Steel Water Tank 500 Ltr Price: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Steel Water Tank 500 Ltr Price

For industries requiring uncompromised hygiene and durability, the 500-liter stainless steel water tank is a critical asset. Whether utilized for pharmaceutical buffering, food and beverage processing, or industrial coolant expansion, stainless steel (SS) offers a lifecycle value that alternative materials cannot match. However, for procurement officers in the USA and Europe, determining an accurate market rate is increasingly complex.

The pricing landscape is volatile and specification-dependent. A cursory market analysis reveals a significant disparity: basic bulk storage units may list as low as $80–$120 (FOB) from high-volume exporters, while specialized vessels featuring agitators, pressure ratings, or 316-grade steel can exceed $1,500.

For B2B buyers, the “sticker price” is rarely the final cost. Variables such as material thickness, steel grade (304 vs. 316), and compliance with Western sanitary standards (CE, ISO) drastically alter the investment. A tank priced at ₹18,700 (~$225 USD) for a local market may not meet the regulatory or shipping requirements for international trade.

This guide cuts through the noise of global sourcing to provide a clear analysis of the steel water tank 500 ltr price. We will cover:

- Cost Drivers: How wall thickness, fabrication complexity, and steel grades impact pricing.

- Market Tiers: Differentiating between economical storage and pharmaceutical-grade pressure vessels.

- Sourcing Strategy: Navigating MOQs, freight logistics, and verifying supplier certifications for Western markets.

Top 10 Steel Water Tank 500 Ltr Price Manufacturers & Suppliers List

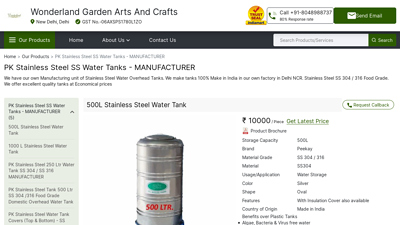

1. PK Stainless Steel SS Water Tanks – MANUFACTURER

Domain: thewonderlandwholesaler.com

Registered: 2024 (1 years)

Introduction: Get Best PriceCall Now. PK Stainless Steel Tank 500 Ltr SS 304 /316 Food Grade Domestic Overhead Water Tank. Rs 10,000 / Piece. PK Stainless Steel Tank 500 Ltr ……

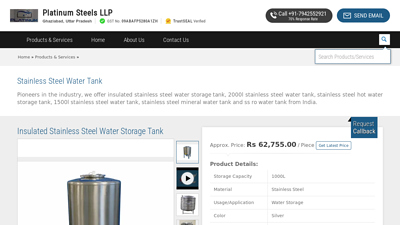

2. Insulated Stainless Steel Water Storage Tank

Domain: platinumsteels.com

Registered: 2023 (2 years)

Introduction: Platinum Steels LLP ; Insulated Stainless Steel Water Storage Tank. Rs 62,755.00 · Insulated Stainless Steel Water Storage Tank · 1000L · Water Storage ; 2000L ……

3. Home | Platinum Stainless Steel 500 ltr Water Tank

Domain: platinumwatertank.com

Registered: 2022 (3 years)

Introduction: Platinum steels products & tanks are anti-corrosive, highly durable, and Maintenance free. High quality stainless steel water tanks. Delivery 100% as per ……

Illustrative Image (Source: Google Search)

4. 500 Gallon Steel Vertical Water Storage Tank – Plastic-Mart

Domain: plastic-mart.com

Registered: 2004 (21 years)

Introduction: In stock 30-day returns500 Gallon Steel Vertical (866) 310-2556 ・ 500 Gallon Steel Vertical Water Storage Tank by Plastic Mart Manufacturer for only $3,778.57 ・ constructed of 304 ……

5. Vertical Stainless Steel Water Tank Prices | Karmod Plastic

Domain: karmodplastic.com

Registered: 2013 (12 years)

Introduction: Tank production is made in 15 different liters and tonnage ・ with Karmod expertise and quality assurance. View Detail 500 Liters ・ manufactured by Karmod ……

6. Stellar Pure – 5 Layer Stainless Steel Water Tank

Domain: sunstellar.in

Registered: 2020 (5 years)

Introduction: Sun Stellar offers the. Sun Stellar SS water containers are available in different capacities, including 500Ltr, Design Life of 15-20 Years and the Warranty ……

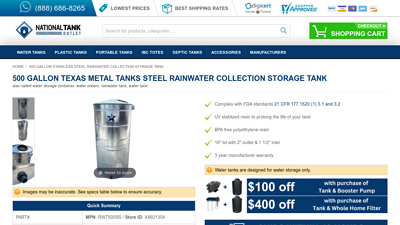

7. 500 Gallon Texas Metal Tanks Steel Rainwater Collection Storage …

Domain: ntotank.com

Registered: 2006 (19 years)

Introduction: In stock $1,250 delivery(888) 686-8265 Lowest Prices Best … Our price is lower than the manufacturer’s “minimum advertised price.” As a result, we cannot show you the price in catalog ……

Illustrative Image (Source: Google Search)

8. Aquasafe 500 Litre SS Water Tank (Price & Features) – RO Traders

Domain: rotraders.com

Registered: 2020 (5 years)

Introduction: Ans: The 500 Litre Aquasafe SS Water Tank costs Rs. 8500/- including GST. Transport charges are additional. The price may vary with respect to ……

Understanding steel water tank 500 ltr price Types and Variations

Understanding Steel Water Tank 500 Ltr Price: Types and Variations

When sourcing 500-liter steel tanks for B2B applications, price is heavily dictated by the specific configuration, material grade, and intended industrial use. While a basic storage tank may cost as little as $120, specialized process tanks with agitators or pressure capabilities can exceed $1,500.

Illustrative Image (Source: Google Search)

Below is a breakdown of the primary types of steel tanks available in the 500-liter capacity, outlining how design complexity impacts the final cost.

