The Ultimate Guide to Cylinder Head Gasket Supplier (2025)

Introduction: Navigating the Global Market for cylinder head gasket supplier

In today’s global marketplace, sourcing a reliable cylinder head gasket supplier is crucial for businesses involved in automotive manufacturing and repair. With the growing complexity of engine designs and the increasing demand for high-performance components, international B2B buyers face significant challenges in identifying trustworthy suppliers that can deliver quality products at competitive prices. This guide aims to alleviate those challenges by providing a comprehensive overview of the cylinder head gasket market, encompassing various types, applications, and essential supplier vetting processes.

Throughout this guide, you will discover actionable insights into the different types of cylinder head gaskets available, their specific applications across various engine types, and the critical factors to consider when selecting a supplier. Additionally, we will explore cost considerations and market trends that can impact your purchasing decisions.

This resource is specifically tailored for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Spain and Saudi Arabia. By equipping you with the knowledge to make informed decisions, this guide empowers you to navigate the complexities of global sourcing confidently. Whether you are looking to enhance your supply chain efficiency or to ensure the highest quality standards in your products, understanding the landscape of cylinder head gasket suppliers is a vital step toward achieving your business goals.

Understanding cylinder head gasket supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufactured to the exact specifications of the original parts | Automotive manufacturers, repair shops | Pros: High compatibility, quality assurance. Cons: Higher cost, limited availability. |

| Aftermarket Gaskets | Produced by third-party manufacturers, often at lower prices | Independent repair shops, DIY mechanics | Pros: Cost-effective, wide variety. Cons: Quality may vary, potential compatibility issues. |

| Performance Gaskets | Designed for high-performance engines, often with enhanced materials | Racing teams, performance tuning shops | Pros: Improved durability, better sealing. Cons: Higher costs, may require specific installation knowledge. |

| Composite Gaskets | Made from a mix of materials (e.g., metal, rubber) for flexibility | General automotive repairs, heavy machinery | Pros: Versatile, good for various applications. Cons: May not withstand extreme conditions as well as metal gaskets. |

| Metal Gaskets | Comprised entirely of metal, providing excellent heat resistance | High-performance and industrial applications | Pros: Exceptional durability, high-temperature resistance. Cons: More expensive, harder to install. |

What Are the Characteristics of OEM Cylinder Head Gasket Suppliers?

OEM cylinder head gasket suppliers produce gaskets that are manufactured to match the exact specifications of the original parts. This ensures high compatibility and reliability, making them ideal for automotive manufacturers and repair shops that prioritize quality. When purchasing from OEM suppliers, buyers should consider the warranty and support offered, as these products often come with guarantees of performance. However, the higher cost and potential limited availability can be drawbacks for some B2B buyers.

How Do Aftermarket Gasket Suppliers Differ?

Aftermarket gasket suppliers provide alternatives to OEM parts, typically at lower prices. These gaskets are produced by third-party manufacturers and are widely used by independent repair shops and DIY mechanics. While they offer a cost-effective solution, buyers must be cautious as the quality can vary significantly. It’s essential to assess the supplier’s reputation and product reviews to ensure compatibility and performance.

What Are Performance Gaskets and Their Applications?

Performance gaskets are designed specifically for high-performance engines and applications, often utilizing advanced materials for better sealing and durability. These gaskets are commonly used by racing teams and performance tuning shops. While they provide superior performance, buyers should be prepared for higher costs and ensure they have the necessary installation knowledge, as improper installation can lead to significant issues.

Why Choose Composite Gasket Suppliers?

Composite gaskets are made from a combination of materials, such as metal and rubber, allowing for flexibility and adaptability in various applications. They are suitable for general automotive repairs and heavy machinery. Buyers appreciate their versatility; however, they may not perform as well in extreme conditions compared to their metal counterparts. It’s important to evaluate the intended application when considering composite gaskets.

What Are the Benefits of Metal Gasket Suppliers?

Metal gaskets are constructed entirely from metal, making them exceptionally durable and resistant to high temperatures. They are commonly used in high-performance and industrial applications where reliability is critical. While their durability is a significant advantage, the higher price point and installation complexity can be challenges for buyers. Evaluating the specific operational conditions is crucial when opting for metal gaskets to ensure they meet the required performance standards.

