpar turf that deteriorates quickly, leading to increased replacement costs and potential reputational damage.

The Solution:

To navigate this challenge, buyers should prioritize sourcing from manufacturers that comply with recognized international standards such as FIFA regulations or ISO certifications. Start by researching manufacturers that provide transparent documentation of their products’ testing and certification. Request samples and conduct independent testing where possible to ensure the turf meets your specific requirements. Additionally, consider forming partnerships with reputable local distributors who can provide insights into the quality of the products and help facilitate better compliance with international standards. Establishing long-term relationships with manufacturers that are committed to quality assurance will help mitigate risks associated with inferior products.

Scenario 2: Understanding the Cost Implications of Installation and Maintenance

The Problem:

Another significant pain point for B2B buyers is the hidden costs associated with the installation and maintenance of artificial turf. Often, buyers focus solely on the initial purchase price, overlooking the potential expenses related to proper installation and ongoing upkeep. In regions like the Middle East and Europe, the climate can influence the longevity and maintenance needs of artificial turf, leading to additional costs that can impact the overall budget.

The Solution:

To address this, buyers should conduct a thorough cost-benefit analysis before committing to a supplier. This includes obtaining detailed quotations that break down not only the purchase price but also the estimated costs for installation and long-term maintenance. Engage with manufacturers who provide comprehensive installation services or can recommend certified contractors experienced in artificial turf. Additionally, inquire about maintenance contracts or warranties that cover potential repairs or replacements. Educating yourself on the specific maintenance requirements of different turf types will also help you make informed decisions that align with your budget and operational capabilities.

Scenario 3: Navigating Environmental and Regulatory Compliance

The Problem:

In today’s market, buyers are increasingly concerned about the environmental impact of artificial turf. This is especially true for B2B buyers in Europe, where regulations around sustainability and recyclability are becoming stricter. Buyers may struggle to find manufacturers that provide environmentally friendly products without compromising on performance. The fear of non-compliance with local regulations can create hesitation in purchasing decisions.

The Solution:

To mitigate this issue, buyers should seek out manufacturers who prioritize sustainability in their production processes. Look for products made from recycled materials or those that are fully recyclable at the end of their life cycle. Request detailed information about the materials used, including certifications that demonstrate compliance with environmental regulations. Moreover, engage in discussions with suppliers about their commitment to sustainability practices and their plans for product end-of-life management. Joining industry groups focused on sustainable practices can also provide valuable insights and connections to like-minded suppliers, ensuring that your procurement aligns with both regulatory demands and corporate responsibility goals.

Strategic Material Selection Guide for artificial turf manufacturer

When selecting materials for artificial turf, manufacturers must consider various factors that influence performance, durability, and suitability for specific applications. Here, we analyze four common materials used in artificial turf production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Which Materials Are Commonly Used in Artificial Turf Manufacturing?

1. Polyethylene (PE)

Key Properties:

Polyethylene is known for its excellent UV resistance, flexibility, and softness, making it a popular choice for residential and commercial applications. It can withstand a temperature range of -50°C to 80°C and is resistant to corrosion from chemicals and moisture.

Pros & Cons:

The primary advantage of polyethylene is its durability and realistic appearance, which mimics natural grass. However, it can be more expensive than other materials, and its manufacturing process can be complex, requiring advanced technology to ensure quality.

Impact on Application:

Polyethylene is particularly suitable for sports fields and landscaping due to its soft texture and ability to withstand foot traffic. It is compatible with various infill materials, enhancing performance.

Considerations for International Buyers:

Buyers must ensure compliance with local regulations regarding environmental impact and safety standards. In Europe, adherence to EN 71-3 (safety of toys) is crucial, while in the Middle East, buyers should check for compliance with local environmental regulations.

2. Polypropylene (PP)

Key Properties:

Polypropylene is lightweight and has a high melting point, making it suitable for high-temperature environments. It is also resistant to moisture and chemicals, providing good durability.

Pros & Cons:

The main advantage of polypropylene is its lower cost compared to polyethylene, making it a budget-friendly option. However, it is less durable and can become brittle over time, especially when exposed to UV light.

