Maximize ROI: The Ultimate Windows Custom Guide (2025)

Introduction: Navigating the Global Market for windows custom

In today’s competitive landscape, sourcing high-quality custom windows can pose significant challenges for international B2B buyers. From navigating diverse market standards to understanding regional preferences, businesses must streamline their procurement processes to meet specific architectural needs. This guide serves as a comprehensive resource, addressing essential aspects such as the various types of custom windows available, their applications in different sectors, and effective supplier vetting strategies.

International buyers, particularly from Africa, South America, the Middle East, and Europe, will find invaluable insights into cost considerations and quality assurance practices to enhance their purchasing decisions. By delving into regional trends and supplier capabilities, this guide empowers businesses to make informed choices that align with their project requirements and budget constraints.

Furthermore, it highlights the importance of understanding local regulations and environmental factors that can influence window selection and installation. Whether you are aiming to enhance energy efficiency or improve aesthetic appeal, this guide will equip you with the knowledge necessary to navigate the global market for custom windows effectively. Prepare to elevate your procurement strategy and foster successful partnerships that drive growth in your projects.

Understanding windows custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Vinyl Windows | Energy-efficient, low maintenance, versatile designs | Commercial buildings, residential complexes | Pros: Cost-effective, durable. Cons: Limited color options. |

| Custom Aluminum Windows | Lightweight, corrosion-resistant, modern aesthetics | High-rise buildings, industrial facilities | Pros: Strong, sleek design. Cons: Higher initial cost. |

| Custom Wood Windows | Natural insulation, aesthetic appeal, customizable shapes | Luxury homes, boutique hotels | Pros: Excellent insulation, customizable. Cons: Requires regular maintenance. |

| Custom Composite Windows | Combines materials for durability and aesthetics | Eco-friendly projects, upscale residential | Pros: Low maintenance, energy-efficient. Cons: Price can be high. |

| Custom Fiberglass Windows | High strength, thermal performance, low expansion | Industrial applications, harsh environments | Pros: Excellent durability, energy-efficient. Cons: Higher upfront costs. |

What are the Characteristics of Custom Vinyl Windows?

Custom vinyl windows are known for their energy efficiency and low maintenance requirements. They are available in a wide range of styles, colors, and designs, making them suitable for various architectural needs. B2B buyers should consider the long-term cost savings associated with energy-efficient features, as well as the durability that vinyl offers. These windows are particularly popular in commercial buildings and residential complexes due to their affordability and performance.

How Do Custom Aluminum Windows Stand Out?

Custom aluminum windows are characterized by their lightweight structure and resistance to corrosion, making them ideal for high-rise buildings and industrial facilities. Their modern aesthetic appeals to contemporary designs, providing a sleek finish. B2B buyers should weigh the initial investment against the long-term benefits, as aluminum windows tend to have a higher upfront cost but offer longevity and low maintenance. Their strength makes them suitable for demanding environments.

Why Choose Custom Wood Windows for Luxury Projects?

Custom wood windows offer a natural insulation solution and a timeless aesthetic that is highly customizable. They are often chosen for luxury homes and boutique hotels to enhance the overall design. However, buyers must consider the need for regular maintenance to preserve the wood’s integrity and appearance. The aesthetic appeal and excellent insulation properties can justify the investment, especially in high-end markets.