Related Video: Ford 4.0L SOHC V6 Head Gasket and Timing Chain Replacement (COMPLETE GUIDE)

Key Industrial Applications of cylinder head gasket supplier

| Industry/Sector | Specific Application of Cylinder Head Gasket Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of Internal Combustion Engines | Ensures engine efficiency and reduces emissions | Material quality, compatibility with engine models, lead times |

| Heavy Machinery | Equipment Manufacturing (e.g., construction, mining) | Enhances durability and performance of machinery | Customization options, certifications, and local regulations |

| Marine | Marine Engine Construction | Increases engine reliability and longevity | Corrosion resistance, marine-grade materials, supplier reputation |

| Aerospace | Aircraft Engine Manufacturing | Meets stringent safety and performance standards | Compliance with aerospace standards, traceability, and testing |

| Renewable Energy | Wind Turbine Gearbox Systems | Improves energy efficiency and reduces operational costs | Adaptability to various turbine designs, sourcing sustainability, and lifecycle management |

How is Cylinder Head Gasket Supplier Used in the Automotive Industry?

In the automotive sector, cylinder head gaskets are vital for sealing the engine’s combustion chamber, thus preventing leaks of fluids and gases. This ensures optimal engine performance and efficiency while minimizing emissions, which is crucial for compliance with environmental regulations. International buyers, particularly from regions like Africa and Europe, should focus on sourcing gaskets that meet specific OEM standards to ensure compatibility with various engine models. Additionally, considering the local climate and operational conditions can help in selecting the right materials that enhance durability.

What Role Does Cylinder Head Gasket Supplier Play in Heavy Machinery Applications?

In heavy machinery, cylinder head gaskets are essential components in engines used for construction and mining equipment. They enhance the engine’s durability and performance under extreme conditions, which is critical for minimizing downtime and maintenance costs. Buyers from South America and the Middle East should prioritize suppliers who can provide customized gaskets that meet the unique specifications of their machinery. Factors such as the gasket’s resistance to high temperatures and pressures, as well as its material properties, should be evaluated to ensure optimal performance.

How Does Cylinder Head Gasket Supplier Impact Marine Engine Construction?

In the marine industry, cylinder head gaskets are crucial for ensuring the reliability and longevity of marine engines. These gaskets prevent leaks, which can lead to severe engine damage and costly repairs. For international buyers, particularly in regions like Europe and the Middle East, sourcing gaskets that are resistant to corrosion and made from marine-grade materials is essential. Suppliers should also demonstrate a strong reputation for quality and reliability, as the safety and performance of marine vessels depend significantly on these components.

What is the Importance of Cylinder Head Gasket Supplier in Aerospace Applications?

In aerospace, cylinder head gaskets are critical for aircraft engine manufacturing, where they must meet stringent safety and performance standards. These gaskets ensure proper sealing under high pressure and temperature conditions. International B2B buyers, especially from Europe, should consider suppliers with proven compliance to aerospace standards and rigorous testing protocols. Furthermore, traceability of materials used in the gaskets is vital, as any failure could have catastrophic consequences in aviation settings.

How Does Cylinder Head Gasket Supplier Contribute to Renewable Energy Solutions?

In the renewable energy sector, particularly in wind turbine gearbox systems, cylinder head gaskets play a significant role in improving energy efficiency and reducing operational costs. They ensure that the gearbox operates smoothly without leaks, which is essential for maximizing energy output. Buyers from regions like Africa and South America should look for suppliers that offer gaskets adaptable to various turbine designs and that prioritize sustainability in their sourcing practices. This alignment with renewable energy goals can enhance the buyer’s corporate responsibility profile.

Related Video: Cylinder Head Manufacturing Process – From Forging to Final Inspection

3 Common User Pain Points for ‘cylinder head gasket supplier’ & Their Solutions

Scenario 1: Sourcing High-Quality Cylinder Head Gaskets

The Problem:

Many B2B buyers, particularly in regions like Africa and South America, struggle with sourcing high-quality cylinder head gaskets that meet their specific engine requirements. Often, suppliers may provide inconsistent quality, leading to engine failures or performance issues. This inconsistency can stem from a lack of quality control measures or insufficient testing of the products before shipment. As a result, buyers face the daunting task of replacing faulty gaskets, which can lead to increased downtime and repair costs.

The Solution:

To mitigate these risks, buyers should prioritize establishing long-term relationships with reputable cylinder head gasket suppliers known for their commitment to quality. Start by conducting thorough due diligence, including checking supplier certifications, customer reviews, and their history of delivering consistent products. It’s also beneficial to request samples for testing and verification before placing large orders. Utilizing third-party testing services can ensure that the gaskets meet industry standards. Additionally, implementing a quality assurance protocol upon receipt of goods can catch potential issues early, minimizing operational disruptions.

Scenario 2: Navigating Technical Specifications and Compatibility Issues

The Problem:

B2B buyers often encounter challenges related to understanding the technical specifications of cylinder head gaskets. Different engines require specific gasket dimensions, materials, and designs. Misunderstanding these requirements can lead to purchasing incompatible products, resulting in costly returns and delays in project timelines. This is particularly problematic in markets with diverse vehicle models and engine types, such as the Middle East and Europe.