Impact on Application:

Polypropylene is often used in non-sporting applications, such as decorative landscaping, due to its lower durability. It may not be suitable for high-traffic areas.

Considerations for International Buyers:

Buyers should be aware of the varying standards for polypropylene products. For instance, ASTM D4976 outlines specifications for PP, which may differ from those in other regions.

3. Nylon

Key Properties:

Nylon is highly durable and has excellent abrasion resistance, making it suitable for high-traffic sports fields. It can withstand extreme temperatures and has a high tensile strength.

Pros & Cons:

The key advantage of nylon is its longevity and ability to maintain its appearance over time. However, it is one of the most expensive materials, which can be a deterrent for budget-conscious buyers.

Impact on Application:

Nylon is ideal for competitive sports fields where performance is critical. Its compatibility with various infill materials enhances its application in high-performance settings.

Considerations for International Buyers:

Nylon products must meet specific standards, such as ASTM F355 for impact testing. Buyers in Africa and South America should also consider local climate conditions, as nylon may perform differently in extreme heat or humidity.

4. Thermoplastic Elastomer (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering flexibility, durability, and resistance to UV light. It performs well in a wide range of temperatures and is environmentally friendly.

Pros & Cons:

The primary advantage of TPE is its eco-friendliness and safety, making it a popular choice for playgrounds and sports fields. However, it can be more costly than traditional materials and may require specialized manufacturing processes.

Impact on Application:

TPE is particularly suitable for applications where safety is paramount, such as playgrounds and recreational areas. Its compatibility with various infill options enhances its versatility.

Considerations for International Buyers:

Buyers should verify compliance with international safety standards, such as EN 1176 for playground equipment. In regions like the Middle East, where heat can be extreme, TPE’s temperature resilience is a significant advantage.

Summary Table of Material Selection for Artificial Turf

| Material | Typical Use Case for Artificial Turf Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Sports fields, landscaping | Excellent UV resistance, realistic appearance | Higher cost, complex manufacturing | High |

| Polypropylene (PP) | Decorative landscaping | Budget-friendly | Less durable, can become brittle | Medium |

| Nylon | Competitive sports fields | High durability, maintains appearance | Expensive | High |

| Thermoplastic Elastomer (TPE) | Playgrounds, recreational areas | Eco-friendly, flexible | Higher cost, specialized manufacturing | High |

This guide provides actionable insights for international B2B buyers seeking to make informed decisions regarding material selection for artificial turf manufacturing. Understanding the properties, advantages, and compliance requirements of each material can significantly impact the success of projects across diverse global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for artificial turf manufacturer

What Are the Main Stages in the Manufacturing Process of Artificial Turf?

The manufacturing process of artificial turf is intricate, involving several critical stages that ensure the final product meets high standards of quality and performance. Understanding these stages is vital for B2B buyers, as it allows for informed decisions when sourcing from international suppliers.

-

Material Preparation: The journey begins with the selection and preparation of raw materials. Polyethylene, polypropylene, and nylon are commonly used polymers, each chosen for their specific properties such as durability and UV resistance. Suppliers should provide Material Safety Data Sheets (MSDS) to verify the quality and specifications of these materials.

-

Forming: In this stage, the prepared materials are transformed into fibers. Advanced extrusion techniques are employed to create tufts of grass, which are then tufted into a backing material. This process often involves the use of specialized machinery that ensures uniformity in fiber length and density, which are crucial for the turf’s performance.

-

Assembly: Once the fibers are tufted, the assembly process begins. The tufts are secured to the backing using adhesive, and additional layers may be added to enhance durability and performance. This stage is essential for ensuring that the turf can withstand heavy foot traffic and environmental conditions.

-

Finishing: The final stage involves quality checks and finishing touches. This includes cutting the turf to specified sizes, applying infill materials if necessary, and performing final inspections to ensure that the product meets all design specifications.

How Is Quality Assurance Implemented in Artificial Turf Manufacturing?

Quality assurance (QA) is a critical component of artificial turf production. A robust QA system helps ensure that the final product not only meets customer expectations but also complies with international standards.

