Save Costs with the Best Stainless Steel Pipe Supplier (2025)

Introduction: Navigating the Global Market for stainless steel pipe supplier

Navigating the global market for stainless steel pipe suppliers presents unique challenges, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. With varying quality standards, supply chain complexities, and fluctuating costs, sourcing high-quality stainless steel pipes can be a daunting task. This guide aims to demystify the procurement process, providing actionable insights that will empower buyers to make informed purchasing decisions.

In this comprehensive guide, we delve into the different types of stainless steel pipes available in the market, including seamless, welded, and decorative options. We also explore their diverse applications across various industries, from construction and manufacturing to oil and gas. Understanding how to effectively vet suppliers is crucial for ensuring that you partner with reliable manufacturers who can meet your specific needs. Additionally, we provide a detailed analysis of cost factors, helping you navigate price variations and negotiate better deals.

By equipping yourself with the knowledge presented in this guide, you will enhance your procurement strategy, mitigate risks, and streamline your supply chain operations. Whether you are seeking suppliers in Mexico, Saudi Arabia, or other key markets, this resource is designed to facilitate your sourcing journey, ultimately leading to successful and sustainable partnerships in the stainless steel pipe industry.

Understanding stainless steel pipe supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seamless Stainless Steel Pipe | Manufactured without seams, offering strength and uniformity | Oil & gas, chemical processing, construction | Pros: High strength, corrosion resistance. Cons: Higher cost, limited sizes. |

| Welded Stainless Steel Pipe | Created by welding flat steel strips together, available in various sizes | Water supply, HVAC, food processing | Pros: Cost-effective, versatile. Cons: Slightly lower strength compared to seamless. |

| Schedule 40 Stainless Steel Pipe | Standard wall thickness, commonly used for various applications | Plumbing, HVAC, industrial applications | Pros: Wide availability, good pressure ratings. Cons: Less suitable for high-pressure applications. |

| High-Pressure Stainless Steel Pipe | Designed for high-pressure environments with thicker walls | Petrochemical, power generation, aerospace | Pros: Exceptional strength and durability. Cons: Heavier, more expensive. |

| Duplex Stainless Steel Pipe | Combines austenitic and ferritic properties for enhanced performance | Marine, chemical, and oil industries | Pros: Superior strength, corrosion resistance. Cons: Higher cost and complexity in sourcing. |

What Are the Characteristics of Seamless Stainless Steel Pipes?

Seamless stainless steel pipes are known for their strength and durability due to the lack of welded seams. This manufacturing process allows for a uniform structure, making them ideal for high-stress applications such as oil and gas exploration and chemical processing. When considering a purchase, B2B buyers should evaluate the specific pressure ratings and sizes required for their projects, as seamless pipes tend to be more expensive and may have limited size options compared to welded alternatives.

How Do Welded Stainless Steel Pipes Differ?

Welded stainless steel pipes are made by joining flat pieces of steel through welding, allowing for a variety of sizes and thicknesses. They are cost-effective and widely used in applications such as water supply and HVAC systems. B2B buyers should weigh the benefits of lower costs against the slightly reduced strength compared to seamless options. Understanding the intended application is crucial, as welded pipes may not be suitable for extremely high-pressure environments.

Why Choose Schedule 40 Stainless Steel Pipes?

Schedule 40 stainless steel pipes feature a standard wall thickness that balances strength and weight, making them a popular choice for plumbing and HVAC applications. They are readily available and offer good pressure ratings for most industrial uses. Buyers should consider the specific pressure requirements of their applications, as Schedule 40 pipes may not perform optimally in high-pressure scenarios.

What Makes High-Pressure Stainless Steel Pipes Unique?

High-pressure stainless steel pipes are engineered to withstand extreme pressure conditions, featuring thicker walls for enhanced strength. These pipes are essential in industries like petrochemical and aerospace, where safety and durability are paramount. B2B buyers should consider the additional weight and cost associated with these pipes, as well as their specific application requirements, to ensure optimal performance.

How Do Duplex Stainless Steel Pipes Perform?

Duplex stainless steel pipes combine the best features of austenitic and ferritic stainless steels, providing superior strength and corrosion resistance. They are particularly suited for marine and chemical applications where exposure to harsh environments is common. Buyers should be prepared for a higher cost and complexity in sourcing these pipes, but the long-term benefits in performance and durability often justify the investment.