The Solution:

To navigate these complexities, buyers should invest time in thoroughly understanding their engine specifications and the corresponding gasket requirements. Create a detailed checklist that includes critical dimensions, materials, and application types for the engines in question. Collaborate closely with suppliers to ensure they provide comprehensive product data sheets that detail all necessary specifications. Additionally, leveraging digital tools such as CAD software can aid in visualizing how gaskets will fit within specific engine models. Regular training for purchasing teams on technical aspects can also enhance their ability to make informed decisions.

Scenario 3: Managing Supply Chain Disruptions

The Problem:

Supply chain disruptions, exacerbated by geopolitical factors or global crises, can severely affect the timely availability of cylinder head gaskets. Buyers in regions like Africa and South America often find themselves in a precarious position when their suppliers face delays, leading to halted production lines and dissatisfied customers. The unpredictability of supply chains can create a ripple effect that damages business relationships and profitability.

The Solution:

To combat supply chain vulnerabilities, B2B buyers should develop a multi-supplier strategy. Instead of relying on a single source, establish relationships with multiple suppliers across different geographical regions. This diversification can help mitigate risks associated with localized disruptions. Additionally, implementing inventory management practices such as safety stock can provide a buffer during unforeseen delays. Buyers should also maintain open lines of communication with suppliers to receive timely updates on stock levels and potential delays. Utilizing technology for supply chain visibility can help in forecasting needs and preparing for potential shortages well in advance.

Strategic Material Selection Guide for cylinder head gasket supplier

What Are the Key Materials for Cylinder Head Gaskets?

When selecting cylinder head gaskets, international B2B buyers must consider various materials, each with unique properties and applications. The most common materials include:

What Are the Key Properties of Composite Materials in Cylinder Head Gaskets?

Composite Materials are often made from a blend of fibers and resins, designed to provide a balance between strength and flexibility.

- Key Properties: Composite gaskets can withstand high temperatures (up to 300°C) and pressures (up to 2000 psi), making them suitable for a variety of engine types. They also offer good corrosion resistance.

- Pros & Cons: They are relatively lightweight and cost-effective, but may not provide the same durability as metal gaskets under extreme conditions. Manufacturing complexity can vary depending on the specific composite used.

- Impact on Application: These gaskets are versatile and can be used in both gasoline and diesel engines. However, they may not be suitable for applications involving aggressive chemicals.

- Considerations for International Buyers: Compliance with standards such as ASTM or ISO is crucial, especially for markets in Europe and the Middle East, where regulations are stringent.

How Do Metal Gaskets Perform in High-Pressure Environments?

Metal Gaskets, particularly those made of stainless steel or aluminum, are designed for high-performance applications.

- Key Properties: Metal gaskets can handle extreme temperatures (up to 800°C) and high pressures (over 3000 psi). They also exhibit excellent corrosion resistance when treated properly.

- Pros & Cons: They offer superior durability and longevity but can be more expensive and complex to manufacture. The rigidity of metal gaskets may lead to challenges in sealing.

- Impact on Application: Ideal for high-performance engines and turbocharged applications, metal gaskets are often used in racing and heavy-duty vehicles.

- Considerations for International Buyers: Buyers should ensure that the metal gaskets meet international standards like DIN or JIS, especially for markets in South America and Africa, where quality assurance is critical.

What Advantages Do Rubber Gaskets Offer for Cylinder Head Applications?

Rubber Gaskets, particularly those made from silicone or nitrile rubber, are commonly used in various automotive applications.

- Key Properties: Rubber gaskets can withstand moderate temperatures (up to 200°C) and pressures (up to 1500 psi). They are flexible and can conform to various surfaces.

- Pros & Cons: They are cost-effective and easy to manufacture but may degrade faster under extreme conditions or exposure to certain chemicals.

- Impact on Application: Suitable for standard automotive applications, rubber gaskets are often used in non-turbocharged engines and lower-performance vehicles.

- Considerations for International Buyers: Compliance with local regulations regarding material safety and environmental impact is essential, particularly in regions with strict environmental laws.

How Do Graphite Gaskets Compare in Terms of Performance?

Graphite Gaskets are known for their excellent thermal conductivity and resistance to high temperatures.

- Key Properties: Graphite gaskets can withstand temperatures up to 1000°C and pressures around 2000 psi. They are chemically resistant and can handle a variety of media.

- Pros & Cons: They offer excellent sealing capabilities but can be more expensive and may require specialized installation techniques.

- Impact on Application: Ideal for high-temperature applications, graphite gaskets are frequently used in industrial engines and heavy machinery.

- Considerations for International Buyers: Buyers should verify that graphite gaskets meet the necessary industry standards, especially in Europe and the Middle East, where compliance is critical.

