The Ultimate Guide to Ball Valves Supplier (2025)

Introduction: Navigating the Global Market for ball valves supplier

In today’s competitive industrial landscape, sourcing reliable ball valves suppliers can pose a significant challenge for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. With the growing demand for these critical components across various sectors—such as oil and gas, water treatment, and manufacturing—understanding the nuances of the global market is essential. This guide is designed to equip you with the knowledge necessary to navigate the complexities of sourcing ball valves effectively, ensuring that you make informed purchasing decisions.

Throughout this comprehensive resource, we will explore the diverse types of ball valves available, their specific applications, and the vital criteria for vetting suppliers. Additionally, we will delve into cost considerations and the factors influencing pricing strategies in different regions, including Colombia and the UAE. By providing actionable insights and practical tips, this guide aims to empower you to identify and collaborate with the most suitable suppliers, ultimately enhancing your operational efficiency and competitive edge.

As you embark on your journey to find the right ball valves supplier, this guide will serve as your trusted companion, helping you navigate the intricacies of the global market with confidence and clarity.

Understanding ball valves supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Ball Valves | Simple design, quick operation, suitable for on/off control | Water supply, HVAC, oil & gas | Pros: Cost-effective, easy installation. Cons: Limited to low-pressure applications. |

| Trunnion Mounted Ball Valves | Supports larger diameters, reduced torque, and higher pressure ratings | Petrochemical, power generation | Pros: Suitable for high-pressure applications. Cons: Higher initial cost. |

| Floating Ball Valves | Ball is held in place by two seats, allows for self-alignment | Chemical processing, food & beverage | Pros: Reliable sealing, good for low to moderate pressures. Cons: Not ideal for high-pressure applications. |

| Electric Actuated Ball Valves | Automated operation, integration with control systems | Industrial automation, water treatment | Pros: Enhanced control, reduces manual labor. Cons: Higher maintenance costs. |

| Pneumatic Ball Valves | Fast operation using compressed air, suitable for remote control | Manufacturing, pharmaceuticals | Pros: Quick response time, good for dynamic processes. Cons: Requires air supply and maintenance. |

What Are Standard Ball Valves and Their Applications?

Standard ball valves are characterized by their straightforward design, which allows for quick and efficient on/off control of flow. They are commonly used in water supply systems, HVAC applications, and the oil and gas industry due to their reliability and cost-effectiveness. When considering a purchase, B2B buyers should evaluate the valve’s pressure rating and compatibility with the media being handled, as these factors can influence operational efficiency.

How Do Trunnion Mounted Ball Valves Differ from Other Types?

Trunnion mounted ball valves are designed to support larger diameters and handle higher pressure ratings. They are ideal for industries such as petrochemical and power generation, where robustness is essential. Buyers should consider the initial investment, as these valves often come at a higher price point, but their durability and performance in high-pressure scenarios can justify the cost in critical applications.

What Makes Floating Ball Valves Suitable for Certain Industries?

Floating ball valves utilize a ball that is held in place by two seats, allowing for self-alignment and reliable sealing. They are particularly suitable for chemical processing and food and beverage applications due to their ability to provide tight seals at low to moderate pressures. Buyers should assess the valve’s pressure ratings and the types of fluids handled to ensure compatibility, as these factors are crucial for maintaining safety and efficiency.

Why Choose Electric Actuated Ball Valves for Automation?

Electric actuated ball valves offer automated operation, making them a popular choice for industrial automation and water treatment facilities. Their integration with control systems enhances operational efficiency and reduces the need for manual intervention. B2B buyers should weigh the benefits of improved control against the potential for higher maintenance costs, as automated systems may require specialized servicing.

What Are the Advantages of Pneumatic Ball Valves in Dynamic Processes?

Pneumatic ball valves are designed for rapid operation using compressed air, making them suitable for dynamic manufacturing environments and pharmaceutical processes. Their quick response times enhance process efficiency, but buyers must consider the need for a reliable air supply and the associated maintenance requirements. Overall, their performance in fast-paced applications can significantly improve operational workflows.

Related Video: Valves Explained – Control Valve Types (Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, etc.)!

Key Industrial Applications of ball valves supplier

| Industry/Sector | Specific Application of ball valves supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Flow control in pipelines and refineries | Enhanced safety and efficiency in fluid transport | Material compatibility, pressure ratings, and certifications |

| Water Treatment | Regulation of water flow in treatment plants | Improved water quality and reduced operational costs | Compliance with local regulations, durability, and maintenance |

| Chemical Processing | Isolation and control of corrosive fluids | Prevention of leaks and enhanced process control | Resistance to chemicals, valve design, and service life |

| Food & Beverage | Control of liquids in production and processing | Compliance with hygiene standards and product integrity | Sanitary design, ease of cleaning, and material safety |

| HVAC Systems | Temperature and pressure regulation in heating/cooling | Energy efficiency and system reliability | Size specifications, actuator compatibility, and installation ease |

How Are Ball Valves Used in the Oil & Gas Industry?

