The Ultimate Guide to 3D Printing Manufacturer (2025)

Introduction: Navigating the Global Market for 3d printing manufacturer

In today’s dynamic global marketplace, navigating the complex landscape of 3D printing manufacturers can be a daunting task for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With an array of options available, sourcing reliable 3D printing solutions that meet specific needs—such as rapid prototyping or customized production—requires a strategic approach. This guide aims to demystify the process of identifying and partnering with reputable manufacturers, ensuring that you make informed decisions that align with your business objectives.

The scope of this comprehensive guide encompasses various aspects critical to the purchasing process, including the types of 3D printing technologies available, their diverse applications across industries, and essential criteria for supplier vetting. We will delve into factors influencing costs, explore best practices for evaluating potential partners, and highlight key trends shaping the future of 3D printing in international markets.

By providing actionable insights and practical tools, this guide empowers B2B buyers to effectively navigate the global 3D printing landscape. Whether you are a procurement officer in South Africa, a manufacturing manager in the UK, or a business owner in Brazil, understanding these elements will facilitate smarter purchasing decisions that enhance operational efficiency and innovation in your organization.

Understanding 3d printing manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Uses thermoplastic filaments; affordable; widely available | Prototyping, tooling, low-volume production | Pros: Cost-effective, easy to use. Cons: Limited material strength, slower than other methods. |

| Stereolithography (SLA) | Utilizes UV light to cure liquid resin; high precision | Medical devices, jewelry, dental applications | Pros: High detail, smooth finish. Cons: More expensive, post-processing required. |

| Selective Laser Sintering (SLS) | Uses lasers to sinter powdered material; strong parts | Aerospace, automotive, complex geometries | Pros: Durable, no support structures needed. Cons: Higher cost, longer production times. |

| Digital Light Processing (DLP) | Similar to SLA but uses a digital light projector; faster | Prototyping, dental, jewelry | Pros: High speed, excellent detail. Cons: Limited material options, requires post-processing. |

| Binder Jetting | Uses a liquid binder to bond powder materials; versatile | Metal parts, sand casting, prototypes | Pros: Wide material range, good for large builds. Cons: Lower strength, post-processing necessary. |

What Are the Characteristics of Fused Deposition Modeling (FDM)?

Fused Deposition Modeling (FDM) is one of the most commonly used 3D printing technologies, particularly favored for its affordability and ease of use. It works by extruding thermoplastic filaments through a heated nozzle, layer by layer. This technology is ideal for businesses looking to create prototypes, tooling, or low-volume production parts. However, buyers should consider its limitations in terms of material strength and speed compared to other methods, especially for applications requiring high durability.

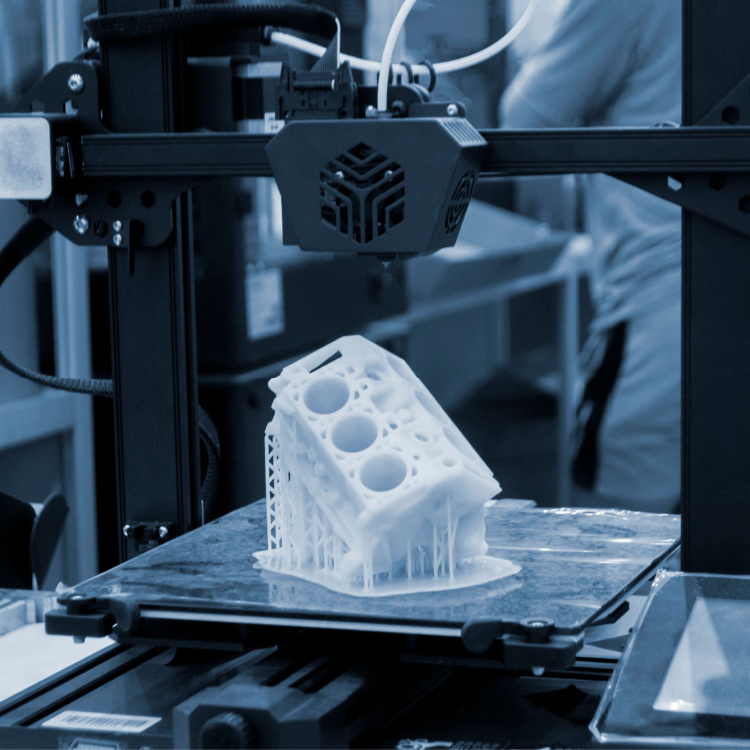

A stock image related to 3d printing manufacturer.

How Does Stereolithography (SLA) Stand Out?

Stereolithography (SLA) is known for its exceptional precision and ability to produce highly detailed parts. It employs a UV light source to cure liquid resin, making it suitable for industries such as medical devices, jewelry, and dental applications. While SLA can deliver superior finishes, the costs are generally higher, and the parts often require post-processing to achieve the desired final quality. B2B buyers should weigh the benefits of detail against the additional expenses and time associated with this method.

What Are the Advantages of Selective Laser Sintering (SLS)?

Selective Laser Sintering (SLS) utilizes lasers to fuse powdered materials into durable parts, making it particularly useful in sectors like aerospace and automotive. This method allows for complex geometries and does not require support structures, which can reduce material waste. However, SLS can be more costly and time-consuming, making it essential for buyers to assess their production needs against the investment required for this technology.

Why Choose Digital Light Processing (DLP)?

Digital Light Processing (DLP) is similar to SLA but leverages a digital light projector to cure resin, resulting in faster production times. This technology is well-suited for rapid prototyping and applications in dental and jewelry manufacturing due to its high speed and excellent detail. However, the limited range of available materials and the need for post-processing can be drawbacks. Businesses should consider whether the speed of DLP aligns with their production timelines and material requirements.