Comparative Overview

| Tank Type | Key Features | Typical Applications | Pros & Cons |

|---|---|---|---|

| Standard Vertical Storage (SS 304/316) | Food-grade finish, leakproof, corrosion-resistant, stackable options. | Potable water storage, F&B ingredient holding, light chemical storage. | Pros: Hygienic, low maintenance. Cons: Not suitable for high pressure. |

| Industrial Process/Mixing Tank | Integrated agitators/mixers, conical bottoms, often jacketed for temp control. | Pharmaceutical compounding, cosmetic mixing, chemical processing. | Pros: High functionality, precise control. Cons: High capital cost, complex installation. |

| Pressurized/Expansion Vessel | Heavy-gauge steel, certified for pressure (ASME/CE), sealed system. | HVAC expansion loops, thermal storage, boiler feed systems. | Pros: Handles thermal expansion/pressure. Cons: Heavy, requires safety certifications. |

| Galvanized Steel Tank | Zinc-coated carbon steel, corrugated or bolted design. | Fire suppression water, agricultural irrigation, non-potable industrial water. | Pros: Cost-effective, rugged. Cons: Prone to rust over time, not food-grade. |

1. Standard Vertical Stainless Steel Storage Tanks

Price Range: $150 – $400 USD

This is the most common category, represented by standard SKU items like the Waternotix SS series or basic Alibaba bulk units. These tanks are engineered for static storage under atmospheric pressure.

- Material Variations: Prices fluctuate based on the steel grade. SS 304 is the industry standard for water, while SS 316 commands a premium (approx. 20-30% higher) for superior resistance to chlorides and harsh chemicals.

- Design Factors:

- Hygiene: “Food grade” certifications and mirror-polished interiors prevent bacterial growth and contamination.

- Structure: Often includes a stand and upper lid. Higher-end models feature “stackable” designs to optimize warehouse space.

- Durability: Manufacturers often cite “100% leakproof” and “corrosion-less” warranties (typically 1 year) as key value drivers.

2. Industrial Process and Mixing Tanks

Price Range: $750 – $1,500+ USD

For B2B buyers in the pharmaceutical, cosmetic, or food processing sectors, a simple holding tank is insufficient. These 500L units are active processing machines rather than passive storage.

- Cost Drivers:

- Agitation Systems: The inclusion of motors, mixers, and agitators (for juices, milk, or chemicals) significantly increases the price.

- Geometry: Conical bottoms for complete drainage and movable caster wheels for facility mobility add to fabrication costs.

- Wall Thickness: These tanks often use thicker gauges (e.g., 2mm+) to withstand the vibration of mixing.

3. Pressurized and Thermal Expansion Tanks

Price Range: $160 – $800 USD

These tanks are critical components in closed-loop systems, such as HVAC or solar heating setups. Unlike storage tanks, they are designed to withstand internal pressure buildup.

- Design Factors:

- Internal Coils: “Double coil” variations (seen in solar applications) allow for heat exchange, pushing the price toward the $600–$800 range.

- Certifications: For USA and European markets, these vessels must meet specific safety standards (CE, ISO, or ASME). Compliance testing adds to the manufacturing overhead.

- Pressure Rating: A tank rated for 10 bar will cost significantly more than one rated for 3 bar due to the required steel thickness and weld quality.

4. Galvanized and Corrugated Steel Tanks

Price Range: $80 – $150 USD

When hygiene is not the priority, galvanized steel offers a budget-friendly alternative to stainless steel. These are typically used for “grey water” or industrial coolant expansion where food-grade certification is unnecessary.

- Cost Efficiency: Carbon steel is cheaper than stainless steel. The galvanization (zinc coating) provides basic rust protection but does not match the longevity or sanitation of SS 304/316.

- Assembly: In the 500L size, these may come as bolted units or welded cylinders. They are the entry-level option for cost-conscious facility managers needing bulk liquid storage without strict purity requirements.

Key Industrial Applications of steel water tank 500 ltr price

Key Industrial Applications of 500L Stainless Steel Water Tanks

When evaluating the steel water tank 500 ltr price for industrial procurement, it is essential to look beyond the initial capital expenditure and consider the operational versatility. A 500-liter (approx. 132-gallon) capacity acts as an ideal “buffer” size—large enough for significant batch processing but compact enough for movable skids and tight facility footprints.

In the US and European markets, where regulatory compliance (FDA, GMP, CE) is paramount, stainless steel (grades 304 and 316) is the material of choice for the following sectors:

Industry Application Matrix

| Industry Sector | Specific Applications | Operational Value Proposition |

|---|---|---|

| Food & Beverage | • Batch mixing (Juice, Milk, Edible Oils) • Ingredient buffering • Fermentation pilot batches |

Hygiene: Food-grade surfaces prevent bacterial growth and contamination. Thermal: Compatible with jacketed cooling/heating coils for pasteurization. |

| Pharmaceuticals & Cosmetics | • Solution preparation (Saline, Syrups) • Perfume & Ethanol storage • WFI (Water for Injection) storage |

Purity: 316L Steel ensures zero leaching or chemical reactivity. Compliance: Meets strict GMP and sanitary standards required in EU/USA. |

| Chemical Processing | • Coolant expansion tanks • Solvent & detergent mixing • Pressure vessels |

Resilience: Withstands high pressures and aggressive chemicals that degrade plastic tanks. Safety: Superior leakproof construction for hazardous liquids. |

| HVAC & Industrial Cooling | • Closed-loop buffer tanks • Thermal energy storage • Hydronic balancing |

Durability: High tolerance for rapid temperature fluctuations without structural fatigue or cracking. |

| Water Treatment | • RO (Reverse Osmosis) permeate storage • Ozone contact tanks |

Stability: Opaque steel blocks UV light, preventing algae growth common in translucent tanks. |

detailed Benefits Justifying the Investment

While the steel water tank 500 ltr price point is higher than polyethylene (plastic) alternatives, the ROI is justified through longevity, safety, and reduced downtime in industrial settings.

1. Uncompromised Hygiene and Cleanability

For sectors like food and pharma, the cost of contamination is catastrophic. As noted in product specifications, stainless steel tanks offer a “corrosion-less” environment with no bacterial growth.

* Surface Finish: High-quality steel tanks feature polished interiors that prevent biofilm accumulation.

* CIP Compatibility: These tanks can withstand harsh Clean-in-Place (CIP) chemicals and high-temperature steam sterilization, which would warp plastic alternatives.

2. Thermal and Pressure Versatility

Industrial processes often require temperature control. A standard 500L steel tank can be customized (or sourced) with features that justify a premium price tag:

* Temperature: Capable of handling boiling liquids (up to 100°C+) for cooking oils or hot water loops.

* Pressure: Unlike atmospheric plastic tanks, steel vessels can be engineered as pressure vessels (ASME/PED rated) for carbonation or pressurized filtration systems.

