Steel Water Tank 2000 Ltr Price: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Steel Water Tank 2000 Ltr Price

For procurement officers and facility managers across the USA and Europe, the 2000-liter (approx. 528 gallon) stainless steel tank represents a critical intersection of capacity and versatility. Whether utilized for potable water storage, chemical processing, or food-grade fermentation, securing the right asset requires navigating a price landscape that is often opaque and highly variable.

The disparity in the steel water tank 2000 ltr price market is significant. A basic SS 304 storage vessel may start as low as $250 USD (ex-works), while specialized jacketed tanks with mixing capabilities can range from $1,500 to $8,000 USD. This variance is driven not just by capacity, but by material specifications—specifically the choice between Grade 304 and 316 steel—and wall thickness ranging from 0.5 mm to over 2 mm.

Buyers must look beyond the sticker price to understand the Total Cost of Ownership (TCO), including freight, compliance with western standards (ASME, CE), and durability against corrosion.

This guide provides a strategic breakdown of the current market, covering:

- Price Benchmarks: Current cost tiers for Standard Storage vs. Industrial Processing tanks.

- Cost Drivers: How material grade (SS 304 vs. SS 316) and thickness impact the final invoice.

- Sourcing Strategy: Navigating supplier discrepancies between domestic fabricators and international platforms like Alibaba.

- Hidden Costs: factoring in fittings, stands, and international logistics.

By the end of this guide, you will be equipped to source high-quality 2000L inventory that meets your operational requirements without overspending.

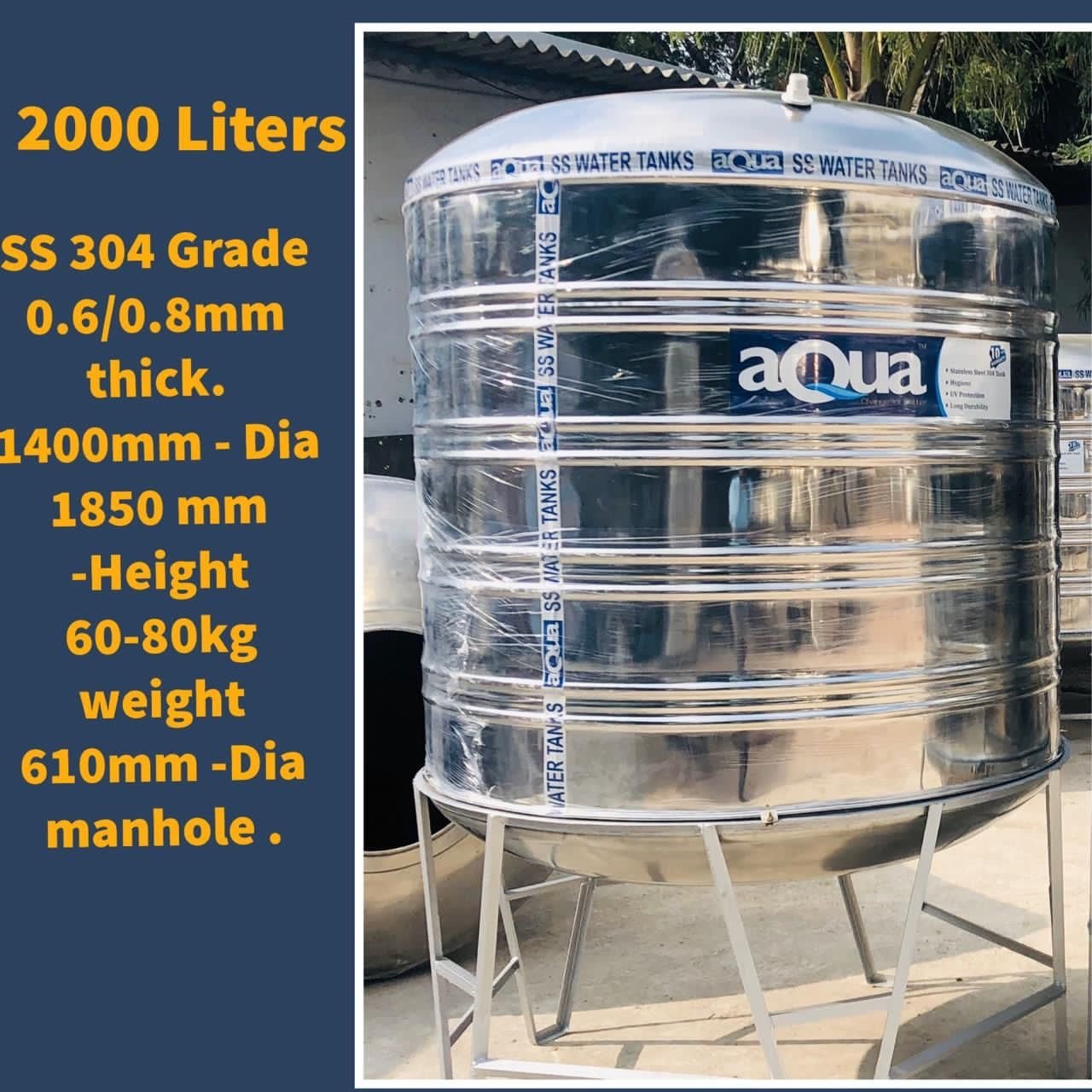

Illustrative Image (Source: Google Search)

Top 10 Steel Water Tank 2000 Ltr Price Manufacturers & Suppliers List

1. 2000 Litre Stainless Steel Water Tank Price

Domain: tankinyou.com

Registered: 2023 (2 years)

Introduction: Our 2000-liter stainless steel water tanks are available in various shapes, sizes, and configurations to suit different requirements. We offer horizontal, ……

2. 2000 Litre Purinox 5 Layer Stainless Steel Water Tanks

Domain: pureversstanks.in

Registered: 2018 (7 years)

Introduction: Discover the 2000 Litre Purinox 5 Layer Stainless Steel Water Tanks, designed with advanced specifications for efficiency and durability, available at ……

3. Aquasafe 2000 Litre SS Water Tank (Today’s Price List) – RO Traders

Domain: rotraders.com

Registered: 2020 (5 years)

Introduction: The basic price of the 2000 Litre Aquasafe SS Tank is Rs. 17,500/- including GST. For 0.5 mm thickness & 316 grade, it’s Rs. 23,500/-….

4. Insulated Stainless Steel Water Storage Tank

Domain: platinumsteels.com

Registered: 2023 (2 years)

Introduction: Insulated Stainless Steel Water Storage Tank. Rs 62,755.00 · Insulated Stainless Steel Water Storage Tank ; 2000L Stainless Steel Water Tank. Rs 98,000 · 2000L ……

Illustrative Image (Source: Google Search)

Understanding steel water tank 2000 ltr price Types and Variations

Understanding Steel Water Tank 2000 Ltr Price: Types and Variations

When analyzing the price of a 2000-liter steel water tank, the cost is primarily dictated by the tank’s configuration, material grade, and intended application. Prices range significantly from entry-level storage units to specialized industrial processing vessels.

