Top 20 Lithium Car Battery Factories You Should Know

Are you feeling overwhelmed by the surge of electric vehicles and the critical need for reliable lithium car batteries? You’re not alone! With the automotive landscape rapidly evolving, finding the right battery manufacturer can make or break your EV experience. Choosing a top-tier lithium battery factory means ensuring quality, longevity, and performance for your electric vehicle. Imagine cruising with confidence, knowing your car is powered by the best technology available.

In this article, we’ll dive into the top 30 lithium car battery manufacturers, exploring their strengths and innovations. Ready to power up your knowledge? Let’s get started!

Top 20 Lithium Car Battery Factory Manufacturers

Battle Born Batteries – Lithium Power Solutions

Domain: battlebornbatteries.com

Registered: 2016 ( 9 years )

Introduction: Battle Born Batteries primarily offers lithium power solutions, including LiFePO4 batteries, smart batteries, heated batteries, and various related products such as chargers, inverters, and solar panels.

Ascend Elements – Engineered Battery Materials Solutions

Domain: ascendelements.com

Registered: 2021 ( 4 years )

Introduction: Ascend Elements produces high-performance, engineered battery materials using the infinitely recyclable elements found in end-of-life batteries and manufacturing scrap, primarily through their patented Hydro-to-Cathode® direct cathode precursor (pCAM) synthesis process.

Businessnc – Lithium-Ion Battery Manufacturing Solutions

Domain: businessnc.com

Registered: 1997 ( 28 years )

Introduction: Microporous is establishing a $1.3 billion lithium-ion battery plant in Virginia.

BSLBATT® – Lithium Batteries for Diverse Applications

Domain: lithium-battery-factory.com

Registered: 2018 ( 7 years )

Introduction: BSLBATT® specializes in manufacturing and supplying a wide range of lithium batteries, including LiFePO4 batteries for various applications such as golf carts, recreational vehicles, floor cleaning machines, aerial work platforms, marine use, agricultural equipment, and construction equipment.

Clarios – Advanced Automotive Battery Solutions

Domain: clarios.com

Registered: 2013 ( 12 years )

Introduction: Clarios specializes in advanced battery technologies, particularly for automotive applications, offering a range of lead-acid and lithium-ion batteries.

Statista – Lithium-Ion Battery Manufacturing Solutions

Domain: statista.com

Registered: 2005 ( 20 years )

Introduction: Lithium-ion batteries produced in the largest factories worldwide.

Batteriesinc – Lithium-Ion Battery Solutions

Domain: batteriesinc.net

Registered: 2000 ( 25 years )

Introduction: Lithium-ion battery cells manufactured through electrode manufacturing, cell assembly, and cell finishing processes.

Li-Cycle – Lithium-Ion Battery Recycling Solutions

Domain: li-cycle.com

Registered: 2016 ( 9 years )

Introduction: Li-Cycle specializes in lithium-ion battery recycling, recovering critical materials from end-of-life batteries to support energy independence.

GlobalX ETFs – Lithium Battery Technology Solutions

Domain: globalxetfs.com

Registered: 2008 ( 17 years )

Introduction: Lithium battery technology products for electric vehicles and energy storage solutions.

Ghafari – Electric Vehicle Battery Solutions

Domain: ghafari.com

Registered: 1996 ( 29 years )

Introduction: A battery production facility integral to Ford’s electric vehicle manufacturing strategy, developed in partnership with SK Innovation.

Acc Emotion – High Performance EV Batteries

Domain: acc-emotion.com

Registered: 2020 ( 5 years )

Introduction: High performance lithium-ion batteries for electric vehicles (EVs) aimed at making green automotive technology accessible to everyone.

CATL – Electric Vehicle Battery Solutions

Dragonfly Energy – Lithium Iron Phosphate Batteries

Domain: dragonflyenergy.com

Registered: 2004 ( 21 years )

Introduction: Dragonfly Energy primarily offers lithium-ion batteries for energy storage applications, specifically using lithium iron phosphate (LFP) chemistry.