How Does Binder Jetting Provide Versatility?

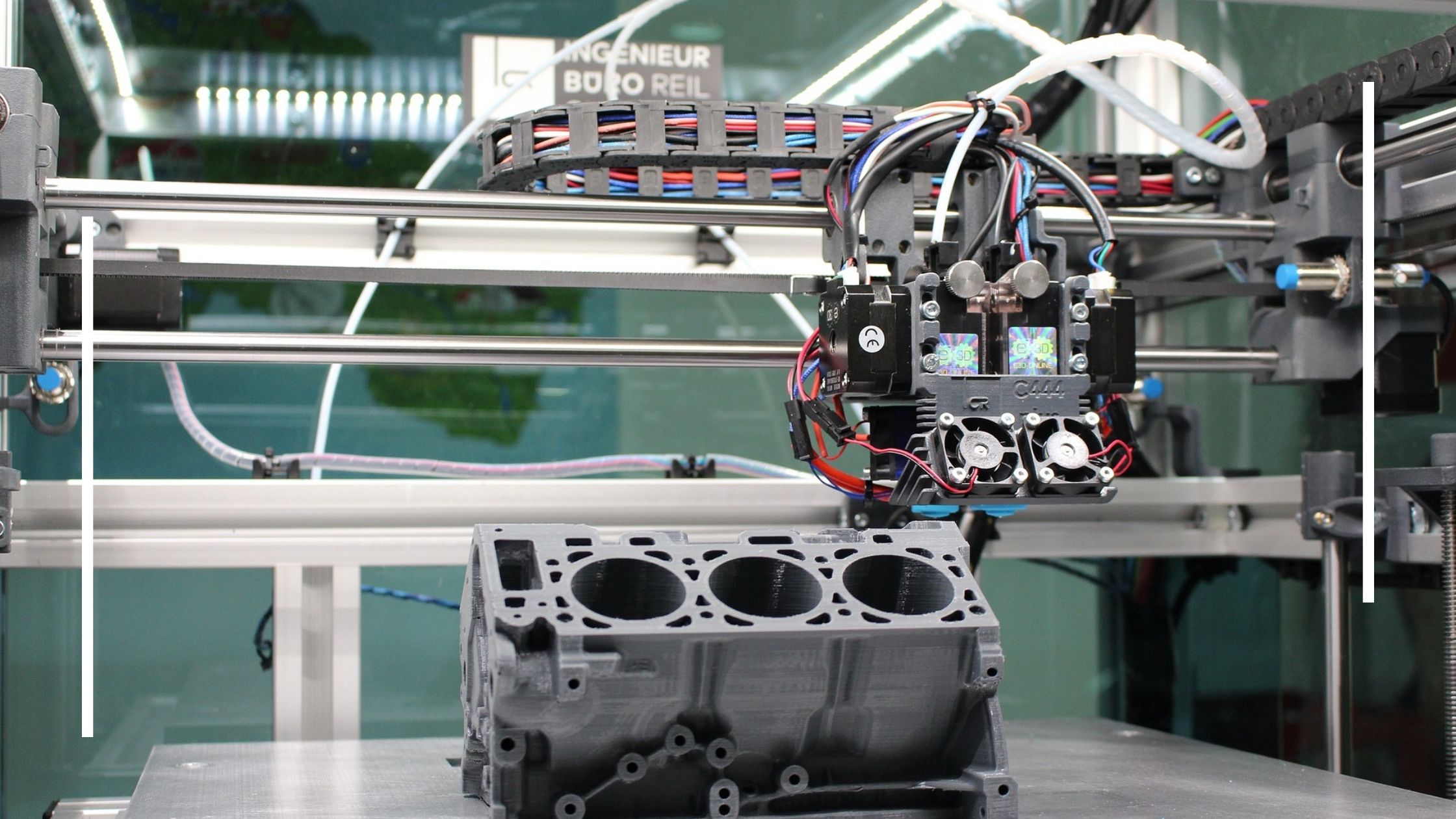

A stock image related to 3d printing manufacturer.

Binder Jetting is a unique 3D printing technology that utilizes a liquid binder to bond powder materials, offering versatility in terms of the types of materials used, including metals and ceramics. This method is suitable for applications like metal parts production and sand casting. While it allows for larger builds and a wide range of materials, the resulting parts may have lower strength and often require post-processing. Buyers should evaluate their specific needs for strength and durability against the advantages of material versatility in Binder Jetting.

Related Video: What is 3D Printing? How It Works, Benefits, Processes, and Applications Explained

Key Industrial Applications of 3d printing manufacturer

| Industry/Sector | Specific Application of 3D Printing Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of lightweight components | Reduces weight and enhances fuel efficiency | Certification requirements and material specifications |

| Healthcare | Custom prosthetics and implants | Improved patient outcomes through personalization | Regulatory compliance and biocompatibility of materials |

| Automotive | Rapid prototyping of parts | Accelerates design cycles and reduces time-to-market | Supplier reliability and production scalability |

| Consumer Goods | Customized packaging solutions | Enhances brand differentiation and customer engagement | Material compatibility and sustainability practices |

| Construction | 3D-printed building components | Cost-effective and rapid construction methods | Local regulations and material sourcing sustainability |

How is 3D Printing Used in Aerospace and What Problems Does It Solve?