In the oil and gas sector, ball valves are critical for controlling the flow of crude oil and natural gas through pipelines and processing facilities. They provide a reliable shut-off mechanism that enhances safety during extraction and transport. International buyers, particularly from regions like Africa and the Middle East, must consider factors such as material compatibility with hydrocarbons, pressure ratings, and industry certifications to ensure the valves can withstand harsh operating conditions.

What Role Do Ball Valves Play in Water Treatment Facilities?

Ball valves are extensively used in water treatment plants to regulate the flow of water during various treatment processes. They ensure optimal flow rates and allow for the isolation of sections within the system for maintenance. Buyers from South America and Europe should prioritize valves that comply with local regulations regarding water quality and safety standards, as well as those that offer durability and low maintenance requirements.

Why Are Ball Valves Essential in Chemical Processing?

In chemical processing, ball valves are employed to isolate and control the flow of aggressive and corrosive fluids. Their design minimizes the risk of leaks, which is crucial for maintaining safety and operational efficiency. Buyers in this sector must focus on sourcing valves that are resistant to specific chemicals, have a robust design, and offer a long service life to reduce downtime and replacement costs.

How Do Ball Valves Contribute to Food & Beverage Production?

In the food and beverage industry, ball valves are vital for controlling liquid flows during production and processing. They must meet stringent hygiene standards to prevent contamination while maintaining product integrity. B2B buyers, especially in Europe and South America, should consider valves with a sanitary design, ease of cleaning, and materials that comply with food safety regulations.

What Benefits Do Ball Valves Provide in HVAC Systems?

Ball valves in HVAC systems are used for temperature and pressure regulation in heating and cooling applications. Their reliable operation contributes to energy efficiency and system reliability, which is critical for businesses looking to reduce operational costs. Buyers should evaluate the size specifications, actuator compatibility, and ease of installation to ensure the valves integrate seamlessly into existing systems.

Related Video: How Ball Valves Work

3 Common User Pain Points for ‘ball valves supplier’ & Their Solutions

Scenario 1: The Challenge of Quality Assurance in Ball Valve Procurement

The Problem:

B2B buyers, particularly from regions like Africa and South America, often face significant challenges when sourcing ball valves due to varying quality standards. Many suppliers may promise high-quality products but fail to deliver, resulting in equipment failures that can halt operations and lead to costly downtime. Buyers may struggle with verifying the quality of materials, manufacturing processes, and compliance with international standards, particularly when dealing with suppliers that may not have established reputations in their markets.

The Solution:

To mitigate the risks associated with quality assurance, buyers should adopt a thorough vetting process when selecting a ball valve supplier. Start by requesting certifications that demonstrate compliance with international standards such as ISO 9001 for quality management systems. Conduct site visits or audits to assess the manufacturing facilities and processes, if feasible. Additionally, leverage third-party testing laboratories to verify the performance of the valves before large-scale procurement. Establishing a relationship with a supplier that offers transparent communication and quality guarantees, such as warranties or service contracts, can further enhance confidence in the procurement process.

Scenario 2: Navigating Complex Shipping and Logistics Issues

The Problem:

For international B2B buyers, especially in the Middle East and Europe, navigating the logistics of shipping ball valves can be a daunting task. Factors such as customs regulations, import duties, and the risk of delays in transit can complicate the procurement process. Buyers often find themselves in a situation where their project timelines are jeopardized due to unforeseen shipping issues, leading to increased costs and frustration.

The Solution:

To streamline the shipping process, buyers should work closely with suppliers that have experience in international logistics. It’s advisable to engage suppliers who can provide comprehensive shipping solutions, including handling customs clearance and understanding local regulations. Establishing a clear communication channel with the supplier regarding shipping timelines and tracking updates can help manage expectations. Additionally, consider using freight forwarders who specialize in industrial equipment to assist with the logistics, ensuring that documentation is properly handled and that deliveries are made on time.

Scenario 3: Understanding Technical Specifications and Compatibility

The Problem:

A common pain point for B2B buyers is the confusion surrounding the technical specifications of ball valves and their compatibility with existing systems. Buyers may encounter situations where the valves they procure do not meet the specific requirements of their applications, leading to inefficiencies or even system failures. This issue is particularly prevalent in industries such as oil and gas, where precise specifications are critical.

