Soda Filling Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Soda Filling Machines

In the highly competitive beverage sectors of the USA and Europe, operational efficiency is the primary driver of profitability. Whether scaling a mid-sized craft brand or upgrading a high-volume industrial facility, the reliability of your soda filling machine dictates both throughput and product integrity.

However, sourcing the right infrastructure involves more than selecting a filler. Modern industrial standards require an integrated ecosystem where premix units—handling deaeration, flavoring, and precise carbonation—work seamlessly with automated filling and sealing lines. Manufacturers face the complex challenge of balancing speed (production capacities often exceeding 3,000 liters/hour) with strict hygiene compliance, such as the necessity for AISI 304 stainless steel construction to meet sanitary regulations.

This guide serves as a strategic roadmap for procurement managers and facility operators. We move beyond basic specifications to analyze the critical components of a modular soda plant, helping you identify solutions that minimize human intervention while maximizing output.

In this guide, we will cover:

- The Integrated Line: How premix units and filling machines function as a cohesive system.

- Production Scalability: Evaluating modular solutions that adapt to business growth.

- Format Versatility: Key differences between automatic bottling and canning configurations.

- Technical Specifications: Essential features for rinse, fill, and seal cycles in automated lines.

Top 10 Soda Filling Machine Manufacturers & Suppliers List

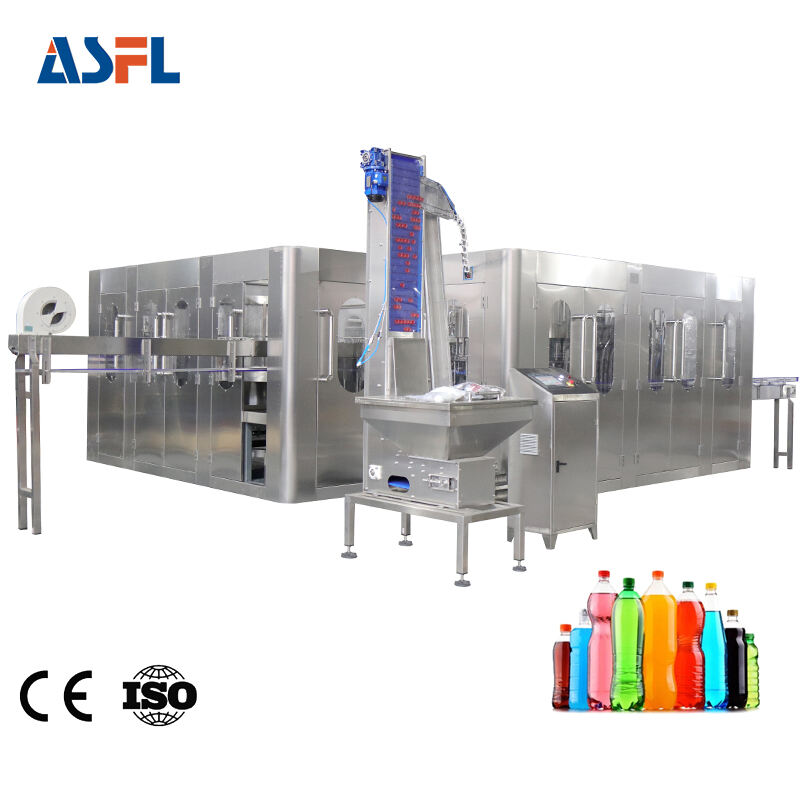

1. Soda bottling plant – Co.Mac. – Comac Group

Domain: comacgroup.com

Registered: 2002 (23 years)

Introduction: Comac manufactures modular soda bottling plants that can be customized to fit in your business size and needs: discover all our solutions!…

2. Top 20 Beverage Filling Machine Manufacturers in 2025

Domain: finbolink.com

Registered: 2023 (2 years)

Introduction: Mic Machinery is one of the leading beverage filling machine manufacturers, supplying advanced filling and packaging systems for global beverage factories. The ……

3. Top Beverage Filling Machine Solutions – Sidel

Domain: sidel.com

Registered: 1996 (29 years)

Introduction: Explore Sidel’s beverage filling machines for unparalleled precision and variety, from PET to glass solutions. Discover more in our category!…

Illustrative Image (Source: Google Search)

4. Best 8 Industrial Filling Machine Manufacturers in 2025 – LIENM

Domain: lienm.com

Registered: 2012 (13 years)

Introduction: Overview of the Best Industrial Filling Machine Manufacturers in 2025 · 1. LIENM – Industrial Filling Machine Experts · 2. PACKO Filling Systems….

5. Top 6 Can Filling Machine Manufacturers – Levapack

Domain: levapack.com

Registered: 2018 (7 years)

Introduction: Your Go-To Guide for the Best 6 Can Filling Machine Manufacturers · Preface · #1 Levapack · #2 Krones AG · #3 SIDEL · #4 Tetra Pak · #5 KHS Group · #6 ……

6. Carbonated Soft Drink Archives – FLSM

Domain: fillers-packer.com

Registered: 2023 (2 years)

Introduction: Top Filling Machinery Manufacturers · (CSD) Beverages Filling Machines · Sizing Up PET Bottle Filling Machines · The Modern Beverage Tunnel Pasteurizer Machine ……

7. Manual Pet Bottle Soda Filling Machine – Akshay Industries

Domain: akshayindustries.net

Registered: 2018 (7 years)

Introduction: We are offering Semi-Automatic PET Bottle soda Filling Machine to our client. “Akshay Industries”, have been successful as one of the leading manufacturers in …Missing: top suppliers…

Illustrative Image (Source: Google Search)

8. Top 10 carbonated beverage filling machine Manufacturers in the …

Domain: newpeakmachinery.com

Registered: 2023 (2 years)

Introduction: These top 10 fizzy drink filling machine manufacturers go the extra mile in providing high quality machines along with excellent service. So, if ……

9. #1 List: Top Beverage Filling Machines in China [2025]

Domain: procoolmfg.com

Registered: N/A

Introduction: China’s top beverage filling machine suppliers like LiDLi, King Machine, and iBottling offer advanced technology, high efficiency, and ……

Understanding soda filling machine Types and Variations

Understanding Soda Filling Machine Types and Variations

Selecting the correct soda filling machine is determined by production volume, container type, and the level of automation required. Based on industry standards and manufacturing capabilities—such as those demonstrated by Comac Group—soda filling technology is generally categorized into three primary variations: Bottle Filling Systems, Can Filling Systems, and Compact/Modular Units for small-scale operations.