American Battery Factory – LFP Battery Solutions

Domain: americanbatteryfactory.com

Registered: 2021 ( 4 years )

Introduction: High-performance prismatic Lithium Iron Phosphate (LFP) batteries manufactured in the USA.

Mdpi – Lithium-Ion Battery Solutions

Domain: mdpi.com

Registered: 2003 ( 22 years )

Introduction: Lithium-ion batteries (LIBs) designed for various applications including e-mobility, stationary energy storage, household tools, and consumer electronics.

Natron – Sodium-Ion Battery Solutions

Domain: natron.energy

Registered: 2017 ( 8 years )

Introduction: Natron Energy offers sodium-ion batteries designed for critical power and industrial applications, including the BluePack™ Critical Power Battery, BlueRack™ 250 Battery Cabinet, and BlueTray™ 4000.

Microvast – Advanced Lithium-Ion Battery Solutions

Domain: microvast.com

Registered: 2006 ( 19 years )

Introduction: Microvast produces innovative and reliable lithium-ion batteries with advanced technologies for transportation, heavy equipment, and energy storage.

Lithium Werks – Lithium-Ion Battery Solutions

Domain: lithiumwerks.com

Registered: 2016 ( 9 years )

Introduction: Lithium Werks offers lithium-ion battery cells, custom battery packs, and battery management systems, focusing on 18650 and 26650 Lithium Iron Phosphate Power Cells.

Tds G – Lithium-ion Batteries for Hybrid Vehicles

Domain: tds-g.co.in

Registered: 2019 ( 6 years )

Introduction: Lithium-ion batteries for hybrid vehicles, manufactured in a joint venture between TOSHIBA, DENSO, and Suzuki.

Thisiskokomo – Lithium-Ion Battery Manufacturing Solutions

Domain: thisiskokomo.com

Registered: 2017 ( 8 years )

Introduction: StarPlus Energy offers lithium-ion battery manufacturing services through two state-of-the-art production plants in Kokomo, Indiana, as part of a joint venture between Stellantis and Samsung SDI.

Category Information

The category of ‘lithium car battery factory’ encompasses facilities dedicated to the production of lithium-ion batteries, which are critical components in electric vehicles (EVs). These factories focus on the synthesis of battery materials, cell assembly, and quality control, ensuring that batteries meet the performance and safety standards required for automotive applications. As the demand for electric vehicles continues to rise, driven by a global push for sustainable transportation, the role of these factories becomes increasingly significant.

Lithium car battery factories not only contribute to the growth of the EV market but also play a crucial role in the transition towards renewable energy. By producing efficient and long-lasting batteries, these facilities help reduce greenhouse gas emissions and reliance on fossil fuels. Furthermore, advancements in battery technology, such as improved energy density and charging speeds, are often developed within these manufacturing plants, making them pivotal to the future of clean energy and mobility.

Application Information

Lithium car battery factories primarily serve the automotive industry, particularly in the production of electric vehicles (EVs). As the demand for sustainable transportation grows, these factories are crucial for manufacturing high-capacity lithium-ion batteries that power EVs, contributing to reduced carbon emissions and enhanced energy efficiency. Additionally, lithium batteries are widely used in energy storage solutions for renewable energy systems. This includes applications in solar and wind energy, where batteries store excess energy for use during low production periods.

Furthermore, the consumer electronics sector benefits from lithium batteries, as they are integral to powering devices such as smartphones, laptops, and tablets. Overall, lithium car battery factories play a vital role in advancing clean technology across multiple industries, including automotive, renewable energy, and consumer electronics.