The following table categorizes the primary types of steel tanks available in the US and European markets, highlighting how design impacts utility and cost.

Comparative Overview of 2000L Steel Tank Types

| Tank Type | Key Features | Typical Applications | Pros & Cons |

|---|---|---|---|

| Standard Vertical Cylindrical | SS 304/316 grade; 0.5mm–2mm thickness; food-grade lining. | Potable water storage; residential and light commercial use. | Pros: Cost-effective; minimal footprint. Cons: Fixed dimensions; difficult to ship in bulk. |

| Modular Panel Tanks | Bolted stainless steel panels; customizable dimensions; on-site assembly. | Large-scale commercial water storage; HVAC systems; fire suppression. | Pros: Easy transport (flat-pack); flexible shapes. Cons: Higher installation labor costs; potential leak points at seams. |

| Horizontal Storage Tanks | Low center of gravity; often skid-mounted; thicker shell for transport. | Mobile water supply; dairy/milk storage; transport logistics. | Pros: Stability; fits in low-height areas. Cons: Larger ground footprint; higher material cost per liter. |

| Industrial Process/Mixing Tanks | Integrated heating/cooling jackets; agitators/emulsifiers; pressure-rated. | Chemical processing; food & beverage mixing; pharmaceutical storage. | Pros: High functionality; precise temperature control. Cons: Highest price point; high energy consumption. |

1. Standard Vertical Cylindrical Tanks (SS 304 vs. SS 316)

The most common variation for pure water storage is the vertical cylindrical tank. Pricing for this category is driven almost entirely by material grade and wall thickness.

- Material Grades:

- SS 304: The industry standard for potable water. It offers excellent corrosion resistance for standard environments.

- SS 316: Contains molybdenum, providing superior resistance to chlorides and acids. This grade commands a premium price (approx. 20-30% higher) and is essential for coastal areas in Europe or the US, or for storing water with high mineral content.

- Thickness Variables: As noted in manufacturing specifications, wall thickness typically ranges from 0.5 mm to 2 mm. A tank with 2 mm thickness will cost significantly more due to the raw material weight but offers a lifespan exceeding 20 years compared to thinner economy models.

2. Modular Panel Tanks

For facilities with restricted access or specific spatial constraints, modular panel tanks are the preferred B2B solution. Unlike welded units, these are priced based on the number of panels and reinforcement required.

Illustrative Image (Source: Google Search)

- Cost Structure: Pricing is often calculated per cubic meter or per panel unit (e.g., \$59 – \$119 per unit).

- Logistics: While the upfront material cost may be comparable to welded tanks, the total landed cost is often lower for international buyers because the tanks are shipped flat-packed, maximizing container space.

- Utility: These are frequently used in US and European commercial buildings where retrofitting a pre-assembled 2000L tank through existing doorways is impossible.

3. Industrial Process and Mixing Tanks

This category represents the upper echelon of the pricing spectrum, with units ranging from \$1,500 to \$3,000+ per set. These are not simple storage vessels but active processing units.

- Integrated Technology: High prices are justified by the inclusion of electric heating elements, emulsifying pumps, and circulation systems.

- Pressure Ratings: Many tanks in this category are pressure-rated (ASME certified for the US market or PED for Europe), requiring thicker steel and rigorous testing, which further elevates the price.

- Sanitary Finish: These tanks often require a mirror polish (Ra < 0.4µm) to prevent bacterial growth for food and pharmaceutical applications, adding labor costs to the final price.

4. Horizontal Storage Tanks

Horizontal tanks address specific stability and height clearance issues. These are common in the dairy and transport sectors.

- Structural Integrity: To maintain structural integrity without the natural strength of a vertical cylinder, horizontal tanks often require thicker shells and internal baffles to prevent liquid surging during transport.

- Pricing Factors: The increased material requirement and specialized cradle or skid mounts result in a higher price per liter compared to vertical equivalents. Market data suggests prices for high-quality sanitary horizontal tanks can range between \$3,500 and \$8,000 depending on the inclusion of cooling jackets and insulation.

Key Industrial Applications of steel water tank 2000 ltr price

Key Industrial Applications Influencing 2000 Ltr Steel Tank Pricing

The cost of a steel water tank 2000 ltr unit varies significantly based on its intended industrial application. While basic storage tanks focus on volume, specialized industries require features such as heating jackets, emulsifying pumps, and high-grade sanitary finishes (SS 316), which drive the price from the baseline of ~$500 USD to upwards of $3,000–$8,000 USD.

The following table outlines the primary sectors utilizing 2000L steel tanks and how specific application requirements impact the engineering and final cost.

Illustrative Image (Source: Google Search)

Industry Application Matrix

| Industry | Primary Application | Material Grade Standards | Price Impact Factors |

|---|---|---|---|

| Food & Beverage | Milk, juice, and potable water storage | SS 304 / SS 316 (Food Grade) | Sanitary welds, conical bottoms for drainage, CIP (Clean-in-Place) compatibility. |

| Cosmetics & Personal Care | Mixing lotions, shampoos, and liquid soaps | SS 316L (High Polish) | Integration of electric heating jackets, emulsifying pumps, and agitators. |

| Chemical Processing | Electrolyte, solvent, and acid storage | SS 304 / SS 316 (Corrosion Resistant) | Wall thickness (2mm+), pressure resistance, and chemical compatibility testing. |

| Agriculture & Irrigation | Bulk water buffer for livestock or crops | SS 304 | UV resistance, algae prevention (zero light penetration), and outdoor durability. |

| HVAC & Fire Safety | Thermal storage or emergency water supply | Carbon Steel (Lined) or SS 304 | Pressure ratings and insulation requirements. |

Detailed Application Analysis

1. Food and Beverage Production

In the US and European markets, regulatory compliance (FDA, EFSA) dictates the specifications for storage vessels.

* Usage: Used as buffer tanks for milk, fermentation vessels for breweries, or raw water storage for bottling plants.

* Value Proposition: Unlike plastic, 2000 litre SS water tanks prevent algae growth and are non-toxic. The inert nature of SS 304/316 ensures zero leaching of chemicals into the product, preserving taste and safety.

* Cost Driver: The requirement for “Food Grade” surfaces and sanitary fittings increases the price compared to general industrial water tanks.

2. Cosmetics and Pharmaceutical Mixing

This sector utilizes the most technically advanced—and expensive—variants of the 2000L tank.