Summary of Material Selection for Cylinder Head Gaskets

| Material | Typical Use Case for cylinder head gasket supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Composite | General automotive applications | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

| Metal | High-performance and racing applications | Superior durability | Higher cost and manufacturing complexity | High |

| Rubber | Standard automotive applications | Cost-effective and flexible | Degrades under extreme conditions | Low |

| Graphite | High-temperature industrial engines | Excellent thermal conductivity | Higher cost and specialized installation | High |

This guide provides a comprehensive overview of the materials available for cylinder head gaskets, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cylinder head gasket supplier

What Are the Key Manufacturing Processes for Cylinder Head Gaskets?

The manufacturing of cylinder head gaskets involves several critical stages that ensure the product meets the stringent requirements of automotive applications. Understanding these processes helps B2B buyers assess the capabilities of potential suppliers.

1. Material Preparation: What Materials Are Used in Cylinder Head Gasket Manufacturing?

The choice of materials is paramount in the production of cylinder head gaskets, as they must withstand high temperatures and pressures. Common materials include:

- Metallic Materials: Such as stainless steel or copper, often used for high-performance gaskets due to their strength and thermal resistance.

- Non-Metallic Materials: Such as composite materials or elastomers, typically utilized for standard applications where flexibility and sealing properties are essential.

Each material undergoes rigorous selection and testing to ensure it meets industry standards. Suppliers should be able to provide documentation regarding the material specifications and certifications.

2. Forming Techniques: How Are Cylinder Head Gaskets Shaped?

The forming stage involves several techniques, including:

- Stamping: Commonly used for metallic gaskets, where sheets of material are cut into the required shapes using dies.

- Molding: Employed for non-metallic materials, where liquid compounds are poured into molds to form the gasket shape.

- CNC Machining: This precision technique is used for complex designs, allowing for tight tolerances and high accuracy.

B2B buyers should inquire about the technology and machinery used by suppliers, as advanced techniques can lead to better quality and consistency.

3. Assembly: What Are the Steps in Gasket Assembly?

In many cases, gaskets consist of multiple layers. The assembly process typically includes:

- Layering: Different materials are stacked to form the gasket. This can involve adhesive bonding or mechanical fastening.

- Cutting and Trimming: Final shapes are refined to ensure they fit precisely onto engine components.

Buyers should understand the assembly methods to ensure that the finished product will meet their specific application requirements.

4. Finishing: How Is the Final Product Prepared for Delivery?

The finishing stage includes processes that enhance the durability and performance of the gaskets, such as:

- Coating: Applying a protective layer to improve resistance to chemicals and temperature.

- Quality Inspection: Each finished gasket undergoes thorough inspection to ensure it meets specifications.

Buyers should confirm that suppliers have a well-defined finishing process that ensures high-quality outputs.

What Quality Assurance Measures Are Important for Cylinder Head Gasket Suppliers?

Quality assurance (QA) is a critical factor in the manufacturing of cylinder head gaskets. International B2B buyers should be familiar with the relevant standards and inspection processes that suppliers should follow.

1. What International Standards Should Suppliers Comply With?

Suppliers should adhere to recognized international standards such as:

- ISO 9001: This standard ensures that organizations meet customer and regulatory requirements through effective quality management systems.

- CE Marking: Essential for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for gaskets used in the oil and gas industry, ensuring that products meet specific operational requirements.

B2B buyers should request certification documents to verify compliance with these standards.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are vital to ensure that the manufacturing process meets the required standards. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to verify quality and specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet all specifications before shipping.

Buyers should ask suppliers about their QC processes and how they manage these checkpoints.

3. What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to ensure the quality and reliability of cylinder head gaskets:

- Leak Testing: To confirm that the gasket will seal effectively under pressure.

- Compression Testing: To evaluate how the gasket performs under compressive forces.

- Material Testing: To assess the properties of the materials used, including tensile strength and thermal resistance.

Understanding the testing methods used by suppliers can help buyers gauge the reliability of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing cylinder head gaskets, B2B buyers should take proactive steps to verify the quality control measures of potential suppliers.

1. What Should Be Included in Supplier Audits?

Conducting supplier audits is an effective way to assess manufacturing processes and quality assurance. Key areas to focus on include:

- Facility Conditions: Ensure that the manufacturing environment is clean and well-organized.

- Process Documentation: Request evidence of documented processes and adherence to standards.

- Training Programs: Verify that employees are trained in quality control procedures.

Buyers may consider third-party audits for an unbiased assessment.

2. How Can Buyers Access Quality Reports?

Suppliers should provide detailed quality reports, which may include:

- Inspection Reports: Documenting results from IQC, IPQC, and FQC.

- Test Certificates: Showing results from various testing methods.

- Compliance Certificates: Confirming adherence to international standards.

Having access to these documents allows buyers to make informed decisions about supplier reliability.