The Solution:

To overcome challenges related to technical specifications, buyers should invest time in understanding their own system requirements before engaging with suppliers. Create a detailed specification sheet that outlines the necessary parameters such as pressure ratings, temperature tolerances, and material compatibility. When communicating with potential suppliers, provide this sheet to ensure they can offer products that meet your exact needs. Furthermore, consider collaborating with an engineering consultant who specializes in valve applications to guide the selection process. This proactive approach not only ensures compatibility but also enhances the overall efficiency and safety of the systems in which the ball valves will be installed.

Strategic Material Selection Guide for ball valves supplier

When selecting materials for ball valves, international B2B buyers must consider various factors, including the properties of the materials, their suitability for specific applications, and compliance with regional standards. Here, we analyze four common materials used in ball valves: stainless steel, brass, PVC, and carbon steel.

What are the Key Properties of Stainless Steel for Ball Valves?

Stainless steel is a popular choice for ball valves due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. Typically, grades like 304 and 316 are used, with 316 offering superior resistance to chlorides, making it ideal for marine applications or environments with high salinity.

Pros and Cons:

– Advantages: Stainless steel valves are durable and can handle extreme conditions, making them suitable for a wide range of applications, including oil and gas, food processing, and chemical industries.

– Disadvantages: The primary downside is cost; stainless steel is more expensive than other materials. Additionally, manufacturing complexity can lead to longer lead times.

Impact on Application:

Stainless steel ball valves are compatible with various media, including corrosive substances, making them versatile across industries. Buyers in regions like Europe and the UAE may prefer stainless steel due to stringent regulatory standards for food and chemical safety.

How Does Brass Perform in Ball Valve Applications?

Brass is another common material for ball valves, known for its excellent machinability and relatively low cost. It typically offers good corrosion resistance, especially in non-corrosive environments.

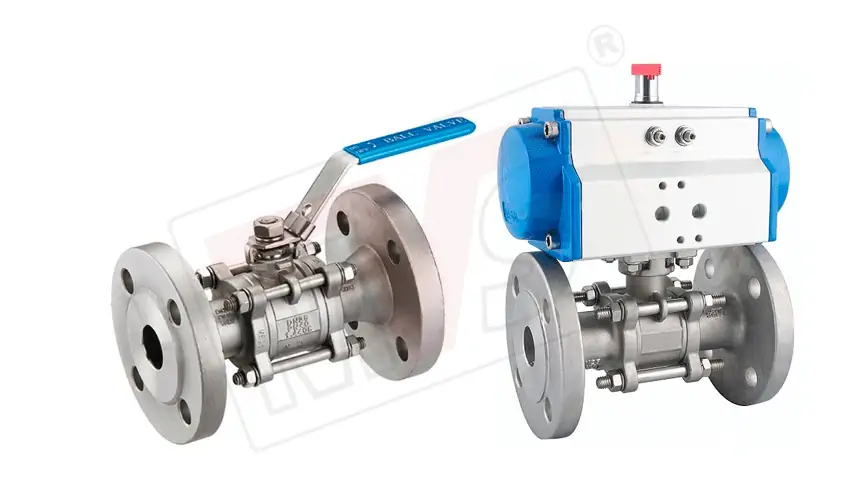

A stock image related to ball valves supplier.

Pros and Cons:

– Advantages: Brass valves are lightweight, easy to install, and cost-effective, making them suitable for plumbing and HVAC applications.

– Disadvantages: Brass may not be suitable for high-pressure applications or environments with aggressive chemicals, as it can corrode over time.

Impact on Application:

Brass ball valves are often used in water supply systems and gas lines. Buyers from South America and Africa may find brass valves appealing due to their affordability, but they should be cautious about the specific media to avoid premature failure.

What are the Benefits of Using PVC for Ball Valves?

PVC (Polyvinyl Chloride) is a plastic material that is increasingly used for ball valves, especially in applications involving water and wastewater management. Its lightweight nature and resistance to corrosion make it an attractive option.

Pros and Cons:

– Advantages: PVC valves are inexpensive, lightweight, and easy to install. They are ideal for low-pressure applications and can handle a variety of chemicals.

– Disadvantages: PVC is not suitable for high-temperature applications and can become brittle over time when exposed to UV light.

Impact on Application:

PVC ball valves are commonly used in irrigation systems and chemical processing. Buyers in regions like Africa may prefer PVC due to its cost-effectiveness and availability, but they should ensure compatibility with the specific chemicals used.

Why Choose Carbon Steel for Ball Valves?

