The 5 Best Calculate Cost Of 3D Printing Calculators of 2025 (Revie…

Finding the Best Calculate Cost Of 3D Printing: An Introduction

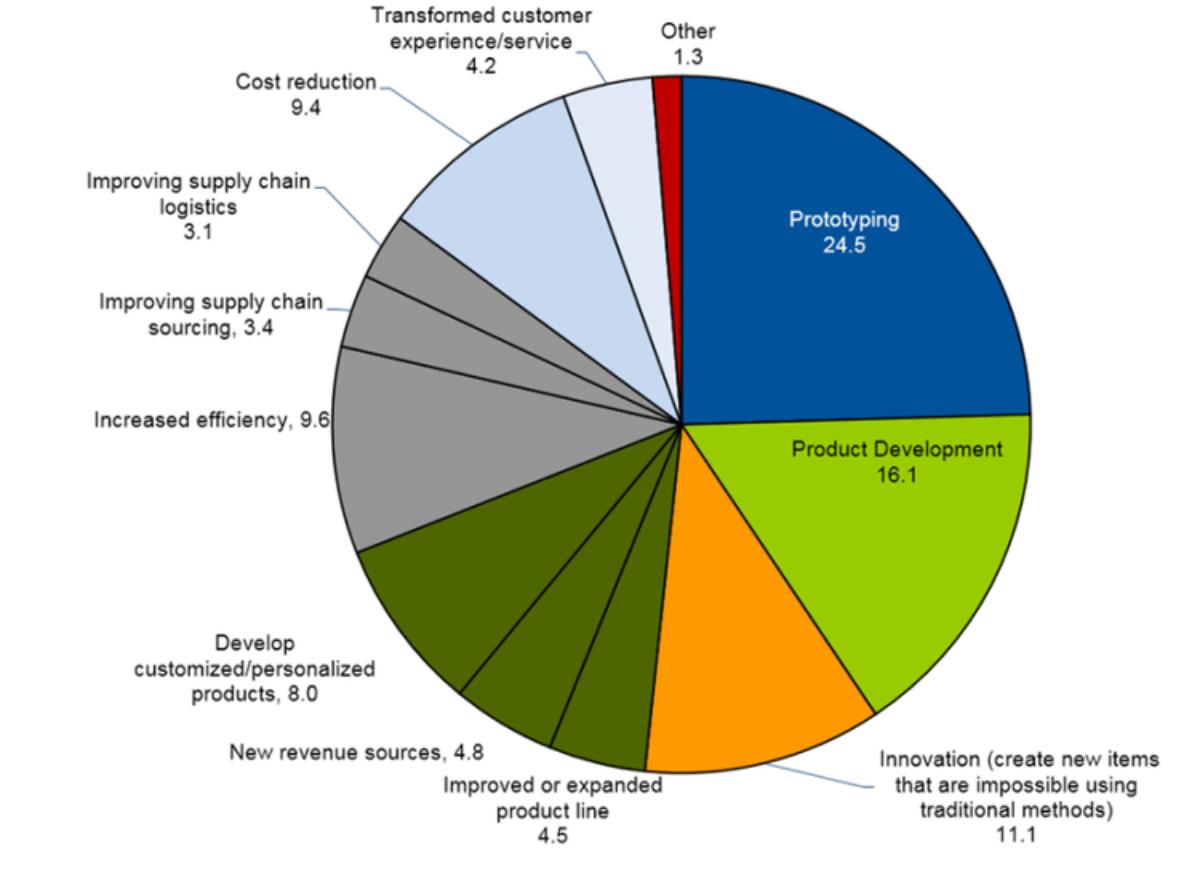

In the rapidly evolving world of 3D printing, accurately calculating the cost of a print job is essential for both hobbyists and professionals alike. Whether you’re running a small business or simply exploring your creative potential at home, understanding the costs associated with materials, labor, and equipment can significantly impact your profitability and project planning. However, with numerous online calculators available, finding a reliable and effective tool can be a daunting task. Many calculators often overlook crucial factors, or they can be overly complicated, leading to confusion and frustration.

This article aims to simplify that search by reviewing and ranking the best online tools for calculating the cost of 3D printing. Our goal is to save you time and effort by presenting a curated list of calculators that stand out in terms of functionality and user experience.

Criteria for Ranking

To determine the top tools, we evaluated each calculator based on several key criteria:

-

Accuracy: We assessed how well each tool captures the various components involved in 3D printing costs, including material costs, labor, and machine upkeep.

-

Ease of Use: A user-friendly interface is crucial. We considered how straightforward it is to input data and interpret results, ensuring that both beginners and experienced users can navigate the tools with ease.

-

Features: We looked for calculators that offer additional functionalities, such as the ability to upload G-code files, choose from various filament types, and calculate electricity costs.

