Powder Packing Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Powder Packing Machines

From pharmaceutical formulations to gourmet spices and industrial chemicals, the demand for precision-packaged powdered goods is surging across US and European markets. For manufacturers, the competitive edge relies heavily on line efficiency and dispensing accuracy. However, selecting the right powder packing machine is no longer a simple procurement decision—it is a strategic one.

The Sourcing Challenge

The global marketplace offers a dizzying array of specifications and price points, creating a “paradox of choice” for procurement managers. On one end of the spectrum, accessible entry-level units—such as the Hanchen or VEVOR 1-200g particle weighing fillers—are available for as little as $219–$290. These semi-automatic machines, often equipped with foot pedals and capable of handling granular products like seeds, tea, and glitter, offer an excellent entry point for boutique operations.

However, for established B2B facilities, the challenge lies in distinguishing between these economical tabletop solutions and the robust, fully automated systems required for high-volume compliance. Misaligning your equipment choice with your production goals can result in costly bottlenecks, inconsistent fill weights, and scalability issues.

What This Guide Covers

This guide provides a technical and commercial roadmap for sourcing powder packaging technology. We will address:

- Technology Tiers: Differences between entry-level particle dispensers and industrial auger fillers.

- Specification Analysis: Understanding capacity ranges (e.g., 0.5g vs. bulk) and automation levels.

- Strategic Sourcing: How to balance initial capital outlay with long-term operational ROI.

Whether you are scaling up from a pilot line or retrofitting a major facility, this guide ensures your investment drives production efficiency.

Illustrative Image (Source: Google Search)

Top 10 Powder Packing Machine Manufacturers & Suppliers List

1. Top 10 Packaging Machine Manufacturers in the USA – HonorPack

Domain: honorpack.com

Registered: 2009 (16 years)

Introduction: The top 10 packaging machine manufacturers in the USA are: HonorPack, Viking Masek, Accutek, Triangle, Packline, Paxiom, Matrix, Alliedflex, Masipack, and K- ……

2. Powder Pouch Packing Machine Manufacturer

Domain: blackforestpkg.com

Registered: 2011 (14 years)

Introduction: As a leading pouch-packing machine manufacturer, we specialize in designing and manufacturing state-of-the-art pouch-packing machines for businesses in various ……

3. Top 5 Powder Packaging Machines for Accurate Results

Domain: spackmachine.com

Registered: 2016 (9 years)

Introduction: Find the right powder packaging machine for optimal efficiency, compliance, and precision. This guide walks you through essential features and benefits….

4. Top 10 Packing Machine Manufacturers in the world – Landpack

Domain: landpack.com

Registered: 2009 (16 years)

Introduction: 1. Landpack-China · 2. Tetra Pak- Switzerland · 3. Krones-Germany · 4. KHS GmbH-Germany · 5. Sidel-France · 6. Syntegon-Germany · 7. MULTIVAC-Germany….

Illustrative Image (Source: Google Search)

5. Powder Packaging Machine – Ahmedabad – Sigma Instrumentation

Domain: sigmainstrumentation.com

Registered: 2012 (13 years)

Introduction: We are among the leading powder packing machine manufacturer in the industry. Our high quality bag filing machines are used to fill granules/powders in bags….

6. Filling Machine – Powder Packing Machine Manufacturer from …

Domain: rishipouchpacking.com

Registered: 2025 (0 years)

Introduction: The manufacturer offers dry fruit, powder, poha, seed, paste, and liquid filling machines, with various capacities and automation levels….

7. Top 5 Milk Powder Filling Machine Manufacturers

Domain: landpack.net

Registered: 2021 (4 years)

Introduction: LandPack. Landpack is a leading manufacturer known for its high-quality packaging machinery, including milk powder filling machines….

8. 12 Powder Filling Machine Manufacturers in 2025 – Metoree

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Here are the top-ranked powder filling machine companies as of November, 2025: 1.Micmachinery.co.,Ltd, 2.Shree Bhagwati Machtech, 3.Adinath ……

Illustrative Image (Source: Google Search)

Understanding powder packing machine Types and Variations

Understanding Powder Packing Machine Types and Variations

Selecting the correct powder packing machinery requires a technical understanding of your product’s flow characteristics (free-flowing vs. non-free-flowing) and your required throughput. While entry-level benchtop units utilize basic weighing mechanisms, industrial-grade lines employ sophisticated auger and pneumatic systems to handle dust and speed.

Below is a comparative overview of the primary machine types available in the US and European markets.

Comparative Overview: Powder Packing Technologies

| Machine Type | Key Features | Best Applications | Pros & Cons |

|---|---|---|---|

| Net Weigh / Vibratory Fillers | Uses vibration to move product into a weigh bucket; high precision load cells; typically semi-automatic. | Free-flowing granules, tea, seeds, glitter, grains, small batches (1g–200g). | Pros: High accuracy, low cost, easy to clean. Cons: Struggles with fine/dusty powders; slower speeds. |

| Auger Fillers | Uses a rotating screw (auger) to drive powder through a funnel; volumetric filling. | Non-free-flowing powders, flour, protein powder, spices, baking mixes. | Pros: Handles dust well, high speed, consistent volume. Cons: Requires tooling change for different fill weights; higher initial cost. |

| Vertical Form Fill Seal (VFFS) | Forms bags from roll stock film, fills, and seals vertically; fully automated. | High-speed production of pillow bags, gusseted bags, and sachets. | Pros: Lowest cost-per-bag; high throughput. Cons: Large footprint; complex setup; not suitable for rigid containers. |

| Rotary Pre-Made Pouch Machines | Picks, opens, fills, and seals pre-made doyen or stand-up pouches. | Premium retail products, superfoods, supplements requiring high shelf appeal. | Pros: Superior bag aesthetics; versatile for different pouch shapes. Cons: High capital investment; limited by pouch cost. |

1. Net Weigh / Vibratory Fillers (Linear Weighers)

Based on current market data for small-to-medium enterprise solutions.

This category represents the entry point for many businesses and is heavily utilized in lab settings, R&D, and boutique manufacturing. As seen in many benchtop “particle weighing” units (e.g., Hanchen, VEVOR), these machines operate on a weigh-and-dispense principle.

Illustrative Image (Source: Google Search)

- Mechanism: The machine uses a vibratory channel to feed the powder into a hopper situated on a load cell. Once the target weight (e.g., 50g) is reached, the vibration stops, and the hopper releases the product.

- Ideal For: Free-flowing products where particle integrity is paramount. Common applications include tea leaves, seeds, pharmaceutical granules, and cosmetic glitters.

- B2B Context: These units are often deployed as semi-automatic stations where an operator holds the bag or bottle under the chute. They are favored for their “intelligent particle weighing” capabilities, often boasting accuracy within ±0.2g for small fills (1-200g range).