* Jacketing: Many 500L models allow for double-wall construction (cooling coils) to maintain precise liquid temperatures for milk or chemical reactants.

3. Modularity and Mobility

The 500-liter size is uniquely positioned for flexible manufacturing.

* Mobility: Many industrial units in this price range come equipped with castor wheels or skid mounts, allowing them to be moved between production lines (e.g., moving a batch of perfume from mixing to bottling).

* Agitation: Steel structural integrity supports heavy, top-mounted mixers and agitators without the sidewall flexing issues seen in polymer tanks.

4. Long-Term Durability (TCO)

In the US and European markets, the Total Cost of Ownership (TCO) is the primary metric.

* UV Resistance: Steel is impervious to UV radiation, allowing for outdoor installation without degradation.

* Impact Resistance: Steel withstands physical impacts in busy warehouse environments better than brittle plastics.

* Warranty: Premium manufacturers often back steel tanks with extended warranties (e.g., 1-year to lifetime on structural integrity), mitigating replacement costs.

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘steel water tank 500 ltr price’ & Their Solutions

3 Common User Pain Points for ‘Steel Water Tank 500 Ltr Price’ & Their Solutions

For B2B procurement managers in the USA and Europe, sourcing 500-liter stainless steel tanks involves navigating significant price disparities and technical specifications. Below are the three most common friction points during the purchasing process and how to resolve them.

1. Ambiguity in Price vs. Material Grade (304 vs. 316)

The Scenario:

A procurement officer finds listings for 500-liter stainless steel tanks ranging from $120 to over $1,200. The visual appearance of the tanks is nearly identical, leading to confusion regarding fair market value.

The Problem:

The “sticker price” rarely reflects the material composition, which is the primary cost driver. Lower-priced units (often under $200) usually utilize thinner gauges of SS 201 or SS 304, which are suitable for basic water storage but prone to corrosion in industrial environments. Higher-priced units utilize SS 316/316L, which offers superior resistance to chlorides and acids but increases raw material costs significantly.

The Solution:

* Define Application First: Specify SS 304 for standard potable water and SS 316 for saline environments, food processing, or chemical storage.

* Request Mill Certificates: Require material test certificates (MTC) to verify the steel grade and wall thickness (e.g., 0.8mm vs. 2.0mm).

* Compare Weight: If specs are unclear, compare the net weight of the tanks. A heavier tank almost always indicates thicker, more durable steel, justifying a higher price point.

Illustrative Image (Source: Google Search)

2. Hidden Logistics Costs & Volumetric Weight

The Scenario:

A buyer calculates the project budget based on the Ex-Works (EXW) or FOB price listed on platforms like Alibaba (e.g., $150/unit). Upon arrival, the landed cost has tripled.

The Problem:

500-liter tanks are high-volume, low-density cargo. While the unit price is low, freight carriers charge based on “volumetric weight” rather than actual weight. Furthermore, importing steel products into the USA or Europe often incurs specific tariffs and anti-dumping duties that are not reflected in the initial vendor quote.

The Solution:

* Request DDP Pricing: Ask suppliers for Delivered Duty Paid (DDP) quotes to see the full landed cost upfront.

* Explore Stackable Designs: Look for conical or tapered designs (as referenced in Alibaba listings) that allow tanks to nest inside one another during shipping, reducing freight volume by up to 50%.

* Source Local for Small Batches: For orders under 5 units, the freight savings from domestic suppliers often outweigh the lower unit cost of international imports.

3. Verification of Hygiene Standards & Leak-Proofing

The Scenario:

A facility manager purchases a “food-grade” 500L tank for a beverage processing line. After installation, the tank develops micro-leaks at the weld seams or shows signs of bacterial accumulation.

Illustrative Image (Source: Google Search)

The Problem:

“Food Grade” is often used loosely in marketing. Inexpensive tanks may use spot welding rather than full argon arc welding, leaving crevices where bacteria grow (biofilm). Additionally, lower-cost tanks often lack proper passivation, leading to immediate surface rust and contamination.

The Solution:

* Audit Weld Quality: Specify “sanitary welds” or “full penetration welds” in the RFQ. Ensure the interior is polished to a specific roughness average (Ra) to prevent bacterial adhesion.

* Demand Warranty & Testing: Prioritize suppliers offering a minimum 1-year warranty on leakage and corrosion (similar to the Waternotix standard).

* Verify Certifications: Ensure the manufacturer holds ISO 9001 certifications and, for US/EU markets, compliance with FDA or CE standards for pressure vessels if the tank is not for ambient storage.

Strategic Material Selection Guide for steel water tank 500 ltr price

Strategic Material Selection Guide for Steel Water Tank 500 Ltr Price

When analyzing the price variances in 500-liter steel water tanks—ranging from approximately $80 for basic galvanized units to over $1,000 for specialized pharmaceutical-grade vessels—material composition is the primary cost driver.

For B2B procurement in US and European markets, understanding the metallurgy is essential to balancing initial capital expenditure (CapEx) against long-term operational costs (OpEx).

Illustrative Image (Source: Google Search)

1. Stainless Steel 304 (Standard Food Grade)

Market Position: Mid-Range Pricing ($200 – $450)

This is the industry standard for potable water storage and food processing. As referenced in market data (e.g., Waternotix listings), these tanks are marketed as “Food Grade,” “100% Leakproof,” and “Corrosion Less.”

- Composition: Contains 18% chromium and 8% nickel.

- Price Justification: The pricing reflects the cost of nickel. It offers the best ROI for standard municipal water storage or neutral pH liquid storage.

- Durability: High resistance to oxidation; typically comes with warranties ranging from 1 to 5 years depending on wall thickness.

2. Stainless Steel 316 (Marine/Chemical Grade)

Market Position: Premium Pricing ($450 – $800+)

Often listed in global marketplaces (e.g., Alibaba) alongside higher price tags, 316-grade steel is required for harsh environments or aggressive fluids.

Illustrative Image (Source: Google Search)

- Composition: Adds 2-3% molybdenum to the standard 304 alloy.

- Price Justification: The addition of molybdenum significantly increases raw material costs but provides necessary resistance to chlorides, saline environments, and acidic solutions.

- Application: Essential for coastal facilities (salt air corrosion) or processing plants involving chemical mixing. Using 304 grade in these environments results in premature pitting, negating any initial price savings.