In the aerospace industry, 3D printing manufacturers produce lightweight components that significantly reduce the overall weight of aircraft. This reduction is crucial for enhancing fuel efficiency and lowering operational costs. Buyers in this sector must consider stringent certification requirements and specific material specifications to ensure safety and compliance with aviation standards. The ability to rapidly prototype and test new designs also allows for quicker iterations, addressing the industry’s need for innovation.

What Are the Benefits of 3D Printing in Healthcare Applications?

3D printing in healthcare is revolutionizing the production of custom prosthetics and implants tailored to individual patients. This personalization leads to improved patient outcomes and satisfaction, as well as reduced surgical times. For international buyers, particularly in regions like Africa and South America, understanding regulatory compliance and ensuring the biocompatibility of materials are critical factors when sourcing these products. Collaborating with local manufacturers can also enhance accessibility and reduce costs.

How Does 3D Printing Accelerate Automotive Prototyping?

In the automotive sector, 3D printing manufacturers facilitate rapid prototyping of parts, enabling companies to accelerate their design cycles and reduce time-to-market. This capability is essential for staying competitive in a fast-paced industry. B2B buyers should focus on supplier reliability and the scalability of production to meet fluctuating market demands. Additionally, understanding the materials used in 3D printing is vital for ensuring durability and performance in automotive applications.

What Are the Advantages of Customized Packaging Solutions with 3D Printing?

The consumer goods industry benefits from 3D printing through the creation of customized packaging solutions that enhance brand differentiation and customer engagement. By using 3D printing, companies can design unique packaging that not only protects their products but also conveys their brand’s identity. Buyers should consider the compatibility of materials with their product lines and explore sustainable practices, as consumers increasingly favor environmentally friendly options.

How is 3D Printing Transforming Construction Methods?

In construction, 3D printing manufacturers are producing building components that facilitate cost-effective and rapid construction methods. This innovation allows for the creation of complex structures that traditional methods may struggle to achieve. For international B2B buyers, understanding local regulations and sourcing sustainable materials is essential to ensure compliance and minimize environmental impact. The potential for on-site printing can also reduce logistics costs, making it an attractive option for construction firms.

Related Video: Stereolithography (SLA) 3D Printing Explained: Guide to Resin 3D Printers

3 Common User Pain Points for ‘3d printing manufacturer’ & Their Solutions

Scenario 1: Navigating Material Selection Challenges in 3D Printing

The Problem: B2B buyers often encounter significant difficulties when selecting the appropriate materials for their 3D printing projects. This challenge is exacerbated by the wide variety of materials available, each with unique properties and applications. For instance, a manufacturing company in South Africa may struggle to determine whether to use thermoplastics, metals, or composites for producing functional prototypes or end-use parts. Misjudging the material can lead to poor product performance, increased costs, and delays in the production schedule.

The Solution: To effectively navigate material selection, buyers should conduct thorough research on the mechanical properties and compatibility of different materials with their specific 3D printing processes. Engaging directly with 3D printing manufacturers to understand their material offerings can provide insights into the best options for specific applications. Additionally, buyers can request sample prints or prototypes using various materials before committing to bulk orders. This hands-on approach allows for real-world testing, ensuring the selected material meets performance requirements and aligns with project goals. Leveraging partnerships with suppliers who offer material testing services can further streamline this process.

Scenario 2: Overcoming Production Scalability Issues in 3D Printing

The Problem: As businesses grow, the demand for increased production capacity often poses a challenge. A company in Europe might initially use 3D printing for small-scale projects but finds it difficult to scale up production without sacrificing quality or increasing lead times. This scenario can lead to bottlenecks, missed deadlines, and ultimately dissatisfied customers, which is especially critical in competitive markets.

The Solution: To address scalability concerns, B2B buyers should evaluate the capabilities of their 3D printing manufacturer regarding production volume and speed. This includes discussing the manufacturer’s technology, such as the use of industrial-grade printers capable of higher throughput. Buyers should also explore whether the manufacturer can integrate automation into their processes, which can significantly enhance production efficiency. Establishing a collaborative relationship with the manufacturer can facilitate the development of a tailored production plan that aligns with projected demand. Regular communication and forecasting can help in anticipating scaling needs and adjusting production schedules accordingly.

Scenario 3: Ensuring Quality Control and Consistency in 3D Printed Parts

The Problem: Quality assurance is a pressing concern for B2B buyers, particularly in industries like aerospace and automotive where precision and reliability are paramount. A buyer from the Middle East may find that the 3D printed components they receive vary in quality, leading to potential failures in critical applications. This inconsistency can stem from variations in the printing process, material batches, or post-processing techniques, which can compromise the integrity of the final product.

The Solution: To ensure consistent quality in 3D printed parts, B2B buyers should prioritize manufacturers that adhere to strict quality control protocols and industry certifications. Requesting documentation on the manufacturer’s quality assurance processes, including regular audits and testing procedures, is crucial. Implementing a robust communication channel for feedback and addressing quality issues promptly can help maintain standards. Additionally, buyers should consider leveraging advanced technologies such as in-process monitoring and data analytics to track quality metrics throughout the printing process. Establishing a partnership with a manufacturer that has a proven track record in quality management will significantly enhance the reliability of the components produced.

Strategic Material Selection Guide for 3d printing manufacturer

What Are the Key Properties of Common 3D Printing Materials?

When selecting materials for 3D printing, international B2B buyers must consider the specific properties that affect product performance. Here, we analyze four commonly used materials: PLA, ABS, Nylon, and TPU. Each material has distinct characteristics that can influence the manufacturing process and the suitability of the final product for various applications.

How Does PLA Perform in 3D Printing Applications?