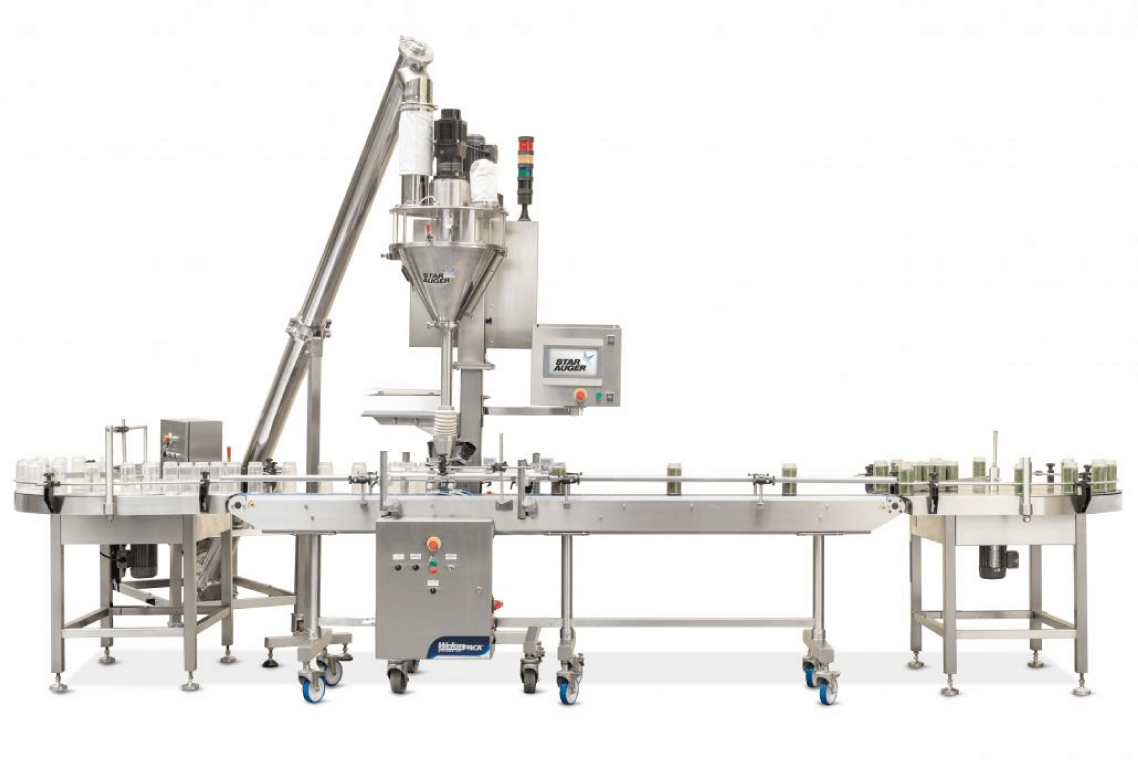

2. Auger Fillers

While vibratory fillers handle granules well, they often fail with fine powders (like flour or cornstarch) which cause bridging or dusting. The Auger Filler is the industrial standard for these materials.

- Mechanism: An auger (screw) rotates inside a funnel. The fill amount is determined by the number of revolutions the screw makes. Agitator blades keep the powder moving to prevent compaction.

- Ideal For: Non-free-flowing powders such as baking flour, milk powder, matcha, and ground spices.

- B2B Context: In the US and European markets, auger fillers are critical for compliance with dust control regulations. They are often integrated into larger VFFS or rotary lines but can serve as standalone semi-auto units for bulk filling rigid containers.

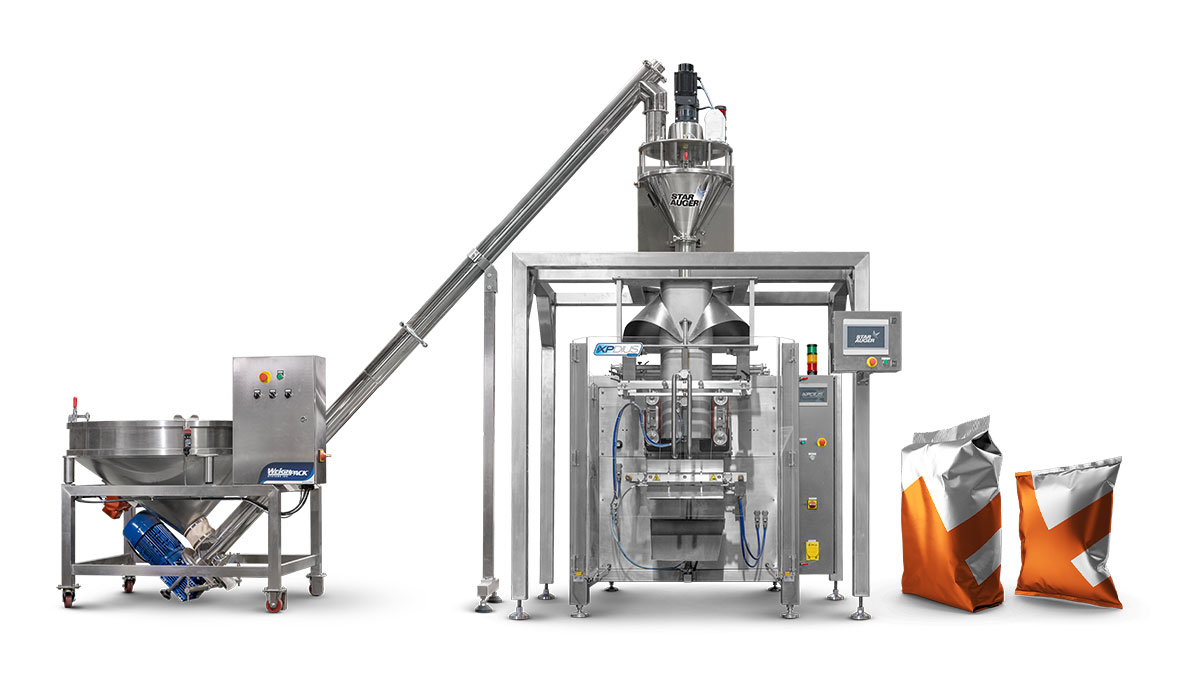

3. Vertical Form Fill Seal (VFFS)

For manufacturers scaling from manual filling to full automation, the VFFS system is the primary solution for flexible packaging.

- Mechanism: The machine pulls flat film from a large roll, forms it into a tube around a filling collar, seals the bottom and vertical seam, drops the powder (usually via an integrated auger or weigher), and seals the top.

- Ideal For: High-volume commodity products like sugar, salt, detergent powder, and coffee.

- B2B Context: VFFS offers the highest ROI for high-volume runs. The operational cost is significantly lower than pre-made pouches because roll-stock film is cheaper. However, changeovers between bag sizes can be time-consuming compared to semi-automatic options.

