The Ultimate Guide to Battery Manufacturer (2025)

Introduction: Navigating the Global Market for battery manufacturer

In today’s rapidly evolving technological landscape, navigating the global market for battery manufacturers presents a significant challenge for international B2B buyers. With the increasing demand for sustainable energy solutions and the rise of electric vehicles, sourcing high-quality batteries that meet specific requirements is essential. This guide is designed to provide comprehensive insights into the diverse types of batteries available, their applications across various industries, and strategies for effectively vetting suppliers.

Buyers from Africa, South America, the Middle East, and Europe—regions with distinct market dynamics—will find actionable information on cost analysis, procurement processes, and quality assurance. By understanding the intricacies of battery technology and manufacturer capabilities, you can make informed purchasing decisions that align with your business goals.

This guide empowers you to assess potential suppliers critically, compare pricing structures, and identify the best options for your unique needs. Whether you’re looking for lithium-ion batteries for consumer electronics or lead-acid batteries for industrial applications, the insights provided will facilitate a smoother sourcing experience. Ultimately, this resource aims to equip you with the knowledge necessary to thrive in the competitive global battery market.

What Are the Key Considerations When Sourcing Battery Manufacturers?

When sourcing battery manufacturers, several key considerations should be prioritized to ensure a successful partnership and quality product acquisition.

How Can You Assess the Reliability of Battery Suppliers?

Assessing the reliability of battery suppliers is crucial in mitigating risks associated with poor product performance and supply chain disruptions.

What Factors Affect the Cost of Battery Procurement?

Understanding the factors that influence battery procurement costs can help you negotiate better deals and optimize your purchasing strategy.

Which Types of Batteries Are Most Suitable for Your Applications?

Identifying the most suitable types of batteries for your specific applications will enhance the performance and longevity of your products.

By diving deep into these topics, this guide will serve as an indispensable tool for B2B buyers aiming to excel in the battery manufacturing sector.

Understanding battery manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lead-Acid Batteries | Cost-effective, robust, and widely used | Automotive, UPS systems, forklifts | Pros: Low cost, high availability. Cons: Heavier, shorter lifecycle. |

| Lithium-Ion Batteries | High energy density, lightweight, and rechargeable | Consumer electronics, EVs, renewable energy storage | Pros: Longer lifespan, faster charging. Cons: Higher cost, thermal management required. |

| Nickel-Metal Hydride | Good energy density, less toxic than Ni-Cd | Hybrid vehicles, power tools | Pros: Environmentally friendly, stable performance. Cons: Self-discharge issues, limited cycle life. |

| Solid-State Batteries | Uses solid electrolytes, enhanced safety | EVs, consumer electronics | Pros: Improved safety, higher energy density. Cons: Currently in development, higher production costs. |

| Flow Batteries | Utilizes liquid electrolytes, scalable capacity | Grid energy storage, renewable integration | Pros: Long cycle life, scalable. Cons: Lower energy density, complex systems. |

What are Lead-Acid Batteries and Their B2B Relevance?

Lead-acid batteries are among the most established battery technologies, known for their cost-effectiveness and robustness. They are primarily used in automotive applications, uninterruptible power supplies (UPS), and forklifts. For B2B buyers, the key considerations include low upfront costs and widespread availability, making them an attractive option for businesses on a budget. However, their weight and shorter lifecycle compared to newer technologies can be drawbacks, especially in sectors where space and longevity are critical.

How Do Lithium-Ion Batteries Benefit B2B Applications?

Lithium-ion batteries have gained popularity due to their high energy density and lightweight design. They are extensively used in consumer electronics, electric vehicles (EVs), and renewable energy storage systems. B2B buyers should consider the longer lifespan and faster charging capabilities of lithium-ion batteries, which can lead to reduced operational downtime. However, the higher initial costs and the need for effective thermal management may pose challenges for some businesses, especially in cost-sensitive industries.

What are the Advantages of Nickel-Metal Hydride Batteries?

Nickel-metal hydride (NiMH) batteries are favored for their good energy density and environmentally friendly characteristics compared to nickel-cadmium batteries. They find applications in hybrid vehicles and power tools. For international buyers, the stability of performance in various temperatures and less toxic materials can be significant advantages. However, potential self-discharge issues and a limited cycle life are factors that businesses should consider when evaluating their long-term viability.

Why Consider Solid-State Batteries for Future B2B Needs?

Solid-state batteries represent a cutting-edge technology that utilizes solid electrolytes, offering enhanced safety and potentially higher energy density. Their applications are emerging in electric vehicles and consumer electronics. B2B buyers should be aware that while solid-state batteries promise significant improvements, they are still in the development phase, leading to higher production costs and limited availability. Companies looking for innovative solutions may find investing in this technology worthwhile for future growth.

What are Flow Batteries and Their Role in Energy Storage?