Carbon steel is known for its strength and durability, making it suitable for high-pressure applications. However, it is less resistant to corrosion compared to stainless steel.

Pros and Cons:

– Advantages: Carbon steel valves are robust and can handle high pressure and temperature, making them suitable for industrial applications.

– Disadvantages: The susceptibility to rusting and corrosion can limit their use in certain environments, requiring protective coatings or additional maintenance.

Impact on Application:

Carbon steel ball valves are often used in oil and gas applications. Buyers in the Middle East, where oil extraction is prevalent, may find carbon steel valves suitable, provided they are aware of the necessary maintenance to prevent corrosion.

Summary Table of Material Selection for Ball Valves

| Material | Typical Use Case for ball valves supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, food processing | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Plumbing, HVAC | Cost-effective and lightweight | Not suitable for high-pressure applications | Medium |

| PVC | Water management, irrigation | Inexpensive and easy to install | Not suitable for high temperatures | Low |

| Carbon Steel | Industrial applications, oil and gas | Strong and durable | Susceptible to corrosion | Medium |

This guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ball valves supplier

What Are the Main Stages of Manufacturing Ball Valves?

Manufacturing ball valves involves a series of critical stages that ensure the final product meets industry standards and client specifications. Understanding these stages can help B2B buyers assess potential suppliers effectively.

-

Material Preparation

– The first step involves selecting high-quality materials, typically stainless steel, brass, or plastic, depending on the application requirements. Suppliers must ensure that the raw materials meet relevant standards, such as ASTM or ISO specifications, to guarantee durability and performance.

– Material testing is crucial here; suppliers often conduct mechanical and chemical tests to verify the material’s integrity before proceeding. -

Forming

– The forming process includes techniques such as forging, casting, or machining. Forging is preferred for high-pressure applications due to its ability to enhance material strength.

– Advanced CNC (Computer Numerical Control) machining is often employed to achieve precise dimensions and tolerances, which are critical for valve performance. -

Assembly

– During assembly, the various components of the ball valve, including the ball, seats, and body, are brought together. This process typically requires skilled labor to ensure that components fit correctly and function optimally.

– Suppliers often utilize automated assembly techniques to enhance efficiency and consistency, reducing the potential for human error. -

Finishing

– The finishing stage involves surface treatments such as polishing, coating, or painting to enhance corrosion resistance and aesthetic appeal. This can include processes like electroplating or powder coating.

– Finishing not only affects the valve’s appearance but also its performance in harsh environments, making it a vital step in the manufacturing process.

How Do Suppliers Ensure Quality Assurance for Ball Valves?

Quality assurance is integral to the manufacturing process, ensuring that ball valves meet international standards and customer expectations. Here’s how suppliers maintain quality:

-

Adherence to International Standards

– Suppliers should comply with ISO 9001 quality management standards, which provide a framework for consistent quality across all manufacturing processes. Additionally, industry-specific standards such as CE marking (for European markets) and API standards (for oil and gas applications) are critical.

– These certifications demonstrate a commitment to quality and reliability, which are essential for B2B buyers. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This stage involves inspecting materials upon arrival to ensure they meet specifications. Any non-conforming materials are rejected at this stage.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early. Techniques such as statistical process control (SPC) are often employed to track process variations.

– Final Quality Control (FQC): After assembly, every valve undergoes rigorous testing, including pressure testing, leakage testing, and functional testing, to confirm it meets the specified performance criteria. -

Common Testing Methods for Ball Valves

– Hydraulic Testing: This test checks for leaks and verifies the pressure rating of the valve. It involves filling the valve with water and applying pressure to ensure it holds without leaking.

– Functional Testing: This ensures that the valve operates correctly under expected conditions. It includes testing the opening and closing mechanisms to ensure they function smoothly.

– Material Testing: Suppliers may conduct hardness tests, tensile strength tests, and metallurgical analysis to confirm that the materials used are suitable for the intended application.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for mitigating risks. Here are some actionable insights:

-

Conduct Supplier Audits

– Regular audits allow buyers to evaluate a supplier’s manufacturing processes and quality assurance practices firsthand. During an audit, buyers can assess compliance with relevant standards and observe quality control checkpoints in action.

– Consider scheduling both announced and unannounced audits to get a comprehensive view of the supplier’s operations. -

Request Quality Control Reports

– Suppliers should provide documented evidence of their quality control processes, including inspection reports, testing results, and certifications. Reviewing these documents can give buyers confidence in the supplier’s adherence to quality standards.

– Look for certifications from recognized bodies, as they validate the supplier’s commitment to quality and performance. -

Engage Third-Party Inspection Services

– Utilizing third-party inspection services can provide an objective assessment of the supplier’s quality control processes. These services can conduct independent audits and testing, ensuring that the valves meet the required specifications before shipment.

