Top Companies for Minimum Order Quantity (MOQ) Insights

Are you struggling to find the perfect manufacturer for your products? With countless options out there, it can feel overwhelming to sift through the noise and identify the right factory that meets your needs. Finding a reliable supplier is crucial; the right partner can elevate your product quality, enhance production efficiency, and ultimately boost your bottom line. Imagine having a list of the top manufacturers that not only meet your specifications but also align with your values and vision.

Ready to take the guesswork out of your sourcing journey? Dive into our comprehensive comparison of the top 30 manufacturers, and discover the best options to propel your business forward!

Top 19 Min Per Manufacturer Manufacturers

Ftc – Federal Trade Regulation Insights

ShipBob – E-commerce Fulfillment Services

Domain: shipbob.com

Registered: 2014 ( 11 years )

Introduction: ShipBob offers fulfillment services that help e-commerce businesses manage their inventory and shipping logistics efficiently.

Cosmosourcing – MOQ Procurement Solutions

Domain: cosmosourcing.com

Registered: 2014 ( 11 years )

Introduction: Minimum Order Quantity (MOQ) refers to the smallest quantity of a product a supplier is willing to sell, crucial for manufacturing and procurement.

Seacomp – Custom Electronic Manufacturing Solutions

Domain: seacomp.com

Registered: 2001 ( 24 years )

Introduction: SEACOMP offers custom electronic manufacturing services, including the production of LCD displays, power and charging systems, and electronic product design.

Wonnda – MOQ Supply Solutions

Domain: wonnda.com

Registered: 2021 ( 4 years )

Introduction: Minimum order quantity (MOQ) refers to the smallest quantity of items a business is willing to sell to a customer in a single transaction, ensuring manufacturers produce sufficient volume to optimize production costs.

Bartleby – Stylish Oxfords and Loafers

Domain: bartleby.com

Registered: 1997 ( 28 years )

Introduction: A small shoe manufacturer makes two styles of shoes: oxfords and loafers.

MINI – Electric and Classic Vehicles

Domain: mini.co.uk

Registered: 1996 ( 29 years )

Introduction: MINI offers a range of vehicles including the MINI Cooper Convertible, MINI Cooper 5-door, All-Electric MINI Cooper, MINI Countryman, John Cooper Works, and All-Electric MINI Aceman, with options for both new and used cars.

Docslides – Vehicle Brake Inspection Services

Domain: docslides.com

Registered: 2014 ( 11 years )

Introduction: The company offers vehicle inspection services focusing on brake systems, including front and rear brake measurements, emergency brakes, and various mechanical components related to vehicle safety.

Quizlet – Educational Flashcards for WorkKeys

Domain: quizlet.com

Registered: 2004 ( 21 years )

Introduction: WorkKeys Level 6 Calculating Rates flashcards

Vcalc – Production Rate Calculation Solutions

Domain: vcalc.com

Registered: 1999 ( 26 years )

Introduction: The Production Rate Calculator computes the length, area, volume, or generic units that can be processed, produced, or consumed over a period of time based on a constant rate.

Dir – Fire-Resistant Doors Solutions

Domain: dir.indiamart.com

Registered: 1996 ( 29 years )

Introduction: The company primarily offers a range of fire-resistant doors, including double doors and sliding doors made from materials such as galvanized iron (GI) and stainless steel (SS).

Zephyr Project – Bluetooth Connectivity Solutions

Domain: docs.zephyrproject.org

Registered: 2013 ( 12 years )

Introduction: Zephyr Project offers a comprehensive set of Bluetooth APIs, particularly focusing on the Generic Access Profile (GAP) and various connectivity features for Bluetooth-enabled devices.

Minimum Wage – Employment Standards Resources

CustomPartNet – Production Time Estimation Solutions

Domain: custompartnet.com

Registered: 2006 ( 19 years )

Introduction: CustomPartNet offers a Production Time Calculator that helps manufacturers estimate production time based on various parameters such as cycle time, defect rate, and machine uptime.

Miclins India – Peristaltic Pumps Solutions

Domain: miclinsindia.com

Registered: 2002 ( 23 years )

Introduction: Miclins India offers a wide range of peristaltic pumps, including the PP series, VSP series, and FSP series, featuring micro-processor based models and fixed speed models with various flow rates.

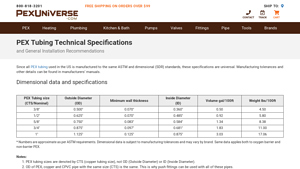

Pexuniverse – PEX Tubing and Plumbing Supplies

Domain: pexuniverse.com

Registered: 2009 ( 16 years )

Introduction: PEX tubing and related plumbing, heating, and HVAC supplies.

Surya Min Chem – Industrial Chemicals Solutions

Domain: suryaminchem.com

Registered: 2010 ( 15 years )

Introduction: Surya Min Chem Pvt Ltd offers a wide range of industrial chemicals including Magnesium Oxide, various pigments, Steric Acid, Organo Clay, Potassium Bichromate, Nitrile Rubber, Carbon Black, and more.