Flow batteries are unique in their use of liquid electrolytes, allowing for scalable capacity and long cycle life, making them suitable for grid energy storage and renewable energy integration. For businesses focused on sustainability and energy management, flow batteries offer the advantage of scalability and longevity. However, their lower energy density and complex system requirements may deter some buyers, particularly in sectors that prioritize compact solutions. Understanding these trade-offs is crucial for informed decision-making in energy management strategies.

Related Video: Types of Lithium Ion Battery

Key Industrial Applications of battery manufacturer

| Industry/Sector | Specific Application of battery manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Energy storage systems for solar and wind power | Enhances energy reliability and efficiency | Battery capacity, cycle life, and compatibility with existing systems |

| Automotive | Electric vehicle (EV) batteries | Supports the transition to sustainable transportation | Energy density, charging time, and temperature tolerance |

| Telecommunications | Backup power solutions for telecom infrastructure | Ensures continuous operation during outages | Size, weight, discharge rate, and environmental conditions |

| Healthcare | Portable medical devices and equipment | Increases mobility and reliability of medical services | Safety certifications, battery life, and charging cycles |

| Consumer Electronics | Batteries for laptops, smartphones, and wearables | Enhances user experience through longer device usage | Energy density, recharge time, and warranty terms |

How are Batteries Used in Renewable Energy Applications?

Battery manufacturers play a crucial role in the renewable energy sector by providing energy storage solutions for solar and wind power systems. These batteries store excess energy generated during peak production times and release it during periods of low generation, ensuring a consistent power supply. For international B2B buyers, particularly from regions like Africa and South America, sourcing batteries that offer high capacity and long cycle life is essential to maximize return on investment. Compatibility with existing solar or wind installations is also a key consideration.

What is the Importance of Batteries in the Automotive Industry?

In the automotive sector, battery manufacturers supply electric vehicle (EV) batteries that are pivotal for the shift towards sustainable transportation. These batteries provide the necessary power to drive electric motors, making them essential for reducing greenhouse gas emissions. Buyers from Europe and the Middle East must consider factors such as energy density and charging time when sourcing batteries, as these directly impact vehicle performance and consumer adoption rates.

How Do Batteries Support Telecommunications Infrastructure?

Telecommunications companies rely on battery manufacturers to deliver backup power solutions that ensure uninterrupted service during outages. These batteries are critical for maintaining operations in remote areas and during natural disasters. For buyers in Africa and the Middle East, sourcing batteries that are robust and can withstand extreme environmental conditions is vital. Key considerations include the battery’s size and weight, as well as its discharge rate, to ensure it meets the specific needs of telecom infrastructure.

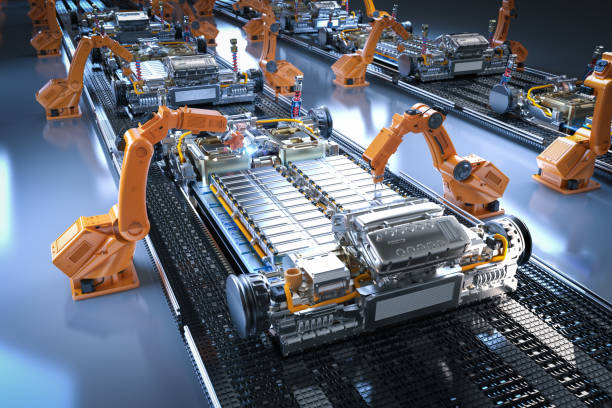

A stock image related to battery manufacturer.

Why are Batteries Essential for Healthcare Devices?

In the healthcare industry, battery manufacturers provide power solutions for portable medical devices and equipment, enhancing the mobility and reliability of healthcare services. These batteries enable devices such as portable ventilators and diagnostic tools to operate effectively in various settings. Buyers from Europe and South America should focus on safety certifications and battery life when sourcing, as these factors are critical for compliance with healthcare regulations and ensuring patient safety.

What Role Do Batteries Play in Consumer Electronics?

A stock image related to battery manufacturer.

Battery manufacturers are integral to the consumer electronics sector, supplying batteries for laptops, smartphones, and wearables. These batteries enhance the user experience by allowing longer device usage without frequent recharging. For B2B buyers, particularly in Europe and South America, key sourcing considerations include energy density and recharge time, as well as warranty terms, to ensure reliability and customer satisfaction in a competitive market.

Related Video: ‘Complete garbage’: GOP uses gimmick to make Trump’s awful spending bill seem like it’s not so bad

3 Common User Pain Points for ‘battery manufacturer’ & Their Solutions

Scenario 1: Inconsistent Battery Performance Across Regions

The Problem: B2B buyers often face challenges with battery performance that varies significantly based on regional climate conditions. For instance, batteries may perform optimally in temperate climates but struggle in extreme heat or cold, leading to decreased efficiency and shorter lifespans. This inconsistency can cause operational delays, increased costs, and customer dissatisfaction, particularly for businesses in Africa and the Middle East where temperatures can soar.