3. Galvanized and Carbon Steel

Market Position: Budget/Industrial Pricing ($80 – $200)

Market analysis shows 500L tanks in this category at the lowest price floor. These are typically corrugated or bolted designs intended for non-potable applications.

- Composition: Carbon steel coated with a layer of zinc to prevent rusting.

- Price Justification: Lower manufacturing and raw material costs.

- Trade-off: The zinc coating eventually sacrifices itself. Once breached, corrosion is rapid. These tanks often require internal liners (PVC or EPDM) to store water safely, which adds to the maintenance budget and complexity.

4. Specialized Configurations (Agitated/Pressure Vessels)

Market Position: High-End Industrial ($1,000+)

While the volume remains 500 liters, the price spikes when the “tank” becomes a “processing vessel.”

Illustrative Image (Source: Google Search)

- Features: As seen in industrial listings, these include double coils for cooling/heating, agitators/mixers, and pressure-rated walls.

- Material implication: Requires thicker gauge steel (often 3mm+) and certified welding to withstand pressure, significantly driving up the price per unit.

Comparative Analysis: Material vs. Price Impact

The following table correlates material grade with expected performance and pricing tiers for a standard 500-liter capacity unit.

| Material Grade | Corrosion Resistance | Primary Application | Maintenance Profile | Relative Price Impact |

|---|---|---|---|---|

| Galvanized Steel | Low (Dependent on coating) | Irrigation, Fire Water, Non-Potable | High (Liner checks, coating repair) | $ (Low) |

| SS 304 | High (Oxidation resistant) | Potable Water, Food & Beverage | Low (Periodic cleaning) | $$ (Mid) |

| SS 316 | Very High (Chloride resistant) | Chemical Processing, Coastal/Marine | Minimal | $$$ (High) |

| Coated/Enamel | Medium-High | Wastewater, Industrial Effluent | Medium (Chip repair sensitive) | $$ (Mid-High) |

Procurement Recommendation: For standard potable water storage in non-coastal US or European facilities, SS 304 represents the optimal balance of price and longevity. For industrial processing or saline environments, SS 316 is the mandatory specification to avoid rapid asset depreciation.

In-depth Look: Manufacturing Processes and Quality Assurance for steel water tank 500 ltr price

In-depth Look: Manufacturing Processes and Quality Assurance

The price variance in 500-liter steel water tanks—ranging from roughly $80 for basic galvanized models to over $1,000 for specialized pharmaceutical-grade vessels—is directly attributable to the manufacturing rigor and quality assurance protocols employed. For buyers in the USA and Europe, understanding these steps is critical to validating vendor quotes and ensuring compliance with sanitary standards.

1. Material Selection and Preparation

The manufacturing cost baseline is established at the raw material stage.

* Grade Selection: “Food grade” typically refers to SS 304, the industry standard for potable water. However, SS 316 is used for higher corrosion resistance (saline environments) or chemical storage, commanding a 20-30% price premium. Cheaper alternatives often use galvanized steel, which offers lower longevity.

* Sheet Thickness (Gauge): Manufacturers offer varying thickness options. A 500L tank requires sufficient structural integrity to withstand hydrostatic pressure without buckling. Thicker gauges increase raw material costs but extend the tank’s lifespan and warranty coverage.

* Preparation: Steel sheets are cut using laser or plasma cutters for precision edges, ensuring tight fit-up for welding.

2. Forming and Fabrication

The transformation of raw sheets into a 500L vessel involves specific forming techniques that impact structural rigidity.

* Corrugation: For cylindrical tanks, the body sheets are often corrugated. This process significantly increases the strength-to-weight ratio, allowing for a durable tank that uses less material, optimizing the price-point.

* Deep Drawing: Top lids and bottom cones are often formed via deep drawing presses. This creates a seamless, hygienic curve that prevents water stagnation and bacterial growth—a key feature cited in premium “corrosion-less” product lines.

3. Assembly and Welding

The integrity of the “leakproof” claim relies entirely on the welding process.

* Seam Welding: Automated seam welders are used for the vertical and circumferential joints. This ensures a consistent bead and minimizes heat-affected zones (HAZ) where corrosion often starts.

* TIG Welding (GTAW): Fittings, outlets, and stands (often included with 500L units) are typically manually TIG welded. High-end manufacturers use argon purging to prevent oxidation on the inside of the weld, a critical step for food-grade compliance.

* Defect Prevention: Poor welding leads to micro-cracks. Premium pricing often reflects skilled labor and slower welding speeds to ensure zero porosity.

4. Surface Treatment and Finishing

Post-fabrication treatment differentiates a sanitary tank from an industrial container.

* Pickling and Passivation: This is a non-negotiable step for stainless steel. It removes weld discoloration and iron contamination, restoring the steel’s passive oxide layer to prevent rust.

* Polishing: Interior surfaces may be polished to a specific roughness average (Ra). Smoother surfaces are easier to clean and resist biofilm formation, a requirement for food and beverage applications in the EU and US.

5. Quality Assurance (QC) and Testing

To justify a warranty (e.g., 1-year or longer), manufacturers must validate the tank before shipping.

Illustrative Image (Source: Google Search)

| QC Test | Method | Purpose | Impact on Price |

|---|---|---|---|

| Hydrostatic Test | Filling tank with water for 24+ hours. | Verifies structural integrity and leak-proof status. | High (Labor/Time intensive). |

| Dye Penetrant | Applying dye to weld seams. | Detects surface cracks invisible to the naked eye. | Moderate. |

| PMI Testing | Positive Material Identification gun. | Verifies the steel grade (e.g., confirming 304 vs. 201). | Moderate (Equipment cost). |

| Dimensional Check | Laser or caliper measurement. | Ensures capacity is exactly 500L and fittings match specs. | Low. |

6. Standards and Certifications

For the US and European markets, adherence to international standards is a primary price driver.

* ISO 9001: Indicates the manufacturer has a consistent quality management system.

* CE Marking: Mandatory for tanks sold within the European Economic Area, certifying conformity with health, safety, and environmental protection standards.

* FDA / NSF/ANSI 61: For tanks intended for potable water in the US, materials must comply with FDA regulations or NSF standards for drinking water system components.

Buyer Note: When comparing the price of a 500L steel tank, verify if the quote includes the cost of the stand, lid, and necessary outlets, as well as the specific grade of steel used. A lower upfront price often signals the omission of pickling/passivation or the use of thinner, non-certified steel.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel water tank 500 ltr price’

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel water tank 500 ltr price’

When sourcing 500-liter steel water tanks for US and European markets, the initial list price is often misleading. The following checklist ensures you evaluate the “Total Landed Cost” and secure a product that meets strict regulatory standards (CE, ISO, NSF).