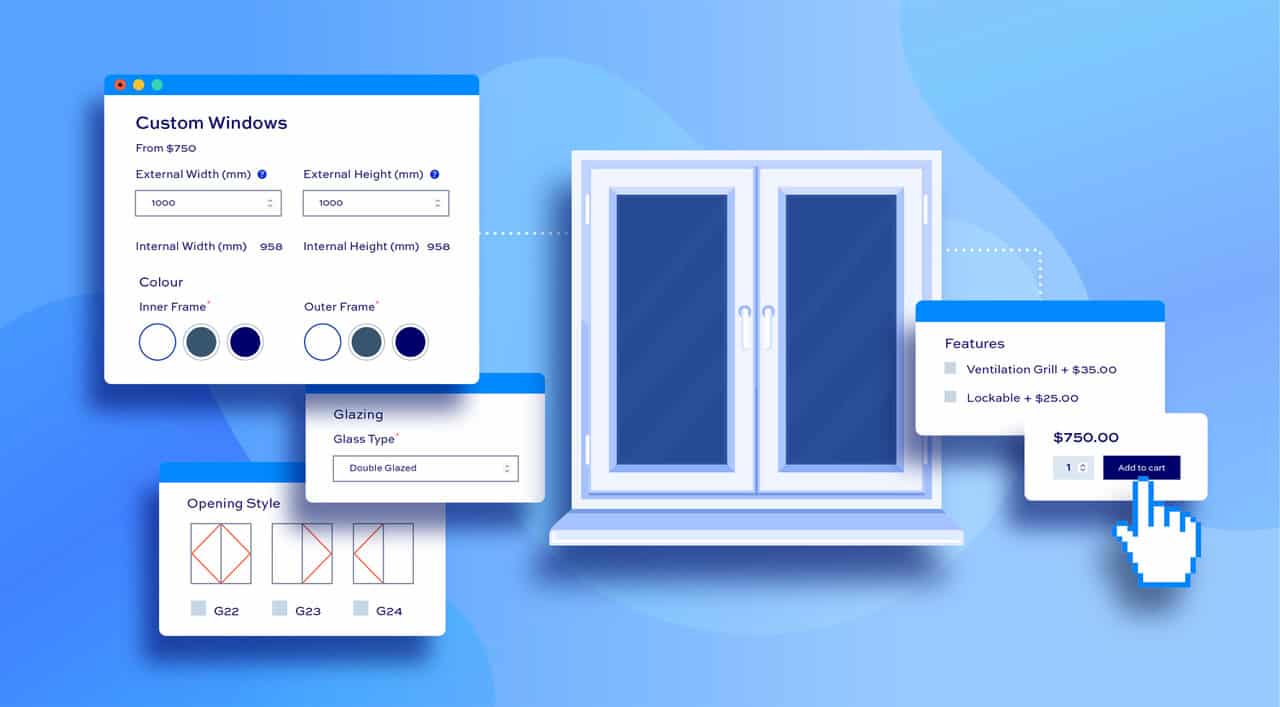

A stock image related to windows custom.

What Makes Custom Composite Windows an Eco-Friendly Option?

Custom composite windows combine various materials to achieve durability and aesthetic appeal, making them a popular choice for eco-friendly projects and upscale residential developments. These windows typically require less maintenance and provide energy efficiency, appealing to environmentally conscious B2B buyers. However, the cost can be higher than traditional materials, so it’s essential to evaluate the potential return on investment regarding energy savings and reduced upkeep.

When Should B2B Buyers Consider Custom Fiberglass Windows?

Custom fiberglass windows are known for their exceptional strength and thermal performance, making them suitable for industrial applications and environments with harsh weather conditions. They exhibit low expansion and contraction, which contributes to their durability. While the initial costs are generally higher, the long-term energy efficiency and low maintenance needs make them an attractive option for B2B buyers looking for reliable solutions in demanding applications.

Related Video: SOAP Web Services 13 – Service Interface and Custom Types

Key Industrial Applications of windows custom

| Industry/Sector | Specific Application of windows custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Custom-sized windows for residential and commercial buildings | Enhanced energy efficiency and aesthetic appeal | Compliance with local building codes and energy regulations |

| Automotive | Custom windows for vehicle manufacturing | Improved vehicle safety and energy efficiency | Material durability and resistance to weather conditions |

| Renewable Energy | Custom windows for solar panel installations | Increased energy capture and efficiency | Compatibility with existing solar technologies and frameworks |

| Marine & Shipping | Custom windows for ships and marine vessels | Enhanced durability and safety in harsh environments | Resistance to corrosion and compliance with maritime standards |

| Electronics & Technology | Custom windows for electronic device enclosures | Better protection against environmental factors | Precision engineering and material quality |

How Are Custom Windows Used in the Construction Industry?

In the construction and architecture sector, custom windows are essential for both residential and commercial buildings. They provide tailored solutions to meet specific design requirements and improve energy efficiency, which is increasingly critical in today’s market. International buyers must consider local building codes, energy regulations, and aesthetic trends to ensure compliance and appeal to local consumers. Custom windows can also enhance the overall aesthetic of a building, providing a competitive edge in the real estate market.

What Role Do Custom Windows Play in the Automotive Sector?

In the automotive industry, custom windows are pivotal in vehicle manufacturing. They are designed to fit specific models, ensuring optimal safety and energy efficiency. These windows can be made from specialized materials that enhance durability and reduce weight, contributing to better fuel economy. For B2B buyers in this sector, sourcing considerations include ensuring compliance with safety regulations and durability standards, as well as the ability to withstand various environmental conditions.

Why Are Custom Windows Important for Renewable Energy Applications?

Custom windows are increasingly used in renewable energy sectors, particularly in solar panel installations. These windows can be designed to maximize sunlight capture, thereby increasing the efficiency of solar panels. For buyers in Africa and South America, where solar energy is a growing market, it’s crucial to source windows that are compatible with existing technologies and frameworks. This ensures that the installation process is seamless and that the systems perform optimally over their lifespan.

How Do Custom Windows Enhance Marine and Shipping Applications?

In the marine and shipping industry, custom windows are vital for ensuring the safety and durability of vessels. These windows are engineered to withstand harsh marine environments, including saltwater and extreme weather conditions. B2B buyers must prioritize sourcing materials that resist corrosion and meet maritime safety standards. Custom solutions can significantly enhance the longevity of ships, ultimately reducing maintenance costs and improving operational efficiency.

What Are the Benefits of Custom Windows in Electronics and Technology?