The Solution: To mitigate these issues, buyers should prioritize sourcing batteries specifically designed for their operational environment. When engaging with battery manufacturers, request data on the battery’s performance in different temperature ranges and humidity levels. Look for manufacturers that provide comprehensive testing results and certifications that demonstrate reliability under various conditions. Additionally, consider investing in battery management systems (BMS) that monitor battery health and performance, allowing for adjustments based on environmental factors. This proactive approach ensures you select a battery that meets your specific needs, reducing the likelihood of performance-related issues.

Scenario 2: Complex Supply Chain and Logistics Challenges

The Problem: Many international B2B buyers encounter difficulties in managing the logistics of battery procurement, especially when dealing with cross-border shipments. Complications can arise from customs regulations, unexpected tariffs, and delivery delays, which can significantly impact project timelines and budgets. This is particularly pressing for companies in South America and Europe where varying regulations complicate the supply chain.

The Solution: To streamline the procurement process, buyers should establish strong relationships with manufacturers who have a proven track record of handling international logistics. It is advisable to work with suppliers who offer end-to-end supply chain solutions, including customs clearance and local warehousing. Additionally, utilize technology platforms that provide real-time tracking of shipments, enabling you to anticipate and manage potential delays effectively. Prioritize manufacturers that offer flexible delivery options and are responsive to your logistical needs, ensuring that you can maintain continuity in your operations.

Scenario 3: Limited Technical Support and After-Sales Service

The Problem: After purchasing batteries, many B2B buyers find themselves lacking sufficient technical support for installation and maintenance. This gap can lead to improper usage, increased failure rates, and ultimately, financial losses. Buyers from Europe may experience this when dealing with manufacturers that do not have a local presence or those that are not responsive to after-sales inquiries.

The Solution: To address this pain point, it is crucial to partner with battery manufacturers that provide comprehensive technical support and after-sales services. Before finalizing a purchase, inquire about the availability of local technicians or support teams who can assist with installation and troubleshooting. Additionally, consider manufacturers that offer training sessions for your staff, ensuring they are equipped to handle the batteries effectively. Establishing a service-level agreement (SLA) that outlines response times for technical support can also protect your investment and ensure you receive timely assistance when needed. By prioritizing manufacturers with robust support systems, you can enhance the longevity and reliability of your battery investments.

Strategic Material Selection Guide for battery manufacturer

What are the Key Materials Used in Battery Manufacturing?

When selecting materials for battery manufacturing, international B2B buyers must consider various factors that affect performance, cost, and compliance. Here, we analyze four common materials used in battery production: Lead, Lithium, Nickel, and Graphite. Each material has unique properties and implications for different applications.

Lead: A Traditional Choice for Batteries

Key Properties: Lead is known for its high density and excellent corrosion resistance. It can operate effectively at a wide range of temperatures, making it suitable for various environments.

Pros & Cons: Lead batteries are durable and have a relatively low manufacturing complexity. However, they are heavy and less efficient compared to modern alternatives. The cost of lead is generally low, but the environmental concerns surrounding lead mining and disposal can pose significant challenges.

Impact on Application: Lead-acid batteries are commonly used in automotive and backup power applications due to their reliability. However, they are not suitable for high-performance applications where weight and efficiency are critical.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local regulations regarding lead usage due to health risks. Compliance with standards such as ASTM and local environmental regulations is crucial.

Lithium: The Future of Battery Technology

Key Properties: Lithium is lightweight and has a high energy density, making it ideal for portable electronics and electric vehicles. It also exhibits excellent thermal stability and a wide operating temperature range.

Pros & Cons: The primary advantage of lithium batteries is their high energy efficiency and long cycle life. However, they can be expensive to produce, and the manufacturing process is more complex than that for lead-acid batteries. Additionally, lithium is subject to supply chain risks due to geopolitical factors.

Impact on Application: Lithium batteries are widely used in consumer electronics and electric vehicles, where performance is paramount. They are not typically used in applications requiring high discharge rates, such as heavy machinery.

Considerations for International Buyers: Compliance with international standards like IEC and UL is essential for lithium battery manufacturers. Buyers in Europe and the Middle East should also consider the EU’s Battery Directive, which mandates recycling and sustainability measures.

Nickel: Versatile and Reliable

Key Properties: Nickel has good corrosion resistance and can operate effectively in various temperatures. It also has a decent energy density, making it a viable option for multiple battery types.

Pros & Cons: Nickel-based batteries, such as NiMH, are known for their durability and reliability. However, they have a lower energy density compared to lithium and are generally heavier. The cost of nickel can fluctuate based on market conditions, impacting overall battery pricing.

Impact on Application: Nickel batteries are often used in hybrid vehicles and power tools due to their ability to handle high discharge rates. They are less common in applications where weight and efficiency are critical.