Related Video: This is How Stainless Steel Pipe Are Manufactured || Production of Pipes

Key Industrial Applications of stainless steel pipe supplier

| Industry/Sector | Specific Application of Stainless Steel Pipe Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Transportation of hydrocarbons and natural gas | High corrosion resistance ensures longevity and safety in harsh environments | Compliance with international standards and certifications, such as ASTM and ASME. |

| Food & Beverage | Manufacturing of processing and storage equipment | Hygiene and durability meet strict health standards, preventing contamination | Certifications for food-grade materials and traceability of raw materials. |

| Chemical Processing | Delivery of corrosive chemicals | Stainless steel pipes withstand high pressures and temperatures, reducing the risk of leaks | Material grade selection based on specific chemical compatibility and pressure ratings. |

| Construction | Structural applications in buildings | Provides strength and durability, enhancing safety and longevity of constructions | Sourcing from suppliers with a reliable track record and quality assurance processes. |

| Pharmaceutical | Transport of active pharmaceutical ingredients (APIs) | Ensures purity and compliance with stringent regulations, avoiding contamination | Certification for pharmaceutical-grade materials and adherence to Good Manufacturing Practices (GMP). |

How is Stainless Steel Pipe Used in the Oil & Gas Industry?

In the oil and gas sector, stainless steel pipes are critical for the safe transportation of hydrocarbons and natural gas. Their high corrosion resistance allows them to endure harsh environments, reducing maintenance costs and downtime. International buyers, particularly from regions like Africa and the Middle East, must ensure compliance with industry standards such as ASTM and ASME. This guarantees that the pipes can withstand the extreme conditions typical in oil extraction and transportation.

What Role Does Stainless Steel Pipe Play in Food & Beverage Manufacturing?

In the food and beverage industry, stainless steel pipes are essential for the manufacturing of processing and storage equipment. Their non-reactive nature ensures that food products remain uncontaminated, adhering to strict hygiene standards. Buyers from South America and Europe should prioritize suppliers that offer certifications for food-grade materials and provide traceability for raw materials to ensure compliance with health regulations.

How is Stainless Steel Pipe Utilized in Chemical Processing?

Stainless steel pipes are widely used in chemical processing for the delivery of corrosive chemicals. Their ability to withstand high pressures and temperatures significantly reduces the risk of leaks, which can be hazardous. International buyers must consider the specific material grade based on chemical compatibility and pressure ratings to ensure optimal performance and safety in their applications.

Why is Stainless Steel Pipe Important in Construction?

In construction, stainless steel pipes are employed in various structural applications, providing essential strength and durability. They enhance the safety and longevity of buildings, making them a preferred choice for many contractors. Buyers should focus on sourcing from suppliers with a reliable track record and robust quality assurance processes, ensuring that the materials meet the rigorous demands of construction projects.

How is Stainless Steel Pipe Used in the Pharmaceutical Industry?

In the pharmaceutical industry, stainless steel pipes facilitate the transport of active pharmaceutical ingredients (APIs). Their ability to maintain purity and comply with stringent regulations is crucial for avoiding contamination. Buyers must ensure that their suppliers provide certification for pharmaceutical-grade materials and adhere to Good Manufacturing Practices (GMP), which are vital for maintaining the integrity of pharmaceutical products.

3 Common User Pain Points for ‘stainless steel pipe supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance Issues in Stainless Steel Pipes

The Problem: One of the most significant challenges B2B buyers face when sourcing stainless steel pipes is the inconsistency in quality. Buyers from regions like Africa and South America often encounter suppliers who provide varying levels of product quality, which can lead to costly project delays or failures. This inconsistency might stem from inadequate quality control measures in the supplier’s manufacturing process or a lack of adherence to international standards, such as ASTM or ISO certifications. For example, a buyer in the Middle East may receive pipes that do not meet the required corrosion resistance specifications, resulting in potential structural failures and financial losses.

The Solution: To mitigate quality assurance issues, buyers should prioritize sourcing from suppliers who have robust quality control systems in place. Start by requesting detailed documentation of the supplier’s quality certifications and their manufacturing processes. It is also advisable to ask for samples of the stainless steel pipes before placing a bulk order to evaluate their quality firsthand. Establishing a close working relationship with the supplier can further enhance communication regarding quality expectations. Additionally, consider implementing a third-party inspection service to verify the quality of materials before they reach your project site. This proactive approach will ensure that the pipes meet your specific requirements and help avoid costly mistakes.

Scenario 2: Understanding Pricing Structures and Hidden Costs

The Problem: B2B buyers frequently struggle with understanding the pricing structures of stainless steel pipes. Buyers from Europe and the Middle East may find that quoted prices do not always reflect the final cost due to hidden charges such as shipping fees, taxes, or tariffs. These additional costs can significantly impact the overall budget, making it difficult for businesses to forecast expenses accurately. For instance, a buyer in Europe may receive a competitive quote for pipes, only to discover substantial shipping fees that push the price beyond budget constraints.

The Solution: To navigate complex pricing structures, buyers should seek detailed quotations that break down all associated costs, including unit prices, shipping, and any potential tariffs. When negotiating with suppliers, be transparent about your budget and ask for all-inclusive pricing to avoid unpleasant surprises. It may also be beneficial to explore bulk purchasing options or long-term contracts, as these could offer better rates and more predictable pricing. Additionally, consider leveraging local suppliers when possible, as they may provide more transparent pricing and lower shipping costs. Always maintain clear communication with the supplier throughout the procurement process to clarify any uncertainties related to pricing.