Step 1: Define Technical Specifications (The “Apples-to-Apples” Check)

Price variations between $80 and $1,000+ on platforms like Alibaba are usually due to material specifications. Define these parameters before requesting quotes:

Illustrative Image (Source: Google Search)

- Material Grade:

- SS304: Standard for potable water and food-grade applications.

- SS316: Required for saline environments or harsh chemical storage (approx. 20-30% higher cost).

- Galvanized Steel: Lower cost, suitable for non-potable agriculture/industrial use.

- Wall Thickness: Specify gauge (e.g., 0.8mm vs. 2.0mm). Thinner tanks are cheaper but prone to denting during transit and failure under pressure.

- Configuration:

- Vertical vs. Horizontal: Vertical tanks are generally cheaper to manufacture.

- Features: Inclusion of stands, manholes, agitators (for mixing tanks), and level indicators will increase the unit price.

Step 2: Supplier Verification & Compliance

For US/EU import, verification is critical to avoid customs seizure or liability issues.

- Certifications:

- Europe: Request CE marking compliance for pressure vessels.

- USA: Verify NSF/ANSI 61 certification if the tank is for potable water.

- General: ISO 9001 for quality management systems.

- Production Capability: Check if the supplier manufactures the tank or assembles it. Manufacturers offer better pricing flexibility on bulk orders (MOQ > 2 units).

- Warranty: Look for a minimum 1-year warranty on the tank body (excluding consumables like seals), similar to the standard offered by retailers like Waternotix.

Step 3: Analyze the Price Structure

Break down the quoted price to understand the true cost.

| Cost Component | Considerations |

|---|---|

| EXW (Ex Works) | The raw price at the factory door. Cheapest on paper, but you bear all logistics risks. |

| FOB (Free on Board) | Includes transport to the port of export. Preferred for accurate comparison between Asian suppliers. |

| MOQ Impact | Suppliers often list prices based on container loads. A “Sample Price” for 1 unit may be 2-3x the wholesale price. |

| Accessories | Ensure lids, stands, and outlet valves are included in the base price, not added as line items later. |

Step 4: Quality Assurance (QA) Checklist

Defects in steel tanks (micro-leaks, corrosion) are costly to rectify post-delivery.

- Leak Testing: Require a hydrostatic leak test report for every unit before shipment.

- Weld Quality: Specify “pickling and passivation” treatment for stainless steel welds to prevent corrosion points.

- Material Verification: Request a Positive Material Identification (PMI) test to prove the steel grade (e.g., confirming it is genuine 304 SS, not 201 SS).

Step 5: Calculate Logistics & Landed Cost

Steel tanks are high-volume, low-weight freight (“cubing out” a container).

- Stackability: Confirm if the tanks are designed to be stacked (nestable) to save shipping volume. Non-stackable tanks significantly increase freight cost per unit.

- Packaging: Ensure tanks are crated or palletized to prevent denting. Loose loading reduces shipping costs but increases damage rates.

- Tariffs:

- USA: Check current Section 301 tariffs on Chinese steel products.

- Europe: Verify anti-dumping duties on imported steel products.

Summary Price Benchmarking (Estimated FOB)

- Economy (Galvanized/Thin SS): $80 – $150 USD

- Standard (SS304, Food Grade): $160 – $350 USD

- Premium (SS316, Pressure/Mixing): $600 – $1,200+ USD

Comprehensive Cost and Pricing Analysis for steel water tank 500 ltr price Sourcing

Comprehensive Cost and Pricing Analysis for 500L Steel Water Tank Sourcing

When sourcing 500-liter steel water tanks for the US or European markets, buyers must analyze the Total Cost of Ownership (TCO), not just the ex-works unit price. Prices fluctuate significantly based on steel grade (304 vs. 316), wall thickness, and intended application (sanitary storage vs. industrial pressure vessels).

1. Market Price Benchmarks (FOB China/India)

The following price bands reflect current B2B market rates based on supplier data from major sourcing platforms.

| Category | Specifications | Price Range (USD/Unit) | Typical MOQ |

|---|---|---|---|

| Economy Grade | Galvanized steel or thin-gauge SS 201; non-potable use; simple corrugated design. | $80 – $120 | 2–5 Units |

| Standard Commercial | SS 304 (Food Grade); 1.0mm–1.5mm thickness; vertical storage; includes lid/stand. | $160 – $300 | 1–5 Units |

| Industrial / Sanitary | SS 316; Polished finish; pressure-rated; often includes agitators or double coils. | $600 – $1,500 | 1 Unit |

Note on Retail vs. Wholesale: Single-unit retail prices for standard 500L SS 304 tanks (e.g., comparable to Waternotix listings) typically hover around $220–$260. Sourcing directly from manufacturers (e.g., via Alibaba) offers significant savings but requires navigating logistics costs.

2. Cost Breakdown Structure

Understanding the cost drivers allows for better negotiation with suppliers.

Illustrative Image (Source: Google Search)

A. Raw Materials (40% – 50% of Cost)

- Steel Grade: The primary cost driver. Stainless Steel 304 is the industry standard for potable water. SS 316 (marine grade) costs approximately 20-30% more but is required for saline environments or harsh chemical storage.

- Thickness: Suppliers often list a base price for 0.8mm thickness. Increasing to 1.5mm or 2.0mm for durability significantly impacts raw material weight and cost.

- Accessories: Lids, stands, and outlet valves (as seen in retail kits) add 5-10% to the bill of materials.

B. Manufacturing & Labor (20% – 30% of Cost)

- Welding Quality: “100% Leakproof” guarantees require TIG welding and rigorous QA testing (hydrostatic testing). Cheap alternatives often use spot welding or sealants that degrade.

- Finishing: Mirror polishing or pickling (to prevent corrosion/bacterial growth) requires skilled labor.

- Certification: CE, ISO, or food-grade compliance certifications add overhead to the manufacturing process but are essential for US/EU regulatory adherence.

C. Logistics & Freight (20% – 30% of Cost)

- Volumetric Weight: A 500L tank is bulky but lightweight. You are paying for “shipping air” unless the tanks are designed to stack or nest.