Considerations for International Buyers: Buyers should be aware of the nickel supply chain and potential ethical sourcing issues. Compliance with standards such as JIS in Japan and DIN in Germany can also affect procurement decisions.

Graphite: Essential for Anodes

Key Properties: Graphite is known for its excellent electrical conductivity and thermal stability. It can withstand high temperatures and has a relatively low density.

Pros & Cons: Graphite is essential for anodes in lithium-ion batteries, contributing to their high performance. However, the mining process can be environmentally damaging, and synthetic alternatives can be expensive.

Impact on Application: Graphite is primarily used in lithium-ion batteries, making it crucial for applications in consumer electronics, electric vehicles, and renewable energy storage.

Considerations for International Buyers: Buyers should consider the environmental impact of graphite sourcing and ensure compliance with sustainability standards. In regions like Europe, increasing regulations around sourcing materials ethically are becoming more prevalent.

Summary Table of Material Selection

| Material | Typical Use Case for battery manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lead | Automotive batteries | Low cost and durability | Heavy and environmentally harmful | Low |

| Lithium | Electric vehicles, portable electronics | High energy density and efficiency | High cost and complex manufacturing | High |

| Nickel | Hybrid vehicles, power tools | Good reliability and durability | Lower energy density and heavier | Medium |

| Graphite | Anodes in lithium-ion batteries | Excellent conductivity and stability | Environmental impact from mining | Medium |

This guide provides a comprehensive overview of strategic material selection for battery manufacturing, catering specifically to international B2B buyers from diverse regions. Understanding the properties, advantages, and limitations of these materials is crucial for making informed procurement decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for battery manufacturer

What Are the Key Stages in Battery Manufacturing Processes?

Battery manufacturing involves several critical stages, each contributing to the overall quality and performance of the final product. The main stages of manufacturing can be summarized as follows:

-

Material Preparation

The process begins with the preparation of raw materials, which may include active materials like lithium, cobalt, or nickel, as well as electrolyte solutions and separators. This stage often involves mixing, milling, and drying processes to achieve the desired particle size and composition. Advanced techniques such as spray drying or co-precipitation may be employed to enhance the properties of the materials. -

Forming

During this stage, the prepared materials are shaped into electrodes. Techniques such as coating, where the active material is applied onto a current collector, are commonly used. This can involve processes like slot-die coating or gravure coating. Proper control of thickness and uniformity is essential to ensure optimal performance. -

Assembly

The assembly phase involves stacking or winding the electrodes with separators and filling the cell with electrolyte. This process requires precision to prevent short circuits and ensure effective ion transport. Automated assembly lines are often utilized to maintain high throughput and reduce human error. -

Finishing

The final stage of manufacturing includes formation cycling, where the cells are charged and discharged under controlled conditions to stabilize their performance. This is followed by the sealing and packaging of the batteries to ensure they are ready for shipment. Quality checks during this phase are crucial to ensure that the batteries meet performance specifications.

How Is Quality Assurance Implemented in Battery Manufacturing?

Quality assurance (QA) is integral to battery manufacturing, ensuring that products meet international standards and customer expectations. The QA process typically involves several checkpoints:

-

International Standards and Certifications

Battery manufacturers should adhere to international quality standards such as ISO 9001, which outlines a framework for quality management systems. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) may apply, depending on the battery’s intended use. Buyers should look for suppliers that possess these certifications as a sign of commitment to quality. -

Quality Control Checkpoints

Quality control (QC) involves systematic inspections at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This includes checking raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify defects early in the process.

– Final Quality Control (FQC): This stage involves rigorous testing of the finished products, ensuring they meet performance and safety standards before shipment. -

Common Testing Methods

Testing methods may include electrochemical impedance spectroscopy, cycle life testing, and safety tests such as thermal runaway assessments. These tests help validate the battery’s performance characteristics, lifespan, and safety under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks. Here are actionable steps to ensure supplier reliability:

-

Conduct Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should consider both scheduled and surprise audits to get a comprehensive view of the supplier’s operations. -

Request Quality Assurance Reports

Suppliers should be able to provide detailed QA reports that outline their QC processes, testing results, and compliance with relevant standards. This transparency helps buyers assess the supplier’s commitment to quality. -

Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These services can conduct audits, perform testing, and verify that the manufacturing processes align with international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control and certification when sourcing batteries:

-

Regional Regulations

Different regions may have distinct regulations regarding battery safety and performance. For instance, the European Union has stringent regulations concerning battery recycling and environmental impact, which should be considered when sourcing from European suppliers. -

Cultural Considerations

Understanding cultural differences in quality expectations can also play a role. In some regions, such as Africa and South America, there may be variations in how quality is perceived and executed, which can affect negotiations and partnerships. -

Supply Chain Transparency

A transparent supply chain can significantly enhance quality assurance. Buyers should seek suppliers who are willing to share their supply chain practices, including sourcing of raw materials and subcontractor management, to ensure consistency in quality across the board.