-

Adherence to International Standards: Many artificial turf manufacturers comply with ISO 9001, which outlines requirements for a quality management system. This certification indicates a commitment to consistent quality and continuous improvement. Other relevant standards include CE marking for products sold in Europe and API certifications for performance criteria.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking for any defects or inconsistencies in the materials.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various checkpoints are established to monitor production quality. This may include regular inspections of tuft density, adhesion strength, and fiber integrity.

– Final Quality Control (FQC): Before shipment, a thorough inspection of the finished product is conducted. This includes testing for colorfastness, UV stability, and overall performance under simulated conditions. -

Common Testing Methods: Various tests are employed to evaluate the performance of artificial turf. These include:

– Abrasion Resistance Testing: Measures the turf’s durability under wear and tear.

– UV Stability Testing: Assesses how well the turf withstands prolonged exposure to sunlight.

– Infill Performance Testing: Evaluates the effectiveness of infill materials in providing support and cushioning.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. This ensures that the products purchased will meet the necessary standards for safety and performance.

-

Conducting Supplier Audits: Buyers should consider performing on-site audits of potential suppliers. This allows for a firsthand evaluation of the manufacturing processes, quality control systems, and compliance with international standards. During audits, buyers can assess the efficiency of QA checkpoints and the overall cleanliness and organization of the manufacturing facility.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their testing methodologies, results, and compliance with international standards. These documents serve as evidence of the supplier’s commitment to quality and can help buyers make informed decisions.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspectors can conduct tests and evaluations based on industry standards, offering an additional layer of assurance to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing artificial turf from international suppliers, buyers must navigate various quality control nuances that can differ by region.

-

Understanding Regional Standards: Different regions may have specific standards and certifications that are recognized locally. For example, while ISO standards are widely accepted, CE marking is particularly important for products sold in the European market. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural and Regulatory Differences: Quality assurance practices can vary significantly across countries. For instance, some manufacturers in developing regions may not have the same level of QA rigor as those in more developed markets. Buyers should consider these differences when evaluating potential suppliers.

-

Building Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better communication regarding quality expectations and improvements. Regular communication can help in addressing any quality concerns proactively, fostering a partnership based on trust and reliability.

By understanding the manufacturing processes and quality assurance measures in the artificial turf industry, international B2B buyers can make informed decisions that align with their quality expectations and regulatory requirements. This knowledge not only aids in supplier selection but also enhances the overall procurement strategy for artificial turf products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘artificial turf manufacturer’

This practical sourcing guide aims to equip international B2B buyers with a structured approach to procuring artificial turf. The following checklist outlines essential steps to ensure a successful sourcing process, tailored to the unique needs and challenges of buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements for artificial turf. This includes the type of turf (e.g., for sports, landscaping, or playgrounds), pile height, density, and UV resistance. Having precise specifications helps suppliers provide accurate quotes and ensures that the product meets your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential manufacturers that specialize in artificial turf. Utilize online directories, industry associations, and trade shows to gather a list of candidates. Pay attention to suppliers that have experience working in your region, as they may better understand local regulations and market demands.

Step 3: Evaluate Supplier Credentials

Why is verifying supplier credentials critical? It ensures that you are dealing with a reputable manufacturer. Request documentation such as ISO certifications, product safety standards, and environmental compliance. This not only assures quality but also mitigates risks associated with substandard products.

- What to check:

- ISO 9001 for quality management.

- ISO 14001 for environmental management.

- Compliance with local regulations regarding materials.

Step 4: Request Samples

Always request samples before making bulk purchases. This allows you to assess the quality, texture, and appearance of the turf. It’s essential to check the samples against your defined specifications to ensure they meet your expectations.

Step 5: Negotiate Terms and Pricing

When you have shortlisted suppliers, engage in negotiations to secure favorable terms. Discuss pricing, delivery schedules, payment terms, and warranty policies. It’s beneficial to compare offers from multiple suppliers to ensure you are getting the best value for your investment.

Step 6: Assess After-Sales Support and Warranty

Understanding the after-sales support and warranty offered by the supplier is crucial for long-term satisfaction. Inquire about installation assistance, maintenance guidance, and the duration of the warranty. Reliable support can significantly affect the durability and performance of your artificial turf over time.