In the electronics and technology sector, custom windows are used to protect sensitive devices from environmental factors such as dust, moisture, and temperature fluctuations. These windows are often crafted from high-quality materials that offer superior protection while maintaining aesthetic appeal. Buyers should focus on precision engineering and the quality of materials when sourcing custom windows for electronic enclosures, as these factors directly impact product performance and longevity.

Related Video: Create Your OWN⚡️CUSTOM Windows ISO with Pre-Installed Software (Safe & FASTEST)

3 Common User Pain Points for ‘windows custom’ & Their Solutions

Scenario 1: Struggling with Compliance and Regulations in Custom Windows

The Problem: Many B2B buyers, especially in regions like Africa and South America, face significant challenges when it comes to compliance with local building regulations and standards. These regulations can vary widely from one country to another, making it difficult to ensure that custom windows meet all necessary requirements. Buyers may find themselves in a situation where they have sourced custom windows that do not adhere to local codes, resulting in costly delays and potential legal issues.

The Solution: To navigate this complexity, it is essential to work closely with local experts who understand the specific regulations in your region. Before placing an order for custom windows, engage a local architect or building consultant who can provide insights into compliance requirements. Additionally, ask suppliers for detailed documentation that outlines how their products meet local standards. This proactive approach not only minimizes risks but also helps streamline the installation process, ensuring that your project stays on schedule and within budget.

Scenario 2: Overwhelmed by Customization Options for Windows

The Problem: B2B buyers often feel overwhelmed by the vast array of customization options available for windows. With choices ranging from materials and colors to energy efficiency ratings and security features, it can be challenging to determine which specifications best suit their project’s needs. This indecision can lead to delays in purchasing decisions, ultimately affecting project timelines.

The Solution: To simplify the decision-making process, create a clear set of criteria based on your project’s goals. For instance, consider factors such as climate, building design, and budget constraints. Engage with suppliers who offer consultation services to help you narrow down your options based on your specific requirements. Utilizing tools like design software can also aid in visualizing how different window styles and features will look in your project, enabling a more informed choice. This structured approach helps streamline your purchasing process and ensures that the chosen custom windows align with your overall design vision.

Scenario 3: Difficulty in Ensuring Quality and Performance of Custom Windows

The Problem: Quality assurance is a critical concern for B2B buyers, particularly when investing in custom windows. In regions like the Middle East, where extreme weather conditions are common, buyers may worry about the durability and performance of the windows they are procuring. Issues such as poor insulation, water leakage, and frame deterioration can lead to significant long-term costs and dissatisfaction.

The Solution: To mitigate these quality concerns, conduct thorough due diligence on potential suppliers. Look for manufacturers with a proven track record and positive customer testimonials. Request samples of the windows to evaluate their quality firsthand. Additionally, consider suppliers who offer warranties and after-sales support, as these can be indicators of a company’s confidence in their product. It’s also beneficial to conduct performance tests—like thermal imaging or water resistance tests—before finalizing your order. By implementing these strategies, you can ensure that the custom windows you choose will withstand the test of time and environmental challenges.

Strategic Material Selection Guide for windows custom

When selecting materials for custom windows, it is crucial to consider properties such as durability, cost, and performance under various environmental conditions. Below, we analyze four common materials used in the production of custom windows, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Aluminum for Custom Windows?

Aluminum is a popular choice for custom windows due to its lightweight nature and high strength-to-weight ratio. It exhibits excellent corrosion resistance, making it suitable for various climates, including humid environments. Aluminum can withstand significant temperature variations, ensuring that it maintains its structural integrity under pressure.

Pros & Cons:

– Pros: Durable, low maintenance, and recyclable. Aluminum windows can be finished in various colors and styles, enhancing aesthetic appeal.

– Cons: Higher initial costs compared to other materials like vinyl. It can conduct heat, leading to energy inefficiencies if not properly insulated.

Impact on Application: Aluminum is compatible with various media types, including residential and commercial applications. However, its thermal conductivity can impact energy efficiency, necessitating the use of thermal breaks.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is essential. Buyers in Europe and the Middle East may prefer aluminum windows that meet specific energy efficiency ratings, while those in Africa and South America might prioritize cost-effectiveness.

How Does Vinyl Compare as a Material for Custom Windows?

Vinyl is another widely used material for custom windows, known for its excellent insulation properties. It is resistant to moisture, rot, and insects, making it ideal for regions with high humidity or pest issues. Vinyl windows also have a good temperature rating, performing well in both hot and cold climates.

Pros & Cons:

– Pros: Cost-effective, low maintenance, and energy-efficient due to its insulating properties.

– Cons: Limited color options and can become brittle over time when exposed to UV light.

Impact on Application: Vinyl windows are particularly suitable for residential applications, where energy efficiency is a priority. However, they may not be suitable for high-end commercial projects due to aesthetic limitations.

Considerations for International Buyers: Buyers should ensure compliance with local building codes and standards, such as DIN in Europe and ASTM in the U.S. Preference may vary by region; for instance, buyers in Europe may seek high-performance vinyl options.