Mppumps – Chemical Pump Solutions

Domain: mppumps.com

Registered: 1998 ( 27 years )

Introduction: CHEMFLO® 9 is a chemical pump designed for various industrial applications, offering reliable performance for handling chemicals.

Online Clothing Study – Apparel Manufacturing Solutions

Domain: onlineclothingstudy.com

Registered: 2011 ( 14 years )

Introduction: The company offers apparel manufacturing services with a focus on accurately calculating production costs using Standard Minute Rate (SMR) and Standard Minute Value (SMV).

Category Information

The term “min per manufacturer” generally refers to the minimum order quantity (MOQ) that a manufacturer requires for a product. This concept is prevalent in various industries, including textiles, electronics, and consumer goods. Manufacturers establish these minimums to ensure cost-effectiveness in production and to manage inventory efficiently. Understanding the MOQ is crucial for businesses, particularly for retailers and wholesalers, as it impacts pricing, inventory management, and cash flow.

By meeting the MOQ, businesses can often negotiate better pricing and secure exclusive products, but it also necessitates careful planning to avoid excess inventory. Overall, “min per manufacturer” plays a significant role in supply chain dynamics, influencing purchasing strategies and operational efficiency.

Application Information

Products and services related to ‘min per manufacturer’ are commonly applied in several key industries, primarily focusing on optimizing production processes and enhancing supply chain efficiency. One major application area is in manufacturing, where companies utilize minimum order quantities (MOQ) to streamline inventory management and production scheduling. This ensures that manufacturers can maintain cost-effectiveness while meeting demand without overproducing. Another significant area is in retail, where businesses set minimum purchase requirements to enhance profitability and reduce excess stock.

Additionally, the food and beverage industry often employs minimum order strategies to manage perishable goods, ensuring that products are fresh and minimizing waste. In the tech sector, companies may use minimum order practices for components to ensure they have sufficient stock for production runs. Overall, these strategies are essential for optimizing operational efficiency across various sectors.

Production Process Information

The production process for ‘min per manufacturer’ related products typically involves several key stages. First, design and planning are crucial, where manufacturers identify product specifications and market needs. This stage ensures that the final product meets both functionality and consumer expectations. Next comes the sourcing of materials, where manufacturers procure the necessary raw materials or components. This step is vital for maintaining quality and cost-effectiveness.

Following this, the manufacturing phase involves transforming these materials into the final product through various processes, such as machining, assembly, or fabrication. Finally, quality control is implemented to ensure that the products meet required standards before they reach the market. This stage helps in reducing defects and enhancing customer satisfaction. Overall, these stages work together to ensure efficient production and delivery of high-quality products.

Related Video

Frequently Asked Questions (FAQs)

What is a minimum order quantity (MOQ) and why is it important?

A minimum order quantity (MOQ) is the smallest number of units a manufacturer is willing to produce for an order. Understanding the MOQ is crucial because it helps you determine if a supplier is a good fit for your business needs. If your order volume is significantly lower than the MOQ, you may need to look for a different manufacturer or negotiate a lower MOQ. Knowing the MOQ also helps in budgeting and planning your inventory.

How do I find manufacturers that meet my specific needs?

To find manufacturers that align with your specific needs, start by conducting online research through platforms like Alibaba, ThomasNet, or Maker’s Row. You can also attend trade shows and industry expos to meet suppliers in person. Additionally, networking within industry forums or groups can lead you to reputable manufacturers. Be clear about your requirements, such as product specifications, quality standards, and production capacity, to streamline your search.

What factors should I consider when evaluating potential manufacturers?

When evaluating potential manufacturers, consider factors such as their experience in your industry, production capabilities, quality control processes, and lead times. It’s also important to look at their communication style and responsiveness, as this will affect your collaboration. Checking reviews, testimonials, and references can provide insight into their reliability and customer service. Lastly, consider their location and shipping options, as these can impact costs and delivery times.

How can I negotiate better terms with manufacturers?

Negotiating better terms with manufacturers involves being well-prepared and confident. Start by researching industry standards for pricing and MOQs so you have a baseline for negotiations. Clearly communicate your needs and be open about your budget constraints. Building a good relationship with the manufacturer can also help; show appreciation for their work and be respectful during discussions. Don’t hesitate to ask for discounts on larger orders or flexible payment terms, as many manufacturers are willing to negotiate.

What should I do if I encounter issues with my manufacturer?

If you encounter issues with your manufacturer, the first step is to address the problem directly and professionally. Clearly communicate your concerns and provide specific examples. Most manufacturers value their relationships and will want to resolve issues amicably. If the problem persists, review your contract for any clauses related to disputes and consider mediation or arbitration if necessary. If all else fails, it may be time to look for a new supplier who better aligns with your expectations and needs.