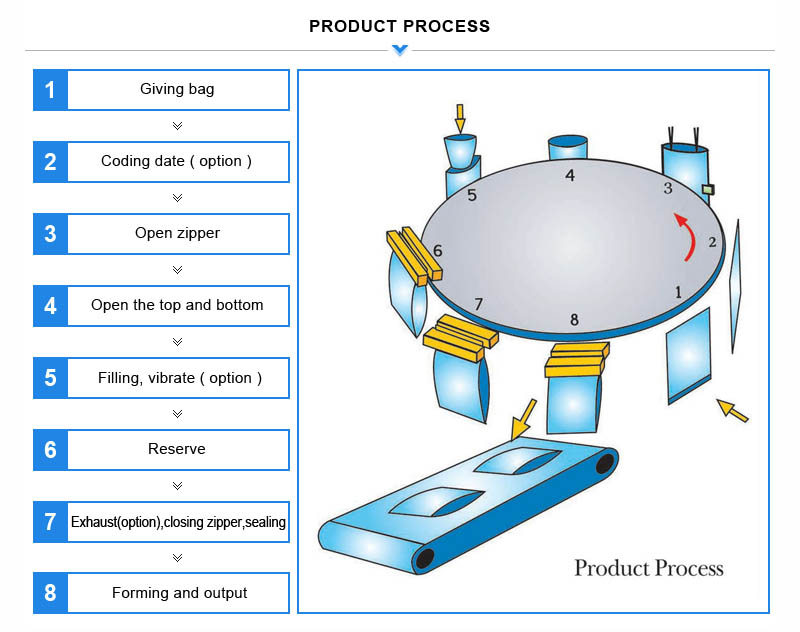

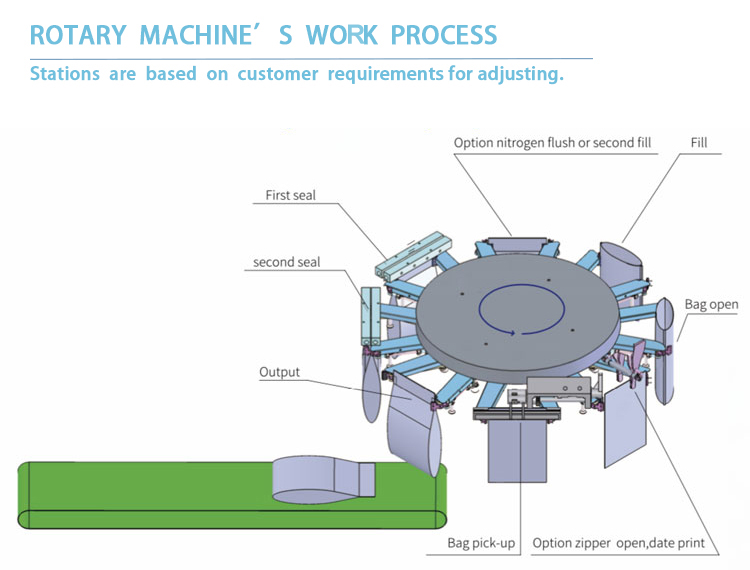

4. Rotary Pre-Made Pouch Packing Machines

This machinery caters to the premium segment of the market, particularly for brands focusing on shelf presence in major retail chains.

- Mechanism: Unlike VFFS, this machine does not make the bag. It utilizes a robotic carousel to grip pre-made pouches from a magazine, open them (using suction), fill them with powder, and heat seal them.

- Ideal For: Premium protein powders, organic superfoods, and specialty ingredients packaged in zipper pouches or stand-up doyen bags.

- B2B Context: While the machinery is capital-intensive, it allows for complex bag shapes and high-quality printing that VFFS cannot match. It is widely adopted by co-packers in the USA and Europe handling multiple SKUs for different clients.

Key Industrial Applications of powder packing machine

Key Industrial Applications of Powder Packing Machines

Powder packing machines are critical infrastructure across multiple sectors in the USA and Europe, ranging from small-scale artisanal production to high-volume industrial manufacturing. While entry-level units (such as those handling 1–200g micro-doses) serve niche markets, industrial-grade systems are essential for maintaining supply chain efficiency, hygiene standards, and weight accuracy.

Illustrative Image (Source: Google Search)

The following table outlines the primary industries utilizing powder packing technology and the specific materials handled.

Industry Application Matrix

| Industry Sector | Typical Powder Applications | Key Packing Requirements |

|---|---|---|

| Food & Beverage | Flour, baking mixes, spices, coffee grounds, tea leaves, milk powder, protein shakes. | Hygiene: FDA/CE compliance (SS304/316 construction). Sealing: Airtight seals to preserve freshness and shelf life. Texture Handling: Ability to handle both free-flowing (sugar) and non-free-flowing (flour) powders. |

| Nutraceuticals & Pharma | Dietary supplements, herbal extracts, medicinal powders, probiotics. | Precision: Extremely high accuracy (±0.1g) to meet dosage regulations. Contamination Control: Dust-proof systems to prevent cross-contamination. |

| Cosmetics & Personal Care | Face powders, bath salts, cosmetic glitters, talc, dry shampoo. | Aesthetics: High-quality pouch/bottle presentation. Delicate Handling: Preventing product degradation during the filling process (e.g., maintaining glitter particle integrity). |

| Agriculture & Veterinary | Seeds, granular fertilizers, animal feed supplements, pesticides. | Durability: Machines must withstand abrasive materials. Volume: Often requires wider filling ranges (from small seed packets to bulk feed bags). |

| Chemical & Industrial | Detergents, dyes, construction grouts, chemical additives. | Safety: Explosion-proof options for volatile powders. Containment: Prevention of hazardous dust leakage into the facility. |

Strategic Benefits for B2B Operations

Implementing automated powder packing solutions offers distinct advantages for manufacturers targeting Western markets, where labor costs are high and regulatory scrutiny is strict.

1. Precision Weighing and Cost Control

As highlighted by market data for particle weighing machines (1–200g range), precision is the primary value driver. In an industrial setting, “product giveaway”—overfilling packages by even a fraction of a gram—can result in significant financial loss over thousands of cycles. Modern volumetric and auger fillers utilize intelligent weighing systems to ensure net weight compliance, drastically reducing raw material waste.

2. Versatility Across Particle Types

Powders behave differently based on environmental factors. A robust packing machine must handle varying consistencies:

* Free-Flowing: Granules, seeds, and salt that flow easily by gravity.

* Non-Free-Flowing: Flour, fine glitters, and starches that clump or bridge.

Advanced machines feature adjustable agitation and vibration settings (often foot-pedal or sensor-activated) to ensure consistent flow regardless of the material’s viscosity or moisture content.

Illustrative Image (Source: Google Search)

3. Regulatory Compliance and Hygiene

For the USA (FDA) and European (EFSA/EMA) markets, sanitary design is non-negotiable. Automated packing machines minimize human contact with the product, reducing the risk of biological contamination. Enclosed filling heads also manage dust generation, protecting operators from inhaling fine particulates (such as silica or active pharmaceutical ingredients) and preventing cross-contamination between batches.

4. Scalability from Lab to Line

The market includes equipment ranging from tabletop units for R&D and small-batch runs (1–50g capacity) to multi-head weighers for mass production. This allows B2B manufacturers to scale their operations using the same fundamental technology, ensuring that a product developed in the lab can be transitioned to the production line without reformulation or packaging redesigns.

3 Common User Pain Points for ‘powder packing machine’ & Their Solutions

3 Common User Pain Points for Powder Packing Machines & Their Solutions

In the USA and European markets, where compliance standards (FDA, CE) and material costs are high, efficiency in powder packaging is non-negotiable. Below are the three most critical friction points operators face with powder filling equipment and the engineering solutions to address them.

1. Inconsistent Fill Accuracy (Product Giveaway)

The Scenario:

A contract manufacturer packages high-value matcha tea or pharmaceutical powders. They aim for a net weight of 50g per pouch.

Illustrative Image (Source: Google Search)

The Problem:

Due to inconsistent bulk density or machine vibration, the equipment drifts. To avoid legal penalties for under-filling, the operator over-compensates, setting the fill to 52g. Over a production run of 10,000 units, the company loses 20kg of premium product—a phenomenon known as “product giveaway” that directly erodes profit margins.

The Solution:

* Gravimetric Filling (Net Weighing): Unlike volumetric fillers (cups/augers) that estimate weight based on volume, gravimetric systems use load cells to weigh the product before dispensing.

* Feedback Loops: Advanced PLCs utilize checkweigher feedback to auto-adjust the auger rotations or vibration intensity in real-time, correcting drift without operator intervention.

* Multi-head Weighers: For granular powders (like seeds or tea mentioned in entry-level listings), multi-head weighers provide the highest combination of speed and accuracy by calculating the best weight combination from multiple buckets.

2. Particulate Dust & Cross-Contamination

The Scenario:

A facility packages both flour-based baking mixes and gluten-free alternatives on the same line.

The Problem:

Fine powders become airborne during the dosing phase (“dusting”). This dust settles on machine sensors, causing maintenance downtime, and infiltrates open mechanical parts, accelerating wear. More critically, airborne dust creates a cross-contamination risk, making it impossible to certify the line as allergen-free or GMP compliant.