What Are the Advantages of Wood as a Material for Custom Windows?

Wood offers a classic aesthetic and is often favored for its natural beauty and insulation properties. It has excellent thermal performance, making it suitable for energy-efficient designs. Additionally, wood can be treated for enhanced durability against moisture and pests.

Pros & Cons:

– Pros: Superior aesthetic appeal and excellent insulation properties. Can be customized easily.

– Cons: Higher maintenance requirements and susceptibility to rot and insect damage if not properly treated.

Impact on Application: Wood is ideal for residential applications where aesthetics are paramount. However, it may not be suitable for extreme weather conditions without proper treatment.

Considerations for International Buyers: Buyers must consider the availability of treated wood and compliance with environmental regulations, particularly in regions like Europe, where sustainability is a key concern.

How Does Fiberglass Stand Up as a Material for Custom Windows?

Fiberglass is gaining popularity in the custom window market due to its strength and thermal efficiency. It is highly resistant to warping, cracking, and fading, making it suitable for various climates. Fiberglass windows can also be painted or stained, offering aesthetic flexibility.

Pros & Cons:

– Pros: Highly durable, low maintenance, and excellent energy efficiency.

– Cons: Higher upfront costs and limited availability in some regions.

Impact on Application: Fiberglass windows are suitable for both residential and commercial applications, especially in areas with extreme weather conditions.

Considerations for International Buyers: Buyers should verify compliance with international standards and consider the availability of fiberglass products in their region, particularly in Africa and South America.

Summary Table of Material Selection for Custom Windows

| Material | Typical Use Case for windows custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Commercial and residential windows | Lightweight and corrosion-resistant | Higher initial costs | Medium |

| Vinyl | Residential windows | Cost-effective and energy-efficient | Limited color options | Low |

| Wood | High-end residential applications | Superior aesthetic appeal | Higher maintenance requirements | High |

| Fiberglass | Residential and commercial windows | Highly durable and low maintenance | Higher upfront costs | High |

This guide provides a comprehensive overview of the materials available for custom windows, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for windows custom

What Are the Main Stages in the Manufacturing Process for Custom Windows?

The manufacturing process for custom windows typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess suppliers and ensure they meet specific quality standards.

Material Preparation: What Materials Are Used in Custom Windows?

The first step in the manufacturing process involves selecting and preparing raw materials, which may include various types of glass, aluminum, PVC, or wood. The choice of material significantly impacts the window’s thermal efficiency, durability, and aesthetic appeal.

During this phase, suppliers often conduct material inspections to verify that the raw materials meet industry standards and specifications. For instance, glass should conform to safety standards such as ANSI Z97.1, while aluminum may need to meet ASTM standards for corrosion resistance.

How Are Custom Windows Formed?

The forming stage is where raw materials are shaped into the desired window profiles. This often involves cutting, bending, or extruding materials. Advanced technologies such as CNC (Computer Numerical Control) machining and laser cutting are commonly employed to ensure precision and minimize waste.

Buyers should inquire about the forming techniques used by suppliers, as these can affect the final product’s structural integrity and performance. Innovative forming methods can also lead to more complex designs, allowing buyers to customize windows to meet specific architectural requirements.

What Does the Assembly Process Entail?

Once the components are formed, they are assembled into a complete window unit. This stage may involve welding, sealing, or mechanically fastening parts together, depending on the material used. Quality assurance during assembly is critical, as any defects can compromise the window’s performance.

B2B buyers should look for suppliers that utilize automated assembly techniques, which can enhance consistency and reduce human error. Additionally, understanding the supplier’s assembly methods can provide insight into their production capabilities and potential lead times.

What Finishing Techniques Are Commonly Used?

The finishing stage encompasses painting, coating, and applying sealants to enhance the window’s appearance and functionality. This is crucial for ensuring that the windows are not only visually appealing but also protected against environmental factors such as UV rays, moisture, and temperature fluctuations.

Buyers should consider the finishing techniques employed by suppliers, as these can influence the longevity and maintenance requirements of the windows. For instance, a high-quality powder coating process can provide superior durability compared to traditional paint.

What Are the Key Quality Assurance Standards for Custom Windows?

Quality assurance (QA) is essential in the manufacturing of custom windows, ensuring that the final products meet specified standards and customer expectations. International standards like ISO 9001 and industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) play a significant role in establishing quality benchmarks.

How Do International Standards Impact Custom Window Quality?

ISO 9001 is a globally recognized standard for quality management systems, emphasizing a process-oriented approach. Suppliers adhering to this standard demonstrate their commitment to continuous improvement and customer satisfaction. B2B buyers should prioritize suppliers with ISO 9001 certification, as this indicates a systematic approach to quality control.

The CE marking signifies compliance with European safety, health, and environmental protection standards. For buyers in Europe, verifying that suppliers hold CE certification is crucial for ensuring product compliance with EU regulations.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Conducted upon receipt of raw materials to verify that they meet specified standards.