3. What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Differences: Different regions may have varying requirements for certifications and testing.

- Cultural Factors: Understanding cultural differences in business practices can help in negotiating quality expectations.

- Logistical Challenges: Consider how shipping and handling may affect product quality upon arrival.

By being aware of these nuances, buyers can better navigate the complexities of international sourcing.

In conclusion, understanding the manufacturing processes and quality assurance measures for cylinder head gaskets is essential for B2B buyers. By focusing on these aspects, buyers can ensure they select reliable suppliers capable of meeting their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cylinder head gasket supplier’

In today’s global marketplace, sourcing from reliable cylinder head gasket suppliers is critical for maintaining operational efficiency and product quality. This step-by-step checklist will guide international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, through the essential steps needed to make informed sourcing decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clarify your technical requirements. Determine the specific type of cylinder head gaskets you need, including dimensions, materials, and performance standards. This clarity not only helps in communicating your needs effectively but also ensures that you receive accurate quotes and samples.

Step 2: Conduct Market Research on Suppliers

Research potential suppliers in the industry to identify those that specialize in cylinder head gaskets. Utilize online platforms, industry directories, and trade shows to gather a list of suppliers. Focus on those with a solid reputation and experience in your specific market or region, as this can greatly influence the quality and reliability of the products.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you consider have the necessary certifications and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management systems. Additionally, check for any industry-specific certifications that may be relevant, depending on your operational requirements.

Step 4: Request Samples and Product Testing

Before making a bulk purchase, request samples of the cylinder head gaskets. Testing these samples is crucial to verify that they meet your technical specifications and performance expectations. Evaluate factors such as durability, fit, and compatibility with your existing machinery to avoid future operational issues.

Step 5: Review Supplier Financial Stability

Assess the financial health of potential suppliers to ensure they can fulfill large orders consistently. Request financial statements or credit reports if necessary. A financially stable supplier is more likely to maintain production quality and deliver on time, which is vital for your supply chain management.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, enter negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your expectations and seek to establish mutually beneficial terms. Consider long-term partnerships that could provide better pricing and reliability over time.

Step 7: Establish Communication Channels

Effective communication is key to a successful supplier relationship. Set up clear channels for ongoing communication, whether through regular meetings, emails, or dedicated account managers. This will help address any issues promptly and ensure that both parties are aligned throughout the procurement process.

By following these steps, B2B buyers can make informed decisions when sourcing cylinder head gaskets, ensuring they partner with reliable suppliers that meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for cylinder head gasket supplier Sourcing

When sourcing cylinder head gaskets, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. Here’s a breakdown of the essential components that influence costs and pricing strategies, along with actionable insights for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Cylinder Head Gasket Suppliers?

-

Materials: The primary cost driver in the manufacturing of cylinder head gaskets is the raw materials used, which often include various grades of rubber, metal, and composites. The choice of material significantly affects durability and performance, impacting the overall cost.

-

Labor: Labor costs vary greatly based on the geographical location of the manufacturer. Regions with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality. Understanding local labor markets is essential for buyers to assess potential suppliers.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility costs. Buyers should inquire about these overheads, as they can significantly affect pricing.

-

Tooling: The initial setup costs for tooling and molds can be substantial, especially for custom gaskets. Buyers should consider whether the supplier has existing tooling for common gasket designs or if new tooling will be necessary, which can increase the upfront cost.

-

Quality Control (QC): Implementing stringent QC processes adds to the manufacturing cost but is crucial for ensuring product reliability. Buyers should evaluate the QC measures in place and consider how they align with their own quality standards.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the chosen Incoterms. Understanding these logistics costs is vital, particularly for international buyers who may face additional tariffs or duties.

-

Margin: Suppliers typically include a profit margin within their pricing. This can vary widely depending on the supplier’s market position and the complexity of the gaskets offered.

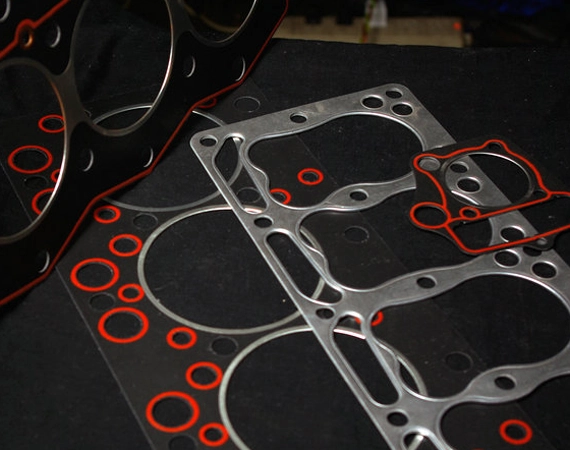

A stock image related to cylinder head gasket supplier.