* Usage: As noted in supplier data, these tanks often function as electric heated mixing tanks for products like liquid shower gels, shampoos, and creams.

* Value Proposition: These tanks are not just for storage; they are active production units. They often feature emulsifying pumps for circulation and jacketed walls to maintain precise temperatures during the blending process.

* Cost Driver: High-end components (mixers, heaters) and SS 316L material construction place these units in the premium price bracket ($3,000+).

3. Chemical and Electrolyte Storage

Industrial safety is the priority for chemical applications.

* Usage: Storage of electrolytes, mild acids, and industrial solvents.

* Value Proposition: Stainless steel offers superior corrosion resistance compared to mild steel and higher structural integrity than polyethylene. For volatile chemicals, the ability to withstand pressure variations is critical.

* Cost Driver: Wall thickness is a major factor here. While a standard water tank may use 0.5mm–1.0mm thickness, chemical tanks often require 2.0mm or greater, significantly increasing the raw material cost.

4. Agricultural and Bulk Water Storage

For large-scale farming operations in Europe and the US, longevity is the key return on investment.

* Usage: Watering livestock and drip irrigation systems.

* Value Proposition: Steel tanks provide a “buy once” solution. They are immune to the cracking and UV degradation that affect plastic tanks over time.

* Cost Driver: These are typically the most entry-level priced steel tanks, often utilizing standard SS 304 with simpler inlet/outlet configurations.

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘steel water tank 2000 ltr price’ & Their Solutions

3 Common User Pain Points for ‘Steel Water Tank 2000 Ltr Price’ & Their Solutions

When sourcing 2000-liter stainless steel tanks for industrial or commercial use in US and European markets, procurement officers often encounter significant disparities in pricing and specification. Below are the three most common friction points and how to navigate them.

1. The “Base Price” Illusion vs. Material Specification

The Scenario: A procurement manager finds a 2000L tank listed for $600, while other quotes range between $1,500 and $3,000. To reduce CapEx, they opt for the lower quote, only to receive a tank that dents easily or corrodes within a year.

The Problem: Drastic price variations are rarely arbitrary; they usually dictate steel grade and wall thickness. Low-end quotes often utilize:

* Thinner Gauge: 0.5mm walls (prone to warping) vs. the industrial standard of 1.5mm–2.0mm.

* Inferior Alloys: Lower grade stainless steel (e.g., 201 series) masquerading as 304 or 316.

* Lack of Certification: Non-food-grade materials used in applications requiring sanitary compliance.

The Solution:

Define the Total Cost of Ownership (TCO) by specifying material requirements in your RFQ (Request for Quotation).

* Mandate Grade: Specify SS 304 for standard water storage or SS 316 for saline/sterile environments (crucial for food/beverage and pharma).

* Define Thickness: Request a minimum wall thickness of 1.5mm to 2.0mm for a 2000L volume to withstand pressure and agitation.

* Verify: Ask for Mill Test Certificates (MTC) to verify the steel composition before finalizing the order.

Illustrative Image (Source: Google Search)

2. Hidden Logistics and Landed Costs

The Scenario: A buyer budgets $2,500 based on the ex-factory price. However, upon arrival, the final invoice balloons to $4,500 due to crating, freight, import tariffs, and last-mile delivery surcharges.

The Problem: A 2000L tank is a high-volume cargo item. Standard marketplace pricing is often FOB (Free on Board), meaning the buyer pays for shipping from the overseas port. For US and European buyers, this excludes:

* Volumetric Weight Shipping: Carriers charge based on volume, not just weight.

* Import Duties: Steel tariffs can add substantial percentages to the cost.

* Port Handling & Inland Freight: Moving a large tank from the port to the facility.

The Solution:

Shift from FOB pricing to DDP (Delivered Duty Paid) or request a “Landed Cost” estimate.

* Consolidate: If buying from overseas (e.g., Alibaba suppliers), ensure the quote includes crating (usually wood) and insurance.

* Local Sourcing: Compare the landed import price against local fabricators. While the unit cost is higher locally, the elimination of international freight and tariffs often equalizes the final price.

3. Incompatible Fittings and Customization Charges

The Scenario: The tank arrives within budget, but the installation team discovers the outlets are BSP (British Standard Pipe) while the facility uses NPT (National Pipe Taper), or the manway is too small for required cleaning protocols. Retrofitting costs thousands in welding and downtime.

Illustrative Image (Source: Google Search)

The Problem: “Standard” 2000L tanks are often mass-produced with generic configurations to keep the advertised price low. Customization is where manufacturers recover their margins.

* Connection Mismatches: US vs. European threading standards.

* Missing Features: Base prices often exclude heating jackets, agitator mounts, or CIP (Clean-in-Place) spray balls.

The Solution:

Treat the tank as a component of a larger system, not a standalone commodity.

* Detailed Schematics: Submit a P&ID (Piping and Instrumentation Diagram) with your inquiry.

* Standardize Connections: Explicitly state connection types (e.g., “2-inch Tri-Clamp” or “1.5-inch NPT”) in the contract.

* Bundle Accessories: Negotiate the inclusion of ladders, level indicators, and mixers upfront. Buying these as a package is often 20-30% cheaper than retrofitting later.

Strategic Material Selection Guide for steel water tank 2000 ltr price

Strategic Material Selection Guide for Steel Water Tank 2000 Ltr Price

When evaluating the steel water tank 2000 ltr price, the primary cost driver is the specific grade of stainless steel and the wall thickness selected. For B2B buyers in the USA and Europe, understanding the relationship between material composition and longevity is critical for calculating Total Cost of Ownership (TCO).

While base units may appear similar, price variances from $1,500 to over $8,000 are dictated by the following material specifications.

1. Stainless Steel Grade: The Price Baseline

The industry standard for 2000-liter tanks revolves around two primary austenitic grades. Your application dictates the necessary grade, which in turn sets the baseline price.

- SS 304 (Standard Food Grade):

- Composition: Contains 18% chromium and 8% nickel.

- Application: Ideal for potable water storage, milk, and standard food ingredients in non-saline environments.

- Price Impact: Represents the mid-range price point. It offers excellent corrosion resistance for standard water storage at a lower cost than 316.

- SS 316 / 316L (Marine/Pharmaceutical Grade):

- Composition: Adds 2% molybdenum to the 304 formula.

- Application: Essential for coastal facilities (high salinity air), chemical storage, or pharmaceutical-grade water (WFI).

- Price Impact: Commands a premium (typically 20–30% higher than SS 304) due to the molybdenum content. However, for harsh environments, this prevents premature tank failure, justifying the higher upfront steel water tank 2000 ltr price.