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources like cornstarch. It has a low melting point, typically around 180-220°C, making it easy to print. PLA is known for its excellent surface finish and vibrant colors.

Pros & Cons:

PLA is durable and offers good rigidity, making it suitable for prototyping and decorative items. However, its low heat resistance can lead to deformation under high temperatures, limiting its use in functional parts. Additionally, while it is cost-effective, the manufacturing complexity is low, making it a popular choice among beginners.

Impact on Application:

PLA is compatible with a variety of media, including food-safe applications, but it should not be exposed to high temperatures or moisture for extended periods.

Considerations for International B2B Buyers:

Buyers from regions like South Africa and Europe should ensure compliance with local regulations regarding biodegradable materials. Standards such as ASTM D6400 for compostability may apply.

What Are the Advantages and Limitations of ABS?

Acrylonitrile Butadiene Styrene (ABS) is a widely used thermoplastic known for its strength and impact resistance. It has a higher melting point than PLA, typically around 210-250°C, allowing for more durable applications.

Pros & Cons:

ABS is highly durable and suitable for functional parts, such as automotive components and electronic housings. However, it can be prone to warping during the printing process, which may require a heated bed for successful printing. The cost is moderate, but the manufacturing complexity is higher due to the need for precise temperature control.

Impact on Application:

ABS is compatible with various environments but can emit fumes during printing, necessitating proper ventilation.

Considerations for International B2B Buyers:

Compliance with safety standards, such as REACH in Europe, is crucial. Buyers should also consider the availability of ABS in their local markets, particularly in regions like South America and the Middle East.

How Does Nylon Enhance 3D Printing Capabilities?

Nylon is a versatile material known for its flexibility, strength, and resistance to abrasion. It typically prints at temperatures between 220-260°C, which allows for high-quality, durable parts.

Pros & Cons:

Nylon’s excellent mechanical properties make it ideal for functional prototypes and end-use parts. However, it can absorb moisture, which may affect print quality and dimensional stability. The cost is relatively high, and the manufacturing process can be complex due to its tendency to warp.

Impact on Application:

Nylon is suitable for applications requiring high strength and flexibility, such as gears and fittings.

Considerations for International B2B Buyers:

Buyers must be aware of moisture control and storage requirements, especially in humid climates like those found in parts of Africa. Compliance with material standards, such as ISO 9001, is also essential.

What Are the Benefits of Using TPU in 3D Printing?

Thermoplastic Polyurethane (TPU) is a flexible material that combines the properties of rubber and plastic. It typically prints at temperatures around 210-230°C.

Pros & Cons:

TPU is highly elastic and resistant to wear and tear, making it ideal for applications like gaskets and seals. However, its flexibility can make it challenging to print, requiring specific settings and techniques. The cost is on the higher end, and the manufacturing complexity is significant.

Impact on Application:

TPU is compatible with various environments and is often used in applications requiring flexibility and durability.

Considerations for International B2B Buyers:

Buyers should consider the availability of specialized printing equipment for TPU and ensure compliance with local regulations regarding flexible materials.

Summary Table of Common 3D Printing Materials

| Material | Typical Use Case for 3D Printing Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, decorative items | Biodegradable, easy to print | Low heat resistance | Low |

| ABS | Functional parts, automotive components | Strong and impact-resistant | Prone to warping | Med |

| Nylon | Functional prototypes, gears | High strength and flexibility | Moisture absorption | High |

| TPU | Gaskets, seals | Highly elastic and durable | Challenging to print | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with their specific manufacturing needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printing manufacturer

What Are the Key Stages of Manufacturing for 3D Printing?

The manufacturing process for 3D printing involves several critical stages that ensure the production of high-quality parts and components. Understanding these stages is essential for B2B buyers aiming to partner with reliable manufacturers.

Material Preparation: How Do You Ensure Quality Raw Materials?

Material preparation is the first step in the 3D printing manufacturing process. This stage involves sourcing and testing raw materials, such as thermoplastics, metals, or ceramics, to ensure they meet specific industry standards. Buyers should inquire about the supplier’s material sourcing practices, as quality raw materials directly impact the final product’s integrity.

Key techniques in this stage include:

- Material Sourcing: Engaging with suppliers who provide certified materials that comply with international standards.

- Pre-processing: Conducting tests on materials for properties like viscosity and particle size, ensuring they are suitable for 3D printing.

B2B buyers can verify the quality of materials by requesting certificates of conformity and test reports from suppliers.

Forming: What Techniques Are Used in the 3D Printing Process?

The forming stage is where the actual 3D printing takes place. Various techniques are employed depending on the desired outcome and material used. Common 3D printing methods include:

- Fused Deposition Modeling (FDM): A widely used technique that extrudes thermoplastic filament layer by layer.

- Selective Laser Sintering (SLS): Utilizes a laser to fuse powdered material, often employed for producing complex geometries.

- Stereolithography (SLA): Involves curing liquid resin with a UV laser, known for high precision and detail.

Understanding these techniques helps buyers identify which methods align with their specific requirements. It is advisable to ask manufacturers about their capabilities and the technology they utilize.

Assembly: How Is Quality Maintained During Assembly?

In the assembly phase, printed parts may need to be combined with other components or subjected to post-processing treatments. This stage can significantly affect the final product’s performance and aesthetics.

Key assembly techniques include:

- Post-Processing: Techniques such as sanding, painting, or coating to enhance surface finish and durability.

- Component Integration: For parts requiring assembly with electronic components, it’s crucial to ensure that the assembly process maintains the integrity of both the printed part and the integrated components.

