Top 27 Rubber Tiles Factory Manufacturers Reviewed

Are you tired of sifting through countless rubber tile suppliers, only to end up frustrated and overwhelmed? Finding the right manufacturer can be a daunting task, but it doesn’t have to be! The quality of rubber tiles significantly impacts durability, safety, and aesthetics, making your choice crucial. Imagine a supplier that not only meets your needs but also offers exceptional service and innovative products.

This guide will unveil the top 30 rubber tile factories that can transform your projects from ordinary to extraordinary. Ready to simplify your search and make an informed decision? Dive into our detailed comparison and discover the best manufacturers that will elevate your flooring game!

Top 27 Rubber Tiles Factory Manufacturers

Roppe – Rubber and Vinyl Flooring Solutions

Domain: roppe.com

Registered: 1996 ( 29 years )

Introduction: Roppe offers a wide range of rubber and vinyl flooring products, including rubber tiles, rubber sheets, multi-use rubber tiles, vinyl tiles and sheets, ESD rubber and vinyl, stair treads, wall bases, and various accessories.

Rubberflooringdirect – Interlocking Rubber Tiles

Domain: rubberflooringdirect.com

Registered: 2008 ( 17 years )

Introduction: Rubber Interlocking Tiles for commercial and residential applications, proudly made in the USA since 1995.

Us – Rubber Tile Solutions

Domain: us.metoree.com

Registered: 2020 ( 5 years )

Introduction: Rubber tiles manufactured by various companies in 2025.

Flexco Floors – Innovative Flooring Solutions

Domain: flexcofloors.com

Registered: 2001 ( 24 years )

Introduction: Flexco Floors offers a wide range of flooring products including wall bases, rubber flooring, vinyl flooring, specialty flooring, stair treads, and accessories. Their products are designed for various market segments such as education, healthcare, government, workplace, retail, hospitality, and marine.

Dinoflex – Recycled Rubber Flooring Solutions

Domain: dinoflex.com

Registered: 1997 ( 28 years )

Introduction: Dinoflex offers a wide range of recycled rubber flooring and surfacing solutions for commercial, institutional, sport, and hospitality applications.

Flooringinc – USA-Made Flooring Solutions

Domain: flooringinc.com

Registered: 2000 ( 25 years )

Introduction: The company offers a variety of flooring products that are made in the USA, including vinyl, laminate, hardwood, and carpet options.

Koffler Sales – Rubber Flooring and Wall Protection Solutions

Domain: kofflersales.com

Registered: 1999 ( 26 years )

Introduction: Koffler Sales Company specializes in rubber floor tiles, commercial tile flooring, and various wall protection products, including wall bases, corner guards, and stair treads.

Gerflor – Sustainable Flooring and Finishing Solutions

Domain: gerflor.com

Registered: 1999 ( 26 years )

Introduction: Gerflor offers safe, sustainable, and decorative solutions for floors, walls, and finishes, designed to meet unique project needs.

Rep Fitness – Rubber Flooring Solutions

Domain: repfitness.com

Registered: 2005 ( 20 years )

Introduction: Rubber floor tiles designed for fitness and gym environments.

Ironcompany – Interlocking Rubber Tiles and Gym Flooring

Domain: ironcompany.com

Registered: 1999 ( 26 years )

Introduction: Interlocking rubber tiles and gym flooring that are durable and eco-friendly.

Continental Flooring – Commercial Rubber Flooring Solutions

Domain: continentalflooring.com

Registered: 2000 ( 25 years )

Introduction: Commercial rubber flooring products including smooth rubber sheet tile, square rubber tiles, rubber floor mats, interlocking tiles, and recycled rubber flooring.

Blackironrubber – Interlocking Rubber Floor Tiles

Domain: blackironrubber.com

Registered: 2000 ( 25 years )

Introduction: Interlocking Rubber Floor Tiles made from durable chemical resistant rubber, designed for easy assembly and a tight fit.

Mannington Commercial – Durable Rubber Flooring Solutions

Domain: manningtoncommercial.com

Registered: 2005 ( 20 years )

Introduction: Rubber Sheet & Tile products designed for commercial spaces, offering durability and performance.

Aochenrubber – Durable Rubber Floor Tiles Solutions

Domain: aochenrubber.com

Registered: 2018 ( 7 years )

Introduction: Rubber floor tiles from AOCHEN are versatile flooring solutions for a wide range of applications, providing durability, safety.

Greatmats – Durable Rubber Flooring Solutions

Domain: greatmats.com

Registered: 1999 ( 26 years )

Introduction: Greatmats offers a variety of rubber flooring products suitable for various applications, including interlocking tiles, rolls, and mats designed for durability and safety.