By focusing on these criteria, we hope to guide you towards the best calculators that will help you make informed decisions in your 3D printing endeavors.

Our Criteria: How We Selected the Top Tools

Selection Criteria for 3D Printing Cost Calculators

In our quest to identify the best online tools for calculating the cost of 3D printing, we established a comprehensive set of criteria. These criteria ensure that the calculators we recommend are not only effective but also user-friendly and reliable. Below are the key factors we considered:

-

Accuracy and Reliability

– The primary function of any cost calculator is to provide accurate estimates. We evaluated the underlying formulas used in each tool to ensure they factor in essential variables such as material cost, labor, and operational expenses. Tools that employ transparent calculations with well-defined parameters were prioritized. -

Ease of Use

– A user-friendly interface is critical for accessibility. We selected calculators that feature intuitive designs, allowing users to input data effortlessly without feeling overwhelmed. The best tools provide clear instructions and a logical flow, making it simple for both beginners and experienced users to navigate. -

Key Features

– We assessed each calculator based on the range of inputs it allows users to specify. Essential features include:- Material Type Selection: Options for various filament types (e.g., PLA, ABS, PETG) to accurately reflect material costs.

- Print Time and Weight Inputs: Users should be able to input or upload G-code files to automatically determine print times and filament weights.

- Electricity and Labor Costs: Options to include power consumption, energy costs per kWh, and labor rates for a comprehensive cost estimate.

- Markup Options: The ability to add a markup percentage for profit calculation.

-

Cost (Free vs. Paid)

– We considered whether the calculators are free to use or require payment. Free tools with robust features were favored, but we also evaluated any paid options that provide superior functionality or additional benefits. Transparency regarding any potential costs associated with using the tool was essential. -

Community Feedback and Reputation

– User reviews and community feedback played a vital role in our selection process. We examined testimonials and ratings from users who have utilized these calculators in real-world scenarios. Tools with positive feedback, active support, and continuous updates were prioritized. -

Additional Resources and Support

– We looked for calculators that offer supplementary resources, such as guides or articles on 3D printing costs, to enhance user understanding. Tools that provide insights into best practices or common pitfalls in 3D printing pricing were highly valued. -

Multi-Currency Support

– Given the global nature of 3D printing, calculators that support multiple currencies were favored. This feature allows users from different regions to calculate costs relevant to their local pricing structures.

By applying these criteria, we aimed to compile a list of the most effective and user-friendly tools available for calculating the costs associated with 3D printing. Each selected calculator not only meets these standards but also provides a valuable resource for both hobbyists and professionals in the 3D printing community.

The Best Calculate Cost Of 3D Printings of 2025

1. 3D Printing Price Calculator

The 3D Printing Price Calculator from Original Prusa is a user-friendly tool designed to estimate the cost of 3D printing projects. Users can easily load a G-code file or manually input print time and filament weight. The calculator comes pre-filled with common values for convenience, while also allowing for customization, making it a versatile option for both beginners and experienced users looking to manage their printing expenses effectively.

- Website: blog.prusa3d.com

- Established: Approx. 12 years (domain registered in 2013)

3. 3D Printing Cost Calculator

The 3D Printing Cost Calculator from Omni Calculator is designed to help users accurately estimate the expenses associated with 3D printing projects. It effectively breaks down the total cost into two main components: material costs, which reflect the specific materials used, and additional expenses related to the printing process. This tool is particularly useful for hobbyists and professionals alike, enabling them to budget effectively and make informed decisions about their 3D printing endeavors.

- Website: omnicalculator.com

- Established: Approx. 11 years (domain registered in 2014)

5. How Much Does a 3D Printer Cost?

The article “How Much Does a 3D Printer Cost?” on Formlabs provides a comprehensive guide to estimating the expenses associated with 3D printing. It emphasizes the importance of calculating material costs by determining the amount needed for a specific part and multiplying it by the material’s price. This tool is essential for budgeting and ensuring cost-effectiveness in 3D printing projects, catering to both hobbyists and professionals.

- Website: formlabs.com

- Established: Approx. 16 years (domain registered in 2009)

How to Get the Most Accurate Results

Double-Check Your Inputs

One of the most critical steps in obtaining accurate results from any 3D printing cost calculator is to ensure that all your inputs are correct. Take the time to verify the values you enter, such as filament weight, print time, and electricity costs. Even a minor error can lead to significant discrepancies in your final cost estimate. If available, use a G-code file to automatically populate fields, as this reduces the chances of manual entry errors. Additionally, keep your calculator open while you gather information, so you can easily cross-reference data from your 3D printing software or material supplier.