- Crating: Steel tanks are prone to denting. Proper wooden crating is non-negotiable for international transit, adding to the unit cost.

3. Strategic Cost Reduction Tips

To optimize landed costs when importing to the USA or Europe:

- Prioritize Stackable Designs: Look for “Stackable Design” or conical shapes (nestable). Shipping fully assembled cylindrical tanks drastically increases freight cost per unit. If nesting isn’t possible, fill the tanks with smaller components (e.g., valves, pipes) during shipping to utilize the empty volume.

- Select the Right Grade: Do not over-specialize. For standard potable water storage, SS 304 is sufficient. Only pay the premium for SS 316 if the tank will hold corrosive liquids or be located in coastal salt-air environments.

- Negotiate “Ex-Works” vs. DDP: While DDP (Delivered Duty Paid) is easier, it is often inflated. For orders exceeding 10 units, manage your own freight (FOB) to control import duties and tariff classifications (HS Codes), particularly regarding steel tariffs in the US.

- Check Warranty Terms: A lower upfront price often hides poor quality. Ensure the supplier offers at least a 1-year warranty on leakage and corrosion (similar to retail standards) to avoid replacement costs.

Alternatives Analysis: Comparing steel water tank 500 ltr price With Other Solutions

Alternatives Analysis: Comparing Steel Water Tank 500 Ltr Price With Other Solutions

When evaluating the steel water tank 500 ltr price for B2B procurement, it is essential to contextualize the initial capital expenditure (CapEx) against alternative materials. While stainless steel (SS) often commands a premium, its value proposition shifts when analyzed against the Total Cost of Ownership (TCO), hygiene requirements, and durability.

The following analysis compares 500L Stainless Steel tanks against their two most common market alternatives: High-Density Polyethylene (HDPE) and Galvanized Steel.

Comparative Price and Performance Matrix

The table below outlines average market pricing (USD/EUR) and technical characteristics for 500-liter capacities.

Illustrative Image (Source: Google Search)

| Feature | Stainless Steel (304/316) | High-Density Polyethylene (HDPE) | Galvanized Steel |

|---|---|---|---|

| Price Range (500L) | $220 – $800+ | $100 – $250 | $150 – $450 |

| Primary Use Case | Food/Pharma, Potable Water, Chemical | Agriculture, Residential, Rainwater | Fire Water, Industrial Non-Potable |

| Corrosion Resistance | Excellent (Native) | High (Non-reactive) | Moderate (Relies on Zinc coating) |

| Hygiene/Purity | Food Grade (No leaching) | Moderate (Risk of biofilm/algae) | Low (Requires internal liners) |

| Lifespan | 20+ Years | 10–15 Years | 15–20 Years (with maintenance) |

| Maintenance | Low (Easy cleaning) | Low | Moderate (Coating checks required) |

> Note on Pricing: Stainless steel pricing varies significantly based on grade (304 vs. 316) and configuration (vertical storage vs. pressure vessels). Basic storage units align with the lower end ($220 range), while specialized mixing or pressure tanks (as seen on Alibaba) reach upwards of $1,000.

Analysis: Stainless Steel vs. HDPE (Plastic)

HDPE tanks represent the lowest entry cost for 500L storage. However, for industrial and commercial applications in the USA and Europe, the price gap reflects a disparity in performance.

- Cost Efficiency: HDPE offers a 40–60% reduction in upfront cost compared to stainless steel.

- Durability Factors: While HDPE is corrosion-proof, it is susceptible to UV degradation and thermal expansion. Over time, plastic tanks in outdoor environments may become brittle.

- Hygiene & Safety: As highlighted in the reference data (Waternotix), stainless steel is “100% leakproof,” “corrosion-less,” and prevents bacterial growth. Conversely, HDPE surfaces can develop biofilm and are difficult to sanitize to pharmaceutical or food-grade standards.

- Verdict: Choose HDPE for non-critical, temporary, or agricultural storage where budget is the primary driver. Choose Stainless Steel for potable water, food processing, or environments requiring sterile conditions.

Analysis: Stainless Steel vs. Galvanized Steel

Galvanized steel is often viewed as the direct industrial alternative to stainless steel, utilizing a zinc coating to prevent rust.

- Cost Efficiency: Galvanized tanks typically sit 20–30% cheaper than 304 Stainless Steel.

- Durability Factors: The protective zinc layer on galvanized tanks eventually wears away, leading to rust, particularly at joints and bolt points. This necessitates the use of internal PVC or EPDM liners, which add to long-term maintenance costs.

- Structural Integrity: Both materials offer high structural strength, unlike plastic. However, stainless steel provides this strength without the risk of heavy metal leaching or lining failures.

- Verdict: Galvanized steel is a viable cost-saving measure for fire suppression systems or raw water storage where purity is not a KPI. For applications where water quality cannot be compromised, the premium for Stainless Steel is offset by the elimination of liner replacements and corrosion repairs.

Conclusion on ROI

While the steel water tank 500 ltr price is higher initially, the investment is justified for B2B buyers prioritizing longevity and purity. Data indicates that a basic SS storage tank (approx. $225) eliminates the recurring replacement costs associated with plastic and the maintenance labor associated with galvanized alternatives.

Illustrative Image (Source: Google Search)

Essential Technical Properties and Trade Terminology for steel water tank 500 ltr price

Essential Technical Properties and Trade Terminology

When analyzing the price of a 500-liter (approx. 132 gallon) steel water tank, buyers must distinguish between base consumer models and industrial-grade vessels. The following technical specifications and trade terms directly influence the unit cost and landed price for US and European markets.

Key Technical Properties Influencing Price

Material composition and fabrication standards are the primary cost drivers. A basic 500L storage tank differs significantly in price from a pressurized or sanitary vessel.

1. Stainless Steel Grades (AISI Standards)

- 304/304L (Standard Food Grade): The baseline for potable water storage. It offers excellent corrosion resistance for standard water chemistry.

- 316/316L (Marine/Pharmaceutical Grade): Contains molybdenum for superior resistance to chlorides and acidic environments.

- Price Impact: 316-grade tanks typically command a 20–30% premium over 304-grade due to higher raw material costs.

2. Wall Thickness and Pressure Ratings

- Gauge/Millimeters: 500L tanks generally range from 0.8mm to 2.0mm thickness. Thicker walls increase durability and lifespan but raise shipping weight and material costs.