The following table outlines the core distinctions between these machine types to assist in B2B procurement decisions.

Illustrative Image (Source: Google Search)

Comparative Overview of Filling Machine Types

| Machine Type | Key Features | Ideal Applications | Pros & Cons |

|---|---|---|---|

| Automatic Bottle Filling Lines | • Integrated rinsing, filling, and capping cycles. • Handles Glass and PET. • PLC-controlled automation. |

• Mid-to-high volume bottling plants. • Brands requiring diverse bottle shapes. |

Pros: High versatility; excellent presentation. Cons: Changeover between bottle sizes can be time-consuming. |

| Automatic Can Filling Lines | • Dedicated filling and seaming units. • Hermetic sealing technology. • Optimized for aluminum supply chains. |

• RTD (Ready-to-Drink) soda markets. • Export-focused production (lightweight). |

Pros: Durable packaging; light protection for product stability. Cons: Seaming precision is critical; less resealable than bottles. |

| Compact / Modular Solutions | • Capacities up to 6,000 bph. • Small footprint designs. • Scalable/customizable modules. |

• Craft soda manufacturers. • Pilot lines or small-batch runs. |

Pros: Lower CapEx; fits limited floor space. Cons: Capped production throughput compared to industrial lines. |

1. Automatic Bottle Filling Machines

Automatic bottle filling machines are the backbone of the traditional soda industry. These units are typically designed as “monoblocks,” meaning they perform multiple functions—rinsing, filling, and capping—within a single, synchronized chassis.

- Process Flow: The cycle begins with an internal rinse to ensure hygiene, followed by isobaric filling (counter-pressure) to maintain carbonation levels, and concludes with capping.

- Hygiene Standards: Top-tier manufacturers utilize AISI 304 stainless steel alloys for all contact parts. This material is essential for the US and European markets to meet strict sanitary regulations and resist corrosion from acidic soda formulations.

- Automation: Modern systems are fully automatic, requiring no human intervention during the cycle. Operators monitor the process via HMI (Human-Machine Interface) control panels, ensuring consistent fill levels and carbonation retention.

2. Automatic Can Filling Machines

As consumer preference shifts toward portability and sustainability, canning lines have become a critical asset. Unlike bottling lines which cap containers, these machines utilize a seaming process.

- Sealing Technology: The defining feature of this type is the seamer. After the soda is filled, the lid is placed and mechanically seamed to the can body. Precision here is paramount to prevent leakage and maintain carbonation.

- Integration: These machines often integrate seamlessly with upstream processing units (such as Premix units) that deaerate, flavor, and carbonate the beverage prior to filling.

- Versatility: While dedicated to cans, these machines can often be adjusted to handle different can heights (e.g., standard 12oz vs. slim cans) with modular change parts.

3. Compact and Modular Filling Solutions

For craft beverage producers or facilities with limited floor space, industrial-scale giants are often impractical. Compact and modular filling machines bridge the gap between manual labor and high-speed automation.

- Capacity: These machines typically handle specific outputs, such as up to 6,000 bottles per hour (bph). This range is ideal for businesses scaling out of manual production but not yet requiring mass-market throughput.

- Modularity: A key advantage is customization. Manufacturers like Comac offer modular designs that allow businesses to configure the plant according to specific size constraints and needs.

- Professional Performance: Despite their smaller size, these units retain the professional features of larger lines, including automatic rinsing cycles and AISI 304 stainless steel construction, ensuring that “small scale” does not imply “lower quality.”

Key Industrial Applications of soda filling machine

Key Industrial Applications of Soda Filling Machines

Modern soda filling machines are the backbone of the carbonated beverage sector, serving a diverse range of production environments from craft producers to large-scale industrial facilities. The following table outlines the primary sectors leveraging this technology, specifically focusing on the capabilities of modular systems like those manufactured by Comac Group.

Illustrative Image (Source: Google Search)

Industrial Application Matrix

| Industry Sector | Primary Container Formats | Key Operational Requirements |

|---|---|---|

| Carbonated Soft Drinks (CSD) | PET Bottles, Glass Bottles, Aluminum Cans | High-speed throughput, precise syrup-to-water ratios, and consistent carbonation levels. |

| Sparkling Water & Seltzers | Glass Bottles, PET | Extreme hygiene standards to maintain flavor neutrality; effective deaeration processes. |

| Energy & Functional Drinks | Slim Cans, PET | Premix integration for complex formulations; hermetic sealing to preserve active ingredients. |

| Craft Soda & Micro-producers | Glass Bottles (Vintage style) | Modular scalability (starting at 3,000 L/h); flexibility for frequent flavor changeovers. |

| Contract Packaging (Co-packers) | Multi-format (Cans & Bottles) | Versatility to switch between bottling and canning lines; adaptable control panels for varying client specs. |

Operational Benefits for B2B Manufacturers

Investing in professional-grade soda filling machinery provides critical advantages for manufacturers targeting US and European markets. Based on industry standards and Comac Group specifications, these benefits include:

1. Integrated Premix Capabilities

High-efficiency industrial lines do not merely fill containers; they process the liquid. Advanced systems utilize Premix Units that combine three critical phases into a single workflow:

* Deaeration: Removal of oxygen from the water to prevent oxidation.

* Flavoring: Precise addition of syrup and sweeteners.

* Carbonation: Injection of CO2 at controlled pressures.

Benefit: This integration eliminates the need for separate processing silos, reducing the facility footprint and ensuring product consistency before the liquid ever reaches the filler.