- In-Process Quality Control (IPQC): Performed during the manufacturing stages to identify and rectify defects early.

- Final Quality Control (FQC): Conducted on finished products to ensure they meet all specifications before shipment.

A stock image related to windows custom.

Buyers should inquire about the specific QC processes employed by suppliers, as thorough inspections at these checkpoints can significantly reduce the risk of defects in the final product.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods for custom windows may vary based on the materials used and the intended application. Common testing methods include:

- Water Penetration Testing: Assesses the window’s ability to resist water leakage under pressure.

- Air Infiltration Testing: Evaluates the window’s resistance to air leakage, which is critical for energy efficiency.

- Structural Testing: Determines the window’s ability to withstand various loads and stresses.

B2B buyers should seek suppliers that conduct these tests in compliance with relevant standards, such as ASTM E1105 for water penetration and ASTM E283 for air infiltration.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality assurance standards, buyers can take several proactive steps:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures firsthand.

- Quality Reports: Requesting documentation of quality control procedures and testing results can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the supplier’s quality practices and compliance with international standards.

By implementing these strategies, B2B buyers from Africa, South America, the Middle East, and Europe can ensure they partner with suppliers that maintain rigorous quality assurance practices.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements and quality assurance practices that may differ by region. For instance, while ISO 9001 is widely recognized, certain countries may have additional local standards or certifications that are relevant to the construction and manufacturing industries.

Understanding these nuances is essential for B2B buyers to ensure compliance with local regulations and to avoid potential delays or legal issues. It is advisable to consult with local industry experts or legal advisors to stay informed about the specific requirements in the target market.

By taking a comprehensive approach to understanding manufacturing processes and quality assurance, international B2B buyers can make informed decisions when selecting suppliers for custom windows, ensuring they receive products that meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘windows custom’

This practical sourcing guide is designed to assist B2B buyers in navigating the complex process of procuring custom windows. With the increasing demand for tailored solutions in various markets, including Africa, South America, the Middle East, and Europe, this checklist will ensure that you make informed and strategic decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical requirements. Consider the dimensions, materials, energy efficiency ratings, and aesthetic preferences. This step ensures that you communicate your needs effectively to suppliers, reducing the likelihood of misunderstandings and misaligned expectations.

Step 2: Research Market Trends and Supplier Capabilities

Understanding the current market trends in custom windows can provide insights into innovative solutions and competitive pricing. Research suppliers’ capabilities in relation to these trends:

– Look for suppliers who are adapting to eco-friendly materials or energy-efficient designs.

– Examine their production capacity to meet your demand.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. Key aspects to verify include:

– Experience: Check how long they have been in business and their portfolio of completed projects.

– Reputation: Investigate online reviews and industry feedback to gauge their reliability and product quality.

Step 4: Verify Supplier Certifications and Compliance

Ensuring that your suppliers meet international and local regulations is critical for avoiding legal issues and ensuring product quality. Look for certifications such as ISO, CE, or other relevant industry standards. This not only guarantees compliance but also reflects a commitment to quality and safety.

Step 5: Request Samples and Prototypes

Before finalizing your order, ask for samples or prototypes to assess the quality and craftsmanship of the windows. This step is vital to:

– Validate the supplier’s claims about material quality and durability.

– Ensure that the final product aligns with your specifications.

Step 6: Negotiate Terms and Pricing

Once you have selected potential suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Consider the following:

– Volume Discounts: Inquire about pricing breaks for larger orders.

– Payment Flexibility: Discuss payment terms that suit your cash flow needs.

Step 7: Establish a Clear Communication Channel

Effective communication is key to a successful partnership. Establish a clear line of communication with your chosen supplier to ensure that any issues are promptly addressed. Regular updates on production timelines, shipping, and potential delays can help maintain transparency and build trust.

By following this checklist, B2B buyers can streamline their sourcing process for custom windows, ensuring they select the right suppliers and products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for windows custom Sourcing

What Are the Key Cost Components in Custom Windows Sourcing?

When evaluating the cost structure of custom windows, several components come into play that significantly influence the overall pricing. Understanding these components can help international B2B buyers make informed decisions.

-

Materials: The type of materials used—such as wood, aluminum, or vinyl—can vary greatly in cost. Specialty materials or those with high thermal efficiency may incur additional expenses. Buyers should assess the long-term benefits of investing in higher-quality materials versus lower-cost alternatives.

-

Labor: Labor costs can fluctuate based on the region where production occurs. For instance, countries in Africa and South America may offer lower labor costs compared to European manufacturers. However, this can also reflect on the skill level and craftsmanship, which is vital for custom products.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and equipment depreciation. Understanding the manufacturer’s overhead can provide insights into pricing and potential areas for negotiation.

-

Tooling: Custom windows often require specialized tooling, which can be a significant upfront investment. Buyers should inquire about these costs and consider them in the total cost of ownership.