Illustrative Image (Source: Google Search)

The Solution:

* Dust Extraction Systems: Integration of vacuum manifolds directly at the filling nozzle to capture airborne particles at the source.

* Enclosed Jaw Drives: Selecting machines where the mechanical drive systems are fully enclosed and separated from the product path (IP65/IP66 rated) to prevent dust ingress.

* Bottom-Up Filling: Using a nozzle that lowers into the bag and rises as the product fills. This reduces the distance the powder falls, minimizing the “cloud” effect.

3. Flow Issues (Bridging and Rat-holing)

The Scenario:

A business attempts to use the same machine for free-flowing granules (e.g., sugar/salt) and non-free-flowing powders (e.g., protein powder/cornstarch).

The Problem:

Non-free-flowing powders are cohesive. They tend to stick together, causing “bridging” (forming an arch over the outlet) or “rat-holing” (tunneling through the center while material sticks to the hopper walls). This results in empty packages, jammed augers, and significant downtime for cleaning.

The Solution:

* Agitators and Ribbon Blenders: Hoppers equipped with independent agitator motors that keep the product moving and break up bridges before they reach the filler.

* Specialized Auger Tooling: Utilizing specific auger screws for different materials (e.g., “free-flow” spinner plates to stop dripping vs. “non-free-flow” augers with aggressive flighting to force product down).

* Vibration Assist: Pneumatic or electric vibrators attached to the hopper walls to induce flow in sticky products.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for powder packing machine

Strategic Material Selection Guide for Powder Packing Machines

Selecting the correct construction materials for your powder packing machinery is not merely a purchasing detail—it is a critical factor in Operational Equipment Effectiveness (OEE), regulatory compliance (FDA/CE), and contamination prevention.

For markets in the USA and Europe, where Current Good Manufacturing Practices (cGMP) are strictly enforced, the material selection must align with the chemical properties of the powder (acidity, abrasiveness, hygroscopy) and the cleaning protocols of the facility.

1. Product Contact Surfaces: The Hygiene Standard

The primary concern for any B2B buyer is the material touching the product. Inadequate selection here leads to cross-contamination and corrosion.

-

Stainless Steel 304 (SS304):

- Role: The industry standard for general food and non-corrosive chemical packing.

- Application: Suitable for dry, free-flowing powders like flour, coffee, sugar, and dry grains (as seen in standard market fillers).

- Benefit: Offers excellent corrosion resistance against standard atmospheric conditions and foodstuffs. It is cost-effective and meets basic FDA requirements.

-

Stainless Steel 316L (SS316L):

- Role: The premium standard for pharmaceutical, nutraceutical, and corrosive chemical applications.

- Application: Required for saline powders, acidic products, or high-value pharmaceuticals where purity is paramount.

- Benefit: Contains molybdenum, which drastically increases resistance to pitting and crevice corrosion, particularly from chloride environments. The “L” stands for Low Carbon, which improves welding characteristics and prevents intergranular corrosion.

-

Surface Finish (Ra Value):

- Material grade is half the battle; surface finish is the other. For sticky powders or high-hygiene requirements, specify a finish of Ra < 0.8µm. Mirror-polished surfaces prevent powder bridging and reduce cleaning time.

2. Seals, Gaskets, and Flexible Components

Hardware durability is irrelevant if seals fail. Leaking seals lead to product loss and environmental contamination.

- Food-Grade Silicone: Standard for flexible connections and gaskets. It provides good thermal stability and elasticity but offers lower chemical resistance.

- PTFE (Teflon): Essential for aggressive chemical powders. PTFE has a low coefficient of friction (aiding flow) and is virtually inert to all chemicals.

- EPDM: Often used when packing powders that may be exposed to steam cleaning (CIP/SIP processes), as it offers excellent heat and steam resistance.

3. Structural and Non-Contact Components

While contact parts require sanitary grades, structural components focus on rigidity and cost-efficiency.

Illustrative Image (Source: Google Search)

- Anodized Aluminum: Frequently used in the drive systems and structural framing of smaller, linear weighers (similar to entry-level units like Hanchen or VEVOR). It is lightweight and corrosion-resistant but cannot withstand caustic washdowns.

- Carbon Steel (Powder Coated): Used for the heavy frames of bulk bag fillers. It must be coated to prevent rust but should never be used in the immediate “drop zone” of the powder to prevent paint chip contamination.

- Full Stainless Construction: For washdown environments (meat, dairy, pharma), the entire frame, including legs and electrical enclosures, should be SS304 to withstand high-pressure water and cleaning agents.

4. Handling Abrasive and Difficult Powders

Standard stainless steel will degrade quickly under the friction of abrasive materials.

- Hardened Coatings: For abrasive powders (e.g., glitter, ceramic powders, glass frit), contact parts such as auger screws and funnels should be treated with hardening agents or ceramic coatings to prevent metal shaving contamination.

- Anti-Stick Treatments: For hygroscopic or sticky powders (e.g., protein powders, milk powder), contact surfaces are often coated with FDA-approved PTFE to ensure consistent flow rates and weighing accuracy.

Comparative Analysis: Material Selection Matrix

The following table outlines the strategic application of materials based on industry verticals and powder characteristics.

| Material | ISO/ASTM Grade | Primary Characteristic | Best Strategic Application | Relative Cost |

|---|---|---|---|---|

| Standard Stainless | SS 304 | General Corrosion Resistance | General Food & Ag: Flour, seeds, coffee, tea, sugar, spices. | $$ |

| Premium Stainless | SS 316L | High Pitting/Acid Resistance | Pharma & Chemical: Saline powders, acids, active pharmaceutical ingredients (APIs). | $$$$ |

| Polymer/Plastic | PTFE (Teflon) | Low Friction & Inert | Seals & Liners: Sticky powders, aggressive chemicals, high-speed flow chutes. | $$$ |

| Elastomer | Food Grade Silicone | Flexibility | Gaskets: Flexible tubing, vibration dampeners, soft connections. | $ |

| Structural Metal | Anodized Aluminum | Lightweight | Machine Housing: Electronic enclosures, non-washdown structural frames. | $$ |

| Structural Metal | Carbon Steel | High Strength | Heavy Framing: Bulk filling frames (must be painted/coated). | $ |

Buyer Note: When sourcing machinery for the US or EU, ensure material certificates (Mill Test Reports) are requested to verify the grade of stainless steel, ensuring compliance with FDA CFR 21 (USA) and EC 1935/2004 (Europe).

In-depth Look: Manufacturing Processes and Quality Assurance for powder packing machine

In-depth Look: Manufacturing Processes and Quality Assurance for Powder Packing Machines

For B2B buyers in the USA and Europe, understanding the manufacturing provenance of a powder packing machine is as critical as the operational specifications. Whether sourcing compact 1–200g particle weighing units or industrial-scale auger fillers, the build quality directly impacts dosing accuracy, hygiene compliance, and equipment longevity.

Illustrative Image (Source: Google Search)

The following sections detail the standard manufacturing lifecycle and quality control protocols required to produce high-performance powder filling equipment.

1. Manufacturing Workflow: From Raw Metal to Finished Machine

The production of a powder packing machine involves four distinct phases, transitioning from raw material fabrication to electronic integration.

Phase I: Material Preparation and Component Sourcing

- Raw Material Inspection: Production begins with the sourcing of food-grade stainless steel (typically SS304 or SS316L for pharmaceutical applications). Metal sheets are tested for thickness consistency and corrosion resistance.

- Component Sourcing: Critical electronic components—such as PLCs, load cells (crucial for the “Intelligent Particle Weighing” features found in modern units), and pneumatic cylinders—are sourced from verified Tier-1 suppliers to ensure compliance with Western electrical standards (UL/CE).