– This step is particularly important for buyers in regions where local regulations may differ from international standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

Navigating the complexities of quality control can be challenging for international buyers. Here are some nuances to consider:

-

Understanding Regional Standards

– Different regions may have varying standards and certifications for ball valves. For instance, the European Union has strict CE marking requirements, while the Middle East may prioritize compliance with local standards such as GCC.

– Buyers should familiarize themselves with these regional standards to ensure that the valves they purchase are compliant and safe for their intended use. -

Cultural and Communication Factors

– Cultural differences can impact quality assurance practices. Buyers should establish clear communication with suppliers regarding quality expectations and standards.

– Building strong relationships with suppliers can facilitate better understanding and adherence to quality protocols. -

Supply Chain Transparency

– Transparency in the supply chain can significantly impact quality control. Buyers should inquire about the supplier’s sourcing practices, sub-suppliers, and any potential risks in the supply chain that could affect quality.

– Establishing clear expectations regarding material sourcing and production practices can mitigate risks associated with quality discrepancies.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting a ball valve supplier. This knowledge not only helps in ensuring compliance with international standards but also aids in establishing long-term, trustworthy partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ball valves supplier’

When sourcing ball valves for industrial applications, particularly in international markets such as Africa, South America, the Middle East, and Europe, having a structured approach is vital. This checklist is designed to guide B2B buyers through the essential steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of sourcing the right ball valves. Determine the size, pressure rating, material compatibility, and type of ball valve (e.g., floating, trunnion-mounted) that fits your application. This clarity will help you communicate effectively with potential suppliers and avoid costly mistakes later on.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Use online platforms, trade directories, and industry-specific forums to create a list of companies that specialize in ball valves. Look for suppliers with a proven track record and good customer reviews, particularly those with experience in your target market regions.

Step 3: Evaluate Supplier Certifications

Before entering negotiations, verify that suppliers possess the necessary certifications such as ISO 9001, API 6D, or CE marking. These certifications indicate adherence to quality management and industry standards, ensuring that the products you receive will meet safety and performance expectations.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request samples of their ball valves. This allows you to assess the quality, material, and functionality firsthand. Ensure that the samples meet your specifications and perform reliably in your intended application.

Step 5: Compare Pricing and Terms

Gather detailed quotes from your selected suppliers, comparing not only the prices but also the terms of sale, including payment options, lead times, and shipping costs. Look for transparency in pricing and any additional fees that may arise. A competitive price is essential, but it should not compromise the quality of the product.

Step 6: Check References and Past Performance

Before finalizing your decision, ask for references from previous clients, especially those in similar industries. Reach out to these references to gauge their satisfaction with the supplier’s products and services. This step can reveal insights into the supplier’s reliability and customer service.

Step 7: Negotiate Terms and Finalize the Contract

Once you have chosen a supplier, engage in negotiations to finalize pricing, delivery timelines, and warranty terms. Clearly outline expectations in the contract, including provisions for quality assurance and penalties for non-compliance. A well-structured contract protects both parties and ensures accountability.

By following this checklist, B2B buyers can navigate the complexities of sourcing ball valves more effectively, ultimately leading to successful procurement and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for ball valves supplier Sourcing

What Are the Key Cost Components in Sourcing Ball Valves?

When sourcing ball valves, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts the pricing. Common materials for ball valves include stainless steel, brass, and PVC. Prices can vary significantly based on the material’s quality and market demand.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and quality control. Regions with higher labor costs may see increased prices, while countries with lower wages can offer more competitive rates.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, benefiting the overall pricing structure.

-

Tooling: The cost of molds and dies necessary for producing specific valve designs can be substantial, especially for custom orders. Tooling costs are often amortized over production runs, impacting the unit price.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can add to the overall cost. Certifications like ISO or API can also influence pricing, as they require adherence to specific standards.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, play a crucial role in the total cost of ownership. The choice of shipping method (air vs. sea) will also affect delivery speed and price.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition and the supplier’s business strategy.

How Do Price Influencers Affect Ball Valve Sourcing?

Several factors can influence the pricing of ball valves:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often attract discounts. Understanding the supplier’s MOQ can help buyers negotiate better pricing, especially when planning for large projects.

-

Specifications and Customization: Customized ball valves designed to meet specific needs may incur higher costs due to additional engineering and manufacturing requirements. Buyers should evaluate whether the customization is essential for their applications.

-

Materials and Quality Certifications: Higher-quality materials and certifications can lead to higher prices. Buyers should assess the necessity of these factors based on their operational needs and industry standards.