Rubbergranules Supplier – Premium Gym Rubber Tiles

Domain: rubbergranules-supplier.com

Registered: 2024 ( 1 years )

Introduction: Premium rubber tiles designed for gym safety and comfort, featuring high-friction and anti-slip properties.

Therubbercompany – Playground Safety Rubber Tiles

Domain: therubbercompany.com

Registered: 2013 ( 12 years )

Introduction: SBR RubbaTile® Rubber Tiles are designed for playground safety surfacing, providing a durable and safe surface for children to play on.

Sunflex Rubber Flooring – Quality Rubber Flooring Solutions

Domain: sunflexrubberflooring.com

Registered: 2021 ( 4 years )

Introduction: Sunflex Rubber Flooring offers a variety of rubber flooring products including standard rubber tiles, poured rubber surfacing, interlocking rubber tiles, crumb rubber granules, rubber mulch, and more.

Modutile – Interlocking Rubber Floor Tiles

Domain: modutile.com

Registered: 2006 ( 19 years )

Introduction: Interlocking Rubber Floor Tiles, 23″x23″ (8mm ~ 5/16″) designed for home gym flooring with a professional grade finish.

Turffactorydirect – Rubber Flooring Solutions

Domain: turffactorydirect.com

Registered: 2010 ( 15 years )

Introduction: Rubber flooring available in various sizes, textures, and colors, suitable for both commercial and residential spaces.

Beka Rubber – Premium Rubber Flooring Solutions

Domain: bekarubber.com

Registered: 2017 ( 8 years )

Introduction: Beka Rubber specializes in the manufacturing of rubber flooring products, including indoor and outdoor rubber tiles, rolls, grass tiles, and various other rubber products for sports and recreational use.

Bioflexrubberflooring – Premium Rubber Flooring Solutions

Domain: bioflexrubberflooring.com

Registered: 2017 ( 8 years )

Introduction: The company primarily offers a range of rubber flooring products including EPDM rubber granules tiles, bioflex EPDM colored rubber tiles, mini power rubber tiles, SBR rubber floor tiles, garage gym floor tiles, rogue multipurpose rubber tiles, soft rubber floor tiles, and fitness gym flooring tiles.

Mats Inc – Interlocking Rubber Flooring Solutions

Domain: mats-inc.com

Registered: 1998 ( 27 years )

Introduction: Interlocking rubber tiles designed for various flooring applications, providing durability and comfort.

Fine Woodworking – Recycled Rubber Flooring Tiles

Domain: finewoodworking.com

Registered: 1998 ( 27 years )

Introduction: 3/8″ thick 2×2 rubber tiles made from recycled tires, available in black with or without specs.

Freedom Fitness Equipment – Premium Rubber Gym Flooring

Domain: freedomfitnessequipment.com

Registered: 2020 ( 5 years )

Introduction: NEW Hammer Clad 1/2″ Premium Rubber Floor Tiles and Gym Tile Flooring Interlock

Classic Rubber Flooring – Eco-Friendly Rubber Flooring Solutions

Domain: classicrubberflooring.com

Registered: 2016 ( 9 years )

Introduction: Classic Rubber Flooring offers a range of rubber flooring products including Rubber Flooring Tiles, Rubber Granules, and Rubber Scrap. Their products are designed to be safe, environment-friendly, cost-effective, and low maintenance.

Ford Tremor – OEM Rubber Flooring Solutions

Domain: fordtremor.com

Registered: 2019 ( 6 years )

Introduction: Ford OEM rubber flooring for vehicles, specifically designed for models like the Ford Tremor.