B2B buyers should verify assembly capabilities by requesting samples and understanding the manufacturer’s assembly protocols.

Finishing: What Are the Essential Finishing Techniques?

Finishing is the final stage where the printed parts receive treatments to meet specific specifications. This may include:

- Surface Treatments: Techniques such as polishing, plating, or applying coatings to improve aesthetics and performance.

- Quality Checks: Conducting dimensional and visual inspections to ensure the parts meet predefined standards.

Buyers should ask suppliers about their finishing processes and whether they adhere to international quality standards.

What Quality Assurance Practices Should B2B Buyers Expect from 3D Printing Manufacturers?

Quality assurance (QA) is critical in the 3D printing industry, where precision and reliability are paramount. Buyers should be aware of the QA practices that reputable manufacturers follow.

Which International Standards Should Be Considered for 3D Printing?

Many 3D printing manufacturers adhere to international quality standards to ensure their products meet global benchmarks. The most relevant include:

- ISO 9001: This standard focuses on quality management systems, ensuring consistent quality in manufacturing processes.

- CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for manufacturers supplying the oil and gas industry, adherence to API standards ensures reliability and safety.

Understanding these standards helps B2B buyers assess the credibility of potential suppliers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are crucial in ensuring that products meet quality standards at various stages of the manufacturing process. The main checkpoints include:

- Incoming Quality Control (IQC): Assessing raw materials before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify any deviations from quality standards.

- Final Quality Control (FQC): Comprehensive inspections conducted on finished products before shipment.

B2B buyers should inquire about these checkpoints and the processes manufacturers have in place to ensure quality at each stage.

What Common Testing Methods Are Employed to Ensure Product Quality?

To ensure product quality, manufacturers utilize various testing methods, including:

- Dimensional Testing: Measuring the physical dimensions of the printed part to ensure they meet specifications.

- Mechanical Testing: Assessing properties like tensile strength, impact resistance, and fatigue to evaluate performance under stress.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or X-ray testing to detect internal flaws without damaging the product.

B2B buyers should ask for detailed test reports to verify the quality of the products they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying a supplier’s quality assurance practices is crucial for mitigating risk and ensuring product reliability. Here are several actionable strategies:

- Conduct Audits: Regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices.

- Request Quality Reports: Ask suppliers to provide detailed reports on their quality control processes and testing results.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices.

B2B buyers should prioritize suppliers that demonstrate transparency and a commitment to quality, especially in regions where standards may vary.

What Nuances Should International Buyers Be Aware of in QC and Certification?

International buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several nuances regarding quality control and certification:

- Regional Standards: Different regions may have specific certifications and standards, making it essential to understand local requirements.

- Certification Validity: Ensure that the certifications provided by suppliers are valid and recognized in your region to avoid compliance issues.

- Cultural Differences: Understanding cultural differences in business practices can help build better relationships and ensure smoother transactions.

By focusing on these aspects, international B2B buyers can enhance their procurement strategies and ensure they partner with manufacturers that uphold high quality and reliability standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printing manufacturer’

The following practical sourcing guide offers a structured approach for international B2B buyers looking to procure services from 3D printing manufacturers. This checklist will help streamline your sourcing process, ensuring you select a supplier that aligns with your technical needs and business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to successful sourcing. This includes defining the materials, dimensions, tolerances, and finish quality required for your 3D printed parts. Having precise specifications helps you communicate effectively with potential suppliers and ensures that you receive accurate quotes.

- Materials: Specify whether you need plastics, metals, or composites.

- Tolerance Levels: Indicate acceptable variations in dimensions to meet your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in 3D printing. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. This step is critical as it sets the groundwork for evaluating the best options available.

- Industry Experience: Look for suppliers with a proven track record in your specific industry.

- Geographical Considerations: Assess suppliers in regions that optimize shipping times and costs, particularly if you are in Africa, South America, or the Middle East.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; arrange for virtual or in-person visits if possible to assess their facilities.

- Technology: Ensure they use state-of-the-art 3D printing technologies that meet your needs.

- Production Capacity: Confirm that the supplier can handle your order volume within your required timelines.

Step 4: Verify Supplier Certifications

Supplier certifications are vital indicators of quality and compliance. Check for relevant certifications such as ISO 9001 for quality management systems or industry-specific certifications relevant to your product.

- Quality Assurance: Certifications indicate a commitment to quality and may reduce risks associated with defective products.

- Compliance: Ensure they comply with local and international regulations, especially if you are importing products.

Step 5: Request Prototypes and Samples

Before placing a large order, request prototypes or samples of your designs. This allows you to evaluate the quality of the 3D printing output and make necessary adjustments to your specifications.

- Testing for Fit and Function: Use samples to test the part’s performance in real-world applications.

- Quality Checks: Assess the finish and detail of the prototypes to ensure they meet your expectations.

Step 6: Negotiate Terms and Pricing

Once you’ve narrowed down your options, engage in negotiations regarding pricing, payment terms, and delivery schedules. Transparency in this step can lead to a more favorable partnership.

- Volume Discounts: Discuss potential discounts for bulk orders.

- Payment Terms: Establish clear payment terms that work for both parties to avoid future disputes.

Step 7: Establish Communication Protocols

Effective communication is vital throughout the sourcing process. Establish clear channels and protocols to ensure that all parties are aligned on expectations and timelines.

- Regular Updates: Set up a schedule for regular check-ins to monitor the progress of your orders.

- Point of Contact: Designate a specific representative from both sides for streamlined communication.

By following this checklist, B2B buyers can navigate the complexities of sourcing 3D printing manufacturers more effectively, leading to better outcomes and enhanced supplier relationships.