2. Wall Thickness and Structural Integrity

Material volume is a direct multiplier of cost. Manufacturers offer variable thicknesses ranging typically from 0.5 mm to 2.0 mm for tanks in the 2000L capacity range.

- Economy (0.5 mm – 0.8 mm): often seen in residential gravity-fed tanks. These carry the lowest price tag but lack the structural integrity for pressurized industrial systems or heavy agitation.

- Industrial Standard (1.2 mm – 2.0 mm): Required for pressure vessels, mixing tanks with emulsifying pumps, or horizontal mounting.

- Cost Implication: A tank with 2.0 mm thickness utilizes nearly double the raw material of a 1.0 mm tank, effectively doubling the material cost component of the final price.

3. Surface Finish and Hygiene

For sectors like Food & Beverage or Pharmaceuticals, the internal finish affects the price.

* 2B Finish: Standard cold-rolled, smooth, and moderately reflective. Standard pricing.

* Mirror/Polished Finish: Required to prevent bacterial growth in milk or pharmaceutical storage. This labor-intensive process significantly increases the unit price.

Material Selection Comparison Matrix

The following table outlines how material choices influence the steel water tank 2000 ltr price and suitability for specific applications.

Illustrative Image (Source: Google Search)

| Material Grade | Recommended Application | Corrosion Resistance | Pressure/Durability | Relative Price Impact |

|---|---|---|---|---|

| SS 304 (0.8mm) | Residential/Light Commercial Water Storage | Moderate | Low (Gravity only) | $ (Lowest) |

| SS 304 (1.5mm+) | Industrial Potable Water, Milk Storage | High | High | $$ (Standard) |

| SS 316 (1.5mm+) | Chemical Processing, Coastal Water Storage | Superior (Saline resistant) | High | $$$ (Premium) |

| SS 316L (Pressure) | Pharmaceutical, Heated Mixing Tanks | Excellent (Intergranular corrosion resistant) | Very High (Pressure Vessel) | $$$$ (Highest) |

Procurement Tip: When requesting quotes for a 2000L tank, specify the fluid specific gravity and operating temperature. A “cheap” quote often indicates a downgrade to SS 202 (non-food grade) or reduced wall thickness (e.g., <0.8mm), which compromises safety in industrial settings.

In-depth Look: Manufacturing Processes and Quality Assurance for steel water tank 2000 ltr price

In-depth Look: Manufacturing Processes and Quality Assurance

For procurement officers in the USA and Europe, understanding the manufacturing workflow of a 2000-liter steel water tank is critical to evaluating price discrepancies. A tank priced at $500 differs significantly from one priced at $3,000, not just in margins, but in fabrication precision, material grade verification, and post-production testing.

The following analysis details how production steps and quality standards directly influence the final B2B pricing structure.

1. Material Preparation and Selection

The baseline cost of a 2000L tank is dictated by the raw material. Manufacturers typically utilize AISI 304 for standard water storage and AISI 316 for harsh environments or saline water.

Illustrative Image (Source: Google Search)

- Sheet Thickness & Tolerance: Prices fluctuate based on gauge. Entry-level tanks may use 0.5mm sheets, while industrial-grade vessels range from 1.5mm to 2.0mm. Thicker gauges require heavy-duty decoiling and leveling machinery, increasing production overhead but ensuring structural longevity.

- Cutting Technology: High-end manufacturers employ CNC Fiber Laser cutting to ensure precision edges (±0.1mm). This reduces gaps during welding, requiring less filler material and resulting in stronger joints. Cheaper alternatives using plasma or shearing methods often result in uneven edges and higher failure rates.

2. Forming and Shaping

The structural integrity of a 2000L vessel is established during the forming phase. The complexity of this stage varies by tank type (cylindrical vs. panel).

- Corrugation (Ribbing): To maintain price competitiveness without sacrificing strength, manufacturers often corrugate the steel sheets. This process increases the moment of inertia, allowing the tank to withstand the hydrostatic pressure of 2 tons of water without buckling, even with thinner walls.

- Hydraulic Pressing (Panel Tanks): For modular tanks (referenced in sourcing data as “Panel Metal Storage”), hydraulic presses stamp 1x1m or 0.5×0.5m panels. The mold maintenance and press tonnage required for consistent panel uniformity add to the fixed manufacturing costs.

- Dishing: For pressure-rated or hygienic tanks, the top and bottom heads are “dished” or spun. This prevents sediment buildup and allows for complete drainage, a requirement for food-grade compliance.

3. Assembly and Welding Protocols

Welding is the most labor-intensive component of the manufacturing process and a primary driver of price variance.

- TIG vs. Seam Welding:

- Automated Seam Welding: Used for the main cylinder body. It is fast and produces a consistent, leak-proof seam.

- Manual TIG Welding: Required for fittings, nozzles, and manholes. High-quality tanks employ certified welders to prevent “sugaring” (oxidation) on the interior weld bead, which is a breeding ground for bacteria.

- Pickling and Passivation: After welding, the stainless steel loses its corrosion-resistant properties at the heat-affected zone. A premium 2000L tank undergoes full-bath pickling and passivation (acid treatment) to restore the protective chromium oxide layer. Budget manufacturers often skip this step or spot-clean, leading to premature rust (tea staining).

4. Quality Assurance (QC) and Standards

For the US and European markets, adherence to ISO and safety standards is non-negotiable. The cost of compliance is built into the unit price.

QC Checkpoints and Price Impact

| QC Stage | Procedure | Impact on Quality & Price |

|---|---|---|

| Material Verification | XRF Analyzer (Spectroscopy) | Ensures the steel is genuine 304/316. Prevents “low-nickel” fraud. |

| Leak Testing | Hydrostatic Test | The tank is filled with 2000L of water and held for 24-48 hours to check for micro-leaks. |

| Weld Integrity | Dye Penetrant Test (DPT) | Reveals surface-breaking defects in welds that are invisible to the naked eye. |

| Hygiene Check | Surface Roughness (Ra) Test | Ensures interior smoothness (Ra < 0.8µm) to prevent bacterial adhesion (crucial for food-grade tanks). |

5. Regulatory Compliance

When sourcing for Western markets, verify the manufacturer adheres to the following to justify the price point:

* ISO 9001:2015: Certification of the quality management system.

* FDA / NSF/ANSI 61: Essential for tanks intended for potable water storage, certifying that materials do not leach contaminants.

* CE Marking (Europe): Required for pressure vessels and machinery, indicating conformity with health, safety, and environmental protection standards.