How Do Price Influencers Affect Cylinder Head Gasket Pricing?

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly influence pricing. Suppliers may offer discounts for larger orders, making it essential for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom gaskets tailored to specific applications typically incur higher costs due to the additional engineering and production complexities. Clear communication of specifications can help avoid unnecessary expenses.

-

Quality and Certifications: Gaskets that meet specific quality standards or certifications (e.g., ISO, OEM specifications) may command higher prices. Buyers should ensure that the supplier’s certifications align with their requirements to avoid future compliance issues.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects who bears the shipping costs and risks, which can ultimately influence the total landed cost of the gaskets. Understanding these terms is critical for accurate cost assessment.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Cylinder Head Gaskets?

-

Negotiate Effectively: Leverage volume purchasing and long-term contracts to negotiate better prices and terms. Establishing a solid relationship with suppliers can also yield additional benefits.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with quality, warranty claims, and potential downtime due to gasket failures. A lower upfront cost may lead to higher TCO if the product quality is subpar.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, trade tariffs, and local market conditions that may impact pricing. Staying informed about geopolitical developments can help mitigate risks associated with sourcing.

-

Request Detailed Quotations: Always ask for a breakdown of costs in supplier quotations. This transparency can help identify areas where costs can be reduced and inform your negotiation strategy.

Disclaimer on Pricing

Prices for cylinder head gaskets can vary widely based on the factors discussed above. Buyers are encouraged to conduct thorough market research and obtain multiple quotations to ensure competitive pricing and value for money.

Alternatives Analysis: Comparing cylinder head gasket supplier With Other Solutions

When evaluating options for sourcing cylinder head gaskets, it is essential to consider viable alternatives that may meet the specific needs of businesses. The right choice will depend on various factors, including performance, cost, and ease of implementation. Below is a comparative analysis of cylinder head gasket suppliers and alternative solutions.

| Comparison Aspect | Cylinder Head Gasket Supplier | Alternative 1: Composite Gasket Technology | Alternative 2: Metal Gasket Solutions |

|---|---|---|---|

| Performance | Reliable sealing under normal conditions; may struggle with extreme temperatures or pressures. | Excellent thermal resistance; ideal for high-performance engines. | Superior durability and can withstand extreme conditions; suitable for racing applications. |

| Cost | Generally lower initial costs; pricing can vary based on material and supplier. | Moderate to high cost due to advanced materials and technology. | Higher upfront cost but may reduce long-term maintenance expenses. |

| Ease of Implementation | Standard installation; widely compatible with various engine types. | Requires specific installation techniques; may need trained personnel. | Often requires specialized installation tools and expertise. |

| Maintenance | Minimal maintenance required; regular checks recommended. | Slightly more maintenance; should be inspected regularly under high-performance conditions. | Low maintenance; can last significantly longer than traditional gaskets. |

| Best Use Case | Suitable for standard vehicles and general applications. | Best for high-performance engines or applications with fluctuating temperatures. | Ideal for extreme performance vehicles and heavy-duty applications. |

What are the Advantages and Disadvantages of Composite Gasket Technology?

Composite gasket technology utilizes advanced materials that enhance sealing performance, especially under high temperatures and pressures. This technology is particularly beneficial for high-performance engines, where traditional gaskets may fail. However, the higher cost and the need for specialized installation can be a drawback for businesses with limited resources or those operating in standard applications.

How Do Metal Gasket Solutions Compare?

Metal gasket solutions are known for their durability and ability to withstand extreme conditions, making them ideal for racing and heavy-duty applications. These gaskets can provide a long lifespan and reduce the frequency of replacements, which can be cost-effective in the long run. However, the initial investment is higher, and the installation may require specialized skills, which could be a barrier for some buyers.

How Can B2B Buyers Choose the Right Solution?

A stock image related to cylinder head gasket supplier.

When deciding on the appropriate solution for cylinder head gaskets, B2B buyers should assess their specific needs, including the type of vehicle or engine, performance expectations, and budget constraints. For standard applications, a reliable cylinder head gasket supplier may suffice. However, for specialized or high-performance needs, investing in advanced composite or metal gasket technologies may yield better long-term results. Conducting thorough market research and considering supplier reputation, warranty options, and after-sales support will also play a crucial role in making an informed decision.

Essential Technical Properties and Trade Terminology for cylinder head gasket supplier

What Are the Key Technical Properties for Cylinder Head Gaskets?