Comprehensive Cost and Pricing Analysis for 3d printing manufacturer Sourcing

What Are the Key Cost Components in 3D Printing Manufacturing?

When sourcing from a 3D printing manufacturer, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: This is often the largest expense, influenced by the type of filament or resin used. High-performance materials like titanium or specialized polymers typically cost more than standard options.

-

Labor: Skilled labor is required for both the operation of 3D printers and post-processing of printed parts. Labor costs can vary significantly based on the region; for instance, labor in South Africa may be less expensive than in Western Europe.

-

Manufacturing Overhead: This includes utilities, maintenance of equipment, and facility costs. Efficient manufacturers may have lower overhead, translating to better pricing for buyers.

-

Tooling: Although 3D printing is often touted for its lack of tooling, some processes may still require specialized tools. Understanding these costs is essential for accurate pricing.

-

Quality Control (QC): Ensuring parts meet specifications can add to costs. Manufacturers with rigorous QC processes may charge more but can provide a higher assurance of quality.

-

Logistics: Shipping costs can vary based on distance, shipping method, and customs duties. For international buyers, understanding Incoterms is crucial to manage these costs effectively.

-

Margin: Manufacturers will include their profit margin in pricing. This can be negotiated based on volume or long-term partnerships.

How Do Price Influencers Affect 3D Printing Costs?

Several factors influence the pricing of 3D printing services, including:

-

Volume/MOQ: Manufacturers often have Minimum Order Quantities (MOQ). Larger orders can lead to volume discounts, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Complex designs or customizations typically incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Choices: The selection of materials not only affects the base cost but can also influence durability and performance, impacting the total cost of ownership.

-

Quality Certifications: Manufacturers with recognized quality certifications may charge a premium. However, this investment can lead to reduced risk and better product performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a track record of quality may command higher prices but offer peace of mind.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the cost and risk during shipping. Choosing the right terms can significantly impact the overall cost.

What Are the Best Negotiation Tips for B2B Buyers in 3D Printing?

To secure the best pricing and terms from 3D printing manufacturers, consider the following strategies:

-

Leverage Volume: If possible, consolidate orders to meet or exceed MOQs, which can unlock better pricing.

-

Request Detailed Quotes: Ask for itemized pricing that breaks down costs. This transparency can help identify areas for negotiation.

-

Build Long-Term Relationships: Establishing a rapport with suppliers can lead to better pricing and priority service over time.

-

Evaluate Total Cost of Ownership (TCO): Assess not only the upfront costs but also the long-term costs related to performance, maintenance, and potential rework.

-

Stay Informed on Market Trends: Understanding market fluctuations in materials and labor can provide leverage during negotiations.

What Should International Buyers Consider Regarding Pricing Nuances?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact the final cost. Locking in prices early or negotiating in stable currencies may mitigate risk.

-

Import Duties and Taxes: Familiarize yourself with local regulations regarding import duties, as these can significantly affect the overall price.

-

Cultural Differences: Understanding regional business practices and negotiation styles can enhance communication and lead to more favorable terms.

Disclaimer on Indicative Pricing

Prices for 3D printing services can vary widely based on numerous factors, including those mentioned above. It is crucial for buyers to conduct thorough research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing 3d printing manufacturer With Other Solutions

Introduction: Why Consider Alternatives to 3D Printing Manufacturers?

In the dynamic landscape of manufacturing, international B2B buyers are increasingly exploring various solutions to meet their production needs. While 3D printing manufacturers offer innovative advantages, it’s essential to assess other viable alternatives that could provide better performance, cost efficiency, or implementation ease. By understanding these options, businesses can make informed decisions that align with their strategic goals.

Comparison Table: 3D Printing Manufacturer vs. Alternatives

| Comparison Aspect | 3D Printing Manufacturer | CNC Machining | Injection Molding |

|---|---|---|---|

| Performance | High precision and customization | High precision with material limitations | High volume production with consistent quality |

| Cost | Moderate initial investment; lower for small runs | High setup costs; economical for large runs | High upfront costs; cost-effective for mass production |

| Ease of Implementation | Relatively simple; requires skilled operators | Complex setup; requires specialized knowledge | Complex tooling; lengthy lead times |

| Maintenance | Low maintenance; regular calibration needed | High maintenance; wear and tear on tools | Moderate; requires upkeep of molds |

| Best Use Case | Prototyping, small batch production | Large production runs with strict tolerances | High-volume production of identical parts |

What Are the Advantages and Disadvantages of CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing method that uses pre-programmed software to control machinery.

Pros:

– Precision: CNC machining is known for its high level of precision, making it suitable for industries that require tight tolerances, such as aerospace and automotive.

– Material Variety: It can work with a wide range of materials, including metals, plastics, and composites.

Cons:

– Cost: The setup costs are significant, making CNC machining less economical for small runs.

– Complexity: The technology requires skilled operators and a longer lead time for programming and setup, which can delay production.

How Does Injection Molding Compare to 3D Printing?

Injection molding is a widely used manufacturing process for producing parts by injecting molten material into a mold.

Pros:

– Cost-Effectiveness for Large Runs: Once the initial mold is created, the cost per unit drops significantly, making it ideal for high-volume production.

– Consistency: Injection molding offers consistent quality across large batches, which is crucial for mass production.

Cons:

– High Initial Investment: The cost of creating molds can be prohibitive, especially for small businesses or startups.

– Limited Flexibility: Changes to design require new molds, which can be time-consuming and costly.

Conclusion: How Can B2B Buyers Choose the Right Manufacturing Solution?