Scenario 3: Managing Lead Times and Delivery Challenges

The Problem: Delays in lead times and delivery can severely disrupt project timelines for B2B buyers. Buyers from regions such as South America and Africa often face challenges related to longer shipping times, customs clearance issues, and local logistical obstacles. For example, a construction firm in Brazil might order stainless steel pipes only to find that delays in shipping result in halting their project, ultimately leading to increased labor costs and client dissatisfaction.

The Solution: To effectively manage lead times and delivery challenges, buyers should start by establishing clear timelines with suppliers during the negotiation phase. Communicate your project deadlines explicitly and inquire about the typical lead times for orders. It can also be beneficial to maintain a buffer stock of essential materials to accommodate any unforeseen delays. Collaborating with suppliers who have a proven track record of reliable delivery can further minimize risk. Additionally, consider using logistics firms experienced in international shipping to streamline customs processes and ensure timely delivery. Regular follow-ups on order status and maintaining open lines of communication with your supplier can help preemptively address potential issues before they escalate.

Strategic Material Selection Guide for stainless steel pipe supplier

What Are the Key Properties of Common Stainless Steel Materials for Pipes?

When selecting stainless steel pipes, international B2B buyers must consider various materials, each with distinct properties that influence performance, durability, and cost. Here, we analyze four common stainless steel grades used in pipe manufacturing: 304, 316, 321, and 410.

1. 304 Stainless Steel

Key Properties: 304 stainless steel is a versatile material known for its excellent corrosion resistance and good mechanical properties. It performs well in temperatures up to 870°C (1600°F) and offers a pressure rating suitable for many applications.

Pros & Cons: The primary advantage of 304 stainless steel is its affordability and ease of fabrication. However, it is less resistant to chlorides compared to other grades, making it less suitable for marine environments.

Impact on Application: 304 is ideal for applications involving food processing, dairy, and brewing due to its non-reactive nature. It is compatible with a wide range of media, including water and mild acids.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM A312. Cost-effectiveness makes 304 a popular choice, but its limitations in highly corrosive environments should be noted.

2. 316 Stainless Steel

Key Properties: 316 stainless steel offers enhanced corrosion resistance, particularly against chlorides and marine environments. It can withstand temperatures up to 870°C (1600°F) and has a higher pressure rating than 304.

Pros & Cons: The main advantage of 316 is its superior corrosion resistance, making it suitable for harsh environments. However, it comes at a higher cost than 304, which may not be justifiable for all applications.

Impact on Application: This grade is commonly used in chemical processing, pharmaceuticals, and marine applications due to its ability to handle aggressive media. It is particularly effective in applications involving seawater and acidic solutions.

Considerations for International Buyers: Buyers from the Middle East and Europe should consider compliance with DIN and JIS standards, as 316 is often specified for offshore and industrial applications. Its higher cost may be offset by its longevity and reduced maintenance needs.

3. 321 Stainless Steel

Key Properties: 321 stainless steel is stabilized with titanium, providing excellent resistance to intergranular corrosion. It maintains good mechanical properties at elevated temperatures, making it suitable for applications up to 900°C (1650°F).

Pros & Cons: The key advantage of 321 is its resistance to oxidation and thermal fatigue. However, it can be more expensive than 304 and may require more complex manufacturing processes.

Impact on Application: This material is ideal for high-temperature applications, such as exhaust systems and heat exchangers. It is compatible with a variety of media, including hydrocarbons and steam.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with specific industry standards (e.g., ASTM A312). The added cost may be justified for applications requiring high-temperature performance.

4. 410 Stainless Steel

Key Properties: 410 stainless steel is a martensitic grade that offers good wear resistance and moderate corrosion resistance. It can be heat-treated to enhance its mechanical properties and withstand temperatures up to 650°C (1200°F).

Pros & Cons: The primary advantage of 410 is its hardness and wear resistance, making it suitable for applications requiring strength. However, its corrosion resistance is inferior to austenitic grades, limiting its use in corrosive environments.

Impact on Application: This grade is often used in applications like valves and pumps, where strength is critical. It is less compatible with aggressive media, which can lead to premature failure.

Considerations for International Buyers: Buyers from South America and Africa should be aware of the limitations in corrosive environments and ensure compliance with ASTM standards. The cost-effectiveness of 410 makes it appealing for specific applications.

Summary Table of Stainless Steel Materials for Pipes

| Material | Typical Use Case for Stainless Steel Pipe Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 | Food processing, dairy, brewing | Affordable and easy to fabricate | Less resistant to chlorides | Low |

| 316 | Chemical processing, marine applications | Superior corrosion resistance | Higher cost than 304 | High |

| 321 | High-temperature applications, exhaust systems | Excellent thermal stability | More complex manufacturing | Med |

| 410 | Valves, pumps requiring strength | Good wear resistance | Inferior corrosion resistance | Low |

This guide provides international B2B buyers with essential insights into the strategic selection of stainless steel pipe materials, helping them make informed decisions based on their specific application needs and regional standards.