Conclusion

Battery manufacturing is a complex process that requires meticulous attention to detail at every stage, from material preparation to final quality assurance. For international B2B buyers, understanding the manufacturing processes and quality control measures is crucial to making informed purchasing decisions. By prioritizing suppliers who adhere to international standards and demonstrating robust QA practices, buyers can ensure that they are investing in high-quality battery products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘battery manufacturer’

To successfully procure batteries for your business, whether in Africa, South America, the Middle East, or Europe, following a structured sourcing checklist is essential. This guide provides actionable steps to ensure you select the right battery manufacturer that meets your specific needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first crucial step. This includes determining the type of batteries you need, such as lithium-ion, lead-acid, or nickel-metal hydride, along with specifications like capacity, voltage, and cycle life. Having precise specifications helps narrow down suppliers who can deliver products that meet your operational demands.

- Consider your application: Is it for electric vehicles, renewable energy storage, or consumer electronics?

- Set performance benchmarks: Define metrics such as discharge rates and environmental conditions.

Step 2: Research Potential Suppliers

Invest time in researching potential manufacturers. Look for companies that specialize in the type of battery you require and have a proven track record in your industry. Utilize online databases, trade shows, and industry publications to gather information about suppliers.

- Check for reviews and ratings: Customer feedback can provide insight into product quality and reliability.

- Explore supplier websites: Look for case studies or white papers that demonstrate their expertise.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial for ensuring product quality and compliance with international standards. Look for certifications such as ISO 9001 for quality management systems or IEC standards relevant to battery safety and performance.

- Ask for documentation: Request copies of certifications to confirm their validity.

- Understand the implications: Certifications can impact product reliability and your business’s reputation.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples to evaluate the product’s performance. Testing samples allows you to assess quality, compatibility with your systems, and overall satisfaction with the product.

- Conduct thorough testing: Assess battery life, charging times, and performance under various conditions.

- Involve your technical team: Ensure that engineers or technicians evaluate the samples against your specifications.

Step 5: Assess Pricing and Payment Terms

Once you have identified potential suppliers, compare pricing structures. Look beyond the initial cost; consider payment terms, volume discounts, and shipping costs, as these factors can significantly affect your total expenditure.

- Negotiate terms: Don’t hesitate to discuss pricing, especially if you plan to place large orders.

- Examine long-term costs: Consider warranty policies and the cost of replacements or repairs.

Step 6: Review Supplier Reliability and Support

Supplier reliability is essential for long-term partnerships. Assess their production capabilities, lead times, and customer support services. A supplier that offers excellent support can be invaluable during emergencies or unexpected issues.

- Check delivery timelines: Ensure they can meet your demand without delays.

- Evaluate customer service responsiveness: Prompt responses to inquiries can indicate a supplier’s commitment to customer satisfaction.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure all terms are documented in a formal contract. This should include pricing, delivery schedules, quality assurance processes, and dispute resolution mechanisms.

- Consult legal experts: Ensure the contract protects your interests and complies with local regulations.

- Clarify responsibilities: Clearly outline the obligations of both parties to avoid misunderstandings.

Following this practical sourcing guide will help you navigate the complexities of selecting a battery manufacturer and secure a reliable partnership that meets your business needs.

Comprehensive Cost and Pricing Analysis for battery manufacturer Sourcing

What Are the Key Cost Components in Battery Manufacturing?

When sourcing batteries, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as lithium, cobalt, nickel, and graphite can vary significantly based on market demand and availability. Buyers should conduct market research to anticipate fluctuations in pricing.

-

Labor: Labor costs can differ based on the region and the skill level required for manufacturing processes. Countries with lower labor costs might offer competitive pricing but may lack advanced manufacturing capabilities.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. High overhead costs can be indicative of advanced manufacturing technologies, which may lead to higher-quality products.

-

Tooling: Initial tooling costs can be significant, especially for custom battery designs. Buyers should consider whether the supplier has the capability to produce the required tooling efficiently.

-

Quality Control (QC): Ensuring that batteries meet safety and performance standards requires investment in QC processes. This cost is crucial for maintaining product reliability, especially in sectors like automotive and renewable energy.

-

Logistics: Transportation and warehousing costs can add to the overall pricing. International buyers must consider the logistics involved in importing batteries, including potential tariffs and shipping fees.

-

Margin: Manufacturers typically add a profit margin to cover risks and ensure sustainability. Understanding the supplier’s margin can aid in negotiating better deals.

How Do Pricing Influencers Impact Battery Sourcing?

Several factors influence battery pricing, which B2B buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can significantly reduce unit costs. Suppliers often provide better pricing for larger orders, which is essential for buyers planning extensive projects.

-

Specifications and Customization: Custom battery designs tailored to specific applications may incur additional costs. Buyers should assess whether the customization justifies the price increase.