When selecting a manufacturing solution, B2B buyers must consider their specific needs, including production volume, material requirements, and budget constraints. 3D printing manufacturers excel in customization and prototyping, making them suitable for businesses seeking flexibility. On the other hand, CNC machining and injection molding are better suited for high-volume production with stringent quality requirements. By carefully evaluating these alternatives, businesses from Africa, South America, the Middle East, and Europe can make strategic decisions that enhance their operational efficiency and drive competitive advantage.

Essential Technical Properties and Trade Terminology for 3d printing manufacturer

What Are the Key Technical Properties in 3D Printing Manufacturing?

When engaging with a 3D printing manufacturer, understanding specific technical properties is essential for making informed purchasing decisions. Below are critical specifications that B2B buyers should consider:

-

Material Grade

Material grade refers to the classification of materials based on their properties and intended use. In 3D printing, common materials include thermoplastics, metals, and ceramics. Each material grade has unique characteristics that affect durability, flexibility, and strength. For B2B buyers, selecting the appropriate material grade ensures the final product meets industry standards and application requirements, reducing the risk of product failure. -

Layer Thickness

Layer thickness is the measurement of each individual layer deposited during the 3D printing process. Thinner layers can produce higher-resolution prints with finer details but may increase production time and costs. Conversely, thicker layers can expedite production but may compromise detail. Buyers should consider their priorities—whether speed, detail, or cost—when discussing layer thickness with manufacturers. -

Tolerance

Tolerance refers to the acceptable deviation from a desired dimension in the final product. In 3D printing, tighter tolerances are crucial for parts that require precise fit and function, especially in industries like aerospace and medical. Understanding tolerance specifications is vital for B2B buyers to ensure compatibility with other components and to avoid costly reworks or failures. -

Print Speed

Print speed is the rate at which a 3D printer can produce an object, typically measured in millimeters per second. Faster print speeds can significantly reduce lead times, which is critical for businesses that rely on quick turnarounds. However, increased speed may affect print quality. Buyers should evaluate their timeline needs against quality requirements to determine acceptable print speeds. -

Surface Finish

Surface finish refers to the texture and smoothness of the printed object’s exterior. Different processes and settings can yield various surface finishes, impacting the aesthetic and functional properties of the final product. Buyers should specify their surface finish requirements to ensure that the product meets branding and usability standards.

Which Trade Terms Should B2B Buyers Understand in 3D Printing?

Familiarity with industry jargon is essential for effective communication and negotiation with 3D printing manufacturers. Here are some common trade terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In 3D printing, working with an OEM can provide buyers with access to specialized components designed for specific applications. Understanding OEM relationships can help buyers identify potential suppliers and partners. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a manufacturer is willing to produce. Knowing the MOQ is crucial for buyers to manage costs and inventory effectively. If a buyer’s needs do not meet the MOQ, they may face higher per-unit costs or be unable to source the required quantity. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. This process is vital for comparing costs and services among different manufacturers. A well-prepared RFQ helps buyers articulate their needs clearly, ensuring they receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are a series of international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is essential for managing logistics and cost allocation effectively, especially for international transactions. -

3D Printing Technology Types

Familiarity with various 3D printing technologies—such as FDM (Fused Deposition Modeling), SLS (Selective Laser Sintering), and SLA (Stereolithography)—is crucial for buyers. Each technology has unique advantages and limitations, affecting material options, production speed, and cost. Understanding these differences helps buyers select the most suitable manufacturing process for their projects.

By grasping these technical properties and trade terms, B2B buyers can engage more effectively with 3D printing manufacturers, ensuring that they make informed decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the 3d printing manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the 3D Printing Manufacturer Sector?

The 3D printing sector is experiencing rapid transformation, driven by technological advancements and shifting market demands. One of the most significant global drivers is the increasing adoption of additive manufacturing across various industries, including aerospace, healthcare, automotive, and consumer goods. This trend is especially pronounced among B2B buyers in Africa, South America, the Middle East, and Europe, where companies are looking to reduce lead times and production costs while increasing customization capabilities.

Emerging technologies such as artificial intelligence (AI) and machine learning are enhancing the efficiency of 3D printing processes, leading to improved quality control and design optimization. Additionally, the rise of Industry 4.0 is fostering a more interconnected manufacturing environment, allowing for real-time data sharing and collaboration among suppliers and manufacturers. This interconnectedness presents a unique opportunity for B2B buyers to streamline their sourcing processes and enhance supply chain visibility.

Another noteworthy trend is the increasing focus on localized production. As international logistics become more complex and costly, companies are seeking to establish regional production hubs. This trend is particularly relevant for buyers in emerging markets, where local sourcing can mitigate risks associated with global supply chain disruptions. Moreover, the growing emphasis on rapid prototyping is enabling businesses to bring products to market faster, giving them a competitive edge.

How Can Sustainability and Ethical Sourcing Impact the 3D Printing Industry?

In today’s market, sustainability and ethical sourcing have become critical considerations for B2B buyers in the 3D printing sector. The environmental impact of manufacturing processes is under scrutiny, and companies are increasingly held accountable for their carbon footprints. As such, businesses are looking for 3D printing manufacturers that prioritize sustainable practices, including the use of biodegradable materials and energy-efficient technologies.

Ethical supply chains are equally important. Buyers are now more inclined to partner with manufacturers that adhere to fair labor practices and transparent sourcing. Implementing sustainability certifications, such as ISO 14001 for environmental management or certifications for recycled materials, can help manufacturers attract buyers who prioritize ethical considerations.