Step 7: Finalize the Contract

Once all terms have been agreed upon, ensure that the contract is comprehensive and covers all aspects of the procurement process. Include clauses related to delivery timelines, quality standards, and penalties for non-compliance. A well-defined contract protects your interests and establishes clear expectations.

By following this step-by-step checklist, international B2B buyers can effectively navigate the sourcing process for artificial turf, ensuring they select the right manufacturer to meet their specific needs.

Comprehensive Cost and Pricing Analysis for artificial turf manufacturer Sourcing

What Are the Key Cost Components in Sourcing Artificial Turf?

When sourcing artificial turf, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, such as polyethylene, polypropylene, and nylon fibers, significantly influences the overall price of artificial turf. Higher quality materials typically yield a more durable product but may come at a premium. Be aware of suppliers who offer lower-quality materials at a reduced price, as this may lead to increased maintenance costs in the long run.

-

Labor: Labor costs can vary significantly based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality. Ensure that the supplier employs skilled labor and adheres to labor regulations to avoid issues that could affect the final product’s quality.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, equipment maintenance, and facility costs. Understanding a supplier’s overhead can provide insight into their pricing structure. Suppliers with higher overhead may charge more, but they might also offer better quality control and production efficiency.

-

Tooling: Customization and specific product specifications often require specialized tooling, which can add to the initial costs. When evaluating suppliers, inquire about the tooling costs associated with your specific needs, as these can vary widely based on the complexity of the designs.

-

Quality Control: Investing in stringent QC processes ensures that the turf meets international standards. While suppliers with rigorous QC measures may charge more, this investment can lead to long-term savings by reducing the likelihood of defects and replacements.

-

Logistics: Transportation costs can significantly impact the overall price, especially for international shipments. Factors such as distance, shipping method, and local tariffs should be considered when calculating total costs. Collaborating with suppliers who have established logistics networks can help mitigate these expenses.

A stock image related to artificial turf manufacturer.

- Margin: Finally, profit margins for manufacturers can differ based on their operational efficiencies and market position. Understanding a supplier’s margin can provide insight into their pricing strategy and potential for negotiation.

How Do Price Influencers Affect Artificial Turf Sourcing?

Several factors influence pricing that international B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to lower per-unit costs. Negotiate MOQs to find a balance that meets your needs without overcommitting resources.

-

Specifications and Customization: Custom designs may incur additional costs. Clearly define your specifications upfront to avoid unexpected charges later in the process.

-

Material Quality and Certifications: Products that meet international certifications may command higher prices. Verify that the supplier can provide the necessary documentation to ensure compliance with your region’s regulations.

-

Supplier Factors: The reputation, location, and operational efficiency of the supplier can greatly influence pricing. Conduct thorough due diligence to identify reliable partners.

-

Incoterms: Understanding Incoterms can help clarify responsibilities regarding shipping, insurance, and tariffs, which can significantly affect overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency in Artificial Turf Procurement?

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially if you are a repeat buyer or if you can commit to larger orders.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial purchase price, consider the TCO, which includes installation, maintenance, and expected lifespan. A higher upfront cost may lead to lower long-term expenses.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to labor costs, material availability, and market demand. Buyers from Africa, South America, the Middle East, and Europe should be prepared to navigate these differences.

-

Stay Updated on Market Trends: Regularly review market conditions and emerging technologies in artificial turf to ensure you are getting the best value.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of artificial turf manufacturing is essential for international B2B buyers. By considering the various cost components, price influencers, and implementing strategic purchasing practices, buyers can optimize their sourcing process and achieve better cost efficiency. Always remember that indicative prices can fluctuate based on market conditions, so continuous engagement with suppliers is key to securing favorable terms.

Alternatives Analysis: Comparing artificial turf manufacturer With Other Solutions

In the rapidly evolving landscape of sports and landscaping solutions, B2B buyers must evaluate various options to determine the most effective product for their needs. Artificial turf manufacturers offer a synthetic alternative for grass, widely used in sports fields, landscaping, and playgrounds. However, several alternatives exist that may align better with specific business requirements or budget constraints. This section explores these alternatives, providing a comprehensive analysis to help international buyers from Africa, South America, the Middle East, and Europe make informed decisions.