-

Quality Control (QC): Implementing robust QC measures adds to the overall cost but is essential for ensuring product reliability and compliance with international standards. Buyers should seek suppliers who prioritize quality, as this can prevent costly issues down the line.

-

Logistics: Shipping and handling costs can vary significantly based on the size and weight of the windows. This is particularly relevant for international buyers who may face additional tariffs or customs fees.

-

Margin: The manufacturer’s profit margin is another critical component. Understanding the typical margins in different regions can help buyers gauge whether prices are fair or inflated.

How Do Price Influencers Affect Custom Windows Sourcing?

Several factors can influence the pricing of custom windows, which buyers must consider when sourcing internationally.

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically lead to lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing capabilities to maximize cost savings.

-

Specifications and Customization: The more customized a product is, the higher the cost. Buyers should clearly define their specifications and weigh the benefits of customization against the associated costs.

-

Material Quality and Certifications: Higher quality materials and certifications (like energy efficiency ratings) can increase initial costs but may lead to savings in maintenance and energy over time.

-

Supplier Factors: The reputation, location, and reliability of the supplier can affect pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining responsibility for shipping costs, risks, and insurance. This knowledge can lead to more favorable terms and reduced overall costs.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings.

-

Research and Benchmarking: Before entering negotiations, conduct thorough research on market prices and competitor offerings. This data can empower buyers during discussions.

-

Leverage Relationships: Building long-term relationships with suppliers can provide leverage in negotiations. Suppliers may offer better pricing or terms to repeat customers.

-

Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider the TCO, which includes installation, maintenance, and energy costs. This holistic view can justify higher upfront costs for better quality products.

-

Flexible Payment Terms: Negotiate payment terms that can ease cash flow, such as longer payment periods or installment plans, which can make larger orders more manageable.

Final Considerations for International B2B Buyers

While prices may vary based on numerous factors, understanding the comprehensive cost structure and pricing influencers of custom windows is essential for making informed purchasing decisions. Always approach sourcing with a clear strategy, focusing on both immediate costs and long-term value. Keep in mind that the prices discussed are indicative and may fluctuate based on market conditions and specific supplier circumstances.

Alternatives Analysis: Comparing windows custom With Other Solutions

When considering ‘windows custom’, it is essential for international B2B buyers to evaluate alternative solutions that may better suit their specific operational needs. This section explores viable alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases to guide decision-making.

Comparison Table of ‘Windows Custom’ and Alternatives

| Comparison Aspect | Windows Custom | Alternative 1: Pre-built Windows | Alternative 2: Linux-based Systems |

|---|---|---|---|

| Performance | High performance for tailored applications | Moderate performance, limited by standard features | High performance, especially for server tasks |

| Cost | Higher initial investment due to customization | Lower cost, generally more affordable | Cost-effective, often open-source |

| Ease of Implementation | Complex, requires skilled developers | Simple, ready-to-use solutions | Moderate complexity, requires IT expertise |

| Maintenance | Ongoing updates and support needed | Minimal maintenance, regular updates provided | Requires technical knowledge for updates |

| Best Use Case | Specific, niche applications needing customization | General business applications | High-performance computing, servers, and development environments |

What Are the Advantages and Disadvantages of Pre-built Windows Solutions?

Pre-built Windows solutions offer a user-friendly alternative to ‘windows custom’. They are designed for quick deployment and ease of use, making them ideal for businesses with limited IT resources. The lower cost is attractive, especially for smaller companies or startups. However, the downside is that these solutions may not meet the specific needs of all businesses, as they can lack the flexibility and advanced features that come with custom development. For companies in Africa and South America, where budget constraints are a primary concern, pre-built options can provide a good balance of functionality and affordability.

How Do Linux-based Systems Compare in Terms of Performance and Cost?

Linux-based systems are another alternative that can be particularly appealing for businesses looking for cost-effective solutions. They are often open-source, which reduces licensing costs significantly. Additionally, Linux excels in performance, especially in server environments, making it a preferred choice for tech-heavy industries in Europe and the Middle East. However, the complexity of implementation can be a barrier, as these systems typically require skilled IT personnel to manage and maintain. For companies with a strong technical background, Linux presents an excellent opportunity to leverage high performance at a lower cost.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between ‘windows custom’ and its alternatives, B2B buyers should conduct a thorough assessment of their operational needs, budget constraints, and technical capabilities. Custom solutions provide unique benefits for specialized applications but come with higher costs and maintenance requirements. Pre-built windows offer a balance of ease and functionality, while Linux-based systems can cater to those needing cost-effective, high-performance options. By aligning their choice with business objectives and resource availability, buyers can ensure they select the most suitable solution for their specific requirements.

Essential Technical Properties and Trade Terminology for windows custom

What Are the Key Technical Properties of Custom Windows?

When selecting custom windows, understanding their technical properties is crucial for B2B buyers. Here are some essential specifications to consider:

1. Material Grade: Why Does It Matter?

The material grade of custom windows influences durability, insulation, and overall performance. Common materials include vinyl, aluminum, and wood, each with distinct properties. For instance, vinyl is known for its energy efficiency and low maintenance, while aluminum offers strength and a modern aesthetic. Choosing the right material grade ensures that the windows meet specific environmental conditions and design requirements.