Phase II: Forming and Fabrication

- CNC Machining & Laser Cutting: High-precision laser cutters shape the hopper, chassis, and discharge chutes. Computer Numerical Control (CNC) ensures tolerances within microns, essential for preventing powder leakage during operation.

- Sanitary Welding: Frames are TIG welded to ensure structural integrity. For food-contact parts, welds are ground smooth and polished to eliminate crevices where powder could accumulate, preventing bacterial growth and cross-contamination.

Phase III: Precision Assembly

- Mechanical Assembly: Technicians install the vibration mechanisms and auger screws. The alignment of the dispensing nozzle relative to the weighing platform is calibrated to ensure the machine can handle diverse densities, from fine flour to granular seeds.

- Electrical Integration: Wiring of the control panel, foot pedals, and optical sensors is conducted. This stage involves programming the logic controllers that manage the “automatic intelligent” features, such as auto-correction for weight deviations.

Phase IV: Final Assembly & Tuning

- Vibration Tuning: For particle filling machines, the vibratory feeder is tuned to ensure consistent flow without segregating the mix.

- Sealing Integration: If the unit includes bagging capabilities, heat-sealing jaws are installed and thermal-tested for uniform temperature distribution.

2. Quality Assurance (QC) Protocols

To meet the stringent requirements of US and EU markets, manufacturers must implement a multi-layered QC strategy.

Factory Acceptance Testing (FAT)

Before shipping, every machine undergoes a rigorous FAT process:

1. Load Cell Calibration: Technicians test the weighing accuracy using certified weights. For a 1–200g filler, the machine must demonstrate repeatability within specified error margins (e.g., ±0.2g).

2. Endurance Testing: The machine is run continuously for 24–48 hours to identify potential overheating in motors or drift in sensor calibration.

3. Material Simulation: The machine is tested with a substance of similar bulk density to the client’s product (e.g., flour substitute or plastic granules) to verify flow rates and discharge speed.

Illustrative Image (Source: Google Search)

Compliance and Certifications

B2B buyers should verify that the manufacturing process adheres to the following standards:

| Standard | Relevance | Target Region |

|---|---|---|

| ISO 9001:2015 | Ensures a consistent Quality Management System (QMS) is in place during manufacturing. | Global |

| CE Marking | Certifies the machine meets EU safety, health, and environmental requirements (Machinery Directive). | Europe |

| GMP (Good Manufacturing Practice) | Essential for machines used in food and pharma; dictates hygiene design (easy cleaning, non-toxic materials). | USA/Europe |

| UL / CSA | Electrical component certification required for insurance and safety compliance in North American facilities. | USA/Canada |

3. Key Differentiators in Manufacturing

High-quality manufacturing distinguishes itself through:

* Modular Design: Allowing for easy replacement of hoppers or sensors without requiring a full machine teardown.

* Surface Finishing: Electropolishing or sandblasting surfaces to reduce friction, ensuring sticky powders (like glitter or protein powder) flow smoothly without clogging.

* Software Logic: Advanced coding that allows the machine to “learn” and adjust vibration intensity based on the flow rate of the specific powder being processed.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘powder packing machine’

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Powder Packing Machine’

Sourcing powder packing machinery requires navigating a market that ranges from entry-level tabletop units (approx. $200–$300) to industrial-grade automation (>$10,000). For buyers in the USA and Europe, prioritizing compliance, voltage compatibility, and material standards is as critical as price.

Use this checklist to streamline the procurement process, from defining requirements to final validation.

Illustrative Image (Source: Google Search)

Phase 1: Requirement Definition (Internal Audit)

Before contacting suppliers, define the physical properties of your product to avoid equipment mismatch.

1. Analyze Powder Characteristics

* Flowability: Is the powder free-flowing (e.g., salt, seeds, tea granules) or non-free-flowing (e.g., flour, protein powder, glitter)?

* Note: Non-free-flowing powders generally require auger fillers rather than vibratory/weighing fillers.

* Dust Factor: High dust levels require enclosed hoppers and dust extraction systems to meet US/EU workplace safety standards.

2. Define Output Specifications

* Fill Weight Range:

* Micro-dosing (e.g., 1–50g for sachets/lab samples).

* Standard Retail (e.g., 1–200g or 0.002–0.44lbs).

* Bulk (1kg+).

* Throughput Speed: Target bags/bottles per minute (BPM).

* Automation Level:

* Semi-Automatic: Foot pedal operation (common in entry-level units like Hanchen or VEVOR).

* Fully Automatic: Integrated conveyor and sealing systems.

Phase 2: Technical Specification Match

Use this table to align supplier offerings with your facility’s infrastructure.

Illustrative Image (Source: Google Search)

| Feature | Specification to Check | Why it Matters for US/EU Buyers |

|---|---|---|

| Voltage | 110V/60Hz (USA) vs. 220V/50Hz (EU) | Importing the wrong voltage requires expensive transformers. Many Amazon-listed units are 110V specific. |

| Material | Stainless Steel 304 or 316 | Mandatory for FDA (US) and GMP (EU) compliance for food/pharma contact parts. |

| Control System | PLC / Touch Screen vs. Analog | Digital weighing leads to higher accuracy (e.g., ±0.2g accuracy on 1-100g fills). |

| Hopper Capacity | Volume (Liters) | Determines refill frequency. Small units often require constant manual refilling. |

Phase 3: Supplier Vetting & Validation

Distinguish between low-cost e-commerce resellers and dedicated OEMs.

Checklist for Sourcing Channels:

Option A: Entry-Level/Pilot Run (Amazon/E-commerce)

Suitable for: Labs, startups, R&D, small batch runs (Budget: $200 – $400).

* [ ] Review Weighing Range: Verify the machine handles your specific density (e.g., a “1-200g” machine may only hold 100g of fluffy flour).

* [ ] Check Return Policy: Ensure a 30-day return window to test flowability.

* [ ] Verify Stock Location: “Free Delivery” often implies domestic warehousing (faster shipping), whereas direct-from-China units have long lead times.

* [ ] Spare Parts: Check availability of replacement vibration springs or sensors.

Option B: Industrial Scale (Direct Manufacturer)

Suitable for: High-volume production lines.

* [ ] Certification: Request CE Declaration of Conformity (Europe) or UL/CSA certification (USA) for electrical components.

* [ ] Factory Acceptance Test (FAT): Request a video call demonstration using your specific powder, not a generic substitute.

* [ ] After-Sales Support: Confirm if the supplier has local technicians or offers remote video troubleshooting in your time zone.

Illustrative Image (Source: Google Search)

Phase 4: Commercial & Logistics

Finalizing the purchase for international or domestic delivery.

- [ ] Incoterms: Clarify shipping terms. For larger machines, DDP (Delivered Duty Paid) is preferred to avoid customs hassles in the US/EU.

- [ ] Lead Time: Distinguish between “In Stock” (usually 2-5 days for units like VEVOR/Hanchen) vs. “Manufacturing Time” (4-6 weeks for custom augers).

- [ ] Warranty:

- Standard: 1 Year (Parts only).

- Red Flag: No warranty specified.

- [ ] Consumables: Order an extra set of sealing bars or dispensing nozzles upfront to prevent downtime.

Phase 5: Arrival & Setup Protocol

- [ ] Sanitization: Run a “clean in place” cycle. Even “new” machines often have manufacturing oils or metal shavings in the hopper.

- [ ] Calibration: Use a certified external scale to verify the machine’s internal counter. Adjust the “vibration intensity” settings to match your powder’s flow rate.

- [ ] Safety Check: Ensure emergency stop buttons are functional and foot pedals have non-slip grips.

Comprehensive Cost and Pricing Analysis for powder packing machine Sourcing

Comprehensive Cost and Pricing Analysis for Powder Packing Machine Sourcing

Sourcing powder packing machinery requires a clear understanding of the disparity between entry-level semi-automatic units and industrial-grade automated lines. For buyers in the USA and Europe, calculating the Total Landed Cost (TLC)—including compliance, logistics, and tariffs—is as critical as the ex-works machine price.

1. Market Price Tiers and Capabilities

The market is segmented by automation level, fill weight accuracy, and speed. Below is a pricing benchmark based on current market data.

| Machine Category | Price Range (USD) | Typical Capacity | Target Application |

|---|---|---|---|

| Entry-Level (Tabletop) | $220 – $300 | 1g – 200g | Lab testing, R&D, boutique startups (tea, glitter, spices). |

| Mid-Range (Semi-Auto) | $1,500 – $5,000 | 500g – 5kg | Small to Medium Enterprise (SME) production; requires manual bag feeding. |

| Industrial (Auto VFFS) | $10,000 – $50,000+ | High Volume | Full-scale factory automation; includes film forming, sealing, and conveying. |

Analysis of Entry-Level Market (Reference Data):

Current sourcing data for tabletop units (e.g., Hanchen, VEVOR) indicates a tight price floor between $219 and $289.

* Specifications: These units typically operate on 110V (US standard), utilize foot-pedal activation, and handle particle weighing between 1-200g.

* Throughput: Suitable for 10–20 packs per minute depending on operator speed.

* Limitation: These are “fillers” only; they do not form bags or seal them automatically.

Illustrative Image (Source: Google Search)

2. Cost Breakdown Structure

Understanding the cost drivers helps in negotiating with suppliers and assessing build quality.

A. Materials and Components (40-50% of Cost)

- Contact Parts (SS304/SS316): For food and pharmaceutical compliance (GMP), hoppers and discharge nozzles must be Stainless Steel 304 or 316. Cheaper units ($200 range) may use lower-grade alloys or plastic internals, reducing longevity.

- Weighing Technology:

- Load Cells: High-precision sensors drive up costs but ensure accuracy within ±0.2g.

- Vibration Systems: Entry-level machines use simple vibratory plates to move powder, which is cost-effective but slower.

- Pneumatics & Electronics: Sourcing machines with branded PLCs (Siemens, Omron) or reliable motors (Stepper vs. Servo) increases upfront cost but reduces maintenance downtime.

B. Manufacturing and Labor (20-30% of Cost)

- Assembly Precision: Powder machinery requires tight tolerances to prevent leakage and cross-contamination.

- Testing: Reputable manufacturers factor in 24-48 hours of “burn-in” testing and calibration with specific powder types (free-flowing vs. non-free-flowing) before shipment.

C. Logistics and Duties (20-30% of Cost)

- Shipping Mode:

- Courier (DHL/FedEx): Viable for the $220–$300 tabletop units (approx. shipping cost $50–$100 depending on origin).

- Sea Freight (LCL/FCL): Required for industrial lines.

- Tariffs (USA/EU):

- USA: Importers must check HTS codes (typically under 8422.30). Be aware of Section 301 tariffs if sourcing from China, which can add significant percentage points to the tax bill.

- Europe: VAT is payable upon entry, along with standard import duties. CE certification is mandatory; ensure the supplier provides a valid Declaration of Conformity.

3. Total Cost of Ownership (TCO) Considerations

When budgeting, B2B buyers must look beyond the sticker price:

* Calibration Waste: High-speed machines may waste product during setup.

* Changeover Parts: Different bag sizes often require different “formers” or auger screws.

* Maintenance: Entry-level machines (vibratory fillers) generally have sealed components that are non-serviceable, effectively making them disposable assets after 2–3 years of heavy use.

4. Strategic Cost-Saving Tips

- Standardize Voltage: Ensure the machine is pre-wired for your region (110V for US, 220V for EU) to avoid purchasing external transformers.

- Bundle Spare Parts: Negotiate a “wear-and-tear” kit (extra gaskets, heating elements, fuses) at the time of purchase. Shipping these separately later can cost more than the parts themselves.

- Correct Sizing: Do not over-procure. If your SKU is 50g of tea, a 1-200g machine (approx. $230) is more efficient and accurate than a 10-1000g machine, which will lack precision at the low end.

- Consolidated Shipping: If buying multiple tabletop units (e.g., for a franchise), consolidate them into a single pallet shipment rather than individual courier parcels to reduce freight costs per unit.

Alternatives Analysis: Comparing powder packing machine With Other Solutions

Alternatives Analysis: Comparing Powder Packing Machines With Other Solutions

For manufacturers in the USA and Europe, the decision to invest in a fully automated powder packing machine involves balancing Capital Expenditure (CapEx) against Operational Expenditure (OpEx)—specifically labor costs and throughput requirements.

Below is a comparative analysis of the Automated Powder Packing Machine against two common alternatives: Manual Filling and Semi-Automatic Tabletop Fillers.

Illustrative Image (Source: Google Search)

Comparison Table: Throughput, Cost, and Scalability

| Feature | Manual Filling Process | Semi-Automatic Tabletop Filler (Entry-Level) | Automated Powder Packing Machine (VFFS/Rotary) |

|---|---|---|---|

| Primary Mechanism | Hand scoop & scale | Vibration/Auger with Foot Pedal Trigger | PLC-controlled Form-Fill-Seal |

| Throughput Speed | 5–10 units/minute | 10–25 units/minute | 40–100+ units/minute |

| Accuracy | Low (Human error variance) | Moderate (±0.2g – ±1g) | High (Precision auger/volumetric) |

| Labor Requirement | High (100% manual) | Moderate (Requires operator for bag holding/pedal) | Low (1 operator monitors multiple lines) |

| Weight Capacity | Unlimited (dependent on scale) | Limited (Typically 1g–200g for tabletop units) | Flexible (grams to kilograms) |

| Packaging Type | Pre-made pouches/jars | Pre-made pouches/bottles | Rollstock film or Pre-made pouches |

| Est. Entry Cost | < $500 (Scales/Sealers) | $200 – $300 (Consumer/Lab grade) | $15,000 – $50,000+ (Industrial grade) |

| Best For | R&D, Prototypes, Home Business | Boutiques, Pilot Runs, Low-Volume SKUs | High-Volume Production, GMP Compliance |

Alternative 1: Manual Filling and Sealing

The Baseline Solution

Manual filling represents the lowest barrier to entry. It involves operators physically scooping powder, weighing it on a bench scale, and sealing the package with a hand sealer.

- Analysis: While CapEx is negligible, this method is unsustainable for scaling B2B operations in Western markets due to high labor costs. Inconsistency in fill weight often leads to “giveaway” (overfilling to ensure compliance), which erodes profit margins on expensive powders like pharmaceutical ingredients or premium matcha.

- Verdict: Viable only for prototype batches or ultra-low volume artisan products where “hand-packed” is a marketing claim.

Alternative 2: Semi-Automatic Tabletop Fillers

The Intermediate Solution (Based on Market Data)

This category includes entry-level particle weighing and filling machines (e.g., brands like Hanchen or VEVOR). These units typically utilize vibration or small augers to dispense a set weight (commonly 1g to 200g) into a container held by an operator, triggered via a foot pedal.

Illustrative Image (Source: Google Search)

- Market Context: Current market data indicates these units are widely available at a low price point ($220–$300). They offer features like “intelligent particle weighing” and can handle granular products (seeds, grains) and fine powders (glitter, flour).

- Pros:

- Accuracy: significantly improves over manual scooping.

- Cost: Extremely accessible for small businesses.

- Footprint: Small enough for tabletop operation.

- Cons & Limitations:

- Disjointed Workflow: These machines only fill. They do not form the bag or seal it. An operator must still hold the bag, trigger the fill, and move it to a separate sealing station.

- Capacity Limits: Most entry-level units max out at 100g or 200g per fill, making them unsuitable for bulk powder packaging.

- Speed: Throughput is limited by the operator’s physical reaction time (pedal press and bag swap).

- Verdict: An excellent bridge solution for laboratories, pilot plants, or boutique brands transitioning out of manual labor, but insufficient for industrial-scale distribution requirements.

The Strategic Advantage of Automated Powder Packing Machines

In contrast to the alternatives above, a fully automated Powder Packing Machine (such as a Vertical Form Fill Seal – VFFS) integrates bag forming (from rollstock), weighing, filling, and sealing into a single continuous process.

Why Upgrade?

1. Labor Reduction: In the US and European markets, where labor can exceed $20/hour, an automated system that replaces 3-4 manual operators delivers an ROI often within 12-18 months.

2. Hygiene and GMP Compliance: Automated systems are generally enclosed (stainless steel construction), reducing product contamination risks—a critical factor for food and pharma certifications.

3. Consistency: Automation eliminates the “human factor,” ensuring every pouch is sealed at the correct temperature and filled to the exact weight, reducing material waste and ensuring regulatory compliance.

Essential Technical Properties and Trade Terminology for powder packing machine

Here is the drafted section, optimized for a B2B audience in the USA and Europe, incorporating the technical data provided and standard industry terminology.

Essential Technical Properties

When sourcing a powder packing machine, technical specifications determine not only production capacity but also compliance with safety standards in US and European markets. Below are the critical properties buyers must evaluate.

Illustrative Image (Source: Google Search)

1. Dosing Mechanism and Accuracy

The core technology that determines how powder is measured.

* Vibratory/Weighing Type: (Common in entry-level models like Hanchen/VEVOR). Uses a load cell and vibration to dispense specific weights (e.g., 1–200g). Best for granules, seeds, and free-flowing powders.

* Auger Filler: Uses a rotating screw for non-free-flowing powders (like flour or protein powder).

* Accuracy Standard: Look for a variance of ≤ ±0.2g for small doses (1–50g) or ±1% for larger volumes to minimize product giveaway.

2. Filling Range and Hopper Capacity

- Filling Range: Defines the minimum and maximum weight the machine can handle per cycle.

- Lab/Pilot Scale: 0.5g – 100g (Ideal for sampling or high-value extracts).

- Production Scale: 10g – 5000g+.

- Hopper Capacity: The volume of powder the machine holds before refilling is required. A larger hopper reduces downtime but requires more floor space.

3. Voltage and Frequency (Regional Compliance)

Electrical compatibility is critical for cross-border procurement.

* USA Market: Requires 110V / 60Hz (Standard) or 220V / 60Hz (Industrial).

* European Market: Requires 220V–240V / 50Hz.

* Note: Many compact machines listed (e.g., 1-200g fillers) are single-phase 110V. Ensure industrial units are wired for your facility’s specific phase (Single vs. Three-phase).

4. Construction Material (GMP Compliance)

To meet FDA (USA) and CE (Europe) health standards, the “wetted parts” (parts touching the powder) must be non-corrosive and easy to sanitize.

* Standard: Stainless Steel 304.

* High-Grade: Stainless Steel 316 (Required for pharmaceutical or highly acidic/corrosive powders).

Technical Specification Summary Table

| Property | Typical Spec (Entry-Level) | Typical Spec (Industrial) | Why it Matters |

|---|---|---|---|

| Throughput | 5–15 bags/min | 30–100+ bags/min | Determines daily output volume. |

| Control System | Intelligent Particle Weighing (Microcomputer) | PLC (Siemens/Omron) + HMI | PLC allows for integration into larger packing lines. |

| Power | 100W – 200W | 1.5kW – 5kW | Higher power is needed for auger torque on dense powders. |

| Actuation | Foot Pedal / Sensor | Pneumatic / Servo | Pneumatic requires an external air compressor. |

Key Trade Terminology for Machinery Sourcing

Understanding these terms is essential for negotiating contracts and logistics with manufacturers.

Commercial Terms

- MOQ (Minimum Order Quantity):

- For machinery, the MOQ is typically 1 Unit.

- For custom printed packaging film (used in VFFS machines), MOQs are often measured in kilograms or meters (e.g., 200kg of film).

- OEM (Original Equipment Manufacturer):

- The factory builds the machine to your specifications (e.g., branding the interface, modifying the hopper size) but sells it under your brand name.

- ODM (Original Design Manufacturer):

- The factory designs a completely new machine based on your conceptual requirements.

Logistics and Compliance

- Lead Time:

- Ex-Stock: 1–3 days (Common for standard 1–200g fillers).

- Production: 15–45 days (For custom industrial lines).

- FAT (Factory Acceptance Test):

- A procedure where the buyer (or a third-party inspector) verifies the machine operates according to specs before it leaves the factory. Highly recommended for orders >$5,000.

- Incoterms (International Commercial Terms):

- EXW (Ex Works): You pay for shipping from the factory floor.

- FOB (Free on Board): Supplier handles costs to the export port; you handle ocean freight and import.

- DDP (Delivered Duty Paid): Supplier handles everything, including customs and delivery to your door. Preferred by smaller US/EU businesses to avoid customs complexity.

Certification Acronyms

- CE Marking: Mandatory for machines sold in the European Economic Area (EEA). Certifies safety and environmental protection.

- UL / ETL: Safety certification often required by insurance companies and local codes in the United States.

- ISO 9001: Indicates the manufacturer follows specific quality management principles.

Navigating Market Dynamics and Sourcing Trends in the powder packing machine Sector

Navigating Market Dynamics and Sourcing Trends in the Powder Packing Machine Sector

The landscape of powder packing machinery is undergoing a significant shift, driven by the dual forces of technological democratization and stringent sustainability mandates. For buyers in the USA and Europe, understanding these dynamics is critical when selecting equipment that balances operational efficiency with regulatory compliance.

The Evolution of Packing Technology: From Volumetric to Intelligent Weighing

Historically, powder packing relied heavily on manual volumetric filling or simple auger systems, which often suffered from accuracy issues due to the varying density of powders.

The market has evolved toward intelligent particle weighing. As evidenced by current entry-level offerings, technology that was once exclusive to high-end industrial lines—such as optical sensors and automated vibration adjustment—is now standard in compact units. Modern machines, even at the benchtop level, utilize microcomputers to control dispensing with precision (often within 0.2g), replacing the “scoop and hope” methods of the past.

Current Market Trends: The Bifurcation of Sourcing

The sourcing landscape has split into two distinct tiers to meet different operational scales:

1. The Democratization of Entry-Level Machinery

There is a surging trend toward “micro-fulfillment” capabilities. Sourcing data indicates a proliferation of compact, semi-automatic powder fillers (typically in the 1g to 200g fill range) available for immediate deployment.

* Accessibility: Brands like Hanchen and VEVOR have standardized the production of benchtop units, driving prices down to the $200–$300 range.

* Agility: Sourcing has shifted from multi-week lead times to “just-in-time” delivery (often under 5 days). This allows R&D labs and small-batch manufacturers in the West to rapid-prototype products without heavy capital expenditure.

* Features: These units typically feature foot-pedal actuation, stainless steel construction for hygiene, and modular designs suitable for granular items like tea, seeds, and glitters.

2. Industrial Automation and Integration

For larger scale operations in Europe and the USA, the trend is Full Line Integration. While entry-level units handle micro-batches, industrial sourcing focuses on:

* PLC Integration: Connecting fillers to upstream mixers and downstream cappers.

* High-Speed Accuracy: Moving beyond the 10-15 bags/minute of semi-auto units to 60+ units/minute.

* Compliance: Adherence to CE (Europe) and FDA/OSHA (USA) standards, which implies higher costs but ensures safety and legality.

Comparative Sourcing Matrix

Buyers should categorize their sourcing needs based on production volume and capital outlay:

| Feature | Entry-Level / Lab Scale | Industrial / Production Scale |

|---|---|---|

| Price Point | $200 – $500 (USD) | $15,000 – $100,000+ (USD) |

| Sourcing Channel | Direct E-commerce (Amazon, Direct) | Specialized OEMs & Distributors |

| Fill Capacity | Micro (0.5g – 200g) | Macro (500g – 25kg+) |

| Automation Level | Semi-Automatic (Foot Pedal) | Fully Automatic (Conveyor fed) |

| Primary Use Case | R&D, Startups, Specialty Batches | Mass Production, Contract Packaging |

Sustainability and Material Compatibility

Sustainability is no longer optional for the Western market; it is a sourcing prerequisite.

- Eco-Film Compatibility: Modern machines are increasingly required to seal heat-sensitive, biodegradable films (such as PLA or water-soluble PVOH) without compromising seal integrity. Older heating elements often burn these delicate materials.

- Energy Efficiency: The shift from pneumatic to servo-driven systems is reducing energy consumption. Even smaller units are being designed with “sleep modes” and lower voltage requirements (110V standard for US entry-level units) to minimize carbon footprints.

- Waste Reduction: The “Intelligent Weighing” systems found in modern fillers drastically reduce product giveaway (overfilling), directly impacting the bottom line and reducing raw material waste.

Frequently Asked Questions (FAQs) for B2B Buyers of powder packing machine

Frequently Asked Questions (FAQs) for B2B Buyers of Powder Packing Machines

1. What is the difference between free-flowing and non-free-flowing powders, and how does it affect machine selection?

The physical characteristics of your product dictate the filling mechanism.

* Free-flowing powders (e.g., granulated sugar, seeds, tea, salt) flow easily under gravity. These are typically handled by volumetric cup fillers or vibratory weigh fillers (common in the 1-200g range).

* Non-free-flowing powders (e.g., flour, fine glitter, protein powder) stick together and resist flow. These require auger fillers (screw conveyors) to force the product into the package and ensure consistent weight.

* Note: Many versatile benchtop machines use vibratory channels suitable for granules but may struggle with cohesive, fine flours without specific agitation features.

2. What are the standard accuracy tolerances for automatic particle weighing machines?

For precision weighing machines (specifically those in the 1g to 200g range), B2B buyers should expect a tolerance of ±0.2g to ±1.0g, depending on the product density and fill speed.

* Micro-dosing: Machines filling 1-50g often feature higher sensitivity sensors to minimize product giveaway (overfilling), which is critical for high-value ingredients like spices or pharmaceutical powders.

* Calibration: Ensure the machine offers an intelligent control panel allowing for “self-correction” or easy tare functions to maintain accuracy over long production runs.

3. Can a single machine handle different packaging formats (e.g., bottles, pouches, and sachets)?

Yes, many semi-automatic and benchtop powder fillers are “container agnostic” regarding the receptacle shape, provided the opening is wider than the discharge nozzle.

* Versatility: Machines equipped with a foot-pedal dispense mechanism allow operators to manually place bottles, pre-made pouches, or jars under the chute.

* Limitations: If you require Form-Fill-Seal (VFFS) capabilities—where the machine creates the bag from film—the equipment is specific to bag width and style. For the 1-200g range referenced, semi-auto fillers offer the highest flexibility for mixed SKUs (bottles and bags).

4. What compliance standards should USA and European buyers look for?

To meet regulatory requirements in Western markets, equipment must adhere to strict safety and hygiene standards:

* Material Contact: All parts touching the powder (hopper, nozzle, tray) must be made of food-grade Stainless Steel 304 or 316.

* Electrical: For the USA, look for UL certification or compatibility with standard 110V/60Hz power. For Europe, CE Marking is mandatory to ensure machinery safety directives are met.

* GMP: The machine design should minimize crevices to facilitate cleaning procedures compliant with Good Manufacturing Practices.

5. How does the “foot pedal” operation compare to fully automatic sensors?

- Foot Pedal (Semi-Automatic): Best for low-to-mid volume production or irregular container shapes. The operator controls the pace, allowing time to settle the powder or adjust the bag. This is standard on entry-level 1-100g fillers.

- Photoelectric Sensors (Automatic): These detect the presence of a container and dispense automatically. This increases throughput but requires a conveyor belt or consistent manual rhythm.

- Recommendation: For B2B buyers scaling up, look for machines that offer switchable modes (Pedal/Sensor) to adapt to different workflow speeds.

6. What is the realistic throughput (PPM) for a 1-200g powder filler?

Throughput depends heavily on the fill weight and operator efficiency.

* Light Fills (1-20g): Expect 15–25 packs per minute (PPM).

* Heavier Fills (100-200g): Speed drops to 6–12 PPM because the vibratory or auger mechanism takes longer to dispense the bulk weight accurately.

* Strategy: To double output without buying a massive industrial line, many facilities operate multiple benchtop units in parallel.

7. How difficult is the cleaning and changeover process between different products?

Cross-contamination is a major risk in B2B powder packaging.

* Disassembly: Look for “tool-free” disassembly where hoppers and discharge chutes can be removed via clamps or thumb screws.

* Sanitization: Stainless steel construction allows for wash-down.

* Changeover Time: For compact weigh-fillers, a complete clean-out (e.g., switching from curry powder to tea) should take less than 15–20 minutes. If the machine requires heavy tooling to clean, it will create significant downtime.

8. What voltage and power requirements are standard for these machines?

Most compact powder filling machines (up to 200g capacity) are designed for standard single-phase power, making them easy to integrate into existing facilities without expensive electrical upgrades.

* USA: Standard 110V.

* Europe: Standard 220V.

* Wattage: These units typically draw low power (e.g., 50W–200W), making them energy-efficient. Always verify the plug type and voltage rating before importing to avoid transformer requirements.

Strategic Sourcing Conclusion and Outlook for powder packing machine

Strategic Sourcing Conclusion and Outlook

The market for powder packing machinery currently offers unprecedented accessibility, characterized by a low barrier to entry for small-scale operations. As evidenced by current market data, semi-automatic particle filling systems (1–200g capacity) are readily available for under $300, allowing startups to automate weighing and filling with minimal capital expenditure.

However, for B2B buyers in the USA and Europe, strategic sourcing must extend beyond initial price points to prioritize scalability, precision, and regulatory compliance (CE/GMP). While entry-level units suffice for R&D or pilot batches, long-term operational efficiency demands equipment that integrates with broader production lines.

Future Outlook and Sourcing Priorities

To maximize ROI, procurement teams should evaluate suppliers based on the following trajectory:

- Versatility: Modern units now handle diverse densities, from fine flours to coarse granules/seeds, without extensive retooling.

- Intelligent Weighing: Look for “Smart Weighing” features that utilize micro-vibration technology to ensure accuracy within $\pm0.2g$, reducing material waste.

- Serviceability: For Western markets, prioritize modular designs that allow for rapid maintenance and easy cleaning to meet strict hygiene standards.

Final Recommendation: Balance immediate budget constraints with future throughput requirements. For high-growth operations, transitioning from tabletop fillers to fully automated vertical form-fill-seal (VFFS) systems will be the critical driver of competitive advantage in 2025 and beyond.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.