Comparison Table of Artificial Turf and Alternatives

| Comparison Aspect | Artificial Turf Manufacturer | Natural Grass | Hybrid Grass |

|---|---|---|---|

| Performance | High durability, consistent playability | Natural feel, variable performance | Combines benefits of both, adaptable |

| Cost | Higher initial investment, lower long-term maintenance | Lower initial cost, ongoing maintenance | Moderate cost, ongoing maintenance |

| Ease of Implementation | Requires professional installation | Simple for small areas, complex for large | Complex installation, requires expertise |

| Maintenance | Minimal (occasional brushing and washing) | High (watering, mowing, fertilizing) | Moderate (less frequent than natural grass) |

| Best Use Case | Sports fields, high-traffic areas | Residential gardens, parks | Sports fields, golf courses |

What Are the Pros and Cons of Natural Grass?

Natural grass is often the most traditional choice for landscaping and sports applications. Pros include a lower initial investment and a pleasing aesthetic that many people prefer. It provides a natural feel and can be beneficial for the environment. However, cons include high maintenance requirements, such as regular watering, mowing, and fertilization, which can lead to higher long-term costs. In regions like South America and Africa, where water scarcity is a concern, maintaining natural grass can be challenging.

How Does Hybrid Grass Compare?

Hybrid grass combines natural grass with synthetic fibers, offering a unique blend of advantages. Pros include reduced maintenance compared to natural grass and enhanced durability. It provides a more natural appearance than artificial turf while still requiring less care. However, cons involve higher installation complexity and costs, which may deter some buyers. This option is particularly appealing for sports facilities in the Middle East and Europe, where climate and usage patterns demand resilient solutions.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right solution for landscaping or sports applications involves careful consideration of the specific needs of your business. Factors such as budget, maintenance capabilities, and the intended use of the space should guide your decision. While artificial turf offers durability and low maintenance, natural and hybrid grass can provide aesthetic and environmental benefits. By evaluating the pros and cons of each option, B2B buyers from diverse regions can make informed decisions that align with their operational needs and financial constraints.

Essential Technical Properties and Trade Terminology for artificial turf manufacturer

What Are the Key Technical Properties of Artificial Turf That B2B Buyers Should Know?

When sourcing artificial turf, understanding its technical properties is crucial for making informed purchasing decisions. Below are some essential specifications to consider:

1. Material Grade: What Should You Look For?

The material grade of artificial turf typically refers to the quality of the polyethylene or polypropylene fibers used. Higher-grade materials are more durable and resistant to UV rays, ensuring longevity in various climates. For B2B buyers, selecting a high-grade material can reduce replacement costs and minimize maintenance, especially in regions with extreme weather conditions.

2. Pile Height: How Does It Affect Performance?

Pile height refers to the length of the grass fibers and is a critical factor in determining the turf’s appearance and functionality. Shorter piles (about 20-30mm) are suitable for sports fields, providing a firm surface, while longer piles (40mm or more) are often preferred for landscaping or recreational use. Understanding pile height helps buyers choose turf that meets their specific application needs.

3. Face Weight: Why Is It Important?

Face weight, measured in ounces per square yard, indicates the density of the turf fibers. A higher face weight typically signifies a more robust and durable product, which is essential for high-traffic areas. B2B buyers should consider face weight when evaluating the longevity and performance of artificial turf, especially for commercial installations.

4. Infill Type and Depth: What Should You Consider?

Infill materials, such as rubber, sand, or a combination of both, play a vital role in the performance and safety of artificial turf. The depth of infill can affect shock absorption, drainage, and overall feel. Buyers should assess the intended use of the turf to determine the appropriate infill type and depth, ensuring optimal performance and safety for users.

5. UV Resistance: How Does It Impact Durability?

UV resistance is a measure of how well the turf can withstand sun exposure without fading or degrading. For buyers in regions with intense sunlight, such as parts of Africa and the Middle East, UV resistance is crucial for ensuring the longevity of the investment. Look for products with a warranty that specifies UV stability to protect against premature wear.