-

Supplier Factors: The supplier’s reputation, reliability, and geographic location can significantly impact pricing. Established suppliers may charge a premium for their perceived quality and reliability.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is crucial. These terms define the responsibilities of buyers and sellers concerning shipping costs, insurance, and risk, which can alter the overall price.

What Are the Best Buyer Tips for Negotiating Ball Valve Prices?

International B2B buyers should consider the following tips to optimize their sourcing strategy:

-

Negotiate Effectively: Always approach negotiations with a clear understanding of your budget and the market rates for ball valves. Leverage multiple supplier quotes to strengthen your position.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, which includes not just the purchase price but also maintenance, operational efficiency, and lifespan of the valves. Sometimes, a higher upfront cost can lead to lower operational costs.

-

Understand Pricing Nuances: Be aware of the nuances related to international trade, such as currency fluctuations and geopolitical factors that can affect prices. This is particularly relevant for buyers in Africa, South America, the Middle East, and Europe.

-

Request Samples: Before committing to large orders, request samples to ensure the product meets your specifications and quality standards. This can prevent costly mistakes later in the procurement process.

-

Stay Informed: Keep abreast of market trends and technological advancements in valve manufacturing. This knowledge can empower you during negotiations and help you make informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for ball valves can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotes from suppliers, as these will provide a more accurate reflection of the current market conditions and specific requirements.

Alternatives Analysis: Comparing ball valves supplier With Other Solutions

Understanding Alternative Solutions to Ball Valves Suppliers

A stock image related to ball valves supplier.

When considering procurement options for ball valves, international B2B buyers should explore various alternatives that may offer unique advantages depending on their specific operational needs. This section provides an analysis of ball valves suppliers compared to two viable alternatives: butterfly valves and gate valves. Each option presents distinct benefits and drawbacks that can impact performance, cost, and implementation.

Comparison Table

| Comparison Aspect | Ball Valves Supplier | Butterfly Valves | Gate Valves |

|---|---|---|---|

| Performance | Excellent for on/off control; provides a tight seal | Good for throttling; less effective sealing | Ideal for full flow; not for throttling |

| Cost | Moderate to high investment | Generally lower cost | Varies widely; can be high for large sizes |

| Ease of Implementation | Straightforward installation; requires skilled labor | Easier to install; less skill needed | Complex installation; requires precise alignment |

| Maintenance | Low maintenance; durable materials | Moderate maintenance; may need regular checks | High maintenance; prone to wear over time |

| Best Use Case | Ideal for high-pressure applications | Suitable for water and gas systems | Best for isolation in pipelines |

Detailed Breakdown of Alternatives

Butterfly Valves

Butterfly valves are designed for quick opening and closing, making them suitable for situations where flow control is essential but not as precise as that offered by ball valves. Their lightweight design allows for easier installation and maintenance, which can reduce labor costs and time. However, they may not provide as tight a seal as ball valves, especially in high-pressure applications. This compromise could lead to leakage issues, making them less ideal for critical operations where fluid containment is paramount.

Gate Valves

Gate valves operate by raising or lowering a gate to control flow, making them excellent for applications requiring full flow with minimal pressure drop. They are often used in larger pipelines where isolation is necessary, but they are not suitable for throttling. Gate valves tend to require more maintenance due to wear and tear on the gate mechanism, which can lead to reliability concerns over time. Additionally, their installation can be complex and may necessitate specialized skills, increasing the total cost of ownership.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between a ball valves supplier and alternative solutions such as butterfly or gate valves, B2B buyers must carefully assess their operational requirements. Considerations such as the specific application, budget constraints, maintenance capabilities, and installation expertise should guide the decision-making process. By aligning the valve type with the intended use case—whether it’s for high-pressure systems, cost-effective installations, or applications requiring reliable isolation—buyers can ensure they select the most suitable solution for their needs. Engaging with suppliers who understand regional compliance standards, especially in diverse markets like Africa, South America, the Middle East, and Europe, will also facilitate a more informed purchasing decision.

Essential Technical Properties and Trade Terminology for ball valves supplier

What Are the Key Technical Properties of Ball Valves?

When sourcing ball valves, it is essential for international B2B buyers to understand the critical technical specifications that can affect performance and compatibility. Here are some key properties:

-

Material Grade: Ball valves are commonly made from various materials such as stainless steel, brass, and PVC. The material grade affects corrosion resistance, pressure handling, and temperature limits. For example, 316 stainless steel is often preferred in chemical applications due to its superior resistance to corrosion.