-

Materials and Quality Certifications: Batteries made with high-quality materials and certified by recognized standards (like ISO or UL) may command higher prices. Buyers should weigh the benefits of investing in quality against potential long-term savings.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better support and warranties.

-

Incoterms: Understanding shipping terms is vital. Incoterms dictate who bears the costs and risks at different points in the shipping process, influencing total expenses.

What Are Effective Buyer Tips for Cost-Efficient Battery Sourcing?

To optimize sourcing costs, B2B buyers can employ several strategies:

-

Negotiation: Always engage in negotiations to explore discounts for larger volumes or long-term contracts. Building a rapport with suppliers can lead to better terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate the overall cost of the battery over its entire lifecycle, not just the initial purchase price. Consider factors like energy efficiency, maintenance, and disposal costs.

-

Stay Informed About Pricing Nuances: International buyers should be aware of regional market trends and economic conditions that might affect battery pricing. For instance, currency fluctuations or changes in import tariffs can impact overall costs.

-

Build Relationships with Multiple Suppliers: Having multiple sourcing options can provide leverage during negotiations and ensure competitive pricing.

-

Understand Local Regulations: Compliance with local regulations can impact costs. Familiarize yourself with the requirements in your region to avoid unexpected expenses.

Disclaimer on Indicative Prices

Prices for batteries can fluctuate based on market conditions and other factors. It is essential for buyers to conduct thorough research and obtain quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing battery manufacturer With Other Solutions

Understanding Alternatives in Battery Solutions

In the rapidly evolving landscape of energy storage and power solutions, international B2B buyers are increasingly faced with a variety of options beyond traditional battery manufacturers. Understanding these alternatives is crucial for making informed decisions that align with specific operational needs and economic constraints. This section compares battery manufacturers with alternative technologies and methods that provide similar functionalities, helping businesses identify the best fit for their requirements.

Comparison Table

| Comparison Aspect | Battery Manufacturer | Solar Energy Storage | Supercapacitors |

|---|---|---|---|

| Performance | High energy density, reliable for long-term use | Limited by sunlight availability, but effective for intermittent power supply | High power density, quick charge and discharge cycles |

| Cost | Moderate to high initial investment | High initial setup costs but lower operational costs over time | Generally lower costs than batteries, but limited storage capacity |

| Ease of Implementation | Requires infrastructure for installation | Complex installation with solar panels and regulatory compliance | Easy to install, especially in existing setups |

| Maintenance | Regular checks needed, recycling required | Minimal maintenance after installation, solar panels generally self-clean | Very low maintenance requirements |

| Best Use Case | Suitable for large-scale applications requiring sustained energy | Ideal for off-grid locations and reducing energy costs | Best for applications needing quick bursts of energy, like regenerative braking |

In-Depth Analysis of Alternatives

How Does Solar Energy Storage Compare to Battery Manufacturing?

Solar energy storage systems utilize solar panels to capture energy during the day and store it for later use. While the initial investment can be high due to the cost of solar panels and installation, the long-term operational savings can be significant, particularly in regions with abundant sunlight. However, the effectiveness of solar storage can be limited by weather conditions and geographical factors, making it less reliable in areas with inconsistent sunlight. Buyers considering solar solutions should evaluate their local climate and energy consumption patterns to determine feasibility.

What are the Advantages of Supercapacitors Over Traditional Batteries?

Supercapacitors offer a different approach to energy storage, characterized by their rapid charging and discharging capabilities. They excel in applications requiring quick bursts of energy, such as in electric vehicles or industrial machinery. While they generally have a lower storage capacity compared to batteries, their longer lifecycle and lower maintenance requirements can provide significant cost savings over time. However, for businesses needing extended energy supply, supercapacitors may not be suitable as a standalone solution and are often used in conjunction with batteries for optimal performance.

Conclusion: How to Choose the Right Energy Storage Solution for Your Business

When selecting the right energy storage solution, B2B buyers should consider their specific operational needs, budget constraints, and the long-term implications of their choice. Battery manufacturers offer reliable performance for sustained energy needs, while solar energy storage can provide significant savings in the right environmental conditions. Supercapacitors, on the other hand, are best suited for applications requiring rapid energy discharge. Evaluating these alternatives against your business’s energy requirements will lead to more informed decisions, ensuring that your chosen solution aligns with your operational goals and financial objectives.

Essential Technical Properties and Trade Terminology for battery manufacturer

What Are the Essential Technical Properties for Battery Manufacturing?

When engaging in B2B transactions for battery manufacturing, understanding the technical properties is crucial for ensuring product quality and compatibility with your specific needs. Here are key specifications to consider:

1. Material Grade

Material grade refers to the specific type of materials used in battery production, such as lithium, cobalt, or nickel. This property affects the battery’s energy density, lifespan, and safety. For buyers, knowing the material grade helps in assessing the battery’s performance and suitability for their applications, whether for electric vehicles or consumer electronics.