2. End-to-End Automation

Modern filling solutions are designed to operate without human intervention during the production cycle. A standard automatic soda filling machine manages the rinse cycle, filling, and capping/sealing sequentially.

Benefit: This reduces labor costs and minimizes human error. Operators can monitor the entire line via centralized control panels, ensuring throughput targets (e.g., up to 6,000 bottles per hour for compact lines) are met consistently.

3. Sanitary Compliance (AISI 304)

For markets with strict regulatory oversight (FDA in the US, EFSA in Europe), material quality is non-negotiable. Leading manufacturers utilize AISI 304 stainless steel alloy for all contact parts.

Benefit: This material offers superior resistance to corrosion and allows for aggressive cleaning cycles, ensuring the final product remains safe, hygienic, and free from metallic contamination.

Illustrative Image (Source: Google Search)

4. Modular Scalability

Production needs vary significantly between a startup and a multinational corporation. Modular plants allow businesses to select specific units—such as a canning line or a bottling line—that fit their current size.

Benefit: Manufacturers can scale their capital equipment investment. A business can start with a compact unit aimed at small activities and expand to higher-capacity lines as market demand increases, without replacing the entire infrastructure.

3 Common User Pain Points for ‘soda filling machine’ & Their Solutions

Based on the provided reference material and industry standards, here is the section on common user pain points and their solutions.

3 Common User Pain Points for Soda Filling Machines & Their Solutions

1. Excessive Foaming & Product Waste

Scenario:

During high-speed production runs, the soda filling machine struggles to manage the pressure difference between the filling valve and the bottle. As the carbonated liquid enters the container, it agitates violently, creating a head of foam that spills over the neck before the cap is sealed.

The Problem:

Excessive foaming leads to significant product loss (spillage), resulting in “sticky” bottles that require additional washing. More critically, it causes under-filled bottles that fail quality control, forcing operators to slow down the entire production line to manage the foam, drastically reducing throughput.

Illustrative Image (Source: Google Search)

The Solution:

Implement Isobaric (Counter-Pressure) Filling Technology integrated with a high-quality Premix Unit.

* Technical Fix: Isobaric fillers pressurize the bottle with CO2 to match the tank pressure before the liquid valve opens, allowing the soda to flow gently by gravity without turbulence.

* Reference Insight: Utilizing a unit like the Comac Premix Unit ensures the beverage is properly deaerated and carbonated before it reaches the filler. Stable carbonation levels effectively minimize the agitation that causes foam, allowing for higher speeds without waste.

2. Inconsistent Carbonation & Fill Levels

Scenario:

A batch of bottled soda reaches the packaging stage, but random spot checks reveal variances in liquid height and carbonation intensity. Some bottles are flat, while others are over-carbonated or filled to different levels.

The Problem:

Inconsistency damages brand reputation and customer trust. Variations in fill level can also lead to legal non-compliance regarding net weight regulations. Furthermore, unstable carbonation can cause bottles to burst or deform during storage and transport.

The Solution:

Adoption of Automated Electronic Control Systems with precision valves.

* Technical Fix: Modern machines replace mechanical float controls with electronic sensors that monitor flow and pressure in real-time, adjusting valves instantly to maintain uniformity.

* Reference Insight: Comac’s automatic soda filling machines feature accessible control panels that allow operators to monitor the entire rinse, fill, and seal cycle. This automation removes human error, ensuring every bottle receives the exact same volume and carbonation level specified in the recipe.

Illustrative Image (Source: Google Search)

3. High Downtime During Changeovers & Cleaning

Scenario:

A manufacturer needs to switch production from a 330ml cola bottle to a 500ml orange soda bottle. The line sits idle for hours while technicians manually swap out star wheels, adjust guide rails, and perform a manual washdown to prevent flavor cross-contamination.

The Problem:

Every minute of downtime is lost revenue. In flexible production environments where multiple SKUs are common, lengthy changeovers and sanitation procedures can consume up to 20-30% of available production time, destroying efficiency.

The Solution:

Modular Machine Design with Automated Cleaning Cycles.

* Technical Fix: Invest in equipment designed for “tool-less” quick changeovers and automated Clean-in-Place (CIP) capabilities.

* Reference Insight: Comac’s modular solutions are customized to fit specific business needs, allowing for faster adaptation to different bottle sizes. Additionally, the use of AISI 304 stainless steel construction combined with automatic rinse cycles ensures that hygiene protocols are met rapidly, drastically reducing the time between flavor changes.

Strategic Material Selection Guide for soda filling machine

Strategic Material Selection Guide for Soda Filling Machines

In the carbonated beverage industry, material selection is not merely a structural consideration—it is a critical compliance and operational safety factor. Soda presents a unique chemical environment: it is acidic (due to carbonation and phosphoric/citric acids), sugary, and filled under pressure.

Illustrative Image (Source: Google Search)

For manufacturers targeting US and European markets, equipment must meet rigorous sanitary standards (FDA, 3-A Sanitary Standards, and EHEDG). Consequently, the construction materials of a filling machine must withstand aggressive Clean-in-Place (CIP) cycles, prevent corrosion, and ensure zero product contamination.

The Industry Standard: Stainless Steel Alloys

The core structure and contact surfaces of any professional soda filling machine must be constructed from high-grade stainless steel.

- AISI 304 Stainless Steel: As highlighted by industry leaders like Co.Mac Group, AISI 304 is the baseline standard for hygiene and safety in soda plants, particularly for Premix Units and filling valves. It offers excellent resistance to corrosion from standard carbonated beverages and sanitizing agents. It is non-porous, easy to clean, and maintains structural integrity under the pressure required for carbonation.

- AISI 316/316L Stainless Steel: For sodas with higher acidity levels (lower pH) or for lines frequently sanitized with harsh chloride-based chemicals, AISI 316 is the superior choice. The addition of molybdenum increases resistance to pitting and crevice corrosion, extending the machine’s lifespan in aggressive production environments.