- Pressure vs. Atmospheric:

- Atmospheric Tanks: Designed for static storage (gravity flow). Lower cost.

- Pressure Vessels: Engineered to withstand internal pressure (e.g., expansion tanks, buffer tanks). Requires ASME (USA) or PED (Europe) certification.

- Price Impact: Pressure vessels are significantly more expensive due to required reinforced welding, thicker steel, and mandatory testing.

3. Construction and Finish

- Welding Quality: Seamless TIG welding prevents bacterial growth and leaks.

- Surface Finish:

- 2B (Mill Finish): Standard industrial look.

- Mirror/Polished (Sanitary): Required for food/beverage/pharma to prevent contamination.

- Corrugated vs. Smooth: Corrugated galvanized steel is often cheaper for bulk storage, while smooth stainless is standard for hygiene.

4. Configuration and Accessories

- Orientation: Vertical (space-saving) vs. Horizontal (low clearance).

- Integrated Components:

- Agitators/Mixers: For processing applications (e.g., mixing juices or chemicals).

- Jacketing: Double-walled coils for heating or cooling contents.

- Skids/Stands: Fixed legs or mobile casters for portability.

Trade Terminology for Procurement

Understanding these terms is essential for negotiating contracts and calculating the Total Cost of Ownership (TCO).

| Term | Definition | Context for 500L Tanks |

|---|---|---|

| MOQ | Minimum Order Quantity | Manufacturers often set MOQs (e.g., 2 units or 1 set) to justify production runs. Lower MOQs often result in a higher per-unit price. |

| OEM | Original Equipment Manufacturer | The supplier manufactures the tank based on your specific engineering drawings (e.g., custom port locations, specific dimensions). |

| ODM | Original Design Manufacturer | You purchase a pre-designed tank from the supplier’s catalog but rebrand it with your logo/labeling. |

| FOB | Free On Board | The seller pays costs to load the goods onto the ship. The buyer pays for ocean freight and insurance. Common in Asian sourcing. |

| EXW | Ex Works | The price of the tank at the factory door. The buyer bears all shipping and export costs. This appears as the lowest price but has the highest logistical burden. |

| CIF | Cost, Insurance, and Freight | The seller pays costs, freight, and insurance to the destination port. Useful for simplified logistics but may hide inflated freight margins. |

Regulatory Compliance (USA & Europe)

For B2B buyers in Western markets, compliance is non-negotiable and affects pricing tiers:

Illustrative Image (Source: Google Search)

- NSF/ANSI 61 (USA): Certification required for water treatment and drinking water components.

- FDA Compliance (USA): Mandatory for food and beverage applications (requires food-grade steel and sanitary welds).

- CE Marking (Europe): Indicates conformity with health, safety, and environmental protection standards within the EEA.

- ISO 9001: Verifies the manufacturer’s quality management system, ensuring consistent defect-free production (e.g., leak-proof guarantees).

Navigating Market Dynamics and Sourcing Trends in the steel water tank 500 ltr price Sector

Navigating Market Dynamics and Sourcing Trends in the Steel Water Tank (500 Ltr) Sector

The 500-liter stainless steel tank segment occupies a critical niche in industrial and commercial procurement. Large enough for SME production lines (micro-breweries, cosmetics, food processing) yet compact enough for modular installation, this capacity class is subject to specific price volatility and sourcing shifts.

For buyers in the USA and Europe, understanding the divergence between raw material costs and value-added fabrication is essential for accurate forecasting.

Market Dynamics: Analyzing the Price Spectrum

The pricing for 500-liter steel tanks is rarely static. It fluctuates based on alloy grade, fabrication complexity, and intended application. Data from major B2B platforms indicates a significant price disparity driven by technical specifications rather than volume alone.

Price Determinants:

- Material Grade (304 vs. 316): Basic water storage often utilizes 304-grade stainless steel. However, sectors requiring high corrosion resistance (pharmaceuticals, saline processing) demand 316-grade, which commands a premium of 20–30% due to molybdenum content.

- Fabrication Complexity:

- Basic Storage: Simple vertical tanks with standard welding and minimal fittings range from $80 to $300 USD (FOB).

- Process Tanks: Units equipped with agitators, heating/cooling jackets (double coils), and pressure capabilities range from $750 to $1,500 USD.

- Volumetric Efficiency: While a 500L tank is a standard SKU, shipping costs per unit are higher compared to flat-pack corrugated options. Stackable designs (as seen in recent listings) are becoming a premium feature to mitigate logistics costs.

Comparative Price Benchmarks (Global Sourcing)

| Tank Type | Specification Highlights | Price Range (USD)* | Target Industry |

|---|---|---|---|

| Basic Storage | Single wall, 304 SS, Standard Manhole | $120 – $300 | Agriculture, Residential Buffer |

| Sanitary/Food | 304/316 SS, Polished finish, Conical bottom | $350 – $800 | F&B, Micro-dairy |

| Process/Mixing | Agitator included, Jacketed, Pressure rated | $1,000 – $1,500 | Cosmetics, Chemical Dosing |

| Corrugated | Galvanized steel, Bolt-assembly | $80 – $120 | Irrigation, Fire Water |

*Based on current B2B listings (e.g., Alibaba) and adjusted for single-unit to low-MOQ sourcing.

Sourcing Trends: Shifts in the Supply Chain

Procurement strategies for US and European buyers are shifting from purely cost-driven models to resilience-focused sourcing.

-

The “China Plus One” Strategy:

While China remains the dominant supplier for bulk stainless steel vessels (offering MOQs as low as 2 pieces), Western buyers are increasingly diversifying. There is a rising trend of sourcing typically higher-margin, pressure-rated vessels from domestic fabricators or near-shore partners (Mexico/Eastern Europe) to ensure compliance with ASME or PED (Pressure Equipment Directive) standards, while relegating simple storage tanks to low-cost Asian markets. -

Standardization of “Ready-to-Ship” Units:

Suppliers are moving away from custom-fabricating every 500L order. Retail-ready units (like those seen from suppliers such as Waternotix) with pre-installed outlets, stands, and lids are becoming common. These “plug-and-play” solutions reduce lead times and installation labor, justifying a higher per-unit price point (approx. $220–$250 retail equivalent) compared to raw industrial tanks.

Illustrative Image (Source: Google Search)

-

Verification and Compliance:

With stricter regulations in the EU and USA regarding water hygiene, verified supplier badges, ISO certifications, and Trade Assurance mechanisms are now non-negotiable for B2B transactions. Buyers are prioritizing suppliers who offer food-grade certification (FDA/EU compliance) over the lowest bidder.