Production Process Information

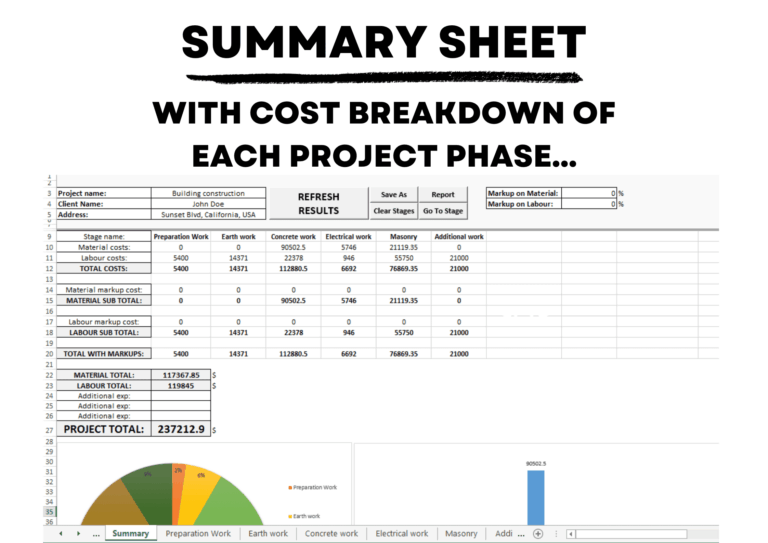

The production of lithium car batteries involves several key stages to ensure high-quality and efficient products. First, raw materials such as lithium, nickel, cobalt, and graphite are sourced and processed. These materials are essential for creating the battery’s components, including the anode, cathode, and electrolyte. Next, these components are assembled in a controlled environment. This stage includes mixing the materials, coating them onto metal foils, and then cutting them into the appropriate shapes.

After assembly, the batteries undergo testing for safety and performance to ensure they meet industry standards. Finally, the batteries are packaged and distributed to manufacturers of electric vehicles. Throughout the process, considerations such as quality control, environmental impact, and supply chain management are crucial to ensure that the production is sustainable and efficient.

Related Video

Frequently Asked Questions (FAQs)

What should I look for when choosing a lithium car battery manufacturer?

When selecting a lithium car battery manufacturer, consider their experience in the industry, production capacity, and technology used in their batteries. Look for certifications such as ISO and UL to ensure quality and safety standards. It’s also beneficial to check their reputation through customer reviews and case studies. Lastly, consider their ability to provide support and service after the sale, as ongoing communication can be crucial for long-term partnerships.

How can I verify the quality of lithium batteries from a supplier?

To verify the quality of lithium batteries, request samples for testing and evaluation. You should also ask for documentation of their testing processes and results, including cycle life, capacity, and safety tests. Inquire about their quality control procedures and any certifications they hold. Visiting the factory for an audit or inspection can also provide insights into their manufacturing practices and quality assurance processes.

What are the typical lead times for ordering lithium car batteries?

Lead times can vary significantly based on the manufacturer, order size, and customization requirements. Generally, standard orders may take anywhere from a few weeks to a couple of months. If you need custom batteries or have large volume orders, it’s wise to discuss timelines upfront and factor in potential delays due to supply chain issues. Always confirm lead times in writing to avoid any surprises.

Are there minimum order quantities (MOQs) I should be aware of?

Yes, most lithium battery manufacturers have minimum order quantities (MOQs) that can range from a few dozen to several hundred units, depending on the supplier and the specifics of the battery. It’s important to discuss MOQs early in your conversations with potential suppliers to ensure they align with your needs. Some manufacturers may offer flexibility for first-time buyers or smaller companies, so don’t hesitate to ask.

What should I consider regarding warranty and after-sales support?

When choosing a lithium battery supplier, carefully review their warranty policies and after-sales support options. A good warranty will typically cover defects in materials and workmanship for a specified period, often ranging from 1 to 5 years. Additionally, inquire about their customer service responsiveness and the availability of technical support. Having a reliable point of contact for troubleshooting and maintenance can make a significant difference in your experience with the product.