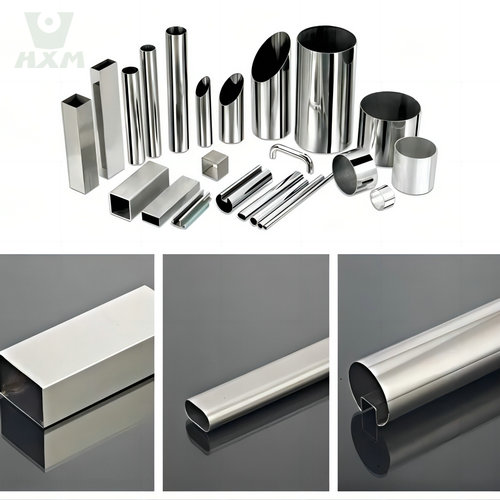

A stock image related to stainless steel pipe supplier.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel pipe supplier

What Are the Key Stages in the Manufacturing Process of Stainless Steel Pipes?

Manufacturing stainless steel pipes involves several critical stages, each designed to ensure the final product meets stringent quality standards. Understanding these processes is vital for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe.

1. Material Preparation: How Is the Raw Material Processed?

The first step in manufacturing stainless steel pipes begins with selecting the appropriate grade of stainless steel, such as 304 or 316, based on the intended application. The raw material is typically in the form of stainless steel coils or sheets.

- Cutting and Sizing: The coils are cut to specific lengths, which can vary based on the pipe dimensions needed.

- Cleaning: The material is cleaned to remove any contaminants, such as oil or dust, which could affect the final product’s quality.

2. Forming: What Techniques Are Used to Shape Stainless Steel Pipes?

Once the material is prepared, the next stage is forming, which involves shaping the stainless steel into pipes.

- Welding: For welded pipes, the edges of the cut sheets are brought together and fused using techniques like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. This ensures a strong, leak-proof seam.

- Seamless Manufacturing: In the case of seamless pipes, the material is heated and pierced to form a hollow tube, which is then further elongated to achieve the desired dimensions.

3. Assembly: How Are Pipes Joined and Prepared for Finishing?

For certain applications, pipes may require additional components such as flanges, valves, or fittings.

- Joining Techniques: Methods like butt welding or socket welding are employed to attach these components securely.

- Quality Checks: Each assembly point should undergo preliminary quality checks to ensure that the connections meet specified tolerances.

4. Finishing: What Processes Ensure the Final Product Meets Standards?

The finishing stage enhances the aesthetic and functional aspects of stainless steel pipes.

- Surface Treatment: Techniques such as pickling and passivation remove oxides and improve corrosion resistance. The surface can also be polished for a smooth finish.

- Coating: For added protection, pipes may be coated with additional materials, depending on their intended use.

What International Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is critical in the manufacturing of stainless steel pipes, ensuring that products meet international and industry-specific standards.

1. What Are the Relevant International Standards?

B2B buyers should be familiar with the following standards:

- ISO 9001: This standard focuses on quality management systems and is essential for suppliers aiming for international credibility. It ensures consistent quality in production and service delivery.

- CE Marking: For products sold in Europe, CE marking indicates compliance with EU safety and environmental regulations.

- API Standards: For those in the oil and gas sector, API (American Petroleum Institute) standards are crucial for ensuring pipe quality and performance.

What Are the Key Quality Control Checkpoints in Stainless Steel Pipe Manufacturing?

Quality control (QC) is vital at every stage of the manufacturing process. Here are the main checkpoints:

1. Incoming Quality Control (IQC)

At this stage, raw materials are inspected for compliance with specifications before being used in production. This includes:

- Material Certification: Verifying mill test reports (MTRs) to ensure materials meet the specified standards.

- Dimensional Checks: Assessing that the incoming materials meet the required dimensions.

2. In-Process Quality Control (IPQC)

During manufacturing, continuous monitoring is essential to maintain quality:

- Welding Inspections: Regular checks on weld integrity and quality, including visual inspections and non-destructive testing (NDT) methods like ultrasonic testing (UT).

- Dimensional Checks: Pipes are measured at various stages to ensure they meet the specified tolerances.

3. Final Quality Control (FQC)

Once the pipes are manufactured, a final inspection is conducted:

- Pressure Testing: Pipes are subjected to pressure tests to verify their strength and leak-proof nature.

- Surface Inspection: Any surface imperfections are checked, and the finish is evaluated.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to mitigate risks.

1. Conducting Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing and quality control processes. Buyers should:

- Request Audit Reports: Suppliers should provide documentation of their internal audits and any third-party audits.

- Visit Manufacturing Facilities: If possible, visiting the supplier’s facility can help buyers assess the manufacturing environment and QC practices firsthand.