Elastomers and Seals: Handling Pressure and Carbonation

Soda filling machines operate under isobaric (counter-pressure) conditions to retain carbonation. The seals and gaskets must maintain a hermetic seal to prevent CO2 loss and foaming.

- EPDM (Ethylene Propylene Diene Monomer): The standard for sealing applications in soda lines. EPDM offers excellent resistance to hot water and steam (essential for sterilization) and is chemically inert to acids and alkalis found in sodas and cleaning fluids.

- PTFE (Teflon): Used in valve seats and high-friction areas. PTFE provides a low coefficient of friction and near-universal chemical resistance, ensuring smooth valve operation during high-speed filling cycles (up to 6,000+ bph).

Surface Finish and Hygiene

Material composition is secondary to surface finish. For B2B buyers in Europe and the USA, “hygienic design” implies specific surface treatments:

- Electropolishing: Contact surfaces should be electropolished to reduce surface roughness (Ra). A lower Ra value prevents bacterial adhesion and biofilm formation, which is critical for sugary beverages prone to yeast and mold growth.

- Weld Quality: All welds must be continuous, ground, and polished to match the surrounding surface, eliminating “dead zones” where product residue can accumulate.

Material Comparison Matrix

The following table outlines the strategic application of materials within a soda filling line.

| Component | Recommended Material | Key Properties | Strategic Value |

|---|---|---|---|

| Product Contact Tank & Valves | AISI 304 / 316L | High corrosion resistance; non-reactive. | Compliance: Meets FDA/EFSA standards. Durability: Withstands carbonic acid and CIP chemicals. |

| Machine Frame & Cladding | AISI 304 | Structural strength; oxidation resistance. | Hygiene: Easy wash-down; prevents rust accumulation in wet filling halls. |

| Dynamic Seals & Gaskets | EPDM (Food Grade) | Thermal stability; elasticity. | Performance: Maintains pressure for carbonation; withstands steam sterilization. |

| Valve Seats / Bushings | PTFE (Teflon) | Low friction; chemical inertness. | Efficiency: Reduces wear on moving parts; extends maintenance intervals. |

| Safety Guarding | Polycarbonate / Safety Glass | High impact resistance; transparency. | Safety: Protects operators from bottle bursts (high pressure) while allowing visual monitoring. |

| Piping & Manifolds | AISI 304 / 316L | Smooth internal finish (low Ra). | Quality: Prevents turbulence and foaming; ensures consistent flow rates. |

In-depth Look: Manufacturing Processes and Quality Assurance for soda filling machine

In-depth Look: Manufacturing Processes and Quality Assurance for Soda Filling Machines

For buyers in the USA and Europe, understanding the manufacturing lifecycle of a soda filling machine is critical for assessing equipment longevity, hygiene compliance, and ROI. The production of these machines involves strict engineering protocols to handle high-pressure carbonation and acidic liquid properties.

1. Manufacturing Process Steps

The construction of a modular soda plant—encompassing the Premix Unit (processing) and the Filling/Capping Unit—follows a four-stage industrial workflow.

Phase 1: Material Preparation and Selection

The foundation of sanitary design lies in metallurgy. Manufacturers utilize high-grade stainless steel to ensure resistance to corrosion from carbonated water and syrups.

* Material Sourcing: Primary structures and contact parts are fabricated from AISI 304 stainless steel (as noted in Comac specifications) or AISI 316. This alloy is selected for its non-reactive properties and ease of sanitization.

* Raw Material Inspection: Steel sheets and components undergo spectrographic analysis to verify alloy composition before entering the production line.

Illustrative Image (Source: Google Search)

Phase 2: Component Forming and Fabrication

Precision machining ensures the machine can handle high-speed rotary movements without vibration.

* CNC Machining: Filling valves, star wheels, and capping heads are machined with micron-level tolerance to ensure airtight sealing during the bottling or canning process.

* Sanitary Welding: TIG welding is employed for all piping and tank joints. Welds are ground smooth and polished to eliminate crevices where bacteria could harbor, ensuring the Premix Unit (deaeration, flavoring, carbonation) meets strict hygiene standards.

Phase 3: Modular Assembly

Modern manufacturing favors modular designs, allowing for customization based on production capacity (e.g., from 3,000 up to 6,000+ bottles per hour).

* Mechanical Integration: Technicians assemble the “Rinse-Fill-Seal” block. This involves syncing the mechanical drive systems to ensure the transition of containers between the rinser, the isobaric filler, and the capper/seamer is seamless.

* Automation Integration: Installation of the electrical panel, PLC (Programmable Logic Controller), and HMI (Human Machine Interface). This stage enables the “completely automatic” functionality, allowing operators to control rinse cycles and fill levels without manual intervention.

Phase 4: Quality Control (QC) and Calibration

Before shipment, the machine undergoes rigorous testing to validate performance against the specified output metrics.

* Dry Cycle Testing: The machine is run without liquid to verify mechanical synchronization and safety interlocks.

* Factory Acceptance Test (FAT): A “wet run” using test bottles and liquid to verify:

* Fill Level Accuracy: Ensuring consistent liquid levels across all valves.

* Carbonation Stability: Verifying the Premix Unit maintains correct CO2 saturation.

* Capping Torque/Seaming Integrity: Testing for leaks and seal strength.

2. Quality Standards and Compliance

To meet the regulatory requirements of Western markets, manufacturers adhere to international quality and safety frameworks.

| Standard | Description | Relevance to Buyer |

|---|---|---|

| ISO 9001 | Quality Management Systems | Guarantees consistent manufacturing processes and traceability of parts. |

| ISO 22000 / HACCP | Food Safety Management | Ensures the machine design prevents physical, chemical, and biological hazards. |

| CE Marking | European Conformity | Mandatory for Europe. Certifies the machine meets EU safety, health, and environmental protection requirements. |

| UL / CSA | Electrical Safety | Critical for USA/Canada. Certifies that electrical components (panels, motors) meet North American safety standards. |

| 3-A Sanitary Standards | Hygienic Equipment Design | Often required in the US market to verify the equipment is easy to clean and sanitize (CIP compatible). |

3. The Role of the Premix Unit in Quality

A distinct advantage in high-end manufacturing is the integration of the Premix Unit. Quality assurance extends beyond the filler to the beverage preparation itself.