2. Capacity (Ah)

Capacity, measured in ampere-hours (Ah), indicates the amount of energy a battery can store and deliver. This specification is vital for buyers to determine how long a battery can power a device before needing a recharge. Understanding capacity allows businesses to choose batteries that meet their operational requirements without compromising efficiency.

3. Voltage Rating

The voltage rating specifies the electrical potential difference between the battery terminals. It is essential for ensuring compatibility with the devices the batteries will power. Buyers must verify that the voltage rating aligns with their system’s requirements to prevent operational failures or damage.

4. Cycle Life

Cycle life denotes the number of complete charge-discharge cycles a battery can undergo before its capacity significantly degrades. This property is critical for buyers looking to minimize replacement costs and maximize performance over time. A higher cycle life indicates a more durable battery, which is especially important for industries that rely on consistent performance.

5. Tolerance Levels

Tolerance levels define the acceptable variations in dimensions or performance specifications of the batteries. These specifications are crucial for ensuring that batteries fit correctly within systems and perform reliably. For buyers, understanding tolerances can prevent compatibility issues and enhance overall system reliability.

What Are Common Trade Terms Used in Battery Manufacturing?

In addition to technical properties, familiarity with industry jargon can facilitate smoother transactions and negotiations in the battery manufacturing sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships is essential as it affects the quality and warranty of the batteries they source. Collaborating with reputable OEMs can ensure reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand when negotiating contracts, as it can influence inventory levels and cash flow. Being aware of MOQs allows businesses to plan their purchases more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For international buyers, submitting RFQs can streamline the procurement process by ensuring they receive comprehensive proposals tailored to their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps buyers clarify who is responsible for shipping costs, insurance, and customs clearance, thereby reducing risks and potential disputes.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For international B2B buyers, knowing the lead time is essential for planning inventory and ensuring that supply chains remain uninterrupted.

Understanding these essential technical properties and trade terms equips international B2B buyers with the knowledge needed to make informed decisions in battery manufacturing, enhancing their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the battery manufacturer Sector

What Are the Key Market Dynamics and Sourcing Trends in the Battery Manufacturing Sector?

The battery manufacturing sector is experiencing significant shifts driven by technological advancements, geopolitical factors, and changing consumer demands. One of the most prominent trends is the increasing adoption of electric vehicles (EVs), which is propelling demand for lithium-ion batteries. This surge is particularly notable in markets across Europe, Africa, and South America, where governments are setting ambitious targets for EV adoption to reduce carbon emissions. Furthermore, the rise of renewable energy storage solutions is creating a parallel demand for efficient and reliable battery systems, thus expanding market opportunities.

Emerging technologies such as solid-state batteries and advancements in battery management systems are reshaping sourcing strategies for international buyers. These innovations promise improved energy density, safety, and longevity, making them attractive options for B2B buyers looking to enhance their product offerings. Additionally, the shift towards local sourcing to mitigate supply chain disruptions caused by geopolitical tensions—especially in regions like the Middle East and Europe—is gaining traction. This trend encourages companies to explore partnerships with local battery manufacturers to ensure a stable supply chain.

Moreover, the integration of digital technologies such as IoT in battery management is revolutionizing the manufacturing process and operational efficiency. B2B buyers are advised to keep an eye on suppliers that leverage these technologies to maintain competitive advantages in the market. The convergence of these trends indicates a dynamic landscape where buyers must stay informed to make strategic sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Battery Manufacturing Sector?

Sustainability has become a cornerstone of modern business practices, particularly within the battery manufacturing sector. The environmental impact of battery production—especially concerning lithium extraction—has raised significant concerns. International B2B buyers must prioritize suppliers that demonstrate a commitment to sustainable practices, such as responsible sourcing of raw materials and recycling initiatives. This is not only a moral imperative but also a business necessity, as consumers increasingly prefer brands that align with their values.

Ethical sourcing is essential for ensuring that materials like cobalt and lithium are obtained without exploiting labor or damaging ecosystems. Buyers should seek manufacturers with certifications like the Responsible Cobalt Initiative (RCI) or the Battery Passport, which promote transparency and accountability in the supply chain. Additionally, suppliers that utilize ‘green’ materials and processes—such as those leveraging recycled metals or renewable energy in production—are becoming more attractive to buyers aiming to enhance their sustainability credentials.

Investing in sustainable sourcing practices can also yield long-term cost savings and improve brand reputation. As regulations around environmental standards tighten globally, companies that proactively adopt sustainable practices will be better positioned to comply and thrive in an increasingly eco-conscious market.

What Is the Brief History of the Battery Manufacturing Sector?

The evolution of battery manufacturing can be traced back to the 19th century, with the invention of the lead-acid battery in 1859 by Gaston Planté, which laid the groundwork for future developments. The mid-20th century saw the introduction of nickel-cadmium (NiCd) batteries, which were widely used in consumer electronics. However, the real game-changer came in the 1990s with the commercialization of lithium-ion batteries, which offered higher energy density and efficiency.