-

Pressure Rating: This specification indicates the maximum pressure the valve can withstand. It is crucial to match the valve’s pressure rating with the application’s operating pressure to prevent leaks or failures. Standard ratings include ANSI Class 150, 300, and 600, with higher classes suitable for more demanding applications.

-

Temperature Range: Understanding the temperature limits is vital, as ball valves may be used in environments ranging from cryogenic conditions to high-temperature processes. This specification ensures that the valve can maintain its integrity and functionality throughout its intended use.

-

Tolerance: Tolerances refer to the acceptable range of deviation in the manufacturing process. High precision is necessary for components that require tight seals to prevent leaks. Buyers should request detailed tolerance specifications to ensure compatibility with existing systems.

-

End Connection Types: Ball valves come with various end connections, such as threaded, flanged, or welded. The choice of connection type should align with the piping system being used, as this impacts installation and overall system integrity.

Understanding these properties allows buyers to make informed decisions, ensuring that the selected ball valves meet their operational requirements and industry standards.

What Common Trade Terminology Should B2B Buyers Know?

In addition to technical properties, familiarity with trade terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM implications is important for ensuring quality and compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers gauge the feasibility of their orders and manage inventory costs effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and availability for specific products. This process helps buyers compare options and negotiate favorable terms.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and manage shipping risks effectively.

-

Lead Time: This term refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for project planning and inventory management, especially in industries with tight deadlines.

-

Certification Standards: Many industries require specific certifications (e.g., ISO, API) to ensure quality and safety. Buyers should be aware of relevant standards that apply to ball valves to ensure compliance and reliability in their applications.

By understanding these technical properties and trade terms, B2B buyers from regions like Africa, South America, the Middle East, and Europe can navigate the complexities of sourcing ball valves more effectively, ensuring that they meet their operational needs and industry regulations.

Navigating Market Dynamics and Sourcing Trends in the ball valves supplier Sector

What Are the Key Market Trends Impacting Ball Valve Suppliers?

The ball valves supplier sector is undergoing significant transformations driven by global industrial growth, technological advancements, and evolving buyer preferences. A key driver of this market is the increasing demand for automation and smart technologies in industries such as oil and gas, water management, and manufacturing. This trend is particularly pronounced in regions like the Middle East, where vast oil reserves necessitate efficient flow control systems.

International B2B buyers from Africa and South America are increasingly looking for suppliers who can offer not only high-quality products but also integrated solutions that enhance operational efficiency. The rise of digital platforms and e-commerce is also reshaping how buyers source ball valves, enabling them to compare products and suppliers more effectively and make informed purchasing decisions.

Emerging technologies, such as IoT and AI, are playing a crucial role in the development of smart ball valves that can monitor performance in real-time, thus reducing downtime and maintenance costs. Additionally, the push towards Industry 4.0 is encouraging suppliers to adopt digital twins and predictive maintenance technologies, further enhancing the value proposition for international buyers.

How Is Sustainability Shaping Sourcing Trends in the Ball Valve Industry?

Sustainability has become a critical consideration for B2B buyers, particularly in regions like Europe and the Middle East, where regulatory frameworks increasingly emphasize environmental responsibility. The environmental impact of manufacturing processes in the ball valves sector is under scrutiny, prompting suppliers to adopt sustainable practices.

Buyers are seeking suppliers who prioritize ethical sourcing and can demonstrate their commitment to reducing carbon footprints. This includes using recycled materials, minimizing waste during production, and ensuring responsible disposal of products at the end of their lifecycle. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers aiming to appeal to environmentally conscious buyers.

Furthermore, the trend towards green materials is gaining momentum. Suppliers that offer ball valves made from eco-friendly materials, such as bio-based plastics or sustainably sourced metals, can differentiate themselves in a competitive market. As the demand for sustainable solutions continues to grow, B2B buyers must ensure that their suppliers align with their environmental goals and ethical sourcing criteria.

What Is the Historical Context of the Ball Valves Supplier Sector?

The ball valves supplier sector has evolved significantly since the introduction of the first ball valve designs in the mid-20th century. Originally developed for simple on-off control applications, advancements in materials and manufacturing processes have led to the creation of more sophisticated designs capable of withstanding extreme pressures and temperatures.

Over the decades, the sector has witnessed the integration of technology into valve design, transitioning from purely mechanical systems to electronically controlled valves. This evolution has been driven by the increasing complexity of industrial processes and the need for more efficient and reliable flow control solutions.