Which Trade Terms Should B2B Buyers Understand When Purchasing Artificial Turf?

Familiarizing yourself with industry jargon can streamline the procurement process and enhance communication with suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of artificial turf, it often indicates that the turf is made by a specific manufacturer who is recognized for quality. Understanding OEM relationships can help buyers identify reliable suppliers and assess product quality.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers as it impacts budgeting and inventory management. Knowing the MOQ helps buyers plan their orders efficiently and avoid excess inventory, especially in markets with fluctuating demand.

3. RFQ (Request for Quotation): How Should You Use It?

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. This process allows buyers to compare prices and terms across multiple suppliers, ensuring they receive the best deal. Crafting a detailed RFQ can lead to more accurate quotes and better negotiation outcomes.

4. Incoterms: Why Are They Important for International Trade?

Incoterms, or International Commercial Terms, are a set of predefined trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, insurance, and risk management. Familiarity with Incoterms can prevent misunderstandings and costly disputes during the procurement process.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing artificial turf, ultimately leading to successful procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the artificial turf manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Artificial Turf Manufacturing Sector?

The artificial turf manufacturing sector is experiencing significant growth, driven by increasing urbanization, a rising focus on sustainability, and advancements in manufacturing technologies. In regions such as Africa and South America, the demand for artificial turf is surging due to the need for durable, low-maintenance landscaping solutions in both residential and commercial spaces. In contrast, Europe and the Middle East are witnessing a shift towards high-performance turf solutions, particularly for sports fields and recreational areas, as cities invest in infrastructure improvements to accommodate growing populations.

A stock image related to artificial turf manufacturer.

Emerging B2B tech trends include the integration of smart technologies in turf solutions, such as sensors for monitoring wear and tear, as well as automated maintenance systems. These innovations not only enhance product longevity but also appeal to buyers looking for cost-effective solutions. Additionally, the rise of e-commerce platforms is transforming the sourcing landscape, allowing international buyers to connect directly with manufacturers, thereby reducing lead times and costs.

How Is Sustainability Influencing Sourcing Decisions in the Artificial Turf Sector?

Sustainability has become a cornerstone of sourcing strategies in the artificial turf manufacturing sector. International buyers are increasingly aware of the environmental impact associated with synthetic materials, leading to a heightened demand for ethically sourced products. Buyers from Africa, South America, the Middle East, and Europe are prioritizing suppliers that demonstrate commitment to sustainable practices, such as using recycled materials and non-toxic production processes.

The importance of ethical supply chains cannot be overstated. Buyers are not only looking for quality products but also for transparency in sourcing. Certifications such as the Global Recycle Standard (GRS) and the Environmental Product Declaration (EPD) are becoming essential for manufacturers to gain trust and secure contracts with discerning buyers. Furthermore, sustainable artificial turf options are gaining traction, with products designed to reduce heat absorption and promote water conservation, appealing to environmentally conscious consumers.

What Is the Evolution of Artificial Turf Manufacturing?

The artificial turf industry has evolved significantly since its inception in the 1960s. Initially developed for sports fields, the technology has progressed to include diverse applications, from residential lawns to commercial landscaping. The introduction of newer materials and improved manufacturing techniques has led to enhanced durability, aesthetics, and functionality of artificial turf products.

Over the past two decades, the industry has seen a marked shift toward sustainability, driven by both consumer demand and regulatory pressures. The latest innovations focus on creating eco-friendly options that mimic the look and feel of natural grass, while also addressing the environmental concerns associated with traditional synthetic materials. As the market continues to evolve, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of artificial turf manufacturer

-

How do I choose the right artificial turf manufacturer for my project?

Selecting the right artificial turf manufacturer involves assessing several factors. Start by researching manufacturers with a solid reputation in your region, particularly those that have experience in projects similar to yours. Evaluate their product range, focusing on quality, durability, and customization options. Request samples to gauge texture and performance. Additionally, check for certifications that ensure compliance with international standards. Engaging in discussions with previous clients can provide insights into reliability and service quality. -

What are the key factors to consider when sourcing artificial turf?