2. Reviewing Quality Control Documentation

Buyers should request comprehensive QC documentation, including:

- Certificates of Compliance: Ensure that the products meet the required international standards.

- Testing Reports: Request detailed reports on the testing methods and results performed on the pipes.

3. Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This can include:

- Pre-shipment Inspections: Before the products are shipped, independent inspectors can verify that the pipes meet the specified requirements.

- Continuous Monitoring: Engaging third-party services for ongoing assessments can help maintain quality standards throughout the supply chain.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

For buyers operating in different regions, it’s essential to understand the nuances associated with quality control and certification:

- Regulatory Differences: Different countries may have varying requirements for certifications. For instance, while CE marking is crucial in Europe, other regions may have different regulatory frameworks.

- Cultural Expectations: Understanding the cultural differences in business practices can also influence supplier relationships and quality expectations.

A stock image related to stainless steel pipe supplier.

By grasping these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting stainless steel pipe suppliers, ensuring they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel pipe supplier’

Introduction

Sourcing stainless steel pipes for industrial applications involves a meticulous process that ensures quality, compliance, and cost-effectiveness. This checklist serves as a comprehensive guide for B2B buyers, particularly from Africa, South America, the Middle East, and Europe. Following these steps will help you make informed decisions and select the right supplier for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for sourcing the right stainless steel pipes. Consider factors such as dimensions, grades, and pressure ratings. Clearly defined requirements help suppliers provide accurate quotes and ensure that the products meet your operational standards.

- Material Grade: Identify the stainless steel grade (e.g., 304, 316) suitable for your application.

- Pipe Size: Specify the diameter and wall thickness based on your project needs.

Step 2: Conduct Market Research for Suppliers

Researching potential suppliers is essential to finding reliable partners. Look for suppliers with experience in your industry and a good reputation in the market. This helps ensure that you’re working with a company that understands your specific needs.

- Industry Reviews: Utilize platforms like LinkedIn, industry forums, and trade associations to gather insights.

- Local vs. International: Consider whether to source locally or internationally based on cost, lead time, and logistics.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is vital. Request company profiles, case studies, and references from buyers in similar industries or regions. This step helps you verify the supplier’s credibility and track record.

- Certifications: Check for relevant industry certifications, such as ISO standards.

- Past Projects: Review their portfolio to see if they have handled projects similar to yours.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes. Comparing pricing is essential, but it should not be the sole factor in your decision-making process. Look for transparency in pricing and any additional costs that might arise.

- Inclusions: Ensure that the quotes include all costs, such as shipping and taxes.

- Payment Terms: Clarify payment terms and conditions to avoid surprises later.

Step 5: Verify Supplier Certifications

Verification of supplier certifications is a crucial step in ensuring compliance with international standards. Certifications indicate that the supplier adheres to quality management systems and industry regulations, which is vital for maintaining product integrity.

- Quality Assurance: Look for certifications like ISO 9001 or specific industry-related certifications.

- Regulatory Compliance: Ensure the supplier complies with local regulations in your country.

Step 6: Conduct a Site Visit or Virtual Tour

If possible, visit the supplier’s facility to assess their manufacturing capabilities and quality control processes. If a physical visit isn’t feasible, request a virtual tour. This can provide insights into their operations and help build trust.

- Production Capacity: Evaluate whether the supplier can meet your demand.

- Quality Control: Observe the quality control processes in place to ensure product standards.

Step 7: Establish Clear Communication Channels

Establishing effective communication channels with your chosen supplier is crucial for a successful partnership. Clear communication helps in resolving issues quickly and ensures that both parties are aligned on expectations.

- Regular Updates: Set up a schedule for regular updates on order status and any changes.

- Point of Contact: Designate a point of contact for seamless communication throughout the procurement process.

By following these steps, you can streamline your sourcing process and establish a fruitful partnership with your stainless steel pipe supplier.

Comprehensive Cost and Pricing Analysis for stainless steel pipe supplier Sourcing

Understanding the cost structure and pricing dynamics of stainless steel pipe suppliers is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis delves into the key components that influence costs and pricing, helping buyers make informed decisions.

What Are the Key Cost Components for Stainless Steel Pipe Suppliers?

-

Materials: The primary cost driver in stainless steel pipe manufacturing is the raw material itself. Stainless steel prices fluctuate based on global market conditions, including demand from industries such as construction, automotive, and energy. Buyers should monitor market trends to anticipate price changes.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, suppliers may offer more competitive pricing. However, regions with higher labor standards may provide better craftsmanship and quality assurance, which could justify higher prices.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive prices. Buyers should inquire about the supplier’s manufacturing practices to understand their cost structure.

-

Tooling: The initial investment in tooling and machinery can be substantial, particularly for custom projects. Suppliers often amortize these costs over production volume, impacting pricing. Buyers should consider the implications of tooling costs when discussing custom specifications.

-

Quality Control (QC): Ensuring product quality is essential, especially for industries with strict compliance standards. Suppliers that invest in rigorous QC processes may charge higher prices but can provide assurance of product reliability and certification.