Understanding the essential technical properties of cylinder head gaskets is crucial for international B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

-

Material Grade

Cylinder head gaskets are typically made from materials like composite, metal, or rubber. The choice of material affects the gasket’s durability, heat resistance, and sealing capability. For instance, metal gaskets are often preferred for high-performance engines due to their strength and ability to withstand extreme conditions. Buyers should ensure that the material grade aligns with their specific engine requirements to avoid premature failure. -

Thickness and Tolerance

The thickness of a cylinder head gasket can significantly impact engine compression and performance. Gaskets are available in various thicknesses, typically ranging from 0.5 mm to 2.0 mm. Tolerance levels are critical as they determine how well the gasket fits between the engine components. A tighter tolerance can lead to better sealing and performance but may require more precise manufacturing processes. -

Temperature Resistance

Cylinder head gaskets must endure high temperatures generated by the engine. The material should be able to withstand temperatures ranging from -40°C to +300°C or more, depending on the application. Buyers should verify that the gaskets meet the temperature resistance standards for their specific engine type to prevent leaks and potential engine damage. -

Compression Ratio

This specification refers to the ratio of the maximum to minimum cylinder volume in an engine. A suitable gasket can optimize the compression ratio, enhancing engine efficiency and performance. Understanding the ideal compression ratio for specific engine applications is essential for buyers looking to improve their engine’s performance. -

Sealability

A gasket’s ability to maintain a seal under various pressures and temperatures is vital. Sealability is influenced by both the material and the design of the gasket. Buyers should look for gaskets that have been tested for leak resistance under operational conditions to ensure reliability.

Which Trade Terminology Should B2B Buyers Know When Sourcing Cylinder Head Gaskets?

Familiarizing yourself with industry jargon can simplify the procurement process. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in another company’s end product. In the context of cylinder head gaskets, OEM gaskets are designed to meet the specifications set by the vehicle manufacturer, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it can affect overall costs and inventory management. Understanding a supplier’s MOQ can help buyers negotiate better pricing and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products. It typically includes details about the required specifications, quantities, and delivery timelines. For buyers, using an RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers to avoid unexpected costs and ensure smooth transactions. -

Lead Time

This refers to the amount of time it takes for a supplier to fulfill an order, from the moment it is placed until it is delivered. For international buyers, understanding lead times is crucial for planning inventory and ensuring timely production schedules. -

Warranty

A warranty provides assurance from the supplier regarding the quality and performance of the gaskets. It typically outlines the conditions under which the warranty is valid, as well as the duration. Buyers should seek out suppliers that offer robust warranty terms to protect their investments.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing cylinder head gaskets, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cylinder head gasket supplier Sector

What Are the Key Market Dynamics and Trends in the Cylinder Head Gasket Supplier Sector?

The global cylinder head gasket market is witnessing significant growth driven by the increasing demand for automotive and industrial machinery. This growth is further propelled by the rising need for durable and high-performance components that can withstand extreme temperatures and pressures. Emerging markets in Africa, South America, and the Middle East are becoming critical players in this sector, primarily due to their expanding automotive industries and infrastructure projects.

Key trends include the integration of advanced manufacturing technologies such as 3D printing and automation, which enhance production efficiency and reduce lead times. Moreover, the shift towards electric vehicles (EVs) is influencing the design and material selection for gaskets, requiring suppliers to innovate and adapt their offerings. As international B2B buyers look for reliable suppliers, understanding local market dynamics and regulatory requirements becomes essential. For instance, buyers from Spain may focus on compliance with EU standards, while those from Saudi Arabia might prioritize suppliers that understand local regulations and environmental considerations.

How Does Sustainability Impact Sourcing in the Cylinder Head Gasket Sector?

Sustainability is becoming a pivotal aspect of the B2B sourcing strategy for cylinder head gasket suppliers. The environmental impact of manufacturing processes, including emissions and waste generation, is under scrutiny. Buyers are increasingly demanding transparency in the supply chain, encouraging suppliers to adopt sustainable practices such as using eco-friendly materials and reducing carbon footprints.

Ethical sourcing is not just a regulatory requirement but also a competitive advantage. Suppliers that can demonstrate sustainability certifications, such as ISO 14001 or adherence to the REACH regulations, are more likely to attract international buyers. Furthermore, the use of biodegradable materials and recyclable components is gaining traction, aligning with global initiatives to minimize waste and promote circular economy principles. This trend is particularly relevant for buyers in Europe, where environmental regulations are stringent, and consumer preferences are shifting towards greener products.

What Is the Evolution of the Cylinder Head Gasket Supplier Sector?

The cylinder head gasket sector has evolved significantly over the past few decades. Initially, gaskets were made from simple materials like paper and rubber, which limited their performance and durability. As automotive technology advanced, manufacturers began to explore more resilient materials, such as composite and metal gaskets, which offer superior thermal stability and pressure resistance.

The introduction of computer-aided design (CAD) and simulation technologies has revolutionized the design process, allowing for more precise and innovative gasket solutions. In recent years, the focus has shifted towards developing high-performance gaskets that can withstand the demands of modern engines, including turbocharged and hybrid models. This evolution reflects the broader trends in the automotive industry towards efficiency, performance, and sustainability, highlighting the importance for international buyers to partner with suppliers that are not only innovative but also responsive to these dynamic market needs.

Conclusion

Navigating the complexities of the cylinder head gasket supplier market requires international B2B buyers to stay informed about emerging trends, sustainability practices, and the historical context of the industry. By focusing on these aspects, buyers can make informed sourcing decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of cylinder head gasket supplier

-

How do I choose the right cylinder head gasket supplier for my needs?

When selecting a cylinder head gasket supplier, consider factors such as product quality, industry reputation, and technical expertise. Look for suppliers with certifications like ISO 9001, which indicates a commitment to quality management. It’s also beneficial to check customer reviews and case studies to gauge their reliability. Additionally, assess their ability to provide customized solutions that meet your specific requirements, especially if you operate in diverse markets like Africa, South America, or the Middle East. -

What are the key quality assurance measures for cylinder head gaskets?

Quality assurance for cylinder head gaskets typically includes material inspections, dimensional checks, and performance testing under simulated operating conditions. Suppliers should adhere to industry standards such as ASTM or SAE. A robust QA process ensures that gaskets can withstand the high temperatures and pressures of engine operations. Ask potential suppliers about their QA procedures and request certifications or test reports to verify compliance with your quality expectations. -

What customization options are available for cylinder head gaskets?

Many suppliers offer customization options for cylinder head gaskets, including variations in thickness, materials, and coatings. Custom gaskets can be tailored to fit specific engine models or performance requirements. When discussing customization, provide detailed specifications and performance criteria to ensure the supplier can meet your needs. This is particularly important for buyers in regions with unique engine configurations or environmental conditions. -

What is the typical minimum order quantity (MOQ) for cylinder head gaskets?

The minimum order quantity for cylinder head gaskets can vary significantly among suppliers. Some may have an MOQ as low as 100 units, while others might require 1,000 or more. It’s crucial to communicate your purchasing needs upfront, especially if you are a smaller business. Suppliers may offer flexibility on MOQs for repeat customers or bulk orders, so it’s worth negotiating to find a suitable arrangement. -

What payment terms should I expect from cylinder head gasket suppliers?

Payment terms can vary widely based on the supplier’s policies and your business relationship. Common arrangements include upfront payments, payment upon delivery, or net payment terms (e.g., Net 30, Net 60). International buyers should also consider currency fluctuations and transaction fees. Always clarify payment terms in advance and consider using secure payment methods, such as letters of credit, to mitigate risks in international transactions. -

How can I ensure timely delivery of cylinder head gaskets?

To ensure timely delivery, establish clear communication with your supplier regarding lead times and shipping methods. Factors such as production schedules, shipping routes, and customs clearance can affect delivery times, especially for international shipments. Consider working with suppliers that have a reliable logistics network and inquire about their ability to provide tracking information. Setting up a contingency plan for potential delays can also help mitigate risks. -

What should I know about import regulations for cylinder head gaskets in my country?

Import regulations for cylinder head gaskets can vary by country, impacting tariffs, taxes, and compliance standards. It’s essential to research your country’s import requirements and consult with customs experts if necessary. For buyers from regions like Africa or South America, understanding local regulations can prevent costly delays and penalties. Ensure your supplier is familiar with these regulations and can provide necessary documentation, such as certificates of origin. -

How do I evaluate the reliability of a cylinder head gasket supplier?

To evaluate the reliability of a cylinder head gasket supplier, conduct thorough due diligence. This includes assessing their manufacturing capabilities, quality control processes, and customer service responsiveness. Request references from other clients, especially those in your industry or region. Additionally, consider visiting their facilities if possible or using third-party audits to verify their operations. A reliable supplier should demonstrate transparency and a commitment to meeting your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cylinder head gasket supplier

In the competitive landscape of the automotive industry, effective strategic sourcing of cylinder head gaskets is paramount for international B2B buyers. By understanding the nuances of supplier selection, including quality, reliability, and cost-effectiveness, businesses can significantly enhance their operational efficiency. Buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers who not only meet stringent quality standards but also demonstrate a commitment to sustainability and innovation.

The key takeaways for successful sourcing include conducting thorough market research, leveraging supplier certifications, and engaging in transparent negotiations. Additionally, fostering strong relationships with suppliers can lead to better terms, improved service, and collaboration on future developments.

Looking ahead, the demand for high-quality cylinder head gaskets is expected to grow, driven by advancements in automotive technology and increasing vehicle production rates. International buyers should proactively seek out suppliers who can adapt to these trends and provide tailored solutions. Embrace strategic sourcing today to ensure your business stays ahead in this evolving market landscape.