* Deaeration: Removal of oxygen to prevent oxidation and foaming.

* Mixing: Precise ratio control of syrup and water.

* Carbonation: Injection of CO2 at controlled temperatures.

By integrating the Premix Unit with the filler, manufacturers ensure that the product entering the bottle is as stable as the machine sealing it, reducing waste and ensuring a consistent consumer experience.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘soda filling machine’

Practical Sourcing Guide: A Step-by-Step Checklist for ‘soda filling machine’

When sourcing soda filling machinery for markets with high regulatory standards like the USA and Europe, precision is paramount. Use this checklist to vet potential manufacturers and ensure the equipment meets industrial hygiene, safety, and efficiency requirements.

Phase 1: Define Production Scope & Capacity

Before engaging suppliers, quantify your specific production needs to filter out incompatible machinery.

Illustrative Image (Source: Google Search)

- Determine Container Type:

- [ ] Bottles: Glass vs. PET? (Requires different handling parts).

- [ ] Cans: Aluminum standard or sleek? (Requires seaming technology vs. capping).

- Calculate Required Output:

- [ ] Small/Craft: Up to 6,000 bottles per hour (BPH).

- [ ] High-Speed Industrial: >6,000 BPH.

- Note: Ensure the machine’s speed matches your upstream Premix Unit capacity (e.g., min 3,000 L/hour).

- Carbonation Requirements:

- [ ] Verify the machine handles your specific carbonation levels (g/L CO2) without excessive foaming.

Phase 2: Technical Specification Audit

Evaluate the machine’s build quality against industry standards.

| Feature | Requirement | Why it Matters |

|---|---|---|

| Material Construction | AISI 304 Stainless Steel (or 316 for high acidity) | Essential for hygiene, corrosion resistance, and FDA/CE compliance. |

| Machine Architecture | Monoblock Design | Combines Rinsing, Filling, and Capping/Seaming in one unit to minimize footprint and contamination risk. |

| Automation Level | Fully Automatic | Must handle rinse cycles, filling, and sealing without human intervention. |

| Control System | PLC with HMI Panel | Accessible interface for monitoring flow rates, pressure, and troubleshooting. |

Phase 3: Upstream Integration (The Premix Factor)

A soda filling machine is only as efficient as the liquid supply. Determine if you require a standalone filler or a complete line integration.

- Premix Unit Integration:

- [ ] Does the supplier offer a compatible Premix Unit?

- [ ] Deaeration: Does the unit remove air before carbonation to prevent oxidation?

- [ ] Dosing: Can it precisely mix syrup/flavor with water?

- [ ] Carbonation: Is the carbonation unit integrated inline?

Phase 4: Supplier Vetting & Compliance

For US and European buyers, regulatory compliance and after-sales support are non-negotiable.

- Modularity & Customization:

- [ ] Is the equipment modular? (Can you expand capacity or change bottle formats later?)

- [ ] Can the layout be customized to fit specific facility dimensions?

- Regulatory Certifications:

- [ ] Europe: CE Marking compliance.

- [ ] USA: UL standards and FDA-compliant contact materials.

- Hygiene Cycles:

- [ ] Does the machine support CIP (Clean-in-Place) protocols?

- [ ] Are dummy bottles included for the cleaning cycle?

Phase 5: Final Purchase Validation

- [ ] Factory Acceptance Test (FAT): Request a video or in-person test run using your specific bottle and liquid type.

- [ ] Changeover Time: Request data on how long it takes to switch between different bottle sizes (should be tool-less or minimal tools).

- [ ] Spare Parts Availability: Confirm the availability of critical spares (gaskets, valves) in your region.

Comprehensive Cost and Pricing Analysis for soda filling machine Sourcing

Comprehensive Cost and Pricing Analysis for Soda Filling Machine Sourcing

Sourcing a soda filling machine represents a significant Capital Expenditure (CAPEX). For buyers in the USA and Europe, pricing is rarely a fixed list price; rather, it is a composite of throughput capacity, material quality, and level of automation.

Below is a breakdown of the cost structure and pricing factors to assist in budget forecasting and negotiation.

1. Capital Cost Breakdown by Component

The “sticker price” of a machine is primarily driven by the quality of materials and the complexity of the engineering.

A. Material Construction (20-30% of Total Cost)

- Stainless Steel Grade: As noted in industry standards (and exemplified by manufacturers like Comac), AISI 304 stainless steel is the baseline for hygiene and safety. Machines utilizing lower-grade alloys (e.g., 201 series) may be 15-20% cheaper upfront but pose corrosion risks with acidic sodas, leading to higher long-term replacement costs.

- Contact Parts: Components that directly touch the beverage (valves, nozzles) often require AISI 316 for higher corrosion resistance, adding a premium to the base cost.

B. The “Heart” of the System: Premix and Carbonation Units

For a complete plant, the filling machine is often paired with a Premix Unit.

* Function: Deaeration, flavoring, and carbonation.

* Cost Driver: Precision in carbonation levels. A unit capable of handling 3,000+ liters/hour with consistent carbonation saturation requires advanced flow meters and pressure sensors, significantly increasing the cost compared to simple batch-mix systems.

C. Automation and Control Systems (25-35% of Total Cost)

The shift from semi-automatic to fully automatic machines is the largest pricing variable.

* PLC and HMI: Top-tier machines utilize name-brand controls (Siemens, Allen-Bradley) which are standard in USA/EU markets for ease of maintenance. Proprietary or obscure control systems reduce upfront costs but complicate repairs.

* Integration: Automatic solutions that combine rinsing, filling, and capping (monoblock systems) reduce footprint but increase engineering costs.