As international markets expand and industries become more interconnected, the ball valves supplier sector continues to adapt, ensuring that it meets the diverse needs of global buyers while addressing challenges such as sustainability and technological advancements. This historical context provides valuable insights for B2B buyers looking to navigate the current market dynamics effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of ball valves supplier

-

1. How do I choose the right ball valve supplier for my business needs?

Selecting the right ball valve supplier involves assessing their industry experience, product quality, and customer support. Look for suppliers with a proven track record in your specific industry, as they will better understand your unique requirements. Additionally, evaluate their certifications, such as ISO standards, which indicate quality management systems. It’s also beneficial to seek suppliers who offer customization options to tailor products to your specifications, ensuring they meet your operational needs. -

2. What factors should I consider when evaluating ball valve quality?

When evaluating ball valve quality, consider materials used, manufacturing processes, and compliance with industry standards. High-quality valves are typically made from durable materials like stainless steel or brass, which resist corrosion and wear. Investigate the supplier’s quality assurance processes, including testing methods and certifications. Finally, read customer reviews and request samples to assess performance and reliability in real-world applications. -

3. What is the typical minimum order quantity (MOQ) for ball valves from suppliers?

Minimum order quantities (MOQs) for ball valves can vary significantly by supplier and product type. Generally, MOQs can range from as low as 10 units to several hundred. It’s essential to discuss your specific needs with the supplier, as some may be flexible with MOQs, especially for first-time orders or long-term partnerships. Understanding their MOQ policies can help you plan your inventory and budget effectively. -

4. What payment terms are commonly offered by ball valve suppliers?

Payment terms for ball valve suppliers can vary widely based on factors like order size and buyer-supplier relationships. Common terms include net 30, net 60, or payment upon delivery. Some suppliers may offer discounts for upfront payments or larger orders. It’s crucial to negotiate terms that align with your cash flow and procurement strategy, ensuring you have the financial flexibility to manage your operations efficiently. -

5. How can I ensure timely delivery of ball valves from international suppliers?

To ensure timely delivery from international suppliers, establish clear communication regarding lead times and shipping logistics. Discuss shipping methods, such as air or sea freight, and their associated timelines. Utilize tracking services to monitor shipments and maintain regular contact with the supplier to address any potential delays. Additionally, consider working with suppliers who have experience in your region, as they will better navigate local logistics and customs. -

6. What are the best practices for vetting ball valve suppliers?

Vetting ball valve suppliers involves several best practices, including checking references, reviewing their production capabilities, and assessing their financial stability. Request documentation for quality certifications and compliance with industry regulations. Conduct site visits if possible, or utilize third-party inspection services to verify their operations. Engaging in thorough due diligence will help ensure you partner with a reliable supplier who can meet your quality and service expectations. -

7. Can I customize ball valves to fit my specific application needs?

Yes, many ball valve suppliers offer customization options to meet specific application requirements. This may include adjustments in size, materials, pressure ratings, and even valve configurations. When discussing customization, provide detailed specifications and any unique operational conditions. Collaborating closely with your supplier during the design process can ensure the final product aligns with your operational needs and enhances performance. -

8. What quality assurance measures should I expect from a reputable ball valve supplier?

A reputable ball valve supplier should implement comprehensive quality assurance measures, including regular testing and inspections throughout the manufacturing process. Expect them to adhere to international quality standards, such as ISO 9001, and provide documentation for product testing results. Additionally, inquire about their warranty policies, as robust guarantees often indicate confidence in their product quality. Establishing clear quality expectations will help ensure you receive reliable and high-performance valves.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ball valves supplier

What Are the Key Takeaways for Strategic Sourcing of Ball Valves?

In conclusion, strategic sourcing of ball valves is essential for international B2B buyers looking to optimize their supply chain and enhance operational efficiency. By focusing on quality, reliability, and supplier partnerships, businesses can secure long-term value. Buyers should prioritize suppliers that demonstrate compliance with international standards and offer robust after-sales support. This not only mitigates risks but also fosters innovation and responsiveness in a competitive market.

How Can International Buyers Leverage Strategic Sourcing for Ball Valves?

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing need for agile sourcing strategies. Engaging with multiple suppliers can provide leverage in negotiations and ensure a steady supply of critical components. Buyers are encouraged to utilize digital platforms for supplier discovery and assessment, ensuring that they can make informed decisions based on comprehensive market insights.

What Does the Future Hold for Ball Valve Sourcing?

Looking ahead, the demand for high-performance ball valves is set to rise, driven by advancements in technology and increased industrialization. International buyers should remain proactive, continuously evaluating their sourcing strategies to adapt to changing market conditions. Embrace innovation in supplier relationships and consider sustainability as a critical factor in your sourcing decisions. By doing so, you can not only enhance your procurement processes but also contribute to a more sustainable industrial future.