-

Logistics: Transportation and shipping costs are significant, particularly for international orders. Factors such as distance, shipping method, and freight costs can add to the total price. Buyers should understand the logistics involved in their procurement to avoid unexpected expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on competition, market demand, and the supplier’s business strategy.

How Do Price Influencers Affect Your Purchasing Decisions?

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate volume discounts, especially if they can commit to higher quantities over time.

-

Specifications and Customization: Customized products may incur additional costs due to specialized manufacturing processes. Buyers should balance the need for customization with the associated costs.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ASTM, ISO) can lead to increased costs. Buyers should evaluate whether the additional investment aligns with their project requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge more due to their quality assurance and service levels.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can affect the overall cost. Buyers should clarify these terms in contracts to avoid misunderstandings.

What Tips Can Help Buyers Optimize Their Costs?

-

Negotiate Effectively: Leverage your position as a buyer by negotiating terms, especially for large orders. Building long-term relationships with suppliers can lead to better pricing over time.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and potential downtime when evaluating suppliers. A slightly higher upfront cost might save money in the long run.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing standards. Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations that may impact pricing.

-

Request Indicative Prices: Always ask for indicative prices before committing to an order. This can help you gauge the market and negotiate better terms.

Disclaimer on Indicative Prices

Prices for stainless steel pipes can vary widely based on market conditions and specific project requirements. The information provided here serves as a general guideline and should not be considered a definitive pricing structure. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing stainless steel pipe supplier With Other Solutions

When considering the procurement of stainless steel pipes, international B2B buyers must evaluate their options carefully. Understanding the alternatives can help businesses make informed decisions that align with their operational needs, budget constraints, and long-term goals. In this section, we will compare stainless steel pipe suppliers with two viable alternatives: PVC piping and carbon steel piping.

| Comparison Aspect | Stainless Steel Pipe Supplier | PVC Piping | Carbon Steel Piping |

|---|---|---|---|

| Performance | High durability and corrosion resistance | Good for low-pressure applications; not heat resistant | Strong and durable; prone to corrosion without treatment |

| Cost | Higher initial investment | Low cost | Moderate cost |

| Ease of Implementation | Requires skilled labor for installation | Easy to install; lightweight | Requires welding and skilled labor |

| Maintenance | Low maintenance; long lifespan | Moderate; prone to cracking over time | High; requires regular maintenance to prevent rust |

| Best Use Case | Industrial applications, high-pressure systems | Residential plumbing, irrigation | Oil and gas, structural applications |

What Are the Advantages and Disadvantages of PVC Piping Compared to Stainless Steel Pipes?

PVC piping is an attractive alternative for many applications due to its low cost and ease of installation. It is lightweight, making it easy to handle and transport, which can significantly reduce labor costs during installation. However, PVC is not suitable for high-temperature applications and can become brittle over time, especially when exposed to UV light. For international buyers in regions with varying climates, this could lead to premature failures and increased replacement costs.

How Does Carbon Steel Piping Compare to Stainless Steel Pipes?

Carbon steel piping offers a strong alternative that is often used in high-pressure applications, particularly in the oil and gas industry. It has a moderate cost and can be a suitable choice for structural applications. However, carbon steel is prone to corrosion and typically requires additional protective coatings or regular maintenance to ensure longevity. This can lead to higher lifetime costs, especially in environments that are prone to moisture or aggressive chemicals.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right piping solution, B2B buyers should consider several factors, including the specific application, environmental conditions, and budget constraints. Stainless steel pipes are ideal for industries that require durability and resistance to corrosion, making them a preferred choice for high-pressure and industrial applications. In contrast, PVC piping may be more suitable for residential projects or low-pressure systems where cost is a primary concern. Carbon steel, while strong, requires careful consideration of maintenance and protective measures.

Ultimately, the choice between stainless steel pipes and their alternatives should align with the buyer’s operational needs and future growth plans. By evaluating the performance, costs, and maintenance requirements of each option, international buyers can make informed decisions that optimize their supply chain and enhance their project outcomes.

Essential Technical Properties and Trade Terminology for stainless steel pipe supplier

What Are the Key Technical Properties of Stainless Steel Pipes?

When sourcing stainless steel pipes, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some of the essential properties you should consider:

1. Material Grade

Material grades for stainless steel pipes are classified based on their chemical composition and mechanical properties. Common grades include 304, 316, and 321.

- B2B Importance: Selecting the right grade ensures that the pipes meet the specific requirements for corrosion resistance, strength, and temperature tolerance. For instance, 316 stainless steel is preferred in marine environments due to its superior resistance to chlorides.

2. Wall Thickness

Wall thickness is a critical specification that affects the pipe’s strength, durability, and fluid flow characteristics. It is typically measured in millimeters or inches.

- B2B Importance: A thicker wall can withstand higher pressures and is less likely to deform under stress. Buyers must choose the appropriate thickness based on the application, whether it’s for oil and gas, chemical processing, or construction.