Sustainability and Lifecycle History

The transition from galvanized steel to stainless steel represents a historical shift toward sustainability and total cost of ownership (TCO).

- Historical Context: Historically, small-volume storage relied on galvanized steel or concrete. While cheap, galvanized tanks were prone to corrosion and bacterial buildup, leading to frequent replacements. The 500L stainless steel market emerged as fabrication costs dropped, making sterile storage accessible to smaller enterprises.

- The Sustainability Advantage:

- Recyclability: Unlike plastic (poly) tanks which eventually degrade and contribute to landfill waste, stainless steel tanks are 100% recyclable at the end of their lifecycle.

- Longevity: A high-quality 304/316 SS tank has a lifespan of 20+ years with minimal maintenance.

- Hygiene: Modern tanks feature “corrosion-less” properties and light-blocking designs that prevent algae growth. This reduces the chemical load required for water treatment, aligning with corporate ESG (Environmental, Social, and Governance) goals.

Strategic Takeaway: When evaluating the 500L steel tank market, buyers must look beyond the sticker price. A $150 tank may incur higher freight and shorter lifespans, whereas a $300+ unit with food-grade certification and stackable design offers better long-term value and regulatory compliance.

Frequently Asked Questions (FAQs) for B2B Buyers of steel water tank 500 ltr price

Frequently Asked Questions (FAQs) for B2B Buyers

1. What is the typical price range for a 500-liter stainless steel water tank in the wholesale market?

The price varies significantly based on specifications. Basic potable water storage tanks typically range from $120 to $350 USD per unit (FOB). However, specialized industrial tanks featuring pressure vessels, agitators, or pharmaceutical-grade finishes can range from $750 to $1,500 USD.

2. How does the grade of stainless steel (304 vs. 316) impact the unit price?

Material selection is a primary cost driver.

* SS 304: The industry standard for general water storage and food-grade applications. It offers a balance of corrosion resistance and cost-effectiveness.

* SS 316: Contains molybdenum for superior resistance to chlorides and saline environments. Expect a 20-30% price premium over SS 304. Buyers in coastal regions or chemical processing sectors should calculate this into their budget for longevity.

3. How do design features like stackability affect landed costs for US and European buyers?

Shipping volume often drives cost more than weight in international logistics. “Stackable” or “nestable” tank designs allow for higher density loading in standard shipping containers. Opting for stackable models can reduce freight costs per unit by 15-25%, significantly lowering the final landed cost compared to rigid, pre-assembled cylindrical tanks.

4. What certifications are critical when sourcing tanks for the US and European markets?

To ensure compliance and avoid customs seizures or liability:

* Europe: Look for CE marking (indicating conformity with health, safety, and environmental protection standards) and ISO 9001 for manufacturing quality.

* USA: Ensure the steel is Food Grade (compliant with FDA regulations) if intended for potable water or consumables.

* General: Verify pressure vessel certifications (e.g., ASME) if the tank will operate under pressure, as standard storage tanks are not rated for pressurized use.

5. How do Minimum Order Quantities (MOQs) influence the price per liter?

Suppliers often set MOQs to offset setup and handling costs.

* Low Volume (2–5 units): Often subject to retail or “sample” pricing, which can be 40% higher.

* Bulk Volume (Container Load): Unlocks wholesale pricing.

* Price Break: Significant unit cost reductions usually occur at the 20ft and 40ft container thresholds due to optimized logistics.

6. What is the difference in cost between a standard storage tank and a tank with an agitator/mixer?

The addition of mechanical components changes the classification from “storage” to “processing.” A standard 500L storage tank may cost $150, whereas a tank fitted with a mixer/agitator, motor mount, and baffles often starts at $1,250. Ensure your Request for Quotation (RFQ) clearly distinguishes between static storage and mixing requirements.

7. Beyond the FOB price, what hidden costs should procurement teams forecast?

When importing steel tanks, calculate the Total Cost of Ownership (TCO) by including:

* Tariffs & Duties: Steel imports often face specific anti-dumping duties in the US and EU.

* Inland Freight: Last-mile delivery for bulky items is costly.

* Fittings & Accessories: Base prices often exclude lids, stands, valves, and level indicators. Confirm if these are included or priced separately (e.g., specialized stands can add $50–$100 per unit).

8. How does the lifespan of stainless steel compare to plastic alternatives regarding ROI?

While a plastic (polyethylene) tank has a lower upfront cost, stainless steel tanks offer a lifespan of 20+ years with resistance to UV degradation, algae growth, and fire. For B2B applications requiring hygiene and durability, the annualized cost of stainless steel is often lower than plastic, which may require replacement every 7–10 years in outdoor or industrial settings.

Strategic Sourcing Conclusion and Outlook for steel water tank 500 ltr price

Strategic Sourcing Conclusion: Navigating 500L Steel Tank Costs

Sourcing 500-liter stainless steel tanks requires balancing upfront unit costs against long-term operational resilience. As evidenced by current market data, the price spectrum is vast, driven primarily by material grade (304 vs. 316), wall thickness, and specialized features like agitators or pressure ratings.

While basic galvanized or standard storage units are available via wholesale channels for as low as $80–$300, specialized industrial vessels often range between $750 and $1,500. For B2B buyers in the USA and Europe, the “sticker price” is only one component of the total landed cost.

Key Procurement Takeaways

- Verify Material Grade: Ensure strictly certified SS 304 or 316 for food-grade applications to avoid contamination risks cited in cheaper models.

- Factor Volumetric Freight: Due to the tank’s bulk, shipping costs can exceed the unit price on low-volume orders.

- Lifecycle Value: Units with 1-year+ warranties and corrosion-resistant engineering offer better ROI than rock-bottom generic options.

| Tank Category | Price Range (Est.) | Ideal Application |

|---|---|---|

| Basic Bulk Storage | $80 – $300 | Irrigation, non-potable storage |

| Certified Food-Grade | $225 – $400 | Potable water, residential/commercial |

| Process/Pressure Vessels | $750 – $1,500+ | HVAC, chemical mixing, pharmaceutical |

Outlook: Prices are expected to track with raw steel and nickel indices. Buyers should lock in supplier contracts that guarantee material certification to mitigate compliance risks in regulated markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.