Illustrative Image (Source: Google Search)

2. Operational Labor and Efficiency Analysis

When calculating ROI, buyers must contrast the machine cost against labor savings.

| Feature Level | Typical Throughput | Labor Requirement | Cost Implication |

|---|---|---|---|

| Semi-Automatic | < 1,000 BPH | High (2-3 operators: loading, capping, packing) | Low CAPEX, High OPEX. Best for pilot lines. |

| Automatic (Entry) | 1,000 – 3,000 BPH | Medium (1 operator for monitoring) | Balanced CAPEX/OPEX. Standard for small breweries/soda startups. |

| High-Speed Industrial | 6,000+ BPH | Low (1 skilled technician for line monitoring) | High CAPEX, Lowest Cost Per Unit. Requires skilled labor for maintenance. |

Note: As highlighted in the reference data, Comac’s automatic solutions cover the rinse, fill, and seal cycles without human intervention, effectively shifting cost from wages to asset depreciation.

3. Logistics, Importation, and Installation

For USA and European buyers sourcing equipment internationally (e.g., from Italy or Asia), “Landed Cost” can exceed the Ex-Works (EXW) price by 15-25%.

- Crating and Packaging: Industrial machinery requires vacuum-sealed, fumigated timber crating to prevent corrosion during sea freight.

- Freight:

- Sea Freight: Standard for heavy machinery. Rates fluctuate based on container availability (20ft vs. 40ft High Cube).

- Inland Transport: Specialized heavy-haul trucking may be required for delivery from the port to the facility.

- Duties and Tariffs:

- USA: Section 301 tariffs or specific machinery duties can add significant percentage points to the invoice value.

- Europe: VAT and compliance with CE marking standards are mandatory and non-negotiable cost factors.

- Installation & Commissioning:

- Budget for manufacturer engineers to travel on-site for 3-7 days.

- Costs include: Daily engineering rates ($800-$1,500/day), flights, accommodation, and per diem.

4. Strategic Tips to Optimize Sourcing Costs

To maximize value without compromising on the AISI 304 hygiene standards or production efficiency:

Illustrative Image (Source: Google Search)

- Opt for Modular Design:

- Instead of buying a machine with excess capacity “just in case,” select a manufacturer (like Comac) that offers modular plants. This allows you to purchase a machine that fits current needs (e.g., 3,000 L/h) and expand modules later, preserving cash flow.

- Standardize Components:

- Request that the manufacturer uses globally available components (e.g., Festo pneumatics, Schneider electrics). This reduces downtime costs by allowing you to source spare parts locally in the USA or Europe rather than shipping them from the OEM.

- Bundle the Premix Unit:

- Sourcing the Premix Unit (carbonation/mixing) and the Filling Machine from the same vendor often allows for package pricing. It also eliminates the “integration cost” of making two different machines communicate.

- Evaluate TCO (Total Cost of Ownership):

- A machine that is 10% cheaper but wastes 5% more product due to poor filling precision (overfill) or high bottle breakage rates will cost more in the first year of operation than the savings on the purchase price. Focus on filling accuracy specs.

Alternatives Analysis: Comparing soda filling machine With Other Solutions

Alternatives Analysis: Comparing Soda Filling Machines With Other Solutions

When evaluating the infrastructure for a soda bottling plant, decision-makers must weigh the benefits of investing in automated industrial machinery against entry-level hardware or outsourcing models.

The following analysis compares Automatic Soda Filling Machines (such as the modular solutions provided by Comac Group) against two primary alternatives: Semi-Automatic/Manual Systems and Contract Packaging (Co-packing).

Comparative Overview

| Feature | Automatic Soda Filling Machine (In-House) | Semi-Automatic / Manual Systems | Contract Packaging (Co-packing) |

|---|---|---|---|

| Throughput | High (3,000+ L/h to industrial scale) | Low (<500 bottles/h) | Variable (Dependent on partner capacity) |

| CapEx | High (Machinery, installation, utilities) | Low (Basic filler, manual capper) | None/Low (Tooling fees only) |

| OpEx (Per Unit) | Low (Economies of scale, reduced labor) | High (Labor-intensive) | Medium/High (Partner margins + logistics) |

| Hygiene & Safety | Excellent (AISI 304 steel, no human contact) | Moderate (Higher risk of contamination) | High (Dependent on partner certifications) |

| Process Control | Full (Rinsing, filling, sealing, carbonation) | Limited (Inconsistent fill levels/carbonation) | Low (External scheduling & QC) |

| Scalability | High (Modular upgrades available) | Limited (Requires more labor to scale) | High (Volume limited only by budget) |

1. Semi-Automatic & Manual Filling Systems

For micro-breweries or artisanal soda startups, manual or semi-automatic counter-pressure fillers are the traditional entry point. These systems require operators to manually load bottles, engage the fill cycle, and transfer units to a capper.

The Trade-off:

While the initial investment is significantly lower, this alternative creates a bottleneck in production speed and consistency.

Illustrative Image (Source: Google Search)

- Hygiene & Material Standards: Unlike industrial machines that utilize AISI 304 stainless steel and automated rinse cycles to ensure sanitation, manual handling increases the risk of bacterial contamination and oxidation.

- Carbonation Consistency: Industrial solutions, such as those integrating a Premix Unit, de-aerate, flavor, and carbonate in a closed loop. Manual systems often struggle to maintain consistent carbonation levels (volumes of CO2) across a production run, leading to product variability.

- Labor Costs: Scaling production with semi-automatic gear requires a linear increase in labor. In contrast, an automatic machine carrying out rinsing, filling, and sealing requires monitoring rather than manual intervention.

Verdict: Suitable only for pilot batches or hyper-local distribution. Once production demands exceed 3,000 liters/hour, the labor costs and quality variance of manual systems become unsustainable compared to automatic lines.

2. Contract Packaging (Co-packing)

Co-packing involves outsourcing the entire production process—from syrup mixing to filling and sealing—to a third-party facility. This allows a brand to market a beverage without owning a soda bottling plant.