3. Tolerance

Tolerance refers to the acceptable limits of variation in the dimensions of the pipes. This includes diameter, length, and wall thickness.

- B2B Importance: Accurate tolerances are essential for ensuring proper fit and function in piping systems. Deviations can lead to installation issues and affect system performance, which can be costly for businesses.

4. Finish

The finish of stainless steel pipes can be polished, brushed, or unpolished. The surface finish affects not only aesthetics but also corrosion resistance and cleaning ease.

- B2B Importance: A smooth finish reduces friction and minimizes contaminants, making it essential for industries like food processing and pharmaceuticals where hygiene is critical.

5. Pressure Rating

Pressure rating indicates the maximum pressure the pipe can withstand under specific conditions. It is often defined by standards such as ASME B36.10 or B36.19.

- B2B Importance: Understanding the pressure rating helps buyers select pipes that can handle the operational pressures of their systems, which is vital for safety and reliability.

What Are Common Trade Terms in the Stainless Steel Pipe Industry?

Navigating the stainless steel pipe market requires familiarity with industry jargon. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end products.

- Relevance: Knowing whether a supplier is an OEM can provide insights into their manufacturing capabilities and quality assurance processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell.

- Relevance: Understanding MOQ is crucial for budgeting and inventory management. It helps buyers gauge whether a supplier can meet their needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services.

- Relevance: Utilizing RFQs can streamline the procurement process, allowing buyers to compare prices and terms from multiple suppliers efficiently.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

- Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, which is essential for smooth cross-border transactions.

5. Certification

Certification refers to official documents that validate a product’s compliance with industry standards, such as ISO or ASTM.

- Relevance: Certifications assure buyers of product quality and safety, which is critical in industries like construction and manufacturing where compliance is mandatory.

Conclusion

Understanding the essential technical properties and trade terminology related to stainless steel pipes is vital for international B2B buyers. These insights can enhance decision-making processes, ensuring that your purchases align with both operational requirements and industry standards.

Navigating Market Dynamics and Sourcing Trends in the stainless steel pipe supplier Sector

What Are the Key Market Dynamics and Trends in the Stainless Steel Pipe Supplier Sector?

The stainless steel pipe supplier sector is experiencing significant shifts driven by several global factors. As industries increasingly prioritize durability and corrosion resistance, the demand for stainless steel pipes is on the rise. Key markets in Africa, South America, the Middle East, and Europe are seeing growth due to urbanization and infrastructural developments. For instance, projects related to oil and gas, construction, and water treatment facilities are particularly prevalent in regions like Saudi Arabia and Mexico, where investments in infrastructure are booming.

Emerging B2B technologies are also reshaping the sourcing landscape. The adoption of digital platforms for procurement is gaining traction, enabling buyers to streamline their sourcing processes and access a broader range of suppliers. Additionally, data analytics are being utilized to forecast demand and manage inventory more effectively. This trend is particularly beneficial for international buyers looking to optimize costs and minimize lead times.

Another significant dynamic is the increasing competition among suppliers. With global supply chains becoming more interconnected, B2B buyers can leverage competitive pricing and quality assurance from suppliers across different regions. Buyers from Africa and South America, for example, can now source high-quality stainless steel pipes from established suppliers in Europe and Asia, allowing for a more diverse supply chain.

How Is Sustainability Influencing the Sourcing of Stainless Steel Pipes?

Sustainability has become a critical consideration for international B2B buyers in the stainless steel pipe sector. The environmental impact of production processes, from raw material extraction to manufacturing, has led to a growing emphasis on ethical sourcing practices. Buyers are increasingly scrutinizing their supply chains to ensure compliance with environmental regulations and to minimize their carbon footprint.

The importance of ethical supply chains cannot be overstated. Suppliers that demonstrate a commitment to sustainable practices—such as using recycled materials or employing energy-efficient manufacturing processes—are becoming more attractive to buyers. Certifications like ISO 14001 for environmental management systems are valuable indicators of a supplier’s commitment to sustainability.

Moreover, the use of ‘green’ materials is gaining momentum. Stainless steel, being 100% recyclable, is inherently a sustainable choice. Suppliers who utilize recycled stainless steel or have sustainable sourcing practices can appeal to environmentally-conscious buyers. This trend not only meets consumer demand for responsible sourcing but also aligns with global sustainability goals, making it a key factor in sourcing decisions.

What Is the Historical Context of the Stainless Steel Pipe Supplier Sector?

The stainless steel pipe supplier sector has evolved significantly over the past few decades. Initially developed in the early 20th century, stainless steel became popular due to its corrosion resistance and strength. The post-World War II industrial boom led to increased applications across various sectors, including construction, automotive, and oil and gas.

In the 1980s and 1990s, advancements in manufacturing technology, such as improved welding techniques and the introduction of high-strength stainless steel alloys, further propelled the sector’s growth. As global trade expanded, suppliers began sourcing materials from different regions, leading to a more competitive market landscape.