Illustrative Image (Source: Google Search)

Summary: When evaluating a quote for a 2000L steel tank, buyers must assess whether the lower price reflects efficient manufacturing or the omission of critical steps like passivation, thickness verification, and hydrostatic testing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel water tank 2000 ltr price’

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel water tank 2000 ltr price’

Sourcing 2000-liter stainless steel tanks for US and European markets requires navigating a wide price variance driven by material grade, wall thickness, and configuration. Prices can range from $200 (thin-walled/panel) to over $3,000 (sanitary/pressure vessels).

Use this checklist to standardize your RFQs and ensure price parity when comparing suppliers.

Step 1: Define Technical Specifications (The Price Drivers)

Before soliciting quotes, strictly define these parameters to avoid mismatched pricing.

Illustrative Image (Source: Google Search)

- Material Grade:

- SS 304: Standard for potable water and general storage.

- SS 316/316L: Required for saline environments, pharmaceutical use, or corrosive liquids. Expect a 20-30% price premium over SS 304.

- Wall Thickness:

- 0.5mm – 0.8mm: Economy grade. Suitable for static residential water storage.

- 1.5mm – 2.0mm: Industrial grade. Required for pressurized systems or heavy-duty commercial use.

- Construction Type:

- Vertical/Horizontal Welded: Delivered fully assembled. Higher shipping costs.

- Panel/Modular Tanks: Shipped flat-packed and bolted on-site. Significantly reduces freight costs for US/EU buyers.

- Pressure vs. Atmospheric: Pressure vessels require ASME certification (USA) or PED (Europe) and cost significantly more.

Step 2: Supplier Vetting & Compliance

For US and European imports, verify the following to ensure the “low price” doesn’t result in rejected customs entry or liability issues.

- Certifications:

- Europe: CE Marking (mandatory for pressure equipment), ISO 9001.

- USA: ASME (for pressure tanks), UL (if electrical heating/mixing is involved), FDA compliance for food-grade seals.

- Supplier History:

- Look for suppliers with 5+ years of manufacturing history.

- Verify Trade Assurance (or equivalent escrow protection) to secure the transaction.

- Reference: Reliable suppliers in this category often display high ratings (e.g., 4.9/5.0) and specific experience in “Stainless Steel Storage Tank” manufacturing.

Step 3: Price Benchmarking Guide

Use this table to evaluate if a quote falls within a realistic market range for a 2000L (approx. 528 gallon) capacity tank.

| Tank Category | Specification | Est. FOB Price Range (USD) | Best Application |

|---|---|---|---|

| Economy Storage | SS 304, 0.5mm-0.8mm, Light Duty | $200 – $500 | Residential water, Rainwater harvesting |

| Industrial Storage | SS 304/316, 1.5mm+, Welded | $600 – $1,200 | Commercial water, Beverage storage |

| Modular/Panel | SS 304, Bolted panels (Unassembled) | $100 – $300 (per cbm) | Large scale projects, Difficult access sites |

| Process/Mixing | SS 316, Agitator, Heated, Pressure | $1,500 – $3,500+ | Chemical mixing, Food processing |

Step 4: RFQ Structure for Accurate Pricing

When contacting suppliers, use this template to get a comparable “landed cost.”

Subject: RFQ for 2000L Stainless Steel Water Tank – [Your Company Name]

Illustrative Image (Source: Google Search)

Specs:

* Capacity: 2000 Liters (Net volume)

* Material: Stainless Steel [304 or 316]

* Thickness: Minimum [e.g., 1.5mm]

* Type: [Vertical/Horizontal/Panel]

* Fittings: [List required inlets/outlets, e.g., 2″ Tri-clamp]Requirements:

1. Please provide FOB Price and estimated DDP Price to [Your Zip Code/Port].

2. Confirm HS Code (Harmonized System) for duty calculation.

3. Provide Mill Test Certificate (MTC) for steel grade verification.

Step 5: Logistics & Landed Cost Calculation

The base price of a 2000L tank is often lower than the shipping cost due to the high volume-to-weight ratio.

- Calculate Volumetric Weight: A 2000L tank takes up significant container space.

- Compare Assembly Options:

- Assembled: High ocean freight, lower installation labor.

- Knock-down (Panel): Low ocean freight, higher on-site assembly labor.

- Check Duties:

- USA: Check Section 301 tariffs if sourcing from China.

- Europe: Check anti-dumping duties on stainless steel products from specific origins.

Comprehensive Cost and Pricing Analysis for steel water tank 2000 ltr price Sourcing

Comprehensive Cost and Pricing Analysis for 2000L Steel Water Tanks

Sourcing a 2000-liter (approx. 528 gallon) stainless steel tank requires navigating a wide price spectrum driven by material grade, wall thickness, and fabrication complexity. For buyers in the USA and Europe, the “sticker price” is only one component of the Total Landed Cost (TLC).

Illustrative Image (Source: Google Search)

Global Market Price Tiers (2025 Estimates)

Prices below reflect FOB (Free on Board) estimates for B2B sourcing.

| Tank Category | Material Grade | Thickness | Price Range (USD) | Typical Application |

|---|---|---|---|---|

| Economy Storage | SS304 (Food Grade) | 0.5mm – 0.8mm | $250 – $650 | Residential water, light agriculture. |

| Standard Industrial | SS304 / SS316 | 1.0mm – 1.5mm | $900 – $2,200 | Beverage storage, commercial water systems. |

| Heavy Duty / Pressure | SS316L | 2.0mm+ | $2,800 – $4,500 | Chemical processing, pressurized systems. |

| Process Tanks | SS316L | Variable | $3,500 – $8,000+ | Mixing tanks with heating jackets/agitators. |

Note: Modular “Panel” tanks are often quoted per square meter or cubic meter ($59 – $119/m³), not per unit. Ensure quotes clarify whether the price includes assembly hardware and sealing materials.

Detailed Cost Breakdown

Understanding the cost drivers allows for better negotiation with suppliers.

1. Material Costs (40-60% of Unit Price)

Stainless steel is a commodity market; tank prices fluctuate with global nickel and chromium prices.

* Grade Impact: SS316 (containing molybdenum for corrosion resistance) typically costs 20-30% more than SS304.

* Thickness Multiplier: Moving from a residential standard (0.5mm) to an industrial standard (2.0mm) quadruples the raw material requirement, significantly impacting the final price.

Illustrative Image (Source: Google Search)

2. Fabrication and Labor (20-30%)

- Welding Quality: Automatic longitudinal welding is cheaper and consistent. Manual TIG welding (required for nozzles, manholes, and custom fittings) increases labor costs.

- Finishing: A standard “2B” finish is standard. Polishing to a mirror finish (Ra < 0.4µm) for sanitary/pharma applications adds significant labor hours.

3. Logistics and Shipping (High Variance)

For a 2000L tank, logistics is often the hidden profit killer.

* Volumetric Weight: A 2000L tank is bulky but light. You are paying to ship air.