2. Tolerance Levels: How Do They Impact Fit and Function?

Tolerance levels refer to the allowable deviations in dimensions during manufacturing. For custom windows, precise tolerances are vital for ensuring a proper fit within frames and preventing air leaks. Tighter tolerances often lead to higher manufacturing costs, but they are essential for maintaining energy efficiency and structural integrity, particularly in regions with extreme weather conditions.

3. Thermal Performance: What Should Buyers Look For?

Thermal performance is measured by the U-factor, which indicates the window’s insulation capabilities. A lower U-factor signifies better insulating properties, crucial for energy conservation and comfort. Buyers should prioritize windows with high thermal performance, especially in areas with significant temperature fluctuations, as this can lead to reduced heating and cooling costs over time.

4. Solar Heat Gain Coefficient (SHGC): How Does It Affect Energy Efficiency?

The Solar Heat Gain Coefficient measures how much solar radiation passes through a window. A lower SHGC is preferable in hot climates, as it minimizes heat gain, thereby reducing cooling costs. Conversely, a higher SHGC may be beneficial in colder regions to maximize passive solar heating. Understanding SHGC helps buyers tailor their window selections based on regional climates.

5. Sound Transmission Class (STC): Why Is Noise Control Important?

The Sound Transmission Class rating indicates a window’s ability to reduce sound transmission. For businesses in noisy environments or urban settings, selecting windows with a high STC rating can enhance comfort and productivity. This property is especially relevant for offices, hotels, and residential buildings located near airports or busy roads.

What Are Common Trade Terms in the Custom Windows Industry?

Familiarity with industry terminology can streamline communication and negotiations. Here are several essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer): What Does This Mean for Buyers?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components that meet their specifications. This is crucial when selecting windows that integrate with existing architectural elements.

2. MOQ (Minimum Order Quantity): How Does This Affect Your Purchasing Strategy?

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ can help buyers plan their orders and manage budgets effectively. It’s essential to negotiate MOQs that align with your project needs, especially for large-scale developments.

3. RFQ (Request for Quotation): Why Is This a Key Step in Procurement?

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. This process allows buyers to compare options and negotiate terms effectively. Crafting a detailed RFQ ensures that you receive accurate and competitive quotes from manufacturers.

4. Incoterms: How Do They Govern International Trade?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade transactions. Familiarity with these terms is crucial for understanding shipping costs, risk management, and delivery timelines. Key terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight), which clarify who is responsible for shipping and insurance during transit.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing custom windows, ultimately leading to better project outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the windows custom Sector

What Are the Key Market Dynamics Affecting the Custom Windows Sector?

The custom windows market is currently experiencing significant growth, driven by increasing demand for energy-efficient and aesthetically pleasing architectural solutions. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate a complex landscape influenced by regional preferences, building regulations, and technological advancements. One of the key trends is the integration of smart technologies into window systems, such as automated opening mechanisms and smart tinting, which enhance energy efficiency and user convenience.

Emerging sourcing trends are also shaping the market. The rise of e-commerce platforms is enabling buyers to access suppliers from various regions, providing opportunities to compare prices and quality easily. Additionally, buyers are increasingly seeking suppliers who can provide customization options to cater to specific local needs and architectural styles. The importance of short lead times and rapid prototyping is becoming crucial, as businesses aim to reduce downtime and meet tight project deadlines.

Furthermore, geopolitical factors and supply chain disruptions, such as those caused by the COVID-19 pandemic, are compelling international buyers to diversify their sourcing strategies. It is essential to evaluate suppliers based on their resilience and adaptability in managing unforeseen challenges, ensuring that projects remain on schedule and within budget.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in the Windows Custom Sector?

Sustainability is no longer just a buzzword; it is a crucial consideration in the custom windows sector. International B2B buyers must recognize the environmental impact of their sourcing decisions. The production of windows can involve significant carbon emissions and resource consumption, making it imperative to choose suppliers who prioritize sustainability. This includes utilizing recycled materials and adopting energy-efficient manufacturing processes.

Ethical sourcing practices are equally important. Buyers should seek suppliers who demonstrate transparency in their supply chains, ensuring that raw materials are sourced responsibly and ethically. Certifications such as LEED (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council) can provide assurance that the products meet high environmental and social standards. Additionally, buyers should inquire about the use of eco-friendly materials, such as reclaimed wood or low-VOC (volatile organic compounds) finishes, which contribute to healthier indoor environments.

By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation, meet regulatory requirements, and appeal to environmentally conscious consumers. This strategic approach not only supports the planet but can also lead to long-term cost savings through energy-efficient products.

What Is the Historical Context of the Custom Windows Market for B2B Buyers?