Moreover, the demand for “green” materials is on the rise. B2B buyers are actively seeking suppliers that offer eco-friendly filaments and resins, which not only reduce environmental impact but also appeal to consumers increasingly concerned about sustainability. By aligning sourcing strategies with these trends, international buyers can foster stronger relationships with manufacturers and enhance their brand reputation in their respective markets.

What Has Driven the Evolution of the 3D Printing Manufacturing Sector?

The 3D printing manufacturing sector has undergone significant evolution since its inception in the 1980s. Initially limited to prototyping, the technology has expanded to encompass a wide array of applications, including end-use parts, tooling, and even bio-printing. The growth of materials science has played a crucial role in this evolution, with advancements leading to the development of high-performance polymers and metals suitable for diverse industrial applications.

Furthermore, the democratization of 3D printing technology, marked by the introduction of affordable desktop printers, has empowered businesses of all sizes to leverage additive manufacturing. As a result, companies in Africa, South America, the Middle East, and Europe are increasingly integrating 3D printing into their production processes, enabling them to innovate and compete on a global scale. This evolution reflects a broader trend of digital transformation in manufacturing, underscoring the importance of staying informed about technological advancements and market shifts for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printing manufacturer

-

How do I evaluate the reliability of a 3D printing manufacturer?

When evaluating the reliability of a 3D printing manufacturer, consider their industry experience, customer reviews, and case studies. Look for manufacturers that have been in business for several years and have a portfolio showcasing successful projects. Engage in direct communication to assess their responsiveness and willingness to address your specific needs. Additionally, inquire about their certifications and adherence to quality standards, which can provide insight into their operational integrity. -

What are the key factors to consider when sourcing 3D printing services internationally?

Key factors to consider include the manufacturer’s technological capabilities, material options, and production speed. Evaluate their ability to customize solutions according to your specifications and their experience with international shipping and logistics. Additionally, consider the time zone differences and cultural nuances that may affect communication and project timelines. Understanding local regulations, tariffs, and import/export restrictions in your target country is crucial for seamless transactions. -

What minimum order quantities (MOQs) should I expect from 3D printing manufacturers?

Minimum order quantities can vary significantly among manufacturers, often depending on the complexity of the project and the materials used. Some manufacturers may offer low or no MOQs for prototyping services, while others may require a minimum order for mass production to ensure cost-effectiveness. Always clarify MOQs upfront and consider negotiating terms that align with your budget and project scope, especially if you are a small or medium-sized enterprise. -

How can I ensure the quality of 3D printed products?

To ensure quality, request samples of previous work to assess the manufacturer’s craftsmanship and material quality. Inquire about their quality assurance processes, including testing methods and compliance with international standards. Establish clear specifications and tolerances for your project, and consider implementing regular check-ins during production. Utilizing third-party inspections can also provide an additional layer of assurance regarding the quality of the final product. -

What payment terms are typically offered by 3D printing manufacturers?

Payment terms can vary widely based on the manufacturer and the scale of your order. Common terms include upfront deposits (typically 30-50%), with the balance due upon completion or delivery. Be sure to discuss payment methods, including wire transfers, letters of credit, or online payment systems. Negotiating flexible terms can be beneficial, especially for larger orders or long-term partnerships, to align with your cash flow and financial planning. -

How do shipping and logistics work for international orders of 3D printed products?

Shipping and logistics for international orders involve several steps, including selecting a reliable freight forwarder and understanding customs regulations in your country. Ensure the manufacturer is experienced in international shipping to mitigate risks and delays. Discuss shipping options, estimated delivery times, and associated costs upfront. Additionally, consider incoterms that define the responsibilities of both buyer and seller in the shipping process to avoid misunderstandings. -

What customization options should I expect from a 3D printing manufacturer?

Most 3D printing manufacturers offer a range of customization options, including material selection, design alterations, and functional enhancements. Discuss your specific requirements and any limitations the manufacturer may have regarding design complexity or material compatibility. It’s also advisable to provide detailed CAD files or prototypes to ensure that the manufacturer fully understands your vision, thereby facilitating better results. -

How can I build a long-term relationship with my 3D printing supplier?

Building a long-term relationship with your 3D printing supplier involves consistent communication, transparency, and feedback. Treat them as a partner rather than just a vendor by sharing your business goals and challenges. Regularly evaluate performance and provide constructive feedback to foster improvement. Consider engaging in joint projects or co-development initiatives, which can strengthen your partnership and encourage loyalty and collaboration over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3d printing manufacturer

In the rapidly evolving landscape of 3D printing, strategic sourcing stands out as a critical component for international B2B buyers. By prioritizing relationships with reliable manufacturers, businesses can ensure access to innovative technologies and cost-effective solutions. Understanding the unique needs of markets in Africa, South America, the Middle East, and Europe allows buyers to tailor their sourcing strategies, aligning with local demand and supply dynamics.

How can strategic sourcing enhance competitive advantage in 3D printing?

Investing time in supplier evaluations, assessing production capabilities, and analyzing logistics will yield significant benefits. By leveraging the strengths of diverse manufacturers, companies can mitigate risks associated with supply chain disruptions and enhance product quality. The collaboration with local entities can also foster innovation, driving customized solutions that cater to specific market requirements.

Looking ahead, the future of 3D printing manufacturing is promising, with advancements in materials and processes set to transform industries. International B2B buyers are encouraged to adopt proactive sourcing strategies that embrace these changes. By doing so, they position themselves not only to meet current demands but also to capitalize on emerging opportunities in this dynamic sector. Embrace the potential of strategic sourcing today to thrive in tomorrow’s market.