* Freight Cost: Shipping a fully welded 2000L tank from Asia to the US/EU can cost nearly as much as the tank itself if not optimized.

* Import Duties:

* USA: Subject to Section 301 tariffs if sourced from China (currently ~25% on specific steel products).

* Europe: Subject to CBAM (Carbon Border Adjustment Mechanism) reporting and potential steel tariffs.

Strategic Sourcing Tips to Reduce Costs

1. Opt for Modular/Panel Tanks for Long-Distance Sourcing

Instead of shipping a pre-welded cylindrical tank, consider Stainless Steel Panel Tanks. These ship flat-packed.

* Benefit: You can fit 10x more capacity in a standard 40ft container compared to pre-welded tanks.

* Trade-off: Requires on-site assembly labor.

2. Standardize Wall Thickness

Suppliers may default to “over-engineering” thickness to avoid warranty claims.

* Action: If the tank is for static water storage (non-pressurized), request a graduated thickness design (thicker bottom, thinner top) or a standard 1.0mm – 1.2mm wall rather than a uniform 2.0mm, provided it meets local structural codes.

3. Consolidate “Dead Space”

If purchasing pre-welded tanks, utilize the empty volume inside the tank during shipping.

* Action: Ask suppliers to pack smaller components (valves, pipes, or smaller 500L tanks) inside the 2000L units (nesting) to maximize container utility.

Illustrative Image (Source: Google Search)

4. Verify Inclusions

Low-end quotes ($200-$400 range) often exclude essential peripherals. Ensure your RFQ (Request for Quote) explicitly asks for:

* Manhole covers

* Inlet/Outlet nipples

* Skid/Stand (Legs)

* Ladder (if vertical orientation requires it)

5. Lifecycle Costing (TCO)

For US/EU markets, a cheaper SS304 tank that corrodes in 5 years due to saline environments is more expensive than an SS316 tank that lasts 20 years. Always specify SS316 for coastal areas or chemical storage.

Alternatives Analysis: Comparing steel water tank 2000 ltr price With Other Solutions

Alternatives Analysis: Comparing Steel Water Tank 2000 Ltr Price With Other Solutions

When evaluating the steel water tank 2000 ltr price for industrial or commercial procurement, it is essential to contextualize the capital expenditure (CapEx) against alternative materials. While stainless steel (grades 304 and 316) offers superior longevity and hygiene, alternatives like High-Density Polyethylene (HDPE) and Fiberglass Reinforced Plastic (FRP) offer different cost structures and performance profiles.

The following analysis compares a standard 2,000-liter (approx. 528 gallon) Stainless Steel tank against its two primary market competitors.

Illustrative Image (Source: Google Search)

Comparative Overview: Price vs. Performance

| Feature | Stainless Steel (304/316) | HDPE (Polyethylene) | FRP (Fiberglass) |

|---|---|---|---|

| Estimated Price Range (2000L) | $1,500 – $4,000 | $400 – $900 | $1,000 – $2,500 |

| Lifespan | 20–30+ Years | 10–15 Years | 15–20 Years |

| Temperature Tolerance | High (Up to 600°F+) | Low (Max ~140°F) | Medium (Max ~200°F) |

| UV Resistance | Excellent (Unaffected) | Moderate (Requires stabilizers) | Good (Painted/Coated) |

| Hygiene & Cleaning | Best (Biofilm resistant, CIP capable) | Good (Porous over time) | Fair (Rougher interior) |

| Pressure Rating | High (Customizable) | Atmospheric only | Moderate |

> Note: Prices are estimates based on current B2B market data for the US and European regions. Stainless steel pricing varies significantly based on gauge thickness (0.5mm to 2mm+) and configuration (jacketed vs. single-wall).

Analysis of Alternative 1: High-Density Polyethylene (HDPE)

The Budget-Conscious Alternative

HDPE tanks are the most common alternative to steel for general water storage. A 2,000-liter poly tank significantly undercuts the steel water tank 2000 ltr price, often costing 60% to 70% less upfront.

- When to choose HDPE: This is the ideal solution for ambient temperature water storage, agricultural irrigation, or rainwater harvesting where sanitary strictness is not critical.

- ** The Trade-off:** The lower price comes with reduced durability. HDPE is susceptible to expansion and contraction cycles, becomes brittle with UV exposure over time, and cannot handle high-temperature sanitation processes (CIP) required in food and beverage or pharmaceutical sectors.

Analysis of Alternative 2: Fiberglass Reinforced Plastic (FRP)

The Corrosive Environment Alternative

FRP tanks occupy the middle ground regarding pricing. They are generally cheaper than high-grade 316 stainless steel but more expensive than HDPE.

- When to choose FRP: Fiberglass is often selected when the stored liquid has high chloride content or specific chemical properties that might pit stainless steel, yet the budget does not allow for exotic alloys (like Hastelloy).

- The Trade-off: While FRP resists specific corrosion types better than 304 steel, it lacks the structural integrity of steel. FRP is prone to cracking under impact and is difficult to recycle at the end of its lifecycle. Furthermore, the interior surface of FRP is not as smooth as polished stainless steel, making it less suitable for applications requiring absolute sterility.

Verdict: Calculating the ROI

While the steel water tank 2000 ltr price represents a higher initial investment, the Total Cost of Ownership (TCO) often favors steel for industrial applications.

Illustrative Image (Source: Google Search)

- Residual Value: Stainless steel tanks retain scrap value; HDPE and FRP often incur disposal costs.

- Maintenance: Steel requires less frequent replacement and allows for high-pressure, high-heat cleaning, reducing downtime in processing plants.

- Durability: As indicated by supplier data, industrial stainless tanks are often rated for decades of use, whereas alternatives may require replacement within 10–15 years.

Recommendation: For potable water, food processing, or high-pressure applications in the US and EU markets, the premium paid for a 2,000-liter stainless steel tank is amortized through longevity and regulatory compliance. For non-critical, ambient storage, HDPE remains the cost-effective choice.

Essential Technical Properties and Trade Terminology for steel water tank 2000 ltr price

Essential Technical Properties and Trade Terminology

When evaluating the price of a 2000-liter (approx. 530 gallon) steel water tank, procurement professionals must distinguish between base-model specifications and industrial-grade features. The following technical properties and trade terms directly influence the final landed cost for buyers in the USA and Europe.

Critical Technical Specifications

The raw material cost and fabrication complexity are the primary drivers of price. For 2000L units, the following specifications define the asset’s value and longevity.

1. Material Grades

The specific alloy used determines corrosion resistance and suitability for potable water (food grade) or chemical storage.