Understand the Underlying Assumptions

Every calculator operates on a set of assumptions, which can significantly influence the final output. Familiarize yourself with these assumptions, such as the average cost of materials, the power consumption of your specific printer, and the expected lifespan of the machine. For instance, some calculators might not factor in maintenance costs or variations in electricity prices based on your location. Understanding these elements will help you interpret the results more accurately and make adjustments as necessary.

Use Multiple Tools for Comparison

No single calculator is perfect, and different tools may provide varying results based on their algorithms and input parameters. To gain a well-rounded perspective on your 3D printing costs, consider using multiple calculators. By comparing the outputs from different tools, you can identify any inconsistencies and arrive at a more reliable estimate. This approach also allows you to see how changes in input variables affect the overall cost, giving you deeper insights into your project’s financials.

Explore Advanced Options

Many calculators come with advanced options that allow for a more granular cost analysis. For example, you might find sections dedicated to labor costs, machine upkeep, and overhead expenses. Don’t hesitate to utilize these features, as they can provide a more comprehensive view of your printing costs. Entering detailed information about your printing process, such as the time spent on preparation and post-processing, can yield a more accurate reflection of your actual expenses.

Review and Adjust for Profit Margins

If you are using the calculator for business purposes, be sure to incorporate a markup to ensure profitability. Many calculators allow you to add a percentage to your total cost, reflecting your desired profit margin. This is essential for pricing your services competitively while still ensuring that your business remains viable. Remember to consider your target market and the typical rates within your area when determining a reasonable markup.

Stay Updated

Lastly, keep yourself informed about changes in material costs, energy prices, and new printing technologies. The 3D printing landscape is continually evolving, and staying updated will help you maintain accurate cost estimates. Regularly revisiting your calculator settings and assumptions based on current market conditions will enhance your ability to make informed decisions about your 3D printing projects.

Frequently Asked Questions (FAQs)

1. What factors influence the cost of 3D printing?

The cost of 3D printing is influenced by several factors, including:

– Material Type: Different filaments (e.g., PLA, ABS, PETG) have varying costs per kilogram.

– Model Size and Complexity: Larger and more intricate models require more material and longer printing times, increasing costs.

– Printer Settings: Layer height, infill percentage, and support structures can affect the amount of filament used and the time taken to print.

– Labor Costs: Time spent on print preparation, monitoring, and post-processing should also be considered.

– Electricity Usage: The power consumption of the printer during the job can contribute to the overall cost, especially for longer prints.

2. How can I calculate the cost of a specific 3D print job?

To calculate the cost of a specific 3D print job, you can follow these steps:

1. Determine Material Costs: Calculate the volume of your model and multiply it by the density of the filament used. Then, multiply by the cost per kilogram of that filament.

2. Estimate Labor Costs: Assess the total time required for preparation and printing, and multiply by your hourly rate.

3. Include Additional Costs: Factor in electricity costs based on your printer’s power consumption and local energy rates, as well as any maintenance or operational costs.

4. Add a Markup: If you’re running a business, consider adding a markup percentage to ensure profitability.

3. Are there online tools available to calculate 3D printing costs?

Yes, there are several online calculators designed specifically for estimating 3D printing costs. Some popular options include:

– Original Prusa 3D Printing Price Calculator: This tool allows users to input details like filament weight, print time, and machine costs to calculate the total price.

– Omni Calculator 3D Printing Cost Calculator: This calculator breaks down costs into material and labor, allowing for customizable inputs based on filament type and printing time.

4. How does the type of filament affect the cost of 3D printing?

The type of filament significantly affects the cost of 3D printing due to differences in pricing, density, and required amounts. For example:

– PLA (Polylactic Acid): Generally one of the more affordable options, costing around $20 per 2.2 lbs spool.

– ABS (Acrylonitrile Butadiene Styrene): Typically slightly more expensive than PLA, often used for its durability.

– Specialty Filaments: Materials like PETG, TPU, or high-temperature filaments can be significantly more expensive, often exceeding $50 per kg, which will increase the cost of printing.

5. Can I make a profit by offering 3D printing services?

Yes, you can make a profit by offering 3D printing services, but it requires careful cost management. To ensure profitability:

– Calculate All Costs: Make sure to account for material, labor, electricity, and maintenance costs.

– Set Competitive Prices: Research market rates for similar services in your area to set competitive pricing.

– Add a Markup: Include a markup percentage on top of your total costs to guarantee a profit margin.

– Market Your Services: Promote your 3D printing services effectively to attract customers and build a sustainable business.

Important Disclaimer

⚠️ Important Disclaimer

The information and reviews in this guide are for educational purposes only and are based on publicly available information. We are not affiliated with any of the tools mentioned. Features and pricing may change. Always conduct your own research before choosing a tool for your needs.