When sourcing artificial turf, key factors include material quality, environmental impact, and supplier reliability. Look for turf made from UV-stabilized polyethylene or polypropylene for durability. Consider the environmental footprint, such as the use of recyclable materials and non-toxic components. Supplier reliability is crucial; verify their production capacity, lead times, and customer service responsiveness. Furthermore, assess their logistics capabilities, especially if you are importing from different regions. -

What customization options are available for artificial turf products?

Many manufacturers offer customization options for artificial turf to meet specific project requirements. These may include variations in pile height, color, and texture to replicate natural grass. Some manufacturers allow for bespoke designs, including logos or patterns for branding purposes. Discuss your needs with potential suppliers to understand their capabilities and any limitations. Customization can enhance the aesthetic appeal and functionality of the turf, making it suitable for various applications, from sports fields to landscaping. -

What are the minimum order quantities (MOQ) for artificial turf purchases?

Minimum order quantities (MOQ) can vary significantly among manufacturers. It is essential to clarify this upfront to avoid unexpected costs. Some manufacturers may have a low MOQ for standard products, while custom designs might require larger orders. If you are purchasing for a smaller project, consider looking for suppliers that specialize in smaller batches or are open to negotiation. Understanding MOQs will help in budgeting and determining whether a manufacturer aligns with your project scale. -

What payment terms should I expect when dealing with international suppliers?

Payment terms can vary widely depending on the manufacturer and the nature of your agreement. Common practices include upfront deposits (usually 30-50%), with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for added security. Always clarify the payment structure before finalizing the order. Additionally, consider the implications of currency exchange rates and international transaction fees, as these can impact overall costs. -

How can I ensure quality assurance when sourcing artificial turf?

To ensure quality assurance, request detailed product specifications and certifications from manufacturers. Look for third-party testing results that verify durability, UV resistance, and safety standards. It’s beneficial to conduct factory visits, if possible, to observe production processes firsthand. Establish a clear quality control agreement that outlines your expectations, including inspection protocols before shipment. Building a strong relationship with your supplier can also enhance transparency and accountability in quality management. -

What logistics considerations should I keep in mind when importing artificial turf?

Logistics play a crucial role in importing artificial turf. Assess the shipping methods available, including air or sea freight, and choose based on your budget and timeline. Understand the customs regulations in your country to avoid delays at the border. Partnering with a logistics provider experienced in handling artificial turf can simplify the process. Additionally, ensure you have a clear understanding of shipping costs, insurance, and potential tariffs that may apply to your imports. -

What are the common challenges faced by international buyers of artificial turf?

International buyers of artificial turf often face challenges such as communication barriers, differing quality standards, and logistical complications. Language differences can lead to misunderstandings regarding product specifications. To mitigate this, ensure clear documentation and confirm details in writing. Variability in quality standards across regions may require thorough vetting of suppliers. Additionally, logistical issues such as delays or unexpected costs can arise, making it crucial to have contingency plans and reliable partners throughout the supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for artificial turf manufacturer

In conclusion, strategic sourcing in the artificial turf manufacturing sector is not just a procurement strategy; it is a pivotal approach that can significantly enhance your competitive advantage. By focusing on supplier relationships, understanding market dynamics, and prioritizing sustainability, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can secure high-quality products while optimizing costs.

What are the key benefits of strategic sourcing for artificial turf buyers? Effective strategic sourcing allows buyers to leverage economies of scale, access innovative materials, and ensure compliance with local regulations. Moreover, aligning with suppliers who prioritize sustainability can lead to enhanced brand reputation and customer loyalty, particularly in environmentally conscious markets.

As the demand for artificial turf continues to grow, driven by urbanization and the need for low-maintenance landscaping solutions, now is the time for buyers to reassess their sourcing strategies. Embrace the opportunity to build robust partnerships with manufacturers who are committed to quality and innovation. By doing so, you position your organization for success in a rapidly evolving marketplace. Engage proactively with suppliers, assess their capabilities, and explore ways to collaborate for mutual growth. The future of artificial turf sourcing is bright, and your strategic decisions today will pave the way for sustainable success.