Today, the battery manufacturing sector is at a pivotal point, driven by the global push for sustainable energy solutions and technological innovation. The historical context provides valuable insights for B2B buyers in understanding the trajectory of battery technology and the importance of selecting suppliers that are not only technologically advanced but also aligned with sustainability goals. As the sector continues to evolve, staying informed about historical trends can aid buyers in making strategic sourcing decisions that align with future market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of battery manufacturer

-

How do I solve challenges in sourcing a reliable battery manufacturer?

To effectively solve sourcing challenges, begin by conducting comprehensive market research to identify potential manufacturers. Utilize platforms like Alibaba or Global Sources to vet suppliers. Look for manufacturers with verified certifications, positive reviews, and a history of successful transactions. Engage in direct communication to assess responsiveness and willingness to accommodate your needs. Consider requesting product samples before making bulk orders to ensure quality aligns with your expectations. -

What is the best battery type for commercial applications in Africa?

The best battery type for commercial applications in Africa largely depends on the specific use case. Lithium-ion batteries are favored for their efficiency and longevity, making them suitable for renewable energy systems like solar. However, lead-acid batteries may be more cost-effective for less demanding applications. Evaluate factors such as energy density, cycle life, and environmental conditions to make an informed decision that aligns with your operational needs. -

How can I customize battery specifications to meet my business needs?

Customizing battery specifications involves close collaboration with your chosen manufacturer. Begin by outlining your specific requirements, such as voltage, capacity, size, and any unique features. Most manufacturers offer customization options, but ensure they have the capability to meet your specifications. Request detailed technical documentation and prototypes to validate that the customized solution meets your performance and safety standards. -

What are the minimum order quantities (MOQ) for battery suppliers?

Minimum order quantities (MOQ) can vary widely among battery manufacturers, typically ranging from 100 to several thousand units. It’s crucial to clarify the MOQ during your initial discussions. Some manufacturers may offer lower MOQs for new customers or pilot projects. Always factor in your inventory needs and potential growth when negotiating MOQ to ensure you can scale effectively without incurring excessive costs. -

What payment terms should I expect when dealing with battery manufacturers?

Payment terms can differ significantly based on the manufacturer’s policies and your negotiation leverage. Common terms include a deposit of 30-50% upfront with the balance due upon shipment. Some manufacturers may offer credit terms for established relationships. Always confirm payment methods accepted (e.g., bank transfer, PayPal) and consider using escrow services for additional security during the transaction. -

How do I ensure quality assurance when sourcing batteries internationally?

To ensure quality assurance, begin with thorough supplier vetting, including checking certifications such as ISO or CE. Request and review product samples to assess quality firsthand. Implement a third-party inspection service before shipment to verify compliance with your specifications. Establish clear quality standards and communicate them upfront to minimize discrepancies during production. -

What logistics considerations should I keep in mind when importing batteries?

When importing batteries, consider the regulatory requirements related to shipping hazardous materials. Familiarize yourself with import tariffs, customs documentation, and any specific transport regulations for your region. Partnering with a logistics company experienced in handling battery shipments can streamline the process. Additionally, factor in lead times for production and shipping to avoid delays in your supply chain. -

How can I build a long-term relationship with my battery supplier?

Building a long-term relationship with your battery supplier involves consistent communication and transparency. Regularly provide feedback on product performance and address any issues promptly. Engage in joint planning sessions to align on future needs and innovations. Establish trust through timely payments and adherence to agreements, which can lead to better pricing and terms as your partnership develops.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for battery manufacturer

What Are the Key Takeaways for B2B Buyers in Battery Manufacturing?

In conclusion, strategic sourcing remains vital for international B2B buyers in the battery manufacturing sector. As the demand for sustainable energy solutions continues to rise, leveraging strategic sourcing can lead to significant cost savings, improved supplier relationships, and access to cutting-edge technologies. Buyers should prioritize establishing partnerships with manufacturers that emphasize quality, sustainability, and innovation, particularly those aligned with international standards.

How Can International B2B Buyers Prepare for Future Trends in Battery Manufacturing?

Looking ahead, the battery manufacturing landscape is poised for transformation, driven by advancements in battery technology and increasing global energy demands. Buyers from Africa, South America, the Middle East, and Europe should remain proactive in assessing market trends and aligning their sourcing strategies accordingly. Engaging with suppliers who are at the forefront of technological innovations can provide a competitive edge.

What Actions Should B2B Buyers Take Today?

To capitalize on these opportunities, international B2B buyers are encouraged to conduct thorough market research, attend industry conferences, and foster collaborative relationships with manufacturers. By doing so, they can not only enhance their supply chain resilience but also ensure they are well-positioned to meet the evolving needs of their customers. Embrace the future of battery manufacturing with confidence—your strategic sourcing decisions today will shape your success tomorrow.