Illustrative Image (Source: Google Search)

| Material Grade | Properties | Price Impact | Best Use Case |

|---|---|---|---|

| SS 304 / 304L | Standard food-grade stainless steel. Excellent corrosion resistance for neutral water. | Baseline | Potable water, general storage, beverage processing. |

| SS 316 / 316L | Molybdenum-added alloy. Superior resistance to chlorides, saline environments, and acidic solutions. | +20% to 30% | Coastal installations, pharmaceutical water, chemical mixing. |

| Carbon Steel | High strength but requires lining/coating to prevent rust. | Lower | Non-potable industrial water, fire suppression (if coated). |

2. Wall Thickness and Pressure Ratings

Price scales non-linearly with thickness due to increased raw material weight and welding requirements.

* Standard Thickness: Ranges from 0.5 mm to 2.0 mm for 2000L tanks.

* Price Implication: A tank with 2.0 mm thickness will cost significantly more than a 0.5 mm variant but offers higher pressure tolerance and structural integrity.

* Pressure Rating: Most standard storage tanks are atmospheric (non-pressurized). Tanks designed for pressure (ASME certified) require thicker walls and dished heads, drastically increasing the price.

3. Tank Configuration and Features

- Orientation: Vertical tanks are generally more cost-effective per liter than horizontal tanks due to simpler saddle/stand requirements.

- Construction Type:

- Welded Cylindrical: Standard for transportable 2000L units.

- Panel/Sectional: Used when access is restricted; assembled on-site. Higher labor/installation cost.

- Integrated Systems: As noted in market data, tanks equipped with heating jackets, agitators (mixing motors), or emulsifying pumps can range from $1,500 to $3,000+, whereas simple storage vessels may start as low as $500 – $1,000 (FOB).

Commercial and Trade Terminology

Navigating supplier quotations requires a clear understanding of B2B trade terms. These factors affect the final invoice and logistics planning.

1. MOQ (Minimum Order Quantity)

- Definition: The lowest quantity a supplier is willing to sell.

- Context: For 2000L tanks, many suppliers offer an MOQ of 1 set. However, ordering a full container load (FCL) rather than a single unit (LCL) often reduces the per-unit shipping cost and may unlock wholesale pricing tiers.

2. OEM vs. ODM

- OEM (Original Equipment Manufacturer): The supplier manufactures the tank based on your specific blueprints (e.g., custom port locations, specific dimensions to fit a facility). This often incurs tooling or setup fees.

- ODM (Original Design Manufacturer): You purchase the supplier’s existing design, potentially re-branded. This is the fastest and most cost-effective route for standard 2000L water storage.

3. Incoterms (Pricing Basis)

Quotations are meaningless without the associated Incoterm:

* EXW (Ex Works): Price includes only the tank at the factory door. Buyer handles all logistics.

* FOB (Free on Board): Supplier covers costs to get the tank onto the ship. Common for imports from Asia to US/EU.

* CIF (Cost, Insurance, and Freight): Supplier covers shipping to the destination port.

* DDP (Delivered Duty Paid): Supplier handles everything, including import duties and delivery to your facility. Highest upfront price but lowest risk.

4. Lead Time

- Production Time: For standard 2000L tanks, production is typically 7–15 days.

- Customization: Adding heating elements, insulation, or custom fittings can extend lead times by 2–4 weeks.

5. Certification Standards

For US and European markets, verify the following to ensure compliance and justify price premiums:

* FDA / 3A Sanitary Standards: Required for food/beverage applications.

* CE Marking: Mandatory for pressure equipment sold in the EEA (Europe).

* ISO 9001: Indicates the manufacturer adheres to quality management systems.

Navigating Market Dynamics and Sourcing Trends in the steel water tank 2000 ltr price Sector

Navigating Market Dynamics and Sourcing Trends in the 2000L Steel Water Tank Sector

The market for 2000-liter stainless steel (SS) water tanks is undergoing a significant shift, driven by strict hygiene standards in the USA and Europe, and the volatility of raw material costs. For B2B buyers, understanding the correlation between technical specifications—specifically steel grade and thickness—and final pricing is critical for accurate procurement forecasting.

Historical Context: The Shift to Stainless Steel

Historically, large-volume fluid storage relied heavily on concrete, galvanized steel, or high-density polyethylene (HDPE). While cost-effective, these materials presented long-term challenges regarding bacterial growth, UV degradation, and leaching.

The modern shift toward stainless steel (specifically 2000L capacities) is driven by the demand for “zero-maintenance” infrastructure. Unlike the periodic lining replacements required for concrete or the UV-cracking risks of plastic, stainless steel offers a permanent solution. This evolution has positioned the 2000L SS tank not just as a storage vessel, but as a compliance asset for industries adhering to FDA (USA) and HACCP (Europe) standards.

Market Dynamics: Decoding the Price Matrix

Pricing for 2000L tanks is rarely static. It is influenced by nickel market fluctuations and manufacturing complexity. Based on current sourcing data, buyers must navigate a wide price spectrum—ranging from basic storage units to complex industrial processing tanks.

1. Material Grade and Thickness

The primary driver of price variance is the steel composition.

* SS 304: The industry standard for potable water. It offers excellent corrosion resistance for standard environments.

* SS 316: Required for coastal areas (saline environments), pharmaceutical applications, or acidic liquid storage. This grade commands a premium (often 20-30% higher) due to the addition of molybdenum.

* Thickness: As noted in manufacturing specifications, wall thickness typically ranges from 0.5 mm to 2.0 mm. A 0.5 mm tank is suitable for static residential water storage, whereas industrial applications requiring pressure handling or mixing capabilities demand 1.5 mm to 2.0 mm thickness, significantly increasing the material cost and final price.

2. Configuration and Customization

Sourcing trends indicate a move away from “off-the-shelf” standard tanks toward customized fabrication.

* Basic Storage: Simple vertical tanks with standard inlets/outlets. (Lower price bracket).

* Process Tanks: Units equipped with heating jackets, emulsifying pumps, or agitators (as seen in recent trade listings). These units, often used for food or chemical processing, can range from $1,500 to over $8,000 depending on the complexity of the peripheral equipment.

Sourcing Trends for USA and European Buyers

When importing or sourcing 2000L tanks for Western markets, three distinct trends are shaping procurement strategies:

- Hygiene-First Design: Buyers are increasingly specifying “food-grade” finishes. This includes demand for smooth internal welds to prevent bacterial harborage and conical bottoms for complete drainage, ensuring compliance with strict health codes.

- Panel vs. Finished Tanks: To mitigate high shipping costs for large volumes (2000L+), there is a trend toward sourcing modular panel tanks (pricing often quoted per cubic meter). These allow for on-site assembly, bypassing the logistical challenges of shipping bulky, pre-fabricated vessels.