The custom windows market has evolved significantly over the past few decades, influenced by technological advancements and changing consumer preferences. Initially dominated by traditional materials such as wood and aluminum, the sector has seen a shift towards more innovative materials like vinyl and fiberglass, which offer enhanced durability and energy efficiency.

In recent years, the focus has shifted towards customization and personalization, driven by the demand for unique architectural designs. This evolution has been supported by advancements in manufacturing technologies, such as computer-aided design (CAD) and automated production lines, which allow for greater precision and flexibility in meeting customer specifications.

Understanding this historical context is essential for B2B buyers as it highlights the importance of staying informed about market trends and innovations. By recognizing how the market has developed, buyers can better anticipate future changes and adapt their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of windows custom

-

How can I ensure the quality of custom windows from international suppliers?

To ensure the quality of custom windows, start by requesting samples before placing large orders. Utilize third-party inspection services to evaluate the manufacturing process and materials used. Additionally, verify that the supplier adheres to international standards and certifications relevant to your market. Establish clear quality assurance protocols and specify your quality expectations in the contract to mitigate risks. -

What factors should I consider when selecting a supplier for custom windows?

When selecting a supplier, consider their experience in the industry, production capabilities, and the variety of customization options they offer. Research their reputation through customer testimonials and case studies, and ensure they have the capacity to meet your order volume and timelines. Assess their compliance with international regulations and trade agreements relevant to your region to avoid potential legal issues. -

What are the common payment terms for international B2B transactions in the windows industry?

Common payment terms in the windows industry may include a deposit upon order placement (typically 30-50%), followed by the balance before shipment or upon delivery. It’s essential to negotiate terms that align with your cash flow while ensuring the supplier feels secure in the transaction. Consider using letters of credit or escrow services to protect both parties during international transactions. -

What is the minimum order quantity (MOQ) for custom windows, and how does it vary by supplier?

Minimum order quantities (MOQ) for custom windows can vary significantly based on the supplier’s production capabilities and market strategy. Typically, MOQs range from 50 to several hundred units. Discuss your requirements with potential suppliers, as some may be flexible with MOQs for new business relationships or trial orders, especially if you can demonstrate potential for future purchases. -

How can I effectively communicate my custom design requirements to international suppliers?

To effectively communicate your design requirements, provide detailed specifications, including dimensions, materials, colors, and any specific functionality (e.g., energy efficiency). Use CAD drawings or detailed sketches to illustrate your vision. Regularly engage in discussions with the supplier, and consider using collaboration tools to share updates and receive feedback throughout the design process. -

What logistics considerations should I keep in mind when importing custom windows?

When importing custom windows, consider the shipping methods and associated costs, including freight, insurance, and customs duties. Research the best shipping routes and carriers that specialize in fragile goods. Ensure that all documentation, such as bills of lading and customs declarations, is accurate to avoid delays. Additionally, factor in the lead time for production and shipping when planning your project timelines. -

How do trade regulations affect the sourcing of custom windows from international suppliers?

Trade regulations can significantly impact the sourcing of custom windows, particularly concerning tariffs, import restrictions, and compliance with safety standards. Familiarize yourself with the trade agreements between your country and the supplier’s country. Ensure that the products meet local regulations, as failure to comply can result in fines or confiscation of goods. Consulting with a trade expert can provide valuable insights into navigating these complexities. -

What should I include in a contract with an international supplier for custom windows?

A comprehensive contract with an international supplier should include detailed specifications for the windows, payment terms, delivery timelines, and penalties for late delivery. Clearly outline the quality assurance processes and any warranties offered. Include clauses for dispute resolution and governing law to protect your interests. Having a well-structured contract minimizes misunderstandings and provides legal protection in case of issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for windows custom

As the demand for custom windows grows in diverse markets, strategic sourcing emerges as a critical factor for B2B buyers aiming to enhance their procurement strategies. By focusing on quality, supplier reliability, and cost-effectiveness, businesses can significantly improve their operational efficiency and product offerings. The ability to source custom windows from both local and international suppliers allows companies to tap into innovative designs and technologies, ensuring they remain competitive in an evolving marketplace.

What Are the Key Benefits of Strategic Sourcing for Custom Windows?

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize building strong relationships with suppliers who understand local regulations and market trends. This not only facilitates smoother transactions but also mitigates risks associated with supply chain disruptions. Furthermore, leveraging digital tools and platforms can enhance visibility into supplier performance and market conditions, enabling informed decision-making.

How Can B2B Buyers Prepare for Future Trends in Custom Windows?

Looking ahead, the integration of sustainable materials and energy-efficient designs will become increasingly important. Buyers should stay informed about emerging trends and innovations in the windows sector to ensure they are making choices that align with market demands and consumer preferences.

In conclusion, the strategic sourcing of custom windows is not just a procurement process; it’s a pathway to achieving long-term business success. B2B buyers are encouraged to actively engage in this strategic approach, fostering partnerships that can lead to greater innovation and resilience in their supply chains. Embrace this opportunity to elevate your business’s potential in the global marketplace.