The Trade-off:

Co-packing eliminates the need for capital expenditure on machinery but sacrifices margin and control.

- Agility and Scheduling: Owning a filling machine allows for “on-demand” production. Co-packing binds the brand to the manufacturer’s schedule, making it difficult to react quickly to market spikes or supply chain issues.

- Customization: Manufacturers like Comac offer modular solutions tailored to specific bottle shapes, cap types, and plant layouts. Co-packers typically offer standard tooling; custom bottle shapes or unique formulations may incur high changeover fees or be rejected entirely.

- Long-term ROI: While co-packing avoids the upfront cost of a machine, the per-unit cost remains static. Investing in an in-house automatic soda filling machine allows the cost-per-unit to drop significantly as volume increases, eventually paying for the asset.

Verdict: Co-packing is a viable strategy for market testing and brand validation. However, for established brands in the USA and Europe aiming to maximize profit margins and control product quality, bringing production in-house with automated machinery is the superior long-term strategy.

Essential Technical Properties and Trade Terminology for soda filling machine

Essential Technical Properties and Trade Terminology

When sourcing soda filling machinery for US and European markets, buyers must evaluate equipment based on specific technical benchmarks that ensure hygiene, efficiency, and product stability. Below are the critical technical properties and trade terms required for commercial negotiation and technical vetting.

Key Technical Specifications

High-quality soda lines generally operate as a “Monoblock” or “Triblock” system, integrating rinsing, filling, and capping into a single automatic unit.

| Property | Standard Specification | Technical Significance |

|---|---|---|

| Construction Material | AISI 304 / 316 Stainless Steel | As highlighted by industry leaders like Comac, AISI 304 is the minimum standard for all contact parts. It resists corrosion from acidic sodas and withstands aggressive cleaning agents. |

| Filling Method | Isobaric (Counter-Pressure) | Essential for carbonated beverages. The machine pressurizes the bottle to match the tank pressure before opening the filling valve, preventing foaming and preserving CO2 levels. |

| Premix Unit | Deaeration + Carbonation | An upstream unit that removes oxygen (deaeration) from the water, blends syrup/flavor, and injects CO2. Minimum industrial capacities often start at 3,000 Liters/Hour. |

| Control System | PLC with HMI | Programmable Logic Controllers (PLC) paired with Human-Machine Interfaces (touchscreens) allow operators to monitor flow rates, pressure, and faults without manual intervention. |

| Production Capacity | BPH / CPH | Rated in Bottles Per Hour (BPH) or Cans Per Hour (CPH). Entry-level industrial lines typically range from 1,000 to 6,000 BPH, while high-speed lines exceed 20,000 BPH. |

| Sanitization | CIP (Clean-in-Place) | An automated system that circulates cleaning and sanitizing solutions through the machine’s pipes and tanks without disassembly. Critical for sugary beverages to prevent bacterial growth. |

Commercial & Trade Terminology

Understanding these terms is vital for navigating supplier contracts and customizing machinery orders.

Manufacturing & Procurement Terms

- MOQ (Minimum Order Quantity): For heavy machinery, the MOQ is typically 1 Unit. However, for consumables (bottles, caps, labels) or spare parts, suppliers may impose MOQs in the thousands.

- OEM (Original Equipment Manufacturer): The supplier manufactures the machine based on their existing design but brands it for the buyer.

- ODM (Original Design Manufacturer): The supplier designs a unique machine or modifies existing architecture to meet specific buyer constraints (e.g., unique bottle shapes or spatial limitations).

- Lead Time: The duration between the receipt of the deposit and the shipment of the machine. For custom soda lines, this typically ranges from 45 to 90 days.

Operational Acronyms

- FAT (Factory Acceptance Test): A trial run performed at the manufacturer’s facility before shipment. The buyer verifies that the machine operates at the promised speed (BPH) and quality standards.

- SAT (Site Acceptance Test): The final testing phase conducted at the buyer’s facility after installation to ensure the equipment works within the actual production environment.

- Changeover Time: The time required to switch the machine from running one bottle size/format to another. Lower changeover times are critical for facilities producing multiple SKUs.

Navigating Market Dynamics and Sourcing Trends in the soda filling machine Sector

Navigating Market Dynamics and Sourcing Trends in the Soda Filling Machine Sector

The beverage manufacturing landscape in the USA and Europe is shifting towards high-efficiency, hygienic, and scalable production lines. For B2B buyers, understanding the trajectory of soda filling technology—from material standards to automation—is critical for making informed capital equipment investments.

Market Trends: The Rise of Integrated and Modular Systems

Current market dynamics favor flexibility over rigid production lines. Manufacturers are increasingly moving away from standalone units toward integrated solutions that combine the soda making and soda filling phases.

- The “All-in-One” Approach: Modern sourcing trends prioritize machines that can handle multiple processes. For example, advanced industrial soda making machines now combine deaeration, flavoring/syrup injection, and carbonation into single Premix Units.

- Modularity and Scalability: Buyers are seeking equipment that grows with production demand. Suppliers like Comac Group are responding with modular plants customizable to specific business sizes, offering capacities ranging from 3,000 liters/hour to high-speed industrial outputs.

- Dual Capability: There is a growing demand for versatility in packaging. Sourcing strategies now favor manufacturers that offer solutions for both bottling and canning within similar infrastructure footprints.

Sourcing Standards: Hygiene and Material Compliance

For the US and European markets, regulatory compliance regarding food safety is non-negotiable. Sourcing trends have heavily consolidated around specific material standards to ensure hygiene and longevity.

- AISI 304 Stainless Steel: This is the current industry benchmark for soda filling and premix units. Its corrosion resistance and ease of sanitation make it the preferred alloy for contact parts, ensuring the final product remains uncontaminated and safe for consumption.

- Rinse-Fill-Seal Logic: To meet strict hygiene standards, buyers are prioritizing automatic machines that integrate the rinse cycle immediately before filling and sealing. This “closed-loop” approach minimizes human intervention and external contamination risks.

Sustainability through Automation and Efficiency

Sustainability in the soda filling sector is driven by waste reduction and energy efficiency. Modern machinery addresses these concerns through advanced automation.

| Feature | Sustainability Impact |

|---|---|

| Premix Unit Integration | Reduces energy consumption by combining deaeration, mixing, and carbonation into one compact footprint rather than three separate machines. |

| Precision Filling | Automatic control panels monitor flow rates to prevent product spillage and overfilling, reducing raw material waste. |

| Compact Design | Smaller machine footprints reduce the energy required for facility climate control and optimize production floor space. |

Historical Context: The Evolution of the Soda Line

The soda filling sector has evolved from manual, labor-intensive mechanical fillers to fully autonomous logic systems.

Illustrative Image (Source: Google Search)

- Early Era: Production relied on separate, disjointed units for mixing syrup and filling bottles, requiring significant manual handling and resulting in inconsistent carbonation levels.

- The Automation Shift: The introduction of automatic rotary systems allowed for high-speed filling but often lacked precise control over the beverage formulation.

- Modern Era (Current State): The industry has arrived at Total Process Integration. Machines now utilize central control panels to manage the entire lifecycle—from the Premix Unit (flavoring and carbonating) to the Filling Unit (rinsing, filling, and capping/sealing)—without human contact. This evolution has democratized access to industrial-grade production, allowing small businesses to utilize technology previously reserved for massive conglomerates.

Frequently Asked Questions (FAQs) for B2B Buyers of soda filling machine

Frequently Asked Questions (FAQs) for B2B Buyers

1. What is the difference between a soda making machine and a soda filling machine?

In an industrial context, a complete soda plant typically combines two distinct units. The soda making machine (often referred to as a Premix Unit) handles the processing: it deaerates the water, adds syrup/flavoring, and carbonates the mixture. The soda filling machine is responsible for the packaging phase: rinsing the containers, filling them with the finished product, and sealing/capping them. For a streamlined production line, buyers should look for manufacturers that offer modular solutions integrating both units.

2. What material specifications are required for regulatory compliance in the USA and Europe?

For soda filling machinery, hygiene and corrosion resistance are paramount due to the acidity of carbonated beverages. The industry standard is AISI 304 stainless steel. This special alloy is highly recommended for all parts in contact with the liquid to ensure compliance with FDA (USA) and CE (Europe) safety and sanitation directives.

3. Can a single filling line handle both bottling and canning?

While some manufacturers offer hybrid solutions, bottling and canning generally require different handling mechanisms for sealing and capping. However, top-tier manufacturers (such as Comac) provide modular solutions for both bottling (glass or PET) and canning. Buyers should specify their container mix during the consultation phase to determine if a versatile line or separate dedicated lines are necessary.

4. What production capacities are available for small vs. large scale operations?

Modern soda filling equipment is scalable.

* Small to Medium Enterprises: Compact bottling machines are available with outputs up to 6,000 bottles per hour (bph).

* Industrial/Large Scale: Premix units typically start with a minimum capacity of 3,000 liters per hour and scale upward significantly for high-volume demands.

Equipment should be selected based on current volume with an allowance for projected growth.

5. How automated are modern soda filling machines?

Current industrial standards demand completely automatic operations to maximize efficiency and hygiene. A standard high-quality machine will manage the entire rinse cycle, filling, and sealing without human intervention. Buyers should prioritize machines featuring accessible control panels that allow operators to monitor the entire process remotely or from a central station.

6. What is a “Premix Unit” and why is it critical to the filling process?

A Premix Unit is the core of the “soda making” phase. It performs three critical tasks before the liquid reaches the filler:

1. Deaeration: Removing air from the original liquid to prevent oxidation.

2. Flavoring: Precise addition of syrup or flavor concentrates.

3. Carbonation: Injecting CO2 to create the fizz.

Integrating a high-efficiency Premix Unit ensures product consistency before it enters the bottling or canning line.

7. Are soda filling machines customizable for limited facility space?

Yes. Leading manufacturers utilize modular designs. This allows the machinery to be customized to fit specific facility layouts and business sizes. Rather than a “one-size-fits-all” approach, B2B buyers should request site-specific configurations that optimize workflow within their existing floor plan.

8. Does the filling machine also handle container cleaning?

Yes. A professional soda filling machine is rarely just a filler; it is typically a “monoblock” system. This means it includes a rinsing unit that cleans the bottles or cans immediately before filling to ensure sanitation, followed by the filling turret, and finally the capping/seaming turret. This integrated approach reduces contamination risks and footprint.

Strategic Sourcing Conclusion and Outlook for soda filling machine

Strategic Sourcing Conclusion and Market Outlook

Strategic sourcing of soda filling machinery represents a critical capital investment balancing immediate operational efficiency with long-term scalability. For buyers in the USA and Europe, where regulatory standards and labor costs are high, the priority must be equipment that ensures absolute hygiene and minimizes human intervention.

The market outlook favors modular, fully automated systems. As demonstrated by industry leaders like Comac, the integration of the “premix” phase (deaeration, flavoring, carbonation) directly with filling and capping units is becoming the standard for reducing footprint and increasing throughput.

Key Sourcing Criteria for ROI

To future-proof your production line, evaluate suppliers based on the following strategic pillars:

| Feature | Strategic Value |

|---|---|

| Material Integrity | AISI 304 Stainless Steel is non-negotiable for meeting strict US/EU hygiene and safety compliance. |

| Modularity | Systems should allow scalability (e.g., starting at 3,000 L/h) without requiring a full line replacement as demand grows. |

| Automation Level | Prioritize “Rinse-Fill-Seal” integration to reduce labor overhead and contamination risks. |

Final Recommendation: Move beyond standalone units. Invest in comprehensive solutions that offer precise control over carbonation levels and packaging versatility (cans vs. bottles) to adapt to shifting consumer preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.

![#1 List: Top Beverage Filling Machines in China [2025]](https://www.cify.info/wp-content/uploads/2025/12/procoolmfgcom-5983.jpg)