- Supplier Verification: With a mix of suppliers from China, the US, and India, B2B buyers are prioritizing “Trade Assurance” and verified manufacturer status over lowest-price bidding to ensure material authenticity (verifying actual 304/316 composition).

Sustainability and Lifecycle Costing

While the initial capital expenditure (CapEx) for a 2000L stainless steel tank is higher than plastic alternatives, the Total Cost of Ownership (TCO) appeals to sustainability-focused organizations.

- Recyclability: Stainless steel is 100% recyclable at the end of its lifecycle, aligning with EU circular economy mandates.

- Longevity: A properly maintained SS tank can last 20+ years without structural degradation.

- Toxicity: SS tanks eliminate the risk of microplastic leaching or chemical reaction with stored water, a key factor for sustainable building certifications (e.g., LEED).

Summary of Sourcing Considerations:

| Feature | Impact on Price | Recommended Application |

|---|---|---|

| Grade SS 304 | Baseline | Potable water, inland storage. |

| Grade SS 316 | High | Pharma, chemical, coastal regions. |

| Thickness <1mm | Low | Residential/Light Commercial gravity storage. |

| Thickness >1.5mm | High | Pressurized systems, mixing tanks, industrial use. |

| Customization | Very High | Heated jackets, agitators, emulsifiers. |

Frequently Asked Questions (FAQs) for B2B Buyers of steel water tank 2000 ltr price

Frequently Asked Questions (FAQs) for B2B Buyers of Steel Water Tank 2000 Ltr Price

1. What is the typical price range for a 2,000-liter stainless steel tank?

The price for a 2,000-liter (approx. 528 gallons) stainless steel tank varies significantly based on configuration.

* Basic Storage Tanks: Prices typically range from $1,500 to $3,500 per unit. These are standard vessels used for simple water storage without pressure requirements.

* Process/Mixing Tanks: Units equipped with agitators, heating jackets, or emulsifying pumps (as seen in Alibaba listings) range from $3,000 to $8,000+.

* Panel Tanks: Modular rectangular tanks may be quoted per cubic meter (e.g., $59–$120/m³), but total installation costs for a 2,000L volume often exceed single-vessel pricing due to assembly labor.

2. How does the stainless steel grade (304 vs. 316) impact the price?

Material selection is the primary cost driver.

* SS 304: The industry standard for potable water and general industrial use. It is the baseline for pricing.

* SS 316/316L: Contains molybdenum for higher corrosion resistance, essential for saline environments, pharmaceutical applications, or acidic liquid storage. Expect a 20% to 30% price premium over SS 304 tanks due to higher raw material costs.

3. Does wall thickness significantly affect the final quote?

Yes. Manufacturers offer thickness options typically ranging from 0.5 mm to 2.0 mm or higher.

* Thinner Walls (0.5–1.0 mm): Lower cost, suitable for static water storage with no internal pressure.

* Thicker Walls (1.5 mm+): Required for pressurized systems, vacuum applications, or tanks with heavy mixers. Increasing thickness from 1mm to 2mm can nearly double the material cost component of the tank.

4. What additional features commonly increase the base price of a 2,000L tank?

Beyond the steel shell, the following specifications will increase the final invoice:

* Jacketed Walls: For heating or cooling applications (e.g., electric heated mixing tanks).

* Agitation Systems: High-shear mixers or low-speed agitators.

* Conical Bottoms: Facilitates full drainage (common in food/beverage) but requires a stand/legs, adding to fabrication costs compared to flat-bottom tanks.

* Polishing: Food-grade or pharmaceutical-grade (mirror) finishes increase labor costs significantly.

5. How do shipping costs compare to the unit price for US and European buyers?

A 2,000-liter tank is voluminous but relatively lightweight, making it “cube out” before it “weighs out.”

* Freight: Shipping costs can range from 20% to 50% of the tank’s value if importing single units from Asia to the US or Europe due to the volume occupied in the container.

* Optimization: Buyers often purchase “nested” sizes (e.g., placing a 1,000L tank inside a 2,000L tank) or flat-pack panel tanks to optimize freight costs.

6. Are there hidden costs in the “per set” or “per piece” pricing listed on B2B platforms?

Yes. Listed prices (e.g., Alibaba ranges) are often FOB (Free on Board) prices. Buyers must calculate the Landed Cost, which includes:

* Ocean freight and insurance.

* Import duties and tariffs (steel tariffs vary by country of origin).

* Customs brokerage fees.

* Local inland transportation from the port to the facility.

7. How does the lifespan of stainless steel justify the price over plastic (poly) tanks?

While a 2,000L HDPE (plastic) tank is significantly cheaper upfront, stainless steel offers a lower Total Cost of Ownership (TCO) for industrial applications:

* Durability: Stainless steel lasts 20+ years, resists UV degradation, and withstands extreme temperatures.

* Hygiene: Zero bacteria growth and biofilm resistance (critical for food/pharma).

* Fire Resistance: Steel tanks are non-combustible, often lowering insurance premiums for facility storage.

8. What certifications should I request that might influence the price?

For US and European markets, compliance adds to the manufacturing overhead but ensures safety and legality:

* ASME (USA): Essential for pressure vessels. Stamped tanks command a premium.

* CE (Europe): Required for pressure equipment sold in the EEA.

* FDA/3-A Sanitary Standards: Required for food and beverage processing. Ensuring food-grade welds and finishes increases production time and cost.

Strategic Sourcing Conclusion and Outlook for steel water tank 2000 ltr price

Strategic Sourcing Conclusion and Market Outlook

Sourcing a 2000-liter stainless steel water tank represents a balance between immediate capital outlay and long-term operational resilience. As analyzed, pricing is not static; it fluctuates drastically based on technical specifications—ranging from approximately $250 USD (basic storage) to over $3,500 USD (sanitary mixing vessels).

Key Sourcing Takeaways

- Material Integrity: For US and European markets, prioritize SS304 for general potable water and SS316 for saline, chemical, or sterile environments. The premium for SS316 is a necessary investment to prevent premature corrosion.

- Wall Thickness & Durability: Entry-level pricing often reflects 0.5mm thickness. For industrial longevity, buyers should specify 1.5mm to 2mm, acknowledging that this will increase material costs by 30-40% but significantly extend service life.

- Landed Cost Reality: Due to the high volume-to-weight ratio of a 2000L vessel, freight costs can rival the FOB unit price. Buyers must calculate the Total Landed Cost, not just the factory gate price.

Future Outlook

Expect steel prices to remain volatile through 2025. Strategic buyers should move away from spot-buying and focus on suppliers who provide ASME (USA) or PED (Europe) certification. Ultimately, the lowest sticker price is often a false economy; the sourcing strategy must prioritize cost-per-year of service life.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.