Today, the sector is characterized by rapid technological advancements and a growing emphasis on sustainability, reflecting the changing needs and values of B2B buyers worldwide. As the market continues to evolve, suppliers must adapt to these trends to remain competitive and meet the expectations of their international clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel pipe supplier

-

How can I verify the credibility of a stainless steel pipe supplier?

To ensure the credibility of a stainless steel pipe supplier, consider the following steps: check their business licenses and certifications, review their financial stability, and look for customer testimonials or case studies. Additionally, inquire about their quality assurance processes and standards, such as ISO certifications. Visiting their facility or requesting product samples can further provide insight into their operations and product quality. Conducting thorough research will help mitigate risks associated with international sourcing. -

What are the common payment terms offered by stainless steel pipe suppliers?

Payment terms can vary significantly among suppliers. Common terms include full payment upfront, a deposit with the balance due before shipment, or net payment terms (like Net 30 or Net 60). Some suppliers may accept letters of credit or escrow services, which can provide added security. It’s crucial to negotiate payment terms that align with your cash flow requirements while ensuring the supplier’s reliability. -

What is the minimum order quantity (MOQ) when sourcing stainless steel pipes?

Minimum order quantities (MOQ) for stainless steel pipes can range from a few tons to several containers, depending on the supplier and the specific product. Factors influencing MOQ include material type, size, and customization requirements. Always clarify the MOQ during negotiations and explore whether the supplier can accommodate smaller orders, especially if you’re testing the market or starting a new project. -

How can I customize stainless steel pipes to meet specific project requirements?

Customization options for stainless steel pipes typically include variations in size, thickness, length, and finish. Most suppliers will work with you to meet specific technical specifications, such as chemical composition and mechanical properties. To initiate customization, provide clear technical drawings or specifications, and discuss any relevant industry standards. Collaborating with suppliers early in the design phase can lead to better alignment with your project needs. -

What quality assurance practices should I expect from a reliable stainless steel pipe supplier?

A reliable stainless steel pipe supplier should have robust quality assurance (QA) practices in place. This includes regular testing of materials and finished products for compliance with international standards such as ASTM, ASME, or EN. Additionally, suppliers should provide certifications for their products, such as mill test reports (MTRs). Inquire about their QA processes, including inspections, testing methods, and traceability of materials. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

When sourcing stainless steel pipes internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Understand the freight options available (e.g., air vs. sea freight) and their associated costs. Collaborate with your supplier to ensure proper documentation for customs clearance, including bills of lading and commercial invoices. Additionally, factor in any potential tariffs or trade agreements that may affect the total landed cost of your order. -

How do I handle disputes with a stainless steel pipe supplier?

Dispute resolution can be complex in international trade. Start by reviewing your contract for any clauses related to dispute resolution, such as mediation or arbitration procedures. Maintain open communication with the supplier to address issues promptly. If informal resolution fails, consider involving a third-party mediator or legal counsel specializing in international trade. Document all interactions and agreements to support your case if formal action becomes necessary. -

What are the benefits of sourcing stainless steel pipes from suppliers in emerging markets?

Sourcing stainless steel pipes from suppliers in emerging markets can offer several advantages, including competitive pricing due to lower labor costs and favorable exchange rates. Many emerging markets are also investing in modern manufacturing processes and adhering to international quality standards, which can improve product reliability. Additionally, establishing relationships with suppliers in these regions can open up new business opportunities and foster collaboration in future projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for stainless steel pipe supplier

What Are the Key Takeaways for Strategic Sourcing of Stainless Steel Pipes?

In the competitive landscape of international B2B procurement, effective strategic sourcing for stainless steel pipes is essential for optimizing supply chains and ensuring product quality. Buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers that demonstrate reliability, transparency, and compliance with international standards. Establishing long-term partnerships with vetted suppliers can lead to cost savings, enhanced product innovation, and improved service levels.

How Can B2B Buyers Enhance Their Sourcing Strategy?

To enhance sourcing strategies, international buyers should leverage data analytics to assess market trends and supplier performance. This approach will facilitate informed decision-making and enable businesses to adapt quickly to changing market conditions. Additionally, fostering open communication with suppliers can drive collaborative solutions, ensuring that both parties meet their operational goals effectively.

What Does the Future Hold for Stainless Steel Pipe Sourcing?

Looking ahead, the demand for stainless steel pipes is expected to rise, driven by industrial growth and infrastructure development across emerging markets. B2B buyers should remain proactive in their sourcing strategies by exploring innovative procurement methods and diversifying their supplier base. Engaging in strategic sourcing not only mitigates risks but also positions companies for sustainable growth in an evolving global marketplace.

As you navigate your sourcing journey, consider the long-term benefits of establishing strong relationships with reputable stainless steel pipe suppliers. Take action today to secure your supply chain and drive your business forward.