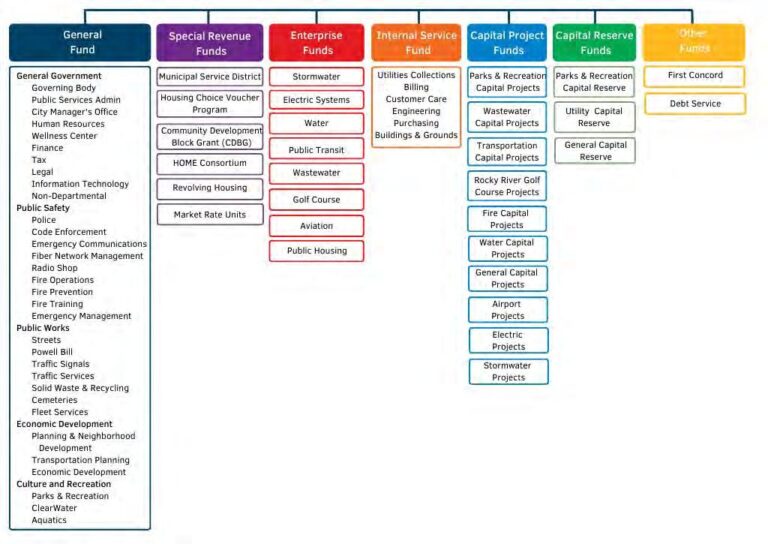

Category Information

The category of “rubber tiles factory” encompasses manufacturing facilities that produce rubber tiles used in various applications, including flooring, playgrounds, gyms, and commercial spaces. These factories typically utilize recycled rubber or new rubber materials to create durable, slip-resistant, and versatile flooring solutions. The production process involves mixing, molding, and curing rubber to form tiles that can be customized in size, color, and texture.

Rubber tiles are significant due to their resilience, ease of maintenance, and sound-absorbing properties, making them ideal for high-traffic areas and environments that require safety and comfort. The demand for eco-friendly and sustainable flooring options has also increased, positioning rubber tiles as an attractive choice for environmentally conscious consumers. As urban development and recreational spaces expand, the role of rubber tiles factories becomes crucial in supplying effective flooring solutions that enhance both functionality and aesthetics.

Application Information

Rubber tiles are widely utilized across various industries due to their durability, safety, and versatility. One of the primary application areas is in sports and fitness facilities, where rubber tiles provide a shock-absorbent surface for gym floors, playgrounds, and athletic tracks. Their ability to reduce injury risks makes them ideal for high-impact activities. Another significant application is in commercial spaces such as retail stores and showrooms, where rubber tiles offer both aesthetic appeal and functionality.

They are easy to clean, slip-resistant, and can withstand heavy foot traffic. Additionally, industrial settings often employ rubber tiles in manufacturing and warehouse environments, providing a safe and resilient flooring option that can handle equipment and heavy loads. Lastly, residential applications are common, with homeowners using rubber tiles for home gyms, basements, and outdoor patios, benefiting from their ease of maintenance and comfort underfoot.

This broad range of uses highlights the versatility of rubber tiles in enhancing safety and functionality across diverse environments.

Production Process Information

The production of rubber tiles typically involves several key stages. First, raw materials such as rubber granules, color pigments, and binding agents are sourced and prepared. These materials are essential for creating durable and attractive tiles suitable for various applications, including flooring and outdoor surfaces. Next, the prepared materials are mixed together to form a uniform blend. This mixture is then poured into molds to shape the tiles.

Once molded, the tiles undergo a curing process, where they are heated to harden and enhance their durability. After curing, the tiles are removed from the molds, inspected for quality, and then packaged for distribution. Finally, considerations such as design, texture, and environmental impact are taken into account to meet customer needs and sustainability goals. This streamlined process ensures that high-quality rubber tiles are produced efficiently.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a rubber tiles factory?

When searching for a rubber tiles factory, consider factors such as their production capacity, quality control measures, and certifications. Look for manufacturers that have a good reputation in the industry and can provide samples of their products. Additionally, check if they have experience in producing the specific type of rubber tiles you need, whether for flooring, playgrounds, or other applications.

How can I verify the quality of rubber tiles from a manufacturer?

To verify the quality of rubber tiles, request samples before placing a large order. Inspect these samples for durability, texture, and color consistency. You can also ask the manufacturer for quality certifications, such as ISO or ASTM standards, which indicate that their products meet specific safety and performance criteria. Reading customer reviews and testimonials can also provide insights into the reliability of their products.

What are the typical lead times for ordering rubber tiles?

Lead times can vary significantly depending on the manufacturer and the size of your order. Generally, you can expect a lead time of anywhere from 2 to 6 weeks for standard orders. For custom designs or larger quantities, it might take longer. Always discuss lead times upfront with the manufacturer to ensure they align with your project timeline.

Are there minimum order quantities I should be aware of?

Yes, many rubber tiles manufacturers have minimum order quantities (MOQs) that you need to meet. This can vary widely depending on the factory and the type of tiles you’re ordering. It’s important to ask about MOQs during your initial discussions to avoid surprises later on. Some manufacturers might be flexible with smaller orders, especially if you’re willing to pay a premium.

What factors affect the pricing of rubber tiles?

The pricing of rubber tiles can be influenced by several factors, including the type of rubber used, the manufacturing process, the complexity of the design, and the quantity ordered. Custom colors or patterns may also increase costs. Additionally, consider shipping and handling fees, as these can add to the overall price. Always ask for a detailed quote that breaks down